The Blue Grass Chemical Agent-Destruction Pilot Plant (BGCAPP), under the management of the Program Executive Officer for Assembled Chemical Weapons Alternatives, is responsible for destroying the chemical weapons stockpile currently being stored at the Blue Grass Army Depot (BGAD). BGCAPP and a facility being built at the Pueblo Chemical Depot to dispose of the chemical agent stored there are parts of the nation’s effort to destroy its chemical agent stockpile in line with its obligations under the Chemical Weapons Convention treaty. The stockpile stored at BGAD consists of 523 tons of mustard agent in projectiles and nerve agents GB and VX in projectiles and rockets. The chemical agent loads in the weapons will be destroyed by chemical neutralization.1 In the neutralization process, the munitions are disassembled, the agents and energetic materials are separated, and the agents are neutralized with caustic (for GB, VX, and energetic materials, such as bursters) or water (for mustard agent), producing effluents called hydrolysates. The hydrolysates will be further treated with supercritical water oxidation (SCWO), which uses water at very high temperature (1200oF) and pressure (3,400 psi).

The rocket portion of the stockpile at BGAD consists of about 70,000 M55 rockets, manufactured in 1961–1965, that contain the cholinesterase-inhibiting nerve agents GB and VX (CMA, 2008). Those agents are organophosphates that are capable of binding the enzyme acetylcholinesterase, which breaks down the neurotransmitter acetylcholine in the neural synapses. When acetylcholinesterase is inhibited, the parasympathetic nervous system is overstimulated by excess acetylcholine, resulting in potentially fatal cholinergic effects. GB is the more volatile of the two agents, and its primary mode of exposure is through the respiratory system; VX is absorbed primarily through skin. The two materials are toxic at very low concentrations. Table 1-1 lists time-weighted average maximum recommended exposure levels for the agents. The short-term exposure level (STEL) is designed to protect employees, and the general population limit (GPL) is designed to protect the community at large. Safe-handling procedures for chemical agent weapons are in Volume 6 of Department of the Army Pamphlet 385–61 (U.S. Army, 2008).

The M55 rockets stored at BGAD will be disposed of in a manner entirely different from that used at the other chemical agent disposal facilities that disposed of M55 rockets. At the other facilities, an entire M55 rocket was cut into pieces and processed through incinerators, but the rockets stored at BGAD will be processed as follows. Pallets of M55 rockets will be transported from their BGAD storage igloos in an enhanced on-site container (EONC), received in the unpack area, and monitored for the

![]()

1The term hydrolysis is used in the chemical demilitarization program.

presence of chemical agent. If chemical agent is detected, the sealed EONC will be opened in the explosive containment vestibule by workers in protective gear, who will overpack any leaking or contaminated rockets; the remaining rockets will proceed to the normal rocket destruction process. If no agent is detected, the rockets will be unpacked from the EONC and placed into the automated rocket handling system (Schlatter, 2010). From that point on, all operations to destroy the agent and warhead bodies will be remotely controlled.

Table 1-1 Time-Weighted Average

Maximum Exposure Limits (μg/m3)

| Time Basis | GB | VX | |

| GPL | 24 hours | 0.001 | 0.0006 |

| STEL | 15 minutes | 0.1 | 0.01 |

SOURCE: U.S Army, 2008.

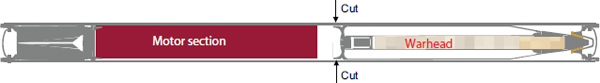

Figure 1-1 is a basic depiction of an M55 rocket in its shipping and firing tube (SFT) and where it will be cut during processing. Figure 1-2 shows a cutaway model of an M55 rocket in flight configuration with fins deployed. The first step in processing the rockets will be for the rocket cutting machine (which works by pressing a rolling blade first against the SFT and then against the rocket body) to cut the fiberglass SFT into two pieces. The forward piece of SFT covering the warhead will be removed, conveyed to the motor shipping room, and placed in a crate. The rocket cutting machine will then make a second cut at the threaded connection between the warhead and the rocket motor. The intact warhead containing the chemical agent, burster, and fuze will be destroyed at BGCAPP by neutralization followed by supercritical water oxidation, as discussed above.

FIGURE 1-1 Simplified diagram of an M55 rocket in its shipping and firing tube, showing where the tube and rocket will be cut. SOURCE: Ron Hawley, Plant General Manager, Bechtel Parsons Blue Grass Team, “Rocket Processing,” presentation to the committee, March 20, 2012.

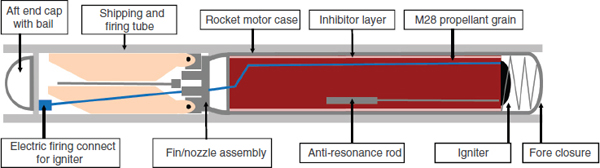

FIGURE 1-2 Cutaway depiction of an M55 rocket in flight configuration with fins deployed. SOURCE: Adapted from CMA, 2008.

The separated rear section of the M55 rocket—containing the M28 rocket propellant, igniter, rocket nozzle, fins and other components—and the fore closure still in

its portion of the SFT will be loaded cut side up into a plywood shipping box designed to hold 30 rocket motors. In this report, the term separated rocket motor will refer to the separated rear section of the M55 rocket (see definition in Appendix A). Figure 1-3 shows a simplified layout of a separated rocket motor. Peak processing rates are projected to be 20 GB-filled or 24 VX-filled M55 rockets per hour; the process will produce like numbers of separated rocket motors each hour.2

The storage boxes containing the separated rocket motors will be placed into an airlock, and the headspace above the motors will be monitored for the presence of any chemical agent above the STEL before being released to the motor packing room and later transportation and disposal. If any agent is detected, the individual separated rocket motors will be manually monitored to determine which ones are contaminated with chemical agent, and entire separated rocket motors that are contaminated will be processed through BGCAPP. This report addresses only separated rocket motors that have been monitored and cleared for disposal either on-site (on BGAD) or off-site (off BGAD). The current plan is to dispose of separated rocket motors outside the BGCAPP facility. The process for clearing the separated rocket motors has yet to be developed and will, of course, need to be negotiated with the Kentucky Department for Environmental Protection.

The BGCAPP facility currently under construction will have the capability of demilitarizing and destroying an entire M55 rocket. Indeed, the original design of the facility included the disposal of the entire M55 rocket in the facility with 18 energetic batch hydrolyzers. As part of a cost-reduction initiative, a decision was made to eliminate all but three of the energetic batch hydrolyzers and to dispose of the separated rocket motors outside BGCAPP. The focus of this report is on the potential sites and technologies that might be used to dispose of the separated rocket motors outside BGCAPP. The options include treatment and disposal on-site or off-site at a commercial or government facility.

FIGURE 1-3 Simplified layout of a separated rocket motor showing its major components.

BGCAPP has identified the disposal of the separated rocket motors as a potentially rate-limiting factor that could affect the overall rate of M55 rocket disposal at BGCAPP. The main reason is related to storage space at BGCAPP. BGCAPP will have about 1.25 days worth of storage space in the munitions demilitarization building for

![]()

2Ron Hawley, plant general manager, Bechtel Parsons Blue Grass Team, “Rocket Processing,” presentation to the committee, March 20, 2012.

separated rocket motors. Any interruption in transportation of rocket motors out of this storage could force a slowing or cessation of M55 rocket processing operations at BGCAPP. Options are needed to address issues of storage, throughput, transportation, and the treatment that will be required to dispose of the roughly 3,350 separated rocket motors that BGCAPP plans to generate each month.3

The National Research Council will establish an ad hoc committee to address these specific tasks:

- Investigate off-site and on-site alternative options for disposal of approximately 70,000 M55 rocket motors stored at Blue Grass Army Depot that are not contaminated by chemical nerve agent contained in the rocket warheads

- Review and examine the status of maturity and assess the likelihood of success for each option

- Consider the feasibility of recycling options for the propellant and rocket motor components

- Assess relevant environmental considerations, including those pertaining to the health and safety of workers, and regulatory requirements such as those stemming from applicable Kentucky Revised Statutes and RCRA regulations

- Examine shipping considerations for implementation of off-site alternatives, including packaging requirements

THE COMMITTEE, REPORT SCOPE, AND PROCESS

The committee is composed of persons who have extensive experience in solid rockets, energetic materials, munitions disposal, hazardous wastes, safety, and public involvement. Several committee members have expertise pertinent to the regulations governing the transport and disposal of various types of munitions and associated hazardous materials. Biographies of all the committee members are in Appendix D.

The committee met three times. The first meeting was held in Richmond, Kentucky, and included a briefing from BGCAPP about the options that have been reviewed for the treatment and disposal of the separated rocket motors and committee discussions to begin framing the approach to the study and the report. The second meeting was held in Washington, D.C. where the committee discussed and developed the report draft. The third meeting was also held in Washington, D.C. At this meeting the committee resolved most remaining issues and laid out the path to achieving committee consensus on the report. Committee activities are summarized in Appendix C.

This report reviews various approaches that could be used for safe disposal of the rocket motors separated from the M55 rockets stored at BGAD. It also discusses issues of safety, storage, throughput, transportation of the separated rocket motors, on-site and off-

![]()

3Kevin Regan, environmental manager, BGAPP project, “Rocket Motor (RM) Disposal,” briefing to the committee, March 20, 2012.

site disposal options, and how public acceptance could influence the disposal of the separated rocket motors. The coverage of the report begins after the M55 rockets have been cut and the separated rocket motors have been monitored and cleared for transportation and disposal off-site.

Chapter 2 focuses on safety—energetics safety, electrical safety, and lead. Although the chemical agent warheads will no longer be present when the separated rocket motors are handled, the separated rocket motors are hazardous in their own right because they contain M28 propellant, which has aged and degraded and will continue to degrade. Explosives safety precautions are necessary in all handling and storage operations that involve the separated rocket motors. Chapter 2 also addresses hazards of electromagnetic radiation to ordnance and risks posed by electrostatic discharge if the igniter leads and shunting are damaged when the rockets are cut.

Chapter 3 is an overview of technologies—primarily chemical and thermal treatment methods—that could be used to dispose of the separated rocket motors. The chapter presents information on both thermal treatment options (open and contained) and chemical treatment options, such as base hydrolysis and supercritical water oxidation. Recycling of the rocket motors is unlikely in that the M28 propellant is old and degraded and contains lead. It would not be practical or cost-effective to reuse the propellant, recover its ingredients, or work it into another form, such as fertilizer. In addition, the SFTs contain polychlorinated biphenyls. The committee envisions that the separated rocket motors will be removed from the SFTs before disposal of the motors, in part to avoid the contamination of disposal waste streams with polychlorinated biphenyls; this is discussed in more depth in Chapter 5. The discussion in Chapter 3 includes recommendations of the technologies that may be best suited for disposal of the separated rocket motors.

The storage of separated rocket motors is discussed in Chapter 4. The storage of the separated rocket motors is a potentially limiting step in M55 rocket disposal at BGCAPP, inasmuch as their disposal will probably proceed at a lower rate than the rocket-cutting operations at BGCAPP. Although the storage of the separated rocket motors is not an explicit item in the statement of task, it is central to the timely processing of M55 rockets through BGCAPP. If the separated rocket motors cannot be transported to a storage or disposal site outside BGCAPP at least as quickly as they are accumulated in BGCAPP, rocket-cutting and warhead-processing operations at BGCAPP would need to be slowed or halted.

Chapter 5 presents some of the specific issues that BGCAPP project management will need to consider when selecting the most appropriate location for disposal of the separated rocket motors. On-site disposal options reviewed by the committee include open burning of the propellant grain at the BGAD permitted explosive hazardous-waste treatment facility; using the D-100 detonation chamber currently operational at BGAD; using alternative technologies, such as explosive destruction technologies, which can be added to BGAD capabilities; and disposal at BGCAPP after completion of all chemical agent destruction operations. Off-site disposal options, in which all the separated rocket

motors would be removed from BGCAPP and BGAD and delivered to other facilities for disposal, are also discussed. The chapter considers transportation issues. For example, the transportation of the separated rocket motors on public roads will need to comply with Department of Transportation regulations and will require appropriate and specialized packaging, whereas on-site transportation will have a different, and potentially less demanding, regulatory framework.

The report contains two appendixes that supplement the committee’s work in the main body of the report. Appendix A sets forth some definitions that are used specifically by this committee. Appendix B reviews the history of public sentiment as it pertains to the committee’s task. Although a consideration of public sentiment is not an explicit item in the statement of task and a rigorous examination of it was beyond the committee’s scope, the committee believed that it would be remiss not to include some discussion of it in that it is likely to figure into the ability to implement any given disposal technology or disposal option. Programs for destroying the chemical munitions stockpile managed by the U.S. Army Chemical Materials Agency4 and the Assembled Chemical Weapons Alternatives5 program have historically been heavily influenced by public sentiment. The concerns of citizens near BGAD, along potential transportation routes, and near potential off-site disposal locations are therefore going to be important in consideration of any decision about the choice of a technology or option (whether on-site or off-site) to dispose of the separated rocket motors.

CMA (Chemical Materials Agency). 2008. Fact Sheet: M55 Rockets, March 5. Available online at http://www.cma.army.mil/fndocumentviewer.aspx?docid=003677976. Last accessed July 5, 2012.

Schlatter, J. 2010. Blue Grass Exchange: Chemical Munitions Destruction: A Rocket’s Path Through the Pilot Plant Facility, April-June. Available online at https://www.pmacwa.army.mil/info/bg_exchange_apr10_rocket_path.html. Last accessed July 5, 2012.

U.S. Army. 2008. Department of the Army Pamphlet 385–61: Toxic Chemical Agent Safety Standards, December 17. Available online at http://www.apd.army.mil/pdffiles/p385_61.pdf. Last accessed June 7, 2012.

![]()

4The U.S. Army Chemical Materials Agency has successfully and safely disposed of the chemical agent and munitions stockpiles at Aberdeen, Maryland; Anniston, Alabama; Johnston Atoll; Newport, Indiana; Pine Bluff, Arkansas; Tooele, Utah; and Umatilla, Oregon. Chemical neutralization was used to dispose of bulk agent at Aberdeen, Maryland, and Newport, Indiana. Incineration was used to dispose of the stockpiles at the other sites.

5In addition to BGCAPP, a facility is under construction at the Pueblo Chemical Depot, in Colorado, to dispose of the mustard agent stockpile there. The agent will be chemically neutralized by hot-water hydrolysis, and the resulting hydrolysates will be processed through a biotreatment system.