Solid-State Lighting Applications

Solid-state lighting (SSL) is a new technology, not simply a refinement of an existing one. New materials and technologies are not only offering substantial improvements in efficiency compared with conventional incandescent lighting, but also opportunities to put light in new and sometimes startling places and modes that are only beginning to emerge in a rapidly changing field. But it also presents significant challenges to end users, designers, the lighting industry, and regulating authorities as they try to cope with the implications of this change in a very basic service.

Incorporating SSL products in a home or office is not always simply a matter of unscrewing one lamp and screwing in another, because they are significantly different in form and function, as described in Chapter 4. At the current stage of development, these new light sources (currently comprising light-emitting diodes (LEDs) and organic LEDs (OLEDs)) have been highly successful for some applications, show promise in many more, and have serious problems that need addressing before they can be used in yet other applications.

SSL is becoming more popular with end users and designers. The general public’s perception is that LEDs are more energy efficient and “advanced.” Users’ expectations are that the SSL quality will be as good as standard lighting products. They also expect that SSL can be applied to existing electrical distribution systems with no problems, which is not always the case.

Advantages of SSL include the following: small size, ease of control, uni-directional distribution, cool beam and color rendering that can be very high and comparable to high fluorescent lamps with high color rendering index (CRI), lower energy use compared to incandescent lamps, high performance in cold environments, long life, and new form factors. Current challenges with SSLs include cost, system and controls compatibility, heat management, power quality, the failure process, color consistency, and glare issues.

Whereas SSL lamps have relatively low lumen output (approximately equivalent to a 60 W incandescent) and the majority produce a unidirectional beam, the best applications currently are those in which the light source is close to the task, lower lumen output is sufficient, and directionality is important. Examples of these best applications are task, undercabinet, track, wall washing, surface grazing, step lights, semi-recess, lower light output street and area lighting, and color changing theatrical lighting.

Challenging applications include omni-directional lighting (e.g., such as those applications for the linear fluorescent lamps) and high output. Examples of these are fluorescent lamp replacements and high output downlights. Street and area lighting is improving dramatically, but high light output and glare are still an issue with poorer quality luminaires.

At this stage of development, the challenges outweigh the advantages for many applications. Of course, what is a challenge in one application can be an advantage in another. However, product development is very active, and the trends are toward decreased cost, better glare control, and better color rendering and color consistency. Standards, guidelines, and better designer/user education are needed to help make SSL ready for successful applications in large-scale markets. The outdoor and residential markets currently offer the greatest opportunities for large-scale deployment because commercial and industrial applications already have low cost and relatively efficient fluorescent and high-intensity discharge (HID) lamps.

This chapter outlines the types of applications where SSLs have been incorporated and evaluates their current status.

Residential lighting typically consists of recessed downlights, wall sconces, pendants or chandeliers, track lighting,

table and floor lamps, and undercabinet and task lighting. Lighting levels are lower than in commercial or industrial applications. Color, brightness, dimming capability, and appearance are extremely important.

Residential users expect SSL to look and act just like their incandescent counterparts. Such attributes as smooth dimming with existing residential dimmers, absence of flicker, absence of radio interference, great color rendition, and equal light output and similar brightness to incumbent lighting technologies will all be imperative for the successful SSL introduction into the residential market. Users also expect to be able to use the new lamps without having to replace existing luminaires (i.e., fixtures using screw-in lamps).

SSL is easily controlled in principle. Dimming is readily available, but flicker, so called “pop-on” effects and lower end drop-out are still apparent in some products. Pop on occurs in two ways: (1) when a preset dimming control is used and lights do not turn on to their pre-set dimming level, but first come on (near) full and then dim down automatically to the preset level and (2) when a slide (or rotary) dimmer is used, lights do not turn on at the low end, but require the slider to be raised to a relatively high level to start the lamp, before dimming to a lower level can be achieved. Lower end drop-out occurs when lights are dimmed but turn off before reaching the desired low level. All of these are symptoms of incompatibility between the LED lamp driver electronics and incandescent dimmers and can be mitigated when the drivers are designed for better compatibility using an industry standard such those of the National Electrical Manufacturers Association (NEMA) on SSL 6 (see Chapter 4). Alternatively, the dimmer can be replaced with a new-generation device that is being designed to operate LED lamps. Existing incandescent dimmers may not work with LED replacement lamps (even though the LED lamps are labeled “dimmable”). In some cases, the dimmers may have to be replaced.

FINDING: Replacing incandescent or fluorescent lamps with LED lamps provides an opportunity to greatly reduce power load and increase lamp life. They can also turn on instantly and are able to dim. The market for these lamps will only expand as the light and color quality improve and the costs are reduced.

If SSL meets the above performance criteria, then long life and low energy use will attract users. If SSL does not meet the criteria, then disappointment and frustration will damage the market, as happened with compact fluorescent lamps (CFLs) (see Chapter 2). Appropriate policies, regulations, and educational campaigns can help avoid this result.

Ambient lighting in commercial sites has been traditionally supplied with linear fluorescents in either recessed troffers, recess parabolics, semi-recess indirect, or pendant mounted with direct/indirect distribution.1 All of these provide uniform omni-directional light distribution, creating uniform ambient lighting.

Accent lighting adds visual interest to an area and is frequently implemented with track lighting supplied with tungsten halogen or ceramic metal halide lamps. Ceramic metal halide track lighting is used in many grocery stores because of the higher light output.

Task lighting offers higher lighting levels for specific areas and has been traditionally supplied with tungsten halogen or CFLs. Task lighting is used primarily in office areas in the form of under-shelf or free-standing desktop luminaires.

In most commercial applications, the lighting system is expected to last for many years, requiring very little maintenance with easy accessibility. Occupants expect controls to perform daylight dimming, occupancy/vacancy sensing, scene controls, and manual dimming.

SSL is becoming more common in commercial applications, especially for use with surface grazing (wall washing, white board lighting, and cove lighting). SSL is ideal for task or personalized lighting and for accent or track lighting. The more difficult applications are general omni-directional ambient lighting now supplied by fluorescent luminaires. The one exception is lower light output, semi-recessed indirect luminaires, which are becoming popular for ambient lighting.

FINDING: The best LED applications take advantage of the directional light put out by LEDs, such as downlights, wall washers, and grazing and accent lighting.

FINDING: Omni-directional LED lamps are not as efficient as linear fluorescent lamps. In order to become a viable replacement alternative for linear fluorescent lamps, SSL products need to improve efficacy, become more omnidirectional, and reduce initial cost in order to compete with fluorescent lamps.

Total harmonic distortion (THD) of the line current and the power factor (PF) of the LED lamps are serious concerns. Most existing commercial buildings have 120/208 or 277/480 volt three-phase electrical distribution systems, where three phases share a neutral. If the THD is too high, the neutral conductor may be overloaded, especially in existing buildings with older electrical distribution systems. In new construction, the most recent National Electrical Code recommends separate neutrals for each circuit to avoid this problem. This issue is discussed in more detail in Chapter 4,

________________

1 A troffer is “a long, recessed luminaire installed with the opening flush with the ceiling.” A pendant is “a luminaire that is hung from the ceiling by supports.” A parabolic is “a luminaire with the light source at or near the focus of a parabolic reflector producing near-parallel rays of light.” Both troffers and parabolics are installed as recessed luminaires. Indirect lighting involves “luminaires that distribute 90 to 100 percent of the emitted light upward” (ANSI/IES, 2010).

where recommendations are made for SSL devices. It should also be noted that when replacement dimmable LED lamps are installed in existing luminaires, many of the existing incandescent dimmers may cause lamp flickering (this issue is also discussed in detail in Chapter 4). Pop-on dimming effects are very similar to those in residential applications and have been discussed above.

FINDING: SSL must have power quality standards to mitigate against high THD, low PF, and repetitive peak current issues.

FINDING: New dimmers must be able to operate LED luminaires and lamps smoothly without perceptible flicker and should be available to dim from 100 percent power to 1 percent power.

Industrial applications typically use a combination of high bay luminaires (directional downlights) or low bay luminaires (omni-directional downlights). Task lighting is also used for specific applications where higher light levels are required, such as in manufacturing facilities. Long-lasting light sources are required for reliability and safety, especially in 24-hour facilities. Controls have typically not been expected in industrial sites but are becoming more popular, especially in applications where daylight can supplement the light level, allowing energy reduction by dimming the interior lights.

Traditionally, high ceilings and harder access has lead many industrial sites to higher-wattage, standard HID luminaires. Standard HID luminaires provide higher light output than fluorescents, but do not last as long (having roughly two-thirds the life). Also, HID lamps have a slow start, requiring several minutes to achieve full light output, making them harder to control with occupancy sensing or daylight on/off switching.

SSL applications are more difficult for industrial applications because of high light level requirements. Also, heat management is difficult in high ceilings where ambient temperatures are higher. In some settings, the failure process may be an issue, because SSLs gradually lose luminous flux rather than burn out. If these issues can be solved, then SSL could provide lower maintenance costs and controllability.

Power quality issues are similar to the commercial applications.

FINDING: Industrial applications of SSL products will require higher light output for ambient lighting because of their use in high ceiling applications.

Roadway and area lighting appear to be one of the fastest growing application markets for SSL. The requirements in such applications for lower light levels (compared to interior applications); larger luminaires with non-confined mounting, mostly open to air, which enhances heat dissipation; performance at cold temperatures; and long life have made SSLs attractive to this rapidly growing market. Traditional outdoor luminaires have used HID lamps, mostly high-pressure sodium (HPS), where the lamp is located inside the luminaire reflector. This configuration has the advantage that the arc tube brightness is typically not viewed by motorists or pedestrians. HPS luminaires have a narrow spectral distribution, which provides poorer color rendering properties than white light sources such as metal halide, induction, and SSL. HID life is mid-range, requiring lamp replacement approximately every 2 to 3 years.

SSL luminaires are uni-directional, unlike HID luminaires, which are more omni-directional. The advantage of using omni-directional HID luminaires is they offer glare control and a soft gradient edge. The disadvantage is that the light from an HID luminaire is harder to control, providing higher lighting levels directly below the luminaire and requiring a large reflector system to control light spillage. The uni-directional properties of SSL mean it can direct light exactly where it is required without unwanted higher light levels below the luminaire while having more light in-between luminaires, which improves overall uniformity. But glare can be greater with the SSL luminaires if the light sources are not shielded with a lens or redirected and diffused by a reflector.

The American Medical Association has issued a policy that states, “Many older citizens are significantly affected by glare as the eye ages, leading to unsafe driving conditions; and glare light is also light trespass and is intrusive and unwanted in households and dwellings; and light trespass has been implicated in disruption of the human and animal circadian rhythm, and strongly suspected as an etiology of suppressed melatonin production, depressed immune systems, and increase in cancer rates such as breast cancers” (Motta, 2009).

FINDING: Discomfort or disability glare can be an issue with directional LED luminaires. Luminaires must be designed so as not to increase glare potential compared to their HID counterparts.

Heat still needs to be managed, especially if the luminaires are left on during the day because of a malfunctioning photocell. However, the superior performance of SSLs at cooler temperatures is an advantage for some applications, such as roadway lighting and signals.

Currently, white LED modules always include a blue LED, which raises environmental concerns similar to those

for the short wavelength components of metal halide and fluorescent lighting. These concerns include photobiological effects and increased skyglow2 (IDA, 2010; Wright, 2011). These effects are most pronounced when lighting is energized all night long.

FINDING: LED white light products produce light in spectral regions that may create environmental and health concerns. These concerns should be recognized in the design and application of LED luminaires.

The long life promised by SSL luminaires has the potential to reduce maintenance, offering not only replacement savings, but also higher reliability. However, SSLs typically do not burn out, but only reduce their light output. So in some applications there may be a liability risk if the SSL is functioning but not producing the expected luminosity. Reduced light output occurred in the past with mercury vapor lighting.

Outdoor SSL luminaires may be dimmed if adaptive standards were to be applied. Adaptive standards are the practice of reducing lighting levels during periods of low activity, such as in the middle of the night when many establishments are closed. This practice is very popular in Europe and is now being introduced into North America through recommendations of the Illuminating Engineering Society (IES) (IES and IDA, 2011). Adoption of such practices would provide communities and property owners the flexibility to reduce lighting levels during periods of low activity, or during peak demand periods, thus saving energy.

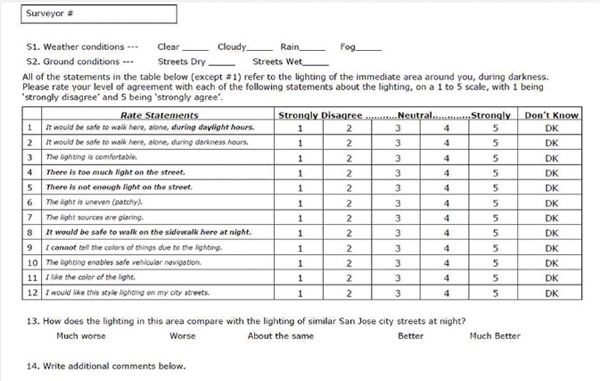

Several cities, such as New York City, San Francisco, Oakland, San Jose, and others have performed extensive LED street lighting demonstration projects (DOE, 2012a) as part of the U.S. Department of Energy’s GATEWAY demonstration program.3 In all of these projects, the predicted and measured energy use and maintenance are lower than for conventional lighting, but illuminance levels are also lower compared to existing HPS street lighting. Additional added benefits include reductions in sky glow and light spillage. Some cities, such as San Jose (Figure 5.1) and Anchorage, conducted controlled public surveys to obtain community feedback on the LED street lighting (Clanton and Associates and VTTI, 2009, 2010). The public preferred the warmer color temperature LED, even at lower lighting levels, compared to the existing higher wattage low pressure sodium (LPS) and HPS street lighting (Gibbons and Clanton, 2011).

FINDING: Exterior lighting is a prime candidate for early adoption of SSL because of the lower lighting levels required in such applications and the optical control, long life, and dimmability characteristics of SSL.

While some of the advantages of SSL are immediately obvious, others are still only possibilities. As new technologies and luminaires are developed, new applications will also emerge, leading to unexpected opportunities in lighting design. Current SSLs offer small size, ease of control, uni-directional light, cool beam, superior color, low energy use, and long life. OLEDs promise entirely new form factors, a prospect that opens up a whole new realm of possible applications. Also, because of control compatibility, SSL can further reduce energy through dimming strategies.

The compact size of the SSL modules offers opportunities to put lighting in areas that previously had restricted luminaire size. But the challenge of managing the heat generated by the LED has prevented a desired reduction in the size of the light source needed for high lumen output. As modules become more efficacious, the size can shrink even more. Shrinking size will allow more opportunities for replacement of additional types of lamps such as high-output MR-16 lamps (see Chapter 1). The MR-16 is an important lamp for retail, hospitality, and residential applications.

SSL products have instant on and off operation without the requirement for a warm-up time, an attribute that is in contrast to that of HID and CFLs. With a dimmable driver, SSL products can be dimmed over a wide range of luminous flux in a smooth manner. Dimming below 10 percent is only available with a select number of drivers but is desirable (see Chapter 4). Smooth dimming is also available with some SSL screw-in incandescent replacement lamps. The appropriate choice of dimmers and drivers for SSL will enable control compatibility, which is critical for intelligent energy control systems.

Some control systems can change the color of light by varying the intensity of different colored LEDs in a red, green, blue system (i.e., one which produces white light by combining red-, green-, and blue-component LEDs). These are currently used mainly in special effects lighting, but have the potential for applications in commercial and highend residential markets. For example, retail venues might wish to vary the color of light in a display to emphasize a product’s features.

________________

2Skyglow is the result of blue light being absorbed or scattered in the atmosphere resulting in a loss of visibility of the night sky, which is of special concern to the astronomy community.

3 DOE GATEWAY demonstrations have the objective to showcase LED products for general illumination. DOE publishes detailed reports and briefs on completed projects. The reports include analysis of data collected, projected energy savings, payback analysis, and user feedback. Adapted from http://www1.eere.energy.gov/buildings/ssl/gatewaydemos.html.

FIGURE 5.1 Subjective lighting survey used by the city of San Jose, California. SOURCE: Clanton and Associates and VTTI (2010).

SSL has unique uni-directional distribution characteristics, providing excellent beam control and allowing the fabrication of luminaires that are ideal for long-distance light distributions. For instance, an entire building façade can be grazed with luminaires located at one level. Accent lighting in retail stores can produce high-quality illumination with little energy. SSL has the potential to put light where it is needed with minimal light spillage, but without appropriate optics it can exhibit a sharp cutoff in illuminance with an abrupt termination of the lighted area. For instance, without appropriate optics roadway lighting may not light the adjacent sidewalks. This attribute of SSL emitters may also make for difficulties in the development of omnidirectional lamps replacements for fluorescent and incandescent lamps. In the future this problem could be solved by proper optical designs.

Because the LED does not emit infrared light as does an incandescent lamp, the beam of light is cool. This makes it ideal for reducing heat on retail products and art work and in other heat sensitive applications. SSLs based on LEDs are currently used in museums (e.g., in Portland, Oregon) and in refrigerated display cases (e.g., Albertsons Grocery in Eugene, Oregon) (DOE, 2012a). Newer domestic refrigerators are also using LEDs for interior lights.

SSL has the potential for superior chromaticity and color rendering. As discussed in Chapters 1 and 3, the spectral output of SSL products can be tuned to create virtually any desired chromaticity. This is required in all applications where the users typically compare the lighting color to recognizable sources such as daylight or an incandescent lamp.

In addition to achieving excellent color rendering, some SSL sources can create desirable effects, such as increasing the saturation of object colors. Opportunities exist to select spectral distributions for specific applications, such as rendering artwork, or narrow spectral distribution, such as amber LED (i.e., LED lights without the blue component) for lighting beach boardwalks near turtle hatching areas where young turtles are at risk because they are attracted to blue light similar to the ocean effervescence (Longcore and Rich, 2005).

When SSL is properly operated within its temperature and operating current ranges, it has a relatively long life, which reduces maintenance and improves reliability. Because SSL may not burn out but only decrease in light output, there is a potential liability issue if light output drops below design levels. Proactive maintenance strategies can be developed to alert users through intelligent controls when SSL drops below 70 percent of initial light output. SSL drivers can be made to adjust operating current so that when lamps are new, the operating current is lower. As lamps age, the operating current increases to maintain consistent light output. Near the end of usable life, indicators may be used to signal low light output.

Luminaires with Entirely New Fonn Factors

Luminaires of entirely new form factors may be developed to take advantage of the unique attributes of LEDs and OLEDs. For instance, neither replacement lamps nor retrofit luminaires capitalize on the very small size of individual LEDs. This characteristic alone, if fully exploited, has the potential to completely change where and how electric lighting is used. The controllability of LEDs is also only beginning to be explored. Common lighting controls now are limited to dimming, occupancy/motion sensing, and daylight sensing. The next generation of SSL luminaires will be able to do those things and perhaps much more: change color, change color rendering properties, and so forth. Because the ability to control different light properties is determined by the components in the product, controls will most likely be considered integral parts of the luminaires. OLED’s unique properties naturally lend themselves to out-of-the-box thinking, and truly novel luminaire designs may emerge with new OLED products. Other applications may include lighted surfaces such as walls, ceilings, and furniture systems.

Adoption of these new and novel types of luminaires would require the most risk and investment by consumers. If a consumer were to become dissatisfied with a very innovative SSL luminaire, reverting to other lighting technologies would be difficult and expensive. Installation of highly innovative luminaires in existing buildings may necessitate major retrofit work. Thus it is likely that early adoption of such luminaires will be in new construction projects that pay attention to lighting design from the early stages of architectural planning.

A small sampling of these types of forward-looking luminaires has been developed. One interesting example is a closet rod embedded with LEDs, which becomes luminous when the closet door is opened (Reo, 2011). This custom-made product illustrates a clever use of controls and great attention to putting light where it is actually needed in a closet. Future lighting may emphasize flexibility and multi-function, as illustrated by a multi-functional OLED luminaire, which consists of multiple, movable OLED panels (Figure 5.2). It is possible that future lighting will make luminaires invisible, as is done by some LED products that are small and thin and intended to be installed in small crevices and recesses in the built environment.4 At this stage, it is impossible to predict all of the forms that future SSL luminaires will assume.

FIGURE 5.2 Example of multi-panel OLED (Canvis® Twist by Acuity Brands). SOURCE: See http://www.acuitybrandsoled.com/creations/canvis-twist/.

FINDING: Were OLEDs to become commercially viable, they would provide an opportunity to change the form factors of how luminaires are designed with smaller sizes, less material, and fewer physical constraints and offer an ability to change from traditional-looking luminaires to internally lighting surfaces and materials.

As with any new technology, the early adopters have highlighted areas in which further improvements are needed to make SSLs fully equivalent across the whole spectrum of lighting applications. Whenever a new technology is introduced, dissimilarities are noticed. For example, when the CFL was introduced to replace the incandescent lamp, users were unhappy with the flickering, slow start-up, color, light intensity, noise, radio static, and lack of dimming. It will be important not to make the same mistakes with SSL introduction (see the Chapter 2 section, “Compact Fluorescent Lamp Case Study”).

At this point, the major challenges to full acceptance of SSL are cost, system and control compatibility, and heat management. These issues are not well understood by most end users, so it falls to the lighting industry to improve

________________

4 See, for example, http://www.youtube.com/watch?v=_8e4iYlNyZI>and www.edgelighting.com.

components and to other professionals to establish standards and recommendations that will ease the introduction of SSL.

The cost for SSL luminaires needs to be reduced for them to be readily accepted. As noted in Chapter 2, it took a combination of technical advances to improve quality and incentive programs to overcome the initial reluctance to adopt CFLs, and their initial cost is still an inhibiting factor.

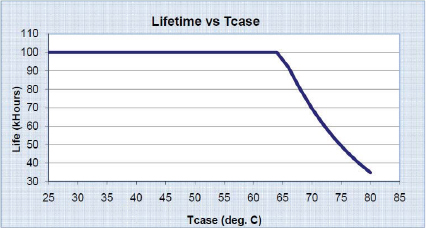

Both initial and replacement costs are major considerations, particularly for SSL luminaires. Many SSL components are integral with the luminaire, making component replacement difficult if not impossible. Instead of replacing a lamp, the entire luminaire would need to be replaced should one of these integral components fail. Progressive manufacturers now construct luminaires for easy component replacement, including such features as removable optical cartridges and quick connects to drivers. Also, driver lives are dependent on operating temperature but, nonetheless, are increasing to match the life of the SSL luminaire (Figure 5.3).

While cost is still a significant barrier to more rapid introduction of SSLs, the expectation is that with the current rate of progress, they will become a cost-effective option in the near future (Bland, 2011).

System and Contro ls Compatibility

Lighting controls can include dimming, occupancy controls, and color control. Current SSLs do not always gracefully mesh with existing installations. One great challenge for designers is selecting compatible drivers for the SSL luminaires. This is also related to dimming compatibility issues. Different drivers have unique operating currents and operational characteristics. If a driver is not compatible, luminaires can flicker, have shorter lives, or not operate at all. Most quality manufacturers now supply the drivers with their luminaires, which avoids confusion.

Drivers must also be compatible with new and existing control systems. Currently, some integrated drivers have power quality problems such as high THD of the line current and low PF. A designer must obtain the list of compatible drivers from the control manufacturer—a method of selection that is awkward, adds design time, and adds difficulty when SSL equipment is substituted for standard fixtures. A NEMA standard for controls, drivers, and SSL compatibility could streamline this process.

Heat management is a huge challenge with SSL applications (see Chapter 4). Luminaires must dissipate heat adequately to maintain life and light output expectations. For SSLs, mounting details can add heat management complexity. For instance, operating temperatures can rise if SSL luminaires are mounted in a confined space, adjacent to insulation, in high temperature environments, or where the heat otherwise cannot be dissipated. An example would be a recessed downlight adjacent to insulation in a nonconditioned area. Another example would be one in which MR16 lamps are installed in open air luminaires where the only heat sink is the socket connection. As operating temperatures increase, life and light output decrease. Non-LED luminaires have an easier chance of dissipating heat compared to LED lamps, where the heat sink is limited to the socket size and cooling fins around the lamp. OLED luminaires do not have as significant heat management issues as LED (refer to Chapter 3) at room temperatures and below, which facilitates installations in more varied environments.

FIGURE 5.3 LED driver life of Philips “Xitanium” driver versus case temperature. SOURCE: Philips Lighting North America (2012).

FINDING: Replacing existing incandescent lamps with LED lamps in existing luminaires may under certain conditions cause the LED to overheat. Examples include downlights adjacent to insulation or in enclosed luminaires. This is true also of the use of SSL in industrial applications having higher ambient temperatures. LED lamp heat management needs to be addressed for all such applications.

SSL products, similar to fluorescents and HID, contain electronic components and without appropriate design can produce poor power quality and exhibit, for example, high THD and low PFs. This is a similar set of issues encountered by early deployments of electronic and hybrid ballasts for compact fluorescents and linear fluorescents lamps. High THD can cause flickering and excess current on shared neutral conductors. Low PF results in line currents higher than necessary to supply the required power.

SSL drivers, similar to fluorescent electronic ballasts, can cause radio interference, which can be annoying, especially to residential users. SSL drivers are required by the Federal Communications Commission to adhere to similar protocols as electronic ballasts in order to avoid these problems.5 This includes the integral drivers in SSL lamps.

Related to power quality, issues such as dimmer range and reliability, maximum/minimum units required on a control, repetitive peak voltage, and in-rush current can cause significant problems if not properly addressed (see “Electric Power Quality” in Chapter 4).

As an SSL product ages, its output gradually declines. It does not simply go dark, but its lumen output declines over time. This could be a liability issue in some applications where a specific level of illumination is required. One promising option to address this is incorporating a driver that will increase the operating current as the LEDs age to keep the luminaire at its specified output.

If SSL is to compete successfully, then its lighting quality should be equal to or better than non-SSL luminaires (IES, 2011, p. 7.64; IALD, 2006). Lighting quality issues include quantity of light, lighting ambiance, glare reduction, and color rendering and consistency (ALA, IES, IALD, 2010).

Light Quantity

When a user installs SSL, they expect that the light will be equivalent to (seem the same as) an incandescent of the specified equivalent wattage. The quantity of light (i.e., the luminous flux measured in lumens) is the easiest metric to use, because it is easily predicted and measured. SSL has been successful in producing a quantity of light similar to standard luminaires in the lower lighting level environments. High lighting levels are currently harder to achieve because of the amount of heat management required with the additional wattage. As SSL modules become more efficacious, higher lighting levels will be achievable that do not encounter these problems in operation.

Lighting Ambiance

Whether a scene is pleasant, spacious, intimate, or dramatic depends on the luminance balance within the scene (IES, 2011, p. 4.26) and how light is layered. For instance, spaciousness is implied when walls and ceilings are evenly lighted. Pleasant scenes may have non-uniform lighting with stronger accent lighting and peripheral wall emphasis (Flynn and Spencer, 1977; IES, 2011). SSLs based on LEDs perform well for surface grazing for walls and ceiling coves and for accent lighting. Applications of SSLs based on OLEDs include lighted surfaces in addition to luminaires.

Examples of installations having lighting layers include uniform ceiling brightness balanced with select wall washing and occasional accent lighting; personal work areas may have under-shelf lighting with adjustable task lighting. All of these layers should be separately controlled to provide the desired luminance balance. The light output of SSL products can be very directionally controlled and, thus, has unique advantages in providing layers of light, especially for surface ambient, accent, and task lighting.

Brightness and Glare

Because SSL lighting is uni-directional, it has the possibility of high brightness, giving luminaires the potential of producing glare if not controlled properly. Luminaires can limit brightness through optical systems either at the module level or within the reflector and lens design. Methods include the use of remote phosphor modules or diffusing lenses or by indirectly lighting via reflectors or surfaces so the individual LEDs are not visible.

Color Rendering, Appearance, and Consistency

To see colors as intended, the lighting system must produce a desired spectral distribution. Lower color temperatures are associated with “warmer” looking light, appropriate in residential, hospitality, and retail applications. Higher color temperature represents “cooler” looking light, which is appropriate in commercial and industrial applications. Exterior applications show a preference for lower color temperatures (Clanton and Associates and VTTI, 2009, 2010).

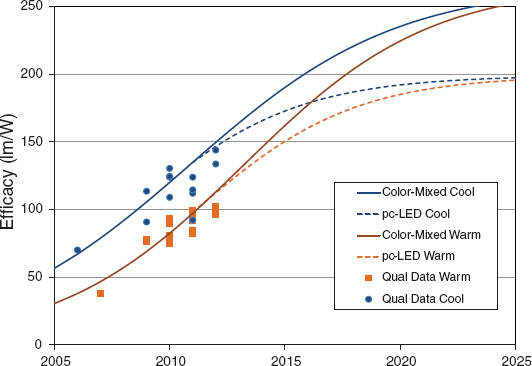

________________

An LED produces light in a narrow spectrum. In order to produce white light from a single LED module, the module is phosphor-coated. Another method of producing white light is combining several different color LEDs. Color rendering, and color rendering indexes, are harder to apply to LED luminaires than standard luminaires (see Chapter 1). Not all LED lamps available in the current market have good color rendering properties. Higher color temperature LED modules are more efficacious, encouraging their application. But the cooler color (bluish tint) associated with them may not be as readily acceptable to users (Clanton and Associates and VTTI, 2009; Clanton and Associates, VTTI, ETA, 2010). SSL luminaires need to increase the efficacy for color temperatures below 3,800 K in order to satisfy user preference for the lower correlated color temperature (CCT) (Figure 5.4).

One significant issue is the consistency of SSL luminaires’ color appearance. If LEDs from different bins are used in the same luminaire or in similar luminaires side by side, the light outputs will not match in color appearance (i.e., the CCT). This is an issue not only during initial installation, but also in deployment because of aging and replacement of luminaires. SSLs need to be consistent between products and guaranteed to provide color-consistent replacement modules in the future.

FINDING: Many LED lamps currently available do not have the same light output and color rendering properties as incandescent lamps. SSL products with improved light output that are color consistent from product to product will be needed for the public to readily accept these as replacements for incumbent lighting technologies.

EVALUATING SSL LIGHTING APPLICATIONS

SSL lighting applications are currently intended to duplicate or be similar to incandescent and fluorescent lighting. SSL has many unique qualities that have not been present before in lamp technology, and these may result in new applications in the future. The attributes of SSL make possible new ways of lighting such as uniform surface washing and grazing, close-to-task effectiveness, and surface integrated light. Tunable spectral distribution adds flexibility for color adjustments.

The current status of SSL applications is summarized below. This is, of course, a snapshot of a moving target, as the field is changing rapidly.

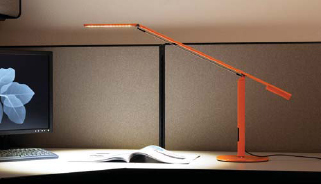

Best. Because the current LED products have relatively low lumen output, the best current applications for SSL are those in which the light source is close to the task and the required lighting levels are low. Examples of these are task

FIGURE 5.4 Current and projected efficacies. NOTE: pc-LED = phosphor-converted LED; lm = lumen; W = watt; Qual = qualified data point having satisfied the criteria for cool white (color rendering index (CRI) of 70-80, correlated color temperature (CCT) of 4,746-7,040 K) or warm white (CRI of 80-90, CCT of 2,580-3,710 K). Results are for 25°C package temperature and are normalized to current densities of 35 A/cm2. SOURCE: DOE (2012b).

(Figure 5.5), under-cabinet or under-shelf, step lighting, and wall washing (Figure 5.6) and cove grazing.

Emerging. Emerging SSL applications include higher output directional lighting. Because heat management may be an issue with higher output lumen packages, higher-efficacy lamps will help with these applications. Examples are accent lighting, downlighting (Figure 5.7), large area grazing, and street (Figure 5.8) and area lighting.

Difficult. Difficult SSL applications include omni-directional lighting. Because LED modules are uni-directional, it is difficult to fabricate luminaires that render them omni-directional. For fluorescent replacements, LEDs offer little advantage if any, and at higher initial cost. Replacements for high wattage A-lamps (i.e., 100 W and higher) are not yet available.

Unique. When commercially available, OLEDs will facilitate applications with new form factors, which is enabled by the manner in which the OLED is essentially the luminaire

FIGURE 5.5 Exampleoftask lighting. “Equo LED Desk Lamp” by KonceptTeclmoJogies, fuc. SOURCE: Next Generation Luminaires, PNNL.

FIGURE 5.6 Example of wall washing. “Stile Styk” by STILE, a brand of SPILIGHTING, Inc. SOURCE: Next Generation Luminaires, PNNL.

FIGURE 5.7 Example of downlighting. Sea Gull Lighting/Juice-Works. SOURCE: Next Generation Luminaires, PNNL.

FIGURE 5.8 Example of street lighting (“RoadStar” by Philips Roadway Lighting). SOURCE: Next Generation Luminaires, PNNL.

(with the addition of a driver). Examples of new form factors include lighted surfaces and objects, which eliminates traditional luminaire aesthetics. Some new forms include foils and moldable and conformable materials. Both OLEDs and LEDs could be used, for example, in a recessed cavity or in places where, for reasons of repair and maintenance, it would otherwise be awkward to install a luminaire.

Both LED and OLED applications may use dynamic controls with spectral distribution tuning, allowing, for example, cooler color temperature appearance during the day and warmer color temperature appearance in the evening. In areas where spectral distribution restrictions are required, such as in environmentally sensitive areas or in areas where melatonin suppression is avoided (i.e., places of sleep for residential and healthcare properties), dynamic tuning could provide solutions.

Post-occupancy assessment (POA) is a valuable tool, especially when deploying a new or emerging technology. POAs can provide valuable positive and negative feedback from users to manufacturers, lighting designers, utilities for rebate programs, and to the Department of Energy’s (DOE’s) SSL programs. Organized POAs may discover an issue that requires mediation before it becomes an established association with SSL, such as dimmer compatibility. Assessments can gather opinions on lighting quality, performance, longevity, economic value, and general expectations. Specific issues may include glare, color, dimming, and flicker.

POAs should be performed in both the commercial and residential applications with subjective evaluations given to the end users. Additionally, issues such as energy use, power quality, longevity, and maintenance could be gathered from building managers and utility groups.

There are several existing POA formats such as Berkeley’s Center for the Built Environment “Occupant Indoor Environmental Quality (IEQ) Survey,”6 but none of them delves into specific SSL issues.

TESTING AND MEASUREMENT STANDARDS

Because of the different spectral, electrical, and thermal characteristics of LEDs, OLEDs, and SSL products, existing standards to measure the photometric properties (i.e., measures of perceived light intensity) and colorimetric properties (i.e., measures of perceived color characteristics) of other lighting technologies frequently cannot effectively be used for SSL. For instance, the temperature of an LED package will affect measurements of light output, lifetime, and color. In such cases, the applicability of a measurement will depend on the effectiveness of the thermal management of that LED package in its ultimate application. Because of this, standards for SSL focus on different stages of the integration of complete lighting products, including LED packages, LED arrays and modules, LED light engines, and integrated LED lamps and luminaires. Additional standards focus on terminology.

Within documentary standards, test and measurement standards simply detail how a device or product is to be measured but do not indicate the desirable results of those measurements. A lighting product does not adhere to a measurement standard; the manner in which its characteristics are measured does. Performance standards, on the other hand, set rules and/or give permissible ranges of measurement outcomes. A lighting product would be said to adhere to a certain performance standard if it met the latter’s requirements. Safety standards, including electrical safety and photobiology (the effects of light on organisms, often concerned with the potential for light sources to damage the human eye), are one type of performance standard.

A number of standards development organizations are involved in recommending test procedures for the measurement of LEDs, OLEDs, and SSL products. The Illuminating Engineering Society of North America (IES), a professional organization dedicated to advancing the art, science, and practice of lighting, has been one of the leaders in the development of standards specifically for SSL and is accredited by the American National Standards Institute (ANSI). ANSI establishes the consensus procedures that are the basis for the development of American National Standards7 and is the U.S. representative to the International Electrotechnical Commission (IEC) and International Organization for Standardization (ISO). The IEC is an international consensus standards organization for electrotechnology. The International Commission on Illumination (CIE) is recognized by ISO and the IEC as an international standards body. Its activities include the development of standards and procedures for the measurement of light and publication of standards and technical reports related to light and lighting. NEMA is primarily a trade association for the electrical manufacturing industry but is also an ANSI-accredited standards development organization. The Underwriters Laboratory is ANSI-accredited and sets safety standards for lighting products.

Test and measurement standards for SSL are rapidly being developed, both within the United States and internationally. Because of the volume of standards produced and frequent new publications, an exhaustive discussion of standards will not be included here. Instead, a few important areas of testing and measurement of SSL are highlighted.

The United States has taken early leadership on several influential standards, such as IES LM-79-08 “Electrical and Photometric Measurements of Solid-State Lighting Products,” which specifies the procedures for measuring total luminous flux, electrical power, luminous efficacy, and chromaticity of SSL integral lamps and luminaires (IES,

________________

6 See http://www.cbe.berkeley.edu/research/survey.htm.

7 Further information is available at http://web.ansi.org/about_ansi/faqs/faqs.aspx?menuid=1.

2008). Despite rapid progress, a number of important test and measurement standards still need to be developed for SSL to be successful.

There is currently no way to measure or estimate the lifetime of SSL luminaires. LEDs do not typically “burn out” or abruptly fail at end-of-life, like an incandescent lamp. Instead, they get dimmer over time, the speed of which depends on exposure to heat and other variables. Standards have made progress on measuring and predicting lumen maintenance (the relationship between temperature, operating time, and light output) for individual LED packages, but the life of an integral lamp or luminaire is determined by more than the LEDs. For example, the failure of an electrical component or darkening of an optical component may limit the lifetime of an SSL luminaire. Predicting and measuring the lifetime of the integration of varying subcomponents makes this topic very technically complicated.

FINDING: There is no standardized method for measuring the lifetime of SSL products.

The CRI is the internationally accepted metric for the evaluation of a light source’s color rendering abilities (CIE, 1995) and was developed in response to the advent of fluorescent lamps. Fluorescent lamps had spectral power distributions (SPDs) unlike anything the lighting industry had used before, and the quality of color rendering from these light sources was highly variable. The calculation of the CRI requires only the spectral power distribution of the light source of interest and is basically a series of colorimetric simulations. In these simulations, the appearance of a predefined set of reflective samples (object colors) is compared when illuminated by the test source and when illuminated by a reference illuminant (blackbody radiator or daylight simulator). If the samples appear identical in both cases, the test lamp would receive a general CRI (Ra) of 100. Deviations in the appearance of the test sample colors lower the score. A number of flaws of the CRI have been recognized for years, but the problems have not been considered important enough to warrant change (CIE, 1999). The problems of the CRI include the use of outdated and obsolete colorimetry (the math used to calculate the appearance of the reflective samples), a set of reflective samples that do not detect certain color rendering problems, and, according to some, an underlying definition of color rendering that does not correspond to actual users judgments of color rendering quality (Davis and Ohno, 2009).

For much of the history of electric lighting, a small number of very large companies produced nearly all of the light sources sold in the world. Each of these companies had the resources and expertise to understand the limitations and flaws in their measurements and ensure that metrics did not lead them to inadvertently create poor products. However, the lighting industry has changed considerably, largely because of SSL. Many smaller companies are now developing lighting products, some with very little experience in lighting, and the metrics used to evaluate light sources need to give users accurate predictions of performance. Furthermore, the problems of the CRI are particularly pronounced for some SSL sources (CIE, 2007). For example, certain LED spectra can render the reflective samples of the CRI very well, but render other object colors poorly.

There is now widespread agreement that a new method is needed to evaluate the color rendering quality of light sources (CIE, 2007), and many different approaches and methods have been proposed (reviewed in Davis and Ohno, 2009; Guo and Houser, 2004). DOE has publicly supported one proposed metric (DOE, 2010), the Color Quality Scale (CQS) (Davis and Ohno, 2010). Although it still uses the CRI, it is the current standard. A technical committee in the CIE was formed in 2006 to recommend a new procedure for evaluating the color rendering of light sources. Because the CIE committee consists of a diverse international group of stakeholders, consensus has not yet been achieved. This is problematic for SSL manufacturers, particularly small companies incapable of performing detailed colorimetric simulations, as they optimize their products to the metric.

FINDING: The CRI does not always yield results that predict or evaluate performance well, so manufacturers cannot rely on it to guide product development.

DOE has actively supported the consensus process for the development of testing and measurement standards. DOE has provided experts and supported their work time for numerous SSL standards committees. The agency also organized and sponsored an SSL standards workshop, as well as several related round-table meetings. Furthermore, DOE uses its demonstration projects to provide input on additional needed standards and provides financial support to the U.S. national committee of the CIE. DOE also funds measurement and standards research at the National Institute of Standards and Technology.

The Commercially Available Light-Emitting Diode Product Evaluation Reporting (CALiPER) component of the DOE program includes verification testing that produces extensive data on individual products. DOE funds independent laboratories to conduct the testing, each focused on one product type (e.g., high-bay luminaires; small replacement lamps (MR16, PAR lamps, and so forth)). The testing follows the IESNA LM-79-08 method of electrical and photometric measurements to verify that lamps are performing according to specifications.

ALA (American Lighting Association), IES (Illuminating Engineering Society), and IALD (International Association of Lighting Designers). 2010. What’s Your Quality of Light? The Lighting Industry’s Call for a Practical Lighting Energy Policy. Dallas, Chicago, and New York: ALA, IES, and IALD.

ANSI (American National Standards Institute) and IES (Illuminating Engineering Society). 2010. Nomenclature and Definitions for Illuminating Engineering. New York: ANSI and IES.

Bland, S. 2011 SSL Manufacturing Issues Prospects for Cost Reduction. Paper presented at presentation to the Committee on Assessment of Solid State Lighting, Washington, D.C., December 1.

CIE (Commission Internationale de l’Eclairage). 1995. CIE 13.3: 1995, “Method of measuring and specifying colour rendering properties of light sources.” Vienna, Austria: CIE Central Bureau.

CIE. 1999. CIE135/2: 1999, “Colour rendering, TC 1-33 closing remarks, CIE Collection in vision and colour and in physical measurement of light and radiation.” Vienna, Austria: CIE Central Bureau.

CIE. 2007. CIE 177: 2007, “Colour rendering of white LED sources.” Vienna, Austria: CIE Central Bureau.

Clanton and Associates and VTTI (Virginia Tech Transportation Institute). 2009. Street Lighting Survey for Commercial Areas in the Municipality of Anchorage. Boulder, Colo.: Clanton and Associates.

Clanton and Associates and VTTI (Virginia Tech Transportation Institute). 2010. Advanced Street Lighting Technologies Assessment Project-City of San Jose. Boulder, Colo.: Clanton and Associates.

Clanton and Associates, VTTI (Virginia Tech Transportation Institute), ETA (Emerging Technologies Associates, Inc.), and City of San Diego. 2010. Advanced Street Lighting Technologies Assessment Project—City of San Diego. Boulder, Colo.: Clanton and Associates.

Davis, W., and Y. Ohno. 2009. Approaches to color rendering measurement. Journal of Modern Optics 56(13):1412-1419.

Davis, W., and Y. Ohno. 2010. The color quality scale. Optical Engineering 49(3):033602.

DOE (U.S. Department of Energy). 2010. “New QCS metric to evaluate color quality of light.” Postings, June 15. Available at http://apps1.eere.energy.gov/buildings/publications/pdfs/ssl/postings_06-15-10.pdf. Accessed September 15, 2012.

DOE. 2012a. Solid-State Lighting GATEWAY Demonstration Results. Available at http://www1.eere.energy.gov/buildings/ssl/gatewaydemos_results.html. Accessed May 23, 2012).

DOE. 2012b. Solid-State Lighting Research and Development: Multi-Year Program Plan. Washington, D.C.: U.S. DOE.

Flynn, J.E., and T.J. Spencer. 1977. A study of subjective responses to low energy and non-uniform lighting systems. Lighting Design and Application 7(2):6-15.

Gibbons, R., and N. Clanton. 2011. Alternative Lighting Design. New York: Illuminating Engineering Society.

Guo, X., and K.W. Houser. 2004. A review of colour rendering indices and their application to commercial light sources. Lighting Research and Technology 36(3):183-199.

IALD (International Association of Lighting Designers). 2006. Multi-Year Plan—The Pilot Light Initiative: for Low-Energy, High-Quality, Sustainable Lighting. Chicago, Ill.: IALD.

IDA (International Dark-Sky Association). 2010. Visibility, Environmental, and Astronomical Issues Associated with Blue-Rich White Outdoor Lighting. Washington, D.C.: IDA.

IES (Illuminating Engineering Society). 2008. Approved Method for the Electrical and Photometric Testing of Solid-State Lighting Devices. The Lighting Handbook. IES LM-79-2008IES. 2011. New York: IES.

IES and IDA (International Dark-Sky Association). 2011. Model Lighting Ordinance (MLO) with User’s Guide. Washington, D.C., and New York: IES and IDA.

Longcore, T., and C. Rich, eds. 2005. Ecological Consequences of Artificial Night Lighting. Washington, D.C.: Island Press.

Motta, M. 2009. U.S. physicians join light-pollution fight. Sky and Telescope online, June 22.

Philips Lighting North America. 2012. LED Driver Lifetime and Reliability. The Netherlands: Koninklijke Philips Electronics N.V.

Reo, A. 2011. “Light for a Better Future.” Presentation to the Committee on Assessment of Solid State Lighting, Washington, D.C.

Wright, M. 2011. Semicon West delivers technology update on LED manufacturing. LEDs Magazine. September.