Internal combustion engines operating on petroleum fuels have powered almost all light-duty vehicles (LDVs) for the past century. However, concerns over energy security from petroleum imports and the effect of greenhouse gas (GHG) emissions on global climate are driving interest in alternatives. LDVs account for almost half of the petroleum use in the United States, and about half of that fuel is imported (EIA, 2011). LDVs also account for about 17 percent of the total U.S. GHG emissions (EPA, 2012).

In response to a congressional mandate in the Senate’s Fiscal Year 2010 Energy and Water Development Appropriations Bill (Report 111-45) for the U.S. Department of Energy, Energy Efficiency and Renewable Energy (DOE-EERE), the National Research Council (NRC) convened the Committee on Transitions to Alternative Vehicles and Fuels (see Appendix B) to assess the potential for vehicle and fuel technology options to achieve substantial reductions in petroleum use and GHG emissions by 2050 relative to 2005. This report presents the results of that analysis and suggests policies to achieve the desired reductions. The statement of task (see Appendix A) specifically asks how the on-road LDV fleet could reduce, relative to 2005,

- Petroleum use by 50 percent by 2030 and 80 percent by 2050, and

- GHG emissions by 80 percent by 2050.

SCOPE AND APPROACH

Four general pathways could contribute to attaining both goals—highly efficient internal combustion engine vehicles (ICEVs) and vehicles operating on biofuels, electricity, or hydrogen. Natural gas vehicles could contribute to the additional goal of reducing petroleum consumption by 50 percent by 2030.

This study considered the following types of LDVs:

- ICEVs that are much more efficient than those expected to be available by 2025;

- Hybrid electric vehicles (HEVs), such as the Toyota Prius;

- Plug-in hybrid electric vehicles (PHEVs), such as the Chevrolet Volt;

- Battery electric vehicles (BEVs), such as the Nissan Leaf; BEVs and PHEVs are collectively known as plug-in electric vehicles (PEVs);

- Fuel cell electric vehicles (FCEVs), such as the Mercedes F-Cell, scheduled to be introduced about 2014; and

- Compressed natural gas vehicles (CNGVs), such as the Honda Civic Natural Gas.

The non-petroleum-based fuel technologies examined in the study are hydrogen, electricity, biofuels, natural gas, and liquid fuels made from natural gas or coal. For each fuel and vehicle type, the committee determined current capability and then estimated future performance and costs, plus barriers to implementation, including safety and technology development timelines. The report also comments on key federal research and development (R&D) activities applicable to fuel and vehicle technologies.

BEVs, FCEVs, and CNGVs1 can operate only on their specific fuel, although hydrogen and electricity can be produced from a variety of sources that might or might not involve the control of emissions of carbon dioxide, the main GHG responsible for human-induced climate change. The engines in ICEVs, HEVs, and PHEVs can use fuels produced from petroleum, biomass, natural gas, or coal.

The committee recognizes the great uncertainties regarding future vehicles and fuels, especially costs, timing of technology advances, commercialization of those advances,

_______________________

1Vehicles that operate on CNG can also be designed as dual-fuel vehicles that can switch to gasoline when CNG is not available, or as hybrid electric vehicles. To keep the analysis manageable, these options are not considered in this report.

and their penetration into the market. As a result, the committee developed a range of estimates for use in this study.

For vehicle technologies, the committee used two sets of assumptions for cost and performance: (1) midrange estimates that are ambitious but reasonable goals in the committee’s assessment; and (2) optimistic estimates which are potentially attainable, but will require greater successes in R&D and vehicle design. Both sets are predicated on the assumption that strong and effective policies are implemented to continually increase requirements or incentives (at least through 2050) to ensure that technology gains are focused on reducing petroleum use and GHG emissions.

Alternate assumptions were also developed for fuels to aid in assessing uncertainties. For example, several production processes were considered for hydrogen and biofuels, and both conventional generation and low-GHG-emission scenarios were considered for electricity.

In its assessment of the current state of LDV fuel and vehicle technologies and their projections to 2050, the committee built on earlier studies by the NRC and other organizations as listed in Appendix D. In addition, the committee examined publicly available literature and gathered information through presentations at open meetings. Insofar as possible, the committee assessed the fuels and vehicle technologies on a consistent and integrated basis. Its approach accounted for important effects, including the following:

- Potential projected performance characteristics of specific vehicles and fuel systems,

- Costs of the technologies including economies of scale and learning,

- Technical readiness,

- Barriers to implementation,

- Resource demands, and

- Time and capital investments required to build new fuel and vehicle technology infrastructure.

The committee also considered crosscutting technologies. For vehicles, these included weight reduction and improvements in rolling and aerodynamic resistance; for fuels, carbon capture and storage (CCS). In addition, the analysis took into account sector-wide effects such as consumer preferences and potential changes in vehicle miles traveled (VMT).

The committee then analyzed the impact of the various options. Vehicle performance was projected using a model developed by the committee and its consultants that estimates the impact of reductions in energy losses. Costs were projected for expected technologies relative to a 2010 base vehicle. These analyses and the results are described in Chapter 2. Efficiencies, costs, and performance characteristics were analyzed consistently for all vehicle classes and powertrain options, with the partial exception of travel range. Fuel technologies were analyzed individually using consistent assumptions and cost data across all fuels as shown in Chapter 3.

The vehicle and fuel data were then used to forecast future LDV fleet energy use and GHG emissions using two models described in Chapter 5. VISION was used to assess technology pathways to on-road fleets in 2050 based on inputs from the vehicle and fuel analyses developed in Chapters 2 and 3. LAVE-Trans—a spreadsheet model that takes into account consumer choices (discussed in Chapter 4), which are affected by vehicle and fuel characteristics, costs, and policy incentives—was used to compare different policy-driven scenarios. These scenarios are not intended as predictions of the future but rather to evaluate the relative potential impact on future petroleum use and GHG emissions of technological success and policy options, and the resulting costs and benefits.

By their nature, all models are simplifications and approximations of the real world and will always be constrained by computational limitations, assumptions, and knowledge gaps. All the models’ estimations depend critically on assumptions about technologies, economics, and policies and should best be viewed as tools to help inform decisions rather than as machines to generate truth or make decisions. The LAVE-Trans model in particular uses the committee’s assumptions about technological progress over several decades, how people behave, what things cost and what they are worth. It predicts, in a formal relational structure, how the vehicle fleet composition would then evolve and what the impact would be on petroleum use and GHG emissions. Some of the LAVE-Trans results were surprising, but the committee examined them and the model, fixed mistakes, and revised assumptions, until it was satisfied with the robustness of the outputs that resulted from the inputs. Even so, there is considerable uncertainty about the results presented here. Input assumptions are estimates that may prove inaccurate. The model’s handling of market relationships may be simplistic. Nevertheless, as described in Chapter 5, the results are robust for a variety of inputs, and, as long as the results are used with an understanding of the models’ strengths and weaknesses, they should be valuable assets in thinking about potential policy actions.

The major results of the committee’s work are listed below; additional findings and policy options are embedded in individual chapters of the report.

MEETING THE GOALS OF REDUCING PETROLEUM USE AND GHG EMISSIONS

Finding: It will be very difficult for the nation to meet the goal of a 50 percent reduction in annual LDV petroleum use by 2030 relative to 2005, but with additional policies, it might achieve a 40 percent reduction.

Future petroleum use is likely to decline as more efficient vehicles enter the market in response to the Corporate Average Fuel Economy (CAFE) standards and GHG requirements for 2025, more than compensating for the increased number

of vehicles on the road and the miles traveled. These vehicles will be mainly ICEVs, with an increasing share of HEVs. In addition, biofuels mandated by the Renewable Fuel Standard (RFS) could displace a significant amount of petroleum fuels by 2030, especially if coupled with advances in processes for producing “drop-in” cellulosic biofuels (direct substitutes for gasoline or diesel fuel).

Additional policy support may be required to promote increased sales of CNGVs, BEVs, and FCEVs. Even then the nation is unlikely to reach a 50 percent reduction in petroleum use by 2030 because very little time remains for achieving the required massive changes in the on-road LDV fleet and/or its fuel supply. Many of the vehicles on the road in 2030 will have been built by 2015, and these will lower the fuel economy of the on-road fleet.

Finding: The goal of an 80 percent reduction in LDV petroleum use by 2050 potentially could be met by several combinations of technologies that achieve at least the midrange level of estimated success. Continued improvement in vehicle efficiency, beyond that required by the 2025 CAFE standards, is an important part of each successful combination. In addition, biofuels would have to be expanded greatly or the LDV fleet would have to be composed largely of CNGVs, BEVs and/or FCEVs.

The committee considers that large reductions in LDV use of petroleum-based fuels are plausible by 2050, possibly even slightly more than the 80 percent target, but achieving reductions of this size will be difficult. A successful transition path to large reductions in petroleum use will require not only long-term rapid progress in vehicle technologies for ICEVs and HEVs, but also increased production and use of biofuels, and/or the successful introduction and large-scale deployment of CNGVs, BEVs with greatly improved batteries, or FCEVs.

Extensive new fuel infrastructure would be needed for FCEVs. CNGVs would require new supply lines in areas where natural gas is unavailable or in limited supply, and many filling stations. The infrastructure needed for BEVs would mostly be charging facilities, since electricity supply is already ubiquitous. The technology advances required do not appear to require unexpected breakthroughs and can produce dramatic advances over time, but they would have to be focused on reducing fuel use rather than allowing increases in performance such as acceleration. Thus, a rigorous policy framework would be needed, more stringent than the 2025 CAFE/GHG or RFS standards. Large capital investments would be required for both the fuel and vehicle manufacturing infrastructure. Further, alternative vehicles and some fuels will be more expensive than the current technology during the transition, so incentives to both manufacturers and consumers may be required for more than a decade to spur purchases of the new technology. Figure S.1 shows potential petroleum use for technology-specific scenarios.

Finding: Large reductions are potentially achievable in annual LDV GHG emissions by 2050, on the order of 60 to 70 percent relative to 2005. An 80 percent reduction in LDV GHG emissions by 2050 may be technically achievable, but will be very difficult. Vehicles and fuels in the 2050 time frame would have to include at least two of the four pathways: much higher efficiency than current vehicles, and operation on biofuels, electricity, or hydrogen (all produced with low GHG emissions). All four pathways entail great uncertainties over costs and performance. If BEVs or FCEVs are to be a majority of the 2050 LDV fleet, they would have to be a substantial fraction of new car sales by 2035.

Achieving large reductions in net GHG emissions from LDVs is more difficult than achieving large reductions in petroleum use. In addition to making all LDVs highly efficient so that their fuel use per mile is greatly reduced, it will be necessary to displace almost all the remaining petroleum-based gasoline and diesel fuel with fuels with low net GHG emissions. This is a massive and expensive transition that, because LDVs emit only about 17 percent of U.S. GHGs, would have to be part of an economy-wide transition to provide major GHG reduction benefits.

The benefits of biofuels depend on how they are produced and on any direct or indirect land-use changes that could lead to GHG emissions. Several studies indicate that sufficient biomass should be available to make a large contribution to meeting the goals of this study, but the long-term costs and resource base for biofuels produced with low GHG emissions need to be demonstrated. Hydrogen and electricity must be produced with low-net-GHG emissions, and the costs of large-scale production are uncertain. Achieving the goals does not require fundamental breakthroughs in batteries, fuel cell systems, or lightweight materials, but significant continuing R&D yielding sustained progress in cost reduction and performance improvement (e.g., durability) is essential.

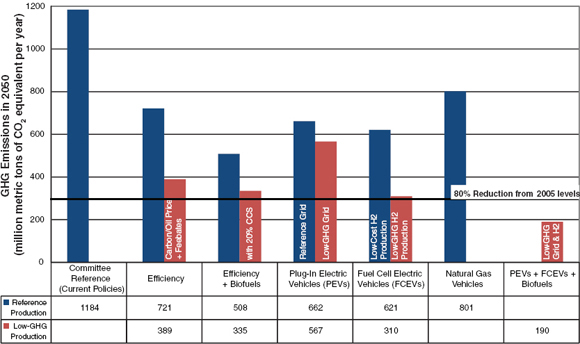

Overall, the committee concluded that LDV GHG emissions could be reduced by some 60 percent to somewhat more than 80 percent by 2050 as shown in Figure S.2. The cost will be greater than that for meeting the 80 percent petroleum reduction goal because options such as CNGVs, or BEVs operating on electricity produced without constraints on GHG emissions, cannot play a large role.

Finding: None of the four pathways by itself is projected to be able to achieve sufficiently high reductions in LDV GHG emissions to meet the 2050 goal. Further, the cost, potential rate of implementation of each technology, and response of consumers and

FIGURE S.1 Estimated U.S. LDV petroleum use in 2030 and 2050 under policies emphasizing specific technologies. Midrange values are the committee’s best estimate of the progress of the technology if it is pursued vigorously. All scenarios except the Committee Reference Case (current policies, including the fuel economy standards for 2025) include midrange efficiency improvements. Controls for GHG emissions from hydrogen and electricity production are not assumed because the main objective is to reduce petroleum use.

FIGURE S-2 Estimated U.S. LDV GHG emissions in 2050 under policies emphasizing specific technologies. All scenarios except the Committee Reference Case (current policies, including the fuel economy standards for 2025) include midrange efficiency improvements. Fuel production for these scenarios is assumed to be constrained by policies controlling GHG emissions (low GHG production).

manufacturers to policies are uncertain. Therefore, an adaptive framework that modifies policies as technologies develop and as conditions change is needed to efficiently move toward the long-term policy goals.

Continued improvements in vehicle efficiency, especially load reduction (e.g., through the use of light weight but strong materials), are essential to achieving high GHG reductions and are included in all scenarios as a key step in improving the feasibility of all the other pathways. In addition, some combination of biofuels, BEVs, and FCEVs (with the last two operating on low-GHG electricity or hydrogen) must play a large role. Given the uncertainties surrounding all four of these pathways, there is no single, clearly supported choice of vehicle and fuel system that will lead to 80 percent reduction in GHG emissions.

Much more efficient or alternative vehicles are currently more costly than today’s ICEVs and their prices are projected to remain high until the newer technologies are more mature. Achieving an extensive transition by 2050 will thus require government action. These transition costs are in addition to those associated with bringing the technologies to readiness and providing needed infrastructure.

Displacing the incumbent ICEVs and petroleum-based fuels will be difficult. Technologies may not be as successful as anticipated, and the policies to encourage them may not be as successful as modeled by the committee. Furthermore the costs would likely be very large early on, with benefits occurring much later in time. It is essential, then, to ensure that policies, especially those that focus on investment in particular technologies, are not introduced too early (for example, before those new fuel and vehicle technologies are close to market readiness, taking into account the best available information on consumer behavior) or too late (for example, not allowing for the benefits of learning to be realized and to contribute to meeting the goals). Further, it is essential that policies are designed so that they can be adapted to changing evidence about technology and market acceptance, and to market conditions.

In pursuing these goals, costs and benefits of the intended action should both be assessed. Action should be undertaken only upon a reasoned determination that the benefits of intended proposed regulation justify its costs. Scenario analysis has identified strong tipping points for the transition to new vehicle technologies. If policies are insufficient to overcome the early cost differentials, then the transition to such technologies will not occur, and the costs will have been largely wasted.

Finding: Substantial progress toward the goals of reducing LDV petroleum use and GHG emissions is unlikely unless these goals are set and pushed on a nationwide basis through strong and effective policy intervention by the federal government.

All four transition paths are based on technology options that are currently more expensive than their ICEV equivalent, and some will require substantial infrastructure changes and possibly consumer adaptation. Thus, success will depend on consistent and sustained policies that support reduced petroleum use and GHG emissions.

Finding: Even if the nation falls short of the 2050 goals, there are likely to be environmental, economic and national security benefits resulting from the petroleum use and GHG emissions reductions that are achieved.

Finding: The CAFE standard has been effective in reducing vehicle energy intensity, and further reductions can be realized through even higher standards if combined with policies to ensure that they can be achieved.

Policy Option: The committee suggests that LDV fuel economy and GHG emission standards continue to be strengthened to play a significant role after model year 2025 as part of this country’s efforts to improve LDV fuel economy and reduce GHG emissions.

Finding: “Feebates,” rebates to purchasers of high-fuel-economy (i.e., miles per gallon [mpg]) vehicles balanced by a tax on low-mpg vehicles is a complementary policy that would assist manufacturers in selling the more-efficient vehicles produced to meet fuel economy standards.

Policy Option: The committee suggests that the U.S. government include “feebates” as part of a policy package to reduce LDV fuel use.

Finding: Several types of policies including a price floor for petroleum-based fuels or taxes on petroleum-based fuels could create a price signal against petroleum-demand, assure producers and distributors that there is a profitable market for alternative fuels, and encourage consumers to reduce their use of petroleum-based fuels. High fuel prices, whether due to market dynamics or taxes, are effective in reducing fuel use.

The impact of increases in fuel prices, especially on low-income and rural households, could be offset by using the increased revenues from taxes or a price floor for reductions in other taxes. Alternatively, some or all of the revenue generated could be used to replace income lost to the Highway

Trust Fund as gasoline sales decline, so that transport infrastructure could continue to be supported.

Finding: Fuel cells, batteries, biofuels, low-GHG production of hydrogen, carbon capture and storage, and vehicle efficiency should all be part of the current R&D strategy. It is unclear which options may emerge as the more promising and cost-effective. At the present time, foreclosing any of the options the committee has analyzed would decrease the chances of achieving the 2050 goals.

The committee believes that hydrogen/fuel cells are at least as promising as battery electric vehicles in the long term and should be funded accordingly. Both pathways show promise and should continue to receive federal R&D support.

Policy Option: The committee supports consistent R&D to advance technology development and to reduce the costs of alternative fuels and vehicles. The best approach is to promote a portfolio of vehicle and fuel R&D, supported by both government and industry, designed to solve the critical technical challenges in each major candidate pathway. Such primary research efforts need continuing evaluation of progress against performance goals to determine which technologies, fuels, designs, and production methods are emerging as the most promising and cost-effective.

Finding: Demonstrations are needed for technologies to reduce GHG emissions at appropriate scale (for example, low-carbon hydrogen and CCS) to validate performance, readiness, and safety. Integrated demonstrations of vehicles and fueling infrastructure for alternative vehicle and fuel systems will be necessary to promote understanding of performance, safety, consumer use of these alternatives, and other important characteristics under real-world driving conditions.

Policy Option: The committee supports government involvement in limited demonstration projects at appropriate scale and at appropriate times to promote understanding of the performance and safety of alternative vehicles and fueling systems. For such projects, substantial private sector investment should complement the government investment, and the government should ensure that the demonstration incorporates well-designed data collection and analysis to inform future policy making and investment. The information collected with government funds should be made available to the public consistent with applicable rules that protect confidential data.

Finding: The commercialization of fuel and vehicle technologies is best left to the private sector in response to performance-based policies, or policies that target reductions in GHG emissions or petroleum use rather than specific technologies. Performance-based policies for deployment (e.g., CAFE standards) or technology mandates (e.g., RFS) do not require direct government expenditure for particular vehicle or fuel technologies. Additional deployment policies such as vehicle or fuel subsidies, or quantity mandates directed at specific technologies are risky but may be necessary to attain large reductions in petroleum use and GHG emissions. For alternative-vehicle and fuel systems, government involvement with industry is likely to be needed to help coordinate commercial deployment of alternative vehicles with the fueling infrastructure for those vehicles.

Policy Option: The committee suggests that an expert review process independent of the agencies implementing the deployment policies and also independent of any political or economic interest groups advocating for the technologies being evaluated be used to assess available data, and predictions of costs and performance. Such assessments could determine the readiness of technologies to benefit from policy support to help bring them into the market at a volume sufficient to promote economies of scale. If such policies are implemented, there should be specific goals and time horizons for deployment. The review process should include assessments of net reductions in petroleum use and GHG emissions, vehicle and fuel costs, potential penetration rates, and consumer responses.

TECHNOLOGY- AND POLICY-SPECIFIC FINDINGS

Vehicles (Chapter 2)

- Large increases in fuel economy are possible with incremental improvements in currently known technology for both load reduction and drivetrain improvements. The average of all conventional LDVs sold in 2050 might achieve CAFE test values of 74 mpg for the midrange case. Hybrid LDVs might reach 94 mpg by 2050. On-road fuel economy values will be lower.

- To obtain the efficiencies and costs estimated in Chapter 2, manufacturers will need incentives or regulatory standards or both to widely apply the new technologies.

- The unit cost of batteries will decline with increased production and development; in addition, the energy storage (in kilowatt-hours) required for a given vehicle range will decline with vehicle load reduction and improved electrical component efficiency. Therefore, battery pack costs in 2050 for a 100-mile real-world

travel range are expected to drop by a factor of about 5. However, even these costs are unlikely to create a mass market for BEVs, because a battery large enough for a 300-mile real-world range would still present significant weight and volume penalties and probably could not be recharged in much less than 30 minutes. Therefore, BEVs may be used mainly for local travel rather than as all-purpose vehicles.

- BEVs and PHEVs are likely to use lithium-ion batteries for the foreseeable future. Several advanced battery technologies (e.g., lithium-air) are being developed that would address some of the drawbacks of lithium-ion batteries, but their potential for commercialization by 2050 is highly uncertain, and they may have their own disadvantages.

- PHEVs offer substantial amounts of electric-only driving while avoiding the range and recharge-time limitations of BEVs. However, their larger battery will always entail a significant cost premium over similar HEVs, and their incremental fuel savings will decrease as the efficiency of HEVs improves.

- The technical hurdles that must be surmounted to develop an all-purpose vehicle acceptable to consumers appear lower for FCEVs than for BEVs. However, the infrastructure and policy barriers appear larger. Well before 2050 the cost of FCEVs could actually be lower than the cost of an equivalent ICEV, and operating costs should also be lower. FCEVs are expected to be equivalent in range and refueling time to ICEVs.

- If CNGVs can be made competitive (with respect to both vehicle cost and refueling opportunities), they will offer a quick and economical way to reduce petroleum use, but as shown in Figure S.2, the reductions in GHG emissions are insufficient for CNGVs to be a large part of a fleet that meets the 2050 GHG goal.

- Although fundamental technology breakthroughs are not essential to reach the mpg, performance, and cost estimates in Chapter 2, new technology developments would substantially reduce the development cost and lead time. In particular, continued research to reduce the costs of advanced materials and battery concepts will be critical to the success of electric vehicles.

Fuels (Chapter 3)

- Meeting the GHG and petroleum reduction goals requires a massive restructuring of the fuel mix used for transportation. The use of petroleum must be greatly reduced, implying retirement of crude oil production and distribution infrastructure. Depending on the progress in drop-in biofuels versus non-liquid fuels, refineries, pipelines, and filling stations might also become obsolete. For BEVs to operate with low GHG emissions, coal- and natural gas-fired electricity generation might have to be greatly reduced unless CCS proves cost-effective. Reliance on natural gas or hydrogen for transportation would require additional infrastructure. With currently envisioned technology, sufficient biofuels could be produced by 2050 to meet the goal of 80 percent reduction in petroleum use if the committee’s vehicle efficiency estimates are attained.

- With increasing economic natural gas reserves and growing domestic natural gas production mostly from shale gas, there is enough domestic natural gas to greatly increase its use for the transportation sector without significantly affecting the traditional natural gas markets. Currently the cost of natural gas is very low ($2.5 to $3.5/million Btu) and could remain low for several decades. Environmental issues associated with shale gas extraction (fracking) must be resolved, including leakage of natural gas, itself a powerful GHG, and potential contamination of groundwater. There are several opportunities, direct and indirect, to use natural gas in LDVs, including producing electricity for PEVs and producing hydrogen for FCEVs. The fastest way to reduce petroleum use is probably by direct combustion in CNGVs coupled with efficiency improvements, but that approach is likely to interfere with achieving the GHG goal in 2050.

- Making hydrogen from fossil fuels, especially natural gas, is a low-cost option for meeting future demand from FCEVs, but such methods, by themselves, will not reduce GHG emissions enough to meet the 2050 goal. Making hydrogen with low GHG emissions is more costly (e.g., renewable electricity electrolysis) or requires new production methods (e.g., photoelectrochemical, nuclear cycles, and biological methods) or CCS to manage emissions. Continued R&D is needed on low-GHG hydrogen production methods and CCS to demonstrate that large amounts of low-cost and low-GHG hydrogen can be produced.

- Natural gas and coal conversion to liquid fuel (GTL, CTL) can be used as a direct replacement for petroleum gasoline, but the GHG emissions from these fuels are slightly greater than those from petroleum-based fuels even when CCS is employed at the production plant. Therefore, these fuels will play a small role in reducing petroleum use if GHG emissions are to be reduced simultaneously.

- Carbon capture and sequestration is a key technology for meeting the 2050 goal for GHG emissions reductions. Insofar as fossil fuels are used as a source of electricity or hydrogen to power LDVs, CCS will

be essential. The only alternatives are nuclear power and renewable energy sources, including biofuels. Applying CCS to biofuel production could result in slightly negative net emissions.

Consumer Barriers (Chapter 4)

- Widespread consumer acceptance of alternative vehicles and fuels faces significant barriers, including the high initial purchase cost of the vehicles and the perception that such vehicles offer less utility and convenience than conventional ICEVs. Overcoming these barriers is likely to require significant government policy intervention that could include subsidies and vigorous public information programs aimed at improving consumers’ familiarity with and understanding of the new fuels and powertrains. Consumers are used to personal vehicles that come in a wide variety of sizes, styles, and prices that can meet most needs ranging from basic transportation to significant cargo hauling. Conventional ICEVs can be rapidly refueled by a plentiful supply of retailers, effectively giving the vehicles unlimited range. Conversely, in the early years, alternative vehicles will likely be limited to a few body styles and sizes and will cost from a few hundred to many thousands of dollars more than their conventional ICEV counterparts. Some will rely on fuels that are not readily available or have limited travel range, or require bulky energy storage that will limit their cargo and passenger capacity.

Additional Findings from Policy Modeling (Chapter 5)

- Including the social costs of GHG emissions and petroleum dependence in the cost of fuels (e.g., via a carbon tax) provides important signals to the market that will promote technological development and behavioral changes. Yet these pricing strategies alone are likely to be insufficient to induce a major transition to alternative, net-low-carbon vehicle technologies and/or energy sources. Additional strong, temporary policies may be required to break the “lock-in” of conventional technology and overcome the market barriers to alternative vehicles and fuels.

- If two or more of the fuel and/or vehicle pathways identified above evolve through policy and technology development as shown in a number of the committee’s scenarios, the committee’s model calculations indicate benefits of making a transition to a low-petroleum, low-GHG energy system for LDVs that exceed the costs by a wide margin. Benefits include energy cost savings, improved vehicle technologies, and reductions in petroleum use and GHG emissions. Costs refer to the additional costs of the transition over and above what the market is willing to do voluntarily. However, as noted above, modeling results should be viewed as approximations at best because there is by necessity in such predictions a great deal of uncertainty in estimates of both benefits and costs. Furthermore, the costs are likely to be very large early on with benefits occurring much later in time.

- It is essential to ensure that policies, especially those that focus on investment in particular technologies, are not introduced before those new fuel and vehicle technologies are close to market readiness and consumer behavior toward them is well understood. Forcing a technology into the market before it is ready can be costly. Conversely, neglecting a rapidly developing technology could lead to forgone significant benefits. Policies should be designed to be adaptable so that mid-course corrections can be made as knowledge is gained about the progress of vehicle and fuels technologies. Further, it is essential that policies be designed so that they can be adapted to changing evidence about technology and market acceptance, and market conditions.

- Depending on the readiness of technology and the timing of policy initiatives, subsidies or regulations for new-vehicle energy efficiency and the provision of energy infrastructure may be required, especially in the case of a transition to a new vehicle and fuel system. In such cases, policy support might be required for as long as 20 years if technological progress is slow (e.g., BEVs with lithium-ion batteries may require 20 years of subsidies to achieve a large market share).

- Advance placement of refueling infrastructure is critical to the market acceptance of FCEVs and CNGVs. It is likely to be less critical to the market acceptance of grid-connected vehicles, since many consumers will have the option of home recharging. However, the absence of an outside-the-home refueling infrastructure for grid-connected vehicles is likely to depress demand for these vehicles. Fewer infrastructure changes will be needed if the most cost-effective solution evolves in the direction of more efficient ICEVs and HEVs combined with drop-in low-carbon biofuels.

- Research is needed to better understand key factors for transitions to new vehicle fuel systems such as the costs of limited fuel availability, the disutility of vehicles with short ranges and long recharge times, the numbers of innovators and early adopters among the car-buying public, as well as their willingness to pay for novel technologies and the risk aversion of the majority, and much more. More information is also needed on the transition costs and barriers to

production of alternative drop-in fuels, especially on the type of incentives necessary for low-carbon biofuels. The models this committee and others have used to analyze the transition to alternative vehicles and/or fuels are first-generation efforts, more useful for understanding processes and their interactions than for producing definitive results.

REFERENCES

EIA (Energy Information Administration). 2011. Annual Energy Review 2010. Washington, D.C.: U.S. Department of Energy.

EPA (Environmental Protection Agency). 2012. Inventory of U.S. Greenhouse Gas Emissions and Sinks:1990-2010. Available at http://www.epa.gov/climatechange/Downloads/ghgemissions/US-GHG-Inventory-2012-Main-Text.pdf.