Storage of Separated Rocket Motors

THE NEED FOR STORAGE SPACE FOR SEPARATED ROCKET MOTORS

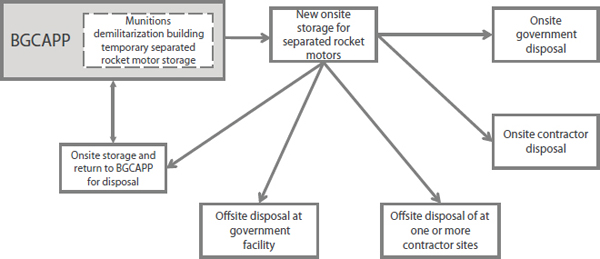

For a variety of reasons (e.g., permit restrictions and throughput capability), the rate at which any given technology disposes of the separated rocket motors1 will probably be lower than the rate of rocket-cutting operations in the Blue Grass Chemical Agent-Destruction Pilot Plant (BGCAPP). Disposal of the separated rocket motors therefore has the potential to be a limiting step in overall M55 rocket disposal. Rocket motor storage and transportation to an eventual disposal facility (either on-site or off-site) will mitigate the impact of the disparate processing rates, but separated rocket motor storage is a potential and serious bottleneck that could affect the planned rate of M55 rocket-cutting operations at BGCAPP. BGCAPP will have temporary storage for the separated rocket motors. However, once the storage area reaches capacity, if the separated rocket motors cannot be transported to an outside storage or disposal site at least as quickly as they are being produced, they will accumulate at BGCAPP, and the planned rocket-cutting and warhead-processing operations would need to be slowed or halted. The centrality of storage of separated rocket motors is shown in Figure 4-1.

FIGURE 4-1 Diagram showing the importance of storage for the disposal of separated rocket motors.

Finding 4-1. The provision of adequate storage space for the separated rocket motors is important for the overall rate of operations for M55 rocket disposal at the Blue Grass

![]()

1See Appendix A for how the committee defines separated rocket motor.

Chemical Agent-Destruction Pilot Plant. Rocket-cutting and warhead-processing operations would need to be slowed or halted if the combination of storage capacity and separated rocket motor disposal could not meet the rate at which separated rocket motors are produced.

REQUIREMENTS FOR STORAGE OF SEPARATED ROCKET MOTORS

It is estimated that the peak processing rate of M55 rockets at BGCAPP will be 20 GB-filled rockets per hour or 24 VX-filled rockets per hour, producing 20 or 24 separated rocket motors, respectively, per hour. Overall, BGCAPP estimates that about 3,350 separated rocket motors would be ready for disposal per month. The munitions demilitarization building is designed for a storage capacity of 1.25 operating days.2 There is currently no additional designated storage space for separated rocket motors at the Blue Grass Army Depot (BGAD) apart from the planned storage area at BGCAPP.

The limited storage capacity subjects the M55 processing operations to delays if unexpected events occur, such as a shutdown of a rocket motor disposal facility in the event of a safety incident or transportation delay. It is important to have storage capacity sufficient to permit continuing rocket processing at BGCAPP if upsets in the schedule of disposal of separated rocket motors occur.

It is also necessary to meet Environmental Protection Agency (EPA) and Kentucky requirements regarding hazardous waste storage. The separated rocket motors are explosive hazardous waste, and Resource Conservation and Recovery Act (RCRA) requirements regarding storage of explosive hazardous waste must be met. Once a rocket motor is separated from the warhead, the motor must be stored in a designated hazardous waste storage site. The planned BGCAPP storage area can serve as a hazardous waste storage site, but accumulating hazardous waste must comply with 40 CFR 262.34, which limits the time that explosive hazardous waste can be stored before being disposed of. Noncompliance with EPA and Kentucky hazardous waste regulations can result in enforcement actions and fines.

CREATING ADDITIONAL STORAGE SPACE AT THE BLUE GRASS ARMY DEPOT

The creation of expanded new safe storage space on site at BGAD outside the physical boundaries of the BGCAPP facility would provide greater assurance that M55 rocket processing could continue without interruption caused by limits on safe storage-space capacity. The committee believes that it is much more likely that substantial additional safe storage space can be created on site at BGAD than at BGCAPP. Furthermore, safe intra-installation transportation will facilitate movement of separated rocket motors to any newly created safe storage space at BGAD.

The requirements for additional safe storage space on site at BGAD depend on many factors. For example, the designated hazard classification of the separated rocket

![]()

2Ron Hawley, Plant General Manager, Bechtel Parsons Blue Grass Team, “Rocket Processing,” presentation to the committee, March 20, 2012.

motors will define the quantity that may be stored at a given location, the distance required between the storage area and other activities, and additional security and siting issues (U.S. Army, 2011). Storage of rocket motors at BGAD would need to be in magazines site-approved for storage of Hazard Class 1 materials. The magazines would also need to meet both RCRA hazardous waste regulations and explosive safety requirements. The site-approved magazines would need to be designated as long-term (180-day) RCRA explosive hazardous waste sites and be managed as such as provided in Section 3500 of RCRA and in 40 CFR 270. (Hazard classification is discussed in more depth in Chapter 2.)

The committee has been informed that preliminary discussions between BGCAPP and BGAD staff indicate that magazine storage space at BGAD is limited and may already be filled to capacity. Nonetheless, because BGAD conducts demilitarization of waste military munitions as part of its mission, the installation may already have RCRA-permitted magazines designated for storage of waste military munitions or other explosive hazardous waste munition components that could be used for storage of separated rocket motors.

Finding 4-2. The planned rocket destruction throughput at the Blue Grass Chemical Agent-Destruction Pilot Plant may be at risk because of insufficient capacity for storage of separated rocket motors.

Recommendation 4-1. Blue Grass Chemical Agent-Destruction Pilot Plant program staff should secure additional space for storage of separated rocket motors. It is essential that discussion with Blue Grass Army Depot staff concerning the option for securing such additional space at the depot be given high priority.

If the separated rocket motors qualify as waste military munitions, an alternative option would be to designate BGAD magazines as conditionally exempt magazines3 for storage of waste military munitions. That would allow long-term storage as long as quarterly monitoring of the condition of the stored materials is documented and records of it are provided to the state. Kentucky has not adopted the Munitions Rule (see 40 CFR 266.202) and has not developed any state-specific military munitions rules. Military munitions are regulated by the Division of Waste Management of the Kentucky Department for Environmental Protection. Regulations for the state's RCRA hazardous waste management, including military munitions, are provided in Title 401, Natural Resources and Environmental Protection Cabinet, Department for Environmental Protection, Chapters 30–36 and 38 of the Kentucky Administrative Rules (KAR), with definitions in Chapter 224 of the Kentucky Revised Statutes (KRS). The process would thus require coordination with the Kentucky Department for Environmental Protection.

![]()

340 CFR 266.205(a) gives the storage requirements (and exemptions) for munitions that are exempted from being considered RCRA hazardous waste, as set forth in 40 CFR 266.203 (3)(1). When following or invoking these definitions and requirements the military calls the storage areas conditionally-exempt magazines.

Finding 4-3. If the separated rocket motors qualify as waste military munitions, magazines could potentially be designated as conditionally exempt to allow long-term storage of separated rocket motors.

RETURNING SEPARATED ROCKET MOTORS TO THE M55 ROCKET STORAGE IGLOOS

One possibility for additional safe storage of separated rocket motors would appear to be returning them to the existing M55 rocket igloos as the igloos are vacated. However, lethal and incapacitating chemical munitions and agents (that is, chemical surety material) are generally stored separately from conventional ammunition and explosives. The igloos in which the M55 rockets were originally stored could not readily be used for storage of the separated rocket motors unless appropriate explosive safety site approvals were obtained. A new application for site approval for storing rocket motors in the original rocket storage igloos would need to be submitted and approved by the Department of Defense Explosive Safety Board. Approval from the Kentucky Department for Environmental Protection would also likely be necessary. The igloos would need to be free of contamination with chemical agents before being reused for storing separated rocket motors. Because of the logistics of the movement of M55 rockets out of the igloos, the turnaround time for producing separated rocket motors that need storage, and the time necessary for obtaining site approvals, returning separated rocket motors to igloos for storage would require much planning and coordination.

Finding 4-4. Reusing emptied M55 rocket storage igloos for storage of separated rocket motors is a possible solution to the problem of inadequate storage space. Pursuing this option would entail much coordination and planning and would take time.

Recommendation 4-2. If a decision is made to pursue this option, Blue Grass Chemical Agent-Destruction Pilot Plant program staff should prepare a plan to convert the M55 rocket storage igloos to hazardous waste storage sites that are also site-approved for the storage of explosives. The plan should include management of the transition without the need to submit separate approval requests one igloo at a time.

PROPELLANT DEGRADATION, STABILIZER DEPLETION, AND STORAGE RISK

It is well understood that double-base rocket propellants, such as the M28 propellant in the M55 rockets, are subject to chemical degradation that decreases their stability in storage and increases storage risk.4 Propellant degradation is mitigated by a chemical additive called a stabilizer, such as 2-nitrodiphenylamine, that is depleted as it traps the reactive gases that result from propellant degradation. Stabilizer depletion in

![]()

4Storage risk is defined in Appendix A.

turn can lead to a risk of autoignition of the propellant. Thus, storage risk increases with storage time. Although stabilizer depletion is known to occur in the case of M28 propellant, previous studies have estimated that the frequency of autoignition of propellant in intact M55 rockets and the overall storage risk are very low (U.S. Army, 2002).

The storage risk may be greater in the case of separated rocket motors than intact M55 rockets. The shipping and firing tube that contains the intact M55 rocket isolates the rocket motor from environmental conditions. During processing at BGCAPP, the shipping and firing tube is cut, and this exposes the separated rocket motor to environmental factors, such as humidity and heat, more than when it is part of an assembled M55 rocket. Humidity can accelerate chemical reactions with the nitrogen oxide gases formed from the degrading nitrate ester. The nitrogen oxide gases accelerate nitrocellulose decomposition and stabilizer depletion; this leads to a self-accelerating cycle. Heat also increases the stabilizer depletion rate in the M28 propellant by increasing the rate of nitrocellulose degradation. The storage of intact M55 rockets in their pallets and in overpacked configurations and their ability to dissipate excess heat from the propellant were studied in 2002. The study found no immediate risk of propellant autoignition in these configurations (U.S. Army, 2002). However, when the rocket motors are separated from the M55 rockets and placed in new packaging, they are in a new configuration, and prior safe-storage assessments may not be directly applicable. Thus, separated rocket motors may have a shorter safe-storage life than assembled M55 rockets.

Finding 4-5. Storage risk may increase more quickly in the case of separated rocket motors than assembled M55 rockets because of the increased environmental exposure of the separated motors. The effects of this environmental exposure on the separated rocket motors have not been characterized.

Recommendation 4-3. The Blue Grass Chemical Agent-Destruction Pilot Plant program staff should dispose of separated rocket motors as soon as possible, using a “first in, first out” protocol to minimize storage time and reduce risk.

U.S. Army. 2002. M55 Rocket Assessment Summary Report, July. Aberdeen Proving Ground, Md.: U.S. Army Program Manager for Chemical Demilitarization.

U.S. Army. 2011. Ammunition and Explosives Safety Standards, Department of the Army Pamphlet 385–64, May 24. Available online at http://armypubs.army.mil/epubs/pdf/p385_64.pdf. Last accessed May 17, 2012.

This page intentionally left blank.