2

Overview of Algal Biofuel Supply Chain

Assessing the sustainability of algal biofuels requires an understanding of the individual components that make up potential supply chains. This chapter focuses on the basic processes of algal biofuel production from the biology and traits of the organisms, to methods for cultivation, and to processing into liquid fuels. It discusses algal strains and the attributes of those strains critical for biofuel production, the photoautotrophic methods for algae cultivation through open-pond and closed photobioreactor systems, the processes for collection and dewatering if necessary, and the processing of algal lipid, biomass, or secreted products into fuels. It provides the basic descriptions of the supply chain components used in later chapters and summarizes some critical process improvements that could enhance the overall sustainability of algal biofuels.

The organisms considered as potential feedstock for algal biofuel production belong to a vast and diverse assemblage of aquatic organisms that carry out oxygen-evolving photosynthesis and lack the stems, roots, leaves, and embryos of plants (Leliaert et al., 2011). The category includes eukaryotic species that are related to the plant lineage and can be further categorized as macroalgae that are large structured species (for example, kelps) or microalgae that are microscopic species (for example, Nannochloropsis spp.). In the context of biofuel, the term “microalgae” also includes cyanobacteria, a diverse prokaryotic lineage whose ancestor gave rise to the plant chloroplast (Keeling, 2010). More than 40,000 species of microalgae have been described, and they collectively cover a comprehensive spectrum of habitats and tolerances of ranges of pH, salinity, and temperature (Van den Hoek et al., 1995; Falkowski and Raven, 1997; Paerl, 2000). McKenzie (2011) estimated that prokaryotic and eukaryotic microalgae are responsible for more than 40 percent of net primary productivity on Earth. Algae can be a more appealing biofuel feedstock than land plants because of their faster biomass doubling cycle, their more accessible forms of stored carbon than

the lignocelluloses used for cellulosic biofuels, and their ability to thrive on water sources and on land sites that are unsuitable for terrestrial farming.

Microalgae contain diverse pigments and metabolites that are desirable as nutritional supplements and colorants. Examples of such products include astaxanthin, an antioxidant derived from the alga Haematococcus, and a high-protein powder derived from cyanobacterial species of Spirulina (Arthrospira) (Gershwin, 2008; Guedes et al., 2011). Commercialscale algal ponds that grow these and other microalgae have operated for more than a decade (Del Campo et al., 2007). However, the scale of deployment for algae cultivation for fuel is expected to be much larger than the scale of algae cultivation for nutraceuticals or other specialty products currently available in the market.

Generating biofuels from algae requires exploiting and expanding the demonstrated commercial-scale growth of algal biomass, and harvesting the relatively accessible carbon stored therein. Carbon is stored within algal cells in various forms, and these molecules can be accessed by different technologies. Both eukaryotic and prokaryotic algal cells are rich sources of polar lipids that are associated with membranes; in some cases, the photosynthetic thylakoid membranes are extensive. Carbon is such a crucial element for algae that it is typical for them to store surplus carbon when cellular division is restricted by some factor other than carbon availability—this situation is termed unbalanced growth. In many eukaryotic microalgae, photosynthetic carbon fixation continues under unbalanced conditions. Under extended periods of environmental stress, the excess fixed carbon is stored in the form of neutral lipids called triacylglycerols (TAGs). TAGs are hydrocarbon chains terminated in a carboxylic acid group. The three carboxyl groups are bound to glycerol through an ester linkage. Biofuels containing hydrocarbon chains longer than six carbons are particularly valued because of their high heats of combustion, volatility, and compatibility with existing engines. As discussed later in this chapter, extracted TAGs can be converted to biodiesel using a number of technologies, including transesterification and hydrotreating. Even algal species that do not store large amounts of TAGs can be converted to biofuels through various chemical conversion technologies. For example, species that store polysaccharides can be fermented to yield ethanol, and other biomass processing technologies, such as gasification, pyrolysis, and hydrothermal liquefaction, have shown great utility for the conversion of whole biomass into biofuels.

The incipient algal biofuel industry is emerging and evolving from its early foundations in algae cultivation for fish feedstuff and for human nutraceuticals. Early technology development of processing algae to fuels emphasized the conversion of neutral lipids (TAGs) to biodiesel. Choices of algal feedstocks have been expanding to address the goals of fuel production rather than nutritional content and to exploit new technologies for processing biomass that extend beyond those that focus on TAGs. Ideal attributes for algal feedstock for fuels include rapid and dense growth; efficient use of nutrients, light, and carbon dioxide (CO2) under a range of temperatures; resistance to pests and predators; accumulation of desirable macromolecules that can be processed into fuels; ease of harvest; and the absence of undesirable by-products.

Commercial and research interest in the United States has focused on microalgae, and these species are emphasized in this report. Microalgae have been reported to reach short-term maximum productivities of 50-60 g dry weight per square meter (m2) per day in CO2-enriched open ponds in Hawaii and California (Sheehan et al., 1998). These and other data on productivity from laboratory-scale experiments have promoted the reputation of microalgae as prime candidates for providing cheap biomass feedstocks for food, feedstuff, or energy. Some authors have extrapolated values of maximal biomass productivity and combined them with maximal oil content to predict oil yields of 100 tonnes per hectare

(ha) per year. Such reports have spurred investment in intensive research on algal biofuel production. However, such high productivity projections have yet to be obtained in largescale, long-term experiments. Serious barriers remain for reproducing optimal growth and productivity conditions at a commercial scale. They include maintaining the stability of the culture and delivering the required nutrients and other resources in an efficient manner at such scales. Current yields from large-scale operations range from 40-60 tonnes dry weight of algal biomass production per ha per year, and conservative projections anticipate up to 100 tonnes dry weight of biomass, or 30 tonnes of biodiesel per ha per year in subtropical or tropical, sunny climates (Scott et al., 2010). Estimated yields from a variety of cultivation systems are discussed later in the chapter.

2.1.1 Strain Diversity

The choice of strains for biomass production depends on the desired product and technology to be used for fuel production, the source, and the type of cultivation facility (open versus closed). Initial efforts using outdoor ponds focused on production of biodiesel by the transesterification of TAGs to produce fatty-acid methyl esters (FAME).1 Therefore, strains that accumulate TAGs were selected. Five groups of microalgae were classified as high priority for biofuel production by the U.S. Aquatic Species Program (Sheehan et al., 1998): diatoms (Bacillariophyceae), green algae (Chlorophyceae), golden-brown algae (Chrysophyceae), prymnesiophytes or haptophytes (including Prymnesiophyceae), and eustigmatophytes (Eustigmatophyceae). Many strains and genera of eukaryotic microalgae are potential high-oil producers for large-scale culture (Sheehan et al., 1998; Rodolfi et al., 2009). These include species of Tetraselmis, Dunaliella, Chlorococcum, Scenedesmus, and Chlorella, and particularly Neochloris oleoabundans and Botryococcus braunii from Chlorophyta; the genera of Amphora, Amphiprora, Cylindrotheca, and Navicula, and the species of Nitzschia dissipata, Phaeodactylum tricornutum, and Chaetoceros muelleri from Bacillariophyta; the species of Nannochloropsis ocalata and N. salina from Eustigmatophyceae; and the genera of Isochrysis and Pavlova from Haptophyta.

Improvements of technologies that convert total biomass to yield drop-in fuels—such as those being pursued by companies such as Inventure (Inventure, 2012), Xtrudx (Xtrudx Technologies, 2012), and Solvent Rescue Limited (Solvent Rescue Limited, 2012) and academic institutions such as Old Dominion University (Hatcher, 2011)—are changing the scope of organisms that are being considered for biofuel production. All categories of algae are rich in polar lipids that can be recovered by such processes, and they have cellulose or other polysaccharide cell walls composed of sugars. Cyanobacteria store excess carbon as glycogen rather than TAGs, and cyanobacteria and macroalgae accumulate quantities of other complex polysaccharides. These and other macromolecules are all potential carbon sources for producing drop-in fuels if appropriate processing technologies are available. In addition, algal carbohydrate potentially can be a feedstock for fermentative fuel production processes that are based on heterotrophic organisms, such as those used by LS9, Inc. (LS9 Inc., 2011) and Solazyme (Solazyme, 2012). Cyanobacteria are used directly for ethanol production by Algenol (Chance et al., 2011a; Algenol Biofuels, 2012). As of 2012, a number of marine macroalgal species are being considered for biofuel production in India. An example

_______________

1 As Chapter 3 discusses, algal triacylglycerols are reacted with methanol to form fatty-acid methyl esters (FAME). Due to its higher viscosity compared to conventional liquid transportation fuels, FAME cannot be used as a drop-in fuel, but can be blended with conventional diesel.

is the red algal species Kappaphycus alvarezii, a species cultivated for its high carrageenan2 content (Russell, 1983; Rodgers and Cox, 1999; Woo et al., 2000). Species of Spirulina have properties suitable for aquaculture, and they are grown at relatively large scales for sale as a nutritional supplement (Earthrise Nutritional, 2009a). Still, the spectrum of cyanobacteria that could be suitable for fuel production is largely unexplored. Prokaryotic algal species provide additional diversity in light harvesting, tolerance of growth habitat and pH, and facility of genetic modification.3 Moreover, some cyanobacterial species are diazotrophs; that is, they are able to fix atmospheric nitrogen (N). Although no current commercial operations rely on a nitrogen-fixing strain, several filamentous strains that have good lightharvesting properties and for which genetic methods are well developed are diazotrophic (Heidorn et al., 2011; Ruffing, 2011). The use of these strains as a biofuel feedstock or as a nitrogen provider for non-fixing strains (to reduce nutrient input) has received little attention.

Clear differences exist in carbon storage forms (important as fuel feedstock), dominant pigments (important for solar energy capture), and accessory pigments such as carotenoids (which can be valuable commercial products) among different algal divisions (Table 2-1). Furthermore, their pigmentation and composition are affected by growth conditions and environmental stress.

Emphasizing individual strains that are intended for monoculture discounts potential advantages that could be associated with mixed cultures. A recent study showed increased lipid production in algal cultures as a function of species diversity in mixed cultures under nutrient-limiting growth conditions (Stockenreiter et al., 2012). However, this effect has been demonstrated only at the laboratory scale or in low-density natural algal populations, and requires confirmation for extended periods of time and at relevant volumes. Moreover, lipid production of mixed algal culture could be different under the nutrient-replete conditions of ponds designed for maximal growth. Mixed cultures might facilitate crossprotection, diversity of products through product conversion, flocculation and harvesting improvements, and efficient use of light in the water column (Stomp et al., 2007). However, mixed cultures increase the heterogeneity of the potential product, which could affect the quality of yield and the ability to optimize the diverse characteristics of the mixture for a single product. The potential to enhance the supply chain of algal biofuel through growth of mixed cultures merits additional research to determine the effects on desirable product yield and biomass accumulation (see section Cultivation in this chapter). Because data are not available for large-scale, mixed-species systems, this report introduces the concept of mixed culture systems but focuses primarily on monoculture systems.

Among the biggest challenges for strain selection is the difficulty of translating desirable strain properties from the laboratory to the field. A desirable strain would have robust growth in open ponds under natural weather and cultivation conditions, and would retain attributes that are selected and measured in the controlled conditions of the laboratory. However, the ability to grow well and compete when exposed to environmental conditions is difficult to predict. Few strains are already proven to be robust in outdoor mass cultivation, and years of investment in time and process went into their commercial development.

_______________

2 A gelatinous substance extracted from red algae and widely used as a stabilizing or thickening agent in industrial, pharmaceutical, and food products.

3 Within the text of this report, the committee will distinguish whether it is discussing “genetic modification” or “genetic engineering” specifically. The committee considers genetic modification to be a general term and includes in its definition any organism whose genetic material has been altered through an array of approaches, including traditional cross breeding, mutagenesis, and genetic engineering. Genetic engineering is a modern technique that enables the introduction of a foreign gene or genes into the genome of an organism through recombinant DNA methods in an attempt to introduce a new trait into that organism.

TABLE 2-1 Characteristics of Photoautotrophic Algaea

|

|

|||||

| Division | Dominant Photosynthetic Pigment(s) |

Accessory Pigments (Carotenoids) | Principal Energy Storage Compound | % Proteinb | % Lipidb |

|

|

|||||

|

Cyanoprokaryota (blue-green algae) |

Phycobilins, Chlorophyll a |

Zeaxanthin, beta-carotene, myxoxanthin, echinenone, canthaxanthin |

Glycogen, other polysaccharides, polyhydroxyalkanoates, |

10-70 |

1-20 |

|

Bacillariophyceae |

Chlorophyll a, |

Fucoxanthin, beta-carotene, diadinoxanthin, diatoxanthin |

Lipid |

5-35 |

5-55 |

|

Haptophyceae |

Chlorophyll a, |

Beta-carotene |

Chrysolaminaran |

5-30 |

5-55 |

|

Chlorophyceae |

Chlorophyll a, |

Lutein, |

Starch |

5-30 |

5->50 |

|

Haptophyceae |

Chlorophyll a, |

Fucoxanthin |

Starch |

5-35 |

5-50 |

|

Raphidophyceae |

Chlorophyll a |

Diatoxanthin |

Lipid |

5-35 |

5-55 |

|

Rhodophyceae |

Phycobilins, |

Starch |

5-15 |

5-15 |

|

|

Phaeophyceae |

Chlorophyll a |

Fucoxanthin |

Starch |

5-15 |

5-15 |

|

Chrysophyta |

Chlorophyll a |

Beta-carotene, fucoxanthin |

Lipids (oil) Leucosin |

20-30 |

30-40 |

|

Eustigmatophyta |

Chlorophyll a |

vialaxanthin, beta-carotene |

Lipids (oil) |

10-30 |

40-65 |

|

|

|||||

a Table shows wide ranges in the percentage of lipids and proteins, reflecting that these and other parameters are dramatically affected by growth conditions.

b Percentages are given as a percent of dry weight.

Successful mass cultivation of new strains likewise will require intensive work to commercialize, whether those strains are native, genetically modified, or bred for improved attributes.

2.1.2 Desirable Strain Properties

Regardless of the technology or strain, the goal is to maximize the quantity of a final product per unit time, area, or water volume. Further, the desire is to maximize the product output per unit input of energy, nutrients, and other resources. Biomass and lipid accumulation per unit time are two measures of productivity (see Rodolfi et al., 2009 for example). Many other criteria are important for selecting algal strains for commercial biofuel production, including variables that alter cost in the supply chain that are important for economic viability (for example, AQUAFUEL, 2009). Ideally, the criteria for strain selection are measurable. Among important selection criteria are:

• Photosynthetic efficiency. The most objective measure to compare productivity of algae with land crops is photosynthetic efficiency. Photosynthetic efficiency is defined as the percent of available light (energy) that is converted into biomass energy. However, this definition might not be the most relevant for a given supply chain, depending on how the biomass will be processed and what the final products and coproducts will be (Box 2-1).

BOX 2-1

Relevance of Photosynthetic Efficiency to Biofuel Production

The amount of biofuel produced per unit of land area is a key parameter in the evaluation of any biofuel production process. Photosynthetic efficiency, a measure of how efficiently light energy is converted to chemical energy, is one of the key determinants of overall biomass yield. The measure relevant to biofuel production is the amount of energy contained in biomass expressed as a ratio of the solar energy supplied (Blankenship et al., 2011). The calculation is performed for a typical area integrated over a year or a growing season. When done this way, values of up to 3 percent have been reported for microalgae (Wijffels and Barbosa, 2010). Some authors choose to calculate photosynthetic efficiency based on only the percentage of photosynthetically active radiation (PAR) present (Ort et al., 2011), or even only the PAR absorbed (Janssen et al., 2001). These calculations lead to considerably higher values and lead to some confusion around the potential for biofuel production from algae.

Further complicating this particular discussion is determination of the heat of combustion, or the heating value,a to be used. For measures of total photosynthetic efficiency, the heat of combustion is generally taken to be the higher heating value of the dried biomass (Jenkins et al., 1998).

The critical feature for this discussion is not the exact efficiency, but rather that the value is far below what should be theoretically possible (Robertson et al., 2011). Indeed, many have lamented that photosynthesis uses one of the “slowest metabolic enzymes in the contemporary biosphere” (Parikh et al., 2006; p.113). Considerable improvement in photosynthesis might be realized by any number of techniques of modern biology. Improvements in photosynthesis would lead directly to more prolific production of biofuels, which would consequently reduce the land, water, nutrient, and energy inputs required. Improvements to photosynthesis would directly improve the sustainability of algal biofuels.

_______________

a “The higher heating value (also known as gross calorific value or gross energy) of a fuel is defined as the amount of heat released by a specified quantity (initially at 25°C) once it is combusted and the products have returned to a temperature of 25°C, which takes into account the latent heat of vaporization of water in the combustion products. The lower heating value (also known as net calorific value) of a fuel is defined as the amount of heat released by combusting a specified quantity (initially at 25°C) and returning the temperature of the combustion products to 150°C, which assumes the latent heat of vaporization of water in the reaction products is not recovered” (DOE-EERE, 2012a).

• Quantity of final products. This category includes the total amount of biomass, its composition, and the products to be refined, extracted, or excreted from the biomass:

• Total caloric value of the biomass (for combustion or a total biomass processing technology).

• Percent lipids and lipid composition (for biodiesel).

• Percent starch and carbohydrate composition (for subsequent fermentation and to identify higher value by-products such as agar).

• Percent protein and protein composition (soluble and insoluble protein for food and feedstuff).

• Total secretion of desirable products.4

• Presence of high-value coproducts.

_______________

4 Some companies, such as Joule and Algenol, have taken a dramatically different approach, relying not on accumulation of biomass, but on the secretion of desirable products from stable algal cultures (Robertson, D.E., S.A. Jacobson, F. Morgan, D. Berry, G.M. Church, and N.B. Afeyan. 2011. A new dawn for industrial photosynthesis. Photosynthesis Research 107(3):269-277). In this paradigm that uses photobioreactors, the criteria for strain selection are different from those used for open ponds. Planktonic unicellular species that would be difficult to protect from grazers and to harvest from ponds, are desirable within bioreactors. Well-developed genetic model organisms that are amenable to genetic engineering (such as Synechocystis sp. strain PCC 6803, Synechococcus sp. strain PCC 7002, and Synechococcus elongatus PCC 7942; and the unicellular green alga Chlamydomonas reinhartii) can be used in the controlled environment of photobioreactors.

• Nutrient and other resource requirements. These include the quantity of nutrients, such as CO2, nitrogen, and phosphorus; the type and quality of the water supply; and siting requirements. Strains could be selected because of their nutrientuse efficiency. Strains also might be selected because of their ability to flourish in brackish or wastewater, which would reduce the demand on freshwater supplies, and in the climatic conditions of a particular site.

• Robustness. This term describes the overall stability of the crop, which depends on resistance to extremes of climate and environmental variables (for example, competitors, pathogens and predators, salinity and dissolved solutes, temperature, and pH). Tolerances to these variables vary widely within the diverse spectrum of microalgae. The ability to thrive in water with various salts, metals, and other solutes could become increasingly important as competition for freshwater use among different sectors increases. Resistance to high pH allows growth in alkaline conditions that favor a monoculture crop over sensitive predators and pathogens. Filamentous species or species with large cell size tend to be more resistant to grazers than unicellular species with small cell size (Tillmann, 2004). Tolerance to a broad range of temperatures could be important if the algae are cultivated in regions with high daily or seasonal fluctuation in temperature. To maintain year-round production, it might be desirable to rotate strains that have different temperature tolerance profiles. The wide spectrum of sites that are under consideration for production ponds will require organisms with different light, water quality, and climatic tolerances. Robustness might be assessed by scoring the strain success under a wide range of potentially relevant conditions such as in Evens and Niedz (2011).

• Harvestability. Harvesting cost and energy consumption can vary dramatically among different algal strains (Uduman et al., 2010). Contributing factors include the sedimentation rate and the capability for induced bioflocculation5 or auto-flocculation. Filamentous strains that can be seined, species with positive buoyancy, or species that settle out of the water column quickly once agitation ceases might not require centrifugation, and they can be harvested easily. Growing mat-forming algae or algal films could facilitate harvesting (Tang et al., 1997), but to the committee’s knowledge, such approaches have not been scaled up. Strategies that rely on harvesting secreted products rather than biomass simplify the harvesting step, but such strategies require photobioreactors for algae cultivation to prevent contamination by microorganisms that would consume the product.

• Processability and extractability. This parameter includes factors that influence the ease of extracting algal oil or processing algal biomass to fuels, for example, cell volume, thickness and toughness of the cell wall, the presence of tough fibers (for example, cellulose and silica) or cell walls, and the moisture content (Brennan and Owende, 2010). A measure for processability and extractability could be the energy input per gram of dry weight necessary for fractionation and full recovery of all biomass components.

• Added value of coproducts. The algal biomass could be used to produce coproducts that have an intrinsic added value, such as carotenoids, phycobilins, docosahexaenoic acid, or eicosapentaenoic acid (Pal et al., 2011). Coproducts can offset some of the costs of the biofuel product. A specification of the compounds and their expected added value per gram of dry biomass needs to be indicated. However, the market value of coproducts could decrease under an excessive-supply and lowdemand condition.

_______________

5 Bioflocculation is the clumping together of microorganisms through biological interactions.

• Local origin of strains. Using locally selected strains could ease management and improve sustainability (RSB, 2011). Some governments have sought to restrict the importation of nonnative species, for example, the 81st Texas Legislature House Bill 3391 (2009). However, the cosmopolitan nature and wind-borne movements of algae make it unlikely that legislation can reasonably define species as native or nonnative. Regardless of legislation, local strains might have unique adaptations to the local climate, water, and possible parasites that imported or laboratory-grown strains might not have.

• Non-toxic. The selection of non-toxic algal strains will increase social acceptability and reduce the potential impacts related to occupational exposures and accidental releases.

2.1.3 Strain Development and Engineering

Modern agriculture has advanced primarily on the development of improved germplasm, and algae cultivation will likely advance using similar approaches. As with traditional agriculture, advances in breeding, mutagenesis, and genetic engineering are likely to play roles in algal germplasm enhancement. Domestication of algae potentially could change their phenotype dramatically because the desired characteristics for production are different from those that have evolved in the selective pressures of the wild and because hypereutrophic aquaculture conditions will support genotypes that would not be fit in natural environments. Breeding and engineering will enable the stacking of desirable traits within a single species or mixture of species. The definition of desirable traits, product type desired, choice of production organism, and specification of growth and harvesting methods will influence the needs for further development on a case-by-case basis.

The understanding of genetics, physiology, and metabolism at present is uneven across the spectrum of genera and species of algae that might have desirable features for algal biofuel production. Major hurdles include the need to develop genetic technologies for new species that have not been domesticated previously and that have desirable characteristics for large-scale cultivation. The application of genomic approaches could accelerate the analysis of new strains by addressing changes in gene expression for a given organism under various conditions and identifying conserved and nonconserved genes among organisms. Those approaches facilitate the identification of candidate genes that might be relevant for particular pathways of interest (Flaherty et al., 2011; Karpowicz et al., 2011; Lopez et al., 2011; Weckwerth, 2011). Cryogenic storage methods, such as those used at the Culture Collection of Algae at the University of Texas (UTEX, 2012), also may prove important to maintaining germplasm stocks and to replenishing pond inocula with a desired genotype after genetic drift of the crop population. Cultured algae, particularly cultures held for more than 10 years in selective media, have been shown to have reduced growth and production of unexpected secondary metabolites (Martins et al., 2004). A factor that might be overlooked in efforts to genetically engineer metabolic pathways in algae is that both eukaryotic and prokaryotic strains possess circadian clocks that time the peaks of daily rhythmic changes in physiological and metabolic functions (Suzuki, 2001; Ditty et al., 2003; Matsuo and Ishiura, 2010; O-Neill et al., 2011). The mechanisms and the physiological and metabolic consequences of circadian rhythms are insufficiently understood in these organisms.

At present, few eukaryotic algal species are readily amenable to breeding or genetic engineering. Published transformation methods are well developed for Chlamydomonas reinhardtii and Phaeodactylum tricornutum. Solazyme appears to rely on genetically engineered

Chlorella species for heterotrophic fermentation of algal oils. About 30 strains of eukaryotic microalgae have been transformed using biolistic bombardment, vigorous mixing with glass beads, electroporation, or deoxyribonucleic acid (DNA) transfer from Agrobacterium tumefaciens. Strains that have been transformed include representatives of green, red, and brown algae; diatoms; euglenoids; and dinoflagellates (Radakovits et al., 2010). However, in many cases the reported transformation is only transient (Radakovits et al., 2010), and these reports have not led to routine adoption and application for most of those strains. Nevertheless, the transformations demonstrate that developing genetic systems for diverse species is possible with focused effort.

Targeted gene inactivation by homologous recombination has been a long-standing challenge for manipulation of Chlamydomonas and other algal nuclear genes. However, Kilian et al. (2011) made progress in this area when they reported successful knockouts of Nannochloropsis sp. nuclear genes encoding nitrate reductase and nitrite reductase. Various genes have been suppressed successfully in Chlamydomonas by interfering ribonucleic acid (RNAs) (Cerutti et al., 2011). High-throughput methods to introduce interfering RNAs could provide an effective way for gene inactivation in diverse strains that do not exhibit homologous recombination of transgenic DNA. Another challenge for nuclear modification is that gene expression is often silenced when heterologous genes are inserted randomly into the Chlamydomonas reinhardtii nuclear genome (Fuhrmann et al., 1999). Manipulation of the chloroplast genome is facile in C. reinhardtii, but not in other algae (Radakovits et al., 2010). A report of stable chloroplast transformation in Porphyridium suggests that chloroplast transformation via homologous recombination might be a universally applicable approach (Lapidot et al., 2002). Waaland et al. (2004) reviewed macroalgal species as candidates for genomic research and concluded that the red alga Porphyra yezoensis exhibits numerous attributes conducive to further analyses. Extensive biochemical and physiological research has been conducted on the macroalgae because of their use in the food industry. Because there is extensive variation in the extent and type of genetic malleability among different algal species, technologies would have to be developed on a case-by-case basis for individual new algal types whose physiological and metabolic properties suggest their potential as production strains. Moreover, it will be highly desirable to develop methods that can be used to more rapidly develop a genetic system de novo in new strains or species as they are discovered.

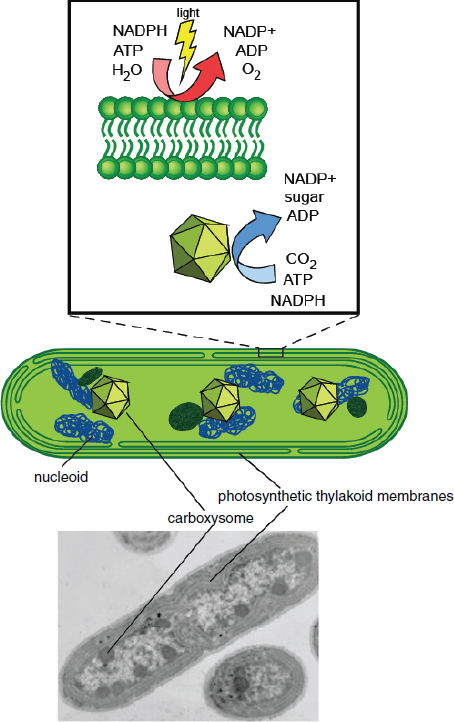

Genetic manipulation is more straightforward among cyanobacteria than eukaryotic algae because prokaryotes are amenable to techniques of bacterial genetics (Figure 2-1); some species are naturally transformable and take up exogenous DNA without specific intervention (Heidorn, 2011; Ruffing, 2011). Figure 2-2 shows some of the biochemical pathways in cyanobacteria that can be engineered to produce different desired products. Methods for gene inactivation via homologous recombination and the stable expression of transgenes, from plasmids or integrated into the chromosome, are well established in at least a dozen diverse species (Ducat et al., 2011; Ruffing, 2011). However, the developed model organisms have been maintained in the laboratory for several decades and are not likely to be suitable for growth under outdoor cultivation conditions. The Spirulina species that grow robustly outdoors have proven recalcitrant to manipulation. Despite some reports of transgenic Spirulina (Toyomizu et al., 2001; Kawata et al., 2004), many laboratories have failed to achieve stable transformation of the organism. This failure is likely, at least in part, due to a host of restriction endonucleases that specifically cleave foreign DNA (Zhao et al., 2006). Steps that protect plasmids by methylation while they are in an Escherichia coli host and before they are introduced to the cyanobacterium by conjugation have facilitated genetic technologies for the nitrogen-fixing filamentous strains Anabaena (Nostoc) sp. PCC

FIGURE 2-1 Overview of cyanobacterial organization.

NOTE: The cartoon diagram in the middle shows the longitudinal section of a representative cyanobacterium (modeled after Synechococcus elongatus). The major features are indicated on the cartoon diagram above and the electron micrograph below.

SOURCE: Adapted from Ducat et al. (2011). Micrograph image courtesy of and reprinted with permission from Lou Sherman, Purdue University.

7120, Anabaena sp. ATCC 29413, and Nostoc punctiforme ATTC 29133 (Elhai et al., 1997). Similar approaches are likely to work for other strains that initially resist transformation. A filamentous cyanobacterium isolated from an outdoor pond that has robust growth properties similar to Spirulina species has been found to be easily manipulated by conjugal introduction of transgenes and transposons (Taton et al., 2012). This finding suggests that diverse cyanobacterial model strains that are more relevant for biofuel development than current laboratory strains could be readily developed.

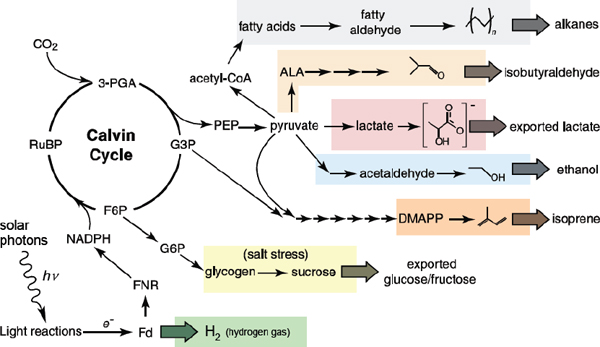

Genetic engineering holds the promise of transplanting completely novel pathways from heterologous sources and making products of tailored composition (Figures 2-1 and 2-2; Ruffing, 2011). Some demonstrations from genetically engineered cyanobacteria include the production of 1-butanol, isobutyraldehyde, N-alkanes, free fatty acids, and sugars from transformable species of Synechococcus (PCC 7002 and 7942), Thermosynechococcus (BP-1), and Synechocystis (PCC 6803) (Atsumi et al., 2009; Niederholtmeyer et al., 2010; Lan and Liao, 2011). Transgenic strains could play an important role in biofuel production, and some companies are making major investments in these technologies (for example, the Exxon Mobil alliance with Synthetic Genomics, Inc.; Marler, 2011; Roessler, 2011) even though

FIGURE 2-2 Schematic representation of engineered biochemical pathways in cyanobacteria.

NOTE: Core metabolism of photosynthetic processes is shown in black text. Branch points used to produce various desired compounds are highlighted in colored boxes. Abbreviations: 3-PGA, 3-phosphoglycerate; FNR, ferredoxin NADP+ reductase.

SOURCE: Adapted from Ducat et al. (2011).

strains have not been used in outdoor systems. The use of engineered strains in outdoor cultivation will be regulated according to the type of genetic modifications applied. The U.S. Environmental Protection Agency (EPA) under the Toxic Substances Control Act (TSCA) recognizes microorganisms that carry sequences from another genus as new organisms that require regulatory permitting (EPA, 2011). Under TSCA, organisms that are modified by technologies based solely on rearranging and reinserting endogenous genetic material into strains of interest are not categorized as genetically modified. Thus, self-cloned species can be used in open ponds without special oversight. Growing genetically modified algae in photobioreactors will follow the same regulatory standards that are common in the fermentation and biotechnology industries.

Irrespective of the algal strain cultivated and its end use, some areas of improvement in strain and cultivation are generally desirable. These include:

• Modulation of carbon allocation.

• Increases in culture density.

• Net increase in photosynthetic efficiency.

• Algal crop protection.

• Other enhancements.

2.1.3.1 Modulation of Carbon Allocation

The basic strategies to adapt microalgae to increased oil production for processing to diesel were summarized by Radakovits et al. (2010). A major target of genetic engineering

is production of algal strains that accumulate and maintain high amounts of oil under high growth rates in continuous cultivation systems. Most eukaryotic algae accumulate increased amounts of oil only in response to nutrient stress or in late exponential growth phase and do so at the expense of a reduced growth rate. Methods to enhance lipid accumulation in algae include enhancing certain enzymatic activities through genetic and transcription engineering approaches (Courchesne et al., 2009; Turchetto-Zolet et al., 2011). Research has focused on identifying the “nutrient stress trigger” that induces TAG accumulation in an effort to make TAG production constitutive. Strains that maintain elevated basal oil content might be produced by mutagenesis or genetic engineering. However, the pathways that regulate stress responses—and key enzymes—that initiate oil production are insufficiently understood at present. Understanding the metabolic regulatory networks that control carbon allocation to carbohydrates and lipid and identifying means to modulate these networks are necessary to achieve constitutively elevated oil yields under continuous growth. Assessments of whether metabolic modifications can be made without genetic tradeoffs that result in suboptimal performance in other aspects of the cells’ metabolism are important.

An array of techniques for improving lipid yields is described in the literature. A few examples are discussed in this section. Genetic manipulation of carbon allocation can enhance lipid production (Li et al., 2011). Starch production is blocked from the sta6 mutant of C. reinhardtii, and its lipid body content increases 30-fold compared to 10-fold in the wild type (Wang et al., 2009). Modifications to improve oil yields have been achieved in oil-seed plants by altering the activities of dozens of genes, each of which results in an increase of a few percent in oil content (Thelen and Ohlrogge, 2002; Lardizabal et al., 2008; Clemente and Cahoon, 2009). Similarly, a broad approach of modifying several genes, which operate in both starch and lipid metabolism, could result in a substantial increase in oil content in algae.

Strategies that target steps in diverse metabolic pathways like starch metabolism, acetyl-coenzyme A (acetyl-CoA) and fatty-acid biosynthesis, and reactions of TAG assembly have shown significant effects on TAG accumulation in some organisms. For example, acetyl-CoA carboxylase overexpression led to “a 40 percent increase in the total fatty acid content of the non-oleaginous yeast Hansenula polymorpha” (Ruenwai et al., 2009). Mutants of Arabidopsis that are deficient in plastid pyruvate kinase had 60 percent less seed oil than the wild type, revealing a major role of this enzyme in pyruvate supply for acetyl-CoA biosynthesis (Baud et al., 2007). Reactions in the latter steps of TAG biosynthetic assembly might provide increased sink strength that could stimulate fatty-acid production (Thelen and Ohlrogge, 2002). Indeed, stimulation in seed oil content of Arabidopsis and rapeseed had been observed when a yeast long chain sn 2 acyltransferase was overexpressed (Zou et al., 1997). The overexpression of a diacylglycerol acyltransferase (DGAT), a committed and final step in TAG biosynthesis, increased seed oil content and seed weight in Arabidopsis (Jako et al., 2001) and tobacco leaves (Andrianov et al., 2009). A specific phenylalanine residue in DGAT was found to be a key determinant of oil content and composition in maize (Zheng et al., 2008), and the corresponding Phaeodactylum gene has been identified. A novel acyl-CoA:diacylglycerol acyltransferase 1-like gene (PtDGAT1) has been cloned and characterized from the diatom P. tricornutum (Guihéneuf et al., 2011) and will be tested in transgenic algae. Structural components of oil globules such as oleosin and caleosin might accelerate oil body formation in oil seeds of higher plants, but an oleosin gene has not been identified in algae. However, a major oil body protein of Haematococcus has been described (Peled et al., 2011).

Manipulating regulatory enzymes (such as transcription factors and signal transduction proteins) has been shown to enhance TAG accumulation in higher plants (Cernac and Benning, 2004) and might be effective in eukaryotic algae. Similar engineering can affect

glycogen accumulation in cyanobacteria (Osanai et al., 2005; Ehira and Ohmori, 2011). Several microRNAs that are differentially expressed in C. reinhardtii, under conditions in which lipid content is changed, were used to develop strains that produce 25 percent more oil than the wild type strain (Maor Sasson, TransAlgae Ltd., Israel, personal unpublished data). The redistribution of carbon from carbohydrates to lipids, higher alcohols, and hydrocarbons requires a better understanding of carbon regulation networks in these species.

2.1.3.2 Increases in Culture Density

The product yield (expressed, for example, as grams per liter per day, or as grams per square meter per day) of an outdoor algal culture is a function of its specific growth rate and its biomass concentration. Thus, maintaining an outdoor culture at its optimal biomass concentration is important to maximizing product yield. However, high cell density reduces light penetration and limits the growth rate of cells below the surface. Although counterintuitive, reducing the light-harvesting ability of individual cells could improve the light availability to the culture and increase overall photosynthetic activity. By reducing wasteful absorption and dissipation of light energy by cells at the surface, excess light is allowed to pass through to cells below. Thus, researchers have proposed selecting and developing strains with low pigmentation level (small light-harvesting antenna6 size) to increase the standing biomass of the culture (Benemann, 1989; Huesemann et al., 2009; Ort et al., 2011). This approach was evaluated in greenhouse conditions and shown to have a positive effect on productivity (Polle et al., 2003). The challenge is to isolate such mutants from the desired strain and to ensure they are stable under long-term outdoor cultivation. More complex culture strategies might facilitate achieving this goal, for example, layering strains that have different antenna sizes and spectra.

Whether factors other than light limit maximum culture densities is unknown. Little work has been done regarding cell-to-cell communication within a given species of microalgae, but evidence of quorum sensing7 (Teplitski et al., 2004; Sharif et al., 2008) and widespread interspecies allelopathic interactions have been reported (Gross, 2003). Endogenous mechanisms that limit population density might exist, in which case genetic modification may improve this aspect for aquaculture purposes.

2.1.3.3 Net Increase in Photosynthetic Efficiency

A long-time goal, as old as the techniques of genetic engineering itself, is to improve photosynthetic efficiency by such alterations as reducing losses from photorespiration, increasing the substrate selectivity of ribulose-1,5-bisphosphate carboxylase oxygenase (Rubisco), and enhancing photosystem stability and efficiency. However, 30 years of efforts in this area have not yielded any progress in higher plants or algae. Recent advances in synthetic biology, by fundamentally redesigning prokaryotic photosynthetic organisms to maximize the production of fuel molecules directly driven by photosynthesis (Chance et al., 2011b; Algenol Biofuels, 2012; Joule Unlimited, 2012), might provide some progress in this field. However, only laboratory-scale or small pilot-scale results have been presented. Atsumi et al. (2009) found that overexpression of Rubisco in transgenic Synechococcus elongatus PCC 7942 led to increased production of isobutyraldehyde without negatively

_______________

6 Light-harvesting antennae are protein-pigment complexes that capture sunlight and direct the radiant energy to the reaction centers.

7 Quorum sensing is the process of cell-to-cell communication in microorganisms that involves the production, release, and subsequent detection of chemical-signal molecules.

affecting photosynthetic oxygen evolution, suggesting that net improvements in carbon fixation are reasonable. Chen and Blankenship (2011) made the challenging proposal that photosynthetic capacity might be expanded by engineering cells to use different chlorophylls to capture a broader range of the light spectrum than non-engineered cells.

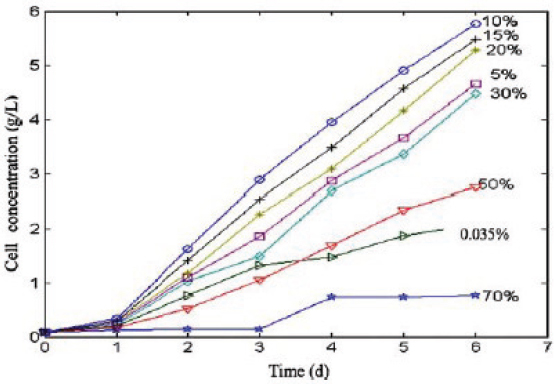

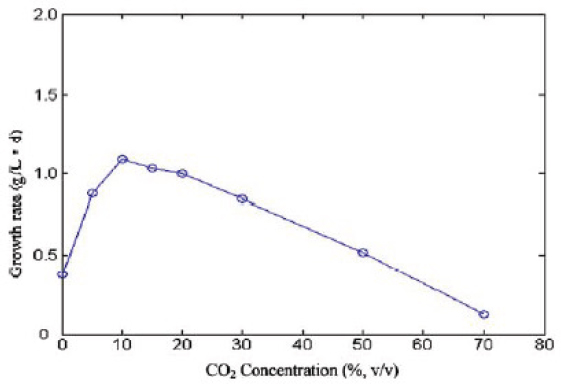

CO2 abatement is a driver for developing algal biofuels. However, with current practices and species, CO2 often is limited in production ponds and photobioreactors, and addition of a CO2 source is a significant production expense. The effects of CO2 concentrations on algal growth are discussed in the cultivation section later in this chapter, and CO2 requirements and sourcing issues are discussed in Chapter 4. Improved carbon concentrating strategies would address this aspect of photosynthetic efficiency. The enzyme carbonic anhydrase is produced by several divisions of algae (Giordano et al., 2005). The enzyme converts bicarbonate to CO2 that is released intracellularly for fixation by Rubisco. Most algae possess C3 metabolism. That is, the enzyme Rubisco is solely responsible for CO2 fixation. The ability of some plants and microalgae (specifically diatoms and dinoflagellates) to use CO2 directly during C4-intermediate metabolism offers promise for reducing bicarbonate limitation (Zimba et al., 1990; Raven, 2010). A November 2011 press release from Iowa State University reports that Spalding et al. increased algal biomass by 50 to 80 percent in C. reinhartii by artificially increasing the expression of genes that encode components of the carbon-concentrating mechanism, which normally is induced only under low CO2 conditions. The cells presumably continue to actively scavenge CO2 even when it is at relatively abundant levels (Iowa State University, 2011).

2.1.3.4 Algal Crop Protection

Events in which the crop dies (pond “crash” or culture collapse) take a toll on resources and could threaten the economic sustainability and the future potential of the algal biofuel industry (see section Cultivation in this chapter). One cause of such culture collapse is the activity of predators on high-density biomass cultures (see section Contamination and Stability of Culture in this chapter). Simple genetic modifications that affect cell size can improve resistance to grazers and could improve harvesting properties at the same time (Jurgens et al., 1999). Focused screens to find mutations that confer resistance to specific pathogens and grazers are likely to improve crop protection. Because their carbon- and nutrient-allocating traits are the results of domestication, crop algae might carry a heavier metabolic burden than invading weed species. For these reasons, trait modification to instill resistance to herbicides, production of antifungals, and anti-grazer properties could be important. Indeed, at least one company has developed a genetically engineered algal strain for use in open ponds that is resistant to herbicides (IP Monitor, 2009; Aravanis, 2011). Some algae are known to increase lipid content when they are exposed to low levels of herbicide (Ma et al., 2002, 2006). However, if residual biomass is to be used for food or feedstuff, possible negative consequences of these traits would have to be considered. Algal species production of allelopathic chemicals could be exploited to enhance or inhibit growth of other organisms in crop cultures (Gross, 2003). The activities, pathways, and genes related to the secondary metabolites of strains of interest need to be characterized to harness the potential of intrinsic growth modulators.

2.1.3.5 Other Enhancements

The list of potential enhancements is open-ended and will expand as the specific algal species are chosen for cultivation and their attributes become apparent and as the

technologies to modify them increase. Some clearly desirable modifications would provide increases in tolerance to temperature, salinity, pH ranges, and metal concentrations. Tolerances to a range of conditions contribute to crop robustness. Prior demonstrations of such modifications include the conversion of freshwater cyanobacteria to use saline water sources (Waditee et al., 2002; Laloknam et al., 2006). Other aspects of the supply chain can be targeted through genetic modifications, including genetic engineering. For example, groups at Los Alamos National Laboratory have transplanted genes from magnetotactic bacteria. These genes direct the production of magnetic nanoparticles in green algae, which allows simple harvesting by magnetic collection of cells and reduces energy input for centrifugation and dewatering steps (Los Alamos National Laboratory, 2011).

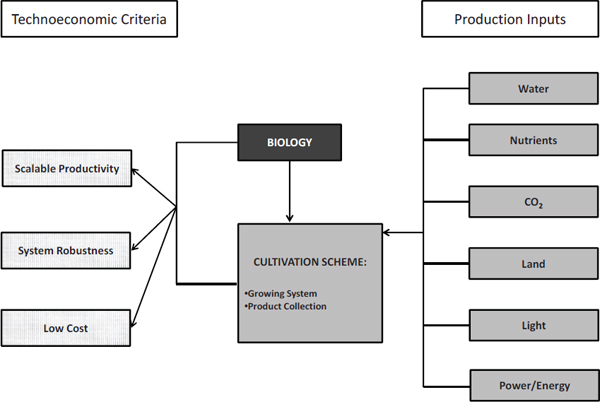

Evaluating the sustainability of algal cultivation systems for biofuel production requires examining the various material and energy inputs needed for the cultivation systems to maintain scalable productivity, maximize system robustness, and minimize costs (Figure 2-3). Scalable productivity refers to a cultivation system’s ability to maintain productivities with respect to algal biomass and algal product (mass/area-time or mass/volume-time) from the laboratory scale to the commercial scale. System robustness refers to a cultivation system’s ability to reliably and dependably deliver consistent productivity and avoid system crashes or failures as a result of either biological or physicochemical causes. Costs pertain to capital and operating costs for a cultivation system.

FIGURE 2-3 Material and energy inputs required by a cultivation scheme. Together with the biological scheme, these inputs determine the cultivation system’s productivity, robustness, and cost.

2.2.1 Overview of Algae-Growing Systems

The commercial large-scale cultivation of microalgae began in earnest in the 1960s with the cultivation of Chlorella in Japan (Tsukuda et al., 1977) and the use of phytoplankton as a feedstuff for animals reared in aquaculture (Duerr et al., 1998). In the 1970s, Spirulina was harvested from Lake Texcoco in Mexico (Durand-Chastel, 1980) and produced in Thailand (Kawaguchi, 1980). By 1980, 46 large-scale facilities operated in Asia producing more than 1,000 kg of microalgae each month (Kawaguchi, 1980). The global production of microalgal biomass was estimated to be more than 5,000 dry tonnes in the year 2005 with a value of more than U.S. $1.25 billion, which excludes the value of processed products (Spolaore et al., 2006). About 3,000 dry tonnes of Spirulina are produced in China, India, Myanmar, the United States, and Japan; 2,000 dry tonnes of Chlorella are produced in Taiwan, Germany, and Japan; and 1,200 dry tonnes of Dunaliella salina are produced in Australia, Israel, the United States, and China (Spolaore et al., 2006). In 2008, the global production of microalgal biomass was estimated to be about 9,000 dry tonnes per year (Benemann, 2008).

In addition to algal biology and the intended algal products, numerous factors are considered in selecting the particular algal cultivation system to be used. These include the availability and cost of land, water, energy, nutrients, and labor, and the climate of the location (Borowitzka, 1992). The characteristics of each cultivation system, including its mixing or hydrodynamic characteristics, light utilization efficiency, ability to control temperature, ability to maintain a unialgal culture, and ease of scaling from laboratory to pilot and commercial scales also are considered (Borowitzka, 1999). The two general types of algal cultivation systems discussed in this report are open-pond systems and closed photobioreactor systems.

2.2.2 Open-Pond Systems

The majority of the large-scale microalgal production systems in commercial operation today are open-pond systems, mainly due to economic factors and ease of scale up. Most commercial-scale microalgal cultivation operations are for producing nutraceuticals, and none of them are for producing fuel. The number of microalgal species that can be grown effectively in open-pond systems is limited by the species’ ability to thrive in particularly selective environments while the ponds remain relatively free of protozoan and other algal species contamination (Borowitzka, 1999; Milledge, 2011). For example, Chlorella is grown in a nutrient-rich medium, Spirulina at high pH and bicarbonate concentration, and Dunaliella salina at high salinity (Borowitzka, 1999; Milledge, 2011).

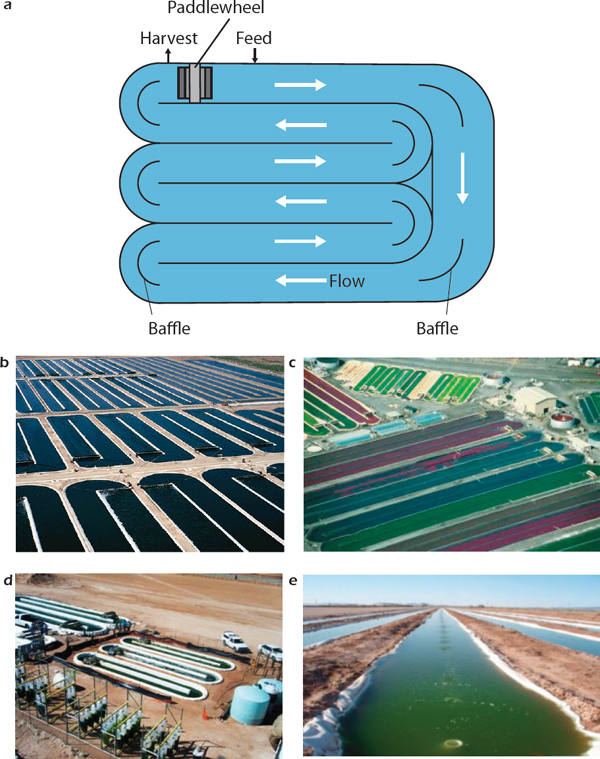

The two most common types of open-pond systems are circular ponds and raceway ponds. Circular ponds are round ponds, with depths of 30-70 centimeters (Moheimani and Borowitzka, 2006). They are typically agitated through a centrally pivoted rotating arm. Ponds up to 45 meters in diameter have been operated in Japan and Taiwan (Becker, 1994). Oscillatoria grown in a circular pond achieved a productivity of about 15 grams dry weight per m2 per day (Sheehan et al., 1998). Mixing efficiency is poor in ponds with diameters greater than 50 meters (Shen et al., 2009). Raceway ponds (Figure 2-4 a-e) are constructed either as single units (Figure 2-4 b-e) or a group of continuous units that are joined together (Figure 2-4a). The raceway channels enable culturing algae in ponds with depths of 15-40 centimeters. The channels are constructed from concrete or compacted earth that might be lined with plastics. A paddle wheel, a propeller, or an air-lift pump operates at all times to agitate and circulate the mixture to prevent algae sedimentation (Becker, 1994; Chen et al., 2009). A key factor in open-pond design and operation is mixing, which evenly distributes

FIGURE 2-4 Open-pond designs for algae cultivation: schematic of raceway design (a), Earthrise raceways (b), Cyanotech raceways (c), Sapphire Energy raceways (d), and Phyco raceways (e).

SOURCES: (a) Adapted from Spirulina Source (Spirulinasource, 1999).

(b) Earthrise (Algae Energy, 2012a). Reprinted with permission from Algae Energy.

(c) Cyanotech (2012). Reprinted with permission from Cyanotech.

(d) Sapphire (Mveda, 2011). Reprinted with permission from Sapphire and Mveda.

(e) Phyco Biosciences (Edwards, 2010). Reprinted with permission from Algae Industry Magazine.

nutrients and exposes algal cells to sunlight and CO2. A velocity of 10-20 centimeters per second (cm/s) prevents algal cells from depositing and settling (Shen et al., 2009). Higher velocities are preferred, but a velocity greater than 30 cm/s could consume too much energy to be economically viable (Sheehan et al., 1998). Earthrise Nutritional, LLC, in California, and Cyanotech Corporation, in Hawaii, have some of the largest algal open ponds lined with plastic liners. Earthrise maintains 30 production ponds each about 5,000 m2 and a series of research ponds (1,000 m2, 200 m2, and 50 m2) (Earthrise Nutritional, LLC, 2009b). Cyanotech has more than 60 ponds, each of which is about 2,900 m2 (Lorenz, 2002; Enay, 2011). The depth of these ponds varies from 30 to 40 centimeters. For raceway ponds, a cell concentration of up to 1 gram dry weight per liter can be achieved, and productivities of 10 to 25 grams dry weight per m2 per day have been reported (Shen et al., 2009). Table 2-2 shows algal productivities for open systems, which vary widely depending on numerous factors, including the type of open system and the algal species grown. Although a productivity of 50 to 60 g dry weight per m2 per day is possible with open systems, achieving even 10 to 20 g dry weight per m2 per day in large-scale systems is difficult on an annual basis because of operational conditions and seasonal variations in temperature and sunlight intensity (Shen et al., 2009).

In a raceway pond of 100 m2, a paddle wheel driven by an electric motor has a power demand of 600 watts (W) (Becker, 1994). The overall energy requirement for paddle wheels in a pond with a roughness coefficient of 0.025 has been estimated at 20 kilowatt hour (kWh) per ha per day for a mixing velocity of 15 centimeters per second and 160 kilowatt

TABLE 2-2 Microalgae Productivities in Open Ponds

|

|

|||||

| Pond Type | Volume (L) | Microalgal Species | Areal Productivity (g DW/m2/d) | Volumetric Productivity (g DW/L/d) | Reference |

|

|

|||||

|

Circular |

1,960 |

Chlorella spp. |

1.61–16.47 |

0.02–0.16 |

Kanazawa et al. (1958) |

|

Circular |

|

Oscillatoria |

15 |

|

Sheehan et al. (1998) |

|

Sloped (cascade) |

1,970 |

Chlorella spp. |

25 |

10 |

Lee (2001) |

|

Slope |

1,990 |

Scenesdesmus obliquus |

24.8 |

|

Becker (1994) |

|

Raceway |

|

Spirulina (Arthrospira) |

9–13 |

|

Olguín et al. (2003) |

|

Raceway |

282 |

Spirulina platensis |

14.47 |

0.183 |

Pushparaj et al. (1997) |

|

Raceway |

300 |

Anabaena spp. |

9.4–23.5 |

0.031–0.078 |

Moreno et al. (2003) |

|

Raceway |

135,000 |

Spirulina (Arthrospira) spp. |

2–17 |

0.006–0.07 |

Jiménez et al. (2003) |

|

Raceway |

|

Dunaliella salina |

1.6–3.5 |

|

García-González et al. (2003) |

|

Raceway |

750 |

Spirulina platensis |

15–27 |

0.06–0.18 |

Richmond et al. (1990) |

|

Raceway |

4,150 |

Phaeodactylum tricornutum |

2.4–11.3 |

0.0028–0.13 |

Laws et al. (1988) |

|

Hybrid system (open ponds and closed photobioreactors) |

|

unknown |

30 (anticipated) |

|

Phycal (2011) |

|

Raceway (proprietary lined “Super Trough System”) |

|

Cyanobacteria spp. |

15.36 (anticipated) |

|

Phyco BioSciences, Inc. (Cloud, 2011a,b) |

|

|

|||||

SOURCE: Adapted from Chen et al. (2009).

hours per ha per day for a mixing velocity of 30 centimeters per second (Benemann, 1986). Other estimates of power requirements for large ponds (for example, Cyanotech’s 2,900 m2 ponds mentioned earlier) range from about 1,200-3,700 W/ha for mixing velocities of 20 to 30 centimeters per second (Pedroni et al., 2001; Frank et al., 2011). A raceway pond of 85 m2 that uses an air-lift pump for circulation has a power consumption of 195 W based on a compressor efficiency of 70 percent and an air demand of 120 liters per second. Ponds in Chile and Brazil have used motor-driven drag boards as an alternative to paddle wheels; the energy requirement was reported to be only 20 percent of the energy needed for a comparable agitation with paddle wheels (Becker, 1994). Laws et al. (1983) introduced the concept of foils that create circular vortices to effectively mix the pond suspension from top to bottom. This is the type of agitation device that Algenol uses in its plastic and covered photobioreactor design (Chance et al., 2011b; see also Chapter 3).

2.2.3 Photobioreactors

Mass cultivation of microalgal species that lack pronounced environmentally selective advantages might require the use of photobioreactors (Milledge, 2011). Photobioreactors are transparent containers or vessels designed to have reduced light path to enhance the amount of available light to the algal cells, and the cultures within are continuously mixed to enhance nutrient distribution and gas exchange. Photobioreactors for microalgae production have an optimal thickness of about 2-4 centimeters (Borowitzka, 1999). The tubular and the flat-plate are the two most common types of microalgal photobioreactors.

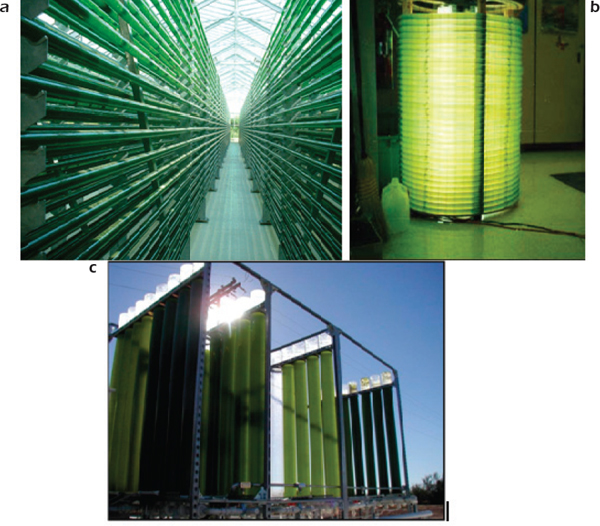

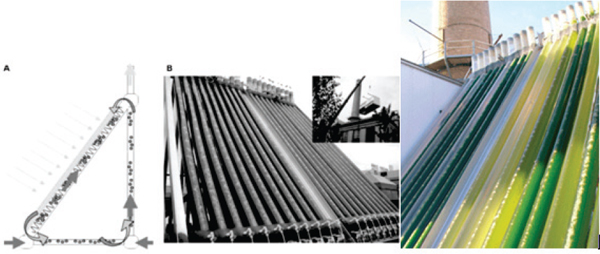

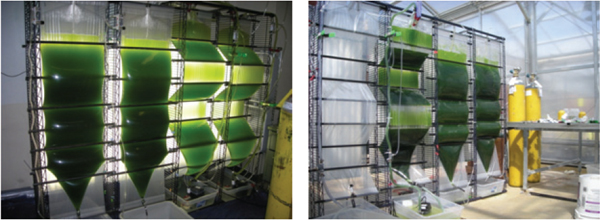

All photobioreactors have large surface to volume ratio (SVR). Because of their widespread availability, tubes long have been used as a basic photobioreactor material. The geometric configurations of tubular photobioreactors span a wide range from straight horizontal, straight vertical, helical, to triangular configurations (Figures 2-5, 2-6). One of the world’s largest photobioreactor facilities is in a greenhouse in Klotze, Germany. This facility consists of straight horizontal tubes stacked in vertical fence-like arrays (Figure 2-7). The facility has a total volume of 700 cubic meters (m3), occupies a total land area of 10,000 m2, and produces 35-41 grams dry weight per m2 per day or 120-140 dry tonnes per year. Algae wall adhesion, biofouling, large pressure drop, and gradients in pH, dissolved oxygen, or CO2 can occur along the tube length. These factors are potential disadvantages of tubular photobioreactors (Chen et al., 2009), which might be resolved by innovative engineering designs.

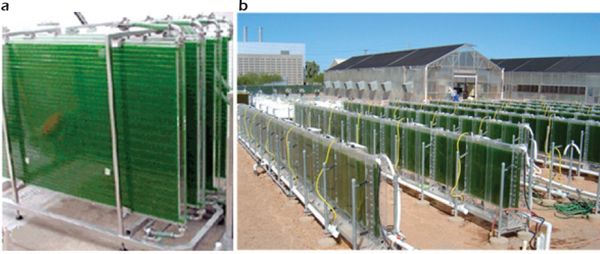

Flat-plate (or flat-panel) photobioreactors are transparent rectangular containers (usually vertical or inclined) with a light path of 1-30 centimeters (Figure 2-8). Flat-plate photobioreactors mix substrate by vigorous air sparging from the bottom.

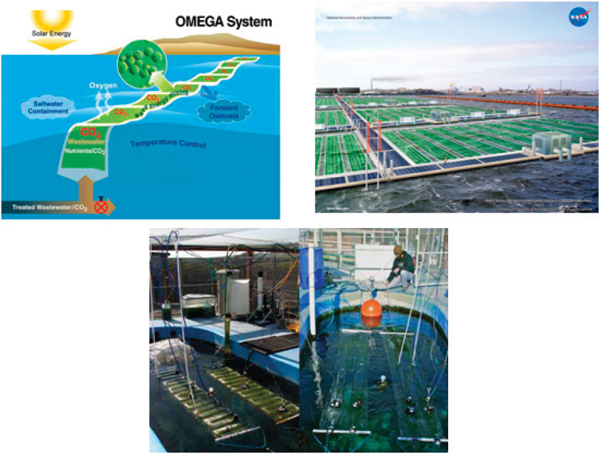

Productivities of algal biomass in photobioreactors vary with the type of geometric configuration used and the algal species grown (Table 2-3). Many novel production systems have been designed and currently are being developed and tested. The new production systems aim to lower construction and maintenance costs close to those of open-pond systems and maintain the high, stable productivity and reduced contamination risk of closed photobioreactors. These systems include the Solix, ACCORDION, Algenol, and the National Aeronautics and Space Administration’s (NASA) Offshore Membrane Enclosure for Growing Algae (OMEGA), and Photon8’s traveling wave system.

The Solix photobioreactor is an elongated (low height-to-length ratio) flat-panel photobioreactor made of plastics. It is designed to bridge the gap from flask to open raceway pond by serving as a controlled-environment test bed or as an algae inoculum scale-up device (Figure 2-9; Solix Biofuels, 2011). The Solix photobioreactor allows for open-pond deployment by using the water as a thermal regulator for open-air field applications. Air sparging for aeration and mixing occurs along the full length of each panel.

FIGURE 2-5 Tubular photobioreactors.

SOURCES: Clockwise from top left:

(a) California Polytechnic State University;

(b) Kennedy et al. (1995); and

(c) NanoVoltaix (2012). Reprinted with permission from Qiang Hu and Arizona State University/NanoVoltaix.

FIGURE 2-6 Triangular external air-lift tubular photobioreactors.

SOURCES: Vunjak-Novakovic et al. (2005). Reprinted with permission from American Chemical Society.

FIGURE 2-7 Tubular photobioreactors of straight horizontal tubes stacked in vertical fence-like arrays housed in a greenhouse in Klotze, Germany.

SOURCE: Algomed. Reprinted with permission from AGU.

FIGURE 2-8 Flat-plate photobioreactors.

SOURCES: (a) Algae Energy (2012b);

(b) NanoVoltaix (2012). Reprinted with permission from Qiang Hu and Arizona State University/NanoVoltaix.

TABLE 2-3 Microalgae Productivities in Photobioreactors

|

|

||||

| Photobioreactor | Volume (L) | Microalgal Species | Productivity (g DW/L/d) |

Reference |

|

|

||||

|

Airlift tubular |

200 |

Porphyridium cruentum |

1.50 |

Camacho Rubio et al. (1999) |

|

Airlift tubular |

200 |

Phaeodactylon tricornutum |

1.20 |

Acién Fernández et al. (2001) |

|

Airlift tubular |

200 |

Phaeodactylon tricornutum |

1.90 |

Molina et al. (2001) |

|

Inclined tubular |

6.0 |

Chlorella sorokiniana |

1.47 |

Ugwu et al. (2002) |

|

Undular row tubular |

11 |

Arthrospira platensis |

2.70 |

Carlozzi (2003) |

|

Helical tubular |

75 |

Phaeodactylon tricornutum |

1.40 |

Hall et al. (2003) |

|

Parallel tubular |

25,000 |

Haematococcus pluvialis |

0.05 |

Olaizola (2000) |

|

Bubble column |

55 |

Haematococcus pluvialis |

0.06 |

López et al. (2006) |

|

Flat plate |

440 |

Nannochloropsis spp. |

0.27 |

Cheng-Wu et al. (2001) |

|

Flat plate |

100 |

Nannochloropsis spp. |

0.30 |

Rodolfi et al. (2009) |

|

ACCORDION |

60 |

Monodus subterraneous |

0.40 |

Cuello and Ley (2011) |

|

|

||||

SOURCE: Adapted from Ugwu et al. (2007). Reprinted with permission from Elsevier.

FIGURE 2-9 Solix photobioreactor.

SOURCE: Reprinted with permission from Solix Biosystems.

NASA’s OMEGA is a flat-panel photobioreactor made of plastic. Inserts of forwardosmosis membranes allow the exit flow of oxygen and water while the photobioreactor is laid down horizontally on a water surface (Figure 2-10; Trent, 2011). OMEGA is designed for deployment on the surface of bodies of saline water (for example, sea and ocean) where it exploits wave movements for mixing culture and regulating temperature. This photobioreactor currently is undergoing redesign to overcome technical challenges; the final design likely will be more complex than its original design and could include some significant deviations (Trent, 2011).

The ACCORDION photobioreactor is a vertical series of flat plastic panels through which the algal suspension is grown in batch or grown continuously recirculated in batch, semicontinuous, or continuous modes (Figure 2-11; Cuello and Ley, 2011). The adjustable alternating vertical and angled flat plates, or alternating angled flat plates, are designed to improve the light incidence on surfaces and enhance the mixing and flow patterns inside the plates. For example, a treatment for a 60-liter ACCORDION photobioreactor with 45° plate angle and liquid flow rate of 14 liters per minute resulted in algal productivity of 0.30 grams of dry weight per day that was statistically indistinguishable from that of a 1-liter shake-flask control. The ACCORDION photobioreactor is a modular design that can be scaled up by adding modules. This is equivalent to open raceway ponds achieving scale up by adding raceway units. The ACCORDION photobioreactor currently is undergoing further design and structural optimization (Cuello and Ley, 2011).

FIGURE 2-10 NASA’s OMEGA photobioreactor.

SOURCE: Trent (2011).

FIGURE 2-11 ACCORDION photobioreactor.

SOURCE: Cuello et al. (2011).

FIGURE 2-12 Algenol photobioreactor.

SOURCES: Chance et al. (2011b); Algenol Biofuels (2012). Reprinted with permission from Ron Chance, Algenol Biofuels.

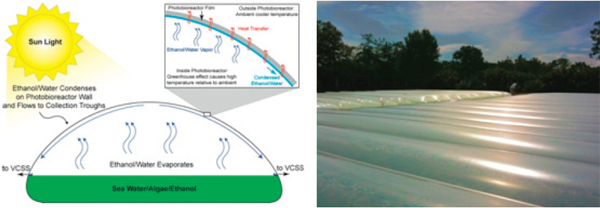

The Algenol photobioreactor is a plastic, horizontal, half-cylinder vessel that uses a hydrofoil that moves back and forth along the longitudinal axis of the photobioreactor to mix substrate (Figure 2-12). The photobioreactor, which is designed for direct ethanol production, is used to culture enhanced cyanobacteria that excrete ethanol into an aqueous medium. The ethanol-water mixture evaporates to form liquid condensate on the photobioreactor’s concave ceiling and flows down both the sides of its internal walls where plastic sleeves catch the ethanol-water condensate and convey it to a collection port at one end of the photobioreactor (Chance et al., 2011b).

2.2.4 Comparison of Open Systems and Closed Systems

Table 2-4 compares open-pond systems and closed photobioreactor systems for photoautotrophic microalgae production. Although outside the scope of this report, the low costs of construction and maintenance constitute one of the biggest advantages of open-pond

TABLE 2-4 Comparison of Open and Closed Algal Cultivation Systems

|

|

|||

| Parameter | Open System | Closed System | Reference |

|

|

|||

|

Cost |

Lower |

Higher |

Shen et al. (2009) |

|

Pumping energy |

Lower |

Higher |

Becker (1994); Shen et al. (2009) |

|

Ease of scale up |

Greater |

Lower |

Shen et al. (2009) |

|

Evaporative water loss |

up to 10 L/m2/day |

Negligible where wind cooling is sufficient; 1-2 L/m2/day when water-spray cooling is used; or similar to open systems if photobioreactors are submerged in ponds for cooling |

Becker (1994) |

|

Land area required |

Higher |

Lower |

|

|

Contamination risks |

Higher |

Lower |

Borowitzka (1999); |

|

Productivity |

Lower |

Higher |

See Tables 2-1 and 2-2 |

|

Productivity stability |

More variable |

Less variable |

Shen et al. (2009) |

|

Sparged CO2 loss |

Higher |

Lower |

Becker (1994); Shen et al. (2009) |

|

|

|||

systems compared to photobioreactors. The conventional view was that the use of openpond cultivation is more likely to achieve the goal of technoeconomic feasibility for producing microalgae for biofuels than the use of photobioreactors. Because of their lower capital costs and simpler designs, open-pond systems are easier to scale up to increase production than photobioreactors. Most photobioreactor configurations are scaled up by multiplying units and by increasing the unit volume. Increasing unit volume of photobioreactors requires adjustments of physical variables to achieve appropriate flow dynamics within the new unit volume. Disadvantages of open-pond systems include losses of water to evaporation, risk of contamination by competing microorganisms, loss of algal biomass due to weather, and loss of introduced CO2. (See Chapter 4 for details on evaporative water loss.)

Advantages of photobioreactors include significantly higher microalgal biomass productivity and greater production stability over time than open-pond systems. For example, the volumetric productivity of Nannochloropsis spp. in photobioreactors could exceed that in open raceways by as much as 16 times (Table 2-4). The risk of biological contamination is much greater in open-pond systems than in closed photobioreactor systems. With the exception of Spirulina and Dunaliella salinas, which are cultivated in open systems under highly selective growing conditions, the lack of competitive advantages of many of the microalgal species being tested for biofuel production in open ponds and their susceptibility to culture crashes are concerns. Thus, the low volumetric productivity and susceptibility to contamination could constitute a substantial risk to the economic sustainability of openpond cultivation systems compared to closed photobioreactor systems.

The utilization efficiencies of some vital input resources in terms of production per unit input—particularly for water and land—are in general lower in open cultivation systems than in closed photobioreactors (Table 2-5; Davis et al., 2011). As noted above, evaporative water loss is of particular concern in open-pond systems. These losses could be as much as 10 liters per m2 per day. Thus, a one hectare open pond could lose 100,000 L of water per day or 36,500,000 liters of water per year. When the cooling of photobioreactors is achieved through water-spray cooling or through submergence in open ponds, the evaporative water loss associated with photobioreactors also can be substantial and as much as in open systems. Table 2-5 further compares the land area requirement, energy consumption, net energy ratio, and other criteria for cultivating Nannochloropsis spp. in an open raceway, flat-plate photobioreactor, and tubular photobioreactor to produce 100,000 kg dry weight (DW) of algal biomass per year (Jorquera et al., 2010). The land area required for the open raceway exceeded that of the tubular photobioreactor by 241 percent and that of the flatplate photobioreactor by 256 percent. The total energy consumption for the open raceway, flat-plate photobioreactor, and tubular photobioreactor were 3.72 watt per cubic meter (W/m3), 53 W/m3, and 2,500 W/m3, respectively. The resulting net energy ratios for oil production, defined as the total energy produced divided by the total energy requirement, were 3.05, 1.65, and 0.07 for the open raceway pond, flat-plate photobioreactor, and tubular photobioreactor, respectively. While the tubular photobioreactor had a net energy ratio of less than 1, and thus consumed more energy than it produced, the net energy ratios for flatplate photobioreactors and open raceway ponds were both greater than 1. Therefore, the favorable energy balance might persist through mass cultivation of Nannochloropsis using either of these methods. However, the 2010 study by Jorquera et al. did not consider the harvest costs and the cost of oil extraction that add significantly to energy consumption. A thorough discussion of life-cycle assessment (LCA) of energy balance for algal biofuels is in Chapter 4. The Jorquera study was part of a meta-analysis that reanalyzed published data to provide an estimate of the energy requirement for fuel production (Liu et al., 2012). The true energy return may not fully be known until full-scale commercial production has been

TABLE 2-5 Comparison of Raceway Ponds, Flat-plate, and Tubular Photobioreactors in Cultivating Nannochloropsis spp. to Produce 100,000 kg DW Per Year

|

|

|||

| Variable | Raceway Ponds | Flat-Plate Photobioreactors | Tubular Photobioreactors |

|

|

|||

|

Annual biomass production (kg/year) |

100,000 |

100,000 |

100,000 |

|

Volumetric productivity (g/L per day) |

0.035 |

0.27 |

0.56 |

|

Illuminated areala productivity (kg/m2 per day) |

0.011 |

0.014 |

0.0081 |

|

Occupied arealb productivity (kg/m2 per day) |

0.011 |

0.027 |

0.025 |

|

Occupied arealb productivity (t/ha per year) |

39 |

99 |

93 |

|

Illuminated areala volume (per m2) |

300 |

50 |

14 |

|

Illuminated areaa/volume ratio (per m) |

3.3 |

19 |

69 |

|

Occupied areab/volume ratio (per m) |

2.3 |

10 |

22 |

|

Biomass concentration (g/L) |

0.35 |

2.7 |

1.02 |

|

Dilution rate (per day) |

0.1 |

0.1 |

0.1 |

|

Area required for biomass production of |

26,000 |

11,000 |

11,000 |

|

100,000 kg/yr (m2) |

|||

|

Reactor volume required for biomass production of |

7,800 |

1,000 |

490 |

|

100,000 kg/yr (m3) |

|||

|

Flow rate required to maintain a 0.1 /day dilution |

780 |

100 |

49 |

|

rate (m3/day) |

|||

|

Hydraulic retention time (volume/flow rate) |

10 |

10 |

10 |

|

Relative oil content (%) |

30 |

30 |

30 |

|

Net oil yield (m3/year) |

33 |

33 |

33 |

|

Oil yield per area (m3/ha per year) |

13 |

32 |

31 |

|

Energy consumption (W/m3) |

3.7 |

53 |

2,500 |

|

Energy consumption required for accumulation of |

29,000 |

54,000 |

1,200,000 |

|

100,000 kg/year biomass (W) |

|||

|

Total energy consumption (kWh/month) |

8,700 |

16,000 |

370,000 |

|

Total energy consumption (GJ/year) |

378 |

700 |

16,000 |

|

Energy produced as oil (GJ/year) |

1,200 |

1,200 |

1,200 |

|

Total energy content in 100,000 kg biomass (GJ/year) |

3,200 |

3,200 |

3,200 |

|

NER for oil production |

3.1 |

1.7 |

0.07 |

|

NER for biomass production |

8.3 |

4.5 |

0.20 |

|

|

|||

aIlluminated area refers to the surface area of a raceway pond or photobioreactor subject to illumination.

bOccupied area refers to the land area occupied by the raceway pond or photobioreactor.

NOTE: Net Energy Ratio (NER) = total energy produced/total energy requirement.

SOURCE: Adapted from Jorquera et al. (2010). Reprinted with permission from Elsevier.

realized. Even then, uncertainty in the estimates of energy return might remain, as in the case of corn-grain ethanol (Hall et al., 2011). Where biofuel feedstocks consist of genetically modified organisms or other organisms of potential societal concern (for example, organisms that have been invasive in one or more environments), photobioreactors may be more acceptable to some communities or individuals.