This chapter discusses the use of optics and photonics in the generation of energy and the use of optics in lighting. Energy use in data centers is discussed in Chapter 3, “Communications, Information Processing, and Data Storage.” Optics and photonics are very important in energy generation, in energy conservation, and in monitoring the effects of both on the environment. The main topic related to energy generation discussed in this chapter is solar energy. As noted in a previous report from the National Research Council (NRC): “Solar energy could potentially produce many times the current and projected future U.S. electricity consumption.”1 Inertial confinement fusion is a potential optical technique that could generate abundant energy in the future2,3 A recent article discusses the National Ignition Facility, which has a near-term goal of achieving ignition (defined as 1-MJ [megajoule] output energy from a fusion burn for 1 MJ of laser energy

_________________

1 NAS-NAE-NRC. 2010. America’s Energy Future: Technology and Transformation. Washington, D.C.: The National Academies Press, p. 20.

2 Lindl, J.D., and E.I. Moses. 2011. Special topic: Plans for the National Ignition Campaign (NIC) on the National Ignition Facility (NIF): On the threshold of initiating ignition experiments. Physics of Plasmas (18)5:050901-050902. DOI: http://dx.doi.org/10.1063/1.3591001.

3 Dunne, M., E.I. Moses, P. Amendt, T. Anklam, A. Bayramian, E. Bliss, B. Debs, R. Deri, T. Diaz de la Rubia, B. El-Dasher, J.C. Farmer, D. Flowers, K. J. Kramer, L. Lagin, J.F. Latkowski, J. Lindl, W. Meier, R. Miles, G.A. Moses, S. Reyes, V. Roberts, R. Sawicki, M. Spaeth, and E. Storm. 2011. Timely delivery of laser inertial fusion energy (LIFE). Fusion Science and Technology 60:19-27.

input into the target system).4 This paper mentions that plans are already underway to define the laser driver for inertial fusion energy applications. However, inertial confinement fusion is not discussed in greater detail in this chapter partially because a current NRC study is specifically addressing this topic; the interim report of that study was recently released.5 Optics can also be used in isotope separation,6 but very little information is available on that subject at the unclassified level, and so it was not considered in this unclassified study. Also, optical sensors can be used to assist in oil drilling and recovery, as is briefly discussed in Box 5.1.

Solar energy is discussed here with respect to its primary use by electric utilities competing against other forms of electricity generation such as new natural gas- or coal-fired electricity generation plants. For an electric utility, sunlight can be concentrated to generate solar power in a manner potentially more cost-effective, depending on the cost of the concentrating technology, than would be possible with competing forms of electricity generation in new electric power plants. Concentrating solar power (CSP) uses a heated liquid and a turbine. The heated liquid stores energy until it is converted to electricity. This is advantageous because one of the issues with solar energy generation is the storage of energy for periods of time when the Sun is not out, such as at night and in overcast situations. Concentrated photo-voltaic (CPV) power generation involves the use of solar cells after the incoming light is concentrated. For CPV, the price of the actual solar cell is not as critical in that the area covered by solar cells can be reduced up to 2,000 times as compared

_________________

4 From Willner, A.E., R.L. Byer, C.J. Chang-Hasnain, S.R Forrest, H. Kressel, H. Kogelnik, G.J. Tearney, C.H. Townes, and M.N. Zervas. 2012. Optics and photonics: Key enabling technologies. Proceedings of the IEEE 100(Special Centennial Issue):1604-1643: “The year 2009 saw the completion of the National Ignition Facility (NIF), a 2-MJ, single shot laser facility at Lawrence Livermore National Laboratory (Livermore, CA) designed to compress targets to generate fusion burns and ignition of a target for energy generation. The NIF laser has now been operating for three years at close to 200 shots per year, with a greater than 95% availability rate for requested shots on targets. The goal in the near term is to achieve ignition defined as 1-MJ output energy from a fusion burn for 1 MJ of laser energy input into the target system. Plans are already underway to define the laser driver for inertial fusion energy applications.” Ibid. p. 1609: “We know that a fusion reaction works at even larger power scales. What we have yet to demonstrate is a nuclear burn in a laboratory under controlled conditions. When this is accomplished, it will be a “man on the moon” moment. Laser inertial fusion will open the possibility of amplifying the laser drive power by 30-100 times and in turn allow the operation of an electrical power plant with GWe output for 35-MWe laser power input. Based on our knowledge of the rate at which new infrastructure is adopted, we can predict that fusion energy will take 25-50 years to make a significant impact on our energy supply. By that time it will probably be known simply as laser energy” (p. 1608).

5 National Research Council. 2012. Interim Report—Status of the Study “An Assessment of the Prospects for Inertial Fusion Energy.” Washington, D.C.: The National Academies Press.

6 Broad, W.J. 2011. “Laser Advances in Nuclear Fuel Stir Terror Fear.” New York Times. August 20. Available at http://www.nytimes.com/2011/08/21/science/earth/21laser.xhtml?pagewanted=all. Accessed July 24, 2012.

BOX 5.1

Oil and Gas Production

Optical systems are increasingly being used by the oil and gas industry as a means for monitoring wells, allowing increased production, and mitigating risks. Industry adoption of optics has been relatively recent, as the high pressure and temperature conditions in a well reduce the lifetime of conventional fiber optics to be substantially shorter than the 20 years over which most wells are expected to produce. Since 2000, fiber-based distributed temperature sensors have become common tools for monitoring the performance of wells, and have proven to be a robust source of information about the well performance.

Distributed temperature sensors rely on the fiber locally changing temperature and scattering light back up the fiber owing to the temperature change. Thus, when combined with a pulsed laser source, the backscattered light allows a temperature profile of the well to be determined. The temperature of the fiber is changed locally owing to fluids flowing into the well bore (Joule-Thomson effect). This information is combined with geothermal models to accurately locate and quantify fluid flows in the well.

More recently, fiber systems have been deployed for distributed acoustic sensing (DAS), to monitor well activity during several phases of well completion. DAS uses a principle similar to that for distributed temperature sensors, but uses acoustic waves generated from within the well to alter the refractive index of the fiber probe. The backscattered radiation from this index variation can be collected and processed to discriminate between various sources and depths. These systems offer reliable discrimination between perforation clusters that are active during the acid injection stage and those that are taking most of the proppant throughout the job. This technology also shows promise for many other functions, such as sand detection and gas breakthrough detection.

SOURCES: Algeroy, J., J. Lovell, G. Tirado, R. Meyyappan, G. Brown, R. Greenaway, M. Carney, J. Meyer, J. Davies, and I. Pinzon. 2010. Permanent monitoring: Taking it to the reservoir. Oilfield Review 22(1):34-41; Molenaar, M., D. Hill, P. Webster, E. Fidan, and B. Birch. 2011. “First Downhole Application of Distributed Acoustic Sensing (DAS) for Hydraulic Fracturing Monitoring and Diagnostics.” Society of Petroleum Engineers Hydraulic Fracturing Technology Conference, January 24-26, 2011, The Woodlands, Tex.

to non-concentrating systems. With CPV, higher-cost, and more efficient, solar cells can be used. The cost of the concentrators will be the main issue, as stated in the NAS-NAE-NRC report Overview and Summary of America’s Energy Future: Technology and Transformation published in 2010: “In general, nearly all of the costs involved in using renewable energy for power generation are associated with the manufacturing and installation of the equipment.”7 For high-concentration CPV, more concentrating options are available for larger electric plants, and so CPV may favor utility-scale plants over the smaller plants used by an individual. Photosynthesis is also briefly discussed below as another method of capturing light from the Sun and turning it into energy. However, it is clear that a successful deployment of

_________________

7 NAS-NAE-NRC. 2010. Overview and Summary of America’s Energy Future, p. 22.

solar power on a large scale in the United States will need the technology to have reached cost parity with current energy sources. The energy delivered to the grid as electricity will, for solar, need to reach “grid parity”; the faster solar power can do that, the better for the U.S. economy as a whole.

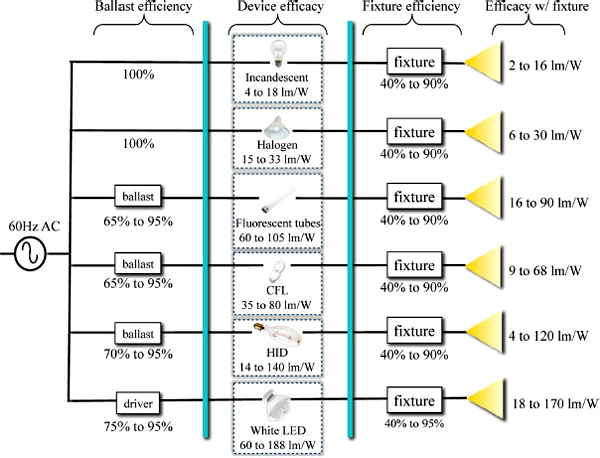

Solid-state (SS) lighting is clearly the next step in lighting. It has already become entrenched in many niche applications and is moving quickly toward adoption as the new standard for general lighting. The record efficiency for SS lighting today is 231 lumens per watt (lm/W),8 compared to 4-15 lm/W for a conventional incandescent bulb, and approximately 55 lm/W for a compact fluorescent bulb. Cost is the main issue preventing widespread adoptions of SS lighting, but substantial progress is being made in lowering the cost of light-emitting diodes (LEDs).

In the 1998 NRC study Harnessing Light: Optical Science and Engineering for the 21st Century,9 solar cells are discussed for space application, with a short section on terrestrial application. At the time of that publication, the cost to purchase solar cell panels for terrestrial application was $4.50 per watt (W), compared to the current cost, which is as low as $0.75/W. LEDs, also called SS lighting, were barely discussed in the 1998 report, in which Figure 3.12 shows efficiencies from 20-80 lm/W for LEDs, compared to the current record of 231 lm/W.

Solar power has received great interest recently as a renewable energy solution capable of providing energy independence and environmental stability while beginning to deliver power at a competitive price. Because of high costs relative to other energy generation technologies, solar power currently satisfies only a small fraction of the world’s energy need. Government support and private investments have led to a boom of technical advances over the past years that have continued to drive solar power toward eventually being a mainstream source of power.10

Solar power has great potential for home, off-grid, and utility-scale generation. Solar cells have become common in applications for which grid power is not accessible (see Figure 5.1) or convenient, such as powering remote devices or small handheld electronics. As will be seen in this chapter, utility-scale solar plants are not yet competitive with alternative sources of energy, yet the cost of solar electricity

_________________

8 More information about Cree is available at http://www.cree.com/press/press_detail.asp?i=1304945651119. Accessed December 17, 2011.

9 National Research Council. 1998. Harnessing Light: Optical Science and Engineering for the 21st Century. Washington, D.C.: National Academy Press.

10 Tyner, C. E., G.J. Kolb, M. Geyer, and M. Romero. 2001. “Concentrating Solar Power in 2001—An IEA/SolarPACES Summary of Present Status and Future Prospects.” International Energy Agency—SolarPACES. Available at http://www.solarpaces.org/Library/docs/CSP_Brochure_2001.pdf. Accessed August 1, 2012.

FIGURE 5.1 Small solar cell installation monitoring the water supply in Shenandoah National Park in Virginia.

is dropping, and it is reasonable to see a future in which solar power will be cost-competitive for new electric power plants.

It typically requires a large capital investment to build solar plants for a life cycle of a few decades, but once built they do not require period payments for fuel, like fossil-fuel-powered electric plants do. Comparisons are therefore somewhat complicated. A common metric for the economic viability of a solar installation is dollars per watt produced ($/W), which divides the module cost by the peak output power.

A more extensive measure of the economic feasibility of a solar power system is provided by the levelized cost of energy (LCOE), which is commonly measured in cents per kilowatt-hour (¢/kWh). This is a more realistic cost for an investor to use when comparing a solar plant to other potential electricity generation alternatives. The LCOE can be expanded to include known factors such as the financing structure of the plant, incentives, and system degradation. Projecting the LCOE accurately requires detailed information both on the system performance over the lifetime of the plant and on the financial structure of the installation.11 The complexity and variability of the assumptions used in this metric highlight a need for

_________________

11 Cambell, M. 2008. “The Drivers of the Levelized Cost of Electricity for Utility-Scale Photovoltaics.” San Jose, Calif.: Sunpower Corporation. Available at http://large.stanford.edu/courses/2010/ph240/vasudev1/docs/sunpower.pdf. Accessed July 24, 2012.

better economic modeling. A solar plant is different from a fossil-fuel electricity generation plant in that most of the cost is in building the solar plant, but no fuel must be purchased on a regular basis.

In 2011, the United States launched the SunShot Initiative (see Box 5.2 and Figure 5.2.1), with the goal of advancing solar technology to be competitive with conventional sources of electricity. This cost comparability, or grid parity, is very important to the widespread adoption of solar power. Traditionally, grid parity is

BOX 5.2

The SunShot Initiative

“The DOE [Department of Energy] SunShot Initiative is a collaborative national initiative to make solar energy cost competitive with other forms of energy by the end of the decade. Reducing the installed cost of solar energy systems by about 75 percent will drive widespread, large-scale adoption of this renewable energy technology and restore U.S. leadership in the global clean energy race.” (See Figure 5.2.1.)

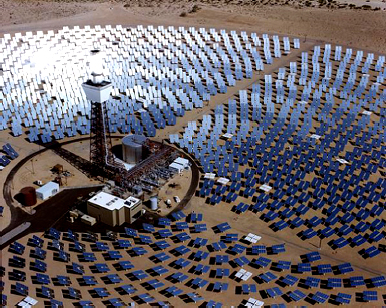

FIGURE 5.2.1 In this photograph of a concentrating solar power (CSP) technology, stretched membrane heliostats with silvered polymer reflectors will be used as demonstration units at the Solar Two central receiver. The Solar Two project will refurbish this 10-megawatt central receiver power tower, known as Solar One. SOURCE: Image available at https://www.eeremultimedia.energy.gov/solar/.

SOURCE: The quotation above from the Department of Energy is available at http://www1.eere.energy.gov/solar/sunshot/. Accessed November 23, 2011.

defined as cost per watt (energy/time) but occasionally as cost per kilowatt-hour (energy). If watts are used, grid parity is reached when the power plants are equal in price to build; if kilowatt-hours are used, grid parity is reached when “selling” the different energy sources costs the same. In the latter case, solar includes the free energy from the Sun, whereas coal-fired electricity generation includes the cost of coal. The goal of competitive solar energy requires an LCOE of approximately $0.06/kWh, which corresponds to approximately $1.00/W installed for a module.12 Installed cost will of course be more than production costs. There are already solar modules less the $1.00/W for module cost.

Solar technologies fall primarily into two broad categories: (1) photovoltaics (PV), which convert solar radiation directly into electricity, and (2) concentrating solar power. CSP uses optical elements to focus the Sun’s energy, and a heated liquid, along with a heat engine, to generate electricity. Once the Sun’s light is focused, it can heat an intermediate material, which can be used to drive a turbine to generate electricity. Concentrated photovoltaics also concentrate the Sun’s radiation, but not to the same extent that CSP does. With CPV, the light is concentrated so that high-efficiency solar cells can be used without there being too much concern about cell cost. The cost of the concentrating optics must of course now be considered. With current solar cells, the temperature of the cells must be kept near room temperature in CPV in order to maintain high efficiency, and so an efficient heat-removal process must be used. CPV solar cells have been measured at 1,000 Suns concentration and 43 percent efficiency,13 and it is anticipated that at least 2,000 Suns concentration can be used, although it may cost some conversion efficiency. Below, solar conversion optics that can work at higher temperatures are discussed. These options also provide the potential to allow higher Sun concentration.

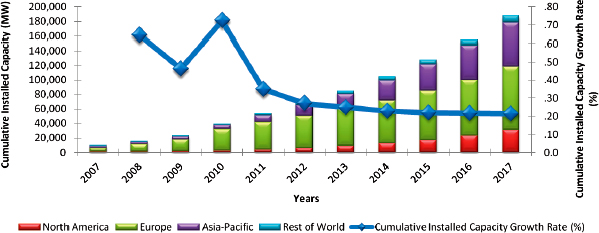

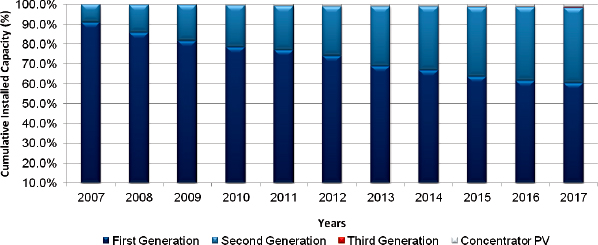

As of 2010, approximately 39,611 megawatts (MW) of PV capacity had been installed around the world, with most of that in Europe.14 Between 2010 and 2017, the installed capacity of PV is expected to increase to more than 185,000 MW, with Europe continuing to have the largest portion, but with the rest of the world gaining market share as costs continue to decrease and newer technologies come to market. The growth projections over this forecast period are shown in Figure 5.2.

_________________

12 More information on the U.S. Department of Energy SunShot Initiative is available at http://www1.eere.energy.gov/solar/sunshot/. Accessed October 25, 2011.

13 Wiemer, M., V. Sabnis, and H. Yuen. 2011. 43.5% efficient lattice matched solar cells. Proceedings of the SPIE 8108:810804-810804-5.

14 In comparison, the total net electricity generation for the United States alone was 602,076 MW in 2010. More information is available at www.eia.gov/electricity/annual/pdf/table1.1.a.pdf. Accessed June 4, 2012.

FIGURE 5.2 Forecasted installed capacity and growth rate of photovoltaic devices divided regionally. The base year is 2010. SOURCE: “Global Solar Power Market.” Frost and Sullivan Analytics. July 2011. Reprinted with permission.

The compound annual growth rate of these devices is projected to be 25 percent from 2010 to 2017.

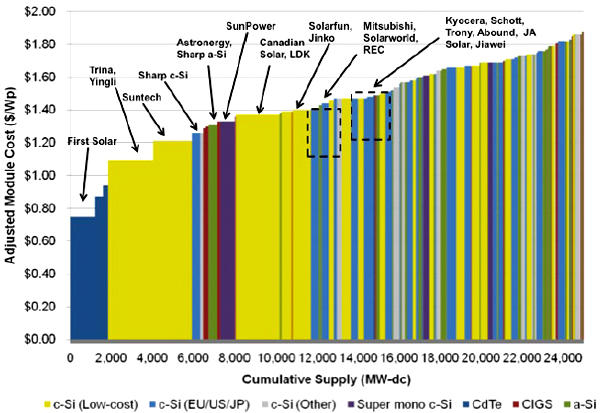

Despite the rapid growth in installed capacity over the next several years, photovoltaics are still expected to provide for only a small part of the energy demand in the regions highlighted in Figure 5.2. As a point of comparison, the total electricity generated in the United States over the last few years has ranged from about 300,000 MW to 400,000 MW.15 The primary barrier preventing wider acceptance of utility-scale PV generation is that it is still expected to be more expensive than alternative energy sources over this 2010-2017 time frame. The PV industry is still largely reliant on government subsidies and incentives to provide power at an LCOE competitive with alternative energy sources. It is expected that a competitive solar technology must be below $1.00/W peak installed cost. Most current PV systems are substantially above this mark, even for the production cost alone, as shown in Figure 5.3. There will be installation costs and possible cost of land use for electric plants. As with all methods of generating electricity, there will be environmental considerations, such as the impact on a desert when large areas are covered by reflectors or solar cells. Current cost figures represent a drastic decrease from the average production cost of $4.50/W in 1998, when the NRC’s Harnessing Light16 was published.

_________________

15 The U.S. Energy Information Administration’s Electricity Monthly Update is available at http://www.eia.gov/electricity/monthly/update/. Accessed July 24, 2012.

16 National Research Council. 1998. Harnessing Light.

FIGURE 5.3 Average cost per watt of current widely deployed photovoltaic technologies in 2011. SOURCE: “PV Technology, Production and Cost Outlook: 2010-2015” (GTM Research). Reprinted with permission.

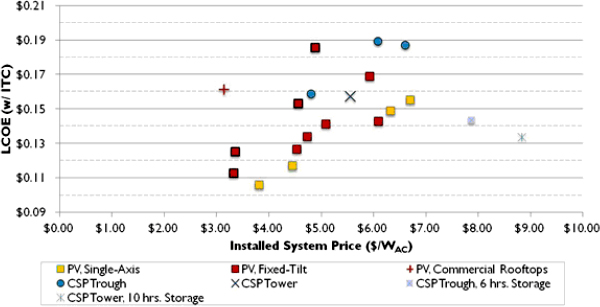

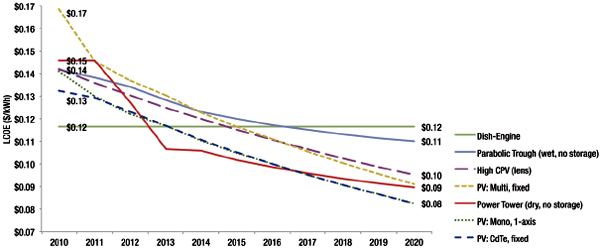

Investor literature for major solar cell manufacturers does promise reaching the cost parity level of $1.00/W for installed cost around 2015.17,18 Obviously investor literature may be optimistic, but major PV solar cell companies at least have plans on how to meet the dollar per watt cost goals. The LCOE of photovoltaics continues to drop due to manufacturing infrastructure improvements and more advanced technologies becoming available.19Figure 5.4 shows installed cost LCOEs for a number of installed projects based on a very recent National Renewable Energy Laboratory article.20

_________________

17 More information on the First Solar corporate overview, third quarter, 2011, is available at http://www.firstsolar.com/. First Solar corporate overview accessed December 7, 2011.

18 More information on the SunPower third quarter 2011 earnings is available at http://us.sunpowercorp.com/. SunPower, November 3, 2011, Supplementary Slides accessed December 7, 2011.

19 For more about information about installed cost time lines for solar technology, see Appendix C in this report.

20 National Renewable Energy Laboratory. 2011. “Cost of Utility-Scale Solar: One Quick Way to Compare Projects.” Available at https://financere.nrel.gov/finance/content/cost-utility-scale-solar-one-quick-way-compare-projects. Accessed July 24, 2012.

FIGURE 5.4 Levelized cost of energy (LCOE) for installed systems. SOURCE: Publicly available data from the websites of the Department of Energy Loan Program Office, Xcel Energy, Green Fire Times, Tri-State Generation, Getsolar, California PUC, Business Wire, U.S. Air Force Academy, Juwi Solar, Winston-Salem Journal, iStockAnalyst, EarthTechling, Environmental Leader, and pv-magazine. Figure from Renewable Energy Project Finance, and available at https://financere.nrel.gov/finance/content/cost-utility-scale-solar-one-quick-way-compare-projects. Accessed July 24, 2012. Reprinted with permission.

Even though Figure 5.4 shows the LCOE for installed systems, there is uncertainty because of assumptions such as expected lifetime.

First-Generation Silicon Cells

Photovoltaic technologies that rely on a silicon (Si) p-n junction are referred to as first-generation technologies, which encompass polycrystalline silicon, mono-crystalline silicon, and silicon ribbon technologies. The typical conversion efficiency of these technologies ranges from 14 to 22 percent for a module. A laboratory record of 25 percent was achieved at the University of New South Wales.21 The theoretical limit for cells of this family is approximately 33 percent conversion efficiency.22

_________________

21 Green, M. 2009. The path to 25% silicon solar cell efficiency: History of silicon cell evolution. Progress in Photovoltaics: Research and Applications 17(3):183-189.

22 Meillaud, F., A. Shah, C. Droz, E. Vallat-Sauvain, and C. Miazza. 2006. Efficiency limits for singlejunction and tandem solar cells. Solar Energy Materials and Solar Cells 90(18-19):2952-2959.

In 2010, over 75 percent of the capacity of PV systems installed was first-generation solar cells.23 Si photovoltaics are the most mature and widely accepted form of PV, and they still exhibit some of the highest conversion efficiencies of available technologies. First-generation PVs are expected to continue to dominate the market through 2017, although they are expected to lose market share to emerging technologies. Production of first-generation solar cells is highly competitive, with no single company holding a market share substantially larger than 10 percent, and different companies leading in each geographic region.24 The focus for advancing first-generation solar cells is on reducing manufacturing costs. It is not expected that this technology will be capable of being produced for less than $1.00/W installed cost. Figure 5.5 shows first-generation solar cells for power company use.

Second-Generation Photovoltaic Technologies

The second-generation solar cells consist of thin films of silicon, or other semiconductors, deposited on glass or flexible substrates. The most prominent thin-film technologies that have emerged are cadmium telluride (CdTe) (see Figure 5.6), thin-film silicon, and copper indium gallium selenide (CIGS). These films do not convert sunlight into electricity as efficiently as the first-generation silicon devices do, but the potential for reduced manufacturing costs makes them attractive. Second-generation photovoltaics accounted for approximately 21 percent of the global installed capacity in 2010 and are projected to gain market share over the next several years, providing 38.0 percent of installed capacity in 2017.25

The second-generation cell accounting for most of this installed capacity is a thin-film CdTe cell. First Solar has commercialized this cell and gained a substantial market share, as the greatly reduced manufacturing cost compensates for the reduced conversion efficiency (approximately 17 percent)26 compared to standard Si panels. Several large-scale solar projects based on CdTe technology have been built, such as the 80-MW facility at Sarnia in Canada shown in Figure 5.6.

CdTe cells have already reached the $1.00/W goal for production cost, but it is not yet clear how this translates into LCOE. For example, CdTe thin films are relatively new, so there has not been enough time to establish the lifetime and

_________________

23 Frost and Sullivan Research Service. 2011. Global Solar Power Market. July. Available at http://www.frost.com/prod/servlet/report-brochure.pag?id=N927-01-00-00-00. Accessed July 24, 2012.

24 Kann, S. 2010. The U.S. Utility PV Market: Demand, Players, Strategy, and Project Economics Through 2015. GTM Research. Available at https://www.greentechmedia.com/research/report/us-utility-pv-market-2015/. Accessed July 24, 2012.

25 Frost and Sullivan Research Service. 2011. Global Solar Power Market.

26 Kanellos, M. 2011. “First Solar Sets Efficiency Record: 17.3% Percent.” Greentech Media. Available at http://www.greentechmedia.com/articles/read/first-solar-sets-efficiency-record-17.3percent/. Accessed June 6, 2012.

FIGURE 5.5 Silicon solar cells deployed for utility power production. SOURCE: Courtesy of Suntech Power Holdings, Inc.

FIGURE 5.6 Eighty-megawatt thin-film cadmium telluride (CdTe)-based solar plant in Canada. SOURCE: Courtesy of First Solar.

degradation rate accurately under actual outdoor conditions. Another concern is that the materials used are rare and extremely toxic. Although initial indicators are that the production and deployment of these cells do not release cadmium into the environment, further adoption will require more extensive environmental impact testing. CdTe technology shows promise of gaining grid parity in a relatively short time frame if these obstacles can be overcome.

An accurate cost benchmark exists for CdTe solar cells. Warren Buffett recently contracted for a 550-MW facility from First Solar for $2 billion,27 which works out to be $3.63/W. First Solar has started building this facility. If $1.00/W is equivalent to 6 ¢/kWh, then the installed facility would be 21.8 ¢/kWh. Although this is more expensive than a fossil fuel plant, California utilities are required to obtain at least 20 percent of their power from renewable sources and are on a path to a 33 percent requirement by 2020.28,29

An alternative embodiment of thin-film technology uses a much more efficient gallium arsenide (GaAs)-based film. A thin-film GaAs solar cell was reported in 2011 by Alta Devices to have an efficiency of 28.2 percent30 for unconcentrated solar illumination, a record for single-junction devices. Using a process known as epitaxial liftoff in order to reduce manufacturing costs, it is projected to be competitive with CdTe cells currently in production on a dollars per watt basis while delivering almost three times the area efficiency when in production. At present this is just a projection, however.

Several immature technologies in development show promise, but they are not ready for large-scale commercialization. These exotic schemes are frequently grouped into the third generation of photovoltaics. Active research is being carried out on dye-sensitized cells, organic cells, nanocrystal cells, photoelectrochemical cells, and other technologies that have potential to dramatically reduce cost and/or increase efficiency compared to current systems.

_________________

27 RTTNews. 2011. “Buffet’s MidAmerican Energy to Buy First Solar’s $2 Bln Power Plant.” Available at http://www.rttnews.com/1776646/buffet-s-midamerican-energy-to-buy-first-solar-s-2-bln-power-plant.aspx. Accessed December 18, 2011.

28 More information on the California Renewables Portfolio Standard is available at http://www.cpuc.ca.gov/PUC/energy/Renewables/index.htm. Accessed December 18, 2011.

29 Sullivan, Colin. 2010. “Calif. Raises Renewable Portfolio Standard to 33%.” New York Times. July 24. Available at http://www.nytimes.com/gwire/2010/09/24/24greenwire-calif-raises-renewable-portfolio-standard-to-3-24989.xhtml. Accessed December 18, 2011.

30 Kayes, B., H. Nie, R. Twist, S.G. Spruytte, F. Reinhardt, I.C. Kizilyalli, and G.S. Higashi. 2011. “27.6% Conversion Efficiency, a New Record for Single-Junction Solar Cells Under 1 Sun Illumination.” 37th IEEE Photovoltaic Specialists Conference 000004-000008.

Concentrated Photovoltaics

Concentrated photovoltaics offer an alternative approach, using inexpensive optics to concentrate light onto a small area of a highly efficient photovoltaic cell. By concentrating light from the Sun (see Figure 5.7), less PV material is required. A limitation for high concentration is that the module must be placed on a solar tracker in order to maintain accurate alignment with the Sun, and the accuracy of the tracker must increase as the concentration of the system increases. This limited acceptance angle also dictates that the system is only able to capture direct sunlight, meaning that it is ineffective on cloudy days. The amount of concentration provided by the optics will produce differing systems, which generally fall into the low-concentration (2-50 times) or high concentration (100-2,000 times) categories. This has some similarities to concentrated solar power, discussed below.

The low-concentration systems typically use conventional single-junction solar cells and rely on the optics being inexpensive enough that the reduced PV material required justifies the added cost of concentrating. These systems can frequently be mounted on a one-axis tracking system, and the cells can usually be kept within their normal operating temperature using passive cooling systems.

The high-concentration systems allow for the use of multi-junction cells in the system.31 Multi-junction cells can reach higher conversion efficiencies than are possible with single-junction PV devices, with the record currently being set by the company Solar Junction at 43.5 percent,32 eclipsing the recent record by Spire Semiconductor, LLC, of 42.3 percent33 conversion efficiency. These cells are expensive, but by reducing the area required for a module by two or three orders of magnitude, the cost can be justified. These cells showed a peak efficiency of 43.5 percent between 400 and 600 Suns concentration and maintained efficiencies above 43 percent at 1,000 Suns concentration.34

A key driving cost of making these cells is the substrate on which the photovoltaic layers are grown. This material is very expensive and currently must be disposed of after a cell is grown on it. Substantial research is being done on the epitaxial liftoff technique, which allows the substrate to be reused for growing successive cells. The disadvantages of CPV systems are primarily the extra cost associated with

_________________

31 Multi-junction solar cells contain several p-n junctions, each of which can be tuned to a different wavelength of light, thus capturing more of the incoming light.

32 Wesoff, E. 2011. “Update: Solar Junction Breaking CPV Efficiency Records, Raising $30M.” Greentech Media. Available at http://www.greentechmedia.com/articles/read/solar-junction-setting-new-cpv-efficiency-records/. Accessed December 25, 2011.

33 Wojtczuk, S., P. Chiu, X. Zhang, D. Derkacs, C. Harris, D. Pulver, and M. Timmons. 2010. InGaP/GaAs/InGaAs 41% concentrator cells using bi-facial epigrowth. 35th IEEE Photovoltaic Specialists Conference 001259-001264.

34 Wiemer, M., V. Sabnis, and H. Yuen. 2011. 43.5% efficient lattice matched solar cells.

FIGURE 5.7 A high-concentration photovoltaic panel using Fresnel lens optics and III-V solar cells. SOURCE: Courtesy of Amonix.

having a precise two-axis tracker and an active cooling system required to maintain a reasonable chip temperature at high concentration, as well as the limitation to the system’s use on sunny days.

Concentrated photovoltaics of both concentration regimes require performance and cost advances before they can become competitive on a utility scale. Moreover, the concentration system, including the tracker, also constitutes a large percentage of the cost. For the high-concentration systems, increasing the performance and reliability of high-efficiency cells will improve the conversion efficiency, and improved thermal management systems would allow the cells to operate at lower temperatures, at which they are more efficient.

Expected Market Share for Various PV Technologies

Over the next few years, it is expected that disruptive new technologies will gradually gain market share from the currently dominant first-generation photovoltaics. It is expected that second-generation photovoltaics will begin to rival the capacity of the first-generation PVs, and concentrating photovoltaics will begin to gain a greater market share.35 Third-generation systems are much more difficult to predict. The estimate of relative capacities of the various technologies over the short term is shown in Figure 5.8.

Concentrating Solar Power Systems

Concentrating solar power provides an alternative to photovoltaics for producing electricity. A key deficiency of photovoltaics is energy storage, as batteries or other means of storage must be employed to store the power generated when the Sun is out.36 The need for storage is mitigated if solar power is used to fill a peak-load requirement to meet air conditioning needs. Peak pricing in some cases has made energy storage less desirable. CSP installations have a much more efficient means of storing energy, as the heated intermediate media can be stored and used on demand. CSP systems can have energy-conversion efficiencies comparable to those of photovoltaics.

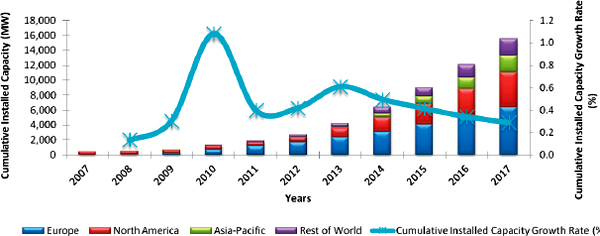

In 2010, the installed CSP capacity around the world was 1,327 MW, with Europe and North America dominating the market. The installed capacity is expected to increase more than 10-fold by 2017, with more than 15,000 MW of expected installed capacity. North America and Europe are expected to maintain dominance in this market, with the rest of the world gaining some market share. The best

_________________

35 Frost and Sullivan Research Service. 2011. Global Solar Power Market.

36 For more about information about supporting technologies associated with solar power, see Appendix C in this report.

FIGURE 5.8 Market share for various photovoltaic (PV) technologies. SOURCE: “Global Solar Power Market.” Frost and Sullivan Analytics. July 2011. Reprinted with permission.

currently implemented CSP installations are producing energy at an LCOE of approximately 12¢/kWh to 15¢/kWh, which is higher than for alternative energy sources. This is expected to drop to below 12¢/kWh by 2017 as manufacturing improves and new technologies are brought to market. CSP functions best on large scales, and thus building an efficient plant requires a large capital investment. The expected growth of installations broken down regionally is provided in Figure 5.9.

FIGURE 5.9 Expected installed capacity of concentrated solar power market divided regionally, and compound annual growth rate; 2010 is the base year. SOURCE: “Global Solar Power Market.” Frost and Sullivan analysis. July 2011. Reprinted with permission.

The compound annual growth rate of the CSP market is expected to be 42.1 percent from 2010 to 2017.37

The most common available form of CSP is the parabolic trough concentrator, as seen in Figure 5.10. These systems are usually set up on one-axis tracking systems, which track the Sun over the course of the day. This type of plant consists of a parabolic mirror focusing sunlight onto a tube of heat-transfer medium, usually oil, which is then heated and used to create steam, which can drive an electric generator. The maximum temperature is limited by the oil-based heat-transfer medium and the lower concentration required with single-axis tracking, limiting the efficiency of these systems to approximately 15 percent.38

As of 2009, parabolic trough concentrators accounted for more than 83 percent of installed CSP capacity.39 The oil intermediate is difficult to store efficiently for use during off-peak hours. Hence it is possible that trough technology with oil intermediates might lose market share and will have a harder time reaching grid parity.40

The solar tower is a relatively recent incarnation of CSP, using a large field of flat mirrors called heliostats to direct incident sunlight to a focal point in a central tower, as shown in Figure 5.11. A heat-exchange medium, usually a molten salt, absorbs the energy and is heated to temperatures up to 1000°C, which can then be used to generate electricity. This larger temperature difference allows more efficient electricity generation than the common trough technology, with conversion efficiencies in the range of 20 to 35 percent.41

Power tower systems offer a much more efficient alternative to the parabolic troughs that currently dominate the CSP landscape. In addition to the greater conversion efficiency, the power towers make more efficient use of the land, and the heliostats are less expensive to manufacture and maintain than the parabolic

_________________

37 Frost and Sullivan Research Service. 2011. Global Solar Power Market.

38 Acciona Energy. Technology and Experience in Concentrating Solar Power. Available at http://www.acciona-energia.com/media/315798/Technology%20and%20experience%20in%20concentrating%20solar%20power.pdf. Accessed October 25, 2011.

39 Greenpeace International. 2009. Global Concentrating Solar Power Outlook 09: Why Renewable Energy Is Hot. Amsterdam, The Netherlands: Greenpeace International. Available at http://www.greenpeace.org/international/en/publications/reports/concentrating-solar-power-2009/. Accessed July 24, 2012.

40 Feldhoff, J.F., D. Benitez, M. Eck, and K.-J. Riffelmann. 2010. Economic potential of solar thermal power plants with direct steam generation compared with HTF plants. Journal of Solar Energy Engineering 32:1001-1009.

41 Hinkley, J., B. Curtin, J. Hayward, A. Wonhas, R. Boyd, C.C. Grima, A. Tadros, R. Hall, K. Naicker, and A. Mikhail. 2011. Concentrating Solar Power—Drivers and Opportunities for Cost-Competitive Electricity. Melbourne, Victoria, Australia: CSIRO Energy Transformed. Available at http://www.garnautreview.org.au/update-2011/commissioned-work/concentrating-solar-power-drivers-opportunities-cost-competitive-electricity.pdf. Accessed July 24, 2012.

FIGURE 5.10 A parabolic trough concentrator solar thermal plant in Nevada. SOURCE: Courtesy of Acciona Solar Power.

FIGURE 5.11 Eleven-megawatt Solar Power Tower near Seville, Spain. SOURCE: Courtesy of Abengoa Solar.

mirrors used in trough systems. A primary drawback of tower technology is the large investment required, with only large-scale plants making economic sense.

Dish concentrators (see Figure 5.12) are an emerging technology that functions on a principle similar to that of a solar tower but is scalable to smaller units. A reflective parabolic dish tracks the Sun and focuses onto a small power-conversion unit. A heat-transfer fluid is heated several hundred degrees Celsius and is subsequently

FIGURE 5.12 A dish solar thermal power generation module test unit in Phoenix, Arizona. The dish is approximately 75 feet in diameter. SOURCE: Courtesy of Southwest Solar Technologies.

used to generate electricity. These systems are expected to have conversion efficiencies similar to those of solar tower concentrators, although dish concentrator systems have not yet been successfully commercialized.

Dish concentrators with a combined capacity of more than 1,700 MW are being developed; over 35 percent of them are in the Asia Pacific region.42 These systems require that an efficient and inexpensive generator be developed on a much smaller scale than that needed for tower systems. These systems lack the centralized storage capability of the power tower approach, and thus alternate storage methods must be employed to store power.

Some research is being conducted on the possibility of integrating CPV and CSP systems. In a photovoltaic system, the energy that is not converted into electrical power is dissipated as heat, which has the potential to be recycled, especially in a concentrated photovoltaic system. This waste heat can either be recycled to generate more electricity or can serve a variety of other uses, such as the heating of water.43 The primary difficulty is that most PV chips become less efficient as they increase in temperature. Wide-bandgap materials will work better for solar cells at higher temperatures, but there will still be a loss of efficiency.44 Researchers at Stanford University are conducting research on a “photovoltaic-like” device that becomes more efficient at higher temperatures, which would be ideal for integration into a hybrid system.45 The Stanford approach, also discussed in a paper by Andrews et al.,46 has calculated efficiencies for an idealized device, which can exceed the theoretical limits of single-junction photovoltaic cells. The device is based on thermionic emission of photoexcited electrons from a semiconductor cathode at high temperature. Temperature-dependent photoemission-yield measurements from gallium nitride (GaN) show strong evidence for photon-enhanced thermionic emission. As mentioned by CleanEnergyAuthority,47 the proposed solar converter

_________________

42 Frost and Sullivan Research Service. 2011. Global Solar Power Market.

43 For information about hybrid solar/wind systems, see Appendix C in this report.

44 Landis, G.A., D. Merritt, R.P. Raffaelle, and D. Scheiman. 2005. High-Temperature Solar Cell Development. Washington, D.C.: National Aeronautics and Space Administration, pp. 241-247. Available at http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20050206368_2005207966.pdf. Accessed July 24, 2012.

45 Schwede, J.W., I. Bargatin, D.C. Riley, B.E. Hardin, S.J. Rosenthal, Y. Sun, F. Schmitt, P. Pianetta, R.T. Howe, Z.-X. Shen, and N.A. Melosh. 2010. Photon enhanced thermionic emission for solar concentrator systems. Nature Materials 9:762-767.

46 Andrews, J.C., F. Meirer, Y. Liu, Z. Mester, and P. Pianetta. 2011. Transmission x-ray microscopy for full-field nano imaging of biomaterials. Microscopy Research and Technique 74(7):671-681.

47 More information is available at www.cleanenergyauthority.com. Accessed August 6, 2012.

would operate at temperatures exceeding 200°C, enabling its waste heat to be used to power a secondary thermal engine, boosting theoretical combined conversion efficiencies above 50 percent. There will be very interesting trade-offs if one decides to optimize a hybrid system. It would be possible to make a system optimized for CSP, operating at high temperatures, and then to add high-temperature solar cells to it to boost efficiency. Alternately it would be possible to design an optimum CPV system with high PV efficiency, and then to add whatever power could be generated using a lower-temperature, and therefore less efficient, heat cycle approach to generate electricity. In general, PV makers and CSP companies have not mixed much, and so this is a somewhat unexplored design space with potential to achieve high efficiency.

LCOE Outlook for Solar Power Compared to Other Current and Possible Future Fuel Sources

The most likely initial geographical locations for commercial utility-scale solar power will have high solar irradiance and high energy prices from alternative sources. For areas with high direct solar radiation, such as the southwestern United States, high-concentration photovoltaics are expected to reach the lowest LCOE of any solar technology. These systems are only viable in areas with little cloud cover, where the direct component of solar radiation is much greater than the diffuse component, and thus can be focused. In areas such as the Southwest, energy storage capability may not be a significant factor owing to peak-load pricing considerations. Additionally, the grid needs to be considered in any final estimates of success for solar power. The NRC’s Overview and Summary of America’s Energy Future: Technology and Transformation states:

Greatly expanding the fraction of electricity generated from renewable sources will require changes in the present electric system because of variability over space and time in the availability of renewables such as wind and the difficulty of scaling up renewable resources. Integrating an additional 20 percent of renewable electricity, whether from wind, solar, or some combination of sources, will require an expansion of the transmission system as well as large increases in manufacturing, employment in the wind power industry, and investment.48

The projected LCOE for various technologies deployed in optimal locations for solar energy is shown in Figure 5.13.49 This forecast cannot predict the effect

_________________

48 NAS-NAE-NRC. 2010. Overview and Summary of America’s Energy Future, p. 21.

49 More information is available on the GTM Research webinar “Concentrating Photovoltaics (CPV): Ready for Take-Off?” September 27, 2011. Available at http://www.greentechmedia.com/events/webinar/concentrated-photovoltaics-cpv-now-an-indispensable-part-of-the-energy-equa/. Accessed July 24, 2012.

FIGURE 5.13 Levelized cost of energy (LCOE) projections for various solar technologies, 2010-2020. SOURCE: “Concentrating Solar Power 2011: Technology, Costs and Markets” (GTM Research). Reprinted with permission.

of disruptive research and development, but it shows that many solar technologies have the potential to compete with conventional energy sources. The same graph also depicts the LCOE for natural gas, which was at $0.10/kWh in 2010 and was predicted to steadily increase to about $0.14/kWh in 2020, a point at which it is possible that many of the solar technologies will be at a lower LCOE. The recent advances in the production of natural gas owing to fracking will change the cost comparison by making natural gas power plants cheaper than previously envisioned. Production of shale gas from fracking has soared 12-fold between the years 2000 and 2011, driving down the price of natural gas.50 As can be seen in Figure 5.13, the cost of solar power is projected to keep dropping, and so even with the lower cost comparison, it is anticipated that at some point, and in certain circumstances, solar power will be cost-competitive.

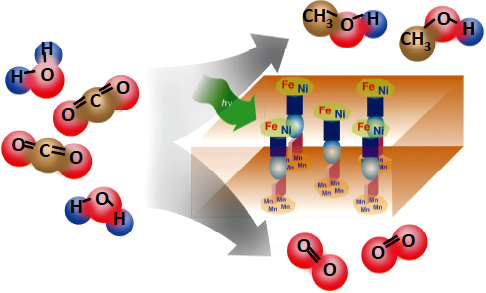

Other alternative methods might become possible in the near future as well. One alternative method of harvesting solar power is through the use of a chemical process that mimics photosynthesis. The creation of fuels from abundant inputs such as water and carbon dioxide (CO2) using sunlight has the potential to offer conventional liquid fuels while still being carbon-neutral (see Figure 5.14). This technology resembles photosynthesis, in that it involves a chemical reaction on a thin membrane, which then splits the products to be fuel and oxygen. In the case of natural photosynthesis these products are sugars as the fuel and oxygen that is

_________________

50The Economist. 2011. “Fracking Here, Fracking There.” Available at http://www.economist.com/node/21540256. Accessed July 24, 2012.

FIGURE 5.14 Water and CO2 are converted catalytically into fossil fuels and oxygen in the presence of sunlight. The membrane separates the fuel from the oxygen. SOURCE: Joint Center for Artificial Photosynthesis, available at http://solarfuelshub.org/home. Reprinted with permission.

released into the atmosphere. Artificial photosynthesis has many different possible inputs and outputs, and research is being pursued to tune the process in order to maximize catalytic conversion into the standard n-hydrocarbons that can easily be used as fuels.

Research to advance artificial photosynthesis is being carried out at the Joint Center for Artificial Photosynthesis in California.51

Incandescent lightbulbs have been in use for well over 100 years. English chemist Humphry Davy demonstrated the first electrically driven incandescent light in 1802. In the ensuing 80 years many people worked on improving the incandescent bulb. Thomas Edison developed the first commercially viable approach.52 These bulbs are not efficient but are still in widespread use, and as a result, lighting

_________________

51 The website of the Joint Center for Artificial Photosynthesis is available at www.solarfuelshub.org. Accessed October 25, 2011.

52 Friedel, R., and P. Israel. 1986. Edison’s Electric Light: Biography of an Invention. New Brunswick, N.J.: Rutgers University Press, pp. 115-117.

consumes more than 20 percent of the electricity used in the United States and Europe and a higher percentage in developing nations.53 Incandescent bulbs radiate most of the input energy as infrared radiation or heat, not as visible light. Halogens have been added to some incandescent bulbs, allowing a higher operating temperature and slightly more efficiency. These are referred to as halogen bulbs, although neither the efficiency nor the lifetime has been changed substantially. In the 1930s, fluorescent bulbs became available. They are significantly more efficient then incandescent bulbs, but they contain mercury, a hazardous material.54 Compact fluorescent bulbs fitting most lamps started to be commercially available in 1985.55 Fluorescent lights take minutes to come to full brightness, which makes some people avoid these lights despite their higher efficiency as compared with incandescent bulbs.56 Color balance can also be an issue for fluorescents, depending on the phosphors used.

Mercury vapor and sodium vapor lamps are another available lighting option. Mercury vapor and sodium vapor lamps can be very efficient, ranging from 100 lm/W up to 150 or even 200 lm/W.57 Vapor lamps are used extensively in street lighting, where their long start-up time is not a significant disadvantage. Although people like the color spectrum of mercury vapor lamps, the United States banned them in 2008 and the European Union is banning them in 2015 because of the mercury usage.58,59 Sodium vapor streetlights have a color spectrum that is less desirable. Figure 5.15 shows the lighting efficiency for various lighting types as of 2008.

A critical factor for consumers purchasing lightbulbs is the light efficiency of the bulb, in terms of both lumens60 per watt and lumens per dollar. At a wavelength of 555 nanometers (nm), a 100 percent efficient light source would produce

_________________

53 Azevedo, I.L., M.G. Morgan, and F. Morgan. 2009. The transition to solid-state lighting. Proceedings of the IEEE 97(3):481-510.

54 It is unlawful to dispose of fluorescent bulbs as universal waste in the states of California, Illinois, Indiana, Michigan, Minnesota, Ohio, and Wisconsin. More information is available at http://www.epa.gov/waste/hazard/wastetypes/universal/lamps/index.htm. Accessed October 25, 2011.

55 Kane, R, and H. Sell, eds. 2001. Revolution in Lamps: A Chronicle of 50 Years of Progress (2nd ed.). Lilburn, Ga.: Fairmont Press.

56 More information is available through General Electric (GE) Lighting, “Why does my compact fluorescent light bulb flicker or appear dim when I first turn it on?” Compact Fluorescent Light Bulb (CFL) FAQs. GE Lighting. Available at http://www.gelighting.com/na/consumer/education/faqs/. Accessed July 24, 2012.

57 de Groot, J.J., and J.A.J.M. van Vliet. 1986. The High-Pressure Sodium Lamp. Cambridge, Mass.: Macmillan Education.

58 Mercury vapor banned in 2008; Energy Policy Act of 2005 (Public Law 109-58).

59 More information on the European Union directive on street, office, and industry lighting is available at http://ec.europa.eu/energy/lumen/professional/legislation/index_en.htm. Accessed July 24, 2012.

60 Lumen (lm) is the International System of Units (SI) unit of luminous flux, which is a measure of the total amount of visible light emitted.

FIGURE 5.15 Efficiency of various types of lighting in 2008. SOURCE: Reprinted, with permission, from Azevedo, I.L., M.G. Morgan, and F. Morgan. 2009. The transition to solid-state lighting. Proceedings of the IEEE 97(3):481-510.

683 lm/W by definition, but for a white light spectrum desired by consumers, maximum light-producing efficiency will be lower, approximately 400 lm/W. A typical 100-W incandescent bulb puts out about 1,500 lm, or 15 lm/W per watt of electricity. Lower-wattage incandescent bulbs are even less efficient. Another important characteristic is the lifetime of the bulb. A longer lifetime will allow for fewer replacements over a given period of time, which is beneficial for cost, labor, and convenience. Lifetime considerations are especially important for bulbs in inconvenient places, or for those that involve a high labor cost to replace. A second benefit of much longer lifetimes will be the innovative use of lighting in areas that are only accessible when a structure is being built. It will be possible to plan lighting use as a one-time installation in areas that are difficult to reach. A pleasing color spectrum can influence the efficiency of a lightbulb; sometimes undesirable color

content can be more efficient than pleasing color content. The format of the bulb and environmental impacts are additional factors. Some bulbs contain mercury, a hazardous material, increasing their environmental impact.

Light-emitting diodes first started to be applied in niche markets like flashlights, where battery usage and ruggedness are important. Traffic lights were another early use, as the long lifetime helped reduce the labor cost of replacing bulbs. LEDs are widely used in cars and are making an entry to headlights as well, although attaining the required brightness for headlights is difficult with LEDs.61 LEDs are frequently used in brake lights owing to the faster turn-on time of LEDs; replacing incandescent bulbs with LEDs in brake lights results in a faster turn-on time by almost 0.2 second. At 60 miles per hour, that translates to approximately 18 feet of additional stopping distance, thus helping prevent collisions. For dashboard lighting, LEDs generally last longer than the life of the vehicle and thus do not require replacement for the life of the vehicle. LED lights are also changing how lights are designed in an automobile, such as with turning-signal lights being deployed on side mirrors for better visibility.

Large flat-panel televisions are becoming reliant on LEDs for lighting, as discussed in this report in Chapter 10, “Displays.” The light modulation in these large displays is still done using a liquid crystal modulator, with LEDs providing the light. Large-display manufacturers such as Samsung have made major investments in LED technology and are gaining increasing market share in the LED industry.

LEDs for lighting purposes are becoming more feasible. Walmart recently replaced the overhead lighting in many of its stores with LEDs.62 A number of cities have replaced the street lighting with LEDs.63,64,65,66 When the cost of labor to replace bulbs is taken into account, this can be economically reasonable even now,

_________________

61 Car LED Lights. 2010. “Car LED Tail Lights: Where to Get Them.” Available at http://www.car-ledlights.com/. Accessed October 25, 2011.

62 Treehugger. 2011. “Lighting the Future: Walmart Converting Hundreds of Stores’ Lot Lighting to LEDs.” Available at http://www.treehugger.com/sustainable-product-design/lighting-the-future-walmart-converting-hundreds-of-stores-lot-lighting-to-leds.xhtml. Accessed November 23, 2011.

63Green Sheet, City of Ann Arbor Environmental News. 2008. “LEDS—Ann Arbor ‘Lights’ the Way to Energy Savings.” Available at http://www.a2gov.org/government/publicservices/systems_planning/Documents/publicservices_systems_envtlcoord_greennews_ledlights_2008_09_08.pdf. Accessed December 23, 2011.

64 “Town of Chapel Hill.” Available at http://www.townofchapelhill.org/index.aspx?NID=1986. Accessed December 23, 2011.

65Los Angeles Times. 2009. “L.A. Mayor Meets with Clinton on City Light Plan.” Available at http://latimesblogs.latimes.com/lanow/2009/02/la-mayor-meets.xhtml. Accessed December 23, 2011.

66 City of Seattle, Washington. 2010. “Seattle City Light Begins LED Streetlight Rollout.” Available at http://www.seattle.gov/light/news/newsreleases/detail.asp?ID=10888. Accessed December 23, 2011.

according to a recent article in the Wall Street Journal.67 As the prices come down and efficiency increases, LEDs are likely to comprise a larger portion of lighting. The same Wall Street Journal article says that when Home Depot dropped the price of an LED bulb equivalent to a 40-W incandescent bulb from $21.00 to $9.97, the sales doubled. Solid-state lighting is used now in locations with inconvenient access due to the long lifetime, often from 30,000 to 80,000 hours. This is an advantage over the nominal 1,000-hour lifetime of incandescent bulbs. Halogen bulbs can have up to 5,000 or 6,000 hours of lifetime, while fluorescent bulbs can run 6,000 to 10,000 hours. Table 5.1 shows some LEDs available in August 2012 from a common supplier.

The Department of Energy issued the “L Prize” to promote the development of efficient lighting (see Box 5.3). In addition to the webpage shown in Box 5.3, a second website (see Table 5.2)68 describes the requirements for the 60-W replacement bulb. There were two submissions for the 60-W replacement “L Prize.” Philips Lumileds Lighting won this prize.

There is an upcoming “21st century” prize, which has not yet been officially published. In spite of that, one LED maker has already announced a bulb that appears capable of meeting the stringent requirements for the 21st century bulb.69 This concept bulb emits 1,331 lumens at 8.7 W with a Color Rendering Index (CRI) of 91 and a warm color of 2800 kelvin (K). A standard 75-W incandescent bulb puts out about 1,170 lumens. Figure 5.16 shows a picture of the bulb.

The United States has two companies in the top-10 list of high-brightness LED manufacturers. These are Philips Lumileds Lighting and Cree.70 Philips also has a strong European presence. Table 5.3, from LED Magazine, gives the top-10 high-brightness LED manufacturers by revenue in 2010.71

There are several key technical challenges to be met before LEDs can be widely deployed in homes for everyday use.

The CRI, a measure of the quality of light, has maximum value of 100. When illuminated by a low-CRI light source, objects appear to be different colors than they would if illuminated by the Sun. To obtain a high CRI, the light source must contain the right colors. This can be accomplished either using fluorescent phosphors,

_________________

67 Linebaugh, Kate. 2011. “The Math Changes on Bulbs: Modern LEDS, While Expensive, Save Companies on Labor.” Wall Street Journal. Available at http://online.wsj.com/article/SB10001424052970203537304577031912827196558.xhtml. Accessed July 24, 2012.

68 More information on the Department of Energy’s “L Prize” is available at http://www.lightingprize.org/requirements.stm. Accessed October 25, 2011.

69Jetson Green. 2011. “Cree Demos 152 LPW LED Bulb Concept.” Available at http://www.jetsongreen.com/2011/08/cree-demos-21st-century-led-bulb.xhtml. Accessed July 24, 2012.

70LED Magazine. 2011. “Strategies Unlimited Unveils Top-Ten List of LED Manufacturers.” Available at http://www.ledsmagazine.com/news/8/2/29. Accessed July 24, 2012.

71LED Magazine. 2011. “Strategies Unlimited Unveils Top-Ten List of LED Manufacturers.”

TABLE 5.1 Selected Light-Emitting Diode (LED) Lightbulbs Available on the Web in August 2012

|

|

|||||

| Bulb | Power (watts) | Lumens | Lumens per Watt | Lifetime (hours) | Price ($) |

|

|

|||||

| MR-16 | 4.5 | 348 | 77 | 30,000 | 19.95 |

| A19 | 8.5 | 610 | 71 | 40,000 | 28.95 |

| PAR 30 | 9 | 673 | 75 | 30,000 | 44.00 |

|

|

|||||

SOURCE: LED Waves. Available at www.ledwaves.com.

or by 3 or 4 narrowband lines at the right wavelengths. In the phosphor converted (PC)-LED approach, an LED emits blue light, generally around 450 to 460 nm. Some of this light is emitted directly, and some of it is down-converted by a phosphor from the 450-to-460 nm wavelength (blue) to longer wavelengths (e.g., green, yellow, red) to produce white light.72 The 3 or 4 line approach is often called RGB, for red, green, blue. If the efficiency of all blue, green, and red LEDs is as high as that of blue LEDs, theoretically about 20 percent higher efficiency can be gained using RGB color rendering compared to blue + phosphor LED due to the narrowband spectra, and another 20 percent can be gained in efficiency because there is no Stokes loss in the phosphor. RGB color rendering is theoretically the most efficient. Unfortunately there are no green LEDs, and also, color shifts during the lifetime of products (as R, G, and B will degrade at different rates). Currently, white LEDs are manufactured with violet/blue LEDs covered with yellow phosphors to convert part of the violet/blue light to yellow. Since the emission wavelength of an LED changes with its drive current, fixture, temperature, and age, the CRI is highly variable. Research on solving the droop problem, efficient phosphors to convert to green and red wavelengths, and efficient yellow/green/red LEDs is important. Many recent promising works are based on nanostructured materials such as InGaN nanowire LEDs and quantum-dot phosphors. For the RGB approach to color rendering, there is a lack of a green LED at the right wavelength, about 540 nm.

The cost of white LEDs is still very high due to the lack of scalability in the manufacturing processes. Often the (In, Al) GaN material is grown by metalorganic chemical vapor deposition (MOCVD) on a sapphire substrate. The sapphire substrate is relatively expensive and does not scale down with increasing wafer size. The processing steps, typically involving a flip-chip or liftoff process to remove the substrate, are complex and difficult to mass-produce. Recently, there has been increased interest in using Si as the substrate for GaN LED manufacturing. This can greatly simplify the substrate removal process, as the substrate cost would

_________________

72 Bardsley Consulting, Navigant Consulting, Inc., Radcliffe Advisors, Inc., SB Consulting, and Solid State Lighting Services, Inc. 2012. Solid-State Lighting Research and Development: Multi Year Program Plan March 2011 (Updated May 2011). Report prepared for Lighting Research and Development Building Technologies Program, DOE. Available at http://apps1.eere.energy.gov/buildings/publications/pdfs/ssl/ssl_mypp2011_web.pdf. Accessed July 24, 2012.

BOX 5.3

Department of Energy Establishes the L Prize

“The Energy Independence and Security Act of 2007 directs the U.S. Department of Energy (DOE) to establish the Bright Tomorrow Lighting Prize (L Prize) competition. The L Prize competition is the first government-sponsored technology competition designed to spur development of ultra-efficient solid-state lighting products to replace the common light bulb.” (See Figure 5.3.1.)

FIGURE 5.3.1 Webpage showing the “L Prize” World Wide Web page (July 2, 2011). SOURCE: Figure available at http://challenge.gov/DOE/43-bright-tomorrow-lighting-prize.

SOURCE: The quotation above from the Department of Energy is available at http://challenge.gov/DOE/43-bright-tomorrow-lighting-prize.

TABLE 5.2 Requirements for a 60-W Incandescent Replacement Lamp

More than 90 lumens per watt

Less than 10 watts

More than 900 lumens

More than 25,000 hour life

More than 90 in Color Rendering Index

Between 2700 and 3000 K in Correlated Color Temperature

SOURCE: Information available at http://www.lightingprize.org/requirements.stm.

FIGURE 5.16 Bulb that exceeds the 21st-century “L Prize” standards. SOURCE: Courtesy of Cree, Inc.

TABLE 5.3 Top-10 High-Brightness LED Manufacturers, by Revenue in 2010

|

|

|

| 2010 Ranking | Company Name |

|

|

|

| 1 | Nichia |

| 2 | Samsung LED |

| 3 | Osram Opto Semiconductors |

| 4 | Philips Lumileds Lighting |

| 4 | Seoul Semiconductor |

| 6 | Cree |

| 6 | LG Innotek |

| 8 | Sharp |

| 9 | Everlight |

| 9 | Toyoda Gosei |

|

|

|

NOTE: Companies have the same ranking when the difference in revenue is within the margin of error. Revenue includes packaged LED sales only.

SOURCE: LED Magazine. 2011. “Strategies Unlimited Unveils Top-Ten List of LED Manufacturers.” Available at http://www.ledsmagazine.com/news/8/2/29.

decrease with increasing size. Finally, the production volume can be easily scaled up, leveraging manufacturing equipment developed for silicon integrated circuits. This makes GaN on Si a promising approach for lowering costs. Recently Bridgelux showed cool-white LED efficiencies as high as 160 lm/W at a correlated color temperature of 4350 K, and warm-white GaN on Si LEDs delivered 125 lm/W at a color temperature of 2940 K and CRI of 80.73 As an alternative to a sapphire substrate, at least one company, Cree, uses SiC. It currently has cost issues similar to those involved in using sapphire but produces the highest-efficiency LEDs. The 231 lm/W record was obtained using an SiC substrate. SiC holds the promise of significantly lower costs74 if SiC can be made on larger wafers and scaled for larger-volume applications.

The alternating current-direct current (AC-DC) converter and heat sink for high-brightness LEDs also contribute to the high cost. LEDs are DC devices and thus require an AC-DC converter for many applications. Due to parasitic series resistance and other irradiative recombination paths, a substantial amount of heat is produced under high current injection, which degrades the LED performance. In fact, the LED chip itself contributes only 40 percent of the total cost of an LED bulb—more than half of the cost is for converter, heat sink, and light ray design.

The LED efficiency at operating temperatures is still low. The high lumen per watt efficiencies reported by various companies and laboratories were typically measured at room temperature, yet during normal operation, the temperature of the device usually rises to 80-100°C. This reduces the efficiency by 15 to 20 percent. To increase the efficiency, a number of aspects have to be improved.

LED package designs need to focus on heat removal to keep operating temperatures low, even for bulbs producing significant light.

The internal quantum efficiency (IQE) of InGaN/GaN quantum wells (QWs) needs to improve. The IQE is defined as the percentage of electron-hole recombinations in the active region that generates light. GaN materials are grown on a sapphire substrate with a large lattice mismatch, which results in a high defect density (approximately 109 cm−3). In addition, there is a greater than 2 percent lattice mismatch between the well and barrier materials for a typical active region, InGaN/GaN QWs, which also leads to defects. These defects present paths for non-radiative recombination of carriers, leading to a reduced IQE and increased heat dissipation in the active region. Improving material quality is thus critical. Many

_________________

73 Nusca, Andrew. 2011. “Bridgelux Shatters LED Efficiency Record with Silicon Tech.” Smart Planet. Available at http://www.smartplanet.com/blog/smart-takes/bridgelux-shatters-led-efficiency-record-with-silicon-tech/18252. Accessed December 18, 2011.

74 Ozpineci, B., and L. Tolbert. 2011. “Silicon Carbide: Smaller, Faster, Tougher.” IEEE Spectrum. Available at http://spectrum.ieee.org/semiconductors/materials/silicon-carbide-smaller-faster-tougher. Accessed July 24, 2012.

recent publications indicate that defects can be greatly reduced in nanostructures grown on lattice-mismatched substrates.75,76

There is a built-in electric field in InGaN QWs grown on a c-plane sapphire, the lowest-cost and most commonly used sapphire substrate. This built-in electric field leads to Quantum-Confined Stark Effect (QCSE) in QWs, causing an even lower IQE and blue-shifted wavelength with current injection. The latter reduces the conversion efficiency of yellow phosphors. Finally, better current-spreading schemes are critical to avoid current crowding, which in turn reduces ohmic heat and Auger recombination. With less heat produced, efficiency droop at high injection current can be suppressed.

Finding: When compared to today’s fossil fuel alternatives, current solar power is not yet cost-effective in most areas for utility-scale application without subsidies. Solar-based electricity generation for utility-scale power is, however, making excellent progress toward the goal of cost parity against fossil-fuel-based electricity generation approaches. It is the opinion of the committee that development of cost-competitive solar power for utility-scale application over the next decade is feasible, and in fact likely. Major solar cell providers have plans to reach cost parity by about 2015. Cost parity will come in stages and initially will occur only in areas of bright sunlight, with expensive alternatives, during peak-load times.

Finding: If cost parity or better is achieved, with solar power becoming the most economically attractive method of building a new electricity generation facility, then much more land will be used for solar power, regardless of the particular solar power approach.

Finding: Optimal solar power concentration approaches are key to effective utility-scale solar power plants in areas with significant direct sunlight.

Finding: The electric grid distribution system can influence the benefits associated with solar power if power can be transferred across time zones, making use of available sunlight in multiple time zones.

Finding: Solid-state lighting is making great progress in efficiency, brightness,

_________________

75 Sburlan, S., A. Nakano, and P.D. Dapkus. 2012. Effect of substrate strain on critical dimensions of highly lattice mismatched defect-free nanorods. Journal of Applied Physics 111(5):054907-054907-6.

76 Zytkiewicz, Z.R. 2002. Laterally overgrown structures as substrates for lattice mismatched epitaxy. Thin Solid Films 412(1-2):64-75.

color balance, and cost and is already very attractive for many niche applications. Solid-state lighting is already cost-competitive for general lighting applications in which significant labor is involved in changing lightbulbs.

Finding: There is no suitable green LED available to allow efficient RGB color rendering.

RECOMMENDATIONS AND GRAND CHALLENGE QUESTION

Key Recommendation: The Department of Energy (DOE) should develop a plan for grid parity across the United States by 2020.

“Grid parity” is defined here as the situation in which any power source is no more expensive to use than power from the electric grid. Solar power electric plants should be as cheap, without subsidies, as alternatives. It is understood that this will be more difficult in New England than in the southwestern United States, but the DOE should strive for grid parity in both locations.

Even though significant progress is being made toward reducing the cost of solar energy, it is important that the United States bring the cost of solar energy down to the price of other current alternatives without subsidy and maintain a significant U.S. role in developing and manufacturing solar energy alternatives. There is a need not only for affordable renewable energy but also for creating jobs in the United States. A focus in this area can contribute to both. Lowering the cost of solar cell technology will involve both technology and manufacturing advances.

This key recommendation leads directly to the fourth grand challenge question:

4. How can U.S. energy stakeholders achieve cost parity across the nation’s electric grid for solar power versus new fossil-fuel-powered electric plants by the year 2020?

The impact on U.S. and world economies from being able to answer this question would be substantial. Imagine what could be done with a renewable energy source, with minimal environmental impact, that is more cost-effective than nonrenewable alternatives. Although this is an ambitious goal, the committee poses it as a grand challenge question, something requiring an extra effort to achieve. Today, it is not known how to achieve this cost parity with current solar cell technologies. Additionally, it is important to recall the statement made in 2010 by the America’s Energy Future Panel on Electricity from Renewable Resources in the report Electricity from Renewable Resources: Status, Prospects, and Impediments.

For the time period from the present to 2020, there are no current technological constraints for wind, solar photovoltaics and concentrating solar power, conventional geothermal, and biopower technologies to accelerate deployment. The primary current barriers are the cost-competitiveness of the existing technologies relative to most other sources of electricity (with no costs assigned to carbon emissions or other currently unpriced externalities), the lack of sufficient transmission capacity to move electricity generated from renewable resources to distant demand centers, and the lack of sustained policies.77

The second major area in which optics can contribute to energy security in the United States is through solid-state lighting.

Key Recommendation: The DOE should strongly encourage the development of highly efficient light-emitting diodes (LEDs) for general-purpose lighting and other applications.

For example, the DOE could move aggressively toward its 21st-century lightbulb, with greater than 150 lm/W, a color rendering index greater than 90, and a color temperature of approximately 2800 K. Since one major company has already published results meeting the technical requirements for the 21st-century lightbulb, the DOE should consider releasing this competition in 2012. Major progress is being made in solid-state lighting, which has such advantages over current lighting alternatives as less wasted heat generation and fast turn-on time. The United States needs to exploit the current expertise in solid state lighting to bring this technology to maturity and to market.

Recommendation: The DOE should:

1. Develop high-temperature solar cells suitable for use in conjunction with CSP systems. These solar cells can provide sunlight conversion to electricity in addition to the CSP thermal conversion. Moderate-efficiency solar cell electricity generation in addition to thermal electricity generation could drive total efficiency greater than 50 percent;

2. Develop more efficient, and less expensive, methods of solar power concentration for both low and high levels of concentration;

3. Develop methods to reduce LED costs, such as growing LEDs on silicon, or increasing SiC wafer sizes, or other LED substrate cost-reduction approaches; and

4. Develop efficient green LEDs to support quality RGB LED color rendering.

_________________

77 NAS-NAE-NRC. 2010. Electricity from Renewable Resources: Status, Prospects, and Impediments. Washington, D.C.: The National Academies Press, p. 4.

Recommendation: Governmental land use planning bodies should consider the potential impacts of a significant increase in land use associated with solar electric power plants.

Recommendation: The DOE and electric utilities should evaluate the electric grid for power movement across multiple time zones and evaluate whether changes should be made to support the period of time when grid parity is reached for solar power.