MATTHEW A. WILLARD

Case Western Reserve University

A fundamental transformation of the transportation sector in the United States is under way (Electrification Coalition 2009). In parallel with advances in renewable energy resources for power generation, the rising use of electric and hybrid electric vehicles (EVs and HEVs) is starting to change the future of civilian transportation. Similar efforts are moving forward for “more electric” ships, aircraft, and other military technologies.

Most people don’t think of magnetic materials in association with EV/HEVs, but they play an important role in improving the efficiency and performance of devices in electric power generation, conditioning, and conversion (Chau and Chan 2007).1 In fact, many functions in modern vehicles would not be possible without advanced magnetic materials: they are used in safety features, engines, controls, braking, and in motors and actuators used for fans, pumps, wipers, and locks.

In transportation technologies, reliability, power density, and overall energy capacity are essential. Yet, despite the vast array of vehicle technologies that use magnets, the unique power systems used to supplement (or replace) the internal combustion engine remain a challenge for magnet designers. Specifically, improvements are needed in “permanent” magnetic materials for motors and generators and in “soft” magnetic materials for inverters and power electronics. In addition, the availability of critical materials for permanent magnets is a growing concern.

__________

1Conversion refers to changes from DC (from batteries) to AC (from generators) and vice versa. Conditioning refers to filtering of electric power. These are accomplished by inverters or power electronics in EVs.

The following sections address state-of-the-art magnetic materials and briefly describe research to improve their performance.

DEFINITION OF TERMS

Two parameters determine magnetic performance: saturation magnetization (“magnetization”) and coercive field (“coercivity”). Magnetization is the density of magnetic moments in a ferromagnetic material. A material with higher magnetization can produce larger external magnetic fields than a same-sized material with lower magnetization, and by the same token requires less material to achieve the same magnetic field.

In addition to the level of saturation magnetization, some magnetic materials, called “soft” magnets, require the application of an external magnetic field to align their magnetic moments and others, called “hard” or permanent magnets, produce significant magnetic field without an applied field. The distinguishing characteristic between these classes of materials is their coercivity, the intensity of the magnetic field required to reduce the magnetization to zero.

Hard and soft magnetic materials were refined during the 20th century to provide optimal performance for applications in which magnetization is either very resistant to switching when a magnetic field is applied (i.e., hard or permanent magnets) or easily switched when a magnetic field is applied (i.e., soft magnets) (Gutfleisch et al. 2011). Hard magnetic materials are characterized by large coercivities (more than ~10 kiloamperes per meter, or kA/m) and greater energy storage, making them useful for motor and generator applications. Soft magnetic materials, which have a low value of coercivity (less than ~400 amperes per meter, or A/m), are used in applications that require easy switching, such as induction motors, inverters, and power electronics (Emadi et al. 2008).

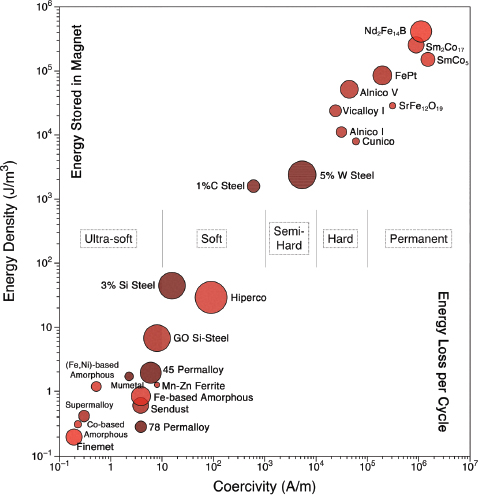

Coercivities available today span 8 orders of magnitude between the softest and hardest magnetic materials (Figure 1). Progress in the development of magnetic materials has been accomplished with jumps in performance when new materials are introduced, followed by incremental steps as compositions and processing steps are refined to provide the best microstructures and phase combinations.2

The following sections focus on each class of magnetic material and some of the current technological issues being addressed by researchers.

PERMANENT MAGNETS

Rare Earths and Their Challenges

High-performance permanent magnets typically used in EVs and HEVs are made of rare earth elements (largely neodymium [Nd] and dysprosium [Dy]), a

__________

2A phase is a chemically distinct region in a material that possesses uniform physical properties.

FIGURE 1 Energy density plotted against coercivity for state-of-the-art magnetic materials. The materials in the top part of the figure are used in applications where the magnetization is fixed in the material, resulting in energy storage in the magnet (i.e., permanent magnet). The materials in the bottom part of the figure are used in applications where the magnetization is switched frequently, resulting in an energy loss per cycle (i.e., soft magnets). Desirable characteristics are maximum energy storage (in permanent magnets) or minimum energy loss (in soft magnets) per cycle. The circle size is proportional to the size of the material’s magnetization. A/m = amperes per meter.

magnetic transition metal element (iron [Fe]), and a metalloid element (boron [B]). The rare earth elements provide a considerable magnetocrystalline anisotropy and are responsible for the energy storage capacity of these alloys, and iron provides a relatively large magnetization. These alloys have been refined over the past 30 years into premier permanent magnet materials with the largest energy storage capability (Figure 1, top). However, the growing market and in some cases the

scarcity of some rare earth elements have driven recent research efforts to consider alternative materials or ways of reducing the amount of rare earth elements in permanent magnets (Alonso et al. 2012; Sugimoto 2011).

Light rare earth elements (e.g., Nd, praseodymium [Pr], lanthanum [La]) are not actually rare—their natural abundances are similar to those of copper and nickel. Why then is there concern about rare earths? First, they are difficult to separate from each other as they bond through 4-d electrons, which are the same for all rare earth elements. Second, they are very reactive with oxygen, adding to the difficulty of refining them as metals. Third, the heavy rare earths (e.g., Dy, terbium [Tb]), which are essential to extend use to the 200°C required for EV/HEV operation, are scarcer than the light rare earths (Gutfleisch et al. 2011). Finally, Chinese companies dominate mining for all rare earths and exports are expected to decline in the coming years because these resources are used entirely for Chinese domestic products. For these reasons, alternative, rare earth—free materials have become a topic of intense research.

Alternatives to Rare Earths?

Theoretically, nanocomposite magnetic materials consisting of a mixture of finely divided regions of soft and hard magnetic phases (less than 10 nm in diameter) can improve energy storage while reducing the rare earth content of the alloy. However, simply mixing the typically available powders (5–10 μm in diameter) of hard and soft magnetic materials and pressing them together to full density will not produce the desired improvement. Rather, the powders would have to be nanoparticles no larger than 15 nm in order to achieve the required microstructure and concomitant improvement in energy storage. If a nanocomposite microstructure were produced, permanent magnets could provide energy storage of ~1.1 MJ/m3—nearly a factor of 3 more than available today—and at 10% of the required amount of rare earths! But since the hypothesis in 1991 of this type of alloy (Kneller and Hawig 1991), it has not yet been demonstrated in the bulk form necessary for motors and generators.

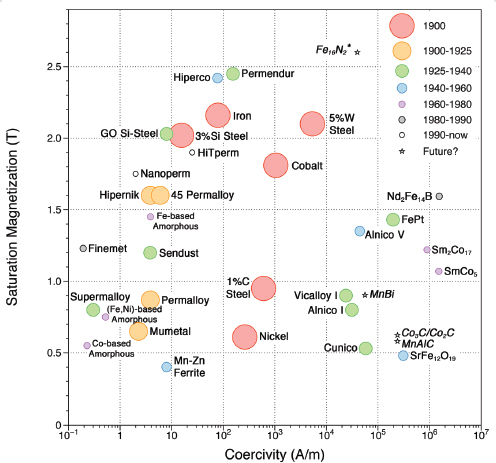

Other, more radical ideas include the complete elimination of rare earths in favor of a variety of unusual substitute materials such as manganese aluminide (MnAlC), manganese bismuthide (MnBi), iron nitride (Fe16N2), and cobalt carbides (Co3C/Co2C). Figure 2 illustrates the differences in magnetization and coercivity of these and other materials.

SOFT MAGNETS

Soft magnetic alloys do not suffer from the same critical materials problem that plagues rare earth permanent magnets. However, the trend to miniaturization of soft magnetic components while maintaining energy efficiency is important as

FIGURE 2 Saturation magnetization plotted against coercivity for state-of-the-art magnetic materials. Symbol size and color identify discovery date. Magnetic softness improves to the left, and magnetic hardness improves to the right. The second star next to Fe16N2 designates an estimate from thin film values. This figure appears in color in the online posting of this article at http://www.nap.edu/catalog.php?record_id=18185.

electrical generation and conversion technologies require more power (Willard and Daniil 2013).

Miniaturization can be achieved by increasing magnetization and/or switching frequency. The latter affords the most significant reduction, but the materials lose some energy as heat (i.e., core losses) during each switching cycle, resulting in energy inefficiency (see Figure 1, bottom). These core losses appreciably increase with switching frequency, so conventional materials do not perform well under these conditions. Suitable candidates for high-frequency use are amorphous

and nanocrystalline alloys, which possess low coercivity and high electrical resistivity. Higher switching frequencies are of increasing importance for vehicle electrification when power electronics are considered for conditioning and conversion because higher frequencies enable greater component miniaturization.

Recent advances in nanocrystalline soft magnetic alloys provide materials that are energy efficient to hundreds of kHz, with larger magnetization than comparable amorphous alloys and good thermal stability (to 500°C in some cases) (Willard et al. 2012). However, mechanical brittleness and difficulties with processing in ambient air have limited the widespread use of these materials.

OUTLOOK

Improvements in soft magnetic properties through continued development in processing-microstructure-property relationships will provide the premier materials of the future. For nanocrystalline soft magnetic alloys, refinement of compositions to enhance energy efficiency (i.e., reduce core losses), mechanical performance (i.e., reduce brittleness), and air-processability are expected to advance this technology in the near future. For permanent magnets, advances in nanostructured composite materials, produced in bulk with crystallographic texture (i.e., crystal alignment), will show the most near-term technology improvement.

With new, rare earth—free options being explored extensively, the future of magnetic materials for vehicle electrification can be viewed optimistically. This is especially true with current research interests in low-cost Fe16N2 and high-anisotropy MnAl compounds. With a considerable investment, as was made for rare earth permanent magnets over the past 30 years, a rare earth—free material capable of operating at temperatures to 200°C is certainly possible in the next 10 to 15 years.

REFERENCES

Alonso E, Sherman AM, Wallington TJ, Everson MP, Field FR, Roth R, Kirchain RE. 2012. Evaluating rare earth element availability: A case with revolutionary demand from clean technologies. Environmental Science and Technology 46:3406–3414.

Chau KT, Chan CC. 2007. Emerging energy-efficient technologies for hybrid electric vehicles. Proceedings of the IEEE 95(4):821–835.

Electrification Coalition. 2009. Electrification Roadmap: Revolutionizing Transportation and Achieving Energy Security. Washington. Available online at www.electrificationcoalition.org.

Emadi A, Lee YJ, Rajashekara K. 2008. Power electronics and motor drives in electric, hybrid electric, and plug-in hybrid electric vehicles. IEEE Transactions on Industrial Electronics 55(6):2237–2245.

Gutfleisch O, Willard MA, Brück E, Chen CH, Sankar SG, Liu JP. 2011. Magnetic materials and devices for the 21st century: Stronger, lighter, and more energy efficient. Advanced Materials 23:821–824.

Kneller EF, Hawig R. 1991. The exchange-spring magnet: A new material principal for permanent magnets. IEEE Transactions on Magnetics 27(4):3588–3600.

Sugimoto S. 2011. Current status and recent topics of rare-earth permanent magnets. Journal of Physics D: Applied Physics 44:064001.

Willard MA, Daniil M. 2013. Nanocrystalline soft magnetic alloys: Two decades of progress. In: Buschow KHJ, ed. Handbook of Magnetic Materials, chapter 4. Amsterdam: Elsevier. In press.

Willard MA, Daniil M, Knipling KE. 2012. Nanocrystalline soft magnetic materials at high temperatures: A perspective. Scripta Materialia 67:554–559.