APPENDIX A

PRESS RELEASE ANNOUNCING FUEL ECONOMY STUDY

December 26, 1990

FOR GENERAL RELEASE

National Research Council

COMMISSION ON ENGINEERING AND TECHNICAL SYSTEMS ENERGY ENGINEERING BOARD

AN EVALUATION OF THE POTENTIAL AND PROSPECTS FOR IMPROVING THE FUEL ECONOMY OF NEW AUTOMOBILES AND LIGHT TRUCKS IN THE UNITED STATES

INTRODUCTION

The purpose of this study is to estimate fuel economy levels that could practically be achieved in new automobiles and light trucks (up to 8500 lbs. gross vehicle weight rating) produced for the United States market in the next decade.

The study has been requested by the National Highway Traffic Safety Administration to ascertain the potential and prospects to improve the fuel economy of new vehicles, while meeting existing and pending environmental and safety standards for the vehicles.

The study will be conducted in two phases. The work under Phase 1 is to be completed by June 30, 1991 and that under Phase 2 by March 31, 1992.

OBJECTIVES

Phase 1 of the study is expected to provide, on a "best judgment" basis, estimates by size class of vehicles (e.g., full-sized, mid-sized, compact, and sub-compact passenger cars, and large and small light trucks) produced by automotive corporations with major

assembly facilities in the United States and Canada of fuel economy practically achievable in the next decade, taking into consideration, as appropriate, provisions of the Clean Air Act Amendments of 1990, the state of the art in the applications of technologies relevant to achieving higher fuel economy and improving safety, and the viability of the domestic automotive industry in the U.S. market. Phase 1 work is also expected to result in the identification of principal barriers in the United States that appear to constrain the rates at which technologies enhancing fuel economy can be introduced and sustained in the marketplace.

Phase 2 of the study will analyze alternative measures to overcome the principal barriers to the technologies considered in Phase 1.

PROPOSED EFFORT

A committee will be appointed by the National Research Council to carry out this study. People with requisite qualifications will be sought for membership on the study committee with expertise in areas such as the following: internal combustion engines, fuels and lubricants, drive trains, automotive structures and materials, emission control systems, vehicle design, manufacturing of cars and light trucks, safety, financial practices and markets relevant to the automotive industry, federal and state regulations under which the automotive industry functions, consumer behavior, and automotive industry/U.S. economy interactions. A committee slate will be sought that is balanced with regard to the science and technology type of credentials and those from other disciplinary areas such as finance, economics, regulations, and behavioral sciences.

In Phase 1, the Committee will rely primarily on mechanisms such as the following to expeditiously obtain information pertinent to the study:

-

The Committee will invite structured presentations, to be delivered at committee meetings and in a workshop forum, from domestic and foreign automobile manufacturers and their suppliers; from representatives of qualified organizations closely involved with but functioning outside of the automotive industry per se; from the National Highway Traffic Safety Administration and its contractors and subcontractors as appropriate; and from other relevant parties (individuals, firms and other entities in the private sector, and government agencies).

-

The Committee will avail itself of the data and analytical resources of the National Highway Traffic Safety Administration that would be relevant to the study including, as appropriate, the resources of the National Highway Traffic Safety Administration's contractors and subcontractors who specialize in studies of the automotive industry and markets. The National Highway Traffic Safety Administration will facilitate the Committee's use of these resources.

-

The Committee will commission expert written reviews of selected topics from the extant literature, for example, trade-offs in automotive design of weight versus safety; dynamics of automotive industry changes since the Arab Oil Embargo of 1973; myths and realities in consumers preferences for automobiles; and so forth.

On the strength of what the Committee ascertains from the foregoing processes, the following tasks will be addressed:

PHASE 1

Task 1

The Committee will evaluate technologies in conventionally powered cars and light trucks that could, in the time frame of the next decade, contribute to improved fuel economy of new vehicles. Examples of technologies that might be presented to the Committee include the following: front-wheel drive; reductions in aerodynamic drag; 4-and 5-speed automatic transmissions; torque converter lockup; electronic and computer controls; continuously variable transmissions; 6-speed manual transmissions; high efficiency accessories; electric power steering; engine improvements (e.g., from components design, controls, materials); 2-cycle engines; diesel engines; improved lubricants; energy storage; reductions in rolling resistance and other driveline losses; weight reductions; reductions in horsepower-to-weight ratios.

In its evaluation, the Committee will consider factors such as the following:

-

The magnitude of fuel economy improvements that can be expected from the technologies, singly or in combinations.

-

The time at which the technologies could be introduced and the rates at which they might penetrate the U.S. market, given existing industrial capabilities in the United States and limitations (e.g., technical, financial, regulatory, organizational, and marketing limitations) to deploying improved or new capabilities in the next decade.

-

Likely effects in the United States of the technologies on initial and life-cycle costs of vehicles and vehicle safety, taking account of the effects on fuel economy of the interaction between and among technologies.

For the purposes of evaluation, the Committee will consider defining a baseline with vehicle size, size mix, equipment and performance consistent with the 1990 model year new cars and light trucks sold in the United States. Measures of fuel economy will be based on the EPA Test Cycle, and assumptions regarding future automotive fuel prices may be based on projections made by the Department of Energy and other sources of such projections available in the public domain.

Task 2

The Committee will identify and describe the principal barriers to the introduction in the United States of the technologies underlying the improvements in the fuel economy of new vehicles.

In performing this task, the committee will use information presented by the automobile manufacturers, by the National Highway Traffic Safety Administration, and by others. Such information is expected to cover topics such as the following: manufacturers' capital and operating costs in aggregate; research and development plans and costs, technology development and manufacturing lead times; tooling, assembly lines, plants and facilities conversion; employment; engineering resources; suppliers' capabilities to meet changes; principal federal and state regulations on environment and safety affecting vehicle design and operation, including new safety standards (e.g., automatic restraints, side and head impact protection, roof crush resistance), Clean Air Act Amendments of 1990, California Air Quality issues, phase-out of chlorofluorocarbons (CFCs); availability and use of alternative fuels; marketability of new vehicles; initial and life-cycle costs of vehicle ownership; competitiveness issues; best-in-the-world vehicles (on the road); prototypes in testing.

It is anticipated that, in the conduct of Tasks 1 and 2, a workshop will be held as described earlier. Proceedings of the workshop will be published promptly on a stand-alone basis.

Task 3

The Committee will prepare estimates by vehicle size class of the fuel economy gains that can be practically achieved in the United States in the next decade. As appropriate, the Committee will condition its estimates in terms of sensitivities expected to selected external factors. Examples of such factors (which may also require assumptions and judgments by the Committee) include the state of the U.S. economy at the end of the decade; world oil prices and availabilities; current product plans of automobile manufacturers; heightened public concerns for safety; and so forth.

The Committee will also prepare estimates, by vehicle size class, of the average incremental first cost per vehicle to the consumer attributable to higher fuel economy (relative to estimates of average life-cycle costs of vehicle ownership and operation), and the incremental annual cost, in aggregate, to the automotive industry in producing higher fuel economy vehicles.

The Committee will not, however, address the formulation of new corporate average fuel economy (CAFE) standards using its estimates of practically achievable fuel economy improvements in new vehicles nor will it, in Phase 1, address other public policy measures to achieve greater fuel economy in new vehicles.

Task 4

The Committee will prepare a Phase 1 report setting forth its findings, the rationale therefor, and the description of the barriers identified in this Phase. A manuscript of this report (after it has been subjected to the National Research Council review process) will be delivered by the National Research Council to the National Highway Traffic Safety Administration by June 30, 1991.

PHASE 2

Task 5

As presently envisioned in Phase 2, the Committee will analyze in greater detail the principal barriers to the market introduction and adoption of the most important technologies considered in Phase 1 and present alternative approaches to overcoming these barriers. The Committee will also consider addressing technologies such as electric and hybrid vehicles that were not considered in Phase 1. In any event, a more specific definition of Phase 2 requirements will be made in conjunction with the National Highway Traffic Safety Administration on the basis of information generated in Phase 1.

Task 6

The Committee will prepare a Phase 2 report setting forth its findings and conclusions. A manuscript of this report (after it has been subjected to the National Research Council review process) will be delivered by the National Research Council to the National Highway Traffic Safety Administration by March 31, 1992.

ANTICIPATED RESULTS

The study will result in two reports, one at the end of each phase, and a published proceedings of a workshop, which will be held in Phase 1.

Committee Agenda:

-

In consultation with NHTSA subsequent to the committee's first meeting, May 13-15, 1991, the date for completing Phase 1 of the study was extended beyond June 30, 1991.

-

The committee held a workshop as part of its second meeting, July 8-12, 1991. The proceedings of the workshop could not, however, be published as originally planned because of time and resource constraints.

-

The schedule for Phase 2 of the study has not yet been determined.

APPENDIX B

PROVEN AUTOMOTIVE TECHNOLOGIES: FUEL ECONOMY AND PRICE IMPLICATIONS

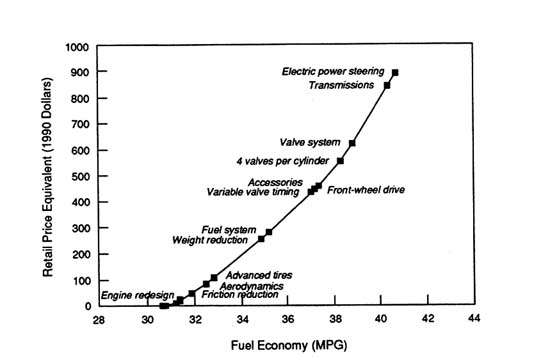

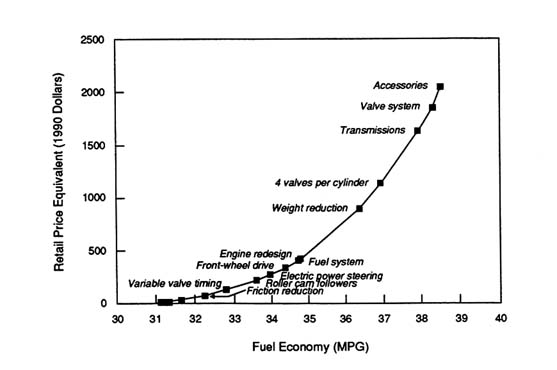

This appendix (1) describes how each proven fuel economy technology works and the aspects of vehicle energy use it affects, (2) examines and compares literature estimates of the improvements in fuel economy that may be achievable for each alternative technology compared with a baseline technology, and (3) examines literature estimates of the retail price equivalent (RPE) of using each alternative technology. The appendix then develops the data bases that underlie the technology-penetration, or shopping cart, projections of fuel economy in Chapter 7.

DATA SOURCES FOR THE SHOPPING CART PROJECTIONS

To implement the shopping cart approach, one must have data on the costs, fuel economy contribution, and market penetration for the technologies of interest. All are difficult to acquire. In practice, costs proved to be more difficult for the committee to estimate than potential fuel economy improvement, because the underlying bases for the costs are less well defined and hitherto not well analyzed. Also, information on costs is proprietary in nature so the open literature is very sparse.

The committee obtained data on the market shares of the technologies in MY 1990 from Energy and Environmental Analysis, Inc. (EEA, personal communication, October 2, 1991) and from SRI International (1991). The EEA provided the committee with estimates of the market shares for the various technologies by size class and by import versus domestic manufacture, for passenger cars and light trucks. The SRI report provided estimates for all passenger cars manufactured by members of the Motor Vehicle Manufacturers Association (MVMA), that is, Chrysler, Ford, General Motors, and Honda of America.1 The committee compared the two sources by computing the sales-weighted average market shares for domestic cars based on EEA's

data and comparing them with the market shares reported for domestic manufacturers in the SRI report. By and large, the estimates are in good agreement. Differences (e.g., market shares of 4-valve engines) seem to arise from the inclusion of Honda's U.S. production in the SRI data and its exclusion from EEA's domestic estimates (Honda's U.S. production is considered imported for corporate average fuel economy [CAFE] purposes).

The percentage improvement in fuel economy that can be ascribed to a given technology continues to be debated among scientists and engineers. While there has been agreement on some technologies, the committee found contention about others. Most of the arguments have to do with the definitions of technologies—the same name is often given to quite different versions of a generic technology in different sources. Some differences have to do with the details of how a technology is implemented. Most engine technologies considered, for example, can be optimized for performance or fuel economy. When optimized for performance, they do not yield as great a fuel economy benefit.

The automotive industry and the U.S. Department of Energy (DOE), together with EEA, a DOE contractor, have spent a considerable amount of time and effort attempting to resolve the debate over fuel economy potential. In meetings over nearly two years, engineers and experts from the domestic manufacturers and DOE have scrutinized definitions, assumptions, and estimation methods. This process produced revisions of several estimates and a narrowing of differences, but not complete agreement. Estimates made by nearly all the major automobile manufacturers have been compiled by Ford Motor Company (1991). Estimates for particular sets of technologies have also been developed by Berger et al. (1990) and by SRI (1991). The committee considered all these sources, which are compiled in Table B-1. It elected to base its shopping cart projections on two sets of estimates—those developed by EEA (1991a) under the sponsorship of DOE and those developed by SRI (1991) under the sponsorship of the MVMA. The SRI estimates, developed to serve as a consensus from the domestic industry, are generally similar, but not identical to the estimates provided by Ford. The EEA and SRI reports are the only sources that provide technology-specific information on both percentage fuel economy improvements and costs. The cost estimates are summarized in Table B-2.

ENGINE TECHNOLOGIES

Under the category of engine technologies in Table B-1 are included those technologies that address the thermodynamic efficiency of combustion, internal engine friction, and pumping losses, as well as energy used by essential engine accessories, such as oil pumps and alternators, and nonessential accessories, such as air-conditioners and power steering.

TABLE B–1 Estimates of Fuel Economy Improvement Potential of Various Technologies (percent)

|

TECHNOLOGY |

BASELINE |

EEA |

SRI |

BSA |

FORD |

GM |

CHRYSLER |

TOYOTA |

HONDA |

NISSAN |

MITSUBISHI |

|

ENGINE TECHNOLOGIES |

|||||||||||

|

GENERAL |

|||||||||||

|

Roller cam followers |

Flat followers |

2.0 |

1.7 |

0.3 |

3.0 |

1.5 |

2.4 |

0.8 |

1.0 |

1.4 |

1.3 |

|

Friction reduction, -10% |

Base 1987 |

2.0 |

2.0 |

|

2.0 |

1.0 |

0.5 |

0.8 |

1.0 |

1.4 |

|

|

Accessory improvement |

Conventional |

0.5 |

0.7 |

|

0.7 |

0.0 |

1.4 |

0.5 |

|

0.2 |

0.8 |

|

Deceleration fuel restriction |

None |

1.0 |

1.0 |

|

1.0 |

|

|

|

|

|

|

|

Compression ratio, +.5 |

9:1 (EEA 4-V only) |

2.0 |

|

1.5 |

1.0 |

|

1.3 |

|

|

1.0 |

|

|

FUEL SYSTEMS |

|||||||||||

|

Throttle-body fuel injection |

Carburetor |

3.0 |

2.6 |

3.0 |

3.0 |

2.5 |

3.4 |

0.8 |

1.0 |

3.3 |

|

|

Multipoint fuel injection |

Carburetor |

5.0 [b] |

4.6 |

3.1 |

6.0 |

4.0 |

4.9 |

2.5 |

3.5 |

4.3 |

|

|

VALVE TRAIN |

|||||||||||

|

Overhead camshaft |

Overhead valve |

3.0 |

2.5 |

1.2 |

3.5 |

1.5 |

2.0 |

|

0.8 |

2.0 |

|

|

4 valves per cylinder |

2 valves |

5.0 |

3.0 |

2.1 |

3.5 |

3.0 |

3.5 |

4.5 |

2.0 |

3.4 |

|

|

Variable valve timing |

Fixed timing |

6.0 |

2.6 |

|

3.0 |

2.0 |

1.5 |

2.0 |

2.5 [c] |

2.7 |

|

|

REDUCED NUMBER OF CYLINDERS |

|||||||||||

|

4-cylinder |

6-cylinder |

3.0 |

0.0 |

1.2 |

-3.0 |

0.0 |

0.0 |

0.0 |

0.0 |

0.0 |

|

|

6-cylinder |

8-cylinder |

3.0 |

1.0 |

-0.9 |

0.0 |

0.0 |

0.0 |

0.0 |

0.0 |

0.0 |

|

|

TRANSMISSION TECHNOLOGIES |

|||||||||||

|

Torque converter lock-up |

Open converter |

3.0 |

2.0 |

2.8 |

2.0 |

3.0 |

3.0 |

2.5 |

3.0 |

3.2 |

|

|

Electric transmission control |

Hydraulic |

0.5 |

0.5 |

0.5 |

0.5 |

0.0 |

0.5 |

0.5 |

0.5 |

0.6 |

|

|

4-speed Automatic |

3-speed auto |

4.5 |

2.8 |

2.9 |

3.0 |

4.0 |

2.0 |

2.3 |

1.8 |

3.0 |

|

|

5-speed Automatic |

3-speed auto |

7.0 |

3.3 |

|

5.0 |

4.5 |

3.0 |

3.5 |

3.3 |

4.0 |

|

|

Continuously variable transmission |

3-speed auto |

8.0 |

4.8 |

|

5.5 |

4.5 |

3.0 |

|

3.8 |

5.5 |

|

|

5-speed Manual [d] |

3-speed auto |

8.0 |

4.8 |

0.0 |

5.5 |

0.0 |

0.0 |

0.0 |

0.0 |

0.0 |

|

|

ROLLING RESISTANCE, AERODYNAMICS, AND WEIGHT |

|||||||||||

|

Front wheel drive |

Rear wheel drive |

10.0 |

0.5 |

0.8 |

1.0 |

0.0 |

|

|

1.1 |

3.0 |

|

|

Aerodynamics |

Base |

2.3 |

2.4 |

2.7 |

2.0 |

3.1 |

2.0 |

2.0 |

1.5 |

1.2 |

1.7 |

|

Weight reduction, -10% |

Base |

6.6 |

5.0 |

9.1 |

5.5 |

8.0 |

5.0 |

5.5 |

5.0 |

6.0 |

|

|

Electric power steering |

Conventional |

1.0 |

1.4 |

|

1.5 |

0.5 |

1.0 |

1.0 |

1.0 |

1.0 |

|

|

Advanced tires, -10% |

Base |

1.0 |

1.0 |

0.6 |

1.0 |

0.5 |

0.5 |

|

|

1.0 |

1.0 |

|

Advanced lubricants |

Conventional |

0.5 |

0.3 |

|

0.2 |

|

|

0.5 |

0.5 |

|

|

|

[a] Fuel economy benefit for EEA incorporated into 4-valve engine. [b] Apportioned to account for incorporation of limited deceleration fuel restriction in multipoint fuel injection. [c] A savings as large as 12.5 percent can be inferred from discussion in Chapter 2 or Appendix C. [d] Fuel economy benefit assumed same as that of CVT over 3-speed automatic transmission. Source: Committee adaptation of summary of presentations to the committee, July 1991, prepared by A. Gilmour (Ford, 1991). Baseline technologies are arbitrary and have been changed from some original sources to put all estimates on a comparable basis. |

|||||||||||

TABLE B–2 Costs of Fuel Economy Improvement Technologies

|

|

|

Data Source and Engine Type |

|

||||

|

|

EEA (1988 $) |

SRI (1990 $) |

|||||

|

TECHNOLOGY |

BASELINE |

4 Cyl |

6 Cyl |

8 Cyl |

4 Cyl |

6 Cyl |

8 Cyl |

|

ENGINE TECHNOLOGIES |

|||||||

|

GENERAL |

|||||||

|

Roller cam followers |

Flat followers |

16 |

24 |

32 |

65 |

65 |

65 |

|

Friction reduction, -10% |

Base 1987 |

30 |

40 |

50 |

60 |

60 |

60 |

|

Accessory improvement |

Conventional |

12 |

12 |

12 |

200 |

200 |

200 |

|

Deceleration fuel restriction |

None |

|

|

|

5 |

5 |

5 |

|

Compression ratio, +.5 |

9:1 (EEA 4-V only) |

|

|

|

1 |

1 |

1 |

|

FUEL SYSTEMS |

|||||||

|

Throttle-body fuel injection |

Carburetor |

42 |

70 |

70 |

65 |

65 |

65 |

|

Multipoint fuel injection |

Carburetor |

90 |

134 |

150 |

215 |

215 |

215 |

|

VALVE TRAIN |

|||||||

|

Overhead camshaft |

Overhead valve |

110 |

160 |

200 |

400 |

400 |

400 |

|

4 valves per cylinder |

2 valves |

140 |

180 |

225 |

400 |

400 |

400 |

|

Variable valve timing |

Fixed timing |

140 |

200 |

267 |

100 |

100 |

100 |

|

REDUCED NUMBER OF CYLINDERS [a] |

|||||||

|

4-cylinder |

6-cylinder |

0 |

(300) |

(550) |

0 |

(300) |

(550) |

|

6-cylinder |

8-cylinder |

300 |

0 |

(250) |

300 |

0 |

(250) |

|

TRANSMISSION TECHNOLOGIES |

|||||||

|

Torque converter lock-up |

Open converter |

50 |

50 |

50 |

56 |

56 |

56 |

|

Electric transmission control |

Hydraulic |

24 |

24 |

24 |

122 |

122 |

122 |

|

4-speed Automatic |

3-speed auto |

225 |

225 |

225 |

230 |

230 |

230 |

|

5-speed Automatic |

3-speed auto |

325 |

325 |

325 |

530 |

530 |

530 |

|

Continuously variable transmission |

3-speed auto |

325 |

325 |

325 |

640 |

640 |

640 |

|

5-speed Manual [d] |

3-speed auto |

|

|||||

|

ROLLING RESISTANCE, AERODYNAMICS, AND WEIGHT |

|||||||

|

Front wheel drive |

Rear wheel drive |

240 |

240 |

240 |

26 |

26 |

26 |

|

Aerodynamics |

Base |

40 |

40 |

40 |

60 |

60 |

60 |

|

Weight reduction, -10% |

Base |

—varies [b] — |

470 |

470 |

470 |

||

|

Electric power steering [c] |

Conventional |

45 |

45 |

45 |

61 |

61 |

61 |

|

Advanced tires, -10% |

Base |

18 |

18 |

18 |

20 |

20 |

20 |

|

Advanced lubricants |

Conventional |

2 |

3 |

3 |

3 |

3 |

3 |

|

[a] Reduced number of cylinders keeping engine displacement constant. Numbers in EEA columns are based on SRI. [b] Based on cost of $0.50 per pound saved (EEA, 1991a) multiplied by 10 percent of average weight of all cars in the size class. [c] Committee estimate based on price of electric power steering for Honda Civic in Japan. Source: Committee estimates based on adaptation of data from EEA (1991b), SRI (1991), and other sources. |

|||||||

General

This subcategory of engine technologies includes those specifically addressing friction reduction and thermodynamic efficiency, as well as certain ones that do not fit under the other subcategories—fuel systems, valve trains, and number of cylinders.

Roller Cam Followers

In conventional engines, intake and exhaust valves are operated by a camshaft whose lobes are in sliding contact with a cam follower. This is a large source of friction in a conventional engine, accounting for up to one-fourth of all engine friction (Ledbetter and Ross, 1990). Roller cam followers incorporate hardened steel roller bearings that reduce this source of friction. They are estimated to increase fuel economy by about 2 percent. Domestic manufacturers tend to give higher estimates than foreign manufacturers, as shown in Table B-1, and they currently make much greater use of roller cam followers, which are already in widespread use in car and light-truck engines of all sizes.

EEA (1991b) estimates that the RPE of roller cams is $4 per cylinder, or $16 for a 4-cylinder engine to $32 for an 8-cylinder. SRI (1991) reports a much higher RPE, $65, as an average for all cars.2

Friction Reduction

About 20 percent of engine power is lost to friction (Office of Technology Assessment [OTA], 1991). The primary sources of friction at moderate engine speeds, in order of importance, are the pistons and rings, valve train, crankshaft, and oil pump (EEA, 1991a). Engine friction has been gradually reduced over several decades. According to SRI, redesign of pistons and rings and modification of bearings throughout the engine could produce an overall 10 percent reduction in engine friction, yielding a fuel economy gain of 1.5 to 2.0 percent. EEA and Ledbetter and Ross (1990) concur with the high end of this range (2.0 percent) for the fuel economy effect of low-tension piston rings, closer machining tolerances for pistons, cylinders and bearing surfaces, and use of lightweight pistons.3 The latter sources point out that the use of lightweight valves and ceramic pistons, titanium valve springs, lightweight composite connecting rods, and two rather than three piston rings, together with oil-pump and crankshaft modifications, could reduce engine friction by another 10 percent, for another 2 percent fuel economy benefit. SRI considers lightweight valve trains separately and estimates a fuel economy improvement of 0.5 percent for that change alone.

Overall, then, a fuel economy improvement of 2 percent for each 10 percent reduction in engine friction, up to a maximum friction reduction of 20 percent, seems to be a reasonable estimate. Although the amount of friction reduction achievable and its impact on fuel economy may vary by engine, there are no inherent limitations on the use of friction-reducing technology in the engine.

The RPE estimates for a 10 percent reduction in internal engine friction are about $50 per car. SRI (1991) puts the RPE at $60, and EEA (1991b) puts the RPE at $30 for a 4-cylinder, $40 for a 6-cylinder, and $50 for an 8-cylinder engine.

Accessory Improvements

Accessories either perform essential engine-supporting functions (e.g., the water pump, oil pump, cooling fan, and alternator) or provide optional services for the driver and occupants (the power-steering pump and air-conditioning compressor). They can account for perhaps 15 percent of vehicle energy requirements (EEA, 1991a). Accessories typically require about the same amount of energy regardless of vehicle size, so they have a somewhat greater proportional impact on the fuel economy of smaller cars. The energy requirements of accessories do not typically increase in direct proportion to engine speed, yet traditional accessory drive mechanisms are geared so that their speed does increase with the engine speed, which results in a poor match between energy inputs and requirements.

Fuel economy can be improved by increasing the efficiency of the accessory system or by better matching its operation to requirements. A great deal of improvement has already been achieved in this area over the past decade. For example, before 1980, most cooling fans were driven by a drive belt operating from the crankshaft. The faster the engine speed, the faster the fan turned. However, at highway speeds the fan is not usually needed, so the energy used to run the fan was wasted. Today, front-wheel drive vehicles are equipped with thermostatically operated electric fans that turn on only when needed.

More generally, accessories driven by a single-speed drive use excessive energy at high engine speeds (SRI, 1991). Variable-speed drives can reduce this waste, but so far the cost and complexity of variable-speed drive systems have not been justified by the 0.5 to 1.0 percent efficiency improvement they can achieve (EEA, 1991a; SRI, 1991). EEA asserts, however, that incremental improvements in drive systems, optimization of fan and pump blade shapes, and reduced heat rejection from the engine can combine to raise fuel economy.

Estimates of the costs of accessory improvements differ, depending on which specific improvements are included. EEA (1991b) estimates an RPE of $12 for an 0.5 percent improvement, excluding use of variable-speed drives and electric power steering. SRI (1991) estimates that the RPE of two-speed accessory drive will be $200. The high and uncertain costs of these technologies support the committee's view that variable-speed drives are not proven technology.

Deceleration Fuel Restriction

Since the momentum of the vehicle actually drives the engine during deceleration, it is possible to restrict the fuel input sharply with no effect on operation. In the extreme, shutting off all fuel flow would require restarting the engine to restore power. This is the version considered by SRI (1991). EEA (1991a) combines a partial

reduction in fuel flow that does not shut off the engine with multipoint fuel injection. Both SRI and EEA conclude that fuel restriction during deceleration can increase fuel economy by about 1 percent. There are no technical limits on the applicability of this technology. SRI (1991) puts its RPE at $5; EEA (1991b) bundles it with multipoint fuel-injection technology, discussed below.

Compression Ratio Increase

All else remaining equal, an engine with a higher compression ratio converts a greater proportion of fuel energy into useful work and a lesser proportion to waste heat; that is, the engine has a higher thermal efficiency. Small changes in engine design to ameliorate the increased tendency to knock (modification of the cylinder heads, electronic engine controls, and addition of knock sensors) can lead to a 5 to 6 percent increase in compression ratio (typically from about 9.0:1 to 9.5:1) with an accompanying 1.3 to 2.0 percent increase in fuel economy (SRI, 1991) and without requiring use of higher octane fuel. Higher compression ratios are generally associated with greater production of oxides of nitrogen (NOx). Such modifications could be made to essentially all gasoline-powered vehicles, although they are most suitable for vehicles that do not already use high compression ratios. The RPE of a compression-ratio increase is estimated by SRI to be very small—on the order of $1—assuming no additional hardware or controls are needed.

Fuel Systems (Throttle-Body And Multipoint Fuel Injection)

In 1975, 95 percent of all passenger cars and 99.9 percent of all light trucks sold in the United States used carburetors. By the 1991 model year the situation was completely reversed: 99.7 percent of all cars and 98.1 percent of all light trucks were equipped with fuel injection (Heavenrich et al., 1991).

Fuel injection has several advantages over carburetion. Because the flow restriction of the carburetor is eliminated and there is no need to preheat the air/fuel mixture, torque and maximum horsepower are increased (Newton et al., 1989). In addition, fuel injection controlled by modern computer-based electronics can better match fuel supply to engine operating conditions, thereby improving drivability, emissions control, and fuel economy. Compared with carburetion, fuel injection leads to a modest reduction in pumping losses in getting air/fuel mixture into the combustion chamber and to a slight reduction in the relative importance of engine friction because power per unit of displacement is increased. Fuel injection is a clear example of a technology that offers significant benefits beyond increased fuel economy.

There are two general types of fuel-injection systems. Throttle-body (or single-point) fuel injection uses one or two injectors to inject fuel upstream of the throttle valve at essentially the same place as from a carburetor. Multipoint fuel injection (MFI) locates an injector immediately upstream of each inlet valve, which enables better control of the air/fuel mixture to each cylinder. Throttle-body injection (TBI) is simpler and cheaper than multipoint injection.

EEA (1991a) estimates the combined fuel economy improvement of TBI at 3 percent, and SRI (1991) suggests a 2.6 percent improvement. Three percent seems a good consensus estimate, as suggested by Table B-1.

According to EEA (1991a), MFI produces an additional 1.2 to 1.5 percent improvement in fuel economy over TBI. SRI (1991) gives a slightly higher estimate of 1.5 to 2.0 percent. MFI allows greater control of fuel flow during deceleration, and it is required for effective deceleration fuel shutoff. EEA includes this effect under MFI, and SRI reports it separately under ''Deceleration Fuel Off." EEA points out that MFI also allows the use of a tuned intake manifold to optimize airflow and that the unheated charge is denser than a preheated charge would be, which increases volumetric efficiency. As a result, EEA points out that an optimized drivetrain would adjust the rear-axle ratio for the slight increase in torque with MFI, which would produce another gain in fuel economy of approximately 0.5 percent. In sum, SRI and most manufacturers suggest a 1.5 to 2 percent gain for MFI over TBI, whereas EEA indicates a 2 percent gain, with an additional 1.0 percent available through deceleration fuel restriction. Thus, the total improvement over a carbureted system is about 5 percent without deceleration fuel shutoff, and about 6 percent with.

Both TBI and MFI systems are applicable to all passenger cars and light trucks with spark-ignition engine. Because of the multiple advantages of the MFI system, it is likely to replace TBI systems by 1995 or shortly after (SRI, 1991).

Cost estimates for TBI systems are in close agreement. EEA (1991b) estimates the RPE at $42 for one-injector and $70 for two-injector systems, while SRI (1991) indicates $65 without specifying the number of injectors (presumably one). These sources do not agree, however, on the RPE of MFI. EEA's estimates range from $48 for a 4-cylinder engine to $80 for 8-cylinders, and SRI reports $215 without specifying engine size.

Valve Train Technologies

Valve train improvements can improve engine efficiency in three areas: (1) pumping losses, (2) engine friction, and (3) thermodynamic efficiency.

Overhead Camshaft

Locating the camshaft above the cylinder heads to operate the valves directly allows several improvements in engine design. Inertial forces in the valve train are reduced because some parts of the traditional arrangement are eliminated. Having fewer moving parts also reduces friction and improves high-speed operation by allowing the valves to be opened and closed more rapidly. Similarly, the total valve-opening time can be reduced, which improves low-speed torque and fuel economy. Finally, some overhead cam (OHC) designs allow increased flexibility in valve location and, therefore, improved shape of the combustion chambers.

All of the above factors allow greater power output for a given engine size. Overhead-valve engines of older design achieved power outputs of about 40 BHP/liter

(brake horsepower per liter of displacement), and modern versions achieve 45 BHP/liter. In comparison, modern OHC engines produce 50 to 55 BHP/liter.

At equal power output, OHC engines achieve better fuel economy than overhead-valve engines, although the exact difference depends strongly on the related changes and design choices that are made. SRI (1991) suggests gains in the range of 1.1 to 2.5 percent without design changes; the General Motors, Ford, and Chrysler estimates are 1.5, 2.0, and 3.5 percent, respectively (see Table B-1). EEA (1991a) reports a 1.0 percent efficiency gain at constant displacement, a 3.0 to 3.8 percent efficiency gain due to a reduction in displacement to achieve constant peak power, and a 1.1 to 1.3 percent loss in efficiency due to a change in axle ratio to compensate for changes in the shape of the torque curve—all of which results in an overall gain of 2.9 to 3.5 percent in fuel economy. There are no limits to the applicability of OHC engines.

The cost penalty of an OHC engine depends primarily on the complexity of the camshaft drive system. There is little inherent reason for an OHC engine to cost more since it has fewer moving parts and does not require any exotic technologies. EEA (1991b) suggests an RPE of $110 for a 4-cylinder engine, $160 for a 6-cylinder, and $200 for 8-cylinders. SRI (1991) reports an average RPE of $400 per engine. The committee believes that both of these estimates may be too high, especially for 4-cylinder engines.

Four Valves per Cylinder

Conventional engines use two valves per cylinder, one each for intake and exhaust. As engine speed increases, the aerodynamic resistance to pumping air in and exhaust out of the cylinder increases. By doubling the number of intake and exhaust valves per cylinder, pumping losses are reduced and useful power output is increased, especially at high engine speeds. Still greater improvements can be achieved by using variable valve timing and lift control to take advantage of the 4-valve configuration (see below). In many cases, the inlet passage to each valve is controlled separately, which further improves the operation of the engine over wide ranges of speed and load.

In addition to enhancing the flow of gases in the engine, the 4-valve design also allows the spark plug to be positioned closer to the center of the combustion chamber, which decreases the distance the flame must travel to complete combustion. In addition, using two streams of incoming gas can help to achieve more complete mixing of air and fuel, further increasing combustion efficiency (Newton et al., 1989). The Honda VTEC-E engine uses this central placement to create optimal conditions for "lean" combustion (see below). Central placement of the spark plug not only promotes more rapid combustion, but also allows the ignition timing to be retarded, thereby decreasing the dwell time of hot gases in the combustion chamber and reducing the formation of NOx (Newton et al., 1989).

Four-valve engines typically produce 10 percent higher torque and 20 percent greater peak horsepower than OHC engines of 2-valve design (EEA, 1991a; Ledbetter and Ross, 1990). SRI suggests a fuel economy gain of 0.8 to 1.3 percent from use of 4-valves, which permits reduction of the engine displacement while maintaining output

power. This estimate apparently ignores the opportunities for more rapid combustion due to a more central location of the spark plug. EEA claims that the spark plug location and improved airflow together allow an increase in compression ratio of about 10 percent (typically to 10:1) without increased octane requirements. EEA breaks down the fuel economy changes resulting from replacing a conventional engine with a 4-valve engine as follows:

|

10 percent decrease in displacement |

+3.8% |

|

5 percent axle ratio increase |

-1.1% |

|

Increase in thermal efficiency |

+2.5% |

|

Increase in valvetrain friction |

-0.5% |

|

Reduced pumping losses |

+0.5% |

|

NET FUEL ECONOMY CHANGE |

+5.2% |

SRI and auto manufacturers suggest that the applicability of 4-valve engines will be limited by their relatively low torque at low engine speeds. Poor low-speed torque would make such engines less suitable for large cars and light trucks. It would also limit their acceptance by consumers who value the acceleration and "feel" of vehicles with high torque at low speed. Fortunately, variable valve timing and lift control have the potential to restore the low-end torque of 4-valve engines and make their torque curves resemble those of 2-valve engines of equal power (see below). In its analysis, the committee assumed that the two technologies are used in combination, so it sees no limits on the use of 4-valve technology in the future.

Four-valve systems are more complex than 2-valve systems and, therefore, are significantly more costly. SRI (1991) suggests that the RPE of a 4-valve single overhead cam (SOHC) engine would be $400 more than a 2-valve SOHC and that a 4-valve dual overhead cam (DOHC) engine would be priced at $650 more than a 2-valve SOHC. EEA (1991b) indicates lower prices: $140 for a 4-cylinder, $180 for a 6-cylinder, and $225 for an 8-cylinder engine.

Variable Valve Timing and Lift Control

Conventional engines use fixed valve timing and lift at all engine speeds. At light loads, closing the intake valve earlier would reduce pumping losses (EEA, 1991a). If valves are opened further and for a longer time at higher speeds, the engine can "breathe" more easily, which produces higher horsepower.

A variety of approaches can be taken to variable valve timing. Honda's lean-burn VTEC-E engine is an example of a 4-valve, variable valve control engine optimized for fuel economy.4 The VTEC-E achieves 15 percent higher torque at 2,000 rpm, and generally higher torque across the range of low rpm, than an equivalent Honda non-VTEC, 4-valve engine (EEA, 1991a; Honda Motor Company, 1991). At

|

4 |

The California version of the VTEC-E uses enhanced exhaust gas recirculation rather than excess air. See Appendix C for a description of lean-burn technology. |

low rpm, one of the two intake valves in each cylinder remains nearly closed, which creates a swirling motion in the combustion chamber that allows a rich air/fuel mixture to be maintained in a vortex near the centrally located spark plug, while the total air/fuel charge remains very lean. (The nominally closed intake valve remains slightly open to prevent accumulation of liquid fuel in the port.) This feature, which is made possible by variable valve control, allows smooth operation under lean-burn conditions at low rpm. In a presentation to the Technology Subgroup of the committee, at its meeting on September 5-6, 1991 in Detroit, Michigan (see Appendix F), Honda asserted that these features produce a 10 to 15 percent gain in fuel economy and that variable valve control alone without lean-burn operation yields a 7 to 8 percent fuel economy benefit.

Honda's estimate of the VTEC-E's fuel economy apparently does not take account of reoptimization of the drivetrain to take advantage of the higher low-rpm torque that variable valve control makes possible. The difference in fuel economy between the VTEC-E (in the 1992 Civic VX) and a non-VTEC 16-valve engine (in the 1992 Civic DX) is 32.3 percent for the lean-burn version and 22.2 percent for the California version without lean burn. Thus, the lean-burn feature may lead to a 10 percent increase in fuel economy benefit.

The Honda Civic VXs use other fuel-saving features, including a 5 percent reduction in weight compared with the DX, reduced tire rolling resistance, reduced aerodynamic drag (about 3 percent), and changes in axle and gear ratios to take advantage of the VTEC's better torque curve (American Honda Motor Company, 1991; Duleep, 1991). These changes (except the axle and gear changes) taken together may account for about 6 percent of the 32.3 percent and 22.2 percent improvements (about 3 percent for weight reduction, 0.7 percent for the drag reduction, perhaps 0.5 percent each for improved lubricants and reduced accessory loads, and 1 to 2 percent for the improved tires). These estimates suggest a gain of 16 percent for variable valve control and the changes in axle and gear ratios it permits. Other modifications of which the committee is not aware may reduce the benefit attributable to variable valve control and associated drivetrain optimization, but probably not by more than a few percentage points.

Honda's VTEC-E demonstrates that a combination of 4-valve per cylinder technology and valve control can produce a fuel-efficient engine with good torque at low engine speed. As a result, the committee see no limitations, other than those due to cost, on the application of 4-valve engines or variable valve timing and lift control.

Variable valve timing applied to an OHC engine would have an RPE of $100 on average, according to manufacturers' estimates reported by SRI (1991). EEA's (1991b) estimates are considerably higher: $140 for a 4-cylinder, $200 for a 6-cylinder, and $267 for an 8-cylinder engine.

Number of Cylinders

During the past decade and a half, the power output of automotive engines per unit of displacement has increased substantially, which suggests the possibility of

continued engine downsizing.5 At equal displacement and peak horsepower, an engine with fewer cylinders has fewer moving parts and a lower ratio of cylinder surface area to volume. The first factor tends to reduce engine friction, and reducing the surface-to-volume ratio tends to improve the thermal efficiency of the engine, although the larger displacement cylinder has an increased tendency to knock. Also, 4-cylinder engines are typically about 40 to 50 pounds lighter than 6-cylinder ones producing the same power (EEA, 1991a).

The auto manufacturers assert that reducing the number of cylinders raises both idle rpm and the speed at which the engine begins to "lug" (SRI, 1991). In a 4-cylinder engine, there are only two power pulses per revolution so no power is being delivered by a piston to the crankshaft about one-sixth of the time (Newton et al., 1989). The low frequency and high amplitude of these power pulses significantly increase the vibration levels of a 4- compared with a 6-cylinder engine and to a lesser extent, of a 6- compared with an 8-cylinder engine. Idle speed can be increased to overcome vibration at idle, but that consumes additional fuel, thus reducing fuel economy. To ensure smooth operation in low-speed driving, gear ratios and lockup speeds must be changed in going from a 6- to a 4-cylinder engine, which generally results in lower fuel economy under otherwise similar conditions.

There is no argument that engines with fewer cylinders experience the above problems, but there is considerable disagreement about whether they offer net fuel economy benefits after modification to produce acceptable vibration. EEA (1991a) estimates that replacing a V-6 engine with an in-line 4-cylinder (I-4) engine of equivalent displacement could reduce friction by 15 percent, resulting in a 3 percent fuel economy benefit. EEA also suggests a 1.6 to 3.0 percent fuel economy gain in moving from a V-8 to a V-6. SRI (1991) reports a 1 percent gain for the switch from V-8 to V-6 and no gain for changing from a V-6 to an I-4, because of the other design changes that are required to hold consumer satisfaction constant. Ford (1991) indicates that the changes necessary to keep consumers equally satisfied in moving from 6 to 4 cylinders would actually produce a fuel economy loss of 3.0 percent.

Whether reducing the number of cylinders is a valid fuel economy option is important for two other reasons. First, engines with fewer cylinders are cheaper to make. SRI suggests a savings of $250 in going from a V-8 to a V-6 engine, and a savings of $300 in converting from a V-6 to a 4-cylinder. Second, several other fuel economy technologies described below also increase an engine's output per unit of displacement, which allows a reduction in engine size for the same power. Reducing displacement generally reduces vibration, which, in turn, allows a reduction in the number of cylinders and produces synergistic fuel economy and cost benefits.

The committee generally assumed that it is practical to decrease the cylinder count by two in future vehicles. That is, six cylinders can be replaced by four, and eight

cylinders by six. The committee further assumes that (1) cylinder count is not reduced for existing 4-cylinder vehicles; (2) changes in cylinder count are in combination with other technological changes that increase peak horsepower per unit of displacement (overhead cam, four valves per cylinder) and preserve low-rpm torque (variable valve timing and life control); and (3) improvements in engine mountings and other areas can reduce the impact on vibration and noise of using engines with fewer cylinders, but some increases in noise, vibration, and harshness are probably unavoidable. The true consumer costs of such changes, therefore, are understated by their RPEs.

Transmission Technologies

Automotive transmissions are a means for varying the ratio of engine speed to vehicle speed, thus allowing the engine to operate somewhere in the optimum speed range and the automobile to operate over a wider range of speeds than would be feasible if the engine were connected directly to the drive wheels.

Transmissions affect fuel economy in two fundamental ways. First, energy is lost to friction within the transmission itself. Second, the wider the ratio range of the gears in the transmission and the more carefully controlled the transmission shift point, the more the engine can be kept in its most fuel-efficient operating regime over a wide range of operating speeds and loads without sacrificing performance. Both aspects can be manipulated to affect fuel economy.

Torque Converter Lockup

The torque converter of an automatic transmission transfers drive power from the engine to the transmission gears; that is, it serves the same purpose as the clutch in a manual transmission except that it also has torque multiplication capabilities. Both slippage and torque multiplication are present when the vehicle is starting from stop or changing gears to allow the synchronization of engine and gears. However, slippage during cruising wastes energy (Ledbetter and Ross, 1990). A torque converter with lockup eliminates slippage when the vehicle is cruising, which makes the converter 100 percent efficient under these conditions. Lockup may be applied to the top gear only, or to lower gears as well.

If engine and transmission speeds are not perfectly matched when the converter locks, a shock is transmitted to the drivetrain that the driver may be able to feel. In addition, the transmission of engine vibration to passengers increases. This has apparently caused some consumer dissatisfaction in the past, particularly in small 4-cylinder vehicles. Improved transmission controls and reduced vibration in 4-cylinder engines should ameliorate these problems and thereby make the lockup feature broadly applicable to cars and light trucks.

There is general agreement that the lockup torque converter increases fuel economy by about 2 to 3 percent. EEA (1991b) and SRI (1991) agree that it adds just over $50 to the price of a vehicle.

Electronic Transmission Controls

Control of automatic transmissions, which is conventionally executed hydraulically, can be improved by using more precise electronic control of gear shifting, with the result that the transmission will operate in the optimum gear a greater proportion of the time. Estimates of the fuel economy benefits of electronic transmission controls in the early 1980s suggested benefits on the order of 3 to 5 percent (EEA, 1991a). Since then, hydraulic systems have been optimized to produce maximum fuel economy over the EPA test cycle. As a result, SRI and EEA agree on a potential additional increase in fuel economy of only 0.5 percent. Others contend that a 1.5 percent increase is possible, perhaps by sacrificing some smoothness of operation for optimum shifting (Ledbetter and Ross, 1990). This technology is widely applicable to cars and trucks. Price estimates differ by a factor of five. EEA (1991b) suggests $24 and SRI (1991) $122.

4-Speed and 5-Speed Automatic Transmissions

In comparison with standard 3-speed automatic transmissions, the additional gear ratios provided by 4- and 5-speed automatics allow the engine to operate closer to its most fuel-efficient regime more of the time. EEA (1991b) claims a fuel economy benefit of 4.5 percent for 4-speed versus 3-speed automatic transmissions. Estimates provided by Chrysler, Ford, and General Motors are 2, 3, and 4 percent, respectively; and SRI suggests that 2.8 percent is achievable (see Table B-1).

For 5-speed versus 4-speed automatic transmissions, SRI (1991) estimates fuel savings of 0.5 percent and EEA (1991a) estimates 2.5 percent. EEA cites a published study by Nissan and unpublished results of tests by Mercedes Benz and Ford that suggest improvements in the range of 2 to 3 percent for 5-speed versus 4-speed transmissions.

Adding gear ratios tends to increase the size, weight, and cost of the transmission, however. Accommodating a 5-speed automatic transmission in minicompact and subcompact cars would be very difficult. Thus, in this analysis, the committee limited minicompact and subcompact cars and light trucks to 4-speed automatics (or continuously variable transmissions, see below), and projected only limited use of 5-speed automatics in the compact class.

As noted, the increased complexity of automatic transmissions with additional gear ratios adds to their cost. SRI (1991) suggests a price increase of $230 in moving from a 3-speed to a 4-speed automatic, and an additional $300 to add a fifth gear. EEA (1991b) is in close agreement about the incremental cost of a 4-speed transmission ($225), but it suggests that a fifth gear would add only $100 to the price.

Continuously Variable Transmissions

The continuously variable transmission (CVT) is based on an entirely different mechanism for connecting the engine and drive wheels in variable ratios. Instead of a set of intermeshing gears of different diameters, one design now in production uses

a continuous, flexible drive belt that engages two variable-diameter pulleys, one connected to the engine and one to the output. Sliding the sheaves of the pulleys together or apart to change their diameters changes the ratio of the rpm of the engine to the rpm of the drive wheels.

Within limits, the CVT offers an infinite number of gear ratios. In addition to allowing operation of the engine at its most efficient point regardless of changes in load and vehicle speed, the jerk-free shifting of gear ratios and absence of shock loading on the drivetrain hold out the possibility of reduced wear and a smoother ride (Newton et al., 1989).

Although there are several CVT designs, only Subaru offers one for sale in the United States. Major obstacles to widespread use of CVTs include the difficulty of control and the inability of existing designs to transmit high torque levels. Microprocessors and electronic controls promise to solve control problems (and also open up the possibility of regenerative breaking; Newton et al., 1989) and increase the fuel-savings potential of CVTs (SRI, 1991).

Newton et al. (1989) suggest that an optimized CVT could increase the fuel efficiency of vehicles engaged in stop-start operation by as much as 22 percent. Estimates for gains using proven technology in passenger cars are much lower. EEA (1991a) suggests that current CVTs can do no better than 5-speed manual transmissions; that is, about a 3.5 percent gain over 4-speed automatics (thus, 8 percent over a 3-speed automatic). Ford and Nissan data suggest 2.5 percent is possible, and General Motors and Chrysler estimate 0.5 and 1.0 percent, respectively, in comparison with 4-speed automatics. SRI (1991) reports that 1 to 2 percent is now possible and that gains in electronic controls are likely to increase the benefit.

EEA (1991b) estimates a price increase for a CVT of $100 per car above a 4-speed automatic and $325 above a 3-speed, and SRI (1991) estimates that a CVT would be priced at $410 more than a 4-speed automatic with torque converter lock-up, which implies an increase of over $600 over a conventional 3-speed automatic.

5-Speed Manual Transmission

Essentially all 4-speed manual transmissions have already been replaced by 5-speed manual transmissions. The theoretical benefit of a greater number of gears is the same as for the 5- versus 4-speed automatic transmission. The manual transmission has the additional advantage over an automatic of lower friction and thus greater efficiency. About a 1 percent fuel economy gain over a 5-speed automatic (or 8 percent over a 3-speed automatic without lock-up) is reasonable. The committee does not have price estimates for 5-speed manual transmissions, although the price is surely less than for 3-speed automatics, perhaps $150 less. However, due to limits on consumer acceptance of manual transmissions, the committee does not foresee major shifts from automatic to manual transmissions in the future.

ROLLING RESISTANCE, AERODYNAMICS, WEIGHT, PERFORMANCE

All of the above technologies are related primarily to the efficiency with which the drivetrain converts energy in the fuel into useful work. Fuel economy can also be increased by decreasing the amount of work necessary to propel the vehicle that is, by reducing energy needed to overcome inertia (weight), aerodynamic drag, and rolling resistance. A variety of technologies help in this regard.

Front-Wheel Drive

Compared with traditional rear-wheel drive, front-wheel drive (FWD) connects the engine to the drive wheels through shorter drive connections, requires a more complex front axle and steering system, moves more of the vehicle weight to the front wheels, and facilitates more efficient use of the interior space of the vehicle.

Despite the very widespread use of FWD and the large amount of accumulated experience, the literature offers quite different estimates of its impact on fuel economy and its cost. The differences seem to arise from different definitions of what is included in this technology. The primary benefit of FWD is that it makes it possible to reduce vehicle weight while preserving interior volume. FWD incorporates the driveshaft, rear axle, and differential in a single unit, which saves about 100 pounds. The FWD transaxle is typically a little more efficient than a rear-wheel-drive driveshaft and differential. SRI (1991) suggests an efficiency gain of 0.3 to 0.5 percent, and EEA (1991a) suggests 1.5 percent.

The majority of the fuel economy benefit of FWD comes from redesigning the vehicle to reduce exterior dimensions, which is facilitated by the transverse engine mounting and the absence of a driveshaft tunnel. During the late 1970s and early 1980s, vehicles were extensively downsized through repackaging associated with FWD and through conversion to unibody construction, without significant reduction in interior volume. A nearly complete transformation from rear- to front-wheel drive was achieved at that time. If one compares the average weight per interior volume for different size classes of vehicles currently being sold, the FWD vehicles have 10 to 19 percent lower ratios of weight to interior volume (EEA, 1991a). Weight reductions of this magnitude would increase fuel economy by 6.6 to 12.5 percent. At the midpoint of this range, the resulting fuel economy improvement for FWD, including efficiency improvement and all weight effects, should therefore be between 10 and 11 percent.

The RPE of FWD drive conversion has been estimated at $240 by EEA (1991b) and at $25 or more by SRI (1991). The SRI estimate does not include the costs of repackaging and major weight reduction, however.

Aerodynamics

Aerodynamic drag is a force opposing the motion of a vehicle that results from the resistance of the ambient air to the movement of the vehicle through it. Quantitatively, drag is proportional to the product of the frontal cross-sectional area of a vehicle, the square of its velocity, and its coefficient of drag (CD). Thus, energy lost in overcoming

aerodynamic drag is related to the CD, which is a function of the shape of the vehicle and the many details of its surfaces.

Reducing cross-sectional area usually reduces the interior size of a vehicle and is thus of limited value in reducing drag. Driving slower reduces drag force, which is a considerable part of the motivation for the 55-mph speed limit. However, changing actual road speeds is not a consideration in EPA's Federal Test Procedure (FTP), so the committee focused on reducing in the drag coefficient as the only available means of reducing drag.

Complete data on drag coefficients for current automobiles are not available. EEA (1991b) has estimated that the average CD for 1988 model year vehicles was in the range of 0.37 to 0.38. Numerous makes and models are available with drag coefficients in the range of 0.30 to 0.33, and the best available models have drag coefficients below 0.30. Therefore, 10 and even 20 percent reductions in CD are entirely feasible. Although drag coefficients for light trucks are not likely to go as low as those of passenger cars, the committee sees no reason that a 10 percent CD reduction for trucks is not equally feasible.

Over the EPA FTP, fuel economy varies with drag (and hence the CD) with an elasticity of 0.2. That is, a 10 percent reduction in CD will produce a 2.3 percent increase in miles per gallon (OTA, 1991), and SRI (1991) cites 2.4 percent.

If reductions in the drag coefficient are timed to coincide with the periodic redesign of vehicles, the extra cost should be small. However, as drag is reduced by more than 10 percent, significant costs must be incurred for such changes as flush windows and improved fit of body parts. Reducing CD below 0.29 may require using a covered underbody, which would have a significant impact on price (EEA, 1991a). EEA (1991b) estimates $32 for the first 10 percent reduction and $48 for the second. SRI (1991) indicates that the first 10 percent reduction will cost more — about $60.

Weight Reduction

Lighter vehicles require less energy to overcome inertial forces (acceleration, hill climbing, and turning).6 Over the EPA test cycle, fuel economy is sensitive to simple weight reduction, with an elasticity of 0.5 (SRI, 1991). That is, a 10 percent weight reduction yields a 5 percent fuel economy increase. Holding performance constant, reduced vehicle weight allows reduced engine power and size, which adds to the fuel economy benefit of direct weight reduction. EEA (1991b) suggests an elasticity of 0.66 for the combined effect (this elasticity is smaller than would be suggested by the independent effects of a 10 percent reduction in weight and a 10 percent reduction in displacement).

Materials substitution and downsizing of components could yield a 10 percent weight reduction in the post-1995 time period, according to SRI. EEA cites work by the Department of Transportation indicating that increased use of high-strength, lowalloy steel, plastics, aluminum, and graphite-fiber-reinforced plastics could reduce vehicle weights by up to 30 percent. A weight reduction of 10 percent during the time frame of this study seems quite feasible and should be applicable to all light-duty vehicle types.

The cost of materials substitution will depend on the details of what materials are substituted where and on the associated changes in part and component designs. SRI (1991) provides estimates of RPEs for weight reductions of 1, 5, and 10 percent over 1995 model year vehicles weighing 3,000 pounds. The RPEs respectively are $50, $120, and $470, for roughly 30-, 150-, and 300 pound reductions in weight. (The price estimate for the 5 percent weight reduction does not appear to be consistent with the other two since it implies costs of under $1 per pound of weight removed. This difference could reflect a different strategy.) EEA (1991a) cites price estimates of $0 to $0.20 per pound of weight removed using glass-fiber-reinforced plastic body panels, and $0.40 per pound for use of aluminum. These estimates would put the price of a 10 percent weight reduction at less than $150.

Electric Power Steering

Electric power steering is one of many types of accessories. It is treated separately here because of its apparently higher cost and uncertainty about its stage of development. Commonly used hydraulic power-steering pumps use a significant fraction of engine power, particularly at low speeds. Replacing them with an electric motor can produce fuel economy gains of 1 percent or more. EEA suggests that the size and power requirements of motors for electric power steering may preclude its application in large vehicles (EEA, 1991a). SRI estimates that the RPE of electric power steering will be $60 or more.

Advanced Tires, Rolling Resistance

Rolling resistance arises primarily from the generation and dissipation of heat due to the periodic flexing of the tires as they bear the weight of the vehicle and provide driving, braking, and cornering forces while rotating. During ordinary driving, only a very small part of tire rolling resistance is due to slippage between the tire and the road and to aerodynamic drag. On the EPA urban driving test cycle, tire rolling resistance consumes about one-fourth to one-third of the energy delivered to the wheels (Ledbetter and Ross, 1990; MacCready, 1989). EEA (1991a) estimates that a 10 percent reduction in tire rolling resistance produces a 2 percent fuel economy benefit over the EPA test cycle. There seems to be good agreement between EEA and SRI (1991) that tire rolling resistance can be reduced by about 10 percent over the next decade or so. The result should be a 2 percent gain in fuel economy, but customer-driven trends toward high-performance tire designs may eliminate half of this gain according to EEA.

The price of reducing rolling resistance is expected to be modest, on the order of $20 per car according to EEA (1991b) and SRI (1991). There should be no limits to applicability of improved tires. However, some trade-offs with wet traction are expected.

Reductions in Performance

In recent years, typical passenger-car and light-truck performance levels have risen substantially. This is true whether performance is measured in acceleration time or horsepower-to-weight ratios (Heavenrich et al., 1991). Since 1987, 0 to 60 mph times have dropped 11 percent for passenger cars and light trucks. Horsepower-to-weight ratios rose by as much as 16 percent and 17 percent for various classes of cars and light trucks, respectively, over the same period. Had performance levels remained constant since 1987, the committee estimates that, on the assumption that a 1 percent reduction in engine performance (horsepower/weight ratio) is associated with a 0.38 percent increase in fuel economy (see Chapter 7), fleet-average fuel economy would now be about 2 mpg higher.

Reducing performance by reducing engine size yields a significant fuel economy benefit, but at the direct cost of performance if engine technology is unchanged. A 10 percent reduction in engine size can increase fuel economy by 3 to 4 percent. There should be no direct price increase associated with performance reduction; in fact, it should reduce cost. However, to the extent that consumers prefer higher performance levels, consumer satisfaction would be reduced.

REFERENCES

American Honda Motor Company, Inc. 1991. Statement of American Honda Motor Co., Inc., on Automotive Technologies for Fuel Economy before the Subcommittee on Environment, House Science, Space, and Technology Committee, October 2, 1991. Washington, D.C.

Berger, J.O., M.H. Smith, and R.W. Andrews. 1990. A system for estimating fuel economy potential due to technology improvements. Paper presented at the workshop of the Committee on Fuel Economy of Automobiles and Light Trucks, Irvine, Calif., July 8-12. University of Michigan, Ann Arbor.

Duleep, K.G. 1991. Honda's new Civic VTEC-E model. Memorandum for Oak Ridge National Laboratory and U.S. Department of Energy, August 14. Energy and Environmental Analysis, Inc., Arlington, Va.

Energy and Environmental Analysis, Inc. 1991a. Documentation of Attributes of Technologies to Improve Automotive Fuel Economy. Prepared for Martin Marietta, Energy Systems, Oak Ridge, Tenn. Arlington, Va.

Energy and Environmental Analysis, Inc. 1991b. Fuel economy technology benefits. Presented to the Technology Subgroup, Committee on Fuel Economy of Automobiles and Light Trucks, Detroit, Mich., July 31.

Ford Motor Company. 1991. Technology benefit/methodology. Attachment 1 of letter of August 14, from Alan D. Gilmour to Richard A. Meserve, chairman of the Committee on Fuel Economy of Automobiles and Light Trucks: table entitled Comparison of Optimum Technology Fuel Economy Percent Benefits Provided to NAS.

Heavenrich, R.M., J.D. Murrell, and K.H. Hellman, 1991. Light-duty Automotive Technology and Fuel Economy Trends Through 1991. Control Technology and Applications Branch, EPA/AA/CTAB/91-02. Ann Arbor, Mich.: U.S. Environmental Protection Agency.

Honda Motor Company, Ltd. 1991. Fuel economy estimate for NAS panel. Presented to the Technology Subgroup, Committee on Fuel Economy of Automobiles and Light Trucks, Detroit, Mich., July 31.

Ledbetter, M. and M. Ross, 1990. Supply curves of conserved energy for automobiles. Proceedings of the 25th Intersociety Energy Conservation Engineering Conference. New York: American Institute of Chemical Engineers .

Newton, K., W. Steeds, and T.K. Garrett. 1989. The Motor Vehicle. 11th ed. London: Butterworths.

Office of Technology Assessment (OTA), U.S. Congress. 1991. Improving Automobile Fuel Economy: New Standards, New Approaches. Washington, D.C.: U.S. Government Printing Office.

SRI International. 1991. Potential for Improved Fuel Economy in Passenger Cars and Light Trucks. Prepared for the Motor Vehicle Manufacturers Association. Menlo Park, Calif.

APPENDIX C

EMERGING ENGINE TECHNOLOGIES AND CONCEPT AND PROTOTYPE VEHICLES

EMERGING ENGINE TECHNOLOGIES

Lean-Burn Engine

Internal combustion engines burn a mixture of fuel and air; the air is the source of oxygen needed to engage in the chemical reaction with the fuel known as combustion, or burning. In standard engines, the ratio of air to fuel is set at or very near that which ensures that there is sufficient oxygen in the mixture to burn all of the fuel, yet not an excess amount of air.

A lean-burn engine is designed and operated so that some excess air over and above that needed for complete combustion is introduced into the combustion chambers. The term lean burn is also sometimes used to describe an engine in which exhaust gases, rather than excess air, are used to dilute the air/fuel mixture. In a lean-burn engine, the air/fuel mixture may be homogeneous (well mixed) or stratified (the fuel is concentrated in only a portion of the mixture). The diesel engine uses stratified lean combustion, and the Honda VTEC-E engine (discussed below) uses a small degree of stratification.

Assuming that the rate and completeness of combustion can be maintained, fuel economy increases with the addition of excess air to the air/fuel mixture (Lichty, 1967). However, wide-open-throttle (WOT) power decreases because not as much fuel is burned. Because of its potential for increased fuel economy, the homogeneous, lean-burn approach was investigated extensively in the 1960s and early 1970s as an alternative emissions-control approach to the three-way catalyst, which requires use of a stoichiometric air/fuel ratio (A/F) of approximately 14.6, when gasoline is the fuel, which yields lower fuel economy. However, at that time, the lean-burn engine could not meet emissions and drivability requirements and its development was discontinued. Its current revival is due to its acknowledged fuel economy advantage, combined with the availability of electronic fuel injection, which makes possible the use of lean-burn conditions in selected portions of the driving cycle.

If the air/fuel mixture is homogeneous and excess air is added beyond that required for complete combustion, production of oxides of nitrogen (NOx) increases up to a maximum and then begins to decrease. However, if recirculated exhaust gas

(usually referred to as exhaust gas recirculation, or EGR), rather than air, is used as the diluent, NOx continually decreases. The explanation is beyond the scope of this report, but it involves the effect of excess oxygen, flame temperatures, and nonequilibrium effects in the decomposition of NOx.

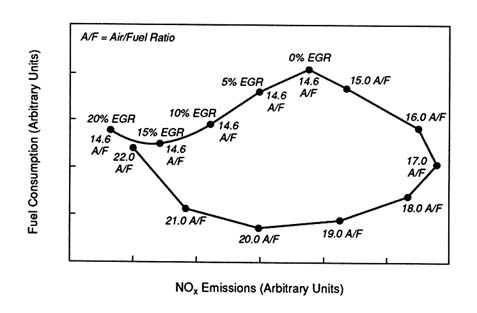

Figure C-1 shows the relationship of fuel consumption to NOx emissions for various combinations of excess air and EGR in the air/fuel mixture. The starting point for the discussion is a stoichiometric air/fuel mixture without EGR (the highest point on the upper curve, where EGR = 0% and A/F = 14.6). As excess air is added (moving to the right from the starting point), NOx production increases, reaching a maximum at an A/F = 17.0. Further addition of air beyond A/F = 17.0 (moving to the left on the lower curve) leads to a continuous decrease in NOx. However, when EGR rather than air is added to a mixture (moving to the left from the starting point), NOx decreases continuously up to 20 percent EGR.

Figure C-1 also illustrates the relationship between fuel consumption and mixture composition, with excess air and with EGR. Again, moving to the right from the starting point (EGR = 0% and A/F = 14.6), adding excess air continuously decreases fuel consumption until an A/F of approximately 20 is reached, after which fuel consumption increases. The explanation for this pattern is also complicated. It involves reduction in the burning rate with increased dilution, reduction in engine pumping losses, and heat transfer. The same but weaker trend—decrease, then a slight increase—is observed for fuel consumption as EGR increases.

FIGURE C-1 Relationship of fuel consumption to production of oxides of nitrogen (NOx) in a lean-burn engine at various air to fuel ratios (A/F) with and without exhaust gas recirculation (EGR).

SOURCE: Adapted from Ford Motor Company (1991).

When excess air is used, the conventional three-way catalyst is not effective in reducing NOx, although it does serve as an oxidizing catalyst for the unburned hydrocarbon (HC) and carbon monoxide (CO) in the lean-burn operating regime if the exhaust temperature is sufficiently high. A three-way catalyst is effective in reducing NOx when EGR is added to a stoichiometric mixture. However, WOT power decreases as either excess air or EGR is added to the air/fuel mixture in an engine since less fuel is burned. Consequently, stoichiometric or richer (excess fuel) air/fuel ratios without EGR are often used at WOT. And, when either excess air or EGR is added, the burn rate decreases and combustion instability increases, so that HC and CO emissions may become excessive.

The Honda VTEC-E engine gives some clues as to the fuel economy potential of lean-burn engines, although determining how much of its performance is due to the lean-burn feature and how much is due to other changes from the standard engine is difficult. It should be noted that the California VTEC-E version uses EGR to dilute a stoichiometric air/fuel mixture, but the VTEC-E for the other 49 states uses excess air as the diluent. As a consequence, the 49-state version has a 44 percent fuel economy increase while the California version has a 34 percent increase.

The Honda Civic VE with VTEC-E engine differs from the standard Honda Civic not only in the use of lean-burn technology but also in use of variable valve timing; an overall 5 percent weight reduction; improved aerodynamics; reduced rolling resistance through the use of special tires, bearings, and seals; reduced accessory load through the use of a ''smart" alternator; reduced engine friction; and a higher rear-axle ratio made possible by the increased torque of the variable-valve-timing system. Because all of these changes can increase fuel economy, it is unclear how much of the fuel economy enhancement of the Civic with VTEC-E over the standard model arises from the engine itself.

Duleep (1991) attributes the 10 percentage point difference in fuel economy improvement between the California and 49-state versions to use of the lean-burn feature in the 49-state model. In Figure C-1, the difference between the minimum fuel consumption using EGR and that using excess air is about 7 to 8 percent. However, since lean-burn conditions are used for only a fraction of the operating regime of engine load and speed, the 10 percent allocation seems generous.