Making Value Through Integrated Innovation, Design, Manufacturing, and Service

Today’s economy is marked by unlimited opportunities to engage in high-value innovation, said Curt Carlson, the chief executive officer of SRI International, in his opening keynote address. Despite the loss of US manufacturing employment over the past three decades, new markets and new opportunities abound. Rapidly advancing technologies such as synthetic biology, advanced robotics, regenerative medicine, advanced sensors, additive manufacturing, and direct digital manufacturing are transforming not just manufacturing but entire approaches to value creation (Box 1-1). “I have never seen more big opportunities in my life for innovation,” he said. “Every field is wide open.”

The communications sector demonstrates obvious examples of the ongoing transformation, said Carlson. Cloud computing and other technologies are creating entirely new opportunities for devices and services. Social media are connecting people in new ways. Similar observations apply in health care, education, energy production, transportation, and many other sectors.

To take advantage of these opportunities, many aspects of the US economy and US policies need to change, said Carlson. The US economy is “stuck” and the nation is drowning in debt. In 2008 the United States led the world in competitiveness. Now it is number five and dropping.

Large companies in the United States used to survive for many decades; now they last less than two on average, Carlson observed.1

___________

1 Foster, R. N., and S. Kaplan. 2001. Creative Destruction: Why Companies That Are Built to Last Underperform the Market—and How to Successfully Transform Them. New York: Currency/Doubleday.

BOX 1-1

Spotlight on Biomanufacturing:

Opportunities and Needs for Value Creation

John Dordick, Howard P. Isermann Professor of Chemical and Biology Engineering and director of the Center for Biotechnology and Interdisciplinary Studies at Rensselaer Polytechnic Institute, talked about a specific area in which advanced manufacturing can change the world: biomanufacturing. Success in biomanufacturing means learning from and improving on the incredible capabilities already found in nature. The biosphere can create everything from the small molecules required for the functioning of cells to single organisms (the fungal mycelia) more than a mile across. “Nature does a remarkable job of biomanufacturing,” Dordick said.

A 787 jet and a cell have about the same number of parts, according to Dordick, but biologists still have vast gaps in their knowledge of how cells operate. Nevertheless, people have been learning how to adapt biological processes to human purposes since our distant ancestors began fermenting liquids and drinking them. Biological processes are used to produce fructose, antibiotics, biofuels, industrial chemicals such as acrylamide and isoprenes, and many other products. Furthermore, the discipline known as synthetic biology, through essentially a modular plug-and-play technology analogous to apps for a mobile phone, offers the hope of creating biological factories for a virtually unlimited number of products.

Dordick discussed three opportunities in particular: bionanotechnology, safe biopharmaceuticals, and personalized medicine.

Bionanotechnology brings together nanotechnology, biotechnology, robotic technologies, microscale systems, and nanoscale systems to form hybrid systems with very specific functions. It offers the hope of developing nanoscale science and engineering to produce biomolecular and chemical building blocks and assembling them in a

Seven years ago, MySpace was the hot technology company, not Facebook. Long-standing companies such as Motorola and Hewlett-Packard are in turmoil. In a world characterized by intense competition, rapid exponential improvement, and unlimited opportunities, value needs to be created faster and in ways that customers want.

variety of forms. It may, for example, yield scaffolds for tissue regeneration, tiny sensors to monitor what happens in the human body, or agents effective against drug-resistant human pathogens.

Safe biopharmaceuticals represent one of the fastest growing segments of the pharmaceutical market. These are complex molecules designed to be safe and effective for the treatment of diseases such as cancer, arthritis, or multiple sclerosis. For example, Dordick and his colleagues have been working on a process to manufacture the coagulant heparin, which is extracted from pig intestines, that would offer many advantages over the traditional source.

Personalized medicine takes this idea farther by investigating the need for drugs on demand that are tailored to each individual. In cancer treatment, the results of a tumor biopsy can point to a specific treatment that is likely to be more effective than others for a particular patient. As researchers learn more about the mechanisms that cause disease, this approach could yield very specific treatments that are customized to the specific form of an individual’s disease.

The major barrier to these technologies is the lack of a business model that can drive them. Developing a single drug can cost well over $1 billion, but in the future drugs will treat smaller and smaller groups of people. Developing a drug for each of these small groups, using current approaches, will be prohibitively expensive.

Transforming the pharmaceutical industry from large volumes of a relatively small number of products to small volumes of a very large number of products will require fundamental changes. Safety testing will need to become quicker and cheaper while delivering safer drugs. Because complete safety can never be guaranteed, people will need to understand the risks and benefits of any new drug or diagnostic. Close links between R&D and manufacturing will be critical to make pharmaceuticals efficiently and safely. No business plan currently exists for personalized medicine, Dordick observed, despite rapid advances in science and manufacturing techniques.

A harmful myth is that value creation is the result of luck or a lone genius. Value creation needs to become a discipline, Carlson said. “It is something that can be learned and proved and taught.” If the necessary skills are disseminated, valued, and supported by an effective innovation “ecosystem,” jobs will increase. He pointed out that many of the

necessary fundamentals are present in the United States: the nation has a positive culture for innovation and entrepreneurship, abundant sources of energy, and a strong R&D infrastructure. But, he added, changes in business processes, education, infrastructure, and government services are essential to take advantage of these inherent strengths.

TECHNOLOGY AND THE TRANSFORMATION OF WORK

Productivity growth in the United States has been accelerating for the past three decades—from 1.6 percent per year in 1980–1989 to 2.1 percent in 1990–1999 and 2.5 percent in 2000–2009. Yet the median income (the point at which half of employees earn more and half less) has been flat for the past decade, and in 2010 fewer Americans were working than in 2000.

Both of these trends have a common cause, said Erik Brynjolfsson, director of the Center for Digital Business, Schussel Family Professor of Management, and professor of information technology at MIT’s Sloan School of Management: rapid technological change. Technologies are now changing so rapidly that the skills of American workers and the structures of US organizations are not keeping up.

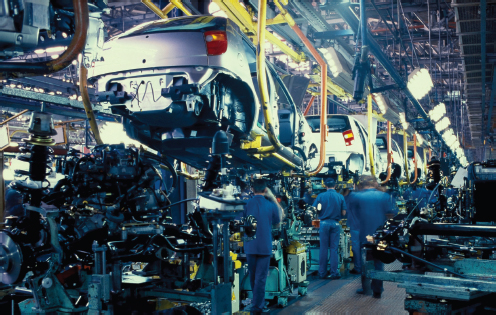

Gary Cowger, chairman and chief executive officer of GLC Ventures, LLC, and former group vice president of manufacturing and labor at General Motors, illustrated the influence of advancing technologies by describing how work changed over his four-decade career in the automotive industry (Box 1-2). Today, approximately 1,500 people in an automobile assembly plant do the work that about 5,000 did in 1965. This was made possible by the development of robotics, high-speed computers, and advanced sensor technologies together with processes—such as design for manufacturability and lean manufacturing—that made the implementation of these technologies effective (Figure 1-1).

The digitization of work is happening throughout the economy, Brynjolfsson said. Technology is changing rapidly and producing tremendous amounts of new wealth. But much of that wealth is going to a small portion of the population. “There is no economic law that says when technology creates wealth that everybody has to benefit equally. Or even that everybody has to benefit, period. It is entirely possible for the pie to grow and for some parts of the pie to get bigger and other parts of it to shrink.” The software entrepreneur who writes a program for people to do their taxes makes many millions of dollars, but accountants lose their jobs or find their wages inexorably squeezed.

FIGURE 1-1 Gary Cowger described how the combination of advanced technologies with design and manufacturing processes that leveraged these technologies transformed the automobile assembly plant so that the same work could be done with one third of the people.

As Brynjolfsson and Andrew McAfee explain in their recent book, the economy is undergoing a profound restructuring.2 Technology has been creating and destroying jobs for hundreds of years, but the pace is quickening, said Brynjolfsson, and the automation of jobs is outpacing the ability of entrepreneurs to create new jobs. “The technology is accelerating, and we think that the economic impacts are going to accelerate as well.”

One possibility is that this trend will reverse and job growth eventually will strengthen. But Brynjolfsson cast doubt on this prospect. As an example, less than ten years ago, economists thought that truck drivers were one example of an occupation that could not be replaced by a computer.3 Yet Google has succeeded in building an automated car

___________

2 Erik Brynjolfsson and Andrew McAfee. 2011. Race Against the Machine: How the Digital Revolution Is Accelerating Innovation, Driving Productivity, and Irreversibly Transforming Employment and the Economy. Digital Frontier Press.

3 Frank Levy and Richard J. Murnane. 2004. The New Division of Labor: How Computers Are Creating the Next Job Market. Princeton, NJ: Princeton University Press.

BOX 1-2

The Past, Present, and Future of Manufacturing Work

To examine the future of work, Gary Cowger, chairman and CEO of GLC Ventures, LLC, who worked with General Motors for more than four decades, looked at how work has changed over that period. He began his career in 1965 at an automotive assembly plant in Kansas City. As an 18-year-old cooperative student, he worked for two years on the assembly line, hanging doors and bolting down seats. At that time, factories were the basic end of the industrial production process, where a pair of good hands was the main requirement.

Since then, the successful application of technology to manufacturing in the automobile industry has boosted productivity while reducing the number of jobs. The standard-sized factory in which Cowger worked employed around 5,000 people to make about 220,000 cars per year. Today, the same type of assembly plant employs approximately 1,500 people and makes about the same number of cars and trucks at a much higher quality level. In 1965, the factory included a roomful of people who went through “a forest worth of wood a month” printing paper manifests to track every single part that went into a car. On the factory floor were at least 120 classifications of workers, both skilled and nonskilled, which “was good for employment but not so good for productivity and flexibility.”

The factory floor began to change in major ways during the 1980s. Company executives began to realize that early investments in computer technology were not paying off as they expected. Much more integration of the total production process was needed. According to Cowger, the company started to recognize that it wasn’t just a technology problem but also a management problem.

Using tools such as computer-aided manufacturing and computer-aided design, managers began to break down the barriers between design, manufacturing engineering, and the factory floor. Design for manufacturability became an important discipline, especially after it became clear that an upfront investment of 5 percent of the overall cost of a product in its design, engineering, and development determines 70 to 75 percent of its total life cycle. “That was a huge shift for us in the way we had been addressing our product development process.”

This integration of processes led to a much greater understand-

ing of the principles of lean production and manufacturing engineering. As knowledge increased, the advent of common systems and global production systems tapped new sources of productivity. The use of high-speed computers, advanced robotics, better sensors, and new materials further added value. Today, every factory worker adds much more value than was the case in 1965. At the same time, the quality of the product has improved dramatically while the lives of workers have improved because they are now the center of the manufacturing system rather than a pair of hired hands.

These complex production processes could not be implemented everywhere in the world, Cowger observed, although many developing countries had a great desire and motivation to become the best and most efficient producers in the world, whether in Mexico, Eastern Europe, Brazil, India, or China. “The lessons that were so hard for us to learn in the developed countries were eagerly adopted by these developing countries.” Because they could not afford all the high-technology equipment common in the developed world, they found innovative and cost-effective ways to implement the ideas embodied in those technologies. And this led to developed countries adopting these new low-cost, leaner approaches in their manufacturing systems as well.

What does all that mean for the future?, asked Cowger. Technology, and computer power in particular, will continue to drive change on the factory floor. Workers will have to be highly educated to use new technologies that will directly influence more and more jobs.

These new technologies will be used equally around the world. According to Cowger, the industry is now truly global and countries will not have a competitive advantage simply by monopolizing the use of a technology. Offices that have been shrinking will become more decentralized. An increasing number of knowledge workers will have the tools to become independent contractors selling their services without leaving their homes. Improvements on the factory floor will continue with the advent of smart sensors, and machines will continue to become more powerful. This will lead to more “lightsout factories” where processes are fully automated and require no human operators on the factory floor, just technicians to monitor the process. With all these developments, the rate of change in manufacturing will continue to increase. While the first learning cycle took more than a decade, “the learning cycle now is a matter of months.”

that can drive through city streets, Brynjolfsson observed. Other jobs thought to be impervious to automation include those requiring both large stores of knowledge and judgment in accessing and sharing that knowledge. But the Watson computer program, which beat the world Jeopardy champion, is being adapted for medical diagnosis, finance, technical support, and many other jobs.

Usual approaches will not solve the problems caused by accelerating technology, Brynjolfsson said. “Big, creative solutions are necessary.”

He suggested that the key to solving the “struggles of the middle class” is to advance workforce skills and support entrepreneurship. People need to learn how to race with technology, not against it, he said. The best chess player in the world today is not a computer or a human but a team of humans and computers working together. In freestyle chess competitions, where teams of humans and computers compete, the winners tend not to be the teams with the most powerful computers or the best chess players. The winning teams are able to leverage the unique skills of humans and computers to work together. “That is a metaphor for what we can do going forward,” said Brynjolfsson: have people and technology work together in new ways to create value.

Brynjolfsson acknowledged that now is a terrible time, perhaps the worst time in history, to be competing with technology, but he added that “there is no better time to be a talented entrepreneur who can take innovations and scale them rapidly, digitally, and globally.” He predicted that manufacturing will surge in the United States because lower wages will not remain a competitive advantage in a world of steadily increasing computer power. At the same time, the most valuable jobs will be those in the design, development, and marketing parts of the product development cycle. Increasing employment in the United States therefore requires support for design and innovation, Brynjolfsson concluded.

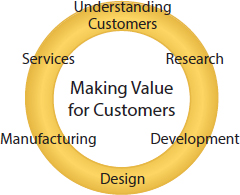

WHAT IS VALUE? AND HOW DO WE MAKE IT?

Improving economic growth and employment requires more than the “spark of imagination,” said Larry Burns, former corporate vice president of R&D at General Motors. A new paradigm is needed for making value (Box 1-3), which he clarified is larger than “making things.” Making things (i.e., manufacturing) is often an important part, but making value requires an integrated system of understanding customers,4 R&D,

___________

4 The term “customer” was used broadly throughout the workshop to refer to a person, group of people, or organization that makes use of a good or service.

FIGURE 1-2 Making value for customers includes making things (manufacturing) as well as understanding customers, research, development, design, and the provision of services.

design, manufacturing, and the delivery of products and services (Figure 1-2). This integrated system requires the creation and delivery of value in the marketplace with a sustainable business model for the enterprise producing it, said Carlson. It is a customer-focused process of connecting important needs with new knowledge.

From a customer’s perspective, value ranges from the strictly utilitarian to the emotional. As an example, Carlson contrasted Nokia, which builds low-cost mobile phones, to Apple, which has created products that have emotional appeal to customers. As a result, Apple’s market capitalization is now almost $600 billion, while Nokia’s is down to $15 billion and declining. “You can’t be on the bottom of the stack any more. You have to work your way up the stack if you want to thrive and be successful.”

Value comes in many forms, Carlson said. It can include the design of a beautiful chair, the invention of the computer mouse, or the development of microcredit, a financing service designed to support entrepreneurship and alleviate poverty by extending very small loans to impoverished borrowers.

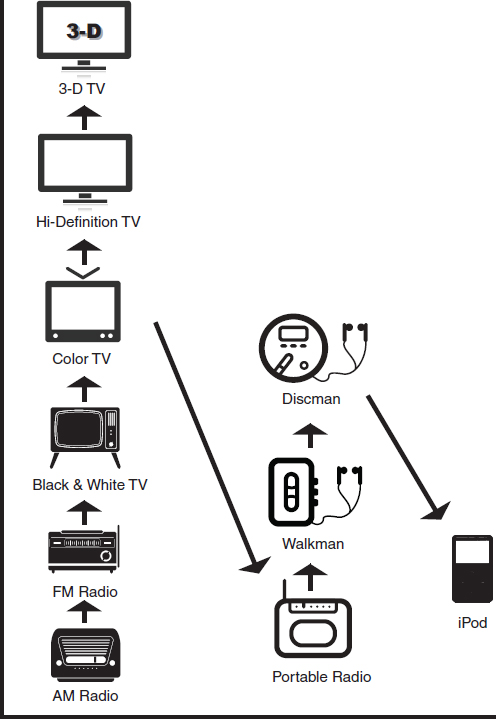

As examples of two people who understood deeply how to make value, Carlson cited Akio Morita, the cofounder of Sony Corporation, and Steve Jobs, the cofounder of Apple, Inc. Both recognized multibillion-dollar opportunities in the “white spaces” of audiovisual communications development across two dimensions of customer value: quality and convenience (Figure 1-3). In the dimension of quality, AM radio

BOX 1-3

Making Value in America

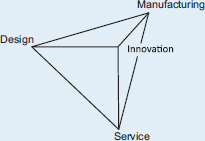

“High-value integrated innovation, design, manufacturing, and service is the primary path forward for the United States to prosper.”

– Panos Papalambros

FIGURE B1-3.1 Innovation, design, manufacturing, and service are tightly linked with each other, forming an integrated whole.

In discussions of the concept at the heart of the workshop—making value through the integration of manufacturing, design, and innovation—participants added a fourth major component: service. These four aspects are both distinct and interconnected, as represented by the pyramid shown in Figure B1-3.1. Panos Papalambros explained that services—such as software upgrades, information gathered about a product, or maintenance and replacement—are important to include because they add value to a product after it is released. Indeed, services are often associated with a product throughout its life cycle, from marketing to design to supply-chain management services.

gave way to FM radio, and black and white TV led to color, high-definition, and now superresolution and three-dimensional TV. In the dimension of convenience, Morita recognized the immense value in portable radios and created a multibillion-dollar company based on that insight. He then invented the Walkman, presaging a world of rich, multimedia personal electronic devices. Steve Jobs furthered this trend with the iPod, a device so convenient that it now can be put on a keychain. In the process, Jobs created a multimillion-dollar business out of almost nothing because he understood the value of convenience to customers.

Several of the breakout groups explored the concept of making

Larry Burns challenged the participants to consider whether integration is necessary to the future prosperity of the United States. Several participants voiced support for Papalambros’ statement quoted above. Chad Syverson articulated the arguments supporting why this path may be necessary rather than an economy based on “pure services.” First, we may lose certain types of very high-level human capital—a large percentage of scientists and engineers in the United States are employed by the manufacturing sector. Second, a manufacturing base may be imperative for national defense. Finally, there is a diversification argument: “you don’t want all your eggs in one economic sector basket.”

One breakout group explored these arguments by trying to identify a first-world country that does not have a significant manufacturing sector. Hong Kong and Iceland were suggested. Jung-Hoon Chun, director of the Laboratory for Manufacturing and Productivity and professor of mechanical engineering at the Massachusetts Institute of Technology, pointed out that these countries worry about their lack of a manufacturing sector. He and his colleagues work with the Hong Kong government, where he said officials worry that the country relies too much on the finance sector. They would like to build up other parts of the economy, Chun said, but are finding it difficult because, although they have research universities, many of their students go abroad to find work once they graduate. It is difficult for the country to retain its talent.

value. According to one group, making value requires understanding the value that people receive from products, explained Panos Papalambros, executive director of interdisciplinary and professional engineering, Donald C. Graham Professor of Engineering, and professor of mechanical engineering at the University of Michigan. To illustrate, he held up two very different products: an iPhone and a bottle of water. The first, he explained, provides convenience, access to rapid information, connectivity, and entertainment; the second, consistency of taste, quality, safety, and convenience. Each has an impact on a person’s lifestyle, which is critical for adding value, Papalambros said; a high-value

FIGURE 1-3 Curt Carlson mapped the timeline of product developments in the audiovisual communications industry along two dimensions of customer value: quality and convenience. “Every white space [on this chart] is another multibillion-dollar business for a company that can see them and take advantage of them.”

product “should make your life easier.” He added that, even if people did not know that they wanted a product, if it adds value, once they have it, they want it and need it.

Papalambros also discussed the importance of services, such as those provided by software and interconnectivity, to understand the value a person gets from a manufactured product. Too often, a manufactured product is thought of as something that is simply produced and delivered. But value comes from how a product is used, said Papalambros, and it can increase over time if the product is designed with that characteristic in mind. A smart phone is an obvious example, because the addition of apps can increase the value of the phone. There are examples from many other industries as well. For instance, a drug designed for one disease may turn out to be a useful treatment for other diseases as information emerges about the drug and its side effects. This increases the value of the drug not from original thinking but from information analysis, said Papalambros. Another example is a navigation system for a car that can produce information useful in the design of future models. In general, any product that has a software component that can be reprogrammed or an ecosystem that can gather information about itself and its uses can improve over time, Papalambros said.

Rebecca Taylor, senior vice president of the National Center for Manufacturing Sciences (NCMS), described the process of increasing the value of existing products. The entire life cycle of a product, from the moment it is delivered to the moment it is no longer needed, can produce value, she said. For example, Rolls-Royce not only produces aircraft engines but also provides performance monitoring, maintenance, and support services throughout the product’s life. Close monitoring of the engines enables Rolls-Royce to predict when they will need maintenance, allowing them to efficiently schedule repairs, as well as informing future engine designs. Both incremental and radical innovation is important for value creation, said Taylor. The internal combustion engine, for example, is 100 years old but keeps getting better. Meanwhile, radical innovations can not only transform an existing product but create new products that transcend the need for an existing product.

Ken Gabriel, acting director of the Defense Advanced Research Projects Agency (DARPA), pointed out that understanding production is crucial to innovation. “To innovate, you must make.” It is a mistake, he said, to think that effective innovation means coming up with a great idea and then passing it to someone else to develop and manufacture a product. A major lesson of DARPA’s history is that this process is not

BOX 1-4

Spotlight on Electronics: Linking Design and Production

When Jonathan Rubinstein, former executive chairman and CEO of Palm, Inc., and a former executive at Apple, took his first job after college with Hewlett-Packard in Fort Collins, Colorado, his goal was to design and build computers, as he had been doing on his own throughout his student years. But the company did not have any openings to build hardware, so instead he went to work in manufacturing engineering. At that time there was a very tight connection between manufacturing and R&D at Hewlett-Packard. “It was a remarkable experience,” he said, that taught him lessons “I would not have normally gotten through our educational system.”

Today, product development and manufacturing still need to be tightly coupled for a product to succeed, said Rubinstein. When Apple was floundering, this approach got it back on track. The iMac was one of the first examples. At that time, the typical design cycle at Apple took two to three years. “We did the iMac in 11 months,” said Rubinstein, “and in doing so we established a whole new process for developing products at Apple.”

Apple applies the same approach to the development and use of materials. For example, the Cube computer was made of clear plastic in a single molded piece. Although the product was a commercial failure, “we learned more about how to do large-scale molding without lines or anything else in it from that product, which then evolved

linear. Idea generation, creativity, technology, and manufacturing all feed on each other and drive better ideas, better manufacturing, and better technology developments. “It is in the making, the doing, that creativity and genius are actually driven,” said Gabriel.

A major focus of the workshop was the proposition that the process of making value requires an integrated system of innovation, design, manufacturing, and services (Box 1-3). “It is the integrated process that leads to success,” Carlson said. “If you put your innovation hat on, you don’t think of them as separate things. You think of them as essential, necessary pieces of the puzzle that all have to fit together.”

Integration of the entire process of making value is happening more and more, said Theresa Kotanchek, Dow’s Global Technology Director

into all the other products at Apple.” Similarly, Apple has developed whole new manufacturing processes to meet design criteria, such as facilities to do high-volume plating for iPods.

The clue to product development is to recognize a need in the marketplace, innovate quickly, and then iterate, said Rubinstein. This observation also applies to the construction of new processes and facilities. A plant in China to do the plating for the iPod Nano went from an empty field to a functioning facility in 11 months. “High risk? Yes. But also high reward. And that comes down to the speed of development and the speed of innovation.”

But high-tech manufacturing of many consumer electronic products in the United States is not practical, said Rubinstein. America does not have enough tooling engineers to do large-scale electronics manufacturing, whereas China has “armies of people.” And the problem is not just tooling engineers. The United States does not have enough “manufacturing engineers, process engineers—a variety of types of engineering.” Even if US colleges and universities were to produce more engineers in general, these kinds of engineers would be in short supply.

Products are not just manufactured in China, Rubinstein reminded the workshop participants. Design teams in the United States collaborate closely with manufacturing teams in China, with travel in both directions, throughout the life cycle of a product. The idea that designers create a product and heave it over the wall to manufacturing “is not how you get fast-paced, high-innovation kinds of products.”

for Asia Pacific and India-Middle East-Africa. Dow’s advanced materials team includes people in the United States and in China literally working side-by-side with the designers of the companies we supply, she said. The people that have a leading influence over the value that is embodied in a product must all work closely together so that the entire supply chain has ownership over the product being created.

Don Norman, cofounder of the Nielsen Norman Group and IDEO Fellow,5 raised the additional point that the integrated process of making value means that customers are increasingly engaged. The model of

___________

5 The IDEO.org Fellowship Program supports design leaders of the future for 12 months to work on social innovation projects (https://www.ideo.org/fellows).

one group of people designing and making things that another group of people uses is out of date, he said. Users modify products they have purchased and then sell them to others, thereby creating value in an iterative loop. For example, Harley Davison motorcycle owners are famous for altering their motorcycles with custom parts and paint. The ability of individuals to design and produce is becoming easier. Individuals can now easily produce, share, and sell books with the rise of self-publishing. The same capabilities are emerging in manufacturing. With new technologies such as low-cost three-dimensional printers, everyone can be engaged in continual design, manufacturing, and innovation, said Norman. “The new model is that we are all producers, we are all designers.”

DOES INTEGRATION REQUIRE COLOCATION?

Does integration of the value chain require colocation of research, design, and manufacturing activities? A couple of breakout groups explored this question.

The importance of geographic colocation depends on the product, the production process, and the industry, said Chad Syverson, professor of economics at the University of Chicago Booth School of Business, who reported back from one of the groups. In general, colocation is more important when the production process is innovative, because process innovation requires learning by doing and trying to figure things out. For example, if the production process involves advanced materials, a new production process is often required for each new product, so close connections are needed between product design, process design, and production. Conversely, colocation is less important if a product is being made through a set of mature, codified processes, even if the product design is very innovative. For example, many semiconductors used in cell phones and computers are designed by companies that have outsourced the fabrication of these devices.

Improved communications technologies make it easier to operate at a distance than in the past, Syverson said. On the other hand, production technologies that are labor or capital intensive may create a greater incentive for colocation. There is no obvious trend one way or the other, Syverson said.

Even when manufacturing can be located in a different place from other parts of the value chain, it is important for designers and innovators to be engaged in the manufacturing process (Box 1-4). It is difficult

to imagine how individuals can innovate on processes, materials, and products if they do not have the chance to see and interact with the manufacturing process, said Bud Peterson, president of the Georgia Institute of Technology. Ken Gabriel gave an example from his experience at Akustica, a technology company he cofounded, illustrating how physical proximity can be important even with advanced communications technologies. A performance issue arose with the production of microphones, he explained, and the engineering team in Pittsburgh worked with the manufacturing team in China for weeks, via web-based conference calls and pictures of the production process, to try to find the problem. Finally, the company sent a staff member to China, Gabriel said, and in 30 minutes the problem was identified.

Willy Shih, professor of management practice at Harvard Business School, observed that many companies have replaced geographic colocation with frequent air travel. In the 1980s, colocation was much more common. But once China opened up its economy, the production costs were so low, Shih said, that “managers threw that out the window and said, ‘We will fill the sky with planes because it is cheaper.’” It’s possible that colocation will again become more important.