Workshop Presentations and Discussions

WELCOME: WHAT IS DMMI? AND MEETING OBJECTIVES

Robert H. Latiff, Chair, DMMI Standing Committee

Dr. Latiff welcomed the participants to this fifth meeting of the National Research Council’s (NRC’s) Standing Committee on Defense Materials, Manufacturing, and Infrastructure (DMMI). The DMMI, which is associated with the NRC’s National Materials and Manufacturing Board (NMMB), was formed at the request of Reliance 21, a Department of Defense (DOD) group of professionals that was established to enable the DOD science and technology (S&T) community to work together to enhance Defense S&T programs, eliminate unwarranted duplication, and strengthen cooperation among the military services and other DOD agencies. As its name indicates, the focus of DMMI is on issues relevant to materials, manufacturing, and the infrastructure that sustains the materials and manufacturing enterprises essential to national defense.

Dr. Latiff noted that this workshop had originated in conversations with members of the Reliance 21 Materials and Processing community of interest on issues of parts obsolescence, diminishing sources for manufacturing, certification of spare parts, requalification of materials, counterfeiting, and other quality assurance and maintenance problems for DOD as defense systems are kept for longer and longer service lives. Dennis Chamot, associate executive director of the NRC’s Division on Engineering and Physical Sciences and currently the acting director of the NMMB, reviewed the NRC procedures applicable to workshops. As such the workshop was

an open meeting, and any publication produced from it would be publicly available. No classified, proprietary, or for official use only (FOUO) information was presented or discussed during it. This workshop summary recounts the discussions and presents the views of individual participants; there are no conclusions or recommendations that reflect a corporate or consensus position of the DMMI, the NMMB, or any other entity of the NRC.

Lewis Sloter, OSD Principal Reliance 21 Materials and Processes Community of Interest

Dr. Sloter described how the Reliance 21 Materials and Processes community of interest had worked with the DMMI to develop a workshop agenda covering the broad area of materials sustainability with respect to defense equipment, infrastructure, and recapitalization. Critical materials substitution and demand reduction were addressed at a previous DMMI meeting and remain a focus of DOD planning. Two weeks before this workshop, the Institute for Defense Analyses (IDA) held a workshop on issues related to specific materials and approaches to reduce vulnerabilities related to them. Sustaining adequate supplies of materiel, particularly with respect to equipment refurbishment and recapitalization, is currently important to planning for future utilization of the mine-resistant ambush protected (MRAP) vehicles fielded during Operation Iraqi Freedom. Normalization and global support for the F-35 Joint Strike Fighter aircraft is another highly topical issue, as is the broad subject of strategic manufacturing and local supply. Materials supply, utilization, certification, and substitution will be important aspects of Pentagon discussions on strategic sourcing, offshoring, and the control and prevention of counterfeit parts in the electronic and mechanical subsystems of critical defense systems. Dr. Sloter said these issues would provide grist for the materials research mill.

Dr. Sloter sees the twenty-first century as a time when material technologies will see significant advances. He expects rapid manufacturing in small volumes to be important in many areas, including pharmaceuticals, mechanical components, and electronic components. New manufacturing, printing, and templating technologies will be among the great opportunities to continue the advances reflected in Moore’s law for microprocessor-based systems. The difficulty will be in making the best use of limited resources to pursue the applied research and development (R&D) opportunities with the greatest potential benefits, given the broad range of opportunities and challenges.

Dr. Sloter was asked for his perspective on how much further improvement can be expected in structural materials, such as materials for hypersonic flight or other cutting-edge applications where material properties are a constraint. Are DOD

priorities being focused more on near-term problems or far? He replied that fundamental, curiosity-driven research, which is long-range and opportunistic with respect to using new discoveries, is very healthy. Near-term sustaining research, broadly speaking, is also very healthy. It is coming out of a period that focused on multiple-point approaches to addressing solutions for specific operational, maintenance, and sustainability problems by the rapid application of relatively mature materials and processes to systems fielding and sustainment. The defense community is also coming out of a long period of ameliorating the environmental impact of materials processes such as plating and coating processes. He is concerned about the prospects for near-term maturation of materials and processes in areas such as hypersonics. Mechanical designs to provide thermal protection are probably ahead of the complementary development of specific materials. In areas like hypersonics, there may be a switch from technology push by innovative material solutions to requirements pull from prototype systems development.

Another participant suggested that some of the challenges appear to be in putting the right teams together to address, from a systems perspective, problems that are multidisciplinary. Is DOD moving toward that team-building approach in any of its programs? Dr. Sloter replied that he has seen a positive trend toward teaming during his 14 years in the Pentagon. He cited as an example the close interactions among Joint Staff, requirements developers in the services, acquisition managers, and industrial base policy staff within the Pentagon. He also sees some good examples of teaming in large integrated programs such as the F-35 Joint Strike Fighter and in some of the integrated teams at the Defense Advanced Research Projects Agency (DARPA). There have also been some lessons learned from programs that did not do as well. He agreed that there was still a long way to go before defense engineering and manufacturing achieve the level of integrated planning characteristic of the automobile industry, for instance.

Several other participants gave examples of defense industry companies that have initiated efforts in integrated computational materials engineering (ICME) in their DOD contract work, without being driven in that direction by DOD program management.

THE AIR FORCE RESEARCH LABORATORY AND MATERIALS ISSUES

Dr. Stevens began by noting that the Air Force Research Laboratory (AFRL) is concerned about the sustainability of future weapon systems, as well as about technology for keeping the existing legacy systems flying. Some of the required technology is related to materials and processes. AFRL’s Materials and Manufacturing

directorate has cradle-to-grave responsibilities for materials and manufacturing, which means it is involved in sustainability and cost of future materials and systems, as well as the life-cycle management problems associated with maintaining and sustaining the aircraft “on the ramp” today. In 2012 the new Air Force Life Cycle Management Center (AFLCMC) was created, replacing the Aeronautical Systems Center. The new center is responsible for supporting aircraft weapon systems through their entire life cycle.

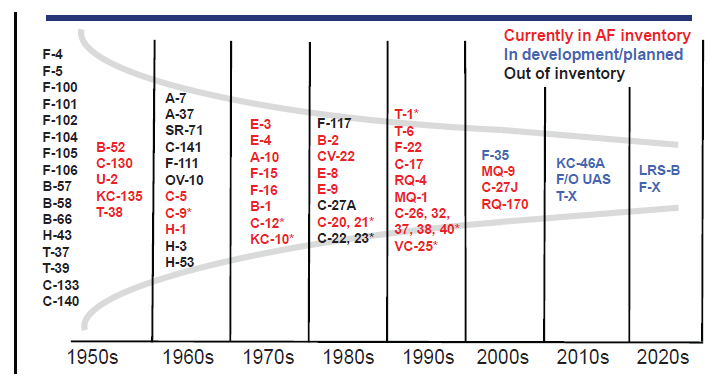

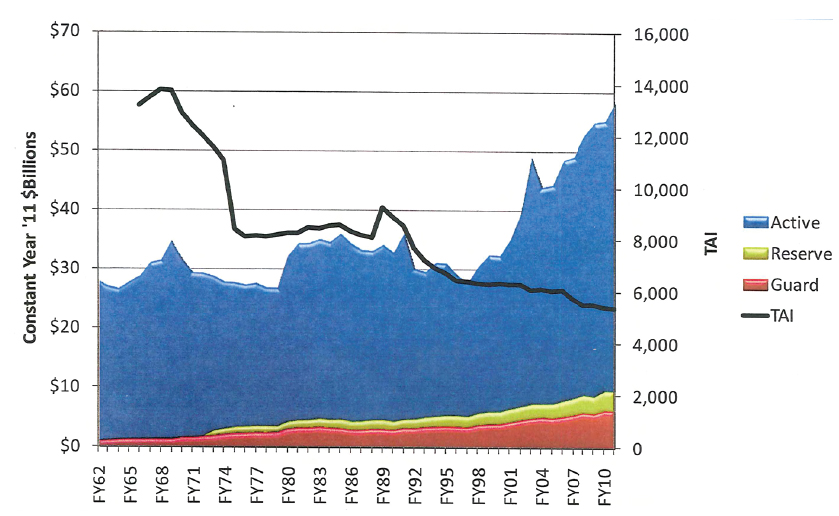

As context for the Air Force’s problem of aging aircraft, Dr. Stevens showed a chart of the systems that had been introduced in each decade since the 1950s, with those still in the inventory shown in red, those out of the inventory in black, and systems in development shown in blue (Figure 1). The average aircraft has been in service for 23 years, with fighter aircraft averaging 22 years, tankers 35 years, and bombers 47 years. Even though the current fleet is the smallest in numbers of aircraft since the inception of the Air Force, the cost of sustaining the fleet continues to rise (Figure 2).

The AFRL sustainment investment is divided among three research thrusts:

• Supporting sustainment of the current fleet (field and depot sustainment);

• Improving fleet health management; and

• Enabling robust design of new systems through use of advanced tools, techniques, and processes.

FIGURE 1 Air Force legacy and projected aircraft inventory. Year of first flight or, as denoted by an asterisk, first appearance of a commercial derivative in the Air Force inventory. SOURCE: AFSAB, 2011, p. 13.

FIGURE 2 Size of total aircraft inventory (TAI) and cost of fleet operation and maintenance, FY 1962-2010. SOURCE: Katherine Stevens, AFRL, “AFRL and materials issues,” presentation to the committee on July 23, 2012, Slide no. 7.

A recent example in the first research thrust was technical information provided to support risk-mitigation actions in response to the discovery that nonconforming titanium had been used to fabricate aircraft parts in the inventory. By identifying the impact of nonconforming material on the parts’ properties to enable a component risk analysis for Air Force weapon systems, the Directorate was able to help limit the scope of the problem. Currently, using a part, component, or subsystem in a different system (aircraft) than the one for which it was qualified or certified requires requalifying or recertifying it for the system(s) of potential use. This pervasive qualification process demonstrates the challenge of ensuring system safety when common materials or components are not properly tracked.

With respect to improving fleet health management, Dr. Stevens said that the ultimate Air Force objective is to move to condition-based maintenance. The Materials and Manufacturing directorate’s research in nondestructive evaluation and inspection (NDE/I), such as research in multilayer crack detection, advances the move toward this objective, as does development of the capability to capture, retain, and rapidly retrieve analyses of materials and component or subsystem health from NDE/I data. In the short term, Air Force depots have adopted high-velocity maintenance for rapid turnaround, and they need appropriate evaluation techniques to support knowledge of systems before the systems or components

reach the depot for maintenance and repair. Techniques for doing this are being developed.

Dr. Stevens remarked that sustainment is potentially a very rich application area for activities under the Materials Genome Initiative (MGI), even though the focus of attention has been on MGI objectives for new materials in new applications. For example, if a system in the fleet has a sustainment problem, reducing the time to fix the problem and certify a new material or new parts can go a long way to keeping aircraft flying. There was further discussion among the participants on the potential impact of MGI on sustainability. One participant said that the same tools needed to enable ICME would also enable more rapid qualification or certification of a replacement material or part. Dr. Stevens added that AFRL has projects and programs that support both ICME and MGI. AFRL’s vision for the future is to move away from the current linear paradigm for the material life cycle—in which material and processes research leads sequentially through materials development, component design, component testing, certification/qualification, manufacturing, and sustainment—to an R&D paradigm in which all these stages in the life cycle are examined interactively and in parallel through an integrated approach.

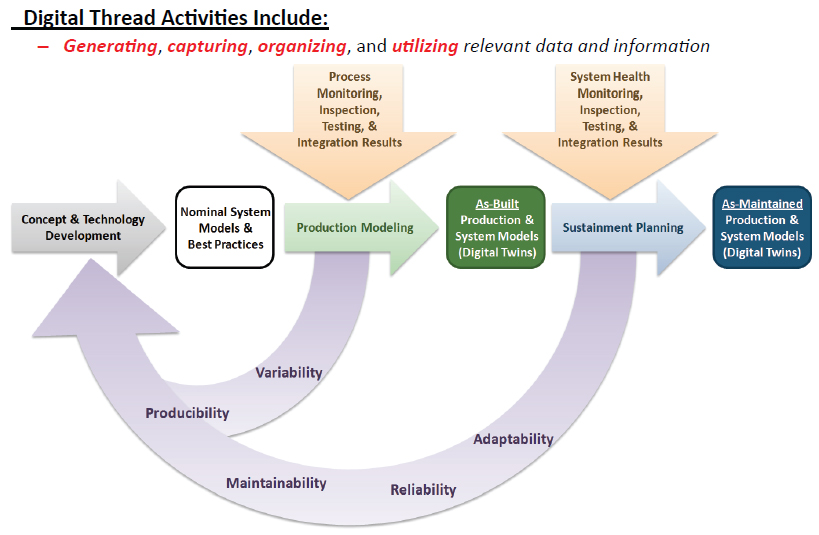

The manufacturing portion of this integrated life-cycle approach includes a concept called “moving manufacturing to the left” (addressing manufacturing issues earlier in the R&D process) and a digital data collection and archiving component called the “cradle-to-grave digital thread.” While the objective of the former is to enable earlier development of game-changing products and manufacturing process technologies, the cradle-to-grave digital thread aims to develop and employ digital environments and tools that increase efficiencies in all stages of the life cycle. Participants noted that one of the challenges for the cradle-to-grave digital thread is capturing computer-aided design/computer-aided manufacturing (CAD/ CAM) or computer augmented design and manufacturing (CADAM) materials from original equipment manufacturers (OEMs) when a product has gone out of production. The challenge is being made more difficult by cost-cutting decisions not to “buy” the data rights from the OEM contractor at the beginning of the acquisition process. This challenge is not unique to the Air Force.

In response to a question, Dr. Stevens said that much of the responsibility for downstream decisions related to materials availability, environmental issues, and so on appear to have been ceded to the OEMs. James Mattice added that responsibility for issues at a life-cycle level formerly resided in the systems engineering function within the cognizant Program Office for acquisition of a system. Under acquisition reforms dating back to the Goldwater-Nichols Act,1 that responsibility has devolved to the OEM. He sees the new AFLCMC as having the potential to help bring some of that responsibility and engineering expertise back under Air Force

_____________

1 Goldwater-Nichols Department of Defense Reorganization Act of 1986, Public Law 99-433.

control. Others commented that information on the manufacturing processes, not just the CAD/CAM designs, is being lost. Dr. Stevens added that a significant issue is that some portion of the data associated with the design of processes, specific configurations, and so on is not owned by the Air Force. There is growing recognition of the importance of capturing key design and production data for the long-term sustainment of aircraft and other complex defense systems.

Referring to the right-hand side of Figure 3, Dr. Stevens said that capturing NDE/I data for individual systems as they go through maintenance during their operational lives is also an essential part of the cradle-to-grave digital thread concept.

Data from all three phases represented in the figure—design, production, and operational maintenance—will be necessary to enable condition-based maintenance and to have a digital representation (digital twin) of each physical system (e.g., each aircraft). The Digital Thread Sustainment Focus at AFRL, which is aimed at integrating data, models, and simulations throughout the system life cycle, includes the following objectives:

• Extending configuration management to include material properties and dimensional variations from production, modifications, and repairs.

FIGURE 3 Air Force manufacturing technology concept of the cradle-to-grave digital thread. Digital thread activities include generating, capturing, organizing, and utilizing relevant data and information. SOURCE: Katherine Stevens, AFRL, “AFRL and materials issues,” presentation to the committee on July 23, 2012, Slide no. 21.

• Providing digital twins representing the current state of a physical component, system, or manufacturing enterprise for condition-based decision making.

• Integrating and visualizing as-maintained representations across the fleet and throughout the supply chain.

• Delivering individual and fleet life-cycle lessons learned back to designers and planners.

In response to a question about the one or two biggest areas where more needs to be done, Dr. Stevens cited the challenge of transitioning technology from the system development and acquisition world to the sustainment world. Different views on which organization has which responsibilities for preparing technology for implementation into sustainment applications are part of this challenge. At least as important are funding problems related to how expenditures are categorized for appropriations (which costs can be recovered from which pot of money). The business case for a sustainment application not only has to make sense on its own but also has to align with the available resources (the pots of money that are not empty).

A second question to Dr. Stevens and the workshop generally was this: What can be done to solve the problem of program-specific certification requirements for the same part or component used in different systems? Dr. Stevens replied that part of the problem could be addressed through new approaches to standardization of specifications. Dianne Chong added that the problem also exists for manufacturers who have merged the operations of multiple acquired companies. The solution there is seen as having a single system for recording and maintaining parts specifications. Corporate- or enterprise-wide initiatives are needed to address the problem of multiple distinct part numbers for what is in reality the same part.

A participant asked if it makes sense for DOD to emulate the best practices that industry has adopted to address problems such as those of multiple specifications for essentially the same part or of different part numbers/identifiers, each with its own specifications, for what is in reality the same physical part. Can the best industry-tested practices be moved into the defense establishment? The discussion of this question revolved around the difficulty of identifying and encouraging best practices across different organizations without becoming caught up in too-rigid specification of standards. Another question was how willing potential competitors might be to share approaches and practices that in some cases they might see as part of their competitive advantage.

On the problem of different OEM part numbers for the same physical part in different systems or in different subsystems or components of the same system, Royce Smith of the Air Force Diminishing Manufacturing Sources and Materiel Shortages (DMSMS) Program said that while it is important to retain the original OEM part numbers in the system used for sustainment, they need to be linked to

one stock number associated with the physical part. A given stock number may be identified by five or ten different OEM part numbers. This point led to clarification of the problem in terms of sharing a common set of qualification and certification requirements for the same physical part in essentially similar applications.

Scott Fish, Chief Scientist, U.S. Army

Dr. Fish began by emphasizing the commonality of the issues that the Army faces with those identified by Dr. Stevens. He first described Army S&T activities in materials and proceeded on to the issues of counterfeit parts, parts obsolescence, and materials shortages.

In addition to its role in the MGI, the Army’s Multiscale Research on Materials focus includes two collaborative research alliances (CRAs): Materials in Extreme Dynamic Environments (MEDE) and Multiscale Modeling of Electronic Materials (MSME). Both CRAs, in which the Army partners with university investigators, involve fundamental research on applying multidomain modeling to investigate and develop multiscale materials. MEDE is aimed at fundamental research on new materials for armor and blast protection applications. MSME is focused on improved sensors and other electronics applications. The kickoff meetings for both CRAs were at the end of July 2012. Both CRAs are taking a materials-by-design approach, with the long-term goal of designing revolutionary materials—structural materials in the case of MEDE, electronic materials in that of MSME—for Army systems. The other military services have representatives monitoring both CRAs, and there have been routine conversations among representatives from the Army and the other services about the research.

In addition, the Army Research Laboratory (ARL) has its own strategic research initiatives, one called Materiel and Devices in Extreme Environments, another, Extreme Energy Science. Dr. Fish expects there will interesting crosstalk between the CRA teams and the ARL activities because new approaches to modeling and to metrics for measuring materials performance are important for all parties.

Dr. Fish next gave four examples of recent Army experience with counterfeit parts. In these four cases, each of which involved a counterfeit microprocessor chip, the routine performance tests carried out at several points in the supply chain did not detect any anomalies. Nor have component or system failures so far been attributed to these four counterfeit parts. Dr. Fish described the corrective actions being taken to deal with the parts that were installed in fielded systems. In addition to remedial actions, the Assistant Secretary of the Army for Acquisition, Logistics and Technology (ASAALT) is taking the following proactive steps to address the counterfeit parts problem:

• ASAALT has established an initial risk management capability for supply chain issues like this. The capability includes increased attention within the government and increased diligence on the part of Army prime contractors and associated intermediate providers in their supply chains to test for part performance compliance.

• ASAALT is continuing to work with the Office of the Secretary of Defense (OSD) to develop a Trusted Supplier standard.

Dr. Fish described the problem of counterfeit parts, particularly counterfeit microelectronic chips, as “very tricky,” given that many of them are passing current quality screening tests. From his understanding of the situation, the current testing requirements are not sufficient to ensure that counterfeit parts like these chips are not getting into fielded systems.

In response to a question, Dr. Fish said that evidence of malicious intent had not been found yet in the examples he described, but investigation of the sources of the counterfeit parts is ongoing. Dr. Fish stressed again that the parts distributor and the prime contractors affected by these counterfeit chips had been quick to notify their DOD customers of the problem, once it was discovered. Dr. Fish was asked if there were sufficient existing legal sanctions against a supplier that intentionally sells parts that it knows to be counterfeit. He said that he was unsure if sanctions might apply to the ultimate supplier or manufacturer of a counterfeitpart, but there are statutes in place that apply to the prime contractors and their tier 2 and tier 3 subcontractors for properly qualifying their suppliers. This led to further discussion of issues surrounding the growing reliance on foreign manufacturers and suppliers located outside the United States and the likelihood that counterfeiting is motivated solely by the economic value of supplying demand for an otherwise hard-to-find authentic part. Also discussed was the type of testing available to detect “added functionality” or location- or target-specific alterations that might be present on counterfeit chips.

Dr. Fish concluded with a list of materials supply and shortage issues that were serious enough to be reported up to Army Headquarters from Army Program Executive Offices (PEOs) because they were viewed as having a significant impact on acquisition costs and schedules:

• Strong nitric acid. An explosion in May 2012 at a major domestic source for this chemical stock will require drawing down reserve stocks until production comes back on line in 12 to 18 months. There are alternative sources, but they do not produce enough to meet demand.

• Aerospace castings. Dr. Fish described the problems of long lead times and late deliveries of these castings as an across-the-board problem for DOD,

based on a recent OSD Industry Study. This is a supplier (capacity) issue rather a materials shortage issue.

• Ammonium perchlorate. The price per pound from the single U.S. supplier of this ingredient for rocket propellant is increasing significantly. Foreign sources exist but are not qualified for U.S. defense requirements. This is a DOD-wide industrial base issue.

• Nitrocellulose and nitroglycerin. Production volume will be reduced during the changeover to a new contractor at the government-owned, contractor-operated facility, which is the only one worldwide with sufficient capacity for nitrocellulose.

• Butanetriol. There is no existing U.S. supplier for this chemical used in rocket motor manufacture. A source is being developed in Memphis, Tennessee.

In response to a question, Dr. Fish agreed that the chemical supply issues in this list stem from the limited market for the chemicals in question, which makes the economic context analogous to that of therapeutics with small markets. Thus, there may be some commonality with the approaches being considered by pharmaceutical manufacturers for therapeutics with small markets but important niche uses. The Army does have authority to use foreign sources that are in NATO countries, and Dr. Fish thought that the butanetriol example was in that category.

Dr. Fish was asked to comment on the difference, from an Army acquisition perspective, between chemical shortages where U.S. industry still has the facility capacity to manufacture (perhaps with adaptation) and chemical shortages where a manufacturing capability no longer exists domestically and the only capacity is foreign-based. Dr. Fish replied that whether the lack of domestic capacity was a critical issue would probably be decided case by case. In general, though, the Army does not presume that all production of a defense-critical chemical or material must be domestic. But there would have to be adequate controls in place on both production and transport to ensure that supply requirements will be met. The overall protection mechanism must be adequate, as the line between domestic and foreign sourcing is not always distinct.

With respect to his examples of single-source specialty chemicals with supply issues, Dr. Fish said that reliance on a sole (domestic) source for a critical material must be paired with a program to stockpile sufficient reserves to carry through an interim supply shortage, as happened for strong nitric acid. That approach works, but it does stress the system.

A related question was whether the new Sector by Sector, Tier by Tier (S2T2) analysis of the defense industrial base provides the services with a tool for assessing their supply vulnerabilities, such as single-source vulnerabilities. Dr. Stevens replied that the Air Force Manufacturing Technology Program has plans to use the S2T2 database as a resource. Dr. McGrath added that there are policy constraints on how

the database will be accessible, given that some of the survey data being collected are business-sensitive and proprietary. This led to discussion among the participants on how PEOs in the DOD acquisition community could make effective use of the S2T2 information without directly accessing the restricted data.

OPEN DISCUSSION: MATERIALS ISSUES AND PROGRAMS TO MITIGATE SHORTAGES

Dr. McGrath suggested that this discussion session should focus on how the prior presentations relate to the following five critical issues, which were called out in the prologue of the workshop’s announcement-agenda document, and whether any additional critical issues have emerged:

• Are there ways to rapidly qualify materials or components when the raw materials or their manufacturing process has been changed?

• How does one economically replicate the production of a part that is no longer made?

• How does one rapidly assure that aftermarket parts have acceptable performance and have not been tampered with?

• How can ICME-like approaches (e.g., MGI) be applied to support the sustainment environment?

• What information from the initial development and production phase needs to be captured to make downstream sustainment easier?

Dr. McGrath suggested that the participants focus on the technology (and policy) issues that pertain to the materials and manufacturing infrastructure rather than more broadly taking on all sustainment issues. From this perspective, he offered the following themes from the prior presentations:

• Dr. Sloter had described DOD’s concerns about supply and substitution, certification, and control of counterfeits. For the S&T community, there are both challenges and opportunities in responding to these concerns.

• Dr. Stevens had provided the sustainment context for these issues as they affect Air Force systems that will be operating for a long time. She described what AFRL—and particularly the Air Force’s Materials and Manufacturing program—is doing about the issues.

• Dr. Fish had noted the commonality of the Air Force issues described by Dr. Stevens and those of the Army. (Dr. McGrath added that, from his experience, the issues also apply to the Navy.) Bringing government and industry together in partnerships such as the new CRAs in multiscale and microstructured materials may be one way to attack the problems. Several participants had suggested that industry best practices could be shared and could be of value to DOD as well.

Dr. Gerhardt added that another aspect of these problems is that they are extremely complex. It is necessary to find ways to repair and maintain complex systems with diverse subsystems, components, and parts, while also developing materials needed for future applications. From her perspective as a materials scientist, a difficulty is that even the smallest change in composition from that of the original part or component can drastically change structure at some scale, which in turn can alter properties that affect the function of that part or component. Solutions need to be worked on from the top down and from the bottom up. The presentations by Dr. Stevens and Dr. Fish illustrated the tremendous complexity of the problems. To make the discussions more fruitful, she suggested distinguishing the following topics:

• Development of new materials.

• How to deal with counterfeit parts.

• How to deal with replacement of parts that are no longer being made.

• Development of standards and, possibly, establishment of policies to guide how these complicated networks of systems can continue to perform adequately.

To elaborate on the last of these topics, Dr. Gerhardt used the example of the development of the IEEE-488 standard to guide the interfacing of computers with equipment.2 All companies that need to provide that kind of interface must adhere to that standard.

In response to Dr. McGrath’s request that participants name one or two issues on which more needs to be done, participants suggested the following issues:

• What can be done (in materials and manufacturing R&D) so that DOD is not facing the same problems 30 years from now that it faces today? Does this mainly involve making policy changes that facilitate the government’s forming long-term relationships with suppliers as opposed to putting supplier

_____________

2 IEEE-488 is a specification for a short-range digital communications bus and was created in the late 1960s for use with automated test equipment.

contracts out for bid every several years, with the new contract going to the lowest-cost bidder without accounting for transfer and start-up problems?

• Are there materials or manufacturing technologies that make parts that are inherently more transferable between systems and applications? What can be done on the production and processing side to make long-term sustainment easier, including easing the problems that occur when an original manufacturer goes out of business or can no longer supply parts? Without exposing proprietary information, what processing information would help a subsequent manufacturer?

• Are there industry best practices in supplier management and manufacturing data capture that could be adopted or adapted by DOD as better ways to do business? A first step would be to benchmark what companies do as best practices in supplier management—for instance, in building and maintaining a network of trusted suppliers. Another example is the commercial companies that remanufacture or salvage engines and other complex subsystems or components of legacy systems.

• The alternative to having an error-proof way to detect functionality that has been added to a counterfeit part, which seems extremely difficult to do, is to have a trusted network of suppliers. This probably requires a combination of technology and policy approaches.

• A participant from a major original equipment manufacturer (OEM) and prime contractor for defense systems said that his department’s procedure for qualifying a supplier includes requiring that the supplier share with the prime all the details of its manufacturing processes. The prime even sends a process expert to the supplier to learn about the process. For this to work, the participant cautioned, there must be adequate trust that proprietary information will not be transferred to others and competitive advantages will not be lost. The continual stream of incremental changes to manufacturing processes is also reported up the chain to the prime. For a small supplier, there are provisions for the OEM to seek an alternative source if the supplier goes out of business or can no longer supply. A second participant from another major OEM said that similar procedures for supplier-partnering are used with their specialty chemicals and materials suppliers.

• The trusted supplier relationship in the preceding item requires a partnership between supplier and customer rather than an adversarial relationship. The customer must follow through on protecting suppliers’ proprietary and competitive information. Government customers have a great deal of difficulty maintaining that kind of relationship because of acquisition requirements for competitive contracting. But for an OEM, these long-term partner relationships are a considerable advantage. The quality of the

technical data provided by a supplier is typically proportional to the level of protection that the supplier’s intellectual property will receive.

• As Dr. Stevens noted in her presentation, transition from the initial acquisition/production environment to a sustainment environment is difficult. Sustainment contractors often do not have the resource base, including personnel with appropriate expertise, to apply the same level of problem analysis and resolution that OEMs provide. Maintenance depot personnel—both government personnel and contractors—prefer to work from technical orders that are written like step-by-step recipes.

• Transfers of production capability from one supplier to another often result in delivery delays that can cause temporary shortages. This can occur when the original supplier sells a product line to another company, as well as when the customer initiates a change in supplier. A good industry practice would be for a supplier to notify customers when any supplier-initiated disruption in supply capability is planned, so the customer can increase inventory to cover a potential delay in the delivery pipeline.

The last of these issues led to discussion of whether three-dimensional printing technology will be able to help provide critical parts whose normal supply pipeline has been disrupted. One challenge to such technologies is that, even when complete CAD/CAM data, including tooling data, are available, suppliers do not allow that information to be used for parts production until they can no longer deliver the parts themselves. A part produced using CAD/CAM data still needs to be qualified, whatever new production process is used, and the qualification process for aviation parts, for example, can take 2-3 years. Another challenge is whether the appropriately qualified material is available. A question arose as to whether there was a formal lessons-learned report from the Army’s Mobile Parts Hospital program, which is basically a mobile machine shop transported on a tractor-trailer.

There may be two distinct categories of problems with counterfeit parts, one participant suggested, with different solutions for each category. The first category concerns the quality of counterfeit parts relative to that of valid, qualified parts. Potential solutions for ensuring parts quality include building trusted supplier relationships, having appropriate policies, and applying appropriate test procedures. The second category, which appears harder to address, concerns attempts, for any number of reasons, to hide some new functionality in the counterfeit part without altering the part’s properties as measured by the quality standards. The part is designed to behave differently, long after it has been delivered, only after receiving an instruction from the originator or under particular predefined conditions. This type of counterfeiting, also called “additive manufacturing,” could potentially be applied to mechanical parts and materials (“cyber-physical” systems), as well as

microelectronic parts and components. Solutions applicable to the quality problems may not solve this second category.

Another participant agreed about the difficulty of addressing the second category of counterfeit problems. Overreliance on standards and on testing to those standards can create a complacency about the security of the supply chain. In reality, this participant said, there is no way to build quality assurance systems that respond to everything that could potentially happen. As complete design and production-process data sets become a standard industry practice, the availability of those data also allows an intentional counterfeiter to know exactly what a counterfeit part should do to remain undetected. Different entities within customer organizations—such as the intellectual property group and the supply chain managers—have to work together.

MATERIALS SHORTAGES AND STRATEGIES TO COUNTER THEM

Dr. Schafrik began by noting the substantial contribution to this presentation by his colleague, Steven Duclos, Chief Scientist and Leader for Material Systems and Nanotechnology, Advanced Technology Programs, GE Global Research.

His first point with respect to abrupt disruptions in material cost or availability is that users need to change from a reactive mode to an approach that uses early understanding of risk to inform early action. Graedel and Cao (2010) compared trends in global demand for metals with trends in ore quality to support their conclusion that users should anticipate increased cost, decreased availability, and increased risks of supply disruption. The typical response today to a materials “crisis”—whether the crisis stems from demand outstripping supply, a mining disruption, export curtailment, or an unforeseen “black swan” event—is to exercise alternative sourcing options while simultaneously pursuing manufacturing efficiencies, recycling, and materials substitution strategies, all in parallel. A strategic response to the crisis would instead rely on assessing the raw materials risk prior to the shortage and then acting to anticipate the risk by identifying alternative sourcing solutions and the serial application of efforts to increase manufacturing efficiencies, recycle, substitute alternative materials, and/or substitute alternative technologies (systems) that do not require the material (Graedel and Cao, 2010).

Dr. Schafrik described the risk assessment process that GE has adopted to be proactive in introducing technical risk reduction programs for materials with high criticality for the company. After a rhenium shortage several years ago, GE began the process of identifying the amount of each strategically important material it

uses per year through a detailed supply chain materials analysis. One risk reduction strategy is to improve the buy-fly ratio for high-risk materials (the amount of material acquired is typically a substantial multiple above the amount of that material in finished systems). Closed-loop recycling systems and materials substitution are also important risk reduction strategies. In addition, designs for engines and other highly complex systems and subsystems are now taking materials availability into account in design decisions. This materials sustainability risk management process is also used for nonmetal materials such as polymers and fibers.

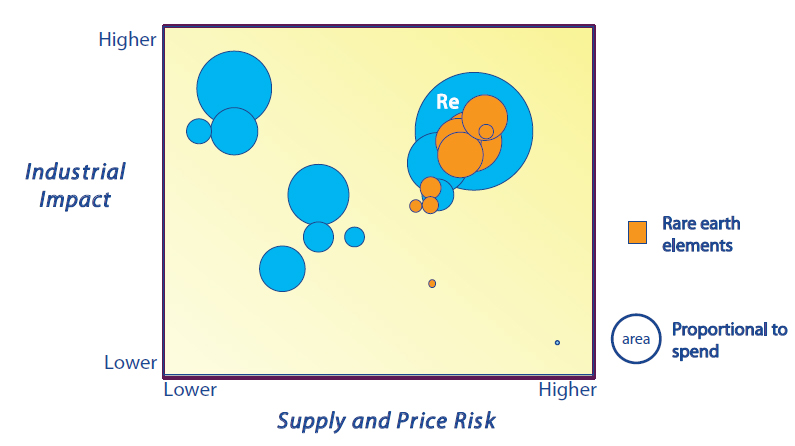

Dr. Schafrik described the general approach to quantitative risk assessment that GE uses, which includes consideration of the total annual expenditure on a particular raw material and quantitative measures of market supply and price risk and the impact of supply restrictions on the company (industrial impact). The three factors are graphed in a criticality diagram for the materials of greatest concern, as shown in Figure 4.

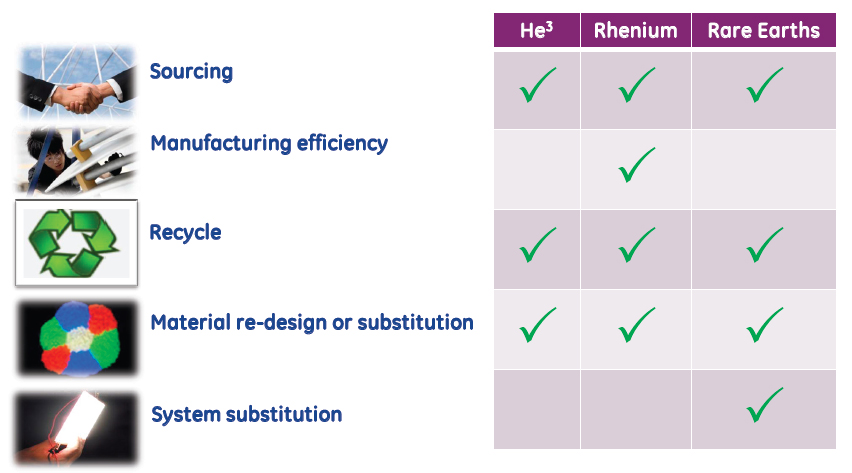

Based on this criticality analysis, the company develops a material sustainability strategy that can include ensuring continued supply by having more than one sourcing option, by increasing manufacturing efficiency—that is, reducing the amount of the material required—by recycling, by reducing or eliminating reliance on a high-risk material by material redesign or substitution, or by substituting an alternative technology that does not use the high-risk material but still satisfies

FIGURE 4 Notional example of a criticality diagram for materials shortage risk assessment. Each circle represents one of the raw materials selected for analysis. SOURCE: Robert Schafrik, GE Aviation, “Materials shortages and strategies to counter them,” presentation to the committee on July 23, 2012, slide no. 13.

FIGURE 5 Overview of sustainability strategies for three critical materials (elements). Each element and each application will use a unique mix of options. SOURCE: Robert Schafrik, GE Aviation, “Materials shortages and strategies to counter them,” presentation to the committee on July 23, 2012, slide no. 15.

customers’ needs. Figure 5 illustrates how the five approaches have been combined in sustainability strategies for three high-risk materials: helium-3 (He3) for neutron detection systems, rhenium, and rare earths. Dr. Schafrik described the details of each approach for these three materials, emphasizing ways in which each strategy requires cooperation among the sourcing, manufacturing, and engineering functions within the enterprise.

In response to a question on recent shortages of particular forms of titanium, Dr. Schafrik said the materials sustainability risk assessment he was describing applied only to the material and not to the availability of the end product. In his view, a shortage of processing capacity is in principle easier to manage than a raw material shortage, since investments can be made to find or create additional capacity. In addition, to avoid processing capacity constraints, the company works with key suppliers to arrive at capacity agreements that are mutually beneficial. In response to another question, Dr. Schafrik said that redesigned production processes do require requalification, but the company has adopted qualification procedures that shorten the time required. For example, ICME was applied to develop and qualify two low-rhenium alloys, reducing from 6 years to 2 the time from start of material

development to Federal Aviation Administration (FAA) qualification of the new materials in a jet engine.

The participants discussed the potential for government funding for recycling of engine and aircraft parts to conserve materials such as metal alloys containing rare earths. One participant noted that regulations requiring destruction of used parts before they could be removed from an Air Force maintenance depot had led to abandoning a program for recycling rhenium alloys from replaced engines and engine parts. Dr. Schafrik responded that, in the commercial aircraft industry, contrary to DOD experience, servicing contracts typically incentivize an airline to return a used turbine blade in exchange for a new one. Other differences between commercial airline and military practice include policies for inspection and replacement of turbine blades.

SUSTAINING AIR FORCE AGING AIRCRAFT INTO THE TWENTY-FIRST CENTURY

Alan C. Eckbreth, Eckbreth Consulting

Dr. Eckbreth chaired the study team that authored the Air Force Scientific Advisory Board (AFSAB) report Sustaining Air Force Aging Aircraft into the 21st Century (AFSAB, 2011). His presentation focused on two parts of the terms of reference for the study:

• Identify specific aircraft systems, in addition to structures and engines, that contribute to the safety, availability, and effectiveness of aging aircraft.

• Identify technology needs and technology approaches that can be applied or developed to extend the life or ease maintenance for these aircraft systems, while facilitating future adaptations and performance enhancements of the aircraft.

The study team defined “sustainment” as the combination of operations and maintenance (O&M) and modifications for upgraded performance (AFSAB, 2011, p. vi). This definition meant that sustainment requires consideration throughout the entire life cycle of the system (aircraft), including both O&M expenditures (Air Force appropriations code 3400) for repair, remanufacture, and replacement and modernization expenditures for research, development, test, and evaluation (RDT&E) (code 3600) and procurement (code 3010) of upgrades.

As context for the problem, the AFSAB report included Figure 1 (also used by Dr. Stevens), showing the diminishing recapitalization of the Air Force fleet over time. Remanufacturing has become increasingly important to the efforts to

keep this aging aircraft fleet flying, a point that Dr. Eckbreth illustrated with a diagram of remanufactured structural parts and subsystems of the KC-135 aircraft. Dr. Eckbreth discussed with several other participants the extent to which the funding of O&M, including remanufacturing and replacement, from one-year funds (code 3400) constrains the ability to plan for and execute a continuing and efficient long-term program for sustainment of aging aircraft. Dr. Eckbreth said the AFSAB study team was told of cases where opportunities to replace an aging part with an improved replacement had foundered because of the obstacles to combining modernization expenses with O&M expenses. He and other participants noted that multiple advisory bodies have recommended policy changes that would enable the military services to more easily access necessary funding, but to no avail.

After describing the various factors that contribute to the increase in programmed depot maintenance costs as the fleet ages, Dr. Eckbreth used the version of Figure 2 (also used by Dr. Stevens in her presentation) as it appeared in the AFSAB report to emphasize that O&M costs for the Air Force fleet have nearly doubled in the past 14 years, even as the total aircraft inventory has continued to decline. In short, as time passes, it is costing more to sustain fewer aircraft.

In addition to cost, other key sustainment effectiveness metrics are also affected as the Air Force fleet ages. Dr. Eckbreth described how the aircraft availability metric is defined (roughly, the percentage of aircraft that are available and mission-capable at a given time)3 and how sustainment issues are making it unlikely that the aircraft availability goals set by combatant commanders can be achieved. Of particular relevance to this DMMI workshop, parts supply issues grow as a system ages:

• Diminishing manufacturing sources and materiel shortages (DMSMS) problems increase as weapon system lives are extended. When the study team met with the Air Force Global Logistics Support Center (AFGLSC), 80 percent of the center’s systems engineering staff was working DMSMS issues.

• Subsystem product life cycles decrease with time, and increasing use of commercial-off-the-shelf (COTS) parts leads to more rapid parts obsolescence and increasing parts supply issues.

• Shortages impact both field level and depot performance.

• Lack of quality and consistency of reports from the Air Logistics Centers (ALCs) on parts replacement actions makes it difficult to forecast supply chain needs.

_____________

3 According to the AFSAB report, aircraft availability is defined as the percentage of a fleet’s total aircraft inventory that is mission capable. “Mission capable” means that the aircraft is available to be scheduled for a mission. (AFSAB, 2011, p. 420).

The study team found that the Air force lacked depot maintenance efficiency metrics and proposed “cost of aircraft availability (AA)” as a measure of depot efficiency. In a resource-constrained environment where the combatant AA targets are routinely not being met anyway, the Air Force should quantify AA/$ as a function of programmed depot maintenance rate (e.g., aircraft per day) and use this efficiency model, as well as AA goals, to analyze and evaluate sustainment initiatives.

Accurate forecasting of parts replacement was identified as a key enabler for increased AA. The report’s second recommendation was to improve supply chain forecasting to minimize field-level maintenance and depot production delays due to parts shortages.

Because S&T investments are critical to reducing maintenance costs, the recommended increased fundamental research efforts at AFRL oriented to legacy aircraft maintenance needs, a process for maturing promising hardware maintenance technologies to technology readiness level (TRL) 6, and full-scale demonstrations to take those new technologies with a high return on investment from TRL 6 to TRL 9 (implementation). The recommended areas for fundamental research included (1) testing for corrosion, stress corrosion cracking, and accelerated (2) leak detection and prevention; (3) wiring fault detection; and (4) research in software verification and validation, self-describing code, software readability interoperability, and other software sustainment areas. The report also discusses specific maintenance technologies that the study team considered to have crosscutting benefits for improving fleet maintenance and sustainment.

In closing, Dr. Eckbreth presented the following summary points as the bottom line from the AFSAB study:

• Aging legacy aircraft will drive sustainment costs ever higher in the coming years.

• Capability upgrades and sustainment of advanced technologies, especially software and avionics, will further stress budgets.

• Introducing AA/$ efficiency metrics will allow the Air Force to gauge depot performance and explore efficacy of improvement programs.

• Commercial airline practices, enhanced supply chain forecasting, more accurate maintenance databases, and S&T maintenance advances will contribute to increasing AA and restraining cost growth.

• Strengthened integrity programs will ensure the airworthiness of aging legacy fleets.

• Maintenance S&T requires increased emphasis to contribute to life extension, expedited inspections, and reduced touch labor.

• Approaches to transition technologies with promising returns on investment need to be adopted to realize the benefits of S&T advances.

During the question and discussion period following Dr. Eckbreth’s presentation, participants described actions that AFRL in particular has taken to address the recommendations of this and other advisory reports on fleet sustainment issues, including corrosion R&D activities currently under way at AFRL. Feasibility of the recommended maintenance and sustainment S&T in an era of declining DOD and Air Force budgets was cited as a key constraint that is still being assessed. Participants also referred to a 2011 report from the Government Accountability Office (GAO) on corrosion issues with the F-35 Joint Strike Fighter (GAO, 2011) and a study from the Center for Naval Analyses on maintenance issues with the KC-135 tanker aircraft fleet (Francis and Boning, 2005).

THE AIR FORCE DIMINISHING MANUFACTURING SOURCES AND MATERIALS SHORTAGES PROGRAM OFFICE

Royce Smith, Lead Program Manager 448th Supply Chain Management Wing, Tinker Air Force Base

Mr. Smith described the work of the 448th Supply Chain Management Wing as managing all the old systems that are being kept flying (“the tired iron”). The 448th Wing, which previously reported to the AFGLSC, is now part of the Air Force Sustainment Center (AFSC). The DMSMS Program Office supports parts supply management for all the older Air Force weapons systems.

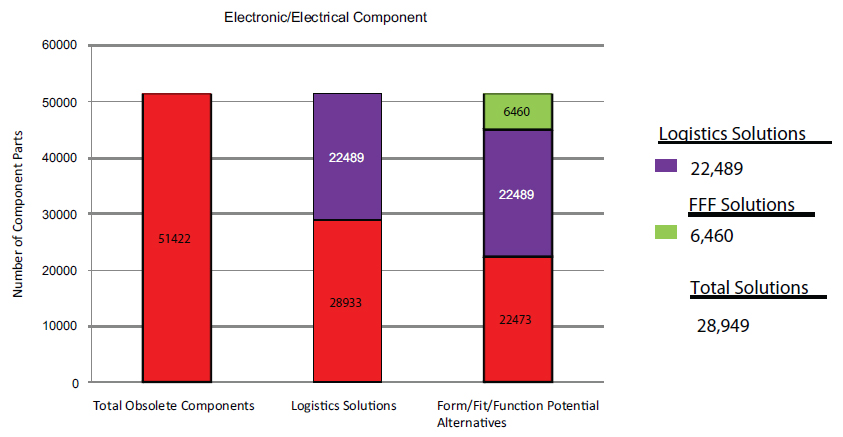

A key information system for monitoring and planning for parts obsolescence in these older flight systems is the Advanced Component Obsolescence Management (AVCOM) system. Due to funding constraints, the process of loading parts information into AVCOM for aircraft subsystems has to be prioritized. The loading process includes data mining from technical orders, from design drawings, and, as a last resort, by going back to the OEM for parts specifications. One integrated circuit (IC), for example, may have more than 122 applications in different assemblies used on different Air Force systems (indicated by unique Weapons System Designator Codes). During each of the steps in the loading process, when mistakes are found in part numbers or specifications, the errors are sent back to the government engineers for correction approval. The AVCOM predictive tool produces reports on whether there is information on manufacturers of the part, how many manufacturers are actively producing a part (two or more, just one, or none), and whether there is a logistics solution for an obsolescent (not currently being manufactured) part. A logistics solution might be having sufficient inventory to meet all expected life-cycle demands. AVCOM can produce alerts on impending obsolescence, analyses of possible form/fit/function replacements for an obsolescent part, an impact analysis for all end items in the inventory that are affected by an obsolescent part, and other kinds of reports. For parts with no current manufacturers and no

FIGURE 6 Status of obsolete parts for subsystems currently in AVCOM system. SOURCE: Royce Smith, 448th Supply Chain Management Wing, Air Force Sustainment Center, “The Air Force Diminishing Manufacturing Sources and Material Shortages Program,” presentation to the committee on July 23, 2012, slide no. 20.

logistics solution settled on yet, the next step is an analysis and resolution process. A joint government—contractor team works on resolving the obsolescence issues for subsystems, in priority order, typically several years before the inventory for the obsolete part is forecast to be exhausted. A final solution may involve a formal Technical Order change to allow use of a replacement part or a redesign package with complete specifications for recreating the part.

For the subsystems and components currently loaded into AVCOM, approximately 51,400 electronic/electrical parts are obsolete (Figure 6) out of a total of about 7 million parts in the system. Of these, logistics solutions have been identified for about 22,500, and form/fit/function replacements4 have been identified for an additional 6,460. Thus, there are, by coincidence, a similar number (about 22,500) of obsolete parts currently identified for which there is not yet a sustainment solution. This analysis takes into account parts that may have been assigned different part numbers over time but are functionally identical. Each year, roughly a million additional parts are added to the AVCOM system as additional subsystems are loaded and analyzed. Thus, the total number of obsolete parts without a solution

_____________

4 A form/fit/function replacement is considered a potential replacement until the cognizant engineering authority for the subsystem that uses it approves it as a replacement.

fluctuates as new parts are loaded while solutions are being found for the parts in priority subsystems.

The overall program objective is to reduce the mission-incapable (MICAP) hours for systems still in the inventory. Reducing MICAP increases AA. During FY 2011, the DMSMS program office resolved 18,482 individual obsolescence issues, valued at an estimated cost avoidance benefit of $707 million. Most of these were for electronic, electrical, and electromechanical parts; some were for mechanical parts.

Next, Mr. Smith described the Air Force role in the Shared Data Warehouse (SDW) information system, which was undertaken several years ago by the Logistics Agency (DLA) to capture and share information about parts that were going out of stock from an established supplier. The warehouse helps provide opportunity for the military services to buy extra inventory of a part before it goes out of production. To illustrate the extent of the problem, the Air Force module of the SDW identified 1,014 next-higher assemblies that were affected by the loss of part or component manufacture during FY 2011. The Air Force hub for the SDW consolidates estimates of the numbers of the part needed by each of the ALCs and sends one requisition request to DLA.

Mr. Smith said the principal way to avoid parts obsolescence in the future will be to use tools like the SDW to buy sufficient inventory before production of the part ends. A limitation, however, is that the manufacturer has to notify some participating part of DOD that it is planning to stop manufacture of particular parts or even to go out of business altogether. Mr. Smith discussed with other participants the problems of finding out when third- and fourth-tier vendors in the supply chain are discontinuing production of needed parts for whatever reason.

In response to a question, Mr. Smith said he could not see a reason, from his perspective, for assigning different degrees of criticality or overall mission impact to a particular part. This led to discussion of differences with commercial airline practice, where some parts are identified as fly-to-failure, meaning that flight safety would not be affected if the part were to fail while the aircraft was in flight. Mr. Smith said that decisions about subsystems or components that are more critical or have higher authority are made by the cognizant engineering authorities for purposes such as determining the priority of subsystems to go through the AVCOM data loading process.

To summarize his argument for the value of proactive DMSMS management by systems like AVCOM and SDW rather than reactive management of obsolescence issues, Mr. Smith characterized the two approaches as follows:

• Reactive DMSMS Management

—Event driven—already behind the curve when notified that a part is not available for a repair;

—Increased risk of impact on mission readiness; and

—Impacts compound as the system ages; cost increases and maintainability decreases.

• Proactive DMSMS Management

—Requires up-front investment and planning;

—Requires accurate and timely information to enable appropriate, efficient response;

—Improves mission readiness by avoiding event-driven surprises without solutions; and

—Facilitates enhancements to system capabilities.

DMSMS assessment needs to be done systemwide and throughout the life cycle, Mr. Smith concluded. During preacquisition planning, if the government is not going to buy all the technical data needed to remanufacture, then performance-based logistics contracts—for example, on contractor logistics support (CLS)—are needed to motivate OEMs to commit to maintaining the system throughout its life cycle.

During the question and discussion period after the presentation, Mr. Smith added that in only a few instances do acquisitions program managers consult with his organization about the potential obsolescence of parts for proposed designs of new systems. In those instances where there has been consultation before acquisition, systems like AVCOM have been useful in identifying obsolete parts in the design, or parts that could become prematurely obsolescent, resulting in recommendations to redesign subsystems to avoid these problems.

Discussion Leaders: Robert E. Schafrik and Alan C. Eckbreth

Dr. Schafrik highlighted the following points for further discussion from the preceding three presentations:

• It is important to be proactive rather than reactive in response to chain shortages and parts obsolescence. Do DOD and/or the defense industry have the knowledge base tools to move from reactive responses to proactive ones?

• Separating S&T-based issues from policy issues. Assuming one cannot do much about the policy issues, what can be done within the current policy context to optimize the effectiveness of the S&T work that has been done?

• What are incentives for industry to help on the sustainment side of the systems life cycle, such as CLS?

• How can maintenance technology be transitioned to the ALCs?

With respect to the third point, a limitation of CLS under current Air Force policy is that 50 percent of the work has to be done within an Air Force ALC.

One participant disagreed with the assumption in the second point that policy issues should not be addressed. The participant suggested that the workshop should at least identify areas where policy changes could be made that would make a real difference in dealing with sustainment problems.

A fifth recurring theme noted by the participants was the importance of capturing and retaining the technical data about materials and parts for use during system sustainment. A relevant policy question is whether DOD should attempt to buy the technical data sufficient to maintain a digital data thread and store the data in an engineering data repository or instead look to OEMs to maintain the data and buy the information as a service. Would a DOD data repository be as complete and accurate and updated as the data OEMs would maintain? Another comment was that it would be important for government to get the technical data rights up front because OEMs might not remain in business and might not be acquired by another government supplier that could retain the data to make them available.

A serious technical question with respect to the digital data thread, however it is implemented, is deciding which data are useful for the long-term sustainment of systems. The participant who raised this point added that the Air Force does not have enough knowledge or data necessary to replicate a part or sustain it over an extended system life cycle. One ongoing effort to define standards for technical data packages, under the Army ManTech program, is Military Standard 31000. Another participant stressed that state-of-the-art technologies to support condition-based maintenance and other advanced sustainability approaches dependent on adequate status information are not being incorporated in new aircraft like the F-35 because of budgeting and contracting (low-bid competition) constraints.

Individual participants then identified the following additional barriers to successful implementation of the digital data thread vision:

• The military’s operational requirements lead to an emphasis on preventive maintenance and replacement rather than the fly-to-failure standard applied to select components by commercial airlines (the difference arises from the operational context of commercial airlines).

• The unreliability of data in existing maintenance databases and the lack of integration and transparency undermine condition-based maintenance.

• Major gaps still exist in the archives of engineering design documentation (e.g., CAD records) for legacy systems.

• Much of the archived electronic documentation is stored in formats that are unreadable by the current generation of design software tools.

• Ongoing upgrades to CAD/CAM tools can lead to subtle differences in how specifications from an earlier generation of the tool software are interpreted on the current version of the tool.

• Changes in manufacturing processes over time can alter the condition of a part even when design and initial manufacturing process documentation are followed; remanufacture to achieve the same functionality can require modifying the design and process specifications.

• Maintenance databases that rely on maintenance technicians to fill out records are subject to human error; automated ways to capture maintenance data are necessary.

Some participants also noted a number of current efforts, such as the Army and OSD ManTech programs, to overcome or at least mitigate these obstacles to data thread implementation. As one participant summarized the situation, the vision for digital data thread applications is way ahead at the “run” stage of implementation, while the actual situation is only at a “walk” or even a “crawl” stage; many incremental steps will be needed to achieve the visionary objectives.

Dr. Sloter commented that several activities at the federal level are pursuing the kind of proactive strategy Dr. Schafrik presented for addressing shortages of critical materials. First, a recent IDA workshop conducted for the DLA Strategic Materials Directorate focused on criticality of materials; the next workshop will focus on vulnerability of materials to supply shortages and other disruptions. Second, a scenario-based planning methodology, which has been applied for more than a decade to the National Defense Stockpile, is being expanded for application to a broader range of materials and material applications. Third, the Department of Energy (DOE) has extensive planning for critical materials in the energy sector, similar to the approaches Dr. Schafrik described. It is soliciting for a critical materials hub that will establish a research capability for critical materials planning. Finally, there is an interagency working group on critical materials in the Office of Science and Technology Policy.

The participants discussed the impact on U.S. companies of the recent additions to the list of substances banned in the European Union by the European Union Registration, Evaluation, Authorisation, and Restriction of Chemical Substances (EU REACh) regulations. Some companies have worked at anticipating which substances would be banned, such as hexavalent chromium; they began R&D for process alternatives and substitutes before the substances to be banned were announced.

Another comment was that advisory studies that make technical recommendations to address materials and manufacturing issues are typically not implemented unless the study also addresses business practices (government, commercial sector, or both, depending on the recommendation) and sources of funding for implementing the recommendations. This participant suggested that any study making recommendations on the workshop’s themes should be a joint study of policies, business practices, technical drivers, and how these factors interact. Recommendations that are perceived by DOD as addressing purely technical issues—even from NRC elite committees—are seldom fully implemented. A complete assessment of the relevant DOD business practices and the financial impact of a recommended change would, this participant suggested, be much more useful to decision than a purely technical assessment. While acknowledging that this suggestion would add to the challenge of preparing the study and would require adding people knowledgeable in DOD operations to the committee, the participant believed that the recommendations would be more likely acted upon.

SENATE ARMED SERVICES COMMITTEE REPORT ON COUNTERFEIT ELECTRONIC PARTS IN THE DOD SUPPLY CHAIN

Joseph M. Bryan, Professional Staff Member Senate Armed Services Committee

Mr. Bryan was the lead staff member for an investigation by the Senate Armed Services Committee into the presence of counterfeit electronic parts in the DOD supply chain (Committee on Armed Services, 2012). The investigation was initiated in March 2011 and dealt primarily with counterfeit electronic parts and components.

An important early finding was that DOD and the large defense contractors were not keeping track of counterfeit parts. The Senate Armed Services Committee relied on testing companies used by DOD, the contractors, and their suppliers for information on counterfeits. The independent testing companies had relatively good records and had found a lot of counterfeit components.

The investigation identified about 1,800 suspect counterfeits, accounting for more than a million counterfeit parts in the defense supply chain. Information was gathered from 9 major contractors and 22 testing companies. Counterfeit parts were found in dozens of weapons systems, including military aircraft, Army thermal weapon sights, and mission computers for the Missile Defense Agency’s Terminal High Altitude Area Defense missile (Committee on Armed Services, 2012, p. ii).

Most of the counterfeits identified in the investigation were previously used parts that had been removed from assemblies and circuit boards and sold as new

parts. The Senate committee traced about 125 counterfeit parts back through the supply chain. About 70 percent came from China. The Air Force reported that one Chinese supplier identified in the investigation had sold more than 84,000 suspect parts into the defense supply chain. Mr. Bryan gave an example of one counterfeit part traced back to a Chinese source through six intermediary purchasers, including the major defense contractor who supplied the part, which was integrated into a subsystem for a Navy helicopter.

As part of the investigation, the Armed Services committee asked GAO to set up a shell company to search the Internet for certain hard-to-find electronic parts, as well as parts marked with incorrect production dates (beyond the date of last actual production) and parts with bogus part numbers. The shell company purchased 16 parts. Every one of the parts that GAO purchased was determined to be counterfeit, and all of the suppliers were based in China.

The investigation found that DOD lacks knowledge of the scope and impact of counterfeit parts on critical defense systems. The overwhelming majority of counterfeit parts in the supply chain had not been reported at the time of the investigation. DLA, which supplies 80 percent of the spare parts used by DOD, neither consistently reported instances of counterfeit parts to the Government–Industry Data Exchange Program nor maintained an internal list of instances in which it had been supplied counterfeit electronic parts. Furthermore, DLA had repeatedly purchased counterfeit parts from the same distributors.

In response to a question on the definition of “counterfeit part” used by the investigators, Mr. Bryan explained that the term included used parts sold as new, parts whose numbers had been changed, and unauthorized copies of the authentic part. This is the same definition used by industry—SAE International Aerospace Standard (AS) 5553-2009. A participant noted that repackaging of commercial-grade parts as military-grade is also a problem, and the participants discussed the negative consequences of using non-military-grade parts or other kinds of counterfeits in military operations. When asked if the investigation had identified any instances of malicious intent beyond economic interest on the part of counterfeiters, Mr. Bryan said that the investigation was unclassified and so had not focused on that issue. Mr. Bryan said that economic interest appeared to be the motivation for most of the cases investigated by the Senate committee. In response to another question, he said that the investigation dealt only with electronic parts, but he was aware of a lot of interest in counterfeit structural parts as well. Other workshop participants described instances of materials substitution and structural parts that had been knowingly misrepresented by a prime contractor or supplier. Instances were discussed where domestic suppliers of counterfeit materials and structural parts simply closed down one shell company operating via the Internet when their counterfeiting was detected and set up another with a different name, often in a different city.

The Senate investigation found that weaknesses in testing practices increased the vulnerability of critical defense systems to counterfeit parts. It also found that neither DOD agencies nor defense contractors were routinely reporting instances of counterfeiting. Failure to report counterfeits when identified allows suspect parts and their suppliers to remain in the defense supply chain. In addition, the investigation found that contractors sometimes seek reimbursement from DOD for the cost of replacing identified counterfeit parts contained in systems they (the contractors) had supplied.

The National Defense Act Authorization for FY 2012 requires, among other things, that counterfeits be reported, that contractors use trusted suppliers, and that a tighter inspection regime for imported electronic parts be implemented. The NDAA also changed the law to prohibit defense contractors from charging the government for the cost of repairing or replacing systems they supply that contain counterfeit parts. Mr. Bryan said that these new statutory requirements will result in regulations requiring DOD and the defense contracting community to set up better systems to track testing and verification and to share that information on counterfeit parts.

After the presentation, the participants discussed weaknesses in the testing practices used by contractors and their suppliers, and the major changes in reliability of the global supply system for electronic parts stemming from used-recycling activities in China, the rapid turnover in manufacturing lines for original, authentic parts, and the growth of Internet-based parts purchasing. There was extended discussion of potential performance-degrading effects of counterfeit parts that seem to work properly in routine testing or testing under unstressed conditions.

COUNTERFEIT PARTS AND PARTS OBSOLESCENCE

To set the stage for her comments on how Boeing deals with parts obsolescence, counterfeit parts, shortages, and other issues raised at the workshop, Dr. Chong gave an overview of Boeing as a global commercial business and described where her organization fits within the company. She stressed that Boeing does not make most of the parts and components it uses: It is highly dependent on its supply chain, which includes 22,000 partners and suppliers. Her organization handles all of the materials R&D and process and manufacturing technology development for Boeing. This includes sustainment support for all Boeing production programs, as well as near-, mid-, and far-term technology R&D. The Boeing materials and parts management organization handles issues related to limited-life parts, COTS hardware, and environmental concerns, as well as obsolete and counterfeit parts.

Counterfeit electronic parts are particularly troublesome for aerospace electronics, Dr. Chong said, because of the wide range of risks they raise: not just system malfunction risk but also mission risk, safety risk, schedule risk, and economic risk. She agreed with comments of earlier participants about the importance of counterfeiting and misrepresentation of materials and structural parts. Sources of information for identifying counterfeits include whistleblowers internal and external to the supply chain intermediaries, as well as testing done by Boeing and its suppliers. When asked if she knew of any instances of industrial sabotage or malicious intent motivating an instance of counterfeiting, she replied that she did not personally know of any; typically it seems to be a case of someone not doing their job with respect to verifying, testing, and reporting. Mergers and acquisitions can also affect supplier processes, particularly for materials and structural parts manufacturing. Even a change from one facility to another within a company that is performing a production process can change product characteristics.

In response to a question about how far down the supply chain Boeing is vigilant about supplier quality assurance and testing, Dr. Chong said that it depends on the supplier and the part or material in question. For materials and structural parts, Boeing uses a system of ongoing audits and inspections. Beyond these internal practices, the company also participates in aerospace industry activities to set standards, including the Aerospace Industries Association Counterfeit Parts Integrated Process Team and the SAE G-19 Committee, which developed the SAE AS 5553 standard for counterfeit parts, which Mr. Bryan had referenced.

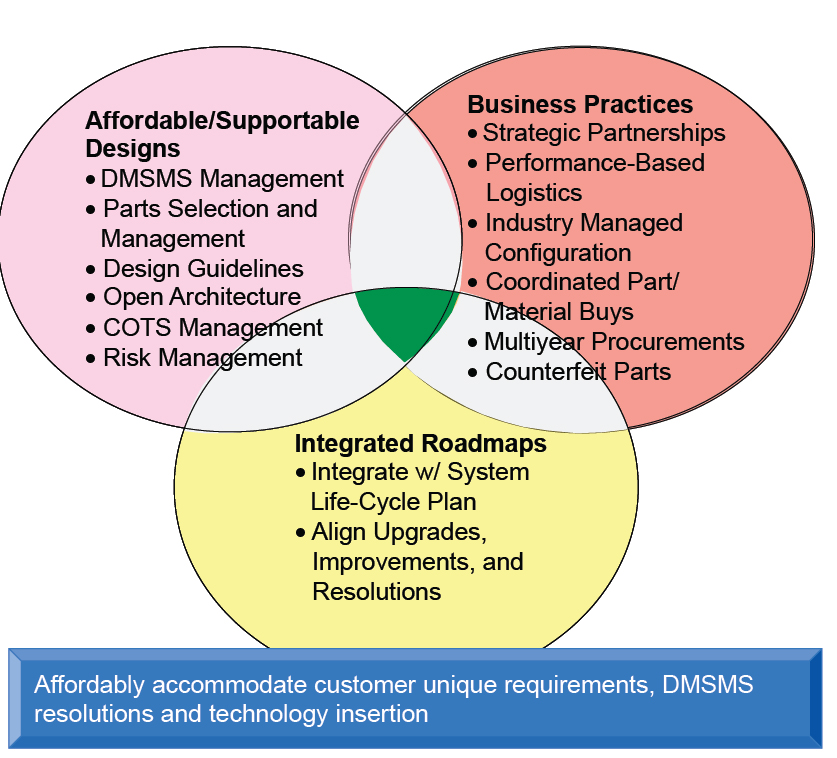

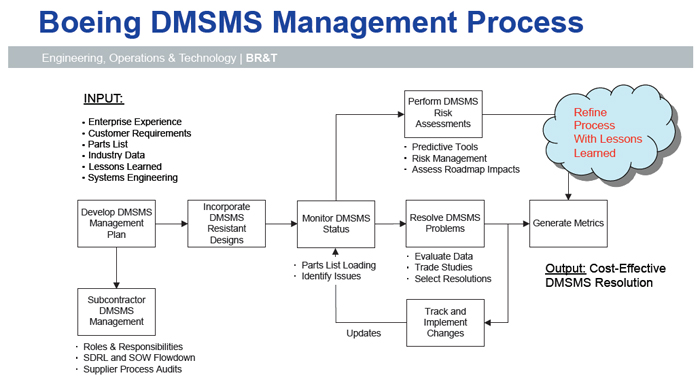

For materials shortages and parts obsolescence, Boeing has strategies to anticipate and plan for events in advance similar to those Dr. Schafrik described in his presentation. Figure 7 lists the approaches that are used in the DMSMS management strategy, while Figure 8 illustrates the steps in one of these approaches, the DMSMS Management Process. Dr. Chang sees counterfeiting as a harder problem to anticipate in advance and address with a standard process.

Sometimes an obsolescence problem comes to attention because a supplier tells Boeing it cannot make a component or part anymore because one of its materials or parts suppliers is no longer making a needed material or part. Later in her presentation, Dr. Chong listed and discussed three major drivers for DMSMS: diminished overall demand; green initiatives and moves to environmentally compliant parts; and extended support periods resulting in product supply–system life cycle mismatches. When a supply discontinuance notice is received, because a supplier is going out of business or is stopping a production line, multiple parts and even families of part types can be affected. The time required to find another supplier depends on many factors, but often identifying a potential supplier is fairly quick; it takes longer to certify the supplier and/ or the replacement product. Boeing is actively investigating computation-based tools that would lessen the amount of testing required to certify a replacement;

FIGURE 7 Elements of overall DMSMS strategy used by a major aerospace systems integrated manufacturer. SOURCE: Dianne Chong, Assembly, Factory, and Support Technologies; Engineering, Operations, and Technology, Boeing, “Counterfeit parts and parts obsolescence,” presentation to the committee on July 24, 2012, slide 13.

most of these tools and associated testing technique development are intended for structural materials certification.