Displays are a critical enabling technology for the information age. Over the last two decades, liquid-crystal displays (LCDs) have become the dominant type of display, displacing the cathode-ray tube (CRT). During this period, LCD technology improved dramatically in several aspects, including resolution, quality, reliability, size, cost, and capability. The 1998 National Research Council report Harnessing Light: Optical Science and Engineering for the 21st Century1 mentioned 10.4-inch LCD displays and postulated the potential for 40-inch plasma displays. Today, LCD displays are ubiquitous. Small ones are used for mobile appliances (cell phones) and e-readers, and large ones for desktop computers, table-based displays, TVs, and wall-mounted displays. However, there is always a drive toward bigger displays.2

LCDs will probably dominate displays for the next decade. There are technical challenges in LCD displays that can be turned into opportunities. For a detailed description of the various display technologies, see Appendix C in this report.

Although they are less developed than LCDs, the use of organic light-emitting diodes (OLEDs) is a growing trend in displays. The fact that the principal pixel component in an OLED display is an LED eliminates the need for external backlighting

_________________

1 National Research Council. 1998. Harnessing Light: Optical Science and Engineering for the 21st Century. Washington, D.C.: National Academy Press.

2 Ultimately, if large generic displays were available at low cost, they could replace larger and larger information devices until movie theater systems and billboards were included.

technology. However, several challenges need to be solved before OLED technology becomes pervasive for large displays, as discussed later in this chapter.

One of the most important trends in recent years is the rapid spread of touch displays. Touch technology already has matured to a point where its performance, reliability, and robustness are outstanding. Touch technology was invented in the United States, and many improvements are still coming from U.S. academic and industrial research and development (R&D) laboratories.3 Given that significant innovations and improvements are expected in the next decade, this field has potential for continued U.S. leadership.

One of the technologies changing how people study, spend leisure time, and get information involves e-readers and computer tablets. Within the next generation, it is possible that people will be dependent on e-readers and tablets for many of their educational and general reading needs. With respect to e-readers, a revolution is taking place, from a simple electrophoretic ink (E-ink) product, to a higher-resolution E-ink, to color-passive LCD, to full-blown LCD-based e-readers. As the displays are improved, there are opportunities to develop low-cost, durable, and green materials and manufacturing processes.

An interesting technology that might have a major impact in the future but will require major investment and innovation is that of flexible displays. Flexible material (such as glass or a polymer) could be used for newspapers, magazines, and work papers. The idea is to simulate the paper media that many people are still using, but with a flexible organic or inorganic material that is essentially a computer system with a wireless transceiver. Such flexible displays could communicate with servers to download information and display it as though it were printed on paper. The flexible materials should be lightweight, sturdy, robust, and reusable and should provide exceptional text, picture, and video quality whether indoors or in bright sunlight (similar to printed-paper quality). To create flexible displays, however, it is necessary to develop flexible substrate materials and processes that exhibit chemical resistance, thermal stability, and endurance of high temperatures and pressures during fabrication.

Most of the current state-of-the-art display technologies require backlighting subsystems to provide the necessary brightness. LCDs do not produce light themselves, and so they need illumination to produce a visible image. In general, backlights are needed to illuminate the display panel from the side or the back.

_________________

3 A Scopus search on “touch display” gives a total of 2,706 publications, of which the following institutions are the top 10 publishers: University of Tokyo (47), Massachusetts Institute of Technology (39), University of British Columbia (29), University of Calgary (23), University of Toronto (22), KAIST (formerly Korea Advanced Institute of Science and Technology) (22), University of Oxford Medical Sciences Division (20), Stanford University (20), Microsoft Research (20), and Carnegie Mellon University (19). SOURCE: Scopus database. Available at http://www.scopus.com/home.url. Accessed November 28, 2011.

Several backlighting technologies exist, and they depend critically on advances in optical and photonic technologies. Solid-state lighting (LEDs) is now replacing most other lighting approaches for backlighting.4,5

Another technology with potential for big future impact and leadership by the United States is three-dimensional holographic displays.6 Uses today are mainly for military applications, but the technology could become widely available if the technology advances and cost declines.

The next few years should see a continuation of the trend of ever-larger displays at lower prices. In addition, higher-quality LED illumination with higher refresh rates (up to 240 hertz [Hz]) will be developed. In the United States, the display market has transitioned to flat panels; LCD displays now account for a high percentage of new sales. Plasma captures a smaller share of the TV market and is expected to decline as a fraction of the total TVs produced.7 There is considerable interest in OLED TVs, but they are at least several years away from capturing a significant share of the market. However, when the remaining technical challenges are solved, OLED displays should become a significant competitor to LCD displays.8 Another big trend is “three-dimensional-ready” televisions, although most of them are limited by the need for special glasses for viewing. Innovations are needed for three-dimensional displays that do not require special glasses. Additional trends for display products include thinner and lower-power-consumption displays. Several countries are beginning to impose restrictions on the total power consumption of display units, forcing manufacturers to come up with better designs, especially for lighting, which consumes approximately 25 to 40 percent of the total display unit power.9 On the notebook computer side, where low power consumption is a major consideration, LED lighting is the dominant technology. For desktops, fluorescent lighting is still being used because thickness and power consumption

_________________

4 Anandan, M. 2008. Progress of LED backlights for LCDs. Journal of the Society for Information Display. Volume 16(2):287-310.

5 Flanders, V. 2012. Liquid Crystal Display and Technology. New Delhi: World Technologies.

6 Zebra Imaging. 2012. Available at http://www.zebraimaging.com. Accessed July 31, 2012.

7 In 2010, LCDs increased by 31 percent to 187.9 million units, while plasma grew by 29 percent to 18.24 million units. Data from Displaybank’s Month-to-Month FPD TV Shipment Information report; see Slipokoyenko Y., ed. 2012. Plasma vs LCD vs LED. Available at http://www.hdtvreviewspro.com/plasma-vs-lcd-vs-led/. Accessed August 2, 2012.

8 Semenza, P. 2010. Display week 2010 review and market outlook: Can OLED displays make the move from the mobile phone to the TV? Information Display 26(8):14-17.

9 Lubarsky, G. 2011. “A Holistic Approach to Reducing Backlight Power Consumption.” How 2 Power Today. Available at http://www.how2power.com/newsletters/1110/articles/H2PowerToday1110_design_TexasInstruments.pdf. Accessed November 28, 2011.

are not critical. Higher refresh rates and three-dimensional displays are beginning to penetrate the desktop market.

Although traditionally associated mostly with “science fiction” movies, the ability to create and view three-dimensional optical holographic images has potential applications in which full three-dimensional viewing is of great benefit, such as in defense, telemedicine, high-skill-level training, and collaborative rapid prototyping. A U.S. company, Zebra Imaging,10 is taking a leadership role in trying to commercialize this technology, and its ZScape holographic motion displays were named by Time magazine as one of the top 50 inventions of 2011.11 With this technology, teams of people can collaborate in real time by viewing lifelike, interactive images from any angle and with fine detail.

This section briefly describes the different display technologies. For a more in-depth description, see Appendix C.

Polarized light and its manipulation are fundamental to the operation of an LCD. Such manipulation allows the creation of light valves (devices for varying the amount of light from an illumination source to a desired target), with millions of miniature valves in a single high-definition display.12 To achieve color, each pixel is subdivided into subpixels, with red, green, and blue (RGB) filters. Transistors on a glass substrate control the voltage and thus the amount of light passed through each subpixel. The early motivation for color LCDs was use in notebook computing. Improvements in LCDs resulted in wider applications and led to the displacement of competing technologies, including CRTs in traditional television sets.

There has been at least some market interest in extending LCDs to three-dimensional displays, exploiting polarization in a different way.13 In one technique, a polarizer on the glasses worn by the viewer matches the orientation of the polarized output of the display. Another possible approach for creating three-

_________________

10 Zebra Imaging. 2012. “Motion Displays.” Available at www.zebraimaging.com/products/motion-displays. Accessed July 30, 2012.

11 Grossman, L., M. Thompson, J. Kluger, A. Park, B. Walsh, C. Suddath, E. Dodds, K. Webley, N. Rawlings, F. Sun, C. Brock-Abraham, and N. Carbone. 2011. Top 50 inventions. November 28. Time magazine. Available at http://www.time.com/time/magazine/article/0,9171,2099708,00.xhtml. Accessed November 15, 2012.

12 For information on the control of polarization in LCD to define color, see Appendix C.

13 For more information, see Appendix C.

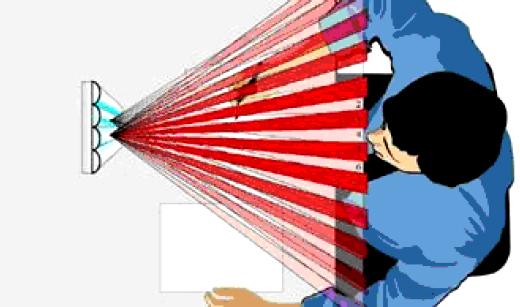

dimensional displays is the use of lenticular arrays14,15 to create a fixed number of viewing zones (usually about seven to nine) in which the left and right images are coherent although with reduced resolution (see Figure 10.1). At present, the acceptance of the latter approach has been limited by restriction of the positions from which the display can be observed; image quality suffers significantly if an improper position is used.

Another trend for LCDs is in providing greater color fidelity than is currently possible. That is related to another recent trend: the replacement of fluorescent tubes with LEDs in the display backlight. The most common backlight now consists of white LEDs, which themselves consist of blue emitters passing through a color-converting phosphor, typically cerium-doped yttrium aluminum garnet (Ce:YAG).

A problem with such white LEDs in an LCD backlight application is that the color filters are not perfect. The light from the green and the red filters overlaps with yellow wavelengths passed by both filters. That results in colors that are less true, so, for example, a completely green image appears more yellow-green than true green.

It has been suggested that the color-filter deficiencies might be addressed by substituting LEDs that emit only in relatively narrow wavelength bands of RGB. Although that might be done with RGB rather than white LEDs, another possibility is that quantum dots (QDs) would substitute for phosphor (see Figure 10.2). QDs would have the advantage of providing much more precise and narrow-wavelength color conversion so that emission of the white LED with QD color conversion would not need to emit at all in the yellow band where the green and red filters overlap. The result would be more pure colors and a broader color gamut.

Of the several kinds of touch technologies, three are most prevalent: resistive, in which a touching object presses down and causes two separated layers to connect to each other at that point; optical, in which a touching object appears as a shadow, and cameras can locate and measure the size of the object; and capacitive, in which an electrically conducting finger touching a screen results in a distortion of the screen’s electrostatic field and a change in capacitance. Resistive touch technology was the first to be used, most commonly in bank automated teller machines and cash registers. It has low cost but low resolution. Optical touch technology was invented and commercialized (for example, the HP 150 PC in 1984) with much

_________________

14 Johnson, R.B., and G.A. Jacobsen. 2005. Advances in lenticular lens arrays for visual display. Proceedings of SPIE—The International Society for Optical Engineering. Volume 5874.

15 Kim, H., and J. Hahn. 2010. Optimal design of lens array for wide-viewing angle multi-view lenticular 3D displays. Proceedings of the International Meeting on Information Display and International Display Manufacturing Conference and Asia Display, October 11-15, 2010, Seoul, Republic of Korea.

FIGURE 10.1 Multiple autostereoscopic viewing zones with lenticular array. SOURCE: International Organisation for Standardisation (ISO) and Organisation Internationale de Normalisation (IEC). 2008. “Introduction to 3D Video.” Available at http://mpeg.chiariglione.org/technologies/general/mp-3dv/index.htm. Reprinted with permission.

FIGURE 10.2 Improved color gamut with quantum dots. SOURCE: Photo Credit: Nanosys/Thom Sanborn. Reprinted with permission.

better resolution and performance, but it was not easily scaled to larger displays. Not until capacitive touch technology was commercialized on a large scale (for example, the Apple iPhone) did consumers begin to expect mobile appliances and laptops to incorporate touch. Regardless of the sensing mechanism (resistive, capacitive, or optical), touch technologies have two important aspects that rely on optics: the display function (brightness, contrast, resolution, refresh rate, and so on) and the construction of the touch sensors.

Capacitive coupling in touch displays exploits the fact that the signal driven on one conductor will couple to an adjacent conductor. Before 2007, this phenomenon was not widely perceived as a good means of implementing touch, although it had been used on all the notebook touchpads since the mid-1990s and on the iPod since 2001. However, as a result of Apple’s introducing its first iPhone, which incorporated projected capacitive multi-touch, considerable new interest in this technology has been generated.

In projected capacitive touch, the display area is divided into a grid of unit cells of roughly 5 mm × 5 mm each, the size commonly selected for the typical size of a fingertip.16 The most common implementation of projected capacitive touch involves a touch sensor array bonded directly behind a cover glass. In the display aperture area, the conductors are transparent and typically made of indium tin oxide (ITO).17,18 The fundamental challenge in projected capacitive touch technology is the poor conductivity of the transparent conductors. The technology requires that the touching instrument (digit) be a conducting one. Thus, a gloved hand or non-metallic pen would not be detected. In addition, the system is typically optimized for the size of a finger, and so using a stylus, even if it is conductive, would result in errors due to poor interpolation. One potential substitute for capacitive touch is optical, but thus far the application of optical sensors has been limited mostly to very large displays. In wall-size optical touch displays, infrared (IR) LEDs and imagers are typically positioned in the upper corners of the array, and retroreflectors are along the sides and bottom. The reflectors return the IR to the imagers unless interrupted by the shadow of a touch.

A plastic front polarizer, which would be prone to damage from touch unless protected by a cover glass, is currently used for LCDs of all sizes. One potential trend could be to eliminate this polarizer by substituting an internal polarizer. Although this would be difficult to achieve, an internal polarizer would sit on the liquid-crystal side of the front color filter glass. With that configuration, the face of

_________________

16 For details about touch displays, their composition, and challenges faced in their development, see Appendix C.

17 Chopra, K.L., S. Major, and D.K. Pandya. 1983. Transparent conductors—A status review. Thin Solid Films 102(1):1-46.

18 Granqvist, Claes G. 2007. Transparent conductors as solar energy materials: A panoramic review. Solar Energy Materials and Solar Cells 91(17):1529-1598.

the display would be the color filter glass rather than the polarizer plastic. Achieving such a substitution would motivate efforts to eliminate the stand-alone cover glass and integrate the protection of a cover into the color filter glass itself.

OLEDs make use of the electrophosphorescence exhibited by some organic molecules to create light directly at the diode itself when desired; the color of the diode can be adjusted by the choice of organic molecules. Therefore, an array of OLEDs can directly generate the displayed image rather than light a modulator, such as an LCD, to create the displayed image. Because the image is directly generated, light is not wasted by attenuating it with the modulator that creates the image, and these displays can be thinner because generating the image is a single-step process. OLED-based displays can therefore be brighter than LCDs and consume less power.19,20 Two principal ways are used to supply the electrical bias to the individual OLEDs in a display: passive- and active-matrix designs.21 In a passive-matrix scheme, the individual anodes and cathodes are connected by perpendicular conducting strips, and external circuitry applies voltages to the rows and columns that are necessary to determine which pixels will be turned on. At present, the external circuitry required for a passive-matrix design results in higher power consumption than is needed with an active-matrix display. Active-matrix displays incorporate a thin-film transistor (TFT) array as part of the device to supply the power to the individual OLEDs. This biasing scheme uses less power than is needed for the passive-matrix design and has a higher refresh rate, and so it is suitable for large displays.22

Because non-rigid substrates can be used, OLED displays can be more robust than displays that incorporate glass. That makes OLEDs potentially useful in applications in which they will be subjected to rough handling, such as in cell phones or other consumer electronics. Furthermore, in the case of completely flexible substrates, the displays could be used in applications in which no other display currently can be contemplated, such as being integral with an article of clothing.

OLEDs offer several advantages over both LCDs and LEDs for small and large

_________________

19 Kelley, T.W., P.F. Baude, C. Gerlach, D.E. Ender, D. Muyres, M.A. Haase, D.E. Vogel, and S.D. Theisset. 2004. Recent progress in organic electronics: Materials, devices, and processes. Chemistry of Materials 16(23):4413-4422.

20 Iwamoto, M., Y. Kwon, and T. Lee. 2011. Nanoscale Interface for Organic Electronics. Singapore. Hackensack, N.J.: World Scientific.

21 Ju, S., J. Li, J. Liu, P. Chen, Y. Ha, F. Ishikawa, H. Chang, C. Zhou, A. Facchetti, D.B. Janes, and T.J. Marks. 2008. Transparent active matrix organic light-emitting diode displays driven by nanowire transistor circuitry. Nano Letters 8(4):997-1004.

22 For more details about OLED displays, see Appendix C.

displays: they can have substrates that are flexible and more impact-resistant than glass or rigid plastic; they have higher brightness than LEDs; they do not require backlighting, as LCDs do, which is a significant power drain that limits battery life; they offer ease of deposition on very large substrates; and they have a larger field of view and a wider operating temperature range than LCDs. However, present OLEDs also have significant disadvantages, including shorter lifetimes23,24 and lower efficiency.

Future flexible displays could be extremely thin, light, and inexpensive. Moreover, flexible displays could enable the display market to expand to new applications, including e-paper and large signage.

In recent years, engineers worldwide have been developing the organic materials and manufacturing processes to make flexible displays a reality. Such new materials could be OLEDs, liquid crystals, and electrophoretic particles. Moreover, plastic substrates and printable semiconductors are now available to help to create flexible back planes. Other key technologies are needed for future flexible LCDs or OLEDs, such as the use of stable and heat-resistant organic materials and low-temperature printing.

In the next decade, flexible substrates (such as thin-film polymers) could have a large impact, enabling the possibility of printing reports on e-paper25,26 that is both thin and reusable. Cell phones could have large displays that could be unfurled. Displays might even be placed on non-flat clothing surfaces. Commercial laboratories are working on flexible displays27 that can be 15-inch displays and larger.

_________________

23 Wellmann, P., M. Hofmann, O. Zeika, A. Werner, J. Birnstock, R. Meerheim, G. He, K. Walzer, M. Pfeiffer, and K. Leo. 2005. High-efficiency p-i-n organic light-emitting diodes with long lifetime. Journal of the Society for Information Display 13(5):393-397.

24 Luiz, Pereira. 2010. Organic Light Emitting Diodes: The Use of Rare Earth and Transition Metals. Singapore: Pan Stanford.

25 Burns, S.E., K. Reynolds, W. Reeves, M. Banach, T. Brown, K. Chalmers, N. Cousins, M. Etchells, C. Hayton, K. Jacobs, A. Menon, S. Siddique, P. Too, C. Ramsdale, J. Watts, P. Cain, T. Von Werne, J. Mills, C. Curling, H. Sirringhaus, K. Amundson, and M.D. McCreary. 2005. A scalable manufacturing process for flexible active-matrix e-paper displays. Journal of the Society for Information Display 13(7):583-586.

26 Blankenbach K., L-C Chien, S.-D. Lee, and M.H. Wu. 2011. “Advances in Display Technologies, e-papers and Flexible Displays.” Proceedings of SPIE—The International Society for Optical Engineering. January 26-27. San Francisco, Calif. Bellingham, Wash.: SPIE.

27 Choi, M.-C., Y. Kim, and C.-S. Ha. 2008. Polymers for flexible displays: From material selection to device applications. Progress in Polymer Science 33(6):581-630.

Although projectors are widely used in schools and for presentations to large audiences, price has been the major factor in their adoption rather than the size, the power consumption, or, to some extent, the brightness of these projectors. In contrast, size, power consumption, and brightness are the dominant technical specifications that inhibit the incorporation of projectors in handheld devices of various types. The market for such battery-powered “personal projectors” is expected to be much larger than that for “traditional” mains-powered projectors.28

Currently, three major technologies are used to project images that are created or transmitted electronically: digital light processors (DLPs), which use an array of micromirrors to create an image by the reflection of light illuminating the mirrors; liquid crystal on silicon (LCoS), which creates an image by modulating the intensity of the light by means of liquid crystals; and beam steering of one or more lasers, which is used to “write” an image directly on a screen. All three are candidates for future development for incorporation in handheld devices. Such devices have strict requirements on energy consumption, as well as size.

Each of those technologies has advantages and disadvantages, and there is no clear overall winner yet. DLP projectors incorporating RGB LEDs have high image quality and low power consumption, but they have lower resolution than LCoS projectors. Laser scanning also has low power consumption, but laser speckle noise affects image quality. In all cases, the challenge is to provide an image that is large enough to be advantageous over a handheld device’s built-in screen and that is bright enough to be seen under less than ideal lighting conditions and is of a quality that end users consider acceptable and to provide this capability without unacceptable battery drain.

Three-Dimensional Holographic Displays

A display can sometimes create the illusion of being three-dimensional when a stereoscopic technology is used to produce images. The human visual system, however, experiences a two-dimensional plane, and it is not true three-dimensional images that are being displayed. In contrast, modern holographic displays are able to produce true three-dimensional images (or holograms) that do not require any

_________________

28 The technology for storing images has completely outpaced the technology of the projectors needed to display them. A carousel holding 140 35-mm slides is comparable in volume to that of the projector. Similarly, 140 plastic foils are comparable in volume to that of a portable overhead projector. In contrast, today it is possible to carry more than 10,000 high-resolution images on a tiny flash drive. This capability is driving the desire to create portable projectors, comparable in size to a cell phone, that are capable of displaying these electronically stored images.

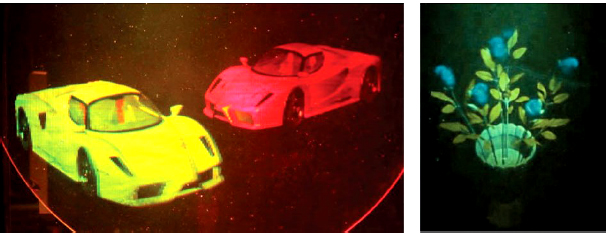

special eyewear (see the two images in Figure 10.3.29 The first interactive three-dimensional holographic system was demonstrated in 1990 at the Massachusetts Institute of Technology Media Lab.30 Note that a simple hologram can be created by superimposing two coherent plane waves; the resulting interference pattern produces a straight-line fringe across the recording medium.

In an electroholographic display, the three-dimensional object is converted into a fringe pattern. To do that, a computer graphic stage is used to perform lighting, shading, occlusion, and rendering to two-dimensional images. For some cases, such as magnetic resonance imaging (MRI) data, this stage is trivial inasmuch as the data may already be stored as three-dimensional voxels, and each voxel might already have the color and shading information. Later, the fringe generation stage computes a large two-dimensional holographic fringe based on the result of the computer graphic stage. It is worth mentioning that significant computing power is necessary to produce realistic computer-generated holograms (real-time three-dimensional displaying and telepresence), and recent progress in digital signal processing has enabled the present advances.

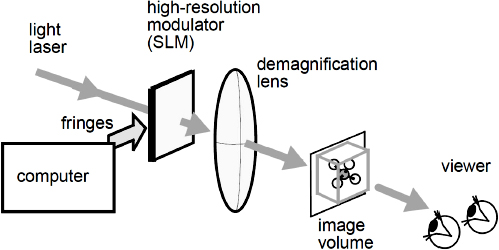

After generation of fringe patterns, spatial-light modulators (SLMs) are used to convert the three-dimensional information in electronic bits into optical photons with a computed holographic fringe pattern. It should be noted that either amplitude modulation or phase modulation can be used in three-dimensional holographic imaging.31 LCDs tend to use phase modulators because of their optical efficiency, and they can have many gray-scale levels that are useful for generating complex images. Acousto-optic modulator SLMs have also been used in holovideo because of their fast response, and this technique was used in the first demonstration of three-dimensional holographic displays (see Figure 10.4).32

The applications of three-dimensional displays are potentially far-reaching and include medical training, military simulation, situational awareness, and entertainment.

_________________

29 Blanche P.-A., A. Bablumian, R. Voorakaranam, C. Christenson, W. Lin, T. Gu, D. Flores, P. Wang, W.-Y. Hsieh, M. Kathaperumal, B. Rachwal, O. Siddiqui, J. Thomas, R.A. Norwood, M. Yamamoto, and N. Peyghambarian. 2010. Holographic three-dimensional telepresence using large-area photore-fractive polymer. Nature 468:80-83.

30 Reichelt, S., R. Haussler, N. Leister, G. Futterer, and A. Schwerdtner. 2008. “Large Holographic 3D Displays for Tomorrow’s TV and Monitors—Solutions, Challenges, and Prospects.” IEEE Lasers and Electro-Optics Society Annual Meeting, November 9-13, 2008, Newport Beach, Calif.

31 Lucente, M. 2003. “Interactive Holographic Displays: The First 10 Years.” In Holography: The First 50 Years, Fournier, J.M., ed. Berlin: Springer-Verlag.

32 Lucente, M. 2003. “Interactive Holographic Displays: The First 10 Years.”

FIGURE 10.3 Pictures of colored holograms. (Left) Hologram of two model cars recorded. (Right) Hologram of a vase and flowers. SOURCE: Reprinted, with permission, from Blanche P.-A., A. Bablumian, R. Voorakaranam, C. Christenson, W. Lin, T. Gu, D. Flores, P. Wang, W.-Y. Hsieh, M. Kathaperumal, B. Rachwal, O. Siddiqui, J. Thomas, R.A. Norwood, M. Yamamoto, and N. Peyghambarian. 2010. Holographic three-dimensional telepresence using large-area photorefractive polymer. Nature 468:80-83.

FIGURE 10.4 Holographic optical modulation using a typical high-resolution spatial-light modulator (SLM). At present, a minimum of 2 million modulation elements is required to produce even a small three-dimensional image the size of a thumb. SOURCE: Lucente, M. 2003. “Interactive Holographic Displays: The First 10 Years.” In Holography: The First 50 Years, Fournier, J.M., ed. Berlin: Springer-Verlag. Reprinted with permission.

As discussed in Chapter 7, the bulk of LCD panel production occurs outside the United States; the leading countries are Korea, Taiwan, Japan, and China.33 In 1998, when Harnessing Light was published, most production had already moved outside the United States. At that time, Japan was dominant, and Korea was just starting to play a big role. The same holds true in the production of touch sensors; Taiwan holds a slightly stronger position than the others. The segment of the touch-display technologies in which the United States leads is the touch controller circuits, in whose production the major firms are Atmel,34 Broadcom,35 and Synaptics.36 In the United States, Corning is producing large sheets of the high-quality glass needed for the display panels (color filter and thin-film transistors) in factories in Kentucky.

The committee believes that the role best played by U.S. companies in the future of displays is in the research and development of new technologies. The committee would like to see a future in which new manufacturing remains in this country.

Key Finding: Although traditional LCD manufacturing has migrated out of the United States, there are opportunities in future display technologies that can give U.S. industry competitive leadership advantages in R&D and manufacturing. They include energy-efficient backlighting, OLED displays and flexible displays, and real-time three-dimensional-holographic displays.

Finding: An overarching issue for U.S. leadership and revolutionary advances in displays involves new materials that are low cost, durable, green, and easy to process. For example, the dominant LCD technology consumes a significant amount of energy; backlighting subsystems consume about 25 to 40 percent of the total display power.

Solid-state lighting (with LEDs) is discussed in Chapter 5. Not only is great progress being made, but it is a field that the United States should emphasize.

_________________

33 National Research Council. 2008. Innovation in Global Industries: U.S. Firms Competing in a New World (Collected Studies), J.T. Macher and D.C. Mowery, eds. Washington, D.C.: The National Academies Press.

34 Atmel Corporation. 2012. See http://www.atmel.com/Default.aspx/. Accessed July 31, 2012.

35 Broadcom Corporation. 2012. See http://www.broadcom.com/. Accessed July 31, 2012.

36 Synaptics, Inc. 2012. See http://www.synaptics.com/. Accessed July 31, 2012.

Recommendation: U.S. private display companies should invest in and take advantage of the development of solid-state lighting for more efficient and uniform illumination of displays.

Recommendation: U.S. private companies and the Department of Defense should ensure a leadership role by funding R&D related to new materials for flexible, low-power, holographic and three-dimensional display technologies.