2

Alternative Vehicle Technologies:

Status, Potential, and Barriers

2.1 INTRODUCTION AND OVERALL FRAMEWORK FOR ANALYSES

Virtually all light-duty vehicles on U.S. roads today have internal combustion engines (ICEs) that operate on gasoline (generally mixed with about 10 percent ethanol produced from corn) or diesel fuel. To achieve very large reductions in gasoline use and greenhouse gas emissions from the light-duty fleet, vehicles in 2050 must be far more efficient than now, and/or operate on fuels that are, on net, not based on petroleum and are much less carbon-intensive. Such fuels include some biofuels, electricity, and hydrogen. This chapter describes the vehicle technologies that could contribute to those reductions and estimates how their costs and performance may evolve over coming decades. Chapter 3 considers the production and distribution of fuels and their emissions.

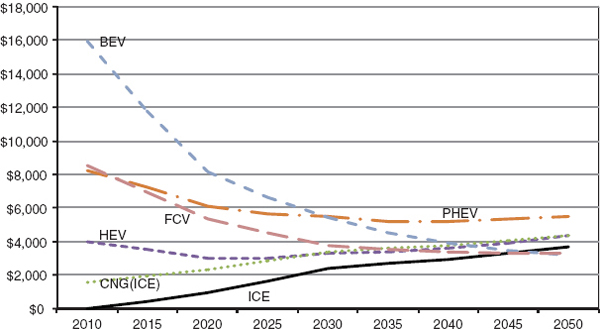

Improving the efficiency of conventional vehicles, including hybrid electric vehicles (HEVs), is discussed first.1 It is, up to a point, the most economical and easiest-to-implement approach to saving fuel and reducing emissions. It includes reductions of the loads the engine must overcome, specifically vehicle weight, aerodynamic resistance, rolling resistance, and accessories, plus improvements to the ICE powertrain and HEV electric systems However, if improved efficiency was the only way to meet the goals, then, for the expected vehicle miles traveled (VMT) in 2050, the average on-road fleet fuel economy would have to exceed 180 mpg.2 Since that is extremely unlikely, at least with currently identifiable technologies, additional options will be needed. Options considered by the committee include biofuels (discussed in Chapter 3), plug-in hybrid electric vehicles (PHEVs), battery-electric vehicles (BEVs [PHEVs and BEVs are collectively referred to as plug-in vehicles, PEVs]), fuel cell electric vehicles (FCEVs), and ICE vehicles (ICEVs) using compressed natural gas (CNGVs).

ICEVs and PHEVs will require little or no modification to operate on “drop-in” biofuels or synthetic gasoline derived from natural gas or coal. Vehicles that are powered by electricity or hydrogen are very different from current vehicles as described later in this chapter. CNGVs are also discussed, as they require a much larger fuel tank and other modifications. Upstream impacts of producing and providing electricity, hydrogen, and CNG are discussed in Chapter 3.

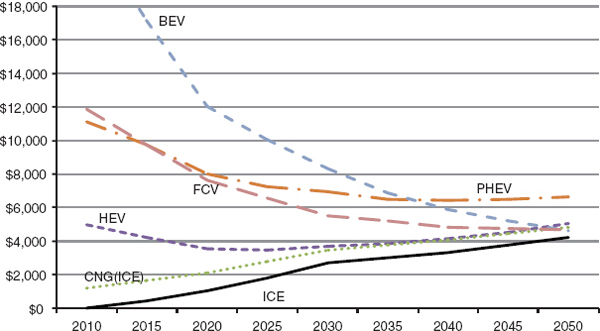

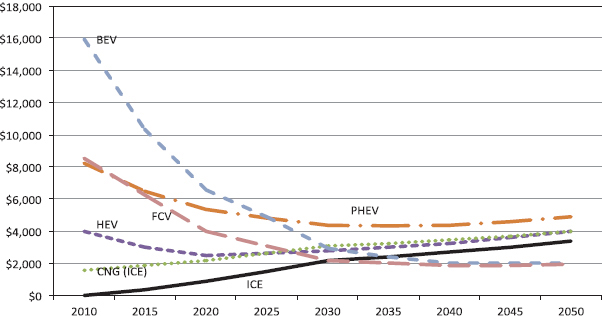

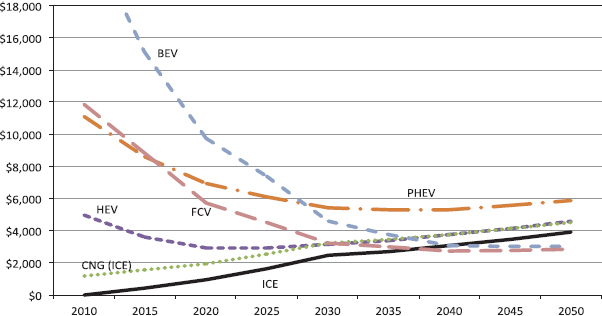

All these alternative vehicle options currently are more expensive than conventional ICEVs. The rate at which research and development (R&D) improves the performance and reduces the cost of new technologies is highly uncertain. To address this uncertainty, the analysis in this chapter considers two technology success pathways. The midrange case is the committee’s best assessment of potential cost and performance should all technologies be pursued vigorously. The committee also developed a stretch case with more optimistic, but still feasible, assumptions about advances in technology and low-cost manufacturing. Details of the technology assessments are in Appendix F.

The committee’s estimates are not based on detailed evaluations of all the specific technologies that might be used by 2050. It is impossible to know exactly which technologies will be used that far in the future, especially since major shifts from current technology will be necessary to meet this study’s goals for reduced light-duty vehicle (LDV) petroleum

_______________________

1All fuel economy (mpg) and fuel consumption numbers discussed in Chapter 2 are based on unadjusted city and highway test results or simulations, and do not include in-use efficiency adjustments.

2To meet the goal of 303 million metric tons of carbon dioxide equivalent (MMTCO2e), 80 percent reduction from the 1514 light duty fleet emissions in 2005, with gasoline responsible for 10.85 kilograms CO2e/gallon (8.92 from the tail pipe, the rest from refining and other upstream activities), at most only 28 billion gallons/year could be used (vs. 125 billion now). VMT in 2050 is expected to be about 5 trillion miles (see Chapter 5). Therefore, if the goal were to be met only with efficiency and no advanced vehicle or fuel technology, average economy would have to be 180 mpg. For this case only, the 80 percent oil reduction goal (28 billion gallons) is identical to the GHG goal.

use and GHG emissions.3 The optimistic and midrange estimates reflect the committee’s appraisal of the overall development challenges facing the general pathways, and the promise of the various technologies that might be employed to meet the challenges. These estimates do not consider issues of market acceptance, which are addressed in Chapters 4 and 5, and are not based on specific policies to encourage market acceptance. Both estimates assume that policies are adopted that are sufficiently effective to overcome consumer and infrastructure barriers to adoption.

The committee reviewed a wide range of studies on technology potential and cost but was not able to find a study based on up-to-date technology assumptions and a consistent methodology for all types of technologies through 2050. The 2017-2025 light duty fuel economy standards were based on analyses that included major improvements in data and estimation of technology benefits and costs, but assessed technology only through 2025 (EPA and NHTSA, 2011). The 2009 MultiPath study (ANL, 2009) used a consistent methodology through 2050, but it lacked this recent data. Thus, the committee performed its own assessment of technology effectiveness and costs, as described below and in Appendix F.

In order to compare technologies, all costs discussed in this chapter assume the economies of scale from high volume production even in the early years when production is low. The modeling in Chapter 5, which estimates the actual costs of following specific trajectories, modified these costs for early and low-volume production.

Great care was taken to apply consistent assumptions to all of the technologies considered. For example, the same amount of weight reduction was applied to all vehicle types, and vehicle costs were built up from one vehicle type to the next (e.g., hybrid costs were estimated based on changes from conventional vehicles, and PEV costs were based on changes from hybrid vehicles). This approach does not reduce the large uncertainty in forecasting future benefits and costs, but it does help ensure that the relative differences in costs between different technologies are appropriately assessed and are more accurate than the absolute cost estimates.

The committee made every attempt to ensure accurate technology assumptions. Fundamental limitations for all technologies were considered for all future assessments, such as the ones discussed below for lithium-ion (Li-ion) battery chemistry and for engine losses. As these limits were approached, the rate of technology improvement was slowed down to ensure that the estimates stayed well short of the limits.

On the other hand, learning occurs primarily because manufacturers are very good at coming up with better and more efficient incremental improvements. For example, 10 years ago technology that uses turbochargers to boost exhaust gas recirculation (EGR) was virtually unknown for gasoline engines. This new development, enabled by sophisticated computer simulations and design, has the potential to improve overall ICEV efficiency by about 5 percent. Certainly some of the currently known technologies will not pan out as planned, but it is equally certain that there will be incremental improvements beyond what we can predict now. The estimates in this chapter reflect an effort to strike a careful balance between these considerations.

Learning also applies to cost. Historically, technology costs have continuously declined due to incremental improvements. For example, 6-speed automatic transmissions, currently the most common type, are cheaper to manufacturer than 4-speed automatic transmissions, thanks to innovative power flow designs that allow additional gear combinations with fewer clutches and gearsets.

Although significant continuing R&D yielding sustained progress and cost reduction in all areas is essential, the technology estimates used for the committee’s analyses do not depend on any unanticipated and fundamental scientific breakthroughs in batteries, fuel cell systems, lightweight materials, or other technologies. Therefore the estimates for improvements may be more readily attained, especially for 2050, when technology breakthroughs are quite possible. For example:

- Batteries beyond Li-ion were not considered for PEVs because the challenges facing their development make their availability highly speculative.

- Fuel cell efficiency gains were much less than theoretically possible, based on the assumption that developers will consider reducing the cost of producing a given power level to be more important.

- Reducing weight with carbon fiber materials was not included in the analyses, because the committee was uncertain if costs would be low enough by 2050 for mass market acceptance.

- The annual rate of reduction for the various vehicle energy losses was assumed to diminish after 2030, usually to about half of the historical rate of reduction or the rate projected from 2010 to 2030. This reflects reaching the limits of currently known technology and implicitly assumes that the rate of technology improvements will slow in the future, despite the current trend of accelerating technology introduction.

- Only turbocompounding was considered for waste heat recovery, even though other methods with much

_______________________

3The committee did not assess GHG emissions from the production of vehicles or include such emissions in its analyses of emissions trends later in this report. Given that vehicles are expected to last about 15 years, any differences in production emissions will not make a large difference in lifetime emissions. In addition, data on emissions from the production of vehicles is poor, and estimates for advanced vehicles in several decades will be even more uncertain.

higher potential waste heat recovery rates are being researched (Ricardo, 2012).

- Radical new ICE combustion techniques with potentially higher thermal efficiency were not considered due to uncertainty about cost and durability. In fact, the assumptions for thermal energy in the committee’s modeling for the 2030 optimistic and 2050 midrange cases were very similar to the efficiency levels considered achievable by Ford’s next generation Eco-Boost engine with “potentially up to 40% brake thermal efficiency … at moderate cost” (Automotive Engineering, 2012).

2.2 VEHICLE FUEL ECONOMY AND COST ASSESSMENT METHODOLOGY

This committee’s approach to estimating future vehicle fuel economy differs from most projections of future ICE efficiency, which have generally assessed the benefits of specific technologies that can be incorporated in vehicle designs (see Appendix F). Such assessments work well for estimates out 15 to 20 years, but their usefulness for 2050 suffers from two major problems. One is that it is impossible to know what specific technologies will be used in 2050. The traditional approaches taken to assess efficiency, such as PSAT and ADVISOR, depend on having representative engine maps, which do not exist for the engines of 2050. The second is that as vehicles approach the boundaries of ICE efficiency, the synergies, positive and negative, between different technologies become more and more important; that is, when several new technologies are combined, the total effect may be greater or less than the sum of the individual contributions.

The three-step approach used here avoids these problems. First, for ICE and HEV technologies, sophisticated computer simulations conducted by Ricardo were used to establish powertrain efficiencies and losses for the baseline and 2030 midrange cases.4 These simulations fully accounted for synergies between technologies. Second, the efficiencies and losses of the different powertrain components and categories were determined. Using these categories to extrapolate efficiencies and losses allowed the committee to properly assess synergies through 2050. Third, the estimates of future efficiencies and losses were simultaneously combined with modeling of the energy required to propel the vehicle as loads, such as weight, aerodynamics, and rolling resistance, were reduced. This approach ensures that synergies are properly assessed and that the modeled efficiency results do not violate basic principles.

The committee estimated conventional powertrain improvements using the results of sophisticated simulation modeling conducted by Ricardo (2011). This modeling was used by the U.S. Environmental Protection Agency (EPA) to help set the proposed 2025 light-duty vehicle CO2 standards. Ricardo conducted simulations on six different vehicles, three cars and three light trucks, which examined drivetrain efficiency (not load reduction) in the 2020-2025 timeframe. The simulations were based on both existing cutting-edge technologies and analyses of technologies at advanced stages of development.

EPA post-analyzed Ricardo’s simulation runs and apportioned the losses and efficiencies to six categories—engine thermal efficiency, friction, pumping losses, transmission efficiency, torque converter losses, and accessory losses. The committee used these results as representative of potential new-vehicle fleet average values in 2025 for the optimistic case and in 2030 for the midrange case. The 2050 mid-level and 2050 optimistic vehicles were constructed by assuming that the rates of improvement in key drivetrain efficiencies and vehicle loads would continue, although at a slower rate, based on the availability of numerous developing technologies and limited by the magnitude of the remaining opportunities for improvement.

Baseline inputs for 2010 ICEVs were developed by the committee from energy audit data that corresponded with specific baseline fuel economy. The model calculates changes in mpg based on changes in input assumptions over EPA’s test cycles. Additional details of the model are in Appendix F. The results were averaged to one car and one truck for analysis in the scenarios, but the analysis for all six vehicles is in Appendix F.

Starting with the results for ICEVs, the energy audit model was then applied to the other types of vehicles considered in this report for each analysis year and for the midrange and optimistic scenarios. PHEVs were assumed to have fuel economy identical to their corresponding BEVs5 while in charge-depleting mode (that is, when energy is supplied by the battery) and to HEVs in charge-sustaining mode (when energy is supplied by gasoline or diesel). Natural gas vehicles were assumed to have the same efficiency as other gasoline fueled vehicles.

Care was taken to use consistent assumptions across the different technologies. For example, the same vehicle load reduction assumptions (weight, aero, rolling resistance) were applied to all of the drivetrain technology packages.

_______________________

4The committee accepts the Ricardo results. However, it should be noted that they are based in part on input data that has not been peer reviewed because it is proprietary.

5The BEVs evaluated have a 100 mile range. BEVs with longer range would have substantially heavier battery packs (and supporting structures), adversely affecting vehicle efficiency. PHEVs might have higher electric efficiency than long-range BEVs.

Variables considered by the model (not all variables were used for each technology) were the following:

• Vehicle load reductions:

—Vehicle weight,

—Aerodynamic drag,

—Tire rolling resistance, and

—Accessory load;

• ICE:

—Indicated (gross thermal) efficiency,

—Pumping losses,

—Engine friction losses,

—Engine braking losses, and

—Idle losses;

• Transmission efficiency;

• Torque converter efficiency;

• Electric drivetrain:

—Battery storage and discharge efficiencies,

—Electric motor and generator efficiencies, and

—Charger efficiency (BEV and PHEV only);

• Fuel cell stack efficiency,

—Also the FCEV battery loop share of non-regenerative tractive energy;

• Fraction of braking energy recovered; and

• Fraction of combustion waste heat energy recovered.

Details of the input assumptions for alternative technologies and of the operation of the model are described in Appendix F.

2.2.2 Vehicle Cost Calculations

Future costs are more difficult to assess than fuel consumption benefits. The committee examined existing cost assessments for consistency and validity. Fully learned out, high-volume production costs were developed as described in this chapter and in Appendix F.

The primary goal was to treat the cost of each technology type as equitably as possible. The vehicle size and utility were the same for all technology types. Range was the same for all vehicles except for BEVs, which were assumed to have a 100 mile real-world range. Care was taken to match the cost assumptions to the efficiency input assumptions. Results from the efficiency model were used to scale the size of the ICE, electric motor, battery, fuel cell, and hydrogen and CNG storage tanks (as applicable). Consistent assumptions of motor and battery costs were used for HEVs, PHEVs, BEVs, and FCVs. Costs were calculated separately for cars and light trucks.

For load reduction, the cost of lightweight materials, aerodynamic improvements, and reductions in tire rolling resistance were assumed to apply equally to all vehicles and technology types.

ICE technology includes a vast array of incremental engine, transmission, and drivetrain improvements. Past experience has shown that initial costs of new technologies can be high, but generally drop dramatically as packages of improvements are fully integrated over time. The incremental cost of other technologies was compared to future ICE costs (FEV, 2012).

For HEVs, costs specific to the hybrid system were added to ICE costs, and credits for smaller engines and components not needed were subtracted to arrive at the hybrid cost increment versus ICE. Similarly, the other vehicle costs were derived from ICEVs by adding and subtracting costs for various components as appropriate. Battery, motor, and power electronics costs were assessed separately for electric drive vehicles.

2.3 LOAD REDUCTION (NON-DRIVETRAIN) TECHNOLOGIES

Many opportunities exist to reduce fuel consumption and CO2 emissions by reducing vehicle loads, as shown in Table 2.1. The load reduction portion of improved efficiency will benefit all the propulsion options by improving their fuel efficiency, reducing their energy storage requirements, and reducing the power and size of the propulsion system. This is especially important for hydrogen- and electricity-fueled vehicles because battery, fuel cell, and hydrogen storage costs are quite expensive and scale more directly with power or energy requirements than do internal combustion powertrain costs. In particular, load reduction allows a significant reduction in the size and cost of electric vehicle battery packs.

TABLE 2.1 Non-drivetrain Opportunities for Reducing Vehicle Fuel Consumption

| Light weighting | Structural materials Component materials Smart design |

| Rolling resistance | Tire materials and design Tire pressure maintenance Low-drag brakes |

| Aerodynamics | Cd (drag coefficient) reduction Frontal area reduction |

| Accessory efficiency | Air conditioning Efficient alternator Efficient lighting Electric power steering Intelligent cooling system |

Reducing vehicle weight is an important means of reducing fuel consumption. The historical engineering rule of thumb, assuming appropriate engine resizing is applied and vehicle performance is held constant, is that a 10 percent weight reduction results in a 6 to 7 percent fuel consumption savings (NHTSA/EPA/CARB, 2010). The committee specifically modeled the impact of weight reduction for each technology type, as this rule of thumb was derived for conventional drivetrain vehicles and other technologies may differ in their response to weight reduction.

A variety of recent studies (see Appendix) have evaluated the weight reduction potential and cost impact for light duty vehicles through material substitution and extensive vehicle redesign. The long-term goal of the U.S. Drive Partnership sponsored by the U.S. Department of Energy DOE) is a 50 percent reduction in weight (DOE-EERE, 2012).6 Lotus Engineering projects a 2020 potential for about a 20 percent weight reduction at zero cost and 40 percent weight reduction potential at a cost of about 3 percent of total vehicle cost, from an aluminum/magnesium intensive design (Lotus Engineering, 2010).

2.3.1.1 Factors That May Affect Mass Reduction Potential

Towing Capacity Mass reduction potential for some light trucks will be constrained by the need to maintain towing capacity, which limits the potential for engine downsizing and requires high structural rigidity. Towing capacity is the only advantage of body-on-frame over unibody construction, thus it was assumed that the historical trend for conversion of minivans and sport utility vehicles (SUVs) from body-on-frame to unibody construction would continue and all vehicles that did not need significant towing capacity would convert to unibody construction. The committee accounted for towing capacity by reducing the weight of body-on-frame trucks (pickups and some SUVs) by only 80 percent of the mass reduction of passenger cars and unibody trucks (minivans and most SUVs). In other words, if a car in 2050 is estimated to be 40 percent lighter, a corresponding mass reduction for a body-on-frame truck would be limited to 32 percent.

Mass Increases Due to Safety Standards Weight associated with increased safety measures is likely to be lower than in the past. The preliminary regulatory impact analysis for the 2025 Corporate Average Fuel Economy (CAFE) standards looked at weight increases for a variety of safety regulations, including proposed rules that would affect vehicles through 2025 and estimated a potential weight increase of 100-120 pounds (EPA and NHTSA, 2011). That is about a 3 percent mass increase, which was factored into the committee’s assessment of weight reduction potential.

Mass Increases for Additional Comfort and Accessories Vehicle weight decreased rapidly in the late 1970s and early 1980s because of high fuel prices and implementation of the initial CAFE standards, then increased significantly during the period from the mid 1980s to the mid 2000s when fuel prices fell and fuel economy standards were kept constant (EPA, 2012). Thus, projecting weight trends into the future is very uncertain.7 Continued weight increases are inconsistent with the assumptions driving this study, i.e., a future that emphasizes improved vehicle efficiency, increased fuel costs, and strong policies to reduce fuel consumption. Not only will manufacturers have strong incentive to reduce weight, but the historical increase in comfort and convenience features is likely to slow and historical increases in weight associated with emission control technology should not continue.8 The committee estimated that weight increases associated with additional comfort and accessories for the midrange scenarios would be roughly half of the historical annual weight increase during a period of fixed fuel economy standards, or 5 percent by 2030 and 10 percent by 2050. This adjustment was applied after the weight reductions considered here for lightweight materials. The optimistic cases did not include weight increases for additional comfort and accessories.

Mass Reductions Related to Smart Car Technology In the 2050 timeframe, a significant portion of LDVs may include crash avoidance technology and other features of smart car technology. Although it is possible that such features might lead to weight reduction, that is speculative and was not considered. The committee also did not consider driverless (or

_______________________

6U.S. DRIVE is a government-industry partnership focused on advanced automotive and related energy infrastructure technology R&D. The partnership facilitates pre-competitive technical information to accelerate technical progress on technologies that will benefit the nation. Further information can be found at http://www1.eere.energy.gov/vehiclesandfuels/pdfs/program/us_drive_partnership_plan_may2012.pdf.

7In addition to weight increases, improvement in powertrain efficiency has been used to increase performance instead of improving fuel economy in the past. The committee concluded that, as for weight discussed above, power is unlikely to grow significantly under the conditions postulated for this study. Past performance increases occurred primarily during periods of little regulatory pressure, and this study assumes that strong regulations or high gasoline prices will be required to reach the levels of fuel economy discussed here. In addition, the average performance level of U.S. vehicles already is high, and many drivers aren’t interested in faster acceleration. Finally, the advanced vehicles expected in the future are likely to operate at high efficiency over a broader range than current engines, so high power engines will detract less from fuel economy. Hence the committee decided that performance increases may not happen to a great degree and, if they did, would likely not have a significant impact on fuel economy in the future.

8Future emission reductions will be accomplished largely with improved catalysts and better air/fuel ratio control—neither of which will add weight to the vehicle.

autonomous) vehicles because it is not clear what the impact on fuel use may be. While they may lead to smaller cars and mass reduction because of improved safety, and driving a given route may be more efficient with computer controlled acceleration and braking and continuous information on congestion, people may be encouraged to live further away from their workplaces and other destinations because they can use the time in their vehicles more productively. More information on the potential impact of autonomous vehicles is in Appendix F.

2.3.1.2 Safety Implications

Any effects of fleet-wide weight reduction on safety will depend on how the reductions are obtained and on the distribution of weight reduction over different size classes and vehicle types. However, the footprint-based standards implemented in 2005 for light trucks and 2011 for cars eliminate any regulatory incentive to produce smaller vehicles, and there are few indications that substantial weight reduction through the use of lightweight materials and design optimization will have significant adverse net effects on safety (DOT, 2006). Advanced designs that emphasize dispersing crash forces and optimizing crush stroke and energy management can allow weight reduction while maintaining or even improving safety. Advanced materials such as high strength steel, aluminum and polymer-matrix composites (PMC) have significant safety advantages in terms of strength versus weight. The high strength-to-weight ratio of advanced materials allows a vehicle to maintain or even increase the size and strength of critical front and back crumple zones and maintain a manageable deceleration profile without increasing vehicle weight. Finally, given that all light duty vehicles likely will be down-weighted, vehicle to vehicle crash forces should also be mitigated, and vehicle handling may improve because lighter vehicles are more agile, helping to avoid crashes in the first place.

2.3.1.3 Weight Reduction Amount and Cost

Table 2.2 summarizes the weight reductions and costs per pound saved that are used in the committee’s scenarios. The table also includes carbon fiber in 2050 for context, even though the committee considers it unlikely that costs will drop sufficiently for widespread use in vehicles and it was not used in the vehicle benefit and cost analyses. As noted above, the midrange case includes some weight growth from additional consumer features.

The costs of weight reduction are ameliorated by the cost savings associated with the corresponding secondary weight savings from downsizing chassis, suspension and engine and transmission to account for the reduced structural requirements and reduced drivetrain loads from the reduced mass. Although estimates of the secondary savings vary, they may approach an additional 30 percent of the initial reduction (NRC, 2011).

2.3.2 Reduced Rolling Resistance

Rolling resistance, and the energy required to overcome it, is directly proportional to vehicle mass. The tire rolling resistance coefficient depends on tire design (shape, tread design, and materials) and inflation pressure. Reductions in rolling resistance can occur without adversely affecting wear and traction (Pike Research and ICCT, 2011). The fuel consumption reduction from a 10 percent reduction in rolling resistance for a specific vehicle is about 1 to 2 percent. If in addition the engine is downsized to maintain equal performance, historically fuel consumption was reduced 2.3 percent (NRC, 2006).

In 2005, measured rolling resistance coefficients ranged from 0.00615 to 0.01328 with a mean of 0.0102. The best is 40 percent lower than the mean, equivalent to a fuel consumption reduction of 4 to 8 percent (8 to 12 percent with engine downsizing). Some tire companies have reduced their rolling resistance coefficient by about 2 percent per year for at least 30 years. Vehicle manufacturers have an incentive to provide their cars with low rolling resistance tires to maximize fuel economy during certification. The failure of owners to maintain proper tire pressures and to buy low rolling resistance replacement tires increases in-use fuel consumption.

For this study, scenario projections of reductions in light-duty new-vehicle-fleet rolling resistance for the midrange case average about 16 percent by 2030, resulting in about a

TABLE 2.2 Summary of Weight Reduction and Costs Relative to Base Year 2010

| Year | Cars and Unibody Light Trucks | Body-on-Frame Light Trucks | |||||||

| Weight Reduction (%) | Cost ($/lb) | Reduction with Weight Growth (%) | Weight Reduction (%) | Cost ($/lb) | Reduction with Weight Growth (%) | ||||

| 2030 | 25 | 1.08 | Midrange 20 | 20 | 0.86 | Midrange 15 | |||

| Optimistic 25 | Optimistic 20 | ||||||||

| 2050 | 40 | 1.73 | Midrange 30 | 32 | 1.38 | Midrange 22 | |||

| Optimistic 40 | Optimistic 32 | ||||||||

| 2050 carbon fiber | 50 | 6.0 | Optimistic 50 | 40 | 6.0 | Optimistic 40 | |||

4 percent decrease in fuel consumption, and about 30 percent in 2050, for about a 7 percent fuel consumption decrease. For the optimistic case, rolling resistance reductions were projected to be about 25 percent in 2030 and 38 percent in 2050.

The fraction of the energy delivered by the drive-train to the wheels that goes to overcoming aerodynamic resistance depends strongly on vehicle speed. Unlike rolling resistance, the energy to overcome drag does not depend on vehicle mass. It does depend on the size of the vehicle, as represented by the frontal area, and on how “slippery” the vehicle is designed to be, as represented by the coefficient of drag. For low speed driving, e.g., the EPA city driving cycle, about one-fourth of the energy delivered by the drivetrain goes to overcoming aerodynamic drag; for high speed driving, one-half or more of the energy goes to overcoming drag. Under average driving conditions, a 10 percent reduction in drag resistance will reduce fuel consumption by about 2 percent. Vehicle drag coefficients vary considerably, from 0.195 for the General Motors EV1 to 0.57 for the Hummer 2. The Mercedes E350 Coupe has a drag coefficient of 0.24, the lowest for any current production vehicle (Autobloggreen, 2009). Vehicle drag can be reduced by measures such as more aerodynamic vehicle shapes, smoothing the underbody, wheel covers, active cooling aperture control (radiator shutters), and active ride height reduction.

For this study’s scenarios, reduction in new-vehicle-fleet aerodynamic drag resistance for the midrange case is estimated to average about 21 percent (4 percent reduction in fuel consumption) in 2030 and 35 percent (7 percent reduction in fuel consumption) in 2050. For the optimistic case, the aerodynamic drag reductions are estimated to average about 28 percent in 2030 and 41 percent in 2050.

2.3.4 Improved Accessory Efficiency

Accessories currently require about 0.5 horsepower from the engine for most vehicles on the EPA city/highway test cycle. While small, this is a continual load that affects fuel economy. Accessory load reductions were assessed using Ricardo simulation results and the EPA Energy Audit data, as described above. Overall, test cycle accessory loads were reduced about 21-25 percent by 2030 and 25-35 percent by 2050.

2.4 DRIVETRAIN TECHNOLOGIES FOR REDUCING FUEL CONSUMPTION

Currently, conventional gasoline-fueled ICE drivetrains generally convert about 20 percent of the energy in the gasoline into power at the wheels. The engine cannot operate at peak efficiency most of the time. Within the engine, energy is lost as heat to the exhaust or transferred to the cooling system. Moving parts create frictional losses, intake air is throttled (called “pumping” losses), accessories are powered, and the engine remains in operation at idle and during deceleration. In the transmission, multiple moving parts create friction, and pumps and torque converters create hydraulic losses. Also, when the vehicle brakes, much of the potential energy built up during acceleration is lost as heat in the friction brakes. Many or most of these losses and limitations can be reduced substantially by a variety of technological improvements. The technologies discussed below are just a few of the options. More information can be found in Appendix F. Note that biomass-fueled vehicles are being treated as conventionally powered vehicles in this study.

2.4.1 Conventional Internal Combustion Engine Vehicles

2.4.1.1 Gasoline Engine Drivetrains

Engines will improve efficiency in the future by increasing the maximum thermal efficiency and reducing friction and pumping losses. There are multiple technology paths for accomplishing these improvements.

Although the dominant technology used to control fuel flow in gasoline engines currently is port fuel injection, engines with direct injection of fuel into the cylinders have been rapidly entering the U.S. fleet. Gasoline direct injection (GDI, or just DI) systems provide better fuel vaporization, flexibility as to when the fuel is injected (including multiple injections), more stable combustion, and allow higher compression ratios due to intake air charge cooling. Direct injection reduces fuel consumption across the range of engine operations, including high load conditions, and increases low-rpm torque by allowing the intake valve to be open longer. Future GDI systems using spray-guided injection can deliver a stratified charge allowing a lean air/fuel mixture (i.e., excess air) for greater efficiency.

One approach that is rapidly penetrating the market is to combine direct injection with down-sized turbocharged engines. Turbocharging increases the amount of fuel that can be burned in the cylinders, increasing torque and power output and allowing engine downsizing. The degree of turbocharging is enhanced by GDI because of its cooling effect on the intake (air) charge and reduction of early fuel detonation. Further efficiency improvements are available with more sophisticated turbocharging techniques (e.g., dual-stage turbochargers) and combining turbocharging with some combination of variable valve timing, lean-burn, Atkinson cycle, and cooled and boosted EGR.

Ricardo developed engine maps specifically for an EGR DI turbo system, which uses the turbocharger to boost EGR in addition to intake air. This recirculates additional cooled exhaust gas into the cylinder to reduce intake throttling (and pumping losses), increase compression ratio, enable higher boost and further engine downsizing, and reduce combustion temperatures and early fuel detonation (Ricardo, 2011). This

engine is projected to have a fuel economy benefit of 20 to 25 percent, compared to the baseline port fuel injected, naturally aspirated engine, by 2020-2025.

Turbocharging with GDI engines is likely to become very common by 2030 because the costs are modest and the fuel economy improvement significant.

Engine friction is an important source of energy losses. Friction reduction can be achieved by both redesign of key engine parts and improvement in lubrication. The major sources of friction in modern engines are the pistons and piston rings, valve train components, crankshaft and crankshaft seals, and the oil pump. Key friction reduction measures include the following (EEA, 2007):

- Low mass pistons and valves,

- Reduced piston ring tension,

- Reduced valve spring tension,

- Surface coatings on the cylinder wall and piston skirt,

- Improved bore/piston diameter tolerances in manufacturing,

- Offset crankshaft for inline engines, and

- Higher-efficiency gear drive oil pumps.

Over the past two and one half decades, engine friction has been reduced by about 1 percent per year (EEA, 2007). Continuing this trend would yield about an 18 percent reduction by 2030, but considerably greater reduction than this should be possible, especially with continued aggressive vehicle efficiency requirements. For example, surface technologies such as diamond-like carbon and nanocomposite coatings can reduce total engine friction by 10 to 50 percent. Laser texturing can etch a microtopography on material surfaces to guide lubricant flow, and combining this texturing with ionic liquids (made up of charged molecules that repel each other) can yield 50 percent or more reductions in friction.

There will also be improvements to transmission efficiency and reductions in torque converter losses. The primary advanced transmissions over the next few decades are expected to be advanced versions of current automatic transmissions, with more efficient launch-assist devices and more gear ratios; and dual-clutch automated manual transmissions (DCTs). Transmissions with 8 and 9 speeds have been introduced into luxury models and some mass market vehicles, replacing baseline 6-speed transmissions. The overdrive ratios in the 8- and 9-speed transmissions allow lower engine revolutions per minute (rpm) at highway speeds, and the higher number of gears allows the engine to operate at higher efficiency across the driving cycle. A 20 to 33 percent reduction in internal losses in automatic transmissions is also possible by 2020-2025 from a combination of advances, including improved finishing and coating of components, better lubrication, improvements in seals and bearings, and better overall design (Ricardo, 2011). Dual clutch transmissions, currently in significant use in Europe, will also improve with the perfection of dry clutches and other improvements, with an additional reduction in internal losses (beyond advanced automatic transmissions) of about 20 percent. Their cost should also be lower than advanced automatic transmissions.

2.4.1.2 Estimation of Future Internal Combustion Engine and Powertrain Efficiency Improvements

As discussed earlier in Chapter 2, the committee estimated conventional powertrain improvements using the results of sophisticated simulation modeling on six different vehicles conducted by Ricardo for baseline (2010) and future (2025) vehicles. EPA post-analyzed Ricardo’s simulation runs and apportioned the losses and efficiencies to six categories—engine thermal efficiency, friction, pumping losses, transmission efficiency, torque converter losses, and accessory losses.

The committee directly used EPA’s 2025 results for the 2030 midrange case to ensure adequate time for the technologies to fully penetrate the entire fleet. These results were also extrapolated to 2050 by assuming that the percent annual improvements in each of the six categories after 2030 would be at most half the percent annual improvement calculated for 2010 to 2030. Optimistic estimates were calculated the same way, except that the Ricardo runs were used for 2025 instead of delaying the results until 2030. The total reductions for the various vehicles and losses are shown in Tables 2.9, 2.10, and 2.11, and in Appendix F.

2.4.1.3 Diesel Engines

This report has not explicitly considered diesel engines. Today’s diesels are about 15-20 percent more efficient than gasoline engines, which would seem to mandate their inclusion in a study of greatly improved fuel economy. The committee ultimately decided, however, that a diesel case would not add significant value to the results of the study, primarily because the efficiency advantage of the diesel will be much smaller in the future as gasoline engines improve. Current diesels have a much higher level of technology than gasoline engines in order to address diesel drivability, noise, smell, and emission concerns, such as direct fuel injection, sophisticated turbocharging systems using variable geometry or dual turbochargers, and cooled EGR systems. As this same level of technology is added to the gasoline engine, the efficiency advantage of the diesel will be much smaller. Another consideration is that combustion technology by 2050 may blur, if not completely eliminate, the distinction between diesel and gasoline engine combustion. For example, diesel engines are reducing compression ratio in order to increase turbocharger boost and reduce emissions, while gasoline engines are increasing compression ratio due to improvements in combustion chamber design, increasing use of

variable valve timing, and better control of EGR. Another example is development of homogenous charge compression ignition engines, which combine features of both gasoline and diesel engines.

2.4.2 Conventional Hybrid Electric Vehicles

HEVs combine an ICE, electric motor(s), and a battery or ultracapacitor. All the energy comes from the fuel for the ICE. HEVs reduce fuel consumption by:

- Turning off the engine during idling, deceleration, and coasting;

- Capturing a percentage of the energy that is normally lost to friction braking (i.e., regenerative braking);

- Engine downsizing (because the electric motor provides a portion of the maximum tractive power required);

- Allowing easier electrification of accessories such as power steering;

- Allowing the engine to operate more efficiently. By using the electric motor to drive the wheels at low load, or by operating the engine at a higher power (and higher efficiency) during low loads and capturing excess energy in the battery; and

- By allowing the use of efficient engine cycles, e.g. Atkinson cycle, that are impractical for conventional drivetrains.

The simplest HEV configuration has a “stop-start” system which shuts off the engine when idling and restarts it rapidly when the accelerator is depressed. These “micro-hybrids” need a higher capacity battery and starter motor than ICEVs. Stop-start systems are rapidly growing and are likely to be universal by 2030 because they are a relatively inexpensive way to achieve substantial fuel economy improvements. The benefits of stop-start systems are included in the committee’s calculations for future ICEV efficiency. The hybrid vehicle projections assess the incremental efficiency above that of the stop-start system.

More complex systems that allow electric drive and substantial amounts of regenerative braking include parallel hybrid systems with a clutch between the engine and the motor, commonly referred to as P2 parallel hybrids (e.g., Hyundai Sonata hybrid). They have an electric motor inserted between the transmission and wheels, with clutches allowing the motor to drive the wheels by itself or in combination with the engine, or allowing the engine to drive the wheels without motor input. Powersplit hybrids (e.g., Prius) are another approach, with two electric machines connected via a planetary gearset to the engine and the powertrain. The committee determined that there is more opportunity for cost reduction on P2 hybrid systems in the future and used P2 systems for the future hybrid efficiency and cost assessments (see Appendix F).

About 60 percent of the fuel energy in an ICE is rejected as heat, roughly evenly divided between the engine cooling system (through the radiator) and the exhaust. Some of this heat can be recovered and used to reduce fuel consumption, especially from the exhaust, which is at a high temperature. Turbines, such as used for turbo-chargers, can generate electric power or transfer power to the crankshaft. Alternatively, thermoelectric couples can generate electric power directly, reducing fuel consumption by about 2 to 5 percent. HEVs would likely benefit more than ICEVs from waste heat recovery, as generated electric power could be used in their hybrid propulsion systems or to recharge the battery. This analysis assumes waste heat recovery systems will be applied starting in 2035, and only to HEVs. More efficient forms of waste heat recovery, such as Rankine cycle devices, were not included in the analyses.

There is some uncertainty about the fuel consumption benefit of advanced hybrid systems in the future. While hybrid systems will improve (more efficient components, improved designs and control strategies), advanced engines will reduce some of the same losses that hybrids are designed to attack (e.g., advanced engines will have reduced idle and braking fuel consumption, yielding less benefit from stopping the engine during braking and idling). In addition, even as hybrid drivetrains improve, conventional ICE fuel consumption will shrink, and the actual volume of fuel saved will go down. As done for ICEVs, the committee used the Ricardo simulations of 2025 hybrid vehicles to directly estimate losses and efficiency for the optimistic case in 2025 and for the midrange case in 2030. Unfortunately, Ricardo did not conduct simulations of baseline hybrid systems, so the annual rate of improvement from 2010 to 2025/2030 was assessed using Ricardo’s ICE baseline simulations and differences in the 2025 simulations for ICE and hybrid vehicles to establish baseline hybrid energy losses. The committee’s estimates are shown in Table 2.3.

TABLE 2.3 Estimated Future Average Fuel Economy and Fuel Consumption

| Cars | Trucks | |||||||||

| Midrange | Optimistic | Midrange | Optimistic | |||||||

| ICE | HEV | ICE | HEV | ICE | HEV | ICE | HEV | |||

| Average Fuel Economy (miles per gallon) | ||||||||||

| 2010 | 31 | 43 | 31 | 43 | 24 | 32 | 24 | 32 | ||

| 2030 | 65 | 78 | 74 | 92 | 46 | 54 | 52 | 64 | ||

| 2050 | 87 | 112 | 110 | 145 | 61 | 77 | 77 | 100 | ||

| Average Fuel Consumption (gallons per 100 miles) | ||||||||||

| 2010 | 3.20 | 2.34 | 3.20 | 2.34 | 4.24 | 3.10 | 4.24 | 3.10 | ||

| 2030 | 1.55 | 1.28 | 1.36 | 1.09 | 2.19 | 1.84 | 1.91 | 1.56 | ||

| 2050 | 1.15 | 0.89 | 0.91 | 0.69 | 1.64 | 1.30 | 1.30 | 1.00 | ||

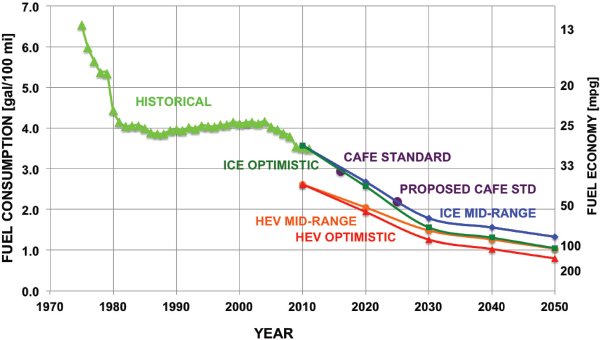

FIGURE 2.1 Historical and projected light-duty vehicle fuel economy.

NOTE: All data is new fleet only using unadjusted test values, not in-use fuel consumption.

While the gains projected by the committee are clearly ambitious, the rate of improvement for conventional vehicles (including use of stop-start systems and advanced alternators) is about 3 percent/year from 2010-2050. Light-duty trucks are expected to improve almost as much. Figure 2.1 compares these rates of improvement to past experience and the 2016 and 2025 CAFE standards. All of the vehicle modeling was assessed as percentage improvements over baseline vehicles. These results were adjusted by the ratio of the baseline used for the modeling in Chapter 5 to the average efficiency of the baseline vehicles used in Chapter 2.

The committee estimated HEV costs by adding the cost of the battery pack, electric motor, and other hybrid system components to the cost previously estimated for conventional vehicles. Credits were also applied for engine downsizing and deletion of the torque converter and original equipment alternator, with the exception that engine size was not reduced on body-on-frame light trucks in order to maintain towing capacity. Weight and other load reductions were incorporated into calculations of the size of the engine, motor, and battery pack for each of the six vehicles. Credits associated with engine downsizing and eliminating the torque converter were subtracted. Except for the battery pack, hybrid system costs were based on detailed and transparent tear-down cost assessments conducted by FEV, Inc., on current production HEV vehicles, with learning factors and suitable design improvements applied to future HEV vehicles (FEV, 2012). Batteries are discussed in Section 2.5, below.

Currently, an HEV costs about $4,000 to $5,000 more than an equivalent ICEV, mostly for the battery, electric motor, and electronic controls. The committee’s total direct manufacturing cost increments for hybrids, compared with 2010 reference vehicles, are shown in Table 2.4. Details on projected costs for hybrid systems are in Appendix F. Retail

TABLE 2.4 Efficiency Cost Increment Over Baseline 2010 Vehicle

| Cars | Trucks | ||||||||

| Midrange | Optimistic | Midrange | Optimistic | ||||||

| ICE | HEV | ICE | HEV | ICE | HEV | ICE | HEV | ||

| 2010 | $0 | $4,020 | $0 | $4,020 | $0 | $4,935 | $0 | $4,935 | |

| 2015 | $435 | $3,510 | $376 | $3,006 | $460 | $4,228 | $400 | $3,601 | |

| 2020 | $986 | $2,989 | $867 | $2,485 | $1,059 | $3,516 | $939 | $2,890 | |

| 2025 | $1,652 | $3,017 | $1,473 | $2,590 | $1,798 | $3,446 | $1,618 | $2,942 | |

| 2030 | $2,433 | $3,280 | $2,195 | $2,765 | $2,676 | $3,711 | $2,436 | $3,160 | |

| 2035 | $2,675 | $3,357 | $2,432 | $2,973 | $2,978 | $3,834 | $2,734 | $3,408 | |

| 2040 | $2,960 | $3,638 | $2,713 | $3,267 | $3,332 | $4,171 | $3,085 | $3,770 | |

| 2045 | $3,288 | $3,949 | $3,036 | $3,577 | $3,738 | $4,540 | $3,487 | $4,142 | |

| 2050 | $3,659 | $4,347 | $3,403 | $3,960 | $4,196 | $5,022 | $3,941 | $4,611 | |

price markups are discussed in Chapter 5. Additional information on how the committee arrived at its estimates of fuel economy improvements and direct manufacturing costs are in Appendix F.

Three distinctly different configurations that utilize battery power for propulsion are in production: HEVs, discussed in the previous section; PHEVs; and BEVs. Each has a rechargeable battery designed for a specific service. The Chevrolet Volt is the first mass-produced PHEV,9 and Nissan’s Leaf the first mass produced BEV10 introduced into the U.S. market. Other manufacturers are introducing electric vehicles of both types over the next several years. Improvements in battery technology will be critical to the success of electric vehicles.

Plug-in hybrids are conceptually similar to HEVs. The same set of improvements in fuel economy that will benefit HEVs will also benefit PHEVs. PHEV batteries have about 4-20 kilowatt-hours (kWh) of stored energy that can be charged from the grid. PHEVs can travel 10 to 40 miles on electricity before the engine is needed. Thus a driver who does not exceed the electric range and charges the vehicle before using it again will use little or no gasoline. However, when driven beyond the charge depletion mode of the first 10 to 40 miles, the vehicles operate as conventional hybrid vehicles (in a charge sustaining mode), eliminating the range anxiety associated with BEVs. PHEV efficiency was assumed to be the same as BEV efficiency when operating on the battery pack and the same as HEV when the engine is running.

A BEV has no engine, a significant cost savings relative to PHEVs, but currently the battery pack for even a small, short-range vehicle is likely to be at least 20 kWh, and a large SUV might require 100 kWh for a range of 200 miles. The Nissan Leaf has a battery of 24 kWh. Battery cost will thus be a key determinant for the success of PHEVs and BEVs. Based on the energy modeling described earlier in this chapter, a car that today gets 30 mpg would, if built as a BEV, require about 26 kWh/100 miles. For a range of 300 miles, the battery would need at least 78 kWh of available energy.11 With current technology and costs, this would be prohibitively expensive, heavy, and bulky for most applications and would take prohibitively long to charge. At $450/kWh, the current battery pack cost estimate (see Section 2.5.3 below), a 78 kWh battery costs $35,000. Prospects for reducing the cost are discussed below.

Other considerations for plug-in vehicles include the range that can be achieved in an affordable vehicle and the time required for recharging. As vehicle weight, aerodynamic resistance, and rolling resistance are improved, range can be improved for the same battery size, or a smaller, less expensive battery may be used for the same range. Many PHEVs and BEVs can be plugged in at home overnight on regular 110 or 220 volt lines. Gradual charging is generally best for the batteries, and night-time charging is best for the power supplier, as power demand is lower than during the day and excess generating capacity is available (see Chapter 3). Fast charging is more challenging for batteries, requires more expensive infrastructure, and is likely to use peak-load electricity with higher cost, lower efficiency, and higher GHG emissions.

2.5.1 Batteries for Plug-In Electric Vehicles

There is general agreement that the Li-ion battery will be the battery of choice for electric vehicles for the foreseeable future. It was developed for the portable electronics industry 20 years ago because of its light weight, superior energy storage capability, and long cycle life, attributes, which also are important for electric vehicles. Cell performance has increased steadily by improvements in the internal electrode structure and cell design and manufacturing processes, as well as the introduction of higher performance anode and cathode materials.

There are several Li-ion chemistries that are being investigated for use in vehicles, but none offers an ideal combination of energy density, power capability, durability, safety, and cost. HEVs are also shifting to Li-ion from the original nickel-metal-hydride chemistry. HEV batteries, which are optimized for high power, may differ from those for PHEVs and BEVs, which will be optimized for high energy and low cost.

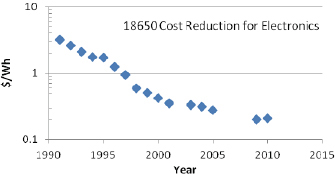

Development of the cylindrical 18650 Li-ion cell for the portable electronics industry is representative of how automotive batteries may develop. In 1991, the cost of the 18650 was $3.17/Wh. Twenty years later, the same cell costs $0.20/Wh, while the charge capacity of the cell went from 1 Amp-hour (Ah) to over 3 Ah in the same volume (see Figure 2.2). These improvements resulted from the introduction of new, high-performance materials, improvements to the cell and electrode structure design, and high volume production processes with reduced wastage. As a rule of thumb for highly automated cell production, cell materials account for about 60 to 80 percent of the cell cost in volume production.12

_______________________

9The Volt’s all-electric range is certified by EPA as 38 miles. General Motors refers to the Volt as an extended range electric vehicle because all power to the wheels is delivered by the electric motor, unlike, say, Toyota’s Prius PHEV. However, both are hybrids in that they have two fuel sources.

10The EPA certified range is 73 miles, but estimates vary widely; also, range is extremely sensitive to weather, driving conditions, and driver behavior.

11Available energy is typically less than nameplate battery pack capacity because batteries may not completely discharge to avoid damage to battery life and loss of power. In addition, available energy could effectively be reduced by energy required to offset the loss of vehicle efficiency caused by the additional weight of a larger battery for longer range.

12As used here, “materials” means processed materials ready for cell manufacture. It does not mean raw materials, which may be much cheaper.

FIGURE 2.2 Cost of the 18650 portable electronics Li-ion cell (current dollars).

SOURCE: H. Takeshita, Tutorials, Florida International Battery Seminars, 1974-2010.

Cells for vehicles are likely to be prismatic (flat plate) or pouch-type rather than cylindrical, because these are easier to cool and arrange in stacks. The production process for flat plate vehicle cells differs from that for cylindrical cells, but it is anticipated that the cost will follow a similar learning pattern as the 18650 cell. Both the Volt and Leaf use a manganese spinel cathode and a graphite anode in a flat-plate configuration with a LiPF6 electrolyte for long cycle life and relatively low cost.

Global R&D activity in Li-ion battery technology is funded at a level of several billion dollars annually. It explores all aspects of the technology and aims to improve energy-storage capacity per unit weight and volume, durability, safety characteristics, operating temperature range, manufacturing processes, and of course cost. Technologies that will offer improved performance without negatively affecting safety, durability, and cost, or, alternatively, improved cost without negatively affecting durability and safety are the only ones likely to find high-volume commercial application. In the next five years or so, optimization of the use of existing materials, engineering optimization of cell and component design, manufacturing process improvement, and economy of scale will support moderate improvements in performance and steady reduction in cost. In the longer term (8 to 15 years), introduction of materials with higher energy density could provide enhanced performance. Further out, probably beyond 2030, new chemistry may be developed but at this point in time no chemistry other than Li-ion is promising enough to be included in this analysis.

2.5.2 Automotive Battery Packs

A battery pack for vehicles consists of an assembly of cells, electrical components, structural components, a cooling system, module management electronics, and battery management system (BMS). A typical pack consists of 30 to several hundred cells configured in a series/parallel arrangement. The series arrangement includes 30 to 100 “virtual” cells in strings that provide a battery voltage of 100 to 400 volts. The virtual cells include a single cell or several cells in parallel to provide the desired Ah capacity. In other combinations, several strings could be put in parallel to provide the total energy capacity required. Cells typically represent 50 to 60 percent of the cost of a battery in HEV applications, 60 to 70 percent of the cost of the pack in PHEV applications and 70 to 80 percent of the cost of pack in BEV applications. The BMS, structural components, electrical components, cooling systems, and assembly account for the balance. While the non-cell portion of the pack grows in complexity and cost from HEVs to PHEVs to BEVs, the number and cost of the cells increases faster.

The BMS is designed to maximize battery life, to minimize the risk of safety incidents, and to communicate to the vehicle controller the state of charge and state of health of the battery. The BMS monitors individual cell voltages, battery current, and battery temperature (measured in several places in the pack). When abnormal cell voltages, temperatures or current are measured, the BMS “takes action” to minimize damage to the battery or risk of safety events.

Estimates of future vehicle battery costs vary widely and depend greatly on assumed production levels as well as technology development. Even current costs are uncertain because of proprietary information, and battery companies may sell batteries below costs in order to gain market share in the early stages of growth. The committee assumed that future costs of Li-ion cells for vehicles are likely to follow a similar (but dropping somewhat more gradually) trajectory as that for the 18650 cell shown in Figure 2.2. Those costs fell in a regular manner for 10 years and then began to level off as production processes matured and improved in reliability. Costs of the battery pack (in addition to the cells) also should decline at about the same rate as cells as manufacturers and suppliers improve designs and production techniques.

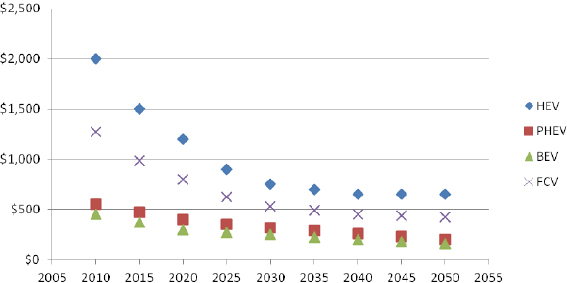

The starting point for the committee’s projected costs for BEV battery packs in Figure 2.3 is $450/kWh for high rates of production.13 Midrange BEV pack costs for 2030 are estimated at $250/kWh and $160/kWh in 2050. Optimistically, pack costs might reach $200/kWh in 2030 and $150/kWh in 2050.

The battery packs used in PHEVs, FCVs, and HEVs are smaller and must still provide high levels of power. This requires the use of batteries with higher power densities, which increases the cost per kWh of energy storage. PHEV pack costs are likely to be $60-70/kWh higher than BEV pack costs. HEV costs are highest because they are much smaller and require different characteristics. Batteries for

_______________________

The processing of these materials is subject to considerable cost reduction, as is the cell manufacture.

13Actual costs for the Leaf and Volt battery packs in 2012 are estimated at about $500/kWh, which reflect lower production volumes. However, note that the Leaf battery does not have a liquid cooling system, and the packs may deteriorate faster. Hence that cost may not be typical.

FIGURE 2.3 Estimated battery pack costs to 2050 ($/kWh).

fuel cell vehicles are between HEVs and PHEVs, as discussed later. Details on the committee’s assessment of batteries are in Appendix F.

Using costs in Figure 2.3, the committee’s estimate for a 30 mile range, as shown in Appendix F, is $4,000 (optimistic) to $4,600 (midrange). In comparison, DOE’s 2015 goal for a battery pack for a PHEV with a 10-mile all-electric range in 2015 is $1,700 and $3,400 for a 40-mile range (Howell and Elder, 2012). PHEV battery costs depend on assumptions such as available energy (state of charge range) as well as how deterioration is handled and the vehicle that is to be propelled, but in general, the committee’s assessment is less optimistic than DOE’s targets.

A battery recycling effort will be needed when large numbers of battery packs reach the end of their useful lifetimes, and that will help to control costs. Recycling already works well for lead acid batteries, almost all of which are returned and the components reused in construction of new batteries.

2.5.4 Battery Technology for Future Applications

Li-ion battery technology for automotive applications may be limited to about 250 to 300 Wh/kg and $175 to $200/kWh (all at the pack level), although this report estimates that costs could get down to $150/kg by 2050. Research work around the world is examining other potential technologies that can yield higher energy density and/or lower cost per unit of energy. As noted before, none of the more futuristic systems has achieved enough maturity to be considered in this evaluation. Lithium sulfur chemistry utilizes a lithium metal anode and a cathode based on sulfur compounds. That system could theoretically double the specific energy of Li-ion batteries and offer competitive cost, but to date the cycling of both electrodes is quite problematic. Even more attention is given to the Li-Air chemistry. This chemistry utilizes lithium-metal anodes and an air electrode so that the cathodic active material (oxygen) is taken from the air and at the charged state does not add to the weight of the battery (the battery gains weight as it discharges). This chemistry can theoretically provide a battery system with a specific energy of several kWh/kg. However, there are multiple independent technical challenges including the cyclability of the lithium electrode, cyclability of the air electrode, charge and discharge rate capability of the air electrode, finding suitable electrolyte, and finding a durable membrane permeable to the electrolyte but impermeable to water and CO2. Several independent breakthroughs would have to occur to make the technology viable, and overall its chance of success is low.

Almost all HEVs and PEVs use rare-earth-based interior permanent magnet (IPM) motors. IPM motors are by far the most popular choice for hybrids and EVs because of their high power density, specific power, efficiency, and constant power-to-speed ratio. Performance of these motors is optimized when the strongest possible magnets (NdFeB) are used. Cost and power density (power density equates to torque and acceleration) are emerging as the two most important properties of motors for traction drives in hybrid and EVs, although high efficiency is essential as well.

China currently has a near monopoly on the production of rare-earth materials, and since 2008 it has steadily raised the price of rare-earth magnet materials to as high as $60/kg. An automotive traction motor uses 1 to 1.5 kg of rare-earth magnet materials, which influences the cost of motors for electric vehicles.

The potential for a future shortage of rare-earth materials has led DOE to search for technologies that either eliminate or reduce the amount of rare-earth magnets in motors. The

TABLE 2.5 Motor Cost Estimates

| HEV/PHEV Costs | BEV/FCEV Costs | ||||||||

| Fixed | $/kW | Fixed | $/kW | ||||||

| Midrange | |||||||||

| 2010 | $668 | $11.6 | $668 | $11.6 | |||||

| 2030 | $393 | $6.3 | $425 | $7.3 | |||||

| 2050 | $322 | $5.2 | $347 | $6.0 | |||||

| Optimistic | |||||||||

| 2010 | $668 | $11.6 | $668 | $11.6 | |||||

| 2030 | $349 | $5.5 | $381 | $6.5 | |||||

| 2050 | $286 | $4.5 | $311 | $5.3 | |||||

DOE strategy continues ongoing cost-reduction efforts for rare-earth-based motors while also searching for new permanent magnet materials that do not use rare earths and motor designs that do not use permanent magnets.

Recently Toyota announced that it has developed a new material with equivalent or superior capability as rare-earth materials for the electric motors in its line of electric vehicles (Reuters, 2012). Toyota has also developed an induction motor that it claims is lighter and more efficient than the magnet-type motor now used in the Prius and does not use rare-earth materials.

In addition, U.S. production of rare-earths is resuming. Therefore, rare-earth materials are not likely to cause major increases in motor costs in the future. Overall, motor costs are likely to decline from about $2,000 now to less than $1,000 in 2050 for a typical electric car. This decline will result from better design and manufacturing and from the smaller size that will be needed to power more efficient future vehicles.

Table 2.5 presents the committee’s motor cost estimates. These are based upon detailed tear-down cost estimates by FEV and include the cost of the motor, case, launch clutch, oil pump and filter, sensors, connectors, switches, cooling system, motor clutch, power distribution, and electronic control module. Some costs are independent of the size of the motor within the range considered here (fixed), and others are directly dependent (variable). Future cost projections included learning and incorporation of the electric motor into the transmission for HEV and PHEV applications. Further details on electric motors are in Appendix F.

2.5.6 Barriers to the Widespread Adoption of Electric Vehicles

2.5.6.1 Battery Cost

Cost is a key issue for the success of the electric vehicle. Lower cost electrode materials will be an important step. Cathode, separator and electrolyte are the main contributors to the cell cost. Most of the new cathode materials are composed of high cost nickel and cobalt materials. However, lower cost, lower performance materials such as lithium iron phosphate and manganese spinel for cathodes and graphite for anodes can be made for about $10/kg or less in large volume. Battery pack costs per kWh are expected to decline by as much as two-thirds by 2050, as noted above, and pack size will also decline as vehicles become more efficient.

2.5.6.2 BEV Range and Recharge Time

Even with expected cost reductions, batteries will still be expensive and bulky, limiting the size that can be installed in most vehicles. BEVs must have reasonable range at reasonable cost if they are to widely replace ICEVs. The average conventional vehicle has a range of at least 300 miles on a tank of gasoline, but more range in a BEV requires a bigger battery, and that raises costs significantly as discussed above. Very few affordable BEVs will greatly exceed 100 miles for the next several years and possibly much longer. An even larger problem is recharge time. Unless batteries can be developed that can be recharged in 10 minutes or less, BEVs will be limited largely to local travel in an urban or suburban environment.

Battery swapping is being tested as a solution to the range and recharge time problems. A vehicle with a nearly discharged battery pack would drive into a station where a large machine would extract the pack and replace it with a fresh one. While battery swapping would, if widely available, solve the recharging and range problems, it also faces significant problems: (1) vehicles and battery packs would have to be standardized; (2) the swapping station would have to keep a large and very expensive inventory of different types and sizes of battery packs; (3) swapping stations are likely to start charging the incoming batteries right away in order to have them available for the next vehicle, possibly aggravating grid peaking problems; (4) batteries deteriorate over time, and customers may object to getting older batteries, not knowing how far they will be able to drive on them; and (5) most battery swapping will occur only when drivers make long trips, thus seasonal peaks in long-distance travel, e.g., during holidays, are likely to aggravate inventory problems. Although Israel has begun development of a battery swapping network and other countries appear to be considering it, the committee considers it unlikely that battery swapping will become an important recharging mechanism in this country.

2.5.6.3 Durability and Longevity

Battery life expectancy is a function of battery design and manufacturing precision as well as battery operating and charging behavior. Rapid charging and discharging can shorten the lifetime of the cell. This is particularly important because the goal of 10 to 15 years service for automotive applications is far longer than for use in electronic devices. Current automotive batteries are not expected to last for 15

years, the average lifetime of a car. Replacing the battery would be a very expensive repair, even as costs decline. Thus improved longevity is an important goal.

2.5.6.4 Safety

Battery safety is a critical issue. There are three major components that characterize the safety of a battery pack: the failure rate of an individual cell, the probability of propagation of a single cell fault to the pack, and the failure rate of the electronics. Li-ion batteries are high-energy-density systems that utilize a flammable electrolyte and highly reactive cathode and anode materials separated by a thin micro-porous separator. The potential thermal energy in the cell is much larger than the electro-chemical energy because the electrolyte is flammable in air and most anodes are metastable compounds that require kinetic protection at the surface. Li-ion cells contain sufficient energy to heat the cell to over 500°C if this energy is released rapidly inside the cell. That could cause neighboring cells to also fail, leading to a catastrophic event. Ensuring safe operation of vehicles that utilize large Li-ion batteries is a significant engineering task that includes the following:

a. Protection from overcharge;

b. Protecting the battery cells from deforming during crash;

c. Reducing the likelihood of an internal short that could develop due to poor cell design or to a manufacturing defect (BMS should remove the cell from the circuit);

d. Designing a cell in such a way that even if an internal short does occur, it does not lead to thermal runaway of the cell;

e. Designing the BMS in such a way that even if a single cell experiences thermal runaway, the process does not propagate to neighboring cells and to the pack; and

f. Avoiding external shorts of the whole battery or sections of it during installation, servicing, or normal usage.

Cell, battery, and vehicle engineers have developed multiple tests to assess the ability of the cell, battery, and vehicle to operate without endangering human life. In most tests, battery failure is allowed but fire or explosions are unacceptable.

The failure rate for Li-ion 18650 cells equates to a reliability rate of about 1 out of 10,000. This level of reliability is not satisfactory for electric vehicle batteries, where 1 out of a million is the minimum required (Takeshita, 2011). Therefore, it is essential to essentially eliminate cell construction defects in the individual cells, as well as defects in the battery pack electronics, in order to virtually eliminate the chances of a catastrophic event. Since increasing the energy density of the cell is associated with an increase of the thermal energy available per unit weight and volume, insuring safety while increasing energy density is particularly challenging.

2.6 HYDROGEN FUEL CELL ELECTRIC VEHICLES

The hydrogen FCEV is an all-electric vehicle similar to a BEV except that the electric power comes from a fuel cell system with on-board hydrogen storage. FCEVs are commonly configured as hybrids in that they use a battery for capturing regenerative braking energy and for supplementing the fuel cell output as needed. Power electronics manage the flow of energy between the fuel cell, battery and electric motor.

The fuel cell system consists of a fuel cell stack and supporting hardware known as the balance of plant (BOP). The fuel cell stack operates like a battery pack with the anodes fueled by hydrogen gas and the cathodes fueled by air. The BOP consists of equipment and electrical controls that manage the supply of hydrogen and air to the fuel cell stack and provide its thermal management. The vehicle is fueled with hydrogen at a fueling station much like gasoline fueling, and hydrogen is stored on the vehicle as a compressed gas or cryogenic liquid in a storage tank.

The key advantages of FCEVs include the following:

- High energy efficiency;

- No tailpipe emissions—neither GHG nor criteria pollutants—other than water;

- Quiet operation;

- Hydrogen fuel can be produced from multiple sources, thereby enabling diversity in energy sources (including low carbon and renewable energy sources) away from near-total reliance on petroleum;

- Full vehicle functionality for safe on-road driving, including 300-mile driving range;

- Rapid refueling; and

- Source of portable electrical power generation for off-vehicle use.

The key challenges of FCEVs are the following:

- Demonstration of on-road durability for 15-year service life;

- Maturation of the technology for cost reduction, greater durability, and higher efficiency; and

- Availability of fuel while few FCEVs are on the road and the eventual production and distribution of hydrogen at competitive costs (discussed in Chapter 3).

Several companies (e.g., Hyundai, Daimler, Honda, and Toyota) have announced plans to introduce FCEVs commercially by 2015, but mainly in Europe, Asia, California, and Hawaii where governments are coordinating efforts to build hydrogen infrastructures.

2.6.1 Current Technology for Hydrogen Fuel Cell Electric Vehicles

2.6.1.1 Fuel Cell Powertrain

The power electronics and electric motor/transmission are similar in efficiency and cost as for PHEVs and BEVs. Future improvements in the performance and cost of those systems will apply to FCEVs as well.

The battery in FCEVs has comparable power but greater energy content than that in current HEVs because it must power driving for 2 to 5 miles while the fuel cell warms up in cold weather. The fuel cell must be sized for nominal driving requirements and efficient operation. The battery will recharge from the fuel cell directly and through regenerative braking.

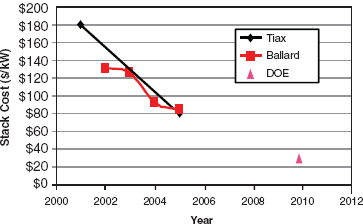

Over the past decade, FCEVs used in demonstration fleets have shown significant technology advances toward commercial readiness in the areas of performance and cost. For example, the cost of automotive fuel cell systems has been reduced from $275/kW in 2002 to $51/kW in 2010 (based on projections of high-volume manufacturing costs), and vehicle range has increased to at least 300 miles (James et al., 2010). Vehicles have demonstrated the capability to meet all urban and freeway driving demands. A remaining development challenge is proving the capability for high load driving at high ambient temperatures.

2.6.1.2 Fuel Cell Systems

Fuel cell stacks currently used in automotive applications are based on the polymer-electrolyte membrane/proton-exchange membrane (PEM). PEMs operate at moderate temperatures that can be achieved quickly so they are suitable for the infrequent and transient usage of on-road automotive service. Catalysts using precious metals (primarily platinum) are needed to promote the hydrogen/oxygen reaction that generates electricity in the fuel cell stack. Improvements in stack durability, specific power and cost have resulted from methods to improve the stability of the active catalytic surface area, and from new membrane materials and structures. For example, stack lifetimes of 2,500 operating hours (equivalent to approximately 75,000 mile range) have been demonstrated in on-road vehicles, and laboratory tests with newer membrane technologies have demonstrated (using accelerated test protocols) over 7,000 hours.

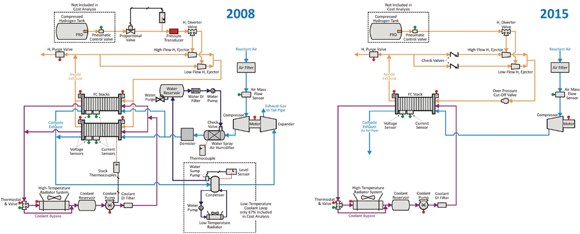

The BOP consists primarily of mature technologies for flow management of fluids and heat. Significant improvements in efficiency and cost result from continuing simplifications in BOP design, as illustrated in Figure 2.4.