APPENDIX E

Double Hull Tanker Design*

DOUBLE BOTTOM HEIGHT REQUIREMENTS

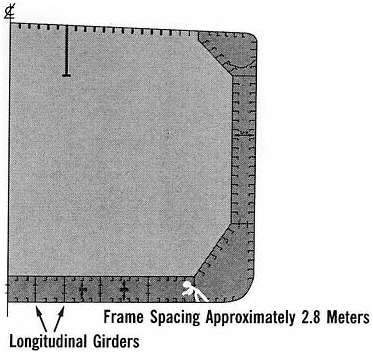

The existing IMO requirements are 1/15th the beam of the ship or two meters, whichever is less. We believe a better criteria would be 1/15th the beam of the ship but in no case less than two meters nor be required to be greater than three meters. Two meters is adequate for smaller vessels; but as the vessel size is increased and structural stiffeners increase in size, personnel access and air circulation become problems if the height of the double bottom is simply limited to two meters. There are many ways to design a double bottom, but in larger size vessels either longitudinals encroach into the available space to make access very difficult or longitudinal girders and transverse frames produce compartments that have the same or worse effect. On the other hand, we believe that three meters is sufficient height, even in the largest size vessels (VLCC's). If the height of the double bottom is increased beyond that, the vessel's stability is further impaired—the greater the double bottom height, the harder it is to design a vessel that has good damage stability characteristics. Furthermore, maintenance of the double bottom overhead becomes more difficult due to accessibility if the height is increased much beyond three meters. To illustrate the situation, compare the access of a "2M" double hull design currently being built in the Far East (Figure E-1) to that of a current Chevron design, Figure E-2. Note that reasonable access is closely linked to structural design, not simply the height/width of void spaces.

FIGURE E-1 Vessel currently being built in the Far East: ballast tank (midships) 2 meters wide.

DOUBLE SIDE TANK WIDTH REQUIREMENTS

Double side tanks require a minimum width of two meters. We believe the criteria should be 1/15th the beam but in no case less than two meters nor be required to be greater than three meters. No reasonable double side tank will be able to prevent a high impact collision from penetrating through the side tank. The width criteria should be established based on a width sufficient to prevent damage to the inner side in a glancing-type contact.

In addition to damage prevention to the inner side, access and maintenance issues must be addressed. This is somewhat less of a problem in the side tanks than in the double bottom tanks because there is less structure in the upper portions of these tanks; but in the bottom part, the problem is the same.

MAINTENANCE AND SAFETY

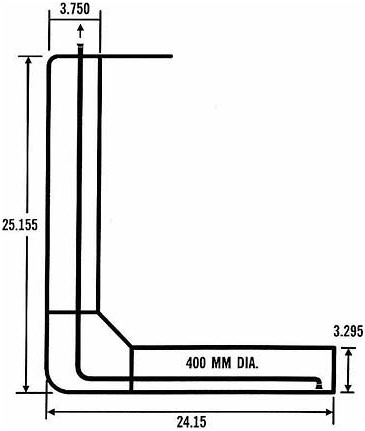

The double hull tanker will require frequent inspection of the double hull spaces to ensure that coating failures and corrosion are detected and dealt with on a timely basis. Therefore, access for maintenance must be sufficient to allow for easy inspection of the spaces and must allow for the effective removal of injured personnel. Openings in the structure at least one meter × 0.6 meter should be provided in every compartment for personnel movement in both the fore and aft and the athwartships directions. Provision for adequate air circulation in all double hull tanks is essential and purge pipes may be required in some locations. Figure E-3 shows the purge pipe arrangement that we made in order to get air circulation through the ballast tanks that have a dead leg at the centerline bulkhead. For entrance of men, it will be necessary to know that there is a satisfactory atmosphere throughout the tank. The more subdivided the tank is, the more difficult this becomes. We believe that a purge line is essential to get proper air circulation in the tank.

COATINGS

The massive amount of ballast tank surface area that is present in a double hull tanker makes corrosion protection a vital issue. These tanks should be coated and protected with cathodic protection methods to provide protection backup when coating failures occur. Failure to do so will result in corrosion and eventual leakage of cargo into the double bottom space with the resulting buildup of explosive vapors. Application of high quality coatings, with cathodic protection systems to give good corrosion protection in the ballast tank spaces will be critical to long-term operation without problems.

DAMAGE STABILITY CRITERIA

The current IMO requirements for damage stability which, in the case of most large tankers, means damage to two tanks. Our experience in grounding incidents is that the longitudinal extent of damage is frequently greater than is provided for under current criteria. We believe a double hull tanker should be able to survive damage which extends the full longitudinal extent of the cargo area of the vessel if the damage does not penetrate the vessel's inner bottom. For a double hull ship, intact stability is reduced by a combination of the higher center of gravity of the cargo and the possible large free surface in the center cargo tanks if a center line bulkhead is not fitted. If a double-bottom centerline bulkhead is fitted and asymmetric flooding can occur when the outer hull is breached, the combination of reduced

FIGURE E-3 Double bottom ''L" tank purging arrangement.

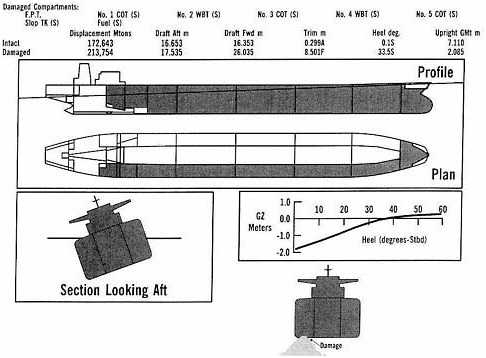

initial stability and the creation of large heeling moments can cause the vessel to capsize when damage extends over less than half the vessel's length. We should strive to require a standard of damage stability that provides for the vessel's survivability at least equal to the survivability of a typical single hull vessel. Figure E-4 shows the free-floating condition of a single hull after being damaged nearly its full length (damaged area shaded). As can be seen, the vessel is heeled to 33.5 degrees but remains afloat.

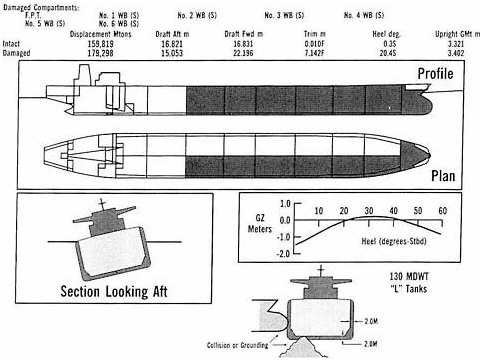

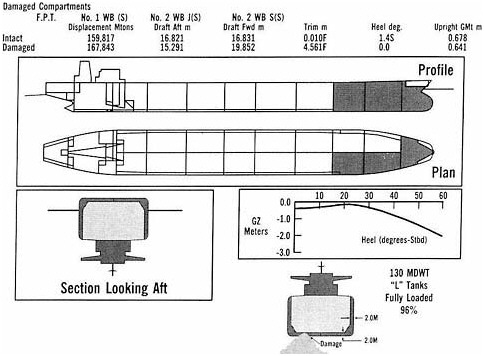

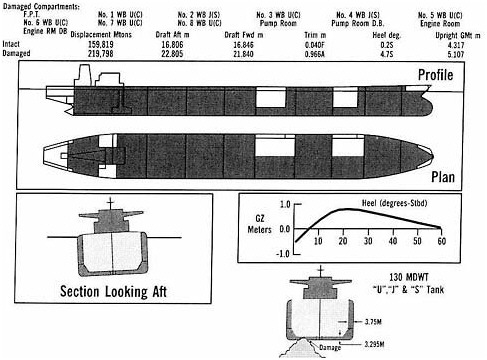

In Figure E-5, we depict an industry standard 130,000 DWT vessel with 2.0 meter double hull and "L" shaped ballast tanks. If it is loaded 98% full

and damaged to the extent indicated in the figures by the shaded areas, it will survive. If it is damaged further (into No. 7 cargo tank), it will capsize. If the same vessel is loaded with a heavier cargo so that, although fully loaded, the cargo tanks are only 96% full, then the vessel capsizes with far less damage (see Figure E-6). While it is prudent good marine practice to fill tanks to 98%, whether it is done in actual practice, is a question.

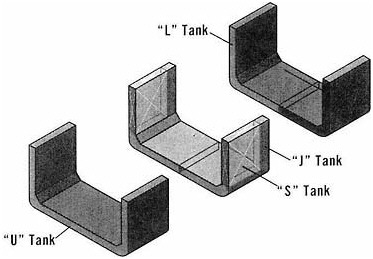

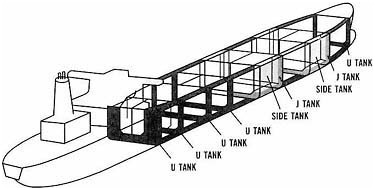

THE CHEVRON DESIGN

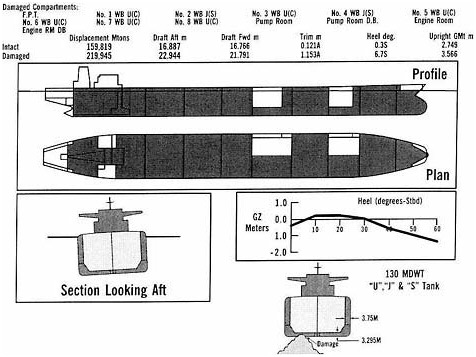

The Chevron 130,000 DWT vessels have double-hull dimensions that meet B-15 criteria and an arrangement of double-hull that allow it to survive substantial bottom damage. It uses a combination of "U", "J", and "S" tanks, as described in Figures E-7 and E-8. It also has access and maintenance arrangements that allow relatively easy inspection and maintenance. We believe, with this design, we've mitigated some of the problems inherent in double-hull designs. The tank arrangement and damage stability characteristics of the Chevron vessel is shown in Figure E-9. The Chevron vessel utilizes many "U'' ballast tanks to minimize the capsizing moments that are created by "L" tanks. The "U" tanks are fine, if full or empty, but create problems during loading and discharge of the vessel if too many are partially full simultaneously. Two sets of "J" tanks were arranged to provide for heel control while working cargo. The "S" tanks were included to provide buoyancy in a damaged condition, as the "U" tanks will flood across the vessel and not cause heeling, but sinkage will be greater. To minimize the free surface effects which could be created inadvertently by flooding too many "U" tanks simultaneously, three center cargo tanks have centerline subdivision bulkheads.

This arrangement has very good damage stability characteristics as shown in Figure E-9. The vessel can be damaged from the bow through to the engine room and remain stable and afloat. The computer-generated sketch of the vessel in this figure doesn't show the starboard side "S" tanks to be undamaged, but that is the case. If loaded to 96%, the stability is reduced, but the vessel survives this condition, as well, as shown in Figure E-10.