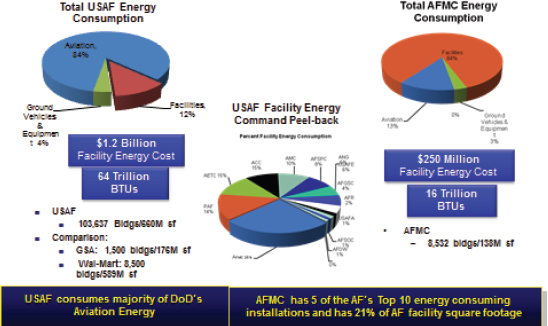

The Department of Defense (DoD) is the largest consumer of energy in the federal government at approximately $20 billion in 2011.1 In turn, the U.S. Air Force is the largest consumer of energy in the DoD, with a total annual energy expenditure around $10 billion.2 As shown in Figure 1-1, about 84 percent of Air Force energy is liquid fuel consumed in aviation, and about 12 percent is energy (primarily electricity) used in facilities on the ground. However, the facilities of some Air Force commands consume a comparatively high proportion of their command’s total energy. For example, in the Air Force Materiel Command (AFMC), 84 percent of energy consumption occurs in facilities (at a cost of $300 million) and only 13 percent is consumed in aviation.3,4

This workshop was concerned primarily with opportunities to reduce energy consumption within Air Force facilities, and particularly to reduce consumption of “process energy,”5 whichincludes energy used in industrial and test operations, laboratories, medical facilities, and data centers. A key focus of the workshop is a subset

______________________

1Col Douglas Wise, Chief, CE Operations and Readiness Division, HQ AFMC/A70, “AFMC Facility Energy Program,” presentation to the workshop on November 5, 2012.

2Ibid.

3Ibid.

4AFMC’s primary mission is supporting weapon system acquisition. This is in contrast to Air Combat Command, a separate Air Force Major Command, which devotes much more resources to aviation-related energy. SOURCES: AFMC Factsheet. Available at http://www.af.mil/information/factsheets/factsheet.asp?id=143. Accessed January 23, 2013. Air Combat Command Factsheet. Available at http://www.af.mil/information/factsheets/factsheet.asp?id=137. Accessed January 23, 2013.

5Air Force Instruction 90-1701 defines “process energy” as “Energy directly consumed in manufacturing, maintenance, equipment overhaul, rehabilitation or refurbishment, destruction, warehousing, and similar processes, not related to the comfort and amenities of the occupants of the facility.”

of process energy termed “industrial process energy” (IPE), which includes the energy-intensive industrial processes that occur within Air Force facilities, such as the following:

• Assembly and disassembly

• Avionics testing

• Engine testing

• Composite construction

• Chemical cleaning

• Heat treating

• Painting and de-painting

• Plating

• Metalworking

• Nondestructive inspection

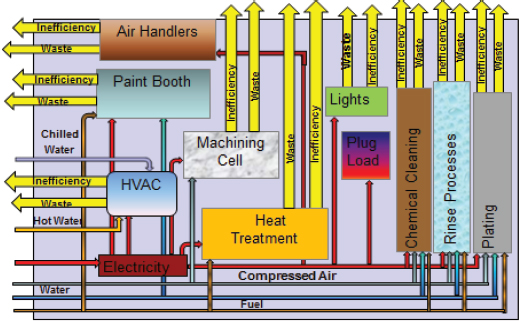

IPE has been defined as “energy consumed by high-intensity processes or mission-critical applications that are not the traditional creature comforts of the building (e.g., heating, cooling, lighting, and domestic hot water)”6 as shown schematically in Figure 1-2. An estimated 35-50 percent of AFMC’s energy consumption at its Air Logistics Complexes (ALCs) is process energy—primarily industrial process energy. Thus, although IPE is not a large fraction of overall Air Force energy use (approximately 1 percent) and has received relatively little attention, investments in IPE efficiency are expected to yield high rates of return. These reductions in energy use enhance overall Air Force energy security; the savings can be applied to enhance mission capability in other areas.

FIGURE 1-1 Breakdown of energy usage in the U.S. Air Force (USAF) and the Air Force Materiel Command (AFMC). NOTE: GSA, General Services Administration; sf, square feet. SOURCE: Col Stephen Wood, Vice Commander, 72nd Air Base Wing, presentation to the workshop, November 5, 2012, Washington, D.C.

______________________

6U.S. Department of Energy, Energy Efficiency and Renewable Energy, Federal Energy Management Program.

FIGURE 1-2 Examples of industrial process energy use and opportunities to improve efficiency. NOTE: HVAC, heating, ventilation, air conditioning. SOURCE: Col Douglas P. Wise, HQ AFMC A70, presentation to the workshop, November 5, 2012, Washington, D.C.

ENERGY REDUCTION GOALS AND MANDATES

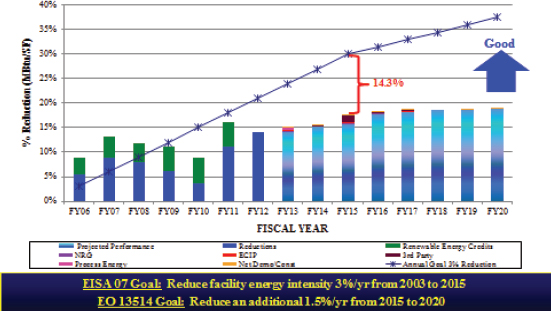

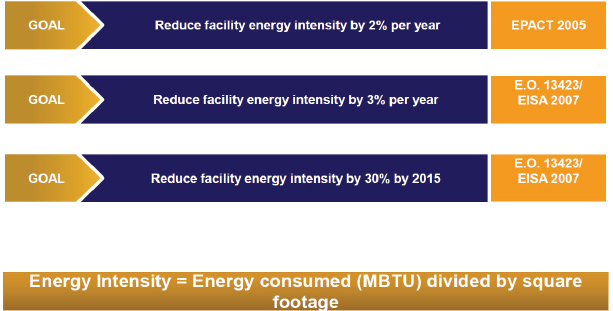

The efforts of the Air Force to reduce energy consumption are driven largely by external goals and mandates derived from congressional legislation—the Energy Policy Act of 2005 (EPACT) (Public Law No. 109-58) and the Energy Independence and Security Act of 2007 (EISA) (Public Law No. 110-140)—and Executive Order 13423 (EOs), shown in Figure 1-3. To date, these goals and mandates have targeted the energy used in facilities only and not the larger amount used in aviation operations. The primary metric used in setting the goals is energy intensity, as measured in British thermal units (Btu) per square foot of facility space. The goal for facility energy is an intensity reduction of 3 percent per year from 2003 to 2015. The Air Force has made considerable progress toward its goals, having invested hundreds of millions of dollars ($274 million in FY 2011) in projects that have reduced facility energy intensity by 16 percent since the base

year, 2003.7 However, as shown in Figure 1-4, AFMC efforts are expected to fall short of the goal of a 30 percent reduction by 2015. Unless changes are made in the way that AFMC operates, targets, and funds energy-efficiency projects, the gap between goals and performance in 2015 is expected to be approximately 14 percentage points. Each additional percent of energy-intensity reduction is estimated to require an investment of $100 million. The AFMC is looking at reducing its use of industrial process energy as a way to help reach its facility energy-reduction goals.

FIGURE 1-3 Mandates and goals for reducing energy intensity in U.S. Air Force facilities. NOTE: EPACT, Energy Policy Act; E.O., Executive Order; EISA, Energy Independence and Security Act. SOURCE: Kevin Geiss, Deputy Assistant Secretary for Energy, U.S. Air Force, presentation to the workshop, November 5, 2012, Washington, D.C.

______________________

7Kevin Geiss, Deputy Assistant Secretary of the Air Force for Energy, “National Academies Workshop: Energy Reduction at Air Force Facilities Using Industrial Processes,” presentation to the workshop on November 5, 2012.

FIGURE 1-4 The gap between mandated reduction in energy intensity at Air Force Materiel Command (AFMC) facilities and actual performance is expected to increase. NOTE: NRG, Energy Conservation Initiative; ECIP, Energy Conservation Investment Program; EISA, Energy Independence and Security Act; EO, Executive Order; SOURCE: Col Douglas Wise, HQ AFMC A70, presentation to the workshop, November 5, 2012, Washington, D.C.

WATER CONSUMPTION GOALS AND MANDATES

In addition to reducing energy intensity at Air Force facilities, another area that the Air Force is targeting for efficiency is fresh-water use. In the United States, water is relatively cheap compared to electricity, but at facilities located on islands or forward operating bases, water must be brought in at great expense. Furthermore, in the next 10 to 20 years, access to potable water is expected to increasingly become an issue. Executive Order 13514 has set a goal of reducing water use by certain federal agencies by 2 percent per year from 2007 to 2020.8 The Air Force is relatively comfortable with its progress in meeting this goal at the moment, but it recognizes that energy use and water use are often interconnected, and it is interested in developing an integrated plan for meeting its energy- and water-reduction goals.

______________________

8For additional information on Executive Order 13514, Federal Leadership In Environmental, Energy, And Economic Performance, see http://www.whitehouse.gov/assets/documents/2009fedleader_eo_rel.pdf. Accessed January 11, 2013.

In April, 2012, the Air Force Deputy Assistant Secretary for Energy requested that the National Research Council (NRC) conduct a workshop titled “Energy Reduction at Air Force Facilities Using Industrial Processes,” and produce a summary report. The terms of reference (TOR) for this workshop are shown in Box 1-1.

BOX 1-1

Terms of Reference

An ad hoc committee will plan and convene one 3-day public workshop to discuss: (1) what are the current industrial processes that are least efficient and most cost ineffective? (2) what are best practices in comparable facilities for comparable processes to achieve energy efficiency? (3) what are the potential applications for the best practices to be found in comparable facilities for comparable processes to achieve energy efficiency? (4) what are constraints and considerations that might limit applicability to Air Force facilities and processes over the next ten (10) year implementation time frame? (5) what are the costs and paybacks from implementation of the best practices? (6) what will be a proposed resulting scheme of priorities for study and implementation of the identified best practices? (7) what does a holistic representation of energy and water consumption look like within operations and maintenance?

The committee will develop the agenda for the workshop, select and invite speakers and discussants, and moderate the discussions.

The topics at the workshop will also consider effective strategies and business approaches to foster culture change and select technology portfolios that could reduce infrastructure energy and water consumption and increase resilience at military installations while assuring energy for mission critical capabilities across the Department of Defense. Special attention will be given to installations that have antiquated facilities, massive industrial processes, and demolition/consolidation opportunities. The workshop will use a mix of individual presentations and question-and-answer sessions to develop an understanding of the relevant issues. Key stakeholders would be identified and invited to participate. One individually authored Workshop Summary document will be prepared by a designated rapporteur.1

___________

1 Finally, it is important to note that this rapporteur-authored workshop summary does not contain consensus findings and recommendations, which are produced only by ad hoc NRC study committees.

WORKSHOP STRUCTURE, SCOPE, AND APPROACH

This 3-day workshop, which took place November 5-7, 2012, in Washington, D.C., consisted of a series of presentations to workshop participants by invited speakers (the workshop agenda is provided in Appendix B), with each presentation followed by general discussion. Broadly, the first day was devoted to presentations on energy-reduction efforts by the Air Force and the other services, the second day to presentations on commercial industry initiatives, and the third day to discussion among all participants.

It quickly became apparent that neither the expertise represented nor the time available would permit an in-depth analysis of energy-reduction opportunities in all of the industrial processes being used at Air Force facilities, as outlined in the first paragraph of the TOR (see Box 1-1). Although some of the presentations—especially those by industry representatives—touched on energy-reduction opportunities in specific industrial operations (e.g., the painting of vehicles at General Motors), most dealt with energy-reduction initiatives, programs, information resources available, and strategies for implementing culture change with respect to how energy is used in the Air Force.