This chapter briefly introduces the key concepts necessary to understand inertial confinement fusion (ICF), inertial fusion energy (IFE), and target physics.

INERTIAL CONFINEMENT FUSION AND INERTIAL FUSION ENERGY

Nuclear fusion—the process by which the nuclei of atoms such as deuterium or tritium combine to form a heavier nucleus, such as that of helium—can release a significant amount of energy. Fusion is the process by which energy is produced in the sun and, on a more human scale, is the one of the key processes involved in the detonation of a thermonuclear bomb.

If this process can be tamed to provide a controllable source of energy that can be converted to electricity—as the nuclear fission process is used in nuclear reactors—then it is possible that nuclear fusion could be a new way to produce low-carbon electricity to meet the growing energy needs of the United States and the world. However, this possibility is far from imminent, and a great deal of scientific and engineering work remains to be done before a commercial nuclear fusion plant can be demonstrated.

For inertial fusion to occur in a laboratory, heating of the fuel material (typically deuterium and tritium) must be confined to a small enough hot spot to overcome the Coulomb repulsion of the nuclei and allow fusion to initiate in a small region of the fuel (“ignition”). If successful, this process will release sufficient energy to sustain the fusion “burn” that will propagate through the fuel, generating a significant energy output. Two concepts are typically discussed for accomplishing

this confinement: (1) magnetic confinement fusion (MCF), in which magnetic fields are used to confine the plasma, and (2) ICF, the topic of the current report, in which a driver delivers energy to the surface of a pellet of fuel, heating and compressing it. Potential drivers include lasers, particle beams, and X-rays, among other concepts.

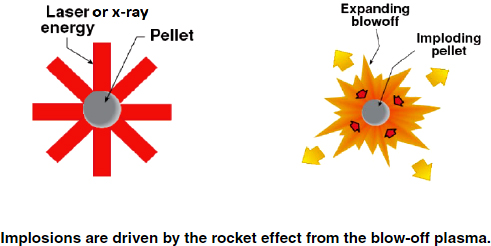

In ICF, energy supplied by the driver is applied, either directly or indirectly, to the outer layer of a fuel pellet that is typically made up of an ablator material (e.g., beryllium, doped plastic, or high-density carbon) that explodes outward as it heats. This outward explosion of the surface layer forces the remainder of the fuel (typically light elements such as deuterium and tritium) to accelerate inward to conserve momentum. The timing of the inward fuel acceleration is controlled carefully in order to compress the fuel using a minimum of energy. At the same time, sudden increases in the driver power profile both accelerate the implosion and send shock waves into the center of the fuel, heating it sufficiently that fusion reactions begin to occur.1

The goal of ICF is to initiate a self-sustaining process in which the energetic alpha particles emitted by the ongoing fusion reactions heat the surrounding fuel to the point where it also begins to undergo fusion reactions. The percentage of fuel that undergoes fusion is referred to as the “burn-up fraction.” The fuel gain G (defined as the ratio of the total energy released by the target to the driving beam energy impinging upon it) depends on the burn-up fraction, and gains greater than about 10 will need to be demonstrated to validate the target physics of any approach to a practical IFE power plant.

Important target physics includes processes that deflect or absorb driver energy within the target; the transport of energy within the target; capsule preheat; conversion of energy to the inward-directed implosion by ablation; fuel compression and heating; thermonuclear reactions; transport and deposition of neutron and alpha-particle energy, resulting in bootstrapping thermonuclear reactions; and hydrodynamic disassembly and output. Models exist for all of these processes, but some are more predictive than others. Some processes are difficult to simulate, such as laser-plasma interactions, the generation and transport of hot electrons in self-consistent magnetic fields, nonlocal-thermal-equilibrium atomic physics, hydrodynamic instabilities, mix, and debris generation. These models continue to evolve to keep pace with experiments. Other processes, such as large-scale hydrodynamics, thermonuclear reactions, and X-ray-, neutron- and alpha-particle transport appear to be simulated adequately using standard numerical models.

The Department of Energy (DOE) is funding multiple efforts to investigate the physics of ICF; many of these efforts have the potential to inform current

__________________

1 What is described here is known as hot-spot ignition; other potential concepts for ignition are being considered and are introduced briefly later in this chapter.

understanding of the prospects for IFE. Over the next several years, experiments will be ongoing at the National Ignition Facility (NIF) at Lawrence Livermore National Laboratory (LLNL) that are aimed at achieving ICF ignition. At the same time, experiments such as those at the University of Rochester’s Laboratory for Laser Energetics, the Naval Research Laboratory, Lawrence Berkeley Laboratory, and Sandia National Laboratories continue to advance our understanding and control of ICF using different technology and physics approaches. However, it should be recognized that up to this point, the majority of the funding and efforts related to ICF target physics are provided by—and related to—the U.S. nuclear weapons program and its stockpile stewardship efforts and are not directly aimed at energy applications.

DOE’s Centurion-Halite program revolved around a series of underground experiments conducted in the 1980s in which target capsules were driven by the energy from nuclear explosions. Additional discussion of the program is provided in classified Appendix D.

BASICS OF ICF TARGET PHYSICS AND DESIGN

Target Design: Direct and Indirect Drive, Z-Pinch

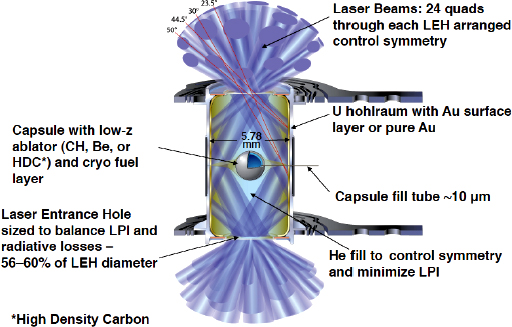

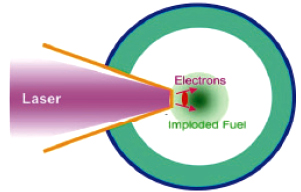

There are two major concepts for ICF target design: direct-drive targets, in which the driver energy (e.g., in the form of laser beams, particle beams, or magnetic field pressure) directly strikes the fuel capsule (see Figure 2-1); and indirect-drive targets, in which the driver energy first strikes a hollow chamber (a “hohlraum”) surrounding the fuel capsule, producing energetic X-rays that compress the fuel capsule (see Figure 2-2). Conventional direct and indirect drive share many key physics issues, such as energy coupling, the need for driver uniformity, and hydrodynamic instabilities; however, there are issues that are unique to each concept.

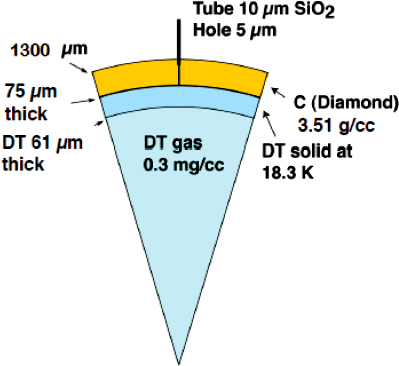

Generally, the elements of the fuel capsule are similar for direct drive and indirect drive, at least with respect to laser drivers. Fuel capsules are typically spherical, with several layers: an outer ablator layer; a layer of cryogenic frozen fuel; and a center of gaseous fuel, typically deuterium-tritium (DT). A sample fuel capsule is shown in Figure 2-3.

Several of the key differences between direct drive and indirect drive for ICF are discussed briefly in the sections that follow.

Direct Drive

Direct-drive concepts for ICF using laser drivers are currently being researched at the University of Rochester’s Laboratory for Laser Energetics (LLE) and the Naval Research Laboratory (NRL). Concepts using heavy-ion beam drivers are being

FIGURE 2-1 In the case of direct drive, the fuel pellet is illuminated symmetrically by the driver energy, resulting in implosion. SOURCE: R. Betti, University of Rochester, “Tutorial on the Physics of Inertial Confinement Fusion,” presentation to the NRC IFE committee on April 22, 2011.

FIGURE 2-2 In the case of indirect drive, driver energy incident on a hohlraum is converted to X-rays, which then impinge symmetrically on the fuel capsule, causing it to implode. This figure shows the laser beam geometry used in the National Ignition Campaign (NIC) at LLNL. LEH, laser entrance hole; LPI, laser-plasma interactions; HDC, high-density carbon. SOURCE: J. Lindl, LLNL, “The National Ignition Campaign on NIF and Its Extension to Targets for IFE,” presentation to the panel on February 16, 2011.

FIGURE 2-3 Section of a spherical fuel capsule design showing the ablator layer (in this case pure carbon), a layer of DT ice, and an inner core of DT gas. SOURCE: J. Lindl, LLNL, “The National Ignition Campaign on NIF and Its Extension to Targets for IFE,” presentation to the panel on February 16, 2011.

studied at Lawrence Berkeley National Laboratory (LBNL), and Sandia National Laboratories (SNL) is developing direct-drive concepts for pulsed-power drivers.

The major benefit of direct-drive target design is the calculated potential for higher energy gain than indirect drive. This relatively large gain is in large part due to avoiding the losses that occur during the conversion of laser beams or particle beams to X-rays in the hohlraum, discussed in detail in the next section. Avoiding these losses results in a higher percentage of driver energy absorbed by the capsule in direct drive, increasing the efficiency and potentially decreasing the size of the driver required.

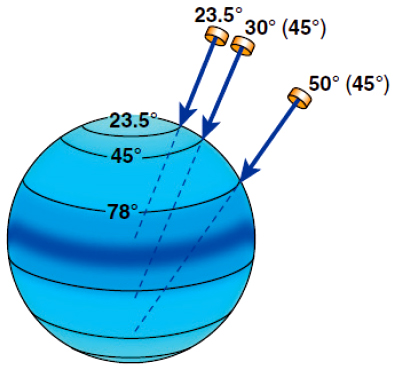

Polar direct drive is a variant of the spherically symmetric, direct-drive illumination geometry shown in Figure 2-1. As shown in Figure 2-4, the driver beams are clustered in one or two rings at opposing poles. To increase the uniformity of the drive, polar drive beams strike the capsule obliquely, and the driver energy is biased in favor of the more equatorial beams. Although the polar illumination geometry is consequently less efficient than the spherically symmetric geometry, it is more compatible with the current NIF configuration.

FIGURE 2-4 In the polar direct-drive illumination geometry, the driver beams are incident from directions above and below the fuel capsule but not near the equator. SOURCE: R. L. McCrory, University of Rochester, “Laser-Driven Inertial Fusion Energy: Direct-Drive Targets Overview,” presentation to the panel on February 16, 2011.

Since the 1980s, there has been an ongoing effort in laser science that has focused on improving the performance of direct-drive laser systems for both solid-state and KrF lasers. For solid-state lasers, these advances include frequency tripling (for improved energy coupling and lower instability growth rates), smoothing by spectral dispersion (SSD), and polarization smoothing, to reduce imprinting of beam nonuniformities on the target. Recently LLE developed SSD with multiple phase-modulation frequencies (Multi-FM) and proposed using this technique to modify the NIF for polar direct drive.

High-energy KrF lasers were developed to utilize the deep ultraviolet (248 nm) wavelength of the system. Induced spatial incoherence (ISI) was developed to smooth the beams, and recently focal zooming2 was demonstrated to improve the efficiency of coupling the laser with imploding targets. Direct-drive target experiments on the OMEGA laser have shown steady improvement toward theoretical

__________________

2 Zooming involves reducing the driver spot size to match the diameter of the imploding capsule, thereby increasing the efficiency of energy coupling between driver and target.

yield limits by combining a large number (60) of laser beams, better laser beam smoothing techniques, and improved beam pointing and target placement at the target chamber center. Although historically much of the discussion of direct-drive fusion has involved laser drivers (e.g., LLE’s work at the OMEGA laser facility and the Nike KrF laser experiments at NRL), direct-drive ICF has potential for use with other drivers. In particular, the panel was briefed on direct-drive targets by members of the LBNL heavy-ion driver program.

However, there are difficulties involved in using direct-drive fusion. A direct-drive capsule must tolerate four major sources of perturbations to ignite and burn: drive asymmetry, inhomogeneous capsule surface finish, ice roughness in the layer between the cryogenic DT and the DT gas; and driver imprint.3 The effects of the driver imprint and drive asymmetry are reduced for indirect drive. In addition, without a hohlraum to protect the capsule from the high temperatures in the chamber, and if there is no buffer gas to protect the chamber walls from emitted alpha particles, alternative methods must be found to address these threats.

Indirect Drive

As shown in Figure 2-2, indirect drive (whether using laser drivers or an alternative driver, such as heavy-ion beams) consists of driver beams entering a hohlraum, which is essentially a hollow cylinder, typically made of gold, or oblong capsule with (in the case of laser drivers) openings on either end. LLNL is currently leading research into indirect-drive concepts for laser-driven ICF at the NIF. The driver beams are directed to enter the openings on either end of the hohlraum and strike the interior of the hohlraum in four circular arrays, two near the center, and two nearer the ends (see Figure 2-2). The energy deposited by the laser beams on the interior of the hohlraum produces a hot plasma that radiates primarily in X-rays at a temperature of about 300 eV, or 3.3 million K. These X-rays are then absorbed by the capsule, resulting in implosion.

A virtue of the hohlraum in an actual IFE target is that it functions as a thermal shroud to protect the integrity of the cryogenic fuel capsule inside the target. This allows the target chamber to contain an inert gas (xenon) at low pressure to help protect the walls of the target chamber from X-rays emitted by high-Z materials in the exploding target.

__________________

3 For laser drivers, driver imprint occurs early in time when the target ablator is cold and dense. It is related to the asymmetries from modulations in individual laser beams (short wavelength) and perturbations from overlapping drive beams or by beams with slightly differing arrival times and angles of incidence (longer wavelength).

Benefits of Indirect Drive for Smoothing

Spatial nonuniformities at any scale can significantly increase the deviation of the actual implosion of an inertial fusion capsule from the conditions it was designed to achieve, with the result that the conditions inside the imploded capsule lie in a less favorable location in thermodynamic phase space than intended. Indirect drive of laser targets was conceived and developed to eliminate the effects of nonuniformities within each laser beam delivered to the target chamber.

The smoothing obtained through the use of indirect drive is a consequence of transforming the energy of each laser from a focused beam into thermal radiation. Any nonuniformity in a laser beam entering an indirect-drive target chamber transfers to the wall of the hohlraum enclosing the target, heating its material to a heterogeneous plasma. This heterogeneity is somewhat smoothed by energy transport processes within the radiating plasma itself, but a stronger smoothing effect occurs because the X-rays originating in each localized mass of plasma affect the entire portion of the target capsule surface to which it has a direct line of sight. The result is that localized variations in X-ray emission are averaged over the capsule surface, and rapid changes of drive conditions over the surface of the capsule are eliminated.

The development and use of indirect drive was the primary focus of LLNL on the 10-beam NOVA laser. This experience led to the development of the NIF indirect-drive configuration, which is much more sophisticated, using 192 laser beams in inner and outer clusters to control symmetry and pulse shape (see Figure 2-2).

Although the capsule absorption of X-rays is more efficient than the direct absorption of laser light in direct-drive fusion, enough energy is lost in the heating of the hohlraum to significantly reduce the efficiency of indirect-drive fusion relative to direct-drive fusion. This results in lower calculated potential gains for indirect-drive fusion targets.

As with direct drive, although its primary development historically has been with laser drivers, indirect drive has been used in IFE system designs with other drivers (e.g., heavy ions and early Z-pinch schemes). The key is to deposit enough energy on the inner surface of the hohlraum to produce a hot plasma that radiates thermal X-rays.

One of the key reasons that indirect-drive targets were developed is that ICF can model on a laboratory scale some aspects of a thermonuclear explosion. This is highly useful for the applications of ICF at the NIF at LLNL that are related to the long-term stewardship of the U.S. nuclear stockpile. This motivation has been a key aspect in the development of the indirect-drive approach for IFE, since one could leverage insights from better-funded weapons programs for the less well funded energy programs. However, there remains debate about whether this

provides significant benefits for energy generation using ICF, and some argue that the indirect-drive approach—if commercialized and distributed overseas—could increase the risk that nuclear weapons knowledge and information will proliferate. This topic is analyzed in more detail in the classified Appendix E and in Chapter 3.

Z-Pinch Target

In recent ICF and IFE studies, Z-pinch targets are imploded by the pressure of ultrahigh magnetic fields generated by high currents (e.g., 20-60 MA for ~100 ns) provided by pulsed-power generators rather than by the ablation pressure generated by illuminating a capsule with a high-power laser. While laser fusion capsules are typically spherical shells, Z-pinch targets are typically conducting cylindrical shells containing DT fuel. Because magnetic field strength increases inversely with the radius of the conductor in which the current flows (I/r), as long as the driver has the appropriate electrical characteristics to deliver current to the increasingly high-inductance target, the magnetic pressure (proportional to B2) continues to grow, accelerating the cylindrical implosion and compressing the fuel. For appropriate design conditions, the DT fuel can be heated to sufficient temperature to initiate fusion reactions and compressed to sufficient areal density (bulk density ñ times fuel radius r) to trap emitted alpha particles and initiate bootstrap heating.

Physics of Different Types of Ignition

Hot-Spot Ignition

Hot-spot ignition, described briefly earlier in this chapter, is the most commonly discussed and best understood method for achieving ignition. Hot-spot ignition refers to the creation of a small central mass of fuel that is heated to temperatures sufficient to begin efficient thermonuclear burn (~10 keV), surrounded by a larger mass of dense but colder fuel that has sufficient areal density (>300 mg/cm2) to trap alpha particles and initiate bootstrap heating.4

The primary reason for utilizing hot-spot ignition is to minimize the driver energy requirements. Heating fuel to 10 keV is energy-intensive, so the goal is to use the driver energy to launch a series of shocks that simultaneously coalesce and heat only a small central mass to fusion temperatures, while quasi-isentropically compressing the main fuel mass as close to the Fermi-degenerate limit (the minimum energy state for high-density matter) as possible. The energy deposited by fusion alpha particles rapidly heats the cold, dense main fuel, causing it to reach

__________________

4 R.L. McCrory, University of Rochester, “Laser-Driven Inertial Fusion Energy: Direct-Drive Targets Overview,” presentation to the panel on February 16, 2011.

thermonuclear burn conditions. The fusion burn terminates when the rapidly heated fuel mass overcomes the inertia of implosion and explodes to lower densities and temperatures where fusion reaction rates rapidly decrease (hence the term “inertial confinement”).

In order to use minimum driver energy, it is important to compress most of the fuel near the Fermi-degenerate adiabat. At least four laser pulses are required to provide the compression energy in a time-dependent fashion that is consistent with this goal. More, smaller pulses—or even a continuous power profile—could also be used, but the four-pulse system is the easiest to control and observe experimentally.

Fast Ignition

In FI, ignition is separated from the compression phase. The fuel is compressed (using lasers or another driver) at a lower velocity than in hot-spot ignition. The goal is to create a fuel mass that has at least the 300 mg/cm2 areal density required to capture alpha particles, but not the DT temperature to initiate fusion burn. The energy to ignite a small portion of this compressed fuel is provided by a high-intensity, ultrashort-pulse laser. For the correct conditions, the thermonuclear burn propagates from this heated fuel volume into the rest of the cold, imploded fuel.

The leading approach to fast ignition uses a hollow cone of high-density material inserted into the fuel capsule so as to allow clean entry of this second laser beam to the compressed fuel assembly (see Figure 2-5). The principle of fast ignition was first demonstrated at the Institute of Laser Engineering in Osaka, Japan, in experiments performed on the Gekko-XII laser (Kodama et al., 2002).

FIGURE 2-5 In this version of fast ignition, a short, high-intensity laser pulse enters the cone of a cone-and-capsule assembly after the fuel capsule has been compressed by an earlier pulse, producing a pulse of hot electrons that initiate fusion. SOURCE: Juan Fernandez, LANL, “Inertial Confinement Fusion Targets at Los Alamos National Laboratory,” presentation to the panel, May 2011.

Shock Ignition

Shock ignition is yet another variant on the theme of slowing the main fuel implosion to minimize driver energy requirements, adding one more drive element to locally heat a limited quantity of fuel to thermonuclear burn conditions and then using alpha-particle deposition to propagate the burn wave into the assembled fuel mass. In shock ignition, rather than using a separate, high-intensity, ultrashort-pulse laser to heat the ignited volume, a short, high-intensity “spike” is added to the end of the main drive pulse shape to launch a very strong shock into the fuel. This inward-propagating shock collides with the outward-propagating shock constituted by the growing region of high-density fuel at the center, producing a spherical shell of fuel at a much higher temperature. The principle of shock ignition has been demonstrated in experiments on the OMEGA laser at LLE (Betti et al., 2007). Since the target has a smaller radius at the time that the high-intensity spike is required to launch the final shock, it is energetically advantageous if the laser optics can accommodate focal zooming or, alternatively, if the high-intensity spike can come from a separate set of lasers with smaller intrinsic spot size. An issue that arises with shock ignition is that the final, high-intensity spike exceeds the threshold for laser-plasma interactions, which can interfere with the desired effect (see further discussion in Chapter 4).

Z-Pinch Ignition

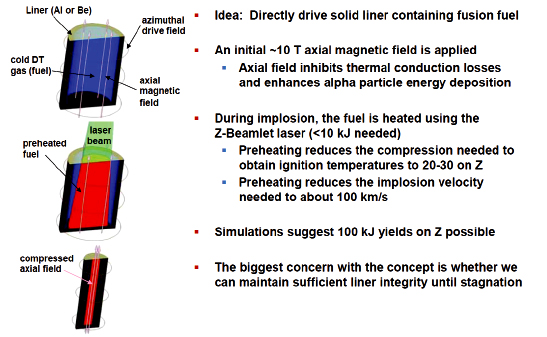

Z-pinch targets need to achieve the same overall fuel parameters—that is, sufficient temperature to initiate thermonuclear burn and area mass density to initiate alpha-particle bootstrap heating of the remaining fuel mass. Since the targets are typically cylindrical, the convergence is only two-dimensional and it is more difficult to meet the ρr criterion. Some target designs work on the hot-spot ignition principle, in which a small central mass is shock-heated to thermonuclear temperatures.

Alternatively, in magnetized-target fusion (MTF), the fuel mass is preheated by an energy source (e.g., a laser beam) to place it on a higher adiabat. Field coils are placed around the target to provide a seed magnetic field throughout the fuel volume. The magnetized, preheated fuel is then imploded at a lower implosion velocity than is used in hot-spot ignition to minimize driver energy requirements. The magnetic field is applied to inhibit fuel cooling during the slow implosion process (i.e., inhibit cross-field transport). The higher initial adiabat allows the magnetically insulated fuel to reach thermonuclear conditions at smaller convergence ratios. The principle of MTF has not yet been successfully demonstrated. MTF is normally considered more as an attempt to find an easier path to ignition rather than as a path to high yield and high gain, but recent numerical simulations

indicate that high-gain MTF is possible using cylindrical implosions with a cryogenic DT layer (Slutz and Vesey, 2012).

What Determines the Degree of Fuel Burn and Gain?

Fusion yield Y scales strongly with capsule absorbed energy (Y ~ E5/3), which implies there is a strong premium on efficiently delivering energy from the driver to the capsule. Energy must be absorbed symmetrically into the fuel to avoid instabilities. Each target design has different transport and deposition issues:

• Indirect drive (e.g., in the NIC at the NIF) requires transport of lasers through a background gas and delivery through laser entrance holes (LEHs) in the hohlraum (see Chapter 4). Most of the driver energy goes to heating the hohlraum wall and the dense plasma blown off the wall, so the process is inherently inefficient.

• Direct drive simplifies transport and focusing issues, but it is critical to avoid the generation of hot electrons (which cause fuel preheat) from laser-plasma interactions. This method is more efficient because it is direct, but symmetry and deposition physics are very important.

• Z-pinches require a direct electrical connection between driver and target through a recyclable transmission line (RTL). As the target implodes and the Z-pinch inductance increases, there may be potential loss regions. Because of the RTL, each shot requires the replacement of substantial structure.

• Heavy ions are charged particles that are susceptible to plasma instabilities when they are focused to the intensities required for ICF (>500 TW). Accelerators work best at low currents, so achieving a high power requires high particle energies, which makes their energy deposition range long. This complicates target design.

As noted above, fusion yield is calculated to scale as absorbed energy E5/3, so delivering more energy to the target results in significantly higher yield. For the same driver energy, direct drive delivers more energy to the fuel than does indirect drive. Implicit in this yield-scaling is the fact that the increasing fusion energy output comes from burning more fuel. Burning more fuel requires compressing more fuel to near Fermi-degenerate conditions, which requires more energy to be absorbed by the target. Since most of the fuel mass is in DT at solid (ice) density, more fuel mass means targets of larger radius. Larger target radius has the additional benefit that it increases the inertial confinement time of the fuel mass (determined by the imploded fuel radius divided by the sound speed) and increases the burn-up fraction of the DT fuel disassembly. The burn-up fraction depends on the areal density of the fuel capsule:

fb = ρr/(ρr + β(T))

where β(T) = 5.5-6.5 g/cm2 for optimal burn conditions. For a burn-up fraction greater than about 1/3, ρr must be greater than about 3 g/cm2.

All designs try to use driver energy efficiently; thus, they implode a cold mass of fuel isentropically and a small amount of fuel to high temperature—either by hot-spot ignition, fast ignition, or shock ignition. Instabilities can limit the propagation of burn from the ignition region to the remaining fuel. “Yield over clean” (YOC) is a measure of the deviation of experiments from ideal simulations.

Spectrum Output

The fusion reaction determines the initial partitioning of energy into alpha particles, X-rays, and neutrons. The spectrum of particles hitting the IFE target chamber wall is a function of the intervening materials, whether from the hohlraum, support structures (e.g., RTLs), or chamber fill gas.

Indirect-drive targets have high-Z materials in the hohlraum that emit copious X-ray radiation. Xenon gas can be used to absorb these X-rays and mitigate chamber wall damage (see Chapter 4). The xenon gas will get hot, but the hohlraum is believed capable of protecting the cryogenic fuel as it transits the chamber.

Direct drive usually assumes a vacuum in the target chamber, because the fuel pellet cannot be thermally insulated from a hot background gas. A shroud containing helium gas at low pressure and temperature has been considered, although it presents many difficulties. Even though the target is made of low-Z materials, there are still X-rays and ions that strike the wall and deposit their energy very locally. Magnetic diversion of ions is being considered in some designs to protect the chamber wall.

Z-pinch reactors would have yields above 1 GJ and RTL structures in the chamber.5 This can lead to debris and shrapnel. The RTLs also can contain substantial residual magnetic field energy, which needs to be accounted for in determining which particles hit the wall. Thick, Li-containing liquid walls can be used to protect the chamber surface from short-range ions, neutrons, and X-rays.

Heavy-ion driver concepts are tending to use liquid walls and perhaps background gases. There do not appear to be any unique or particularly challenging aspects to the heavy-ion output spectrum as compared with laser direct-drive or indirect-drive systems.

__________________

5 M. Cuneo et al., Sandia National Laboratories, “Pulsed Power IFE: Background, Phased R&D, and Roadmap,” presentation to the NRC IFE committee on April 1, 2011.

Target Injection and Fabrication

For energy to be produced in a fusion reactor, the target (which is the fuel source) will be obliterated. Thus, for IFE to produce a steady flow of energy, a steady supply of new targets must be introduced into the system. The more frequently the targets are introduced and converted into energy, the more power is produced; and similarly, the more energy that is available in each target, the more power is produced. It is the details of these targets, and how efficiently the energy is released, that distinguish the different concepts for IFE. These differences and technical challenges are discussed in detail in Chapter 4.

How frequently targets can be introduced into the fusion reactor (the repetition rate) is determined by engineering practicalities of each fusion concept. The repetition rate for the concepts discussed here varies from 0.1 to 20 Hz. These values are calculated estimates; the technical challenges of delivering targets into the fusion chamber at these rates with the required precision, while preserving the integrity of the target, has been—in the absence of a comprehensive IFE program—only superficially addressed. Specific engineering concepts will require comprehensive testing to determine whether the proposed repetition rates, and subsequent power production, are feasible. Equally important is to understand whether any degradation to the configuration of the target during this injection process could reduce fusion performance below the calculated performance.

Operating a fusion reactor at a repetition rate of 20 Hz will consume 1.728 million targets per day. No credible process for cost-effectively producing this number of targets has been developed. Current ICF experiments show that there is a technical path for manufacturing targets that meet critical specifications; whether this technical path is a viable method for mass-producing targets remains to be established. These considerations are discussed next.

Target Injection

For laser-driven IFE, the target injection process poses four challenges: accuracy and repeatability (both spatially and temporally) of target placement, ability to track the target, target survival, and clearing of the chamber. These challenges are discussed in the following paragraphs.

A necessary condition for achieving the optimal energy output from each target is that the target be uniformly compressed by the laser beams. This requires the target to arrive at the same point in space and at the same instant as the multiple laser beams. For the direct-drive target, the target must be within 20 µm (rms between the centerline of laser beamlets to the centerline of the target). Concepts developed

and tested as part of the High Average Power Laser (HAPL) program6 (see Box 4-2 in Chapter 4) showed that a surrogate target could be repeatedly placed within 10 mm of target chamber center, where a final engagement system does the final pointing. For the indirect-drive targets currently under development, the target is required to be within 100 µm of the focus of the laser beam,7 which appears to be within the capabilities of the system developed by the HAPL program; however, one difference between the direct- and indirect-drive approaches to fusion is that the indirect-drive approach has a higher gas pressure in the reactor chamber that may affect the repeatability of the injection process (Norimatsu et al., 2003). These are issues to be resolved in a technology development program.

The second challenge is the ability to track the target to make real-time, minor corrections to the pointing of the laser beams at the target. Here technical progress was achieved during the HAPL program by demonstrating the ability to track a target moving at 5 m/s and to steer beams in real time so as to engage it with ± 28 µm accuracy (Carlson et al., 2007). The system has been designed assuming an injection velocity of 50 m/s.

The third technical challenge is to preserve the target’s critical specifications until the moment of the implosion. The problems are significantly different in this case for direct- and indirect-drive targets. For indirect-drive targets, the surrounding hohlraum will provide thermal protection. However, laser access to the target is through thin membranes (<0.1 ìm thick) at each end of the hohlraum, and these holes will allow a sizeable heat load (both radiative and conductive) to be delivered to the target. The radiation portion of this heat load is reduced by the presence of internal shields within the hohlraum, which will also disrupt convective cells, but the conductive heat load is unaffected and the target’s temperature is calculated to rise ~85 mK, which is less than the 100 mK ceiling specified in one system design.8 The benefit of these structures to the target’s preservation is appreciable; however, this benefit comes at the cost of a complex structure that needs to be built to high precision, and this precision must be maintained during the acceleration loads that the target experiences when it is injected into the reactor. These loads to the target assembly have been calculated and are stated to be acceptable.9

For direct-drive targets, target survival is the major challenge. The exact heat load to the target is strongly dependent on engineering parameters such as the gas pressure in the reactor chamber, the time the target is inside and exposed to the environment, and the temperature of the reactor; heat fluxes in excess of 1 W/cm2

__________________

6 J. Sethian, Naval Research Laboratory, “The HAPL Program to Develop the Science and Technologies for Direct-Drive Laser Fusion Energy,” presentation to the panel on September 20, 2011.

7 M. Dunne, LLNL, “LIFE Target System Performance,” presentation to the panel on July 7, 2011.

8 Ibid.

9 Ibid.

to the target will compromise the target’s performance (Tillack et al., 2010; Bobeica, Ph.D. thesis; Bobeica et al., 2005).

Multiple strategies are envisioned for minimizing the heat load; two possibilities are to add protective layers to the outer surface of the target and to minimize the gas pressure in the reactor (Petzoldt et al., 2002). Testing such strategies is a critical step in determining the engineering feasibility of the laser direct-drive fusion energy option.

Finally, it is necessary to clear the chamber of debris between shots. In the past, there has been a tendency to minimize this problem because the other issues appear so much more daunting. However, new concepts, higher repetition rates (with incrementally more mass injected into the chamber per unit time), and the possibility of increasing the gas pressure in the reactor to improve the durability of the reactor structure (high gas pressure will reduce the X-ray and ion-induced damage to the chamber wall) complicate the process of clearing the chamber.

Concepts for injecting targets for pulsed-power fusion energy are radically different and less fully developed than their laser-driven fusion energy counterparts. The signature difference is that targets are consumed at a rate of 0.1 Hz and that the target is a more massive structure (up to 50 kg) that includes transmission lines that couple the power to the target.10 Removing spent targets and installing new targets will be done using automated machinery.11 While this process is conceptually feasible, there remain substantial engineering considerations that need to be resolved to determine whether this process can be completed within 10 seconds.

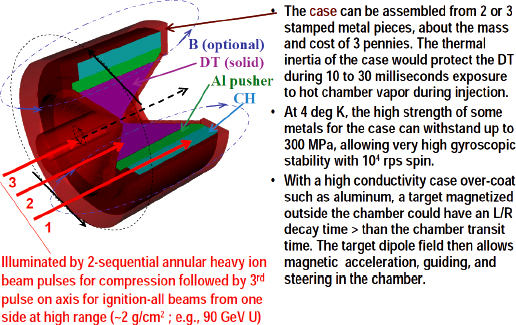

The heavy-ion fusion energy concepts originated as a variation of laser-driven concepts in which the driver energy is supplied by heavy ions accelerated by a linear accelerator. Subsequently, a variety of target-design concepts have been proposed: an indirect-drive design (3-4 GeV Bi+1); polar direct-drive design (3 GeV Hg+1); and a single-sided direct-drive configuration (90 GeV U+4).12 The target-design concepts use indirect-drive, direct-drive, and single-sided direct-drive configurations. The target injection challenges are similar for heavy-ion and laser-driven fusion: the indirect-drive target benefits from the thermal shielding provided by the hohlraum, while the direct-drive target remains vulnerable to the hostile environment of the reactor chamber. Beyond these commonalities with laser-driven fusion, no target injection concept specific to heavy-ion fusion has been proposed.

__________________

10 M. Herrmann, Sandia National Laboratories, “Z-pinch Target Physics,” presentation to the panel on February 17, 2011.

11 M. Cuneo et al., Sandia National Laboratories, “The Potential for a Z-pinch Fusion System for IFE,” presentation to the panel on May 10, 2011.

12 B.G. Logan, Lawrence Berkeley National Laboratory, “Heavy-Ion Target Design,” presentation to the panel on July 7, 2011.

Target Fabrication

Before the targets can be injected into the reaction chamber they must be fabricated to tight tolerances, which requires a well-understood and reliable process that is suitable for mass production. The mass fabrication challenges posed for the different types of targets vary significantly, although there are technologies common to many of the targets that will benefit all concepts for fusion energy. In this section, the key challenges are outlined for the production of these targets for laser drivers, pulsed-power drivers, and heavy-ion drivers.

Targets proposed for each of the fusion energy concepts have equal mixtures of deuterium and tritium as the fuel. This fuel is confined in a spherical capsule for the laser-driven concepts and most of the heavy-ion concepts or in a conical “X-target” (see Figure 2-6) or cylindrical structure (see Figure 2-7) for direct-drive heavy-ion fusion and pulsed-power fusion, respectively. Fabrication of the conical and cylindrical structures appears to be straightforward, though the exact specifications are not yet well defined or tested. Fabrication of the spherical capsules is complicated—partially owing to the design and partially owing to the tight tolerances and stringent specifications. Researchers making these targets for the ICF and the HAPL programs produced targets with specifications that are acceptable for the laser-driven fusion concepts; however, it remains to be demonstrated that the fabrication process can be scaled to satisfy the requirements of an IFE program.

FIGURE 2-6 The heavy-ion-driven “X-target” concept. B, magnetic field; CH, plastic. SOURCE: B. Grant Logan, LBNL, “Heavy-Ion Target Design,” presentation to the panel on July 7, 2011.

FIGURE 2-7 The cylindrical magnetized liner inertial fusion (MagLIF) target concept. SOURCE: S.A. Slutz, SNL, “Design and Simulation of Magnetized Liner Inertial Fusion Targets,” presentation to the panel on May 10, 2011. Top image adapted from S.A. Slutz et al., Pulsed-power-driven cylindrical liner implosions of laser preheated fuel magnetized with an axial field, Physics of Plasmas 17:056303 (2010).

Indirect-Drive Targets

The indirect-drive targets proposed for laser-driven IFE (e.g., in the LIFE point design) are a modification of the target currently used at the NIF. The fundamental design is the same: DT fuel is contained inside a capsule that is supported inside a hohlraum. However, there are differences in both the capsule and the hohlraum. The capsule is a bilayered structure with an outer layer of high-density carbon (diamond) and an inner layer of low-density hydrocarbon foam. The hohlraum is elliptical (rather than cylindrical as is the NIF target) and made from lead rather than gold. Additionally, internal membranes (“shine shields”) are introduced to prevent the capsule having a direct line of sight to the laser entrance holes in the hohlraum. The capsule is postulated to be manufacturable using a combination of microfluidic and vapor deposition techniques, and the DT fuel is added by drilling a hole 5 µ in diameter in the capsule and sealing it once the fuel is inserted. Cooling the target assembly liquifies the DT fuel, which is wicked into the foam layer to make a uniformly thick fuel layer. New technologies will be required to form the

foam layer inside an existing capsule, and those technologies need to be consistent with a credible mass-production process.

Direct-Drive Targets

The direct-drive target proposed for fusion energy bears a close resemblance to the direct-drive target that is proposed for experiments at the NIF.13 The fusion energy target is a spherical foam capsule that is slightly larger than the NIF direct-drive target. The outer surface of the foam capsule has a fully dense plastic overcoat (to retain the fuel) and a thin reflective metallic coating to reduce the radiative heat load to the ice. Additional outer layers may be needed to provide greater protection to the target when it is injected into the reactor chamber. The DT fuel is diffused into the plastic shell, and the target assembly is cooled to form the uniformly thick ice layer.

The manufacturing processes for both laser-driven target designs are scalable for mass production. However, it remains to be demonstrated that these processes can achieve the production yield required for a fusion plant given the specifications that are required. At this point, such processes are near14 but have not yet been proven for mass production. Any changes in the target design to improve the implosion physics (resulting from experiments at the NIF) are likely to be dimensional changes that can be easily accommodated by the existing manufacturing process instead of changes in configuration that would require new technologies.

Two of the targets designs that are proposed for the heavy-ion driven fusion concept use indirect- and direct-drive implosion symmetries, so the manufacturing challenges are the same as for laser-driven fusion targets. A third more recently proposed target design is a single-sided direct-drive concept where liquid DT fills an X-shaped volume (two cones joined at the apex; see Figure 2-6). No production method has been proposed, nor are any tolerances proposed for the design, although it appears this target will have similar constraints and technical challenges as the other targets.

The pulsed-power fusion energy targets are distinctly different from the other fusion energy targets. There are multiple designs; one is a cylinder made from beryllium and filled with cryogenic DT gas. This target will be straightforward to manufacture and is considerably less complex than the other target designs. However, the additional components that are needed to inject this target into a

__________________

13 P.B. Radha, University of Rochester, “Polar-Drive Target Design,” presentation to the panel on July 7, 2011.

14 J. Sethian, NRL, “The HAPL Program to Develop the Science and Technologies for Direct-Drive Laser Fusion Energy,” presentation to the panel on September 20, 2011, and M. Dunne, LLNL, “LIFE Target System Performance,” presentation to the panel on July 7, 2011.

pulsed-power fusion reactor must be better defined to fully evaluate the technological challenges to making the entire target assembly.15

Factors Most Likely to Determine the Cost of Targets

It is important to appreciate that the technologies for making most of the components of the targets exist already; targets are being successfully manufactured for the existing ICF program, and with a few exceptions, any changes to the target to adapt it for energy applications appear to be technically feasible.

Much of the cost of the ICF target today is due to the quality assurance process, in which each target must be thoroughly evaluated because the yield of acceptable targets is so low. Any future IFE technology program will need to evaluate whether current technologies can (1) produce a more consistent product and (2) maintain the high production yield when scaled to mass production.

The material and production costs for manufacturing the targets appear to be acceptable and will benefit from the economies of large-scale production if a viable process is developed. The costs for developing the manufacturing process and constructing the manufacturing facilities are less predictable, with the latter depending strongly on the former. However, these are one-time costs that when amortized over the number of targets that are produced during the projected lifetime of the plant will likely be a small component in the cost of each target.

A contributor to the cost of the target is the cost of the tritium fuel. Fusion energy has the appeal and requirement that tritium be bred in a reactor and be self-sustaining. Neutrons from the deuterium-tritium fusion process interact with a surrounding blanket of lithium/beryllium and produce proportional quantities of tritium. Once the plant is initially fueled with tritium, the cost of sustaining the fuel will be primarily the cost of extracting tritium from the by-products of the nuclear reaction and the cost of controlling the radiological hazards. (Deuterium, the other component of the fuel, is extracted from water.)

Tritium Inventory Considerations

A consideration for selecting a target production concept, and possibly even a fusion energy concept, is the amount of tritium that is required to maintain the power plant in constant operation. While tritium-breeding will allow a facility to be self-sustaining, the complexity of recovering tritium from the breeder and reactor-chamber effluent, and then refueling the targets, will scale with the complexity of the operation and amount of tritium in the facility.

__________________

15 S.A. Slutz, SNL, “Design and Simulation of Magnetized Liner Inertial Fusion Targets,” presentation to the panel on May 10, 2011.

Minimizing the amount of tritium in a power plant was an important consideration in designing the indirect- and drive-direct targets.16 More ambitious ideas were proposed for the indirect-drive concept that will require additional scientific and technical development to realize: drilling a hole in the target to add the fuel (and then resealing the hole) and achieving a uniformly thick fuel layer by suspending the fuel as a liquid within a foam layer. Combined, they would reduce the tritium inventory to less than 1 kg17 by recycling tritium through the facility in less than 8 hours. The first approach adds steps to the manufacturing process and should be technically feasible; the latter approach is also technically feasible, but it is unclear whether the liquid fuel can be cooled below its freezing point and still remain a liquid, which is what has to be done to achieve the gas density required in the capsule. If this is not possible, then an alternative and lengthier process is needed to form the ice layer, which would increase the tritium inventory.

Minimizing the tritium inventory was a less important consideration for developing the direct-drive target. In any case, target tritium inventory for the direct-drive targets is much higher than for the current indirect-drive configuration. About 10 times more tritium is present in this target than in the indirect-drive target. Additionally, tritium is diffused into the capsule instead of flowing through a hole, which takes 2 to 4 days because of the fragility of the target and the quantity of fuel that has to be added.18 The process for forming the ice layer adds about 12 hours to the production cycle, which is the same process that the indirect-drive concept will use if it is not possible to subcool the liquid layer sufficiently to achieve the desired gas density.

Two main contributors to the total tritium inventory of an IFE plant will be these:

• The amount of tritium that is trapped inside the target during the target assembly phases and

• The amount that is entrained in the tritium-breeding and recovery processes (from the gaseous effluent from the reaction chamber).

At this stage, there is insufficient information to know the optimum balance between these sources and whether the effort to minimize the amount of tritium in the target assembly process is worth the added manufacturing and technical complexities.

__________________

16 M. Dunne, LLNL, “LIFE Target System Performance,” presentation to the panel on July 7, 2011.

17 M. Dunne et al., LLNL, “Overview of the LIFE Power Plant,” presentation to the panel on April 6, 2011.

18 J. Sethian, Naval Research Laboratory, “The HAPL Program to Develop the Science and Technologies for Direct-Drive Laser Fusion Energy,” presentation to the panel on September 20, 2011.