3

Pathways for Algal Biofuel Production

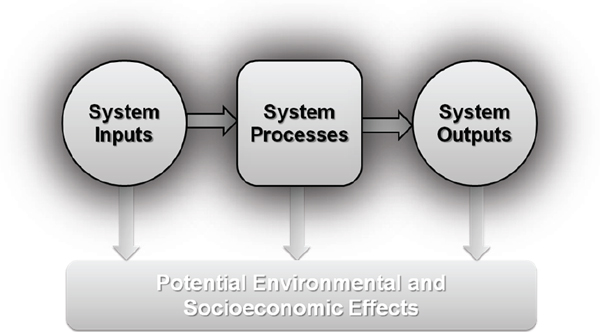

The set of processes that lead from algae cultivation to collection and harvest, and finally to fuel conversion is termed the pathway for algal biofuel production. This chapter describes several contrasting pathways that lead from algae cultivation to fuel production. The pathways described here are used in subsequent chapters to provide a framework for understanding the sustainability impacts of different approaches for producing algal biofuels. The intent is to group pathways that share common processes to help contrast resource requirements and impacts of different approaches and to help clarify the key biological and engineering advances that are needed to improve sustainability.

3.1 FEATURES OF BIOFUEL PATHWAYS

Pathways for producing liquid biofuels share many common features regardless of the biomass feedstock being used. All have a cultivation step, a collection or harvest step, and a processing or finishing step. Some land-based crops are used or being considered for use as biofuel feedstock because of their ability to produce oils, their ability to produce carbohydrates that are readily converted to fuels by microbial action, or their ability to fix carbon with low input. Oil-producing crops, such as soybean, jatropha, and camelina, are harvested and the oil is separated for subsequent processing. Sugar in sugarcane and starch in corn grain can be converted efficiently to ethanol by yeast and bacteria. Dedicated energy crops, such as poplar, switchgrass, and Miscanthus, are selected because of their growth with low inputs of nutrients or their ability to store carbon in soil (Tilman et al., 2006; Pyter et al., 2009; NRC, 2011). The lignocellulosic biomass can be converted chemically, thermochemically, or biologically to liquid fuels (NAS-NAE-NRC, 2009). There are algal biofuel systems analogous to each of these feedstock types. Analysis of the options in the cultivation, collection, and processing of algae is complicated by the vast number and complexity of options. As discussed in more detail in Chapter 4, these options affect the resource requirements needed to produce fuels. Analyzing all possible pathways in this report is not practical. However, the pathways can be grouped by the main features they share that are affecting resource use and energy balance. A few representative pathways are analyzed to illustrate the current state of the technologies and where advances are needed to reduce the resource requirements.

Trends observed in the science and technologies for other biofuel production are likely to occur in algal biofuel production as the latter develops as an industry. These trends include improvements in biomass production and total biomass processing discussed in Chapter 2, and the increasing comparative analysis of the full life-cycle impacts and requirements for various sources of alternative liquid fuels through the use of life-cycle assessments (LCAs) discussed in Chapters 1, 4, and 5. An additional trend is the move toward drop-in fuels that are compatible with existing infrastructure for petroleum-based fuels. Ethanol and fatty-acid methyl esters (FAME; or commonly called biodiesel) have compatibility and performance issues in vehicles that hamper their adoption (NAS-NAE-NRC, 2009; NRC, 2011). Current trends are moving toward production of pure hydrocarbon fuels or blendstocks that are compatible with existing fuel infrastructure and vehicle technologies (NREL, 2006).

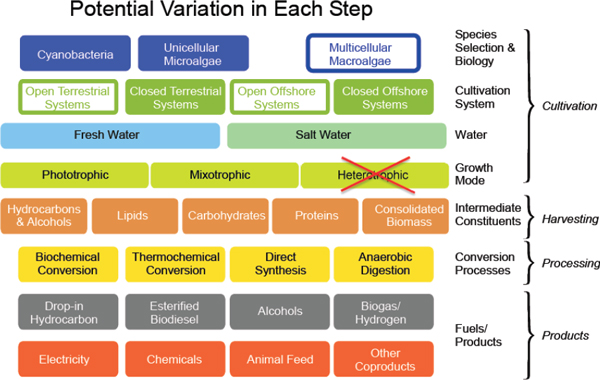

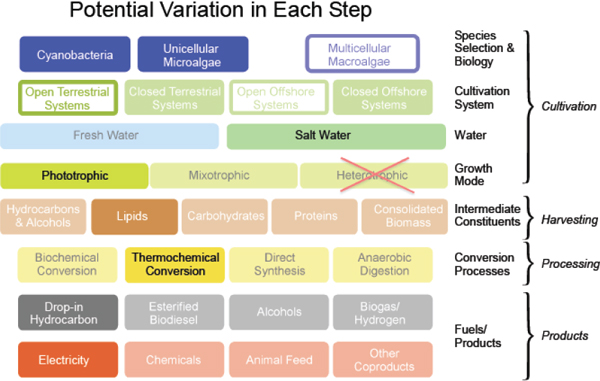

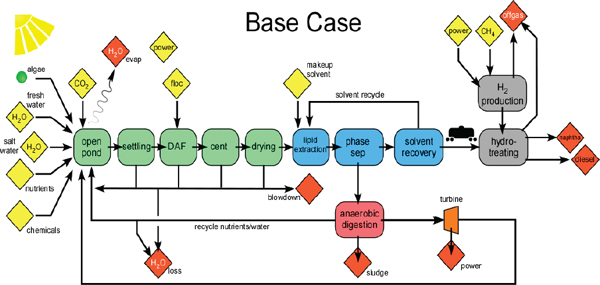

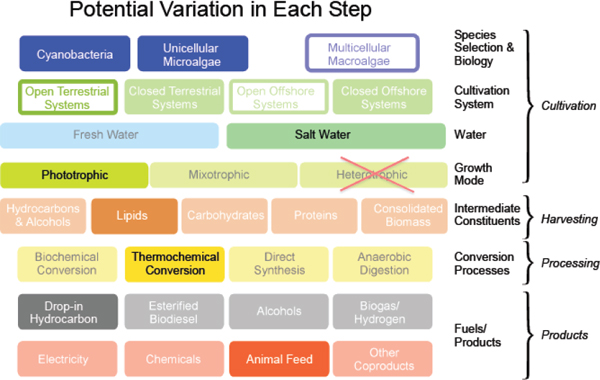

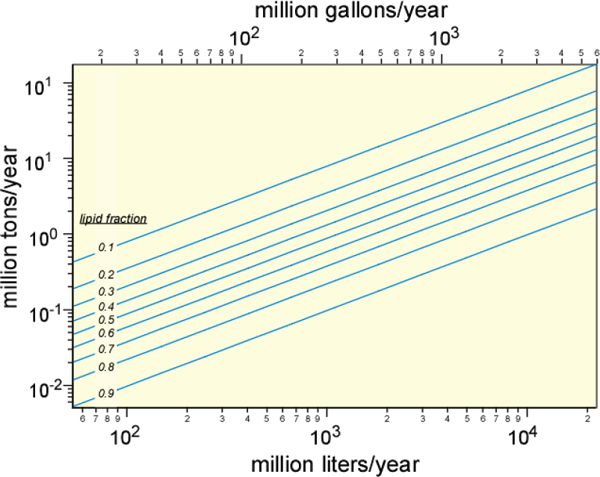

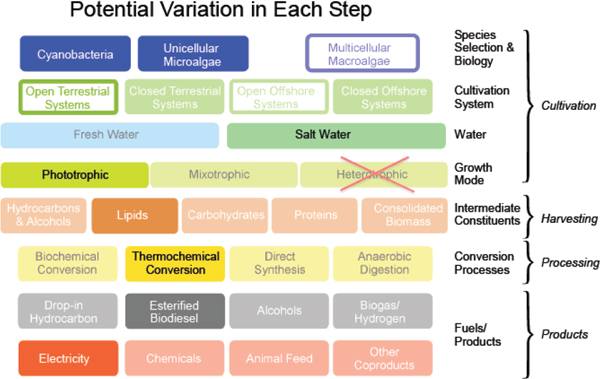

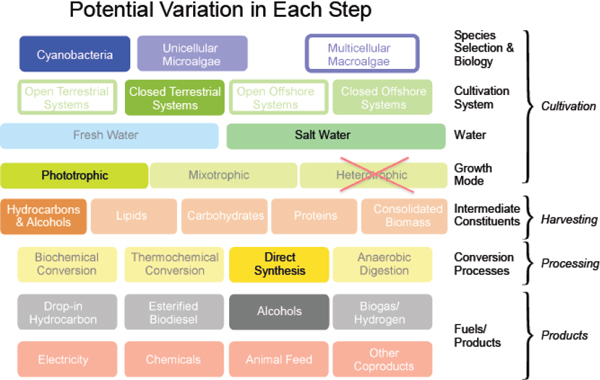

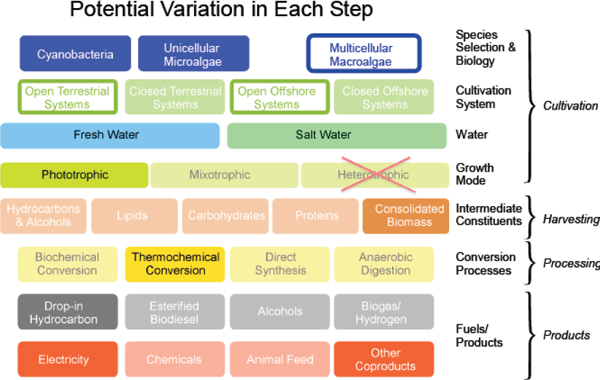

The production of fuels and energy from algae is not an established industry and a variety of production systems have been proposed. Figure 3-1 is a simplified diagram that attempts to limit and group the potential steps in the algal biofuel production pathway. Each row of the diagram details a processing step or process option. Different combinations of cultivation and processing options have resulted in more than 60 different proposed pathways for producing algal biofuels.

As noted in Chapter 1, this study focuses on algal production systems that rely directly on photosynthesis (see Figures 3-1 and 3-2). Heterotrophic cultivation is, by design, outside the scope of this report. The exclusion of heterotrophic production from this report is not a judgment on the validity of these approaches but a reflection of the requirement to study photosynthetic algae as a feedstock for fuel production. This report examines pathways for producing liquid transportation fuels from algae. Gaseous power generation and hydrogen production are not discussed. Proteins are considered only as coproducts.

From the perspective of this study, the large number of possible designs of an algal biofuel pathway means that a small number of the most likely designs need be chosen

FIGURE 3-1 Pathways for cultivating and processing algae to fuels and their products.

NOTE: Heterotrophic routes are outside the scope of this analysis.

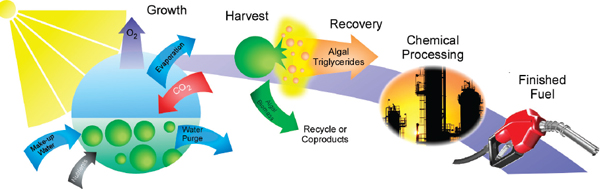

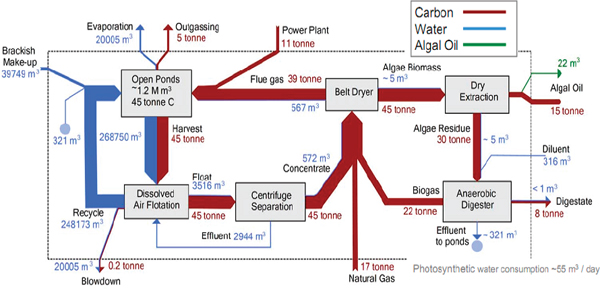

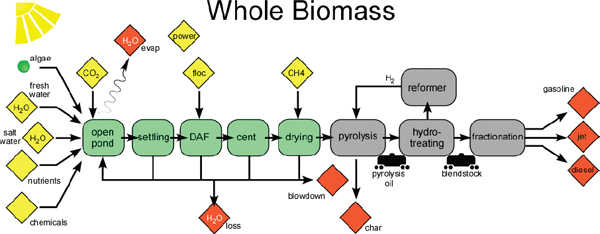

FIGURE 3-2 An example of processes involved in converting algae to fuels.

and used as a framework for the analysis of sustainability. The pathways help illustrate the resource requirements and potential impacts associated with greatly scaling up various approaches to produce algal biofuels. These pathways also allow different approaches to be compared and contrasted directionally, enabling conclusions to be drawn, pitfalls identified, and potential solutions drafted. The reference pathway is drawn from the recent National Renewable Energy Laboratory techno-economic analysis of algal biofuel production (Davis et al., 2011).

3.2 REFERENCE PATHWAY–RACEWAY POND PRODUCING DROP-IN HYDROCARBON

For the purpose of this discussion, the reference pathway assumes that microalgae are cultivated in saline water in an open raceway pond. Algae are harvested and lysed to release lipids, which are collected for further processing into green diesel1 (also called renewable diesel), a drop-in hydrocarbon fuel (Figure 3-3).

Under the reference pathway, lipid-producing species are selected, and recovered lipids are converted by known chemical processes to yield hydrocarbon fuels. The chemical structures of these hydrocarbon fuels are oxygen-free and appropriate for use in aviation and as on-road fuels. Lipid recovery in the most often described processes requires that the cells be destroyed (lysed) and cell membranes ruptured to release intracellular oils. The algal triacylglycerol can be processed in several ways. Similarly, the remaining cellular mass can have different uses. Two of the uses being considered are recycling back to algae cultivation or selling as a coproduct. For the reference case, the biomass is treated anaerobically to produce biogas for power generation, with the effluent being returned to the culture to provide needed nutrients. According to Davis et al. (2011), this treatment recovers almost all of the biomass phosphate and much of the nitrogen (N) used during cultivation.

The reference pathway is further amplified in Figure 3-4, which shows the details of the processing steps. For this and subsequent figures, several conventions have been adopted. Yellow diamonds show the inputs to the system and orange the outputs. Green process steps represent those associated with algae cultivation, light blue with lipid collection, and

FIGURE 3-3 Reference pathway: Open raceway pond producing green diesel, a drop-in hydrocarbon fuel.

_______________

1 Green diesel is a product of hydrotreating of triglycerides.

FIGURE 3-4 Inputs and outputs of the reference pathway.

NOTES: Reference pathway uses open raceway pond to produce algae for processing to green diesel. Tankcar symbol reflects only the option for separating the lipid production remote to the fuel processing. DAF is dissolved air flotation, cent is centrifugation.

grey with chemical processing. Algae are harvested and ruptured during the oil extraction, resulting in an oil and a lipid-extracted biomass. The reference pathway assumes that the algal biomass is first recovered by flocculation by adding a chemical agent such as chitosan (Davis et al., 2011). Material is recovered by dissolved air flotation (DAF). In DAF, air is introduced to lift the algae to the surface where it can easily be recovered. DAF increases the algal biomass to liquid ratio, but centrifugation is still required to reduce water content for subsequent oil recovery. The lipid-extracted biomass is digested anaerobically to produce high-quality energy, and its nutrient content is returned to the algal culture. The hydrotreating of algal lipids to produce pure hydrocarbon fuels is analogous to second generation biodiesel production, which is based on seed crops to produce green diesel (NREL, 2006). This pathway represents what the committee believes to be the one of the most probable pathways for producing drop-in fuels from algae based on the current state-of-the-art technologies for cultivation and processing.

Hydrotreating is used to convert raw triacylglycerol into a drop-in hydrocarbon fuel (Olusola et al., 2009; Serrano-Ruiz et al., 2012). Hydrotreating is a traditional refinery operation that serves to remove heteroatoms from incoming fuels, hydrogenate olefinic species to alkanes, and, potentially, to do some chain cleavage. Its main function with regard to lipids is to remove oxygen from the feedstock, thereby making alkanes out of the lipid chains, propane out of the glycerol backbone, and water out of all oxygen molecules (Davis et al., 2011). Processing algal lipids by hydrotreating offers several advantages. First, a drop-in replacement fuel is produced. Drop-in hydrocarbon fuels are increasingly desired, and their production is accomplished by collecting algal triacylglycerol as an intermediate product. This intermediate product can be shipped efficiently to refineries for inclusion in the conventional fuel pool. Triacylglycerol also can be processed near the cultivation facility. There are scale advantages in the hydrotreating that might favor transportation to a larger facility fed by many algae farms. Among them is the requirement for hydrogen. Supplying

hydrogen by pipeline or from a dedicated central facility likely has significant economic benefits. Leveraging current processing assets provides a cost benefit during production. Another advantage is that heteroatoms, in addition to oxygen, are removed, just as in conventional refinery operation. Finally, hydrotreating is well known with currently existing unit operation at refineries. Therefore, integration into existing assets is a relatively easy transition.

Much of the energy discussion in the preceding section dealt with energy use in the cultivation and harvest components, which are color-coded green in Figure 3-4. Many of the completed LCA studies on energy use and greenhouse-gas (GHG) emissions that are discussed in Chapters 4 and 5 have not included next-generation green diesel production in their analyses. The pathway illustrated in Figure 3-4 introduces fossil energy inputs in the form of hydrogen production for use in refinery operations. LCAs on algal biofuels made by hydrotreating are not yet available. Thus, comments on the energy consumption and LCA for this reference pathway are made based on analogies. Studies comparing the production of drop-in hydrocarbon to conventional esterified biodiesels (FAME) suggest that the conversion could be similar to or better than conventional biodiesel in terms of fossil fuel inputs and GHG emissions (Kalnes et al., 2008). It can, therefore, be inferred that production methods relying on hydrotreating have the potential to be as good as or better than conventional biodiesel while yielding a fuel with better properties than FAME.

The reference pathway shows a dry process in which biomass is collected and dried prior to extraction of oil. In that process, oil extraction is accomplished with the aid of solvents that require purification prior to reuse. Figure 3-5 shows the energy and water requirements for a pathway that uses such a dry process. The collection, drying, and extraction components require significant levels of energy inputs and have the potential for innovation to reduce overall energy use. Wet processes—where the cell membranes are disrupted in the aqueous medium to release the lipids which phase separate to enable collection— are likely to have considerably lower energy use than dry processes (Beal et al.,

FIGURE 3-5 Carbon and water flow in the reference case scenario: Open raceway pond producing green diesel.

SOURCE: Marler (2011). Reprinted with permission from the American Chemical Society.

2011). The high content of neutral oils also may eliminate the need for solvent extraction. These types of innovations are important for energy balance.

Phosphorus (P) within the organism in the form of phospholipids presents additional complexity in processing algae into fuels. These molecules are detrimental to downstream processing and in end-use can inhibit or poison catalysts used in fuel conversion and can damage vehicle catalytic converters (Fan et al., 2010). ASTM D6751-11b, which is the standard specification for biodiesel fuel blend stock for middle distillate fuels, specifies maximum P content allowable in biodiesel blend stock. P compounds are removed using the degumming technology developed for use with seed oils (Lurgi GmbH; AlfaLaval, 2010). Most commonly, phospholipids are converted to immiscible solids that are then removed by centrifugation. Methods of extracting phospholipids include water, acid, or enzymatic degumming. The most commonly used acid is phosphoric acid. Any of these methods produces a crude gum stream for disposal or alternative use. Acid and enzymatic degumming, while truly catalytic, require acid and enzyme additions.

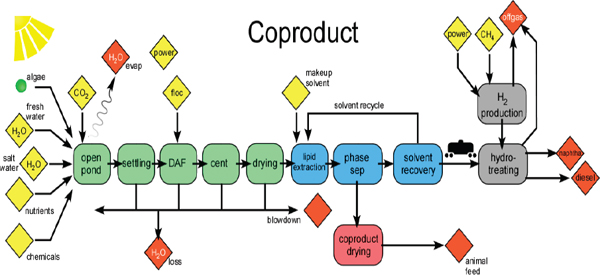

3.3 ALTERNATIVE PATHWAY #1—RACEWAY POND PRODUCING DROP-IN HYDROCARBON AND COPRODUCTS

The next pathway, illustrated in Figures 3-6 and 3-7, assumes that the algal biomass has sufficient value so that it provides a significant revenue stream. This pathway assumes that the biomass has value in the unprocessed and dewatered state, and that subsequent processing to recover minor valuable components is not done.

FIGURE 3-6 Alternative pathway #1: Open raceway pond producing green diesel, a pure hydrocarbon fuel with coproduct for sale.

FIGURE 3-7 Inputs and outputs of the alternative pathway #1: Open raceway pond producing green diesel with fuel and animal feedstuff as coproducts.

This pathway results in the increased nutrient requirements for algae cultivation compared to the reference pathway because of the loss of biomass nutrients from direct coproduct sales. The scale of biofuel production has a large impact on the volume, and therefore the value, of coproduct streams. The committee believed that coproducing high-value products, such as chemical feedstocks, with biofuels would be viable only on a small scale. If large quantities of high-value algal products are coproduced with biofuels, the coproduct value likely decreases with market saturation. A coproduct that is likely to have a large enough market to absorb the large quantities produced is animal feedstuff. The coproduct value depends on the composition of the animal feedstuff and the characteristics of the market in which it would be sold.

Coproducing algal biofuels and high-value products has been suggested as a strategy to address the challenge of making algal biofuels economically viable. The strategy has proven to be contentious at several levels. Coproducts are strongly linked to the economics and LCAs of algal biofuel production. The economics of algal biofuel production are outside the scope of this analysis, but are a key reason for the importance of coproducts. Coproducts are proposed as a means to improve the economics of algal biofuel production. Economic benefit comes at a cost, however, and a simple analysis is presented to explain the impacts and potential concerns. First, some general comments can be made based on published works and presentations to the committee. Perhaps the strongest statements heard involved the strategy of LiveFuels, Inc. in testimony before the committee (Morgenthaler-Jones, 2011). The presenter believed that the economics of producing algal biofuels at a cost that is competitive with fossil fuels is impossible. The company’s focus moved to fish production with a coproduct oil outlet. The majority of the revenue is now envisioned to come from fish, and all oils produced (fish oil for human or animal nutritional supplements and biofuels for transportation) are sold. Others have taken a more measured approach and have claimed that coproducts could contribute to the profitability of algal biofuels while their market develops, and the cost of algal biofuel production would decrease with efficiency improvements and economies of scale.

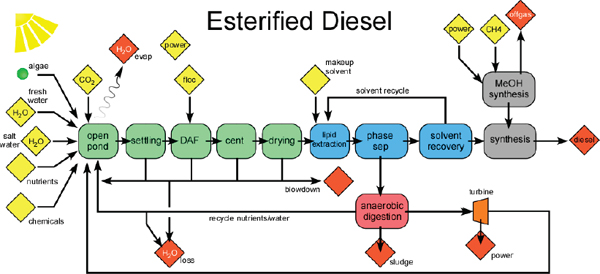

FIGURE 3-8 Annual residual biomass production, in million tonnes per year, shown as a function of annual fuel production and lipid fraction.

NOTES: A single algal biofuel refinery is likely to have a capacity of 90 million liters per year. Current algae are cultivated in the 20 to 30-percent lipid mass fraction range. Five percent of annual U.S. consumption of transportation fuels is about 39 billion liters.

The amount of residual biomass increases quickly as the scale of biofuels increases. Residual biomass is a function of the amount of fuel produced and the fraction of the total dry biomass. Plotting residual biomass as a function of both lipid fraction and annual fuel production indicates the magnitude of the issue (Figure 3-8). An algal biofuel refinery sized equally to a typical 95 million liter (25 million gallon) transesterification biodiesel refinery yields more than 180 thousand tonnes of residual biomass at a 30 percent lipid fraction. If an industry capable of supplying 3.8 billion liters (1 billion gallons) was built, which is still only one-tenth of what the fuel ethanol is in the United States today, the residual biomass would reach 7.7 million tonnes. As discussed with respect to the reference pathway, this residual biomass can be used in anaerobic digestion to produce power, but some sludge would remain and require disposal. (Waste management is discussed in Chapter 5.) The alternative pathway #1 considers using this residual to produce coproducts such as animal feedstuff.

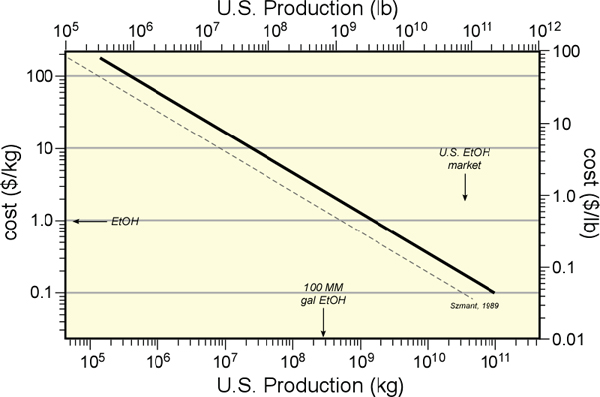

Although coproduction of fuel and other products can improve the economics of algal biofuels, it has limited potential and cannot be the single remedy to improving the economic viability of widespread and large-scale deployment of algal biofuels. (See Appendix G for details.) Markets tend to correlate scale and price of sale, which is the cost of production

FIGURE 3-9 Chart showing the general power law dependence of a materials cost with production scale.

NOTES: As scale increases, price generally decreases. This is true both for fuel components and coproducts. The dotted line shows Szmant’s original curve and the solid line is inflation corrected to 2010.

SOURCE: Adapted from Szmant (1989).

plus return on capital. This is frequently overlooked as coproducts are touted as a significant source of additional revenues for an economically suspect fuel production process. The correlation is somewhat poor across different products, but for a single product, scale and price are related by a power law (Figure 3-9). This means that doubling scale reduces price more than double. For materials intended to be sold into the massive fuels market, coproduct volumes swell rapidly with the scaling of fuel production unless a wide variety of coproducts for different markets are produced. From a resource sustainability perspective, the reference pathway described earlier closely represents the economic analyses and LCAs that have been completed. The use of anaerobic digestion to return nutrients to the algae cultivation and electrical power to the algal biofuel production system is a key component of alternative pathway #1. Removing the residual biomass as a coproduct, therefore, affects the energy balance of fuel production and the required nutrient load.

3.4 ALTERNATIVE PATHWAY #2–RACEWAY POND PRODUCING FAME

Most of the reports on algal biofuels assume that FAME is produced. FAME is not a hydrocarbon fuel, but an ester made by transesterification of the triacylglycerol. This pathway most closely approximates conventional biodiesel in the way that crude bio-oil is converted to a transportation fuel (Figure 3-10). Algal triacylglycerol are reacted with methanol to form FAME or so-called biodiesel (Figure 3-11; Van Gerpen, 2005). FAME

FIGURE 3-10 Alternative pathway #2: Open raceway pond producing esterified biodiesel, also known as fatty-acid methyl esters (FAME).

FIGURE 3-11 Inputs and outputs of the alternative pathway #2: Open raceway pond producing a fatty-acid methyl ester (FAME).

has poor cold-flow properties and cannot be used as pure components in cold environments. The increased viscosity relative to hydrocarbon diesel makes FAME difficult to pump. Even in mixtures, cloud point issues can occur when wax crystals begin to form. The wax crystals can lead to gel formation, which is incompatible with engine operation.

Biodiesel-containing mixtures have higher cloud points and pour points (the temperature at which the fuel has gelled so it no longer flows) than pure hydrocarbon diesels. Therefore, biodiesel usually is blended with petroleum-based diesel for final use. Because of its higher oxygen content, FAME has 10 percent lower energy content than hydrocarbon diesel; hence, it has reduced vehicle mileage per gallon in use. FAME biodegrades with long-term storage because of its chemical activity, and exposure to air and water accelerates the degradation (NRC, 2011). However, FAME can be made with relative efficiency at small scales so that algal processing and finished fuel production can occur at the same site. It also has low sulfur content and aromatics, and therefore results in low particulate emissions when the fuel is combusted. Coproduct glycerol also is produced in this pathway, but glycerol has a low market value.

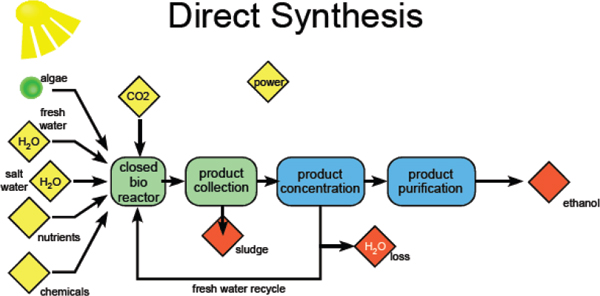

3.5 ALTERNATIVE PATHWAY #3–PHOTOBIOREACTORS WITH DIRECT SYNTHESIS OF ETHANOL

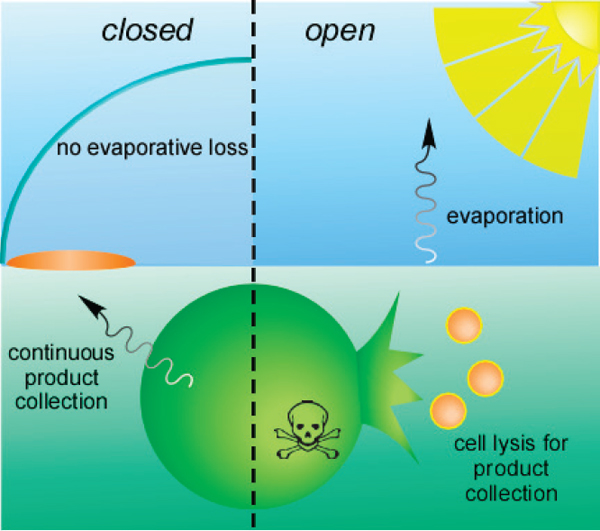

Previously described processes for algal biofuel production have focused on openpond systems for algae cultivation, and most analyses indicate that photobioreactor systems are cost prohibitive for the production of fuels (Williams and Laurens, 2010). At present, photobioreactor systems are used to produce algal biomass for high-value products, such as nutraceuticals and cosmetic ingredients (BioProcess Algae, 2011; Boussiba, 2011; Photon8, 2011; Thomas, 2011). The next pathway described assumes that a marine species of algae or cyanobacteria directly produce a valuable fuel product (Figure 3-12). Direct synthesis of fuel components virtually requires that the algae or cyanobacteria be cultivated in

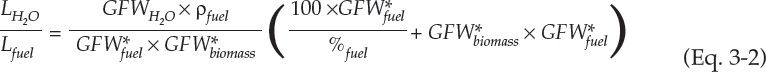

FIGURE 3-12 The Algenol direct synthesis pathway uses a closed reactor with an organism that directly produces alcohols.

FIGURE 3-13 An illustration of the key differences between direct synthesis and the more common practice of cell lysis for lipid collection and why closed systems are required for continuous collection of volatile products.

a closed photobioreactor to prevent product degradation. This option differs dramatically from the production of lipids that require rupture of the cell membrane to harvest. Harvest is continual, with the organism releasing product into the media continuously. The algal or cyanobacteria culture can be stable for months. This pathway cannot be carried out in an open pond because the rate of fuel synthesis is believed to be about the same as the rate of microbial degradation. In addition, volatile products would be lost to evaporation (Figures 3-13 and 3-14).

The alternative pathway #3 is effectively the Algenol process, as it was described to the committee (Luo et al., 2010; Chance et al., 2011). Other companies known to be pursuing direct production are Joule Unlimited and Synthetic Genomics, Inc. Publications from Joule indicate that pure hydrocarbons are the company’s preferred target product (Robertson et al., 2011; Joule Unlimited, 2012).

The Algenol process uses a marine species of cyanobacteria to directly produce ethanol (see also Figure 2-12 in Chapter 2). Algenol reactors are polyethylene bags. The cyanobacteria release ethanol into the supporting media, which then partitions between the liquid and photobioreactor headspace. Ethanol produced is trapped in the closed photobioreactor. Solar energy penetrating the bag forms a kind of “solar still.” Primary collection of dilute ethanol is mostly solar driven, but subsequent purification steps require input of fossilderived energy to produce an alcohol fuel product that meets fuel specifications.

FIGURE 3-14 Inputs and outputs of the alternative pathway #3: Photobioreactors with direct synthesis of ethanol.

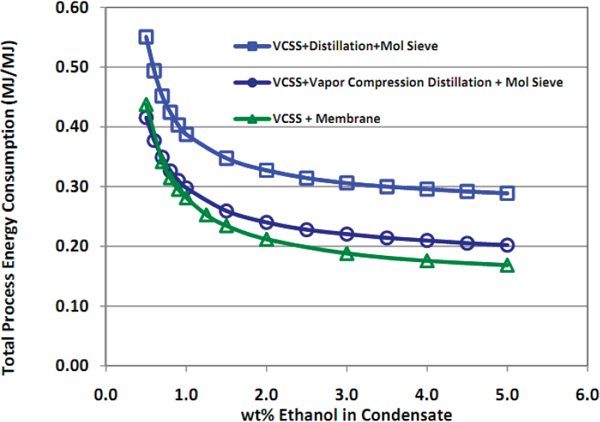

Algenol measured the concentration in the ethanol condensate in the photobioreactor and found that to be 0.5 to 2.0 percent (Chance et al., 2011). The energy required to recover the alcohol as useable fuel largely determines the energy return and, hence, the GHG emissions for the process. Figure 3-15 shows the impact of the ethanol concentration on the energy consumption of the entire process. A combination of separation methods (for example, vapor compression stream stripping, molecular sieve, vapor compression distillation, distillation, and membrane) is needed for ethanol separation. The energy balance results are generally favorable; that is, more energy is retained in the fuel than is required to make it (Luo et al., 2010). The energy return on investment of this pathway reported to the committee by a representative of Algenol is within the range of 1.2 widely reported for corn-grain ethanol and 8 reported for ethanol from sugarcane (Chance et al., 2011). However, these results and those for other algal biofuels systems were not obtained from fully scaled-up demonstration facilities.

Comparison of the Algenol results to other studies on algal biofuels is favorable in terms of energy and other resource requirements. Eliminating the need for dewatering reduces energy requirements and is a clear advantage of processes that directly produce fuel. Also inherent to a closed photobioreactor system are the advantages of lower water and nutrient consumption and reduced risk of contamination. The capital cost is a frequently cited concern for biofuel-producing closed photobioreactor systems (Benemann, 2008; Williams and Laurens, 2010), but it is not addressed in this report.

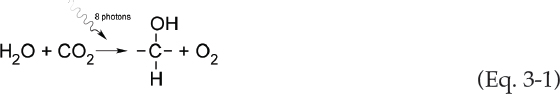

Water use can be significantly reduced in a closed bioreactor, but cannot be fully eliminated. Water is lost to photosynthesis and in processing. Irrespective of whether marine or freshwater algae are used, fresh water addition or water purge is required to maintain water level and key concentrations, such as salinity. Photosynthesis consumes water:

FIGURE 3-15 Process energy requirements as a function of the alcohol concentration in the condensate.

NOTE: The energy requirement is affected by the choice of subsequent purification technology. Vapor compression steam stripping (VCSS), molecular sieve (Mol Sieve), and vapor compression distillation are methods for ethanol separation.

SOURCE: Chance et al. (2011). Reprinted with permission from Ron Chance, Algenol Biofuels.

For every carbon fixed, at least one water molecule is reacted (Eq. 3-1). Even in the case of no evaporative loss and full recycle of process water, water is consumed because of photosynthesis. This amount can be estimated from the stoichiometry of photosynthesis and fuel production. The limiting cases for a closed system are shown in Figure 3-16.

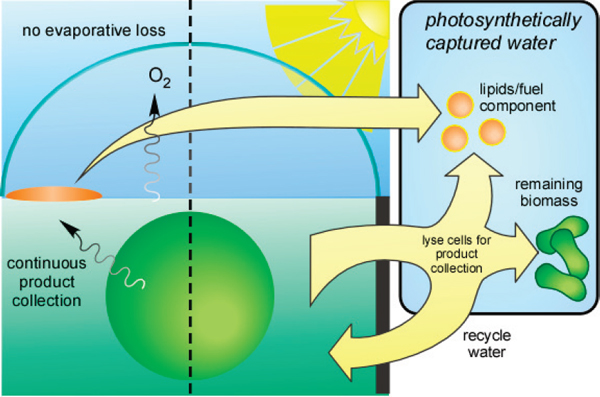

The water consumed during photosynthesis depends on the apportioning of the fixed carbons in biomass or fuel component. In the case of the Algenol design referenced here, all the fixed carbons are effectively in the fuel component, which is ethanol that has a gram atomic weight of 46 grams/mole. The carbon average molecular weight is 46/2 or 23 grams/mole. The carbon average molecular formula for biomass is CH2O, with a carbon average molecular weight of 30 grams/mole. Lipids have a carbon average molecular weight of approximately 16 grams/mole. The equation for the amount of water lost to photosynthesis per liter of fuel produced is:

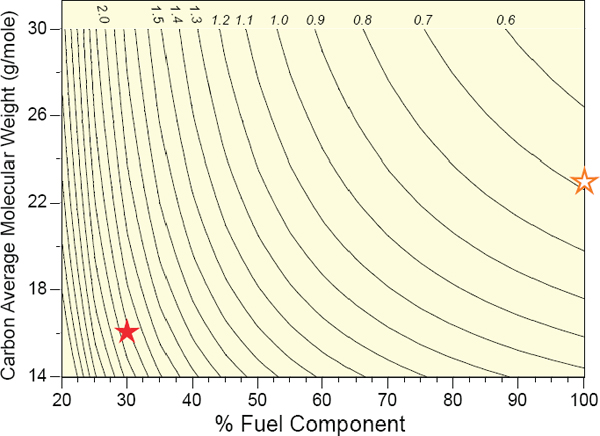

where the GFW* are the carbon average molecular weight of the fuel component or residual biomass (Eq. 3-2). Figure 3-17 shows the water to fuel volume ratio as a function of the

FIGURE 3-16 Water consumption by photosynthesis in the production of algal biomass for fuels.

NOTES: In the case of a stable culture that continuously secretes products for collection, there are no residual biomass carbons. In contrast, water was consumed fixing the carbons in both the residual biomass and the fuel component in the case where algal cells are destroyed to collect lipids or to be processed to fuel.

carbon average molecular weight of the fuel component and the fuel component mass ratio in the dry biomass. Using a closed photobioreactor to make ethanol from cyanobacteria consumes less than 1 liter of water per liter of ethanol for photosynthesis. As discussed in the previous chapter, water consumption through photosynthesis for lipid-forming algae is at least three times higher.

3.6 ALTERNATIVE PATHWAY #4–WHOLE-CELL PROCESSING

Thermochemical pathways for processing biomass to fuels have garnered interest as the focus shifts away from production of alcohols and esters and toward production of “drop-in” hydrocarbon fuels (Figure 3-18; Huber and Dale, 2009). Figure 3-19 shows the detail input and output of a thermochemical pathway—pyrolysis. Anaerobic heating of virtually any biomass causes thermal degradation that begins to fractionate the biomass into gaseous, liquid, and solid components (Mohan et al., 2006). Subsequently, liquid fractions can be upgraded by hydrotreating to yield a hydrocarbon fuel. The final fuel products are compatible with existing petroleum refinery infrastructure. An advantage of thermochemical technologies is that they are largely feedstock agnostic and can accept any type of biomass, including biomass of aquatic microalgal and macroalgal species. Pyrolysis is the only process discussed that easily accepts macroalgal species.

Lipid-producing microalgae are not required for fuel production in this pathway. Algal strains or mixed cultures are selected for their high biomass productivity and ability to fix

FIGURE 3-17 Curves showing the volume ratio of water consumed in photosynthesis per liter of fuel component produced assuming a fuel component density of 0.88 kg/L.

NOTES: The orange star approximates the Algenol direct ethanol synthesis assuming that ethanol is produced in a stable culture that produces no residual biomass. The red star is shown for reference and approximates the case for a lipid forming algae at 30-percent lipid.

FIGURE 3-18 Overview of the whole-cell processing to make drop-in replacement fuels. The key feedstock is the entire cellular biomass.

FIGURE 3-19 Inputs and outputs of the alternative pathway #4: Pyrolysis of cellular biomass and hydrotreating to yield hydrocarbon blendstock.

NOTES: Several options exist for the pyrolysis of algal biomass. Shown here is a two-stage conversion where tank cars indicate that it is possible to transport both pyrolysis oil and blendstock.

carbon. Algae would have to be harvested, dewatered, and likely dried for use as feedstock. Aquatic species present a challenge to a pyrolysis process because of the water they carry into the process. Water serves as a largely unreactive diluent that saps away heat during the pyrolysis step. As a diluent, water reduces efficiency of attempts to recover value from the gas streams.

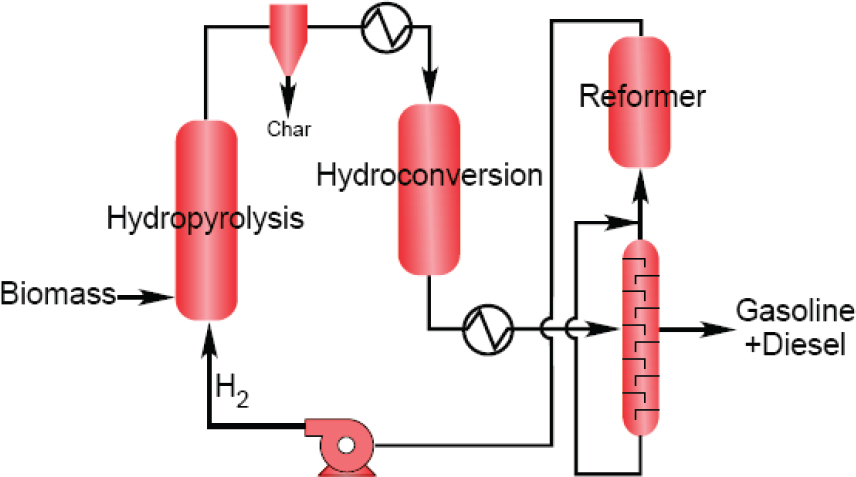

Several options exist for the pyrolysis process (Huber et al., 2006). Pyrolysis oil intermediates pose some technical challenges. Pyrolysis oil is acidic and reactive, and storage without stabilization is a challenge (Mohan et al., 2006; Hatcher, 2011). Integrated hydropyrolysis and hydroconversion (IH2) is a combined hydropyrolysis and hydrotreating process developed by the Gas Technology Institute and collaborators and funded by the Department of Energy. IH2 has many promising attributes and has been claimed to successfully process algae at high yield (Marker et al., 2010; Sims, 2011). The particular combination of steps is claimed to avoid pyrolysis oil issues. The IH2 technology uses low-pressure hydrogen together with a proprietary catalyst to remove virtually all of the oxygen present in the starting biomass (Figure 3-20). Production of exportable steam is possible, and is likely suitable for offsetting some of the energy requirements for drying. The hydrogen required for the process is produced through steam reforming of the off-gas stream of methane and other hydrocarbons from the process. Pilot-scale testing was promising and several demonstration units are now under construction. GHG reduction potential is reported to be lower than competing processes (Marker et al., 2010; Sims, 2011).

Literature on performance of this process is limited. Yields of product fuels have ranged from 26 to 46 percent on a dry, ash-free basis depending on feedstock. This represents more than 70 percent efficient energy conversion for the highest yield. This process was selected for comparison because of reports suggesting that supplemental energy and hydrogen are not required. As a result, there are no extra feed or effluent streams that would affect the analysis of the overall environmental footprint of fuel production. Projects are moving forward using this technology for the conversion of algal biomass.

FIGURE 3-20 IH2 process schematic.

SOURCE: Adapted from Marker et al. (2010).

Many other processes for extracting fuel from microalgae are being discussed and investigated. Lack of published or available data on key sustainability metrics means that little can be said about the sustainability attributes of other potential pathways relative to pathways discussed earlier. In addition to the pyrolysis route described above, microalgal systems that use thermochemical transformation techniques to process whole algal cells are beginning to be tested. These systems appear to have energy requirements similar to other production techniques in which the cells are killed to harvest product. Clearly, thermochemical pathways can manufacture a range of fuel products. Whether the subsequent energy use in processing offers advantages from an energy or emissions perspective is unclear. These whole-biomass systems offer the advantage that cultivation is not limited to oleaginous species. Species can be grown at maximum carbon fixation rates to feed processes that retain high fractions of the fixed carbon in their final fuels. Examples of whole organism conversion technologies include (Gouveia, 2011; Hatcher, 2011):

• Fermentation of algal biomass to yield alcohols or hydrocarbons;

• Gasification and syngas conversion to alkanes, alcohols, or aromatics (through methanol and subsequent conversion);

• Gasification and syngas conversion to alcohols by conventional catalysis;

• Gasification and syngas conversion to alcohols by syngas fermentation;

• Anaerobic digestion to methane (making no liquid fuel); and

• Hydrous pyrolysis (Hatcher, 2011).

These techniques are not widely used and could be put into wider practice (Gouveia, 2011). High water content is not a desirable characteristic of feedstock for fuels. The

fundamentals of water removal from the product are critical in any discussions about largescale fuel production. Laboratory-scale or pilot-scale techniques that use solar drying are relatively slow, require large land areas, and are not likely to scale up commercially.

This chapter describes and contrasts pathways that lead from algae cultivation to fuel production. Many technical options exist for each individual component in the processing pathway (for example, algae can be cultivated in an array of open ponds or closed photobioreactor systems with different designs). This chapter illustrates how particular individual components are linked together to constitute the pathway for algal biofuel production and how categorizing these processes into several distinctive pathways can help with the analysis of the sustainability impacts of algal biofuels. This chapter further discusses the potential fuel products and coproducts from various production pathways. In concert with Chapters 4 and 5, the reference and alternate pathways demonstrate the sustainability issues for the photosynthetic methods of producing fuels from microalgae and highlight potential improvements that might alleviate critical sustainability concerns.

Though this chapter focuses on describing algal biofuel production pathways that are further considered in following chapters, it is the only part of the report that considers the value-added propositions associated with coproducts. The committee believed that coproducing high-value products, such as nutraceutical products, with algal biofuels would be viable only on a small scale. If large quantities of high-value algal products are coproduced with biofuels, the value of coproducts likely decreases with market saturation. Animal feedstuff is the only coproduct that is likely to have a large enough market to absorb the large quantities produced if algal biofuels are produced at commercial scale. The coproduct value depends on the composition of the animal feedstuff and the characteristics of the market in which it would be sold. In general, coproduct volumes swell with the scaling up of algal biofuel production, potentially saturating markets for these products unless a wide variety of coproducts for different markets are produced.

AlfaLaval. 2010. Multiple choice for fats and oils refining. Available online at http://local.alfalaval.com/en-us/key-industries/food/fatsandoils/Documents/PFT00355EN_Degumming_neutralization.pdf. Accessed December 21, 2011.

Beal, C.M., R.E. Hebner, M.E. Webber, R.S. Ruoff, and A.F. Seibert. 2011. The energy return on investment for algal biocrude: Results for a research production facility. Bioenergy Research: DOI: 10.1007/s12155-011-9128-4.

Benemann, J.R. 2008. Opportunities and challenges in algae biofuel production. Available online at http://www.fao.org/uploads/media/algae_positionpaper.pdf. Accessed October 21, 2011.

BioProcess Algae. 2011. Questionnaire reply from BioProcess Algae. Received by the NRC Committee on the Sustainable Development of Algal Biofuels on September 27.

Boussiba, S. 2011. Questionnaire reply from AlgaTechnologies, Kibbutz Qetura. Received by the NRC Committee on the Sustainable Development of Algal Biofuels on July 6.

Chance, R.R., B. McCool, and J.D. Coleman. 2011. A Cyanobacteria-Based Photosynthetic Process for the Production of Ethanol. Presentation to the NRC Committee on Sustainable Development of Algal Biofuels on June 13.

Davis, R., A. Aden, and P.T. Pienkos. 2011. Techno-economic analysis of autotrophic microalgae for fuel production. Applied Energy 88(10):3524-3531.

Fan, X., R. Burton, and G. Austic. 2010. Conversion of degummed soybean oil to biodiesel: Optimization of degumming methods and evaluation of fuel properties. International Journal of Green Energy 7(6):593-599.

Gouveia, L. 2011. Microalgae as a Feedstock for Biofuels: Springer. Available online at http://www.springer.com/life+sciences/microbiology/book/978-3-642-17996-9. Accessed December 21, 2011.

Hatcher, P.G. 2011. The ODU algae to biodiesel project. Presentation to the NRC Committee on the Sustainable Development of Algal Biofuels on August 24.

Huber, G.W., and B.E. Dale. 2009. Grassoline at the Pump. Scientific American (July):52-59.

Huber, G.W., S. Iborra, and A. Corma. 2006. Synthesis of transportation fuels from biomass: Chemistry, catalysts, and engineering. Chemical Reviews 106(9):4044-4098.

Joule Unlimited. 2012. Frequently asked questions. Available online at http://www.jouleunlimited.com/faq. Accessed March 9, 2012.

Kalnes, T.N., T. Marker, D.R. Shonnard, and K.P. Koers. 2008. Green diesel production by hydrorefining renewable feedstocks. Biofuels Technology (October):7-11.

Luo, D.X., Z.S. Hu, D.G. Choi, V.M. Thomas, M.J. Realff, and R.R. Chance. 2010. Life cycle energy and greenhouse gas emissions for an ethanol production process based on blue-green algae. Environmental Science and Technology 44(22):8670-8677.

Lurgi GmbH. 2012. Edible oil yechnology—Oilseed extraction and edible oil refining. Available online at http://lurgi.com/website/fileadmin/user_upload/1_PDF/1_Broshures_Flyer/englisch/0314e_Edible_Oil_Technology.pdf. Accessed July 20, 2012.

Marker, T., M. Linck, and L. Felix. 2010. Integrated Hydropyrolysis and Hydroconversion (IH2) Process for Direct Production of Gasoline and Diesel Fuel from Biomass. Paper read at the BIOMASS 2010, March 30-31, Arlington, VA.

Marler, D. 2011. An Assessment of the Environmental Performance of Algal Biofuels. Presentation to the NRC Committee on Sustainable Development of Algal Biofuels on September 8.

Mohan, D., C.U. Pittman Jr, and P.H. Steele. 2006. Pyrolysis of wood/biomass for bio-oil: A critical review. Energy and Fuels 20(3):848-889.

Morgenthaler-Jones, L. 2011. Algae + fish: Food, fuel and more. Presentation to the NRC Committee on Sustainable Development of Algal Biofuels on September 8.

NAS-NAE-NRC (National Academy of Sciences, National Academy of Engineering, and National Research Council). 2009. Liquid Transportation Fuels from Coal and Biomass: Technological Status, Costs, and Environmental Impacts. Washington, DC: The National Academies Press.

NRC (National Research Council). 2011. Renewable Fuel Standard. Potential Economic and Environmental Effects of U.S. Biofuel Policy. Washington, DC: The National Academies Press.

NREL (National Renewable Energy Laboratory). 2006. Biodiesel and Other Renewable Diesel Fuels. Golden, CO: National Renewable Energy Laboratory.

Olusola, J.O., M.M. Adediran, A.K. Oluseyi, and U.L. Ajao. 2009. Processing of triglycerides to diesel range hydrocarbon fuels: easily practicable small scale approach. Energy and Environment 20-21:1325-1341.

Photon8. 2011. Questionnaire reply from Photon8. Received by the NRC Committee on the Sustainable Development of Algal Biofuels on November 18.

Pyter, R., E. Heaton, F. Dohleman, T. Voigt, and S. Long. 2009. Agronomic experiences with Miscanthus x giganteus in Illinois, USA. Biofuels: Methods and Protocols 581:41-52.

Redfield, A.C. 1958. The biological control of chemical factors in the environment. American Scientist 46:205-221.

Robertson, D.E., S.A. Jacobson, F. Morgan, D. Berry, G.M. Church, and N.B. Afeyan. 2011. A new dawn for industrial photosynthesis. Photosynthesis Research 107(3):269-277.

Serrano-Ruiz, J.C., E.V. Ramos-Fernandez, and A. Sepulveda-Escribano. 2012. From biodiesel and bioethanol to liquid hydrocarbon fuels: New hydrotreating and advanced microbial technologies. Energy and Environmental Science 5(2):5638-5652.

Sims, B. 2011. GTI signs licensing agreement with Shell Group subsidiary. Available online at http://www.bio-refiningmagazine.com/articles/5239/gti-signs-licensing-agreement-with-shell-group-subsidiary. Accessed June 12, 2012.

Szmant, H.H. 1989. Organic building blocks of the chemical industry. New York: Wiley.

Thomas, H. 2011. Questionnaire reply from Open Algae. Received by the NRC Committee on the Sustainable Development of Algal Biofuels on July 5.

Tilman, D., J. Hill, and C. Lehman. 2006. Carbon-negative biofuels from low-input high-diversity grassland biomass. Science 314(5805):1598-1600.

Van Gerpen, J. 2005. Biodiesel processing and production. Fuel Processing Technology 86(10):1097-1107.

Williams, P.J.L.B., and L.M.L. Laurens. 2010. Microalgae as biodiesel and biomass feedstocks: Review and analysis of the biochemistry, energetics and economics. Energy and Environmental Science 3(5):554-590.