This chapter addresses crosscutting issues that are important to the success of the Partnership in meeting its goals. They have all been commented on in the National Research Council’s (NRC’s) Phase 1, 2, and 3 reviews, and much of the background is not repeated here (NRC, 2005, 2008, 2010). In this Phase 4 review, the committee emphasizes those issues that still require attention. The areas addressed here are (1) program decision making; (2) safety, codes and standards; (3) the grid interaction technical team (GITT), which addresses the interface between electric vehicles (EVs) and the electric grid; and (4) environmental implications of alternative pathways.

Overview

The topics of strategic planning, program management, and decision making within the U.S. DRIVE Partnership are all closely related, and they all critically depend on systems analysis. As described in Chapter 1, the Partnership is a research and development (R&D) program that focuses on critical transportation technology and fuel challenges for vehicles; if successfully met, these challenges could significantly lower U.S. petroleum consumption and greenhouse gas (GHG) emissions while continuing to meet stringent criteria pollutant standards. The Partnership’s individual technical teams, which include members from the U.S. Department of Energy (DOE), national laboratories, the automotive original equipment manufacturers (OEMs), energy companies, and power companies, work primarily at the vehicle component level and on the production, distribution,

and delivery of hydrogen; in addition, there is recent attention on the interface between the nation’s electricity delivery system and the charging of EVs (e.g., plug-in hybrid electric vehicles [PHEVs] or battery electric vehicles [BEVs]). There are annual DOE program reviews, in addition to many DOE-sponsored conferences and workshops, as well as their considerable participation in professional society conferences, to help keep all participants on the Partnership technical teams well informed. To these teams are added a vehicle systems and analysis technical team (VSATT) and a fuel pathway integration technical team (FPITT) that is focused on hydrogen. This organizational structure (shown in Figure 1-2 in Chapter 1) is based on project activities that focus on individual technical issues, as well as on total vehicle system integration and the total fuel chain. In addition, there is a need in the Partnership for a broader strategic perspective, which ostensibly the Executive Steering Group (ESG) provides. The system integration and performance issues require a systems analysis approach on several levels, necessitating a variety of systems analysis tools.

Systems Analysis

In its previous reports, the NRC recommended substantial activity to develop systems analysis tools to help the Partnership meet its goals. For example, in the NRC Phase 1 report, it was recommended that “an ongoing, integrated, well-to-wheels assessment be made of the Partnership’s progress toward its overall objectives” (NRC, 2005, p. 9). In the NRC Phase 2 report, it was recommended that “the DOE should accelerate the development and validation of modeling tools that can be used to assess the roles of various propulsion systems and vehicle technologies and fuels, and utilize them to determine the impact of the various opportunities on the overall Partnership goals of reducing petroleum use and air pollutant and greenhouse gas emissions” (NRC, 2008, p. 13).

In the Phase 3 report, it was recognized that the Partnership had made substantial progress on the development and application of these systems analysis tools, that “well-to-wheels” (or “source-to-wheels”) analysis was now routinely used across the Partnership, and that modeling and simulation tools were widely used within the technical teams (NRC, 2010, p. 34). In the current review, the committee found continued widespread use of systems analysis tools, including the migration to using the Autonomie model developed under a Cooperative Research and Development Agreement (CRADA) between the Argonne National Laboratory (ANL) and General Motors (GM), with architecture based on the Systems Analysis Toolkit (PSAT) model described in the Phase 3 report. Overall, the development and deployment of systems analysis tools and models at the vehicle and fuel pathway level continue to be impressive and fully responsive to the committee’s specific prior recommendations. However, the VSATT and FPITT systems analysis teams operate in a reactive support role to the individual technical teams: indeed, in the transition from the FreedomCAR and Fuel Partnership

to U.S. DRIVE, the VSATT adopted “a renewed focus as a service organization to the other technical teams.”1 The application of systems analysis to the overall guidance and management of the Partnership and the determination of technical directions in pursuit of the Partnership’s overarching goals relating to U.S. petroleum consumption and GHG emissions continue to be much less transparent. In the Phase 2 report (NRC, 2008, p. 30), it was noted that “there is no lack of technical review of the individual program elements, but what is missing is analysis of the quantitative impact on the overall goals of reducing petroleum use and pollutant and greenhouse gas emissions.” In the Phase 3 report, it was observed that, despite some encouraging progress, “this remains an area in which the committee strongly encourages additional emphasis” (NRC, 2010, p. 35).

Once again, whereas the committee finds the operation of the technical teams and the integration of the systems analysis functions within those teams to be exemplary, the application of systems analysis to strategic decision making is lagging, especially concerning alternative pathways to achieving objectives such as reduced U.S. consumption of petroleum and reduced production of GHGs (see Chapter 1 for a brief discussion). It is not apparent that critical issues being investigated by the technical teams are guided and prioritized by an overall program imbued with an understanding of the scale and limits of these technical improvements and how they affect larger program goals. Additionally, the results and implications of systems analyses conducted by the technical teams have crosscutting implications for research direction and goals throughout the program. The potential exists for implicit conflict among the respective goals of the various technical teams: for example, simply seeking the highest-efficiency electric drive components may incur costs that would be better spent on alternative battery chemistry, and these trade-offs can only be made across the Partnership, driven by systems analysis. (It appears that industry is making these kinds of trade-offs in its own in-house decisions by, for example, sometimes adopting induction motors instead of more efficient but more costly permanent-magnet [PM] motors.)

Another example is the acceptance by U.S. DRIVE of 70 MPa (10,000 psi) as the de facto hydrogen storage tank pressure, on the premise that “higher density is better.” This acceptance occurred without any apparent overall systems analysis considering not only onboard storage objectives, but also such factors as required compression energy, tank weight and cost trade-offs, or infrastructure ramifications. Consideration of all relevant factors could conceivably lead to the conclusion that, say, 8,000 psi would represent a better overall compromise. It is imperative that the Partnership’s ESG, Joint Operations Group, or other program decision-making group continually strive to understand such implications and adapt research plans as technology or other critical factors change: in effect, provide overall portfolio management.

__________________

1 L. Slezak, Department of Energy, “Vehicle Systems and Analysis Technical Team,” presentation to the committee, January 26, 2012, Washington, D.C.

As a part of the committee’s work, it reviewed the electrical storage projects currently managed by DOE’s Advanced Research Projects Agency-Energy (ARPA-E). ARPA-E is beyond the scope of U.S. DRIVE; indeed it is not even part of DOE’s Office of Energy Efficiency and Renewable Energy (EERE), in which the U.S. DRIVE activities reside, but these projects complement the U.S. DRIVE technology portfolio. It is noteworthy that ARPA-E features, by design, an aggressive portfolio management approach. The committee believes that the U.S. DRIVE Partnership could benefit by exploring and applying some aspects of this portfolio approach, to address both system-wide trade-offs and uncertainty in the externalities affecting the program.

Portfolio Strategy for Managing Uncertainty

Each pathway for vehicle technology and its associated fuel supply (electricity, hydrogen, or liquids) poses unique near-term and long-term uncertainties. Many of the policies and actions that affect these pathway uncertainties reside beyond the influence of the U.S. DRIVE Partnership, yet their outcomes strongly influence the cost, marketplace attractiveness, and policy desirability of the competing pathways. This kind of context uncertainty cannot be eliminated, but rather must be managed by the U.S. DRIVE Partnership.

For example, the timing and extent of any transition to a low-carbon U.S. electricity system cannot reasonably be predicted. Yet this transition will strongly influence the cost and environmental impact of the electric vehicle (EV) pathway, and to a lesser extent that of hydrogen produced through electric energy. Or consider a second example of contextual uncertainty—the cost of natural gas. If natural gas supplies prove as abundant and inexpensive as some forecasts hold, then this resource could become the chief source of hydrogen well beyond the transition period. But if these estimates prove overly optimistic for reasons that cannot now be known, then some alternative will have to be developed. The issue for the U.S. DRIVE Partnership is how much to rely on natural gas and how much to invest in some hedged alternative, the classical dilemma of context uncertainty.

Much evidence shows that research management under context uncertainty is best accomplished through a portfolio strategy that balances risks and potential benefits across alternative futures, for example, by a consideration of uncertainties about technological progress and U.S. energy system characteristics. In the development of such a strategy, special attention should be paid to contextual scenarios that have differing impacts across several technology and fuel pathways. These portfolios can be informed by analytic methods such as real options analysis, scenario planning, or expert elicitation.

Recommendation 2-1. The U.S. DRIVE Partnership should adopt an explicitly portfolio-based R&D strategy to help DOE to balance the investment among alternative pathways along with the more traditional reviews of the progress of

individual pathways. Furthermore, this portfolio-based strategy should be based on overall systems analysis performed by a proactive vehicle systems and analysis technical team and fuel pathway integration technical team.

The Phase 3 report expressed concern that the ESG, charged with overall Partnership guidance, had not met for almost 2 years, leaving an apparent vacuum in the realm of guidance at the senior-leadership level (NRC, 2010, p. 35). The ESG did finally meet for the first time in 4 years, in June 2011, and has scheduled annual meetings starting in October 2012. However, given the pace of relevant developments in both technology and policy, this meeting schedule seems barely adequate to “set high-level technical and management priorities for the Partnership” as specified in its charter (U.S. DRIVE, 2012).

In summary, the two systems analysis teams have done excellent work and have made great progress at the microlevel. Nonetheless, despite signs of improvement, it is still unclear to the committee how and whether this work is being adequately applied at the senior-leadership level within DOE or the Partnership to guide overall Partnership direction.

Scope of the Partnership

In the evolution of the Partnership from the Partnership for a New Generation of Vehicles (PNGV) through U.S. DRIVE’s immediate predecessor, the FreedomCAR and Fuel Partnership, to the U.S. DRIVE Partnership, the scope and nature of the Partnership have changed considerably. The PNGV involved seven federal government agencies, with the Department of Commerce in the lead, whereas the U.S. DRIVE Partnership is led exclusively by DOE. The PNGV had specific objectives unique to the Partnership; U.S. DRIVE has a broader set of general goals, which are shared by other DOE programs and initiatives. In the words of the U.S. DRIVE Partnership Plan, published in February 2012:

It is a non-binding, non-legal, voluntary government-industry partnership focused on advanced automotive and related energy infrastructure technology research and development (R&D). Specifically, the Partnership facilitates pre-competitive technical information exchange [emphasis added] among experts who interact as equal partners to discuss R&D needs, develop joint goals and technology roadmaps, and evaluate R&D progress. The Partnership itself does not conduct or fund R&D; each partner makes its own decisions regarding the funding and management of its projects. (U.S. DRIVE, 2012)

In light of the above, it is difficult to separate the activities and results directly attributable to U.S. DRIVE and those resulting from other complementary initiatives by DOE and/or the industry partners. Some of these complementary activities, such as the 21st Century Truck Program (21CTP), which pursues similar technologies applicable to heavy-duty vehicles, are subject to separate NRC review. The committee requested clarification from DOE as to which of these

activities should be considered within the U.S. DRIVE Partnership for the purposes of this review. Table 2-1 was provided by DOE in response to this request.

Despite this difficulty, which is discussed further in Chapter 5, “Adequacy and Balance of the Partnership,” the activities of the individual technical teams appear to be well focused and directed, as noted above. However, the network of potentially complementary or overlapping DOE-sponsored initiatives almost places DOE in a “systems integrator” role, without a transparent overall decision-making process.

Under the preceding PNGV structure, there was a clear process for consensus decision making, and a schedule of “downselects” as various candidate technologies either achieved their goals or were discarded. With the evolution through the FreedomCAR and Fuel Partnership to the U.S. DRIVE Partnership, no such comparable process appears to exist. With the exception of a steady reduction in funding for hydrogen and fuel cell activities (from roughly 70 percent at the beginning

| DOE Program | DOE Subprogram/ Budget Line Item |

U.S. DRIVE Technical Area |

| Hydrogen and Fuel | Fuel Cell Systems R&D | Fuel Cells |

| Cell Technologies | Hydrogen Fuel R&D | Hydrogen Production Hydrogen Storage |

| Safety, Codes and Standards | Codes and Standards | |

| Systems Analysis | Fuel Pathway Integration | |

| Technology Validation | a | |

| Market Transformation | a | |

| Education | a | |

| Manufacturing R&D | a | |

| Vehicle Technologies | Batteries and Electric Drive R&D | Electrochemical Energy Storage Electrical/Electronics |

| Vehicle Systems, Simulation and Testing | Vehicle Systems Analysis Grid Interaction | |

| Advanced Combustion Engine R&D | Advanced Combustion and Emission Control | |

| Materials Technology | Materials | |

| Fuels Technologies | Not formally included in U.S. DRIVE | |

| Outreach, Deployment and Analysis | Not formally included in U.S. DRIVE | |

NOTE: R&D, research and development.

a Not formally included in the U.S. DRIVE Partnership.

SOURCE: Provided to the committee by DOE in response to committee questions.

of FreedomCAR to approximately 20 percent in the FY 2013 DOE budget request; see Chapter 5, Table 5-3), the majority of the candidate technologies and pathways in the Partnership portfolio continue to be supported some 10 years later, with no visible signs of the application of overall systems analysis or other high-level management to focus the efforts on technologies and pathways with the greatest chance of success. The rather amorphous nature of the U.S. DRIVE Partnership and the need to consider market and commercialization factors in overall portfolio management make the role of the Executive Steering Group critical.

Recommendation 2-2. The Executive Steering Group (ESG) should meet regularly and provide the necessary guidance and leadership in developing strategy and programs to meet goals for the reduction of greenhouse gases and petroleum dependence. Furthermore, the ESG should insist that all analyses conducted by and for the U.S. DRIVE Partnership reflect the system-wide full life cycle.

Associate Members and Supply-Chain Participation

Participation in the FreedomCAR and Fuel Partnership, now the U.S. DRIVE Partnership, has expanded to include an additional automotive OEM, energy companies, and electric utilities. Most recently, the technical teams are adding selected associate members to bring additional perspective and expertise. As of April 24, 2012, the Partnership had selected the following nine associate members, with three more yet to be named:

• Advanced combustion and emission control technical team associate member:

— Michigan State University

• Codes and standards technical team associate member: Not yet announced

• Electrical and electronics technical team associate member:

— Deere & Company

• Electrochemical energy storage technical team associate member: Not yet announced

• Fuel cell technical team associate member:

— Rochester Institute of Technology

• Fuel pathway integration technical team associate member:

— Air Products and Chemicals

• Grid interaction technical team associate members:

— Northeast Utilities

— Tennessee Valley Authority

— Midwest Independent Transmission System Operator, Inc. (MISO)

• Hydrogen delivery technical team associate member:

— Praxair

• Hydrogen production technical team associate member:

— SunCatalytix

• Hydrogen storage technical team associate member:

— University of Michigan

• Materials technical team associate member:

— Morgan Olson Corporation

• Vehicle systems and analysis technical team associate member: Not yet announced

The committee sees much to be gained from the addition of associate members, for two reasons: (1) additional membership can expand the scope of technology opportunities available to the U.S. DRIVE Partnership, and (2) additional membership can expedite commercial application of new technologies by connecting the U.S. DRIVE Partnership more completely with the automotive supply chain, where commercial innovation increasingly occurs.

Although the new additions of associate members are surely a promising beginning, they seem to consist largely of universities and large companies. In contrast, new emerging ventures are less well represented, yet such companies could bring significant value for the reasons discussed below.

Over the past 15 years a new competitive dynamic has emerged among R&D-intensive industries like road mobility: it involves a rapid growth in arrangements for the exchange of new technologies, new products, and new services. Automotive OEMs and suppliers typically formalize these arrangements as joint R&D ventures, licensing (and cross-licensing) of intellectual property, and joint production arrangements.

Three closely linked characteristics of the business environment motivate these exchanges: the growing cost of maintaining a vertically integrated R&D program, the need for speed in moving vehicles to market, and the desire to become profitable at low production volumes. As a consequence, research and development, innovation, and scale-up are increasingly accomplished throughout the supply chain, and greater than 50 percent of the value added in automobiles is now provided by suppliers. Many OEMs are reaching out to the entrepreneurial sector through in-house venture funds.

This emerging architecture suggests that the U.S. DRIVE Partnership could benefit from greater participation by companies in the supply chain, which would improve program guidance and increase the pace at which the technologies developed by R&D are brought to market.

Recommendation 2-3. The U.S. DRIVE Partnership should continue its inclusion of innovative supply-chain companies and should expand this approach to emerging entrepreneurial companies with relevant technological capabilities. When new entrepreneurial ventures are being considered for associate membership,

the committee recommends a systematic vetting process much like the “due diligence” process of venture-capital investors.

The safety, codes and standards (SCS) activity is focused exclusively on safety issues related to hydrogen. R&D is conducted in selected areas and DOE provides technical expertise to several standards development organizations (SDOs). SDO committees are generally staffed by interested volunteers and follow American National Standards Institute (ANSI) procedures on consensus building and voting for approval. Draft standards are available in several areas (hydrogen vehicles, hydrogen storage systems, and fueling stations), but few have been finalized. In some areas (e.g., hydrogen storage tanks) there is an international effort to create a global technical regulation (GTR) that will be adopted by individual countries.

Significant progress in the development of safety-related codes and standards has been made over the past several years. Several standards organizations (e.g., the Society of Automotive Engineers [SAE], CSA America, the International Organization for Standardization [ISO], and others) have issued draft or Technical Information Reports (TIRs), but few have finalized, approved standards. Extensive testing of Type 1 high-pressure (steel) tanks for forklifts and other industrial trucks has occurred. Risk-based quantitative risk assessment has been extended from fueling station separation distances to tunnels and indoor refueling. The SAE hydrogen (H2) tank standard (J2579) has become the basis for the recently issued draft Global Technical Regulation (GTR) (SAE, 2009; Nguyen, 2010).

The current goal of the codes and standards technical team is to have all necessary hydrogen standards (for both vehicles and fueling infrastructure) in place by 2020. Given that most of the major automotive OEMs have announced plans for a limited introduction of hydrogen fuel cell vehicles (HFCVs) in the 2014-2016 time period, this goal should be accelerated if possible. Unfortunately the budget for this program has decreased from more than $15 million in FY 2008 to just $5 million in the proposed FY 2013 budget. There is still substantial work to be done to finalize these standards and to show by experiment that they will provide adequate public safety when large numbers of vehicles are deployed.

The initial rollout of HFCVs is expected to be small (a few hundred to a few thousand vehicles), and the vehicles will be sold in areas that already have fueling infrastructure. These areas are expected to be in Japan, Germany, California, Hawaii, and maybe South Korea. Clusters of stations will then expand in additional geographic areas along with connecting links between clusters on major highways. For this reason it is desirable to accelerate the finalization of codes and standards to the 2014-2016 time frame.

There are several efforts in the hydrogen storage area to reduce the cost and weight of high-pressure H2 tanks. The lower limit of both cost and weight will undoubtedly be set by safety considerations. This will inevitably require

an extensive and rigorous tank testing program to ensure that adequate safety margins are maintained.

An extensive testing program was carried out by Sandia National Laboratories on Type 1 (steel) tanks for industrial trucks. The safety standards that have been developed (like SAE J2579) have not been validated with sufficient tests to ensure that they will separate good tanks from bad tanks. Further safety testing needs to be done with Type 3 and 4 tanks. (Type 3 tanks have metallic liners and composite fiber overwraps, and Type 4 tanks have plastic liners and composite fiber wraps.)

Response to Recommendations from the Phase 3 Review

The Partnership agreed with the SCS recommendations in the NRC (2010) Phase 3 review except for two of these recommendations. It did not agree with establishing an emergency response R&D program for alternative fuels because it does not consider that to be precompetitive R&D. Historically the hydrogen codes and standards technical team has exclusively covered HFCVs and hydrogen fueling stations. Apparently the Partnership and the associated codes and standards technical team are unwilling to follow the Phase 3 recommendations to expand their scope to cover the entire fuel pathway from source to vehicle, or to cover other vehicle/fuel types, including electric vehicles. Perhaps another team or office needs to be formed to address the end-to-end (well-to-wheels) safety analysis and to make sure that all of the regulations, codes, and standards (RCSs) are in place.

Appropriate Government Role

It is not only appropriate but essential that the government fund the majority of the RCS development, adoption, and domestic and international harmonization. These are unlikely to be accomplished by industry alone (although industry provides a great deal of volunteer labor to the various safety committees).

Recommendations

The most recent plans of the SCS program have the goal of having the RCSs ready by 2020. This delay from earlier goals was likely caused by budget cuts in recent years. Stations are being built now (in certain areas), and commercial leases and sales of HFCVs may begin as early as 2014.

Recommendation 2-4. The Partnership should place a much higher priority on the safety, codes and standards (SCS) program and accelerate the date for final regulations, codes, and standards to 2014. The committee still recommends that, if the budget allows, the scope of the SCS program be expanded to cover all vehicle/fuel combinations being considered by DOE. This would include natural

gas, battery electric vehicles, plug-in hybrid electric vehicles, biofuels, and other combinations that are appropriate.

Further safety testing of high-pressure tanks is needed.

Recommendation 2-5. The Partnership should plan and execute a tank testing program for the Type 3 and Type 4 tanks that are expected to be used in passenger vehicles.

The program has done extensive fuel cell testing to determine allowable limits on impurities in the H2 fuel. This is appropriate for the high-pressure, compressed-gas tanks that are expected to be used initially.

Recommendation 2-6. As candidate materials are identified, the Partnership should expand the safety, codes and standards program to identify new contaminants that may be given off by adsorbent or chemical storage systems. These activities should be coordinated with the Storage Systems Center of Excellence at the Savannah River National Laboratory.

Over the years the SCS program has supported some H2 sensor development for stationary applications (fueling stations). No work has been done on low-cost sensors for vehicle installation.

Recommendation 2-7. The Partnership should consider phasing out and turning over to industry for commercialization the stationary H2 sensor effort that has been supported for several years and consider starting a new program on inexpensive H2 sensors for vehicles.

Electric and/or hydrogen vehicles can pose a hazard to emergency responders. How do the responders protect themselves from a vehicle that has been extensively damaged by a crash or fire?

Recommendation 2-8. The Partnership should consider starting a hydrogen vehicle emergency response R&D effort similar to that now being conducted for electric and plug-in vehicles. One of the issues that should be studied is how to depressurize a damaged tank.

THE GRID INTERACTION TECHNICAL TEAM

Mission

The mission of the grid interaction technical team is to support a transition scenario to large-scale electrified vehicle charging with transformational technology, proof of concept, and information dissemination. A collaborative effort is

underway to address the interests of U.S. DRIVE partners and other stakeholders so as to identify and support the reduction of barriers to the large-scale introduction of grid-connected vehicles.

Scope

The scope of the GITT work is interaction between light-duty vehicles that have to “plug in” to the grid to recharge their batteries (e.g., in general, EVs that are light-duty BEVs or PHEVs), the charging infrastructure, and the electric power grid, focusing on the following key areas:

• Electric distribution and smart-grid interface,

• Interface of the “plug-in” vehicle to the local power distribution network,

• Government policy impact analysis,

• Consumer usability, and

• Life cycle and total cost of ownership.

Major Challenges and Barriers

The GITT lists its major challenges and barriers as follows: (1) developing and verifying EV-grid connectivity and communication, (2) enabling EV-grid interoperability, and (3) facilitating the development of regional standards and recommendations. Challenges and possible barriers to standards development are regional standards, such as “GB standards”2 from China and recommendations such as those of the European Automobile Manufacturers’ Association (ACEA) in Europe. The GITT has recently had some success in supporting global cooperation and harmonizing standards and component compatibility. Examples are cooperative agreements between the United States and the European Union and between the United States and China, joint activities such as pilot projects to facilitate common standards, and the development of standards for laboratory test procedures and protocols. Additional attention to identifying and remedying security vulnerabilities of communications for EV supply equipment (EVSE) hardware and software is warranted. The team could play a part in this research.

Plans and Implementation

The R&D tasks and projects of the GITT are focused on near-term implementation with long-term impact. In addition to continuing its support of codes and standards, the team’s present agenda includes the following:

__________________

2 GB standards are the Chinese national standards issued by the Standardization Administration of China.

• Convenient charging, and

• Smart charging and communications.

Results

A model streamlining process is ready to be adapted and used by local governments, installers, and inspectors for permitting and inspecting residential charging stations.

The development and demonstration of measurement and communications modules are laying a foundation for measurement and communication within the vehicle and between the vehicle and home and energy service providers. An end-use measurement device (EUMD) accurately measures energy consumption and communicates with the energy service provider/home area network (HAN). Two-way messaging from the vehicle to the EVSE and the HAN, the smart meter, and the distribution transformer has been demonstrated.

Organization and Contacts

In addition to the national laboratories noted in this section, the main participants in the GITT work currently are the U.S. Council for Automotive Research (USCAR), DTE Energy, Southern California Edison, Tesla, and the Electric Power Research Institute (EPRI).

The National Renewable Energy Laboratory (NREL) is one of the leading participants in this work. The NREL, ANL, Idaho National Laboratory, Pacific Northwest National Laboratory, and Oak Ridge National Laboratory are also working with the Society of Automotive Engineers to support the development effort by supplying reference materials to chairing committees, and developing hardware, test fixtures, and testing equipment.

Future Plans

Top priorities for the GITT work are now focused on the needs and technical issues of developing the EV-grid interface. They are as follows:

• Demonstrate communication and control of direct current (dc) charging,

• Verify and validate cybersecurity standards,

• Develop a prototype wireless charging test fixture,

• Update the EUMD,

• Develop communication and control of off-board wireless charging electronics, and

• Directly support SAE standards committees.

The DOE budget for activities supporting grid integration objectives in FY 2011 was $1.9 million (estimate based on “shared” elements of DOE’s Vehicle Systems budget) and an estimated $2.0 million for FY 2012.

Outreach and Partnerships

The GITT participants have leveraged their collective resources well by participating through the SAE and other professional organizations in the development of standards for battery charging. It also coordinates the efforts of standards organizations and groups that are developing hardware. These activities are necessary and should be continued as the smart grid and electric vehicle power systems continue to develop.

One outreach, however, seems underdeveloped by the GITT—that is, engaging the state regulatory agencies that control the economic incentives for electric utility companies. By regulating the price that can be charged for electric service, these agencies can provide powerful incentives for retail customers to use electricity at the most economic and environmentally friendly times. In the case of plug-in vehicles using Level 1 or Level 2 battery charging systems, well-designed rate structures could encourage the recharging of vehicle batteries during off-peak hours, typically at night, when the cost of service is lowest. If fast-charging (in less than 15 minutes) systems come into commercial use, the challenge of providing incentives for both consumers and providers of electricity through rate design will increase markedly (see Chapter 4 for a complete discussion of this topic).

In addition, the committee notes the growing controversies over individual privacy and data security that now surround social media. Widespread vehicle recharging does not yet rise to this level of public concern, nor does the committee have any evidence that it will. Nevertheless, privacy and data security issues similar to those that attend the smart grid are likely to apply to the vehicle-charging infrastructure as well. The committee suggests that the GITT remain alert to these. The GITT should be mindful of these and should share best practices in safety codes and emergency response with localities nationwide. And finally, the prospective emergence of fast charging (e.g., Level 3) could also raise issues of public safety.

Wireless charging is a convenient way to charge electric vehicles that increases the flexibility of charging opportunity. The system consists of a low-profile transformer whose primary is on the floor and secondary on the undercarriage of the vehicle. The size of the charger is kept low by using high frequencies, of the order of 100 kHz. This is a relatively new idea that needs development beyond a proof of concept. If successful, it may lead to a next generation in which these transformer primaries are buried in parking spots and can deliver bursts of charge when a vehicle is stopped for a short time. The next step may be dynamic—with

the vehicle being continuously or occasionally charged as it drives along a roadway. The convenience of wireless charging has to be balanced against the lack of knowledge of the safety, charge efficiency, and cost of this charging mode.3 Furthermore, the reliability of such a process and standards have to be established for large-scale implementation. Preliminary economic analysis and standards work on wireless charging are being conducted at the national laboratories, and a 3-year program funded at $4 million per year is being initiated to develop wireless charging, system integration, and technology demonstration.

Recommendation

Greater outreach is needed by the GITT to the state regulatory agencies. The National Association of Regulatory Utility Commissioners could provide an efficient channel for reaching the regulatory community, but contact with individual state commissions will also be needed.

Recommendation 2-9. The grid integration technical team should make a special effort to work with utility regulatory commissions throughout the United States to (1) help identify the best practices in rate regulation that could advance the deployment of plug-in vehicles if widely used and (2) communicate the advantages from these best practices accruing to the public and to state and local officials.

ENVIRONMENTAL IMPLICATIONS OF ALTERNATIVE PATHWAYS

Overview

As noted in the NRC’s Phase 1, 2, and 3 reports, it is critical to understand the environmental implications of the full life cycle of alternative fuel pathways, including hydrogen, electricity, biofuels, or other energy source/vehicle combinations being developed that can potentially reduce the consumption of petroleum and reduce greenhouse gas emissions relative to conventional light-duty vehicles (NRC, 2005, 2008, 2010). Researchers conducting life-cycle assessments for passenger transportation would consider the environmental impacts of the materials processing, supply chains, manufacturing, use, and end of life for both the proposed transportation energy sources and the vehicles themselves. Life-cycle assessment, coupled with the fields of industrial ecology and materials flow analysis, can inform policy makers and researchers about the cradle-to-grave impacts of technology decisions (Hendrickson et al., 2006; Brandão et al., 2012; Rogers and Seager, 2009; Graedel and Allenby, 2004; NRC, 2004). By assessing life-cycle impacts, the U.S. DRIVE Partnership can increase the likelihood that

__________________

3 For example, there may be public concerns about the health and safety effects of electromagnetic radiation.

petroleum reduction and GHG emissions goals are achieved as well as minimize the risk of unforeseen system-wide risks to the environment.

Neither fuel cell nor all-electric vehicles produce tailpipe emissions; the use of these vehicles would thus assist in alleviating local pollution from light-duty vehicles. However, considerable emissions could result from producing the vehicles and storage batteries and producing and delivering fuels, as well as from vehicle disposal. Since publication of the Phase 3 report (NRC, 2010), current research has quantified various environmental aspects of lithium-ion (Li-ion) storage battery production, with several of these works noting the potential of air pollutants and GHGs from battery production to reduce some benefits of battery use in passenger transportation (Dunn et al., 2012; Gaines et al., 2011; Majeau-Bettez et al., 2011; Michalek et al., 2011; Notter et al., 2010; Zackrisson et al., 2010; Hawkins et al., 2012). The Argonne National Laboratory produces a version of the Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation (GREET) model focused on materials and manufacturing impacts from the vehicle cycle that can also aid in decision making in this area (Argonne National Laboratory, 2011). In addition to the potential impacts of storage battery production, there have been public concerns regarding the large-scale disposal and recycling of storage batteries of various chemistries in a future with widespread adoption of electrified vehicles. The Phase 3 report recommended that the Partnership “should undertake a review of the state of methods and case studies that have been carried out on environmental impacts related to the technologies under development” (NRC, 2010, p. 55). The Partnership agreed and had identified several studies in its response to the report (DOE, 2010). The integration of current and emerging life-cycle assessment research on vehicle, storage battery, and systems materials, and on production for the U.S. DRIVE portfolio of vehicle technologies, as well as the conduct of research to minimize life-cycle environmental impacts, would help to maximize the large potential benefits of electric and fuel cell vehicles.

Electric power generation, hydrogen, and other fuels also generate life-cycle impacts from fuel procurement, production, and infrastructure (Heath and Mann, 2012; Argonne National Laboratory, 2011; Cetinkaya et al., 2012; Lucas et al., 2012; Alvarez et al., 2012). Because the vehicle-use phase accounts for the majority of life-cycle energy use, achieving large life-cycle GHG and air emissions reductions with fuel cell and electrified vehicles is dependent on the production and delivery of low-emissions electricity and hydrogen (Argonne National Laboratory, 2011; Michalek et al., 2011; Elgowainy et al., 2010; Samaras and Meisterling, 2008). Additionally, electricity emissions vary by region, but considerable uncertainty remains in assigning local emissions factors (Weber et al., 2010), and new loads displace disparate marginal generation fuels (Siler-Evans et al., 2012). The comparative analysis of fuel-cycle impacts of electricity, hydrogen, and other fuels used in vehicles is termed “well-to-wheels” or “source-to-wheels” analysis, and well-to-wheels air emissions and GHGs can be estimated with the GREET model (Argonne National Laboratory, 2011).

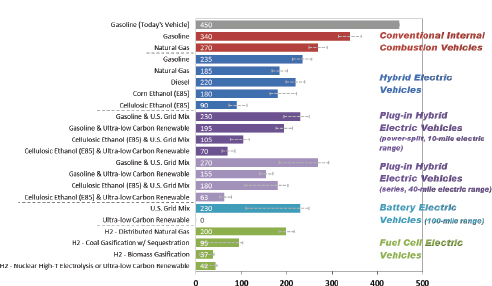

Due to the inherent uncertainty surrounding emissions from future electricity and hydrogen production and delivery, the Phase 3 report recommended that the links between the systems analysis teams and the technical teams be strengthened and that “technological goals and targets should include consideration of priorities established in systems analysis, and systems analysis should be conducted on emerging technologies identified by the technical teams” (NRC, 2010, p. 55). The Partnership agreed with this recommendation and stated in its response that technical teams and systems analysis teams use the GREET model and systems analysis to track progress and identify technical areas for improvement (DOE, 2010). Progress toward this goal and evidence of appropriate systems analysis were apparent in several presentations delivered by U.S. DRIVE to this committee in 2011 and 2012. The DOE produced a well-to-wheels analysis, shown in Figure 2-1, on the GHG emissions of various technologies for a future midsize vehicle. The uncertainty bands presented demonstrate the impacts of potential vehicle fuel economy and fuel pathways improvements. One potential area of enhancement is for the U.S. DRIVE teams to include vehicle-cycle impacts into such analyses, such as those from the GREET vehicle-cycle model, to understand the full-life-cycle implications, and to use these results as decision-making aides in structuring a balanced R&D portfolio. Regularly updated and publicly available

FIGURE 2-1 Department of Energy estimation of well-to-wheels greenhouse gas emissions for a projected state of technologies in 2035-2045 for a future midsize car. NOTE: Ultra-low-carbon renewable electricity includes such sources as wind and solar. The analysis does not include the life-cycle effects of vehicle manufacturing and infrastructure construction/decommissioning. SOURCE: http://hydrogen.energy.gov/pdfs/10001_well_to_wheels_gge_petroleum_use.pdf.

charts similar to Figure 2-1 would help stakeholders understand systems impacts and identify potential improvements.

Finally, while Corporate Average Fuel Economy (CAFE) standards affect average GHG emissions from vehicles, the possibility of broader legislation putting a price on economy-wide GHG emissions will affect the economic viability of many future vehicle pathways. U.S. DRIVE can use existing well-to-wheels and vehicle-cycle GHG emissions data to contribute to an understanding of how different levels of GHG pricing could influence economic viability among future vehicle pathways, and use these assessments to inform the broader research portfolio.

The NRC’s Phase 3 report recommended that the Partnership should consider incorporating the broader scope of a “cradle-to-grave” analysis rather than a “source (well)-to-wheels” approach in program planning from production to recycling in order to better consider total energy consumption, total emissions, and the total environmental impact of various energy/vehicle pathways and technologies (NRC, 2010). The Partnership agreed (DOE, 2010), and U.S. DRIVE has made progress toward this recommendation, as is evident in several systems analysis presentations and discussions with this committee. However, continued integration of life-cycle impacts and potential improvements into decision making and R&D portfolios would increase the likelihood that the U.S. DRIVE Partnership would achieve GHG goals as well as minimize environmental impacts. U.S. DRIVE’s integrated R&D and its portfolio planning would benefit from going beyond a “cradle-to-grave” approach and instead adopting a “cradle-to-cradle” approach, which would optimize processes for limited waste, maximized recycling, and reduced embodied energy of materials used to manufacture critical technology components (McDonough et al., 2003). Other impacts of alternative transportation pathways, such as water use (Harto et al., 2010), remain important areas for integration into U.S. DRIVE systems analysis.

The composition of the electricity grid, which grew and evolved with the economy over the past century, is well outside the scope and control of U.S. DRIVE. However, U.S. DRIVE has the potential to influence the technologies and costs of a future hydrogen production and delivery infrastructure and currently conducts some research on low-carbon hydrogen production.

Recommendations

A life-cycle approach for energy storage batteries can ensure that environmental externalities, including GHGs, conventional pollutants, human health impacts, resource depletion, water use and quality, toxic releases, and others, are minimized for such batteries.

Recommendation 2-10. The U.S. DRIVE Partnership should integrate a life-cycle assessment approach into its research portfolio for energy storage batteries,

fuel cell stacks, power electronics, hydrogen fuel tanks, and other advanced vehicle components in order to gain an understanding of the potential environmental impacts of materials processing, supply chains, manufacture, and vehicle use and end of life. U.S. DRIVE should anticipate the potential risk and environmental externalities of battery production and end of life and should research methods to minimize these impacts.

The continued integration of life-cycle impacts and potential improvements into decision making and R&D portfolios would increase the likelihood that the U.S. DRIVE Partnership would achieve GHG goals as well as minimize environmental impacts. Life-cycle analyses are difficult to do comprehensively. They need to adhere to established life-cycle assessment research methods, include sensitivity analysis, be explicit about uncertainties, and be transparent so that all assumptions can be understood and refined.

Recommendation 2-11. The Executive Steering Group as well as the systems analysis teams of the U.S. DRIVE Partnership should identify pathways for fuel cell vehicles and electric vehicles to achieve large life-cycle GHG reductions and structure risk-weighted R&D portfolios to increase the likelihood of achieving these goals at competitive costs. U.S. DRIVE should also update and publicly publish comparisons of per-mile life-cycle GHG emissions across vehicle technologies regularly so that stakeholders can understand all assumptions made, be aware of systems impacts, and identify potential improvements.

Alvarez, R.A., S.W. Pacala, J.J. Winebrake, W.L. Chameides, and S.P. Hamburg. 2012. Greater focus needed on methane leakage from natural gas infrastructure. Proceedings of the National Academy of Sciences 109(17):6435-6440.

Argonne National Laboratory. 2011. The Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation (GREET) Fuel Cycle Model version 1, 2011, and Vehicle Cycle Model Version 2.7, 2011. Chicago, Ill.: U.S. Department of Energy.

Brandão, Miguel, Garvin Heath, and Joyce Cooper. 2012. What can meta-analyses tell us about the reliability of life cycle assessment for decision support? Journal of Industrial Ecology 16:S3-S7.

Cetinkaya, E., I. Dincer, and G.F. Naterer. 2012. Life cycle assessment of various hydrogen production methods. International Journal of Hydrogen Energy 37(3):2071-2080.

DOE (U.S. Department of Energy). 2010. Actions, Evidence, and Response to the Review of the Research Program of the FreedomCAR and Fuel Partnership: Third Report. December. Washington, D.C.: FreedomCAR and Fuel Partnership.

DOE. 2012. Overview of Safety, Codes, and Standards—DOE Hydrogen Program. U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy. Available at www.hydrogen.energy.gov/pdfs/.../scs000_ruiz_2012_o.pdf.

Dunn, J.B., L. Gaines, M. Barnes, J. Sullivan, and M.Q. Wang. 2012. Material and Energy Flows in the Materials Production, Assembly, and End of Life Stages of the Automotive Lithium-Ion Battery Life Cycle. ANL/ESD/12-3. June. Argonne, Ill.: Argonne National Laboratory.

Elgowainy, A., J. Han, L. Poch, M. Wang, A. Vyas, M. Mahalik, and A. Rousseau. 2010. Well-to-Wheels Analysis of Energy Use and Greenhouse Gas Emissions of Plug-in Hybrid Electric Vehicles. ANL/ESD/10-1. Argonne, Ill.: Argonne National Laboratory.

Gaines, L., J. Sullivan, A. Burnham, and I. Belharouak. 2011. Life-cycle analysis of production and recycling of lithium ion batteries. Transportation Research Record: Journal of the Transportation Research Board 2252(1):57-65.

Graedel, T.E., and B.R. Allenby. 2004. Industrial Ecology and Sustainable Engineering. Englewood Cliffs, N.J.: Prentice Hall.

Harto, Christopher, Robert Meyers, and Eric Williams. 2010. Life cycle water use of low-carbon transport fuels. Energy Policy 38(9):4933-4944.

Hawkins, T.R., B. Singh, G. Majeau-Bettez, and A.H. Strømman. 2012. Comparative environmental life cycle assessment of conventional and electric vehicles. Journal of Industrial Ecology. Published online October 4. Available at http://onlinelibrary.wiley.com/doi/10.1111/j.1530-9290.2012.00532.x/full.

Heath, Garvin A., and Margaret K. Mann. 2012. Background and reflections on the life cycle assessment harmonization project. Journal of Industrial Ecology 16:S8-S11.

Hendrickson, C.T., L.B. Lave, and H.S. Matthews. 2006. Environmental Life Cycle Assessment of Goods and Services: An Input-Output Approach. Washington, D.C.: Resources for the Future.

Lucas, Alexandre, Rui Costa Neto, and Carla Alexandra Silva. 2012. Impact of energy supply infrastructure in life cycle analysis of hydrogen and electric systems applied to the Portuguese transportation sector. International Journal of Hydrogen Energy 37(15):10973-10985.

Majeau-Bettez, Guillaume, Troy R. Hawkins, and Anders Hammer Strømman. 2011. Life cycle environmental assessment of lithium-ion and nickel metal hydride batteries for plug-in hybrid and battery electric vehicles. Environmental Science and Technology 45(10):4548-4554.

McDonough, W., M. Braungart, P.T. Anastas, and J.B. Zimmerman. 2003. Applying the principles of green engineering to cradle-to-cradle design. Environmental Science and Technology 37(23):434-441.

Michalek, Jeremy J., Mikhail Chester, Paulina Jaramillo, Constantine Samaras, Ching-Shin Norman Shiau, and Lester B. Lave. 2011. Valuation of plug-in vehicle life-cycle air emissions and oil displacement benefits. Proceedings of the National Academy of Sciences 108(40, October 4):16554-16558.

Nguyen, N. 2010. Hydrogen Fueled Vehicle Global Technical Regulation and Research and Development. Washington, D.C.: U.S. Department of Transportation, National Highway Traffic Safety Administration. Available at http://www1.eere.energy.gov/hydrogenandfuelcells/pdfs/ihfpv_nguyen.pdf.

Notter, Dominic A., Marcel Gauch, Rolf Widmer, Patrick Wäger, Anna Stamp, Rainer Zah, and Hans-Jörg Althaus. 2010. Contribution of Li-ion batteries to the environmental impact of electric vehicles. Environmental Science and Technology 44(17):6550-6556.

NRC (National Research Council). 2004. Materials Count: The Case for Material Flows Analysis. Washington, D.C.: The National Academies Press.

NRC. 2005. Review of the Research Program of the FreedomCAR and Fuel Partnership: First Report. Washington, D.C.: The National Academies Press.

NRC. 2008. Review of the Research Program of the FreedomCAR and Fuel Partnership: Second Report. Washington, D.C.: The National Academies Press.

NRC. 2010. Review of the Research Program of the FreedomCAR and Fuel Partnership: Third Report. Washington, D.C.: The National Academies Press.

Rogers, Kristin, and Thomas P. Seager. 2009. Environmental decision-making using life cycle impact assessment and stochastic multiattribute decision analysis: A case study on alternative transportation fuels. Environmental Science and Technology 43(6):1718-1723.

SAE (Society of Automotive Engineers). 2009. “Technical Information Report for Fuel Systems in Fuel Cell and Other Hydrogen Vehicles: Product Code: 2579.” January 6. Available at http://standards.sae.org/j2579_200901/.

Samaras, Constantine, and Kyle Meisterling. 2008. Life cycle assessment of greenhouse gas emissions from plug-in hybrid vehicles: Implications for policy. Environmental Science and Technology 42(9):3170-3176.

Siler-Evans, Kyle, Inês Lima Azevedo, and M. Granger Morgan. 2012. Marginal emissions factors for the U.S. electricity system. Environmental Science and Technology 46(9):4742-4748.

U.S. DRIVE. 2012. US DRIVE, Driving Research and Innovation for Vehicle Efficiency and Energy Sustainability. Partnership Plan. February. Washington, D.C.: U.S. Department of Energy.

Weber, C.L., P. Jaramillo, J. Marriott, and C. Samaras. 2010. Life cycle assessment and grid electricity: What do we know and what can we know? Environmental Science and Technology 44(6):1895-1901.

Zackrisson, Mats, Lars Avell, and Jessica Orlenius. 2010. Life cycle assessment of lithium-ion batteries for plug-in hybrid electric vehicles—Critical issues. Journal of Cleaner Production 18(15):1519-1529.