This chapter discusses the vehicle systems technology areas that the Partnership is addressing in its research and development (R&D) programs, which include the following: (1) advanced combustion, emission control, and fuels for internal combustion engines (ICEs); (2) fuel cells; (3) hydrogen storage onboard a vehicle; (4) electrochemical energy storage or technologies for storing electricity onboard a vehicle; (5) electrical propulsion systems; and (6) materials for reducing the weight of a vehicle. The reader is referred to the presentations from the Partnership to the National Research Council’s (NRC’s) Committee on Review of the U.S. DRIVE Research Program, Phase 4, on the various technical areas (Appendix D provides a list of the presentations to the committee at its meetings). The presentations can all be found in the project’s Public Access File, available through the National Academies Public Access Records Office. Chapter 4 addresses issues associated with hydrogen, electricity, biomass-based fuels, and natural gas.

ADVANCED COMBUSTION ENGINES, EMISSION CONTROL,

AND HYDROCARBON FUELS

Introduction and Background

It will take decades to develop and integrate non-internal combustion engine propulsion systems into becoming a significant fraction of the total U.S. mobility fleet. The internal combustion engine will be the dominant power plant for mobility systems for at least the next 20 to 30 years (NRC, 2008, 2010). Consequently it is important to maintain a dedicated effort directed at ICE improvement within the U.S. DRIVE research portfolio.

Furthermore, there is reason for optimism that the drive-cycle-based efficiency of ICEs can be improved, both through engine-based advancements and through hybridization, such that the fuel consumption of engine-powered vehicles can be significantly reduced. Also, the engine has a sophisticated and mature manufacturing basis and is capable of using a range of fuels, from petroleum to liquid-based biofuels to gaseous fuels, derived from a variety of feedstocks. Liquid fuels offer the attractive characteristic of having very high energy per unit of mass and energy per unit of volume. This characteristic facilitates long-range and/or sustained high-power-output vehicle operation. There will be, for many decades, applications for which the ICE-powered vehicle is the best choice.

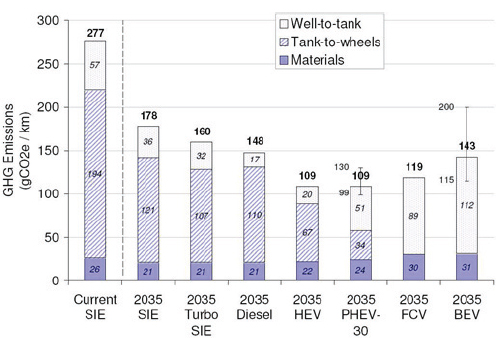

Life-cycle analyses reported in the literature, such as that shown in Figure 3-1, suggest that total greenhouse gas (GHG) emissions for future high-technology ICE-powered vehicles1 will be made competitive with non-ICE-powered vehicles on a basis of total GHG life-cycle emissions, while still meeting stringent air quality regulations (Weiss et al., 2000; Bandivadekar et al., 2008). Uncertainty bars in Figure 3-1 denote well-to-tank GHG emissions for electricity generated from coal (upper bound) and natural gas (lower bound). For the well-to-tank GHG emissions from hydrogen fuel cell vehicles (HFCVs; shown as “FCV” in Figure 3-1), it is assumed that the hydrogen fuel is steam-reformed from natural gas at distributed locations and compressed to 10,000 psi.

The advanced combustion and emission control (ACEC) technical team of U.S. DRIVE is the Partnership’s technical interface with the research community’s activities in advanced combustion and emission control. The goals, technical targets, and program structure of the ACEC technical team build on those from the FreedomCAR and Fuel Partnership, which in turn built on the goals and targets from the Partnership for a New Generation of Vehicles (PNGV). For the FreedomCAR program, the advanced combustion and emission control targets and results were as follows:2

• Peak engine brake thermal efficiency (BTE) of 45 percent

—This BTE was demonstrated with a light-duty diesel engine and an H2-fueled ICE.

• Oxides of nitrogen (NOx) and particulate matter (PM) emissions for light-duty diesel engines at Tier 2 Bin 5 (T2B5) standards

— Twelve vehicle models that met this target were commercially available in the 2012 model year (MY).

__________________

1 Hybrid electric vehicles and plug-in hybrid electric vehicles are included in this classification because the engine still plays a major role as the energy converter between the fuel energy and work delivered to the wheels.

2 R. Peterson, General Motors, and K. Howden, Department of Energy, “Advanced Combustion and Emission Control Technical Team,” presentation to the committee, January 26, 2012, Washington, D.C.

FIGURE 3-1 Predicted comparative total greenhouse gas emissions for current spark ignition engines (SIEs) and potential 2035 propulsion systems. NOTE: Acronyms are defined in Appendix E. SOURCE: Bandivadekar et al. (2008).

• Power-train cost of $30/kW

— This cost target guidance and status are currently under evaluation by U.S. DRIVE.

To push past the targets of the FreedomCAR and Fuel Partnership, the U.S. DRIVE Partnership addressed three engine technology pathways: (1) hybrid optimized (low-level power density), (2) naturally aspirated (mid-level power density), and (3) downsized and boosted (high-level power density); it identified engine efficiency metrics at three load conditions: peak efficiency; 2-bar brake mean effective pressure (BMEP)—2,000 revolutions per minute (rpm); and 20 percent of peak load—2,000 rpm.

The specific 2020 stretch targets were set relative to 2010 MY engines for each technology pathway. Table 3-1 shows a compilation of these targets for each engine technology pathway for each of the three metric conditions. Standard fuels, either gasoline or diesel, are considered in specifying the performance metrics.

For each of the three pathways being pursued to achieve the targets shown in Table 3-1, the fundamental approach and issues being addressed are these:

1. High-efficiency combustion with low engine-out emissions

— Low-temperature combustion (LTC)

TABLE 3-1 Advanced Combustion and Emission Control Efficiency Baselines (2010) and Stretch Targets (2020)

| 2010 Baselines | 2020 Stretch | |||||||

| Technology Pathway | Fuel | Peak Efficiency (%) | Efficiencya @ 2-bar BMEP and 2,000 rpm (%) | Efficiencya @ 20% of Peak Load and 2,000 rpm (%) | Peak Loadb at 2,000 rpm | Peak Efficiency (%)c | Efficiencyc @ 2-bar BMEP and 2,000 rpm (%) | Efficiencyc @ 20% of Peak 2,000 rpm (%) |

| Hybrid application | Gasoline | 38 | 25 | 25 | 9.3 | 46 | 30 | 30 |

| Naturally aspirated | Gasoline | 36 | 23 | 23 | 10.7 | 43 | 28 | 28 |

| Downsized boosted | Gasoline | 37 | 22 | 29 | 19 | 44 | 27 | 35 |

| Diesel | 40 | 26 | 32 | 21 | 48 | 31 | 38 | |

aEntries in percent brake thermal efficiency (BTE).

bEntries in bar of brake mean effective pressure (BMEP).

cEntries in percent BTE that are equal to 1.2 times the corresponding baseline BTE.

SOURCE: R. Peterson, General Motors, and K. Howden, Department of Energy, “Advanced Combustion and Emission Control Technical Team,” presentation to the committee, January 26, 2012, Washington, D.C.

— Dilute spark-ignited combustion

— Clean diesel

2. Improved efficiency with waste energy recovery

— Solid-state and mechanical approaches

— Improved air handling and lubricants

3. Efficient aftertreatment systems that reduce the energy penalty and meet emissions regulations

— NOx, PM, hydrocarbons (HC), and carbon monoxide (CO)

At first glance the above list of technology pathways appears to focus on development-type issues that would best be addressed by industry as part of product development. However, the barriers to achieving the targets given above are fundamental understandings of the controlling phenomena for each pathway, and this is the focus of the U.S. DRIVE activities. The optimization of the interaction among the following is very complicated: the ambient conditions; the details of the gas exchange processes (intake and exhaust processes, exhaust gas recirculation [EGR], boost, intercooling, manifold geometry, valving events, etc.); the in-cylinder processes (injection characteristics, in-cylinder flow, combustion chamber geometry, fuel chemistry, etc.); and the exhaust-gas aftertreatment system (PM traps, NOx reduction systems, CO and HC oxidation systems, etc.) for minimum fuel consumption while meeting emissions standards. To address these challenges, industry uses analysis-led design, in which computational fluid dynamics (CFD) is used to predict the optimum combinations of power-train system control parameters for each engine operating regime.

This process is only as good as the accuracy and fidelity of the CFD programs being used. Consequently, the lack of a detailed fundamental understanding of the various thermo-fluid-chemical processes and their incorporation into CFD submodels is a barrier to further engine system optimization. Certain aspects of the challenges that industry must deal with are not understood at this time: for example, there is no accepted explanation for how lubricating oil is involved in the particulate formation processes within the engine cylinder. This is a relevant example of the importance of a lack of fundamental understanding, because higher-efficiency engines will rely on controlled air-fuel heterogeneity within the cylinder, which can lead to significant nanoparticle formation. Lack of understanding of the detailed processes occurring in the combustion chamber, like the particulate formation, subsequently impedes the optimization of engine performance through simulation.

The engine combustion and emission research community is collaborating with industry to address these fundamental issues through experiment and simulation. To best duplicate the conditions in which to probe a deeper fundamental understanding of these phenomena, researchers perform experiments and simulations in representative engine geometries under real operating conditions.

The primary framework through which the U.S. DRIVE ACEC technical team engages with research activities on combustion and emission controls is through the U.S. Department of Energy’s (DOE’s) Office of Vehicle Technologies Program (VTP). This office supports fundamental research in combustion, energy recovery, and aftertreatment performance. Within these programs there is participation from industry, DOE national laboratories (Argonne National Laboratory [ANL], the Sandia National Laboratories [SNL] Combustion Research Facility, Oak Ridge National Laboratory [ORNL], Pacific Northwest National Laboratory [PNNL], Lawrence Livermore National Laboratory [LLNL], and Los Alamos National Laboratory [LANL]), and universities.

DOE’s vision of the collaborative activities between national laboratories, universities, and industry is a progression from fundamental to applied research to technology maturation and deployment. Fundamental R&D is the focus of activities at the following:

• Sandia National Laboratories

— E.g., Combustion Research Facility (lean-burn, LTC, advanced direct injection)

• Pacific Northwest National Laboratory

— E.g., catalyst characterization (NOx and PM control)

• Argonne National Laboratory

— E.g., x-ray fuel spray characterization

• Lawrence Livermore National Laboratory

— E.g., chemical kinetics models (LTC and emissions)

• Los Alamos National Laboratory

— E.g., CFD modeling of combustion (KIVA code development)

• Universities

— Complementary research

The fundamental to applied bridging R&D is performed at the following:

• Oak Ridge National Laboratory

— E.g., experiments and simulation of engines and emission control systems (bench-scale to fully integrated systems)

• Argonne National Laboratory

— E.g., H2-fueled ICE, fuel-injector design

Finally, competitively awarded cost-shared industry R&D is done by the following:

• Automotive and engine companies and suppliers

— E.g., engine systems and enabling technologies (sensors, variable valve actuation, waste heat recovery)

The advanced combustion and emissions control program is well managed. The organizational structure of its activities involves memoranda of understanding between companies and government laboratories. It is usual for individual projects to include one or more of the national laboratories, a university, and an industrial partner. To ensure relevance, industry cofunding or matching is often required.

In addition to the regular research meetings within a specific project, two formal research reviews are held each year, one at the Sandia Combustion Research Facility in Livermore, California, and one at the U.S. Council for Automotive Research (USCAR) in Southfield, Michigan. The researchers also participate in the DOE Annual Merit Review.

Additional avenues for technical interchange are promoted through CLEERS (Crosscut Lean Exhaust Emission Reduction Simulation) and the Engine Combustion Network (ECN).

CLEERS sponsors monthly teleconferences and an annual workshop to promote the development of improved computational tools for simulating realistic full-system performance of lean-burn diesel/gasoline engine and associated emission control systems. This activity helps in the development of emission control models that are integrated into vehicle simulations for drive-cycle analysis within the vehicle systems and analysis technical team (VSATT).

The ECN supports a website and teleconferences to share and leverage research between experimenters and modelers on direct-injection fuel sprays and combustion.

Overview of Technologies Being Investigated

To implement new combustion strategies, effective exhaust-gas energy recovery, and aftertreatment systems that promote efficient engine operation, the air handling, combustion, and exhaust subsystem must be optimized as a system. Such optimization requires advanced computational fluid dynamics. It is now common that the design of a new power-train system is led by CFD. To extract increasingly better performance from the power train requires more accurate and detailed computational models. These models are developed through the coupling of fundamental experiments and computational submodel development. This is the interface at which the U.S. DRIVE effort is focused.

In the area of high-efficiency combustion, the emphasis continues to be on low-temperature combustion. LTC is in essence controlled knock, and it relies on the auto-ignition chemistry of the fuel. Regardless of the fuel, the underlying approach to achieving acceptable LTC is the same. One wants to get the fuel vaporized and partially mixed with the cylinder gases such that when the auto-ignition chemistry reaches the point of ignition, the energy release is volumetric. Furthermore there needs to be sufficient inhomogeneity of the mixture within the combustion chamber that the entire mixture does not auto-ignite all at once, which would lead to excessive rates of pressure rise. This inhomogeneity can be in

temperature, air-fuel ratio, or degree to which the local mixtures have kinetically traversed their auto-ignition pathway. If this is achieved, the engine efficiency is higher and the in-cylinder emissions are very low. The approach taken to control LTC will be dependent on the fuel type—gasoline-like, diesel-like, or dual fuels— and the load demanded of the engine. Since the NRC (2010) Phase 3 review of the FreedomCAR and Fuel Partnership carried out in 2009, five new combustion projects have been started to address these challenges.

Regardless of how efficient the engine is, there will always be some usable energy in the exhaust that leaves the cylinder. As the engine efficiency gets higher, the usable energy in the exhaust gets smaller. Thermodynamically, it is known that as the portion of recoverable energy in the exhaust decreases, the efficiency of an exhaust-gas energy recovery system also decreases. However, in the quest to maximize engine efficiency, gains can still be made by the inclusion of exhaust-gas energy recovery systems. This imposes challenging constraints on the cost-benefit assessment of implementing energy recovery systems in the exhaust, and on maintaining a highly efficient exhaust-gas aftertreatment system.

The fundamental research being pursued on exhaust-gas energy recovery within the ACEC technical team is to develop energy recovery systems that maximize the conversion of usable exhaust energy in ways that are economically viable. Research programs addressing exhaust-gas energy recovery involve electricity generation with thermoelectrics, as well as more efficient turbomachinery and air handling. In addition, work is being supported on advanced lubricants, improved friction management, and materials for higher operating pressures and temperatures.

Within the aftertreatment research programs, there are activities on developing efficient catalysts that operate at lower exhaust temperature, improved NOx and PM aftertreatment systems, reducing the platinum group metal (PGM) requirement for the aftertreatment systems, and combining multiple aftertreatment systems into a single unit.

The predictive capabilities of the current CFD programs are good. The simulation code used most widely at this time is KIVA III, developed by DOE. KIVA is an open-source-code program, which allows researchers to incorporate new understanding directly into the code for any aspect of the thermophysical processes occurring within the engine. For example, improved kinetic schemes for different fuel types or new submodels that more accurately represent liquid fuel-combustion chamber surface interactions can be implemented into the code and then exercised for more detailed predictions of combustion results. However, KIVA III is more than 12 years old and lacks important, modern numerical technologies such as parallel computing and using an object-oriented structure. Having an up-to-date, open-source CFD program for researchers to use is a critical aspect of achieving the improvement potential of the ICE and aftertreatment power trains.

The DOE is supporting work on a new version of the code, KIVA IV. To date the code has not been widely adopted. Discussions of committee members3 with academic users led to a list of possible reasons for the code not being widely adopted:

• A code with KIVA IV’s level of physics and geometry (engines) needs to be modular and needs to have a data structure that is object-oriented.

• The current effort allocated does not appear to provide the level of development support required for doing an acceptable job—an increased effort was suggested by academic users and submodel developers.

• Code development for KIVA needs to be strongly tied to the activities of its “customers,” which are predominantly the universities where the advanced submodels are being developed and implemented.

• Intellectual property (IP) issues associated with the code and submodels may be jeopardizing the open-source designation. If this key element is lost, the university following could disappear, which seems to be happening.

Perhaps if a more active interface could be established between researchers working on the code development, university and research groups developing submodels, and industry partners, who will be the ultimate users of the code, the adaptation of the new code could be expedited.

The energy companies continue to be engaged, and the program of Fuels for Advanced Combustion Engines (FACE), organized under the Coordinating Research Council (CRC), is supplying an important database for quantifying the impact of fuel characteristics on engine emission processes and alternative combustion process facilitation.

In response to questions from the committee, U.S. DRIVE Partnership officials commented that natural gas is not included in the Partnership’s technical scope. The committee believes that in light of the increased supply of natural gas and the high interest in using it to displace petroleum, an assessment should be made of whether natural gas is in any way an enabler for achieving U.S. DRIVE goals. For example, does natural gas facilitate the advanced combustion modes under investigation within U.S. DRIVE?

The ACEC technical team’s responses to the recommendation of the previous review were good. The team is continuing to look for opportunities to enhance collaboration and has a program in KIVA code development. As discussed above, the committee believes that the KIVA code development effort could be improved. The ACEC technical team is making more use of the vehicle simulation that is being developed by the VSATT, and although it is not engaged in biofuels research, the team is aware of activities in the field. Also, the approach being

__________________

3 In particular, David Foster, committee member, had discussions with academic users.

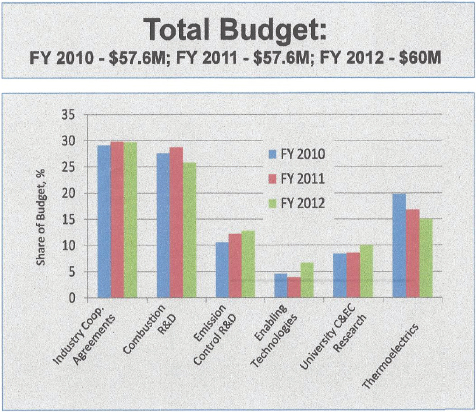

FIGURE 3-2 Department of Energy advanced combustion engine research and development (R&D) funding—FY 2010 to FY 2012. SOURCE: R. Peterson, General Motors, and K. Howden, Department of Energy, “Advanced Combustion and Emission Control Technical Team,” presentation to the committee, January 26, 2012, Washington, D.C.

taken within the ACEC technical team’s programs in developing kinetic models for combustion process simulation is compatible with the inclusion of compositional changes that could occur to the fuel when biomass-derived compounds are blended with the fuel.

Funding

Even though the U.S. DRIVE Partnership’s ACEC technical team does not exercise control over a budget, it did offer to the committee an overview of the DOE funding within the advanced combustion and emission control programs for FY 2010 through FY 2012 (see Figure 3-2).

Within the scope of the U.S. DRIVE goals, the work allocation for the continued development of the ICE and vehicle electrification seems appropriate.

This section presents a summary of accomplishments related to R&D activities in the areas of advanced combustion, emission control, and fuels for internal combustion engines.4

Low-temperature combustion has proven to be an effective means of improving closed-cycle efficiency and reducing the formation of NOx and particulates. By reducing the formation of NOx, both the cost and the complexity of additional aftertreatment can be reduced. The benefits of LTC are known, and include dramatic reductions in the formation of NOx. However, controlling the in-cylinder processes leading to successful LTC operation is a challenge. The ACEC technical team has demonstrated a number of successes both in the control of LTC and in expanding its operational range within the engine duty cycle.

One example of this success is a project at ANL where researchers were able to use 87 research octane number (RON) gasoline in a 1.9-liter turbocharged engine while retaining a full load range and diesel levels of efficiency with substantially reduced NOx.

The Sandia National Laboratories achieved indicated thermal efficiencies as high as 48 percent by using partial fuel stratification in a boosted homogeneous charge compression ignition (HCCI) engine.

The ORNL has a project using E85 (a mixture of 85 percent ethanol and 15 percent gasoline) in a spark-assisted HCCI engine. A 17 percent increase in indicated thermal efficiency was achieved as compared to that of gasoline and over a wide range of loads.

The use of two fuels, while adding some complexities and costs, also adds to the capabilities of controlling combustion and emissions. Reactivity controlled compression ignition (RCCI) engines involve the in-cylinder blending of two fuels with differing reactivity in order to tailor the reactivity of the fuel charge. Researchers at ORNL and the University of Wisconsin have used a diesel/gasoline multicylinder engine RCCI to demonstrate efficiencies up to 5 percent greater than diesel efficiencies. To better understand how dual fuels provide the benefits, fuel mixing and RCCI combustion were imaged from inside an optical engine by researchers at SNL and the University of Wisconsin.

In other combustion research approaches, researchers from ANL, SNL, and the Ford Motor Company, using advanced direct injection of hydrogen, were able to achieve 45.5 percent peak brake thermal efficiency of a hydrogen-fueled ICE. Further, it is expected that minimal exhaust aftertreatment will be required to meet stringent emission goals. The researchers were also able to demonstrate a part-load efficiency of 31 percent while meeting T2B5 emissions standards.

__________________

4 A full summary of accomplishments can be found in U.S. DRIVE Highlights of Technical Accomplishments: 2011, available at http://www1.eere.energy.gov/vehiclesandfuels/pdfs/program/2011_usdrive_accomplishments_rpt.pdf.

Detailed CFD and supporting experimental activities are critical to achieving more efficient combustion modes. The Lawrence Livermore National Laboratory has developed new approaches to computing fuel combustion chemistry using desktop-scale workstations, containing graphical processing units (GPUs) in addition to conventional central processing units (CPUs), that result in about an order-of-magnitude decrease in computation time.

Additional accomplishments relate to improved understanding of engine lubrication, spray and combustion modeling, EGR control, and exhaust energy recovery. The ORNL, working with Cummins, Inc., has developed a fiber-optic probe with laser-induced fluorescence to provide an accurate measurement of fuel dilution in engine oil. This technology has already been licensed to industry.

Researchers at ANL, the University of Illinois at Chicago, and Caterpillar have developed a new spray model for diesel engines that accounts for effects such as cavitation and turbulence in addition to aerodynamic breakup.

There are several other ICE-related projects that have added to industry’s ability to produce more efficient engines with lower emissions. Among those, SNL established the ECN, an international, multi-institutional collaboration with goals of improving the understanding of spray nozzles and increasing the capability of developing predictive spray models. Also, ORNL, the University of Michigan, and Ford Motor Company have provided a new understanding of EGR fouling mechanisms that can lead to improved EGR heat exchanger designs.5

Other important projects include collaboration between Ford Motor Company, Wayne State University, and ConceptsNREC to improve turbocharger design so as to improve engine efficiency while increasing rated power. Finally, through DOE working with Ford Motor Company, an improved aftertreatment system to minimize NOx emissions with selective catalytic reduction (SCR) was developed.

Conclusions

The ACEC technical team is making good progress. It is doing a good job at maintaining a close and constructive working relationship with the stakeholders within the vehicle and energy community. It is critical for the technical team to maintain this collaboration and to look for ways to make it even stronger.

The major barrier to implementing advanced combustion, aftertreatment, and fuel technologies continues to be an insufficient knowledge base. For example, the understanding necessary to control low-temperature combustion over a large portion of the engine map is a fundamental area appropriate for federal support. Topic-specific understanding is critical to continued improvement of the ICE power train; also critical is understanding of the system-level interactions between

__________________

5 Further details on this work can be found at http://www1.eere.energy.gov/vehiclesandfuels/pdfs/deer_2011/tuesday/presentations/deer11_styles.pdf.

the energy carrier, the energy release process, and the final emission cleanup.6 Continued close collaboration between DOE and industry is necessary to allow newly developed understandings to transition into the industrial laboratories and to enable the identification of new areas where enhanced understanding will be most beneficial. Even though the thrust of current activities within the U.S. DRIVE Partnership is to develop the technologies necessary to meet performance targets, being able to implement the technologies into vehicles that are affordable will ultimately determine their success.

The ACEC technical team is a well-managed activity and should be recognized for its accomplishments. However, the committee does have two recommendations that it believes will make the program stronger and more complete.

Recommendations

Because computational fluid dynamics plays an indispensable role in future engine-power train system development, having a robust, modern code in which researchers can integrate and exercise improved submodels is critical. The U.S. DRIVE Partnership is working on the next generation of KIVA, but KIVA IV may not be widely adopted by the research community.

Recommendation 3-1. The DOE should undertake a larger effort on the next generation of KIVA in order to be successful in facilitating such a resource. There should be a more formal collaboration established among the industry stakeholders, university stakeholders, and the DOE researchers doing the development work for KIVA IV. Efforts should be made to implement a modular and object-oriented structure to the code that is most useful to the ultimate stakeholders.

Domestic natural gas reserves and production are growing rapidly, providing for possible future use in ICE vehicles.

Recommendation 3-2. U.S. DRIVE should make an assessment of whether natural gas can be an enabler for achieving the advanced combustion modes currently being pursued in its research portfolio.

Fuel cell vehicles, under development globally, are based on a technology that can ultimately result in a zero-emissions and fossil-fuel-free option for transportation applications, and can help meet the vision of the U.S. DRIVE Partnership. Elegantly simple in concept, it has been a costly and daunting task to develop

__________________

6 Hybrid electric and even plug-in hybrid electric power trains are included in the general classification of power train.

fuel cell technology for vehicular applications. This has been partly due to the expectation that at the time of the rollout of such vehicles, the new technology would mimic current ICE vehicle operational standards and turn-key performance under all conditions at a competitive cost. The challenge has also partly rested with the fact that fuel cell power plant and ancillary subsystems are unrelated to any power-train technology previously used in conventional vehicular applications. In development for well over two decades, the vehicle original equipment manufacturers (OEMs) have now engineered, built, and tested fuel-cell-powered prototype vehicles, which appear to have met many consumer expectations with respect to vehicle performance. Automotive OEMs, with the assistance of suppliers and end users in the United States, have now begun to generate statistically significant on-road performance data leading to further confidence in the technology, engineering refinements, and identification of areas requiring further development. If the hydrogen fueling infrastructure, currently in its infancy, can evolve based on renewable hydrogen generation processes, there is a good chance that the vision of the U.S. DRIVE Partnership and its predecessor organizations will be achieved. Regardless of the source of the hydrogen, the development of a production and distribution infrastructure is clearly essential for the possible success of widespread hydrogen fuel cell vehicles (see Chapter 4).

The DOE’s primary role in fuel cell R&D is to facilitate the advancement of precompetitive technology that is considered longer term and high risk. These are projects that, if successful, will provide the OEMs with “next-generation” technical options. Assessment of the approximately 300 projects currently funded by DOE indicates that approximately 65 percent fall within the technology readiness levels (TRLs) of 2 and 4—that is, basic research efforts as well as activities related to analytical and experimental proof of concepts.7 Only a small percentage (7 percent) of funding is allocated to nearer-term initiatives (TRL 7).

The lifetime of the fuel cell stack is still a limiting factor. The current stack life is approximately half of the targeted lifetime as set forth by the Partnership. The 5,000-hour target required with minimal degradation has still not been achieved, as reported by the National Renewable Energy Laboratory (NREL) in on-road vehicle tests (Wipke et al., 2012); however, proton exchange membrane (PEM)-based bus stack lifetimes have exceeded 10,000 hours with similar technology. Advancements in systems engineering focusing on stack operation will also play a role in meeting the lifetime targets. Reports by NREL on fuel cell performance in on-road vehicle tests, based on 2009 vehicle technology, indicate that significant advancements have been achieved (Wipke et al., 2012).

Recent results presented at the 2011 and 2012 DOE Annual Merit Review meetings have indicated that the key issues impacting fuel cell performance are under investigation at the national laboratories, within academia, and in industry.8

__________________

7S. Satyapal, Department of Energy, “Fuel Cell Technologies Overview,” presentation to the committee, December 5, 2011, Washington, D.C.

Degradation mechanisms and performance limitations of the fuel cell power module are now the focus of such efforts, leading to a better understanding of the primary life-limiting issues. Reports from the Annual Merit Review over the past 3 years continue to show that laboratory tests of single cells have in many cases surpassed the program lifetime target (Debe, 2011, 2012), yet the laboratory and on-road test results are still in need of addressing operability and performance issues. As a result, technology and stack operating modes tested in the laboratory and those encountered during on-road vehicle tests are now being coordinated. The conclusions and outcomes of such efforts are essential to the delineation of the technical issues that need to be addressed when moving from the laboratory to real-world applications.

Assessment of the Program and Key Achievements

The fuel cell activities and resultant achievements can be grouped into three categories: (1) on-road vehicle performance, (2) longer-term R&D, and (3) near-term programs to support the secondary activities, including cost and engineering modeling, as well as programs focused on the adoption of the technology. All three areas have progressed at various paces since the Phase 3 NRC (2010) review.

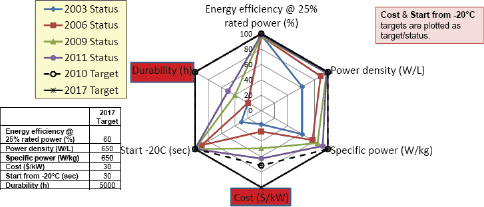

Fuel Cell Vehicle Performance

On-road tests of hundreds of vehicles have been completed since the NRC (2010) Phase 3 review. Although it is difficult to state conclusively the magnitude and extent of the progress, such results are impressive, as reported by NREL (see Figure 3-3). It is significant that the results of the on-road field vehicle demonstration programs were generated with vehicles using 2009 or earlier technology. Additional progress has been made since then by the OEMs. The past and current status of selected metrics, including power density (W/l) and specific power (W/kg), cost, durability, start times at –20°C, and energy efficiency at 25 percent rated power are presented in the spider chart in Figure 3-3. It is clearly evident that all of the metrics have met or are approaching the 2017 targets except for cost and durability. Significant progress has been made in the past 8 years.

Long-Term R&D

Long-term programs account for 65 percent of the fuel cell activities, ranging from proof of concept to applied engineering efforts. The topics addressed in this category are for the most part continuation and follow-on programs of prior efforts. This continuity is critical, as the programs that have survived the go/no-go decisions are the ones deemed to have the most significant potential.

__________________

8 See DOE’s Annual Merit Reviews, at http://www.annualmeritreview.energy.gov/.

FIGURE 3-3 Spider chart of fuel cell performance results versus targets for various years. SOURCE: C. Gittleman, General Motors, and K. Epping Martin, Department of Energy, “Fuel Cell Technical Team,” presentation to the committee, January 26, 2012, Washington, D.C.

There are new programs, but the number and magnitude have been limited. Since the Phase 3 review, five proposed efforts have been funded. New research efforts have originated through other offices besides the Office of Energy Efficiency and Renewable Energy (EERE), including the Office of Basic Energy Sciences (BES) and Small Business Innovation Research (SBIR) programs.

The accomplishments and progress considered significant in the past few years focus on the two main barriers, durability and cost. With respect to the barriers, the primary emphasis has been on the membrane electrode assembly (MEA), consisting of catalysts and membranes sandwiched between two carbon-based gas diffusion layers. The assembly is then placed between two plates, resulting in anode and cathode compartments (the cell). The cells are then stacked on one another until the desired voltage-current specification is met. Catalysts, predominately platinum group-based, are formulated with binders and/or ionomeric materials (proton conducting polymer) and fabricated into an electrode layer, which is applied to either the membrane or gas diffusion media. The majority of the currently funded efforts are on performance and durability aspects of carbon-free supported catalysts, non-precious metal catalysts, the quantity of catalysts required per cell, as well as on lower-cost, durable membranes. If success is achieved in any one of the above areas, the attractiveness of the fuel cell from a cost and durability perspective would be greatly enhanced. As noted in its recommendations, the committee believes that these activities should be increased in scope and that the budget should be adjusted to reflect the change.

Recent progress at the laboratory level has been promising, but it in no way implies the successful viability or the adoption of the advancements in fuel cell stacks when used in vehicles. With that said, recent work reported by Argonne

National Laboratory (Myers et al., 2011, 2012) at the 2011 and 2012 DOE Annual Merit Review meetings on determining the fundamental degradation mechanisms of MEAs has provided invaluable insight into the science of the failure modes of the catalysts and membranes. A number of other efforts to change catalyst supports, the architecture of the catalyst layers, and the work to develop non-precious metal catalysts will benefit from the findings of this effort. As the MEA is a complex “system,” changes in any one component will impact the functionality and performance characteristics of the entire assembly. As a result, advancements and scientific findings in each area must be thoroughly communicated, including to the industrial partners who will ultimately fabricate the MEA in high volumes. An assessment of the interrelationships of the fuel cell technical team with associated organizations indicates that the dissemination of information is taking place at the appropriate level on the membrane and electrode topics.

The catalyst development efforts have resided mainly at the national laboratories, where steady progress has been made in enhancing the catalytic activity as a function of the amount of catalyst required to support the reactions. The development of carbon-free supported catalysts is also underway. Durability, stability, and poisoning issues remain, but the results are promising, and as such these activities are essential if the ultimate targets are to be met. For example, at the national laboratories, fundamental electrochemical-catalyst modeling to predict performance-cost benefits is underway, as are activities to improve the understanding of the platinum core shell catalysts and the promising Pt3Ni(111) alloys, among others, and the impact of processing and operating conditions on them. Non-precious metal catalysts are also being investigated. Industrial organizations, predominately the ones that will eventually be part of the backbone of the supply chain, are engaged, with 3M being an example. The 3M activity on the nanostructured thin film (NSTF) electrode is showing good progress, not only from a catalysis perspective but also from the electrode layer architecture and the impact of water dynamics in a functioning MEA. The contributions of 3M with respect to the effect of gas diffusion media on performance offer another example of the interrelationships of the different layers within the MEA.

Because catalysts are at the heart of the electrochemical process and are a major cost component of the stack, research activity in this area is considered significant and appropriate and should be continued. It should be noted that selected aspects of catalyst and electrode technology used in fuel cells may provide guidance and direction in other electrochemical processes as well (e.g., batteries).

Proton exchange membranes are composed of complex polymers that must be able to transport protons efficiently with minimal resistance and at the same time exhibit acceptable mechanical strength and low gas permeability. They must be low cost and be able to be easily manufactured. The polymer/membrane development is a long and costly process. The DOE is aware of this and has been appropriately supporting new membrane development for a number of years in academia and national laboratories and within industrial organizations.

TABLE 3-2 Fuel Cell Stack and Stack Component Progress in Relation to the U.S. DRIVE 2010 and 2017 Targets

| 2010 Target | 2011 Status | 2017 Target | |

| Fuel cell stack durability (hr)a | 5,000 | 3,700 | 5,000 |

| Fuel cell stack cost ($/kWe)b | 25 | 22 | 15 |

| Membrane electrode assembly (MEA) cost ($/kW)b | 14 | 13 | 9 |

| MEA total Pt group metal total content (g/kW) | 0.15 | 0.19c | 0.125 |

| Non-Pt catalyst activity per volume of supported catalyst (A/cm3 @ 800 mVIR-free) | 130 | 127d | 300 |

| Bipolar plate cost ($/kW)b | 5 | 5 | 3 |

aProjected time to 10 percent voltage degradation from the technology validation activity.

bCost status is from 2011 DTI study; costs are projected to high-volume production (500,000 stacks per year). Available at http://www.hydrogen.energy.gov/pdfs/review11/fc018_james_2011_o.pdf.

cM. Debe, U.S. Department of Energy Hydrogen and Fuel Cells Program 2011 Annual Merit Review Proceedings, May, 2011. Available at http://www.hydrogen.energy.gov/pdfs/review11/fc001_debe_2011_o.pdf.

dP. Zelenay, H. Chung, C. Johnston, N. Mack, M. Nelson, P. Turner, and G. Wu. 2011. FY 2010 Annual Progress Report for the DOE Hydrogen Program. DOE/GO-102011-3178. U.S. Department of Energy, February, p. 816.

SOURCE: C. Gittleman, General Motors, and K. Epping Martin, Department of Energy, “Fuel Cell Technical Team,” presentation to the committee, January 26, 2012, Washington, D.C.

The focus has appropriately been on membranes that can operate with reduced hydration requirements and/or higher operating temperatures and at the same time exhibit higher conductivities. The committee sees less value in supporting membrane-based subsystem development—for example, in enthalpy exchange processes—as this is more of an engineering initiative and not deemed long-term, high-risk research. The financial resources used to fund the near-term engineering initiatives should be reallocated to topic areas that impact the durability and/or cost issues.

Table 3-2 summarizes the fuel cell stack and stack component progress against the 2010 and 2017 targets.

Near-Term Supporting Efforts

The DOE and the U.S. DRIVE Partnership have developed additional mechanisms by which the key fuel cell issues are addressed. Although the programs highlighted above are selected through the DOE solicitation-proposal process, working groups have been formed to facilitate better communication among the stakeholders and are also being asked to focus on the most critical needs (e.g., durability, modeling, and catalysis). The teams are led by national laboratory representatives and involve catalyst and membrane suppliers as well as fuel cell companies, vehicle OEMs, and other participants. As articulated by the

fuel cell technical team during the review process, the primary objectives are to (1) promote sharing in the learning, (2) prevent duplication of effort, and (3) disseminate the findings to the fuel cell community. The committee sees this activity as a valuable means to maximize progress and learning through such a coordinated effort. Cooperation among the team members on critical precompetitive research topics will accelerate and facilitate solutions for the entire industry.

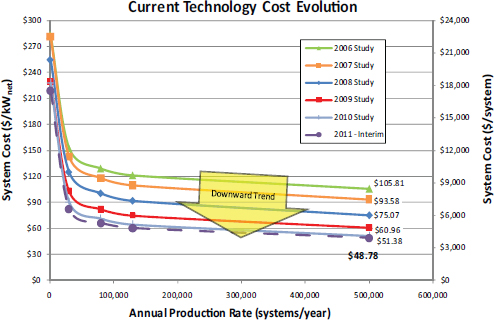

The past three NRC reviews of this program have expressed concerns that the cost assessments as reported are difficult to endorse fully as the technology was still evolving, the supply chain immature, and the technology used by the OEMs unknown to the assessment committee. The Phase 3 report (NRC, 2010) noted that even with these uncertainties, the estimated costs for the fuel cell system (for 500,000 per year production) represented a reference point from which to measure cost-reduction progress. As the $30/kW target is still quite challenging, the technical development and cost-reduction efforts currently underway must be appropriately funded. Figure 3-4 presents the reported cost estimates for the fuel cell system for the last 5 years. The most recent estimate is also included (2011).

Although it is difficult to validate the absolute value of the reduction in system costs, the trend is quite apparent. New manufacturing initiatives will further impart greater certainty in the numbers, as will commitments to the OEMs by the

FIGURE 3-4 Cost estimate on a dollars per kilowatt ($/kW) basis for the fuel cell system, not including onboard hydrogen storage. SOURCE: C. Gittleman, General Motors, and K. Epping Martin, Department of Energy, “Fuel Cell Technical Team,” presentation to the committee, January 26, 2012, Washington, D.C.

supply chain. As technology development efforts continue to progress, it is not possible to know at this time if there will be a significant impact on cost. High-volume vehicle production will not result in economies of scale with respect to the price of platinum. Platinum costs can be mitigated by recycling strategies, but the stack lifetime issue will impact maintenance and stack replacement costs until such time as durability issues are resolved. As it is not apparent that lifetime targets will be met any time soon, DOE should consider including, as part of its modeling efforts, not only the original bill of materials but also a realistic assessment of component replacement costs for the near term.

In addition to component costs, manufacturing processes must be efficient in leading to a high yield of finished goods. The membrane electrode assembly, the heart of the power generation unit, is a complicated and costly five-layer package composed of membranes and catalyst layers sandwiched between gas diffusion media. The intimate bonding of the various layers is critical, as are catalyst functionality and membrane conductivity. If any element of the five layers is jeopardized or incorrectly assembled and then incorporated into stacks, the problem is not likely to surface until preliminary stack qualification testing. At that point the entire stack would have to be rebuilt and the suspect cells removed. This is a costly and time-consuming process. Sophisticated electroanalytical methods are now currently used to assess small, laboratory single cells, especially alternating current (ac) impedance spectroscopy from which membrane and electrode viability can be assessed. These methods have not been fully developed for online, continuous, web-based, stand-alone membrane electrode assemblies.

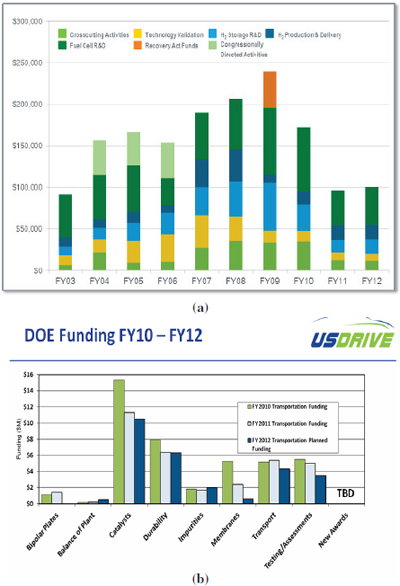

Program Funding

The annual funding for hydrogen and fuel cell R&D since 2003 is presented in Figure 3-5(a). The breakdown of how the funds have been appropriated with respect to fuel cell R&D since the Phase 3 review is shown in Figure 3-5(b). In the latter years it is evident that fuel cell R&D has seen a significant reduction in funding. It is also evident from Figure 3-5(b) that the bulk of the funding has focused on the most critical technical issues, namely, catalysts and membranes. This trend continues as the proposed FY 2013 budget (DOE, 2012a) for the DOE hydrogen and fuel cell R&D has been further reduced by greater than 20 percent, to about $80 million, down from $104 million in FY 2011 and $170 million in FY 2010. The fuel cell systems R&D budget, relevant to this review, has seen a decrease in funding from $75 million in FY 2010 to $43 million in FY 2012.

The budget reductions have resulted in a limited but more focused and coordinated set of initiatives (Figure 3-5[b]). Although fuel cell technology has progressed, the current status is that further advancements are still needed. The funding reductions have impacted to varying degrees the approximately 300 hydrogen and fuel cell projects currently under contract with DOE, as well as the number of new awards made under recent solicitations. Offsetting this to some

FIGURE 3-5 Historical and current Department of Energy (DOE) budgets for hydrogen and fuel cell research and development (R&D), FY 2003 through FY 2012. (a) Annual DOE funding for hydrogen and fuel cell R&D, FY 2003 through FY 2012. (b) DOE funding for various fuel cell R&D areas, FY 2010 through FY 2012. SOURCE: C. Gittleman, General Motors, and K. Epping Martin, Department of Energy, “Fuel Cell Technical Team,” presentation to the committee, January 26, 2012, Washington, D.C.; and S. Satyapal, Department of Energy, “Fuel Cell Technologies Overview,” presentation to the committee, December 5, 2011, Washington, D.C.; Sunita (2011). (b) (b) Figure 3-5 (b)

extent is the coordination of activities with other organizations—for example, with the Office of Basic Energy Sciences, which has contributed to key fundamental learning and advancements. It is important that conclusions regarding the status and needs of the program not be improperly derived. The benefits of prior DOE funding are just now becoming apparent and quantifiable. Over the past decade, 183 prototype vehicles have been involved in actual on-road tests, more than 500,000 vehicle trips have been documented, and 3.5 million miles have been driven—all of which have contributed to the assessment and validation of the technology and the identification of areas requiring further technical enhancement. This learning impacts the supply chain as well because component suppliers are responsible for developing and ultimately manufacturing what goes into a vehicle. Given that suppliers are the predominant recipient of DOE funding, budget reductions may impact them as well.

Significant Barriers and Issues

As highlighted throughout this review, cost and durability issues remain significant impediments to meeting the fuel cell program targets. Both are technical issues and must ultimately be addressed through continued activities in fundamental and applied R&D efforts.

If progress toward meeting the targets is to continue in the aforementioned topic areas, the activities addressing them must remain intact, in some cases for extensive periods of time. Although the OEMs are making progress, what is reported to the committee is not necessarily derived from the most recent technical advancements, but rather from older vehicle performance test programs that take time to develop statistically significant and meaningful results. These results then provide direction to the fuel cell technical team, followed by DOE solicitations. It is important but difficult to maintain a coordinated, longer-term, proactive effort among the various stakeholders, including the OEMs, the national laboratories, private industry, and academia, especially in the face of uncertain funding. The majority of the Fuel Cell Technologies Program funding should be directed toward next-generation technical solutions that will be important in meeting the goals of the entire program. The lack of continuity of funding as a result of budget limitations is a serious issue.

Response to Phase 3 Recommendations

The Phase 3 review presented four recommendations regarding fuel cell activities (NRC, 2010). The recommendations addressed (1) increased funding levels and support for the enhancement of key system components, including stack technology; (2) ensuring that non-OEM cost and systems modeling activities utilize the most recent, up-to-date, vehicle technical know-how, design, and componentry; (3) the development of alternative pathways in the event that the primary paths fail

to yield desired results; and (4) the subjecting of currently funded nonperforming programs or efforts to an accelerated go/no-go assessment if they are deemed not to be of value to the vehicle program. It is noted by the committee that the majority of the recommendations were adequately addressed by DOE, some more so than others. Although not called out specifically in a formal response, in many cases elements of some of the recommendations can be found in existing funded programs. With that said, the recommendation to increase funding in the most critical area, specifically, stacks—that is, durability, catalyst, and membrane development—is not apparent from the FY 2010-2012 budget allocations.

Appropriateness of Federal Funding

The committee believes that R&D that has been supported by DOE related to fuel cells is appropriate for federal funding. R&D in this area is important for giving the nation a range of options for energy conversion across several applications and for providing needed energy savings and emissions reductions. Significant progress has been made to date; nonetheless, barriers that need to be addressed by research remain. Continued R&D support for fuel cells is necessary to make the progress needed to meet the ultimate goals set by DOE.

Observations and Conclusions

Based on the advancements that the automotive companies have made on their HFCVs and assuming that part of these advancements have been due to Partnership efforts, it can be concluded that significant progress has been made since the Phase 3 NRC (2010) report. It should be noted that such technologies were in part derived from DOE funding and coordinated efforts with the prior FreedomCAR and Fuel Partnership and current U.S. DRIVE Partnership programs. Furthermore, investigations on fundamental issues related to durability and performance have been expanded in scope and have begun to yield insight not only into degradation mechanisms but also in terms of providing guidance for developing next-generation catalysts and electrodes. Both are necessary if the performance targets are to be met. Progress has been made in other areas as well and should not be dismissed. It is important to provide continuous support for R&D in these areas if targets are to have any likelihood of being met.

Fuel cell stack cost and durability are still the two major areas that have not simultaneously met targeted levels. Stack lifetimes have exceeded 50 percent of the targeted 5,000 hours in real-world on-road vehicles. Fuel cell costs for a 500,000 per year production level have been projected to have dropped since the last report, from $60-$70/kW in 2009 to $49/kW in 2011.9 Further reductions

__________________

9 C. Gittleman, General Motors, and K. Epping Martin, Department of Energy, “Fuel Cell Technical Team,” presentation to the committee, January 26, 2012, Washington, D.C.

will potentially come over time, as learning from on-road vehicle performance and technologies with reduced platinum loadings are adopted. Advanced catalysts have been and continue to be developed, including platinum-free systems. Such programs have emanated from academia, industry, and, most important, from the national laboratories. New developments take significant time and testing resources by the fuel cell OEMs before they can be fully adopted. This activity represents significant financial resources.

Statements by OEMs in this country and by other global automotive companies have indicated that vehicles in limited quantities will be placed in predetermined locations worldwide, partly gated by the availability of hydrogen refueling facilities, in the 2014-2016 time frame. This activity coincides with the timing of the original technology roadmap milestone of the FreedomCAR and Fuel Partnership whereby in 2015 there would be a commercialization readiness decision. Considering the global economic downturn and the budget constraints of late, the vehicle engineering accomplishments attest to the commitment of automotive manufacturers to fuel cell vehicles and thus to the importance of the Partnership’s enabling R&D. The expected onset of fuel cell vehicle deployment is impressive.

Activities within the program encompass not only the technical elements of the stack but also a number of focus areas that address market adoption and analyses, as well as a host of technical and nontechnical topics. In light of the budget data presented in Figure 3-5 and the criticality of the technical issues (durability and cost), the “balance” of the entire program as assessed by the percentage of funding in less critical areas over others of greater importance can be called into question.

Recommendations

The adoption of fuel cell vehicles is partly dependent on the durability and the cost of the technology. Fuel cell development is an important element of the U.S. DRIVE Partnership and, if successful, the chances of meeting the long-term goal of reducing greenhouse gas emissions and U.S. dependence on foreign oil are increased. Fuel cell R&D activities that address the remaining technical challenges and costs have decreased annually since the NRC’s Phase 3 review. This decline negatively impacts the development of future solutions that the developers will have available to meet the near- and long-term targets.

Enhanced catalyst, electrode, and membrane robustness would improve the likelihood that fuel cell stacks achieve the 5,000-hour life target. Such research efforts are generally long-term programs, as new catalysts, membranes, and related stack initiatives must progress from fundamental research activities all the way through lifetime and performance testing, and then vehicle qualification. These types of R&D activities must remain a high priority in order to ensure that next-generation robust stack component solutions become available.

Recommendation 3-3. The DOE should increase the efforts related to the development of new catalysts, membranes, and related membrane electrode assembly components for proton exchange membrane (PEM)-based fuel cells. The focus should be on materials, performance, durability, and, ultimately, on manufacturability.

As noted throughout this major section on fuel cells, cost is the other major challenge besides durability. There are two primary cost-reduction pathways: subsystem process optimization and specific component cost-reduction initiatives. For example, technical innovations might result in the simplification or elimination of subsystems or, when it comes to stack components, lower platinum loadings as well as lower-cost membranes and plate hardware. Emerging modeling capabilities can be used for sensitivity analysis and can guide resource allocation to the areas that will have the greatest impact on performance, endurance, and cost at the system level.

Recommendation 3-4. The DOE should increase efforts for the cost reduction initiatives for fuel cells taking into account the entire system, including balance of plant. Emerging modeling capabilities should be used for sensitivity analysis and for guiding resource allocation to the areas that will have the greatest impact on performance, endurance, and cost at the system level.

A number of emerging alternative fuel cell concepts, if successfully developed, may provide options for the OEMs in future generations of fuel cell vehicles. An alkaline fuel cell that uses membrane technology is one such example; a fuel cell concept that employs a flowing catholyte concept is another. Although PEM technology is well embraced by the automotive OEMs, it is imperative that novel fuel cell concepts be assessed critically and, if considered potentially attractive, also be explored and, as appropriate, directly or indirectly supported by DOE in its long-term, high-risk portfolio of projects.

Recommendation 3-5. Either in coordination with other organizations, such as the Office of Basic Energy Sciences or DOE’s Advanced Research Projects Agency-Energy (ARPA-E), or directly, DOE should consider supporting new and innovative alternative fuel cell concepts.

High-volume manufacturing methods for fuel cell stack components, in particular for the membrane and electrode assemblies, will need to incorporate (electro-) analytical quality-control methods to assess membrane and electrode viability prior to assembly into stacks. Such methods are utilized in laboratory fuel cells, but they are not currently developed for high-speed web-based manufacturing processes. If successfully developed, the information will be able to identify stacks that have inherent flaws within the membrane, interfacial region, and electrode layers.

Recommendation 3-6. U.S. DRIVE should encourage projects that address the use of real-time, in situ electroanalytical quality-control methods to assess membrane and electrode performance characteristics during the continuous manufacturing web-based process.

Background

The mission of the hydrogen storage technical team is to “accelerate research and innovation to achieve commercially viable hydrogen storage technologies that meet U.S. Drive goals.”10 The onboard hydrogen storage goal is for “a >300 mile driving range across different vehicle platforms without compromising cargo space or performance.” The program scope is to “review and evaluate materials and systems research regarding hydrogen storage onboard light-duty vehicles and provide feedback to DOE and partnership stakeholders … generate goals and performance targets for hydrogen storage onboard vehicles … collaborate with other technical teams and assist the partnership in regards to hydrogen storage.” The work of the hydrogen storage technical team on onboard storage is most important to the U.S. DRIVE Partnership as a whole given the criticality of hydrogen storage to the performance of PEM fuel-cell-powered vehicles. The hydrogen storage system characteristics determine the amount of hydrogen that can be stored on the vehicle and the corresponding miles traveled between refueling as well as fuel storage costs.11

Materials-based solutions are the long-term option for onboard hydrogen storage. In the past decade, DOE established four hydrogen storage centers of excellence (COEs). Three materials centers of excellence (Chemical Hydrogen Storage COE, Metal Hydrides COE, and Hydrogen Sorption COE) operated from 2005 through 2010 and are now closed; final reports were issued April 2012.12 The fourth is the Hydrogen Storage Engineering COE. The COE proved to be an outstanding management concept that enabled the assembly of the right skills and resources for good collaboration to be brought to the work, a systematic down-select decision process, high-quality and consistent communication among the partners, and the development of intellectual property. Through these centers of excellence more than 400 compounds were investigated for their hydrogen sorption and release characteristics, and computationally millions of materials were studied. The work of these centers and related independent projects was a

__________________

10 N. Stetson, Department of Energy, and S. Jorgensen, General Motors R&D, “Hydrogen Storage Tech Team,” presentation to the committee, January 26, 2012, Washington, D.C. Also see http://www.hydrogen.energy.gov/storage.html.

11 See www.hydrogen.energy.gov/annual_review10_proceedings.html and http://www.hydrogen.energy.gov/annual_progress11.html.

12 See http://www1.eere.energy.gov/hydrogenandfuelcells/hydrogen_publications.html#h2_storage.

well-organized systematic effort. This work involved extensive collaborations. In total, 45 universities, 15 companies, and 15 federal laboratories participated. A number of materials identified in this work are still considered to have potential, but storage weight, volume, performance, and cost are still a challenge. A brief description of the center accomplishments follows.

• Chemical Hydrogen Storage COE. Los Alamos National Laboratory, the lead laboratory for the Chemical Hydrogen Storage COE, worked closely with PNNL and other partners. A major accomplishment of the center was to demonstrate that chemical reprocessing of spent fuel is feasible. The highest-capacity material identified was based on ammonia borane, which was shown to release 2 to 2.5 moles of hydrogen (13-16 weight percent [wt%]) below 200°C with good stability. Research studies led to new understanding of the kinetics and nucleation of dehydrogenation. Additional findings related to materials processing and materials modification for improved performance and for ease of regeneration at a favorable cost. The COE received 16 patents.

• Hydrogen Sorption COE. The Hydrogen Sorption COE, led by NREL, was challenged to obtain high gravimetric and volumetric storage of hydrogen compared with compressed storage and at ambient temperatures. Work was focused on materials that gave excess storage capacities greater than 6 wt% and 40 g/L at pressures less than 200 bar (ca. 20 MPa) and storage temperatures above 77 K. Major findings overall include new materials for cryogenic storage on high specific surface area sorbents by optimizing pore size distributions, metal organic frameworks that exhibit enhanced di-hydrogen binding, and ambient-temperature storage by means of spillover and coordinatively unsaturated metal clusters. Also, measurement capabilities were improved and materials design was accelerated with coupled theory and experimental efforts. The COE produced more than 200 peer-reviewed publications, stimulated progress worldwide, and fostered spin-off for other sorption applications.

• Metal Hydride COE. The Metal Hydride COE, which was led by SNL, had five projects: (1) destabilized hydrides with enhanced kinetics (LiBH4/Mg2NiH4); (2) complex anionic hydride materials (e.g., boron hydride); (3) amide/imide storage materials (e.g., LiMgN); (4) alane; and (5) engineering analysis and design. The COE expanded the knowledge of metal hydrides hydrogen storage material and issued 279 publications. The boron hydride system showed remarkable properties reversibly, storing 12 wt% hydrogen. In spite of these favorable properties, no single material was identified that meets all criteria. A breakthrough theoretical method was developed for the rapid screening of materials, and a new theoretical method, prototype electrostatic ground state, from the theory group enables the prediction of crystal structures of unknown compounds.

TABLE 3-3 FY 2010-FY 2012 Hydrogen Storage Research and Development Budget and FY 2013 Budget Request

| Year | Budget ($ millions) |

| FY 2009 appropriated | 59.20 |

| FY 2010 appropriated | 32.00 |

| FY 2011 appropriated | 15.00 |

| FY 2012 appropriated | 17.50 |

| FY 2013 requested | 13.00a |

aHydrogen Storage is included within the Hydrogen Fuel R&D request ($27 million).

SOURCES: DOE (2010a, 2011); Stetson (2010, 2011, 2012); S. Satyapal, Department of Energy,

“Fuel Cell Technologies Overview,” presentation to the committee, December 5, 2011, Washington, D.C.

• Hydrogen Storage Engineering COE. The more recently established Hydrogen Storage Engineering COE at Savannah River National Laboratory (SRNL) has as its mission to “address significant engineering challenges associated with the development of lower pressure materials based hydrogen storage systems for hydrogen fuel cell and internal combustion engines for light duty vehicles.”13 Reported accomplishments to date include the development of hydrogen storage system models, the establishment of a baseline for materials properties that is used to guide the development of storage systems, assessment of the current status of all storage system approaches versus targets, and the identification of technology gaps that help to focus R&D. Modeling work on metal hydride hydrogen storage systems was completed.

The coordination with the DOE Office of Basic Energy Sciences is continuing. Twenty BES-funded projects were included in the Annual Merit Review held in May 2012. Work is underway to strengthen all national collaborations (within the DOE and across agencies including the U.S. Department of Transportation [DOT], the U.S. Department of Defense [DOD-Defense Logistics Agency], the National Institute of Standards and Technology [NIST], and the National Science Foundation [NSF]).

The FY 2011 budget for the onboard hydrogen storage activities has seen a decrease of 75 percent from FY 2009 and a 60 percent decrease in the number of projects for the same time period. The materials development work has experienced the largest decrease, with the closing of three materials centers of excellence. New work on advanced compressed gas tanks is anticipated in the FY 2012 budget plan. See Table 3-3 for recent appropriations and the FY 2013 budget request for hydrogen storage R&D.

__________________

A new roadmap that will guide the research is in final development, having been last updated in 2007. The target levels for onboard hydrogen storage first established in 2003 are in review. The DOE is reevaluating the performance metrics in comparison to available fuel cell, hybrid, and electric vehicle performance data. The current and projected target levels are shown in Tables 3-4 and 3-5.

The capabilities of various storage systems have been determined from engineering models of the various technologies. Progress is being made, and several targets have been met for some technologies, but no technology meets all targets simultaneously. Cost is an issue for all technologies.

The key system issues and challenges have been identified in terms of the following criteria:

• Sufficient storage for driving range without impacting vehicle performance,

• Kinetics,

• Safety,

• Capacities,

TABLE 3-4 Onboard Hydrogen Storage Technical Targets, 2010, 2017, and Ultimately

| Target | Units | 2010 | 2017 | Ultimate |

| System gravimetric density | wt% | 4.5 | 5.5 | 7.5 |

| kWh/kg | 1.5 | 1.8 | 2.5 | |

| System volumetric density | g/L | 28 | 40 | 70 |

| kWh/L | 0.9 | 1.3 | 2.3 | |

| System fill time for 5-kg fill | min | 4.2 | 3.3 | 2.5 |

| kg H2/min | 1.2 | 1.5 | 2 | |

| Svstem cost | $/kg H2 $/kWhne[ | TBD | TBD | TBD |

| Minimum delivery temperature | °C | –40 | –40 | –40 |

| Maximum delivery temperature | °c | 85 | 85 | 85 |

| Minimum full flow rate | (g H2/s)/kW | 0.02 | 0.02 | 0.02 |

| Onboard efficiency | % | 90 | 90 | 90 |

| Cycle life (1/4 tank to full) | Cycles | 1,000 | 1,500 | 1,500 |

| Fuel cost | $/gge at pump | 3-7 | 2-4 | 2-4 |

| Loss of usable H2 | (g H2/hr)/kg H2 | 0.1 | 0.05 | 0.05 |

| “Well” to power plant efficiency | % | 60 | 60 | 60 |

| Fuel purity | % dry basis | 99.97 | 99.97 | 99.97 |

| Transient response | s | 0.75 | 0.75 | 0.75 |

| Start time to full flow (–20°C) | s | 15 | 15 | 15 |

| Start time to full flow (20°C) | s | 5 | 5 | 5 |

NOTE: TBD, to be determined.

SOURCE: See http://www1.eere.energy.gov/hydrogenandfuelcells/storage/pdfs/targets_onboard_hydro_storage.pdf; N. Stetson, Department of Energy, and S. Jorgensen, General Motors R&D, “Hydrogen Storage Tech Team (HSTT),” presentation to the committee, January 26, 2012, Washington, D.C.

TABLE 3-5 Current Status of Various Onboard Hydrogen Storage Technologies

| Current Status | Gravimetric (kWh/kg-system) | Volumetric (kWh/L-ystem) | Cost ($/kWh) |

| 700 bar (ca. 70 MPa) compressed (Type IV)a | 1.7 | 0.9 | 18.9 |

| 350 bar (ca. 35 MPa) compressed (Type IV)a | 1.8 | 0.6 | 15.5 |

| Cryo-compressed (276 bar)a | 1.9 | 1.4 | 12 |

| Metal hydride (NaAlH4)b | 0.4 | 0.4 | 11.3 |

| Sorbent (MOF-5; 200 bar)b | 1.7 | 0.9 | 18 |

| Off-board regenerable (AB)b | 1.4 | 1.3 | N/A |

NOTE: Cost targets are being finalized and are expected to be released soon. Also, the Environmental Protection Agency (EPA) defines 33.7 kWh of electricity as equivalent to 1 gallon of gasoline. AB, ammonia borane; N/A, not available.

aBased on TIAX/ANL projections.

bBased on Hydrogen Storage Engineering Center of Excellence projections

SOURCE: Stetson (2012).

• Impurities,

• Heat management,

• Efficiency,

• Cost,

• Durability, and

• Engineering and manufacturing.

In spite of rather rapid and impressive advances in hydrogen storage capacity by metal organic frameworks (MOFs) and covalent organic frameworks (COFs), the temperature and pressure required to achieve high capacities are far from DOE’s targets, and there are no systems identified yet that can do so.

System cost has proven to be a challenge for all promising materials and systems. Currently 80 percent of the hydrogen sorption projects have been discontinued on the basis of budgets or project results. Down-selects (go/no-go points) led to a decision to stop hydrolysis program work. Project down-selects by the Hydrogen Storage Engineering COE have resulted in phasing out work on metal hydrides (75 percent discontinued) and solid-phase chemical hydrogen (95 percent discontinued) materials engineering. Clearly, creative ideas need to be developed, and a plan is needed that will lead to fundamentally new ideas.

Compressed gas storage is the near-term path to commercialization. Compressed gas storage levels at 35 MPa and 70 MPa are near to the 2015 target for gravimetric storage but are only about 45 percent and 66 percent, respectively, of the volumetric target. The 70 MPa is preferred by the automotive OEMs because it offers greater vehicle range and is becoming the de facto standard storage pressure, but it can lead to additional refueling costs for pre-cooling and higher compression energy. The National Aeronautics and Space Administration (NASA) White Sands Facility offers expertise in composite pressure vessel testing, including

pressure failure analysis, nondestructive evaluation, structural analysis, burst tests, and fire safety.14

Assessment of Progress and Key Achievements

Key achievements since the NRC (2010) Phase 3 review are in the area of cryo-compressed hydrogen, hydrogen sorbents, chemical hydrogen storage, and metal hydrides. The cryo-compressed system has demonstrated 10.4 kg of usable capacity that is greater than the 2017 target, but the cost is estimated to be $12/kWh. A smaller tank has been designed that delivers 5.6 kg of H2 (LLNL). The tank must be filled with liquid hydrogen to achieve maximum capacity, and the length of time that the tank is idle before venting hydrogen (dormancy) is an issue.

Two hydrogen sorbents have exhibited materials capacities greater than 8 wt% and 28 g/L at 77 K and 7 MPa. This work was done at Northwestern University (Cu-MOF, a copper-containing metal organic framework) and at Texas A&M University (PPN[porous polymer network]-4(Si)). PPN-4(Si) is a highly stable porous polymer network with ultrahigh gas uptake capacity. Chemical hydrogen storage systems are on a path to exceed the 2017 system targets, but off-board regeneration efficiency is still an issue. Ammonia borane and alane, chemical hydrogen storage materials, have demonstrated release kinetics and spent fuel regeneration. Both materials have greater than 10 wt% hydrogen (LANL/PNNL and Brookhaven National Laboratory [BNL]/SRNL). One metal hydride, Mg(BH4)2, has demonstrated a reversible material capacity of greater than 12 wt%, but the temperature and pressure are too extreme for onboard use (University of Hawaii and SNL).

The Hydrogen Storage Engineering COE provides a coordinated approach to the engineering R&D of materials-based hydrogen storage. This COE has completed an integrated system model for hydrogen storage and established a state-of-the-art baseline against the 2010 targets for all three materials classes. This modular approach allows each system to be run through simulated drive cycles to predict performance. This work has enabled the COE to down-select systems for further development.

Compressed hydrogen is the near-term option for onboard hydrogen storage. A major barrier, however, is the cost of the storage system, cited to be $2,800 for a 5-kg H2 system.15 The U.S. DRIVE Partnership defines 1 kg of hydrogen to be equivalent to 1 gallon of gasoline. A 300-mile driving range will thus require 5 to 10 kg of hydrogen depending on vehicle characteristics such as size and weight. Approximately 75 percent of the cost is the carbon-fiber composite and 50 percent of that cost is the precursor fiber. The DOE, in concert with the U.S.

__________________

14 See http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20080029396_2008026596.pdf.

15 N. Stetson, Department of Energy, and S. Jorgensen, General Motors R&D, “Hydrogen Storage Tech Team (HSTT),” presentation to the committee, January 26, 2012, Washington, D.C.

DRIVE hydrogen storage technical team, has recently initiated several projects that address cost:

• Development of textile-grade polyacrylnitrile, PAN (ORNL),

• Development of melt spinable PAN (ORNL-Virginia Polytechnic Institute and State University),

• Development of nano-reinforced CFCs (Applied Nanotech, Inc.; SBIR), and

• Investigation of basalt glass fibers (Quantum Technologies; SBIR).

The first project aims to produce high-strength carbon fibers from commodity textile-grade PAN fibers.

A workshop with various stakeholders was held in February 2011 to address opportunities for cost reduction of composite storage tanks.16 In December 2011, DOE announced four projects totaling more than $7 million to advance hydrogen storage technologies for fuel cell electric vehicles. These 3-year projects are listed in Table 3-6.