LASER-DRIVEN, INDIRECT-DRIVE TARGETS

Current Status

No laser fusion target has yet achieved ignition or breakeven,1 but current understanding leaves open the possibility that given time, funding, and the existence of alternative design options with sufficient margin for ignition and a gain of one, ignition might eventually be achieved.

The current U.S. program aimed at achieving ignition, the National Ignition Campaign (NIC), lays out a path via laser indirect drive (ID), and significant progress has been made along that path, although not enough either to demonstrate success or to conclude that ignition cannot be achieved. It is the understanding of this panel that the current program plan anticipates a demonstration of ignition sometime after the beginning of FY2013, although the planning document scheduled that event for the end of FY2012. The closest Level 1 milestone as of this writing is to achieve, in FY2012, significant alpha-heating of a capsule’s fuel. The expected signature of such an event is the production of at least 1016 deuterium-tritium (DT)-equivalent neutrons. The significance of this milestone is that it would indicate that fusion bootstrapping of the ion temperature in the capsule fuel had occurred—a prerequisite to achieving fusion ignition and energy gain.

__________________

1 Breakeven occurs when fusion gain equals unity—that is, when the fusion energy released in a single explosion equals the energy applied to the target.

The NIC Rev 5.0 target is designed to operate using indirect drive of a frequency-tripled (3ω) laser to reduce the negative effects of laser-plasma interactions (LPI) (see Box 4-1).

Box 4-1

Laser-Plasma Interactions

In laser-driven inertial confinement fusion (ICF), the capsule implosion is driven by thermal pressure.1 Thus, the incident laser energy must be absorbed by matter and thermalized, either in the outer shell of the capsule (direct drive) or in the inner walls of the hohlraum (indirect drive), which become plasmas. The variety of LPI that take place when an intense laser pulse hits matter have been studied for more than 50 years; they have been a key limiting factor in laser ICF, and are still incompletely understood.

LPI that absorb and thermalize laser energy are desired. Undesirable, parasitic LPI include backscattering of laser light, which can result in loss of energy; cross-beam energy transfer among intersecting laser beams, which can lose energy or affect symmetry; acceleration of suprathermal “hot electrons,” which then can penetrate and preheat the capsule’s interior and limit later implosion; and filamentation, a self-focusing instability that can exacerbate other LPI.

LPI are worse at longer laser wavelengths, so all modern drivers currently operate in the “blue” (3ω Nb:YAG at 353 nm) or ultraviolet (KrF at 248 nm). Moreover, lasers can be modulated so as to substantially ameliorate parasitic LPI by spectral broadening, spatially incoherent filtering, and/or polarization diversity, and great progress has been made over several decades on all the main kinds of laser drivers on such beam smoothing.2 Since LPI are threshold effects, target designers attempt to keep laser intensities below the threshold of major harm. However, neither fundamental understanding nor simulation are good enough to do so a priori; well-diagnosed experiments remain essential for LPI control.3

LPI are currently important in the National Ignition Campaign (NIC) indirect-drive targets. Overall, backscattered light losses appear to be 10-15 percent of the incoming laser energy; however, the inner beams backscatter more because of their greater path length in the hohlraum plasma. Stimulated Raman scattering (SRS) of the inner beams appears to play a significant role in causing drive asymmetry and hohlraum temperature deficits.4 The asymmetry has been controlled by the use of cross-beam energy transfer mediated by Brillouin scattering, but fundamental understanding and simulation of this effect are incomplete, and its repeatability has not been established experimentally. Experiments so far are said to indicate that hot electrons are below the design threshold, but more diagnostics are needed, because hot electrons, if actually present, could explain the currently observed anomaly in capsule adiabat. Furthermore, other laser-produced sources of preheat, such as gold M-band emission, will require quantification in this new cross-beam environment.

Rapidly increasing computer performance has enabled LPI calculations that were unimaginable just 12 years ago, but full-scale National Ignition Facility (NIF) simulations remain beyond reach.5 The Lawrence Livermore National Laboratory (LLNL) typically performs single-or multiquad simulations using pF3D on the largest advanced simulation and computing (ASC) platforms. Improvements in hohlraum modeling have changed plasma conditions and the location of backscatter in LPI simulations, bringing them into better agreement with measurements. Recent simulations show that overlapping quads and spatial nonuniformities act to increase laser reflectivity. Simulations have suggested potential ways to mitigate the effect of overlap

beam intensity on SRS, including changing the hohlraum aspect ratio and changing the pointing of inner cone quads. Substantial computational and experimental resources are being devoted to LPI issues within the NIC.

LPI for direct-drive targets are under experimental and theoretical study at the Laboratory for Laser Energetics (University of Rochester) (LLE);6 the most important effect appears to be cross-beam energy transfer, which results in 20 percent energy losses in capsule experiments on OMEGA. The relatively short beam paths in coronal plasma suggest that other LPI, and hot electrons, may be controllable in the extrapolation to ignition targets for direct drive, though most of the key experiments remain to be done. However, the greater laser intensities needed for shock ignition may cause harmful LPI; this must be studied. OMEGA EP7 will be an important platform for studying direct-drive LPI issues at inertial fusion energy (IFE)-relevant plasma scale lengths. Naval Research Laboratory (NRL) is performing complementary LPI experiments at 248 nm on Nike.8 Two-plasmon decay experimental data seem to agree with thresholds calculated using simple plane-wave-based threshold formulas, confirming the classical wavelength scaling. In direct drive, the initial target aspect ratio can be modified to limit the intensity and mitigate LPI risk at the penalty of greater sensitivity to Rayleigh-Taylor hydroinstabilities.

Increased LPI intensity thresholds and greater hydrodynamic efficiency for short wavelengths should combine to give better overall stability in direct-drive implosions. The NRL baseline shock ignition target is above the two-plasmon decay threshold during compression (Liu and Rosenbluth, 1976). Extending the Nike laser to 20 kJ would provide a useful capability to study LPI and hydrodynamics at 248 nm in IFE-relevant scale-length plasmas and compare them with OMEGA extended performance and NIF data.

Plasma physics, including LPI, involves many degrees of freedom on a huge range of length scales; moreover, nonlocal propagation by electromagnetic fields and fast electrons are important. For these reasons, a priori simulation of a full-scale target will be impossible for the foreseeable future, although impressive simulations are now feasible for fundamental processes and small-scale regions. Future development of subgrid and mesoscale modeling on full-scale systems would help to understand the experiments and support better target design, but would require a large effort to create and perfect.

_________________

1 Radiation pressure of the laser light itself is too small by many orders of magnitude.

2 D. Montgomery, LANL, “Overview of Laser Plasma Instability Physics and LANL Understanding,” presentation to the panel on September 21, 2011.

3 M. Rosen, LLNL, “Understanding of LPI and Its Impact on Indirect Drive,” presentation to the panel on September 21, 2011.

4 Ibid.

5 D. Hinkel, LLNL, “State of the Art for LPI Simulation,” presentation to the panel on September 21, 2011.

6 D. Froula, LLE, “Laser-Plasma Interactions in Direct-Drive Implosions,” presentation to the panel on September 21, 2011.

7 OMEGA EP (extended performance) is an addition to OMEGA and extends the performance and capabilities of the OMEGA laser system. It provides pulses having multikilojoule energies, picosecond pulse widths, petawatt powers, and ultrahigh intensities exceeding 1020 W/cm2.

8 A. Schmitt, NRL, “Assessment of Understanding of LPI for Direct-Drive (KrF),” presentation to the panel on September 21, 2011.

Recent and Upcoming Work

Recent work on indirect-drive laser fusion has brought the NIC program to the point where it has transitioned from preparation for the actual ignition campaign to the campaign itself. The latter involves optimization of a set of parameterized characteristics of the target and laser system in order to achieve conditions under which ignition could be anticipated to occur; the development of these “tuning parameters” has itself been one of the areas of development, in part because most of the tuning campaigns will require the use of specially designed capsules to enable data acquisition of the type and accuracy needed for that specific campaign.

Four key input variables are to be optimized in the NIC tuning campaigns:

• The implosion adiabat (usually designated á), which strongly affects the resistance of the capsule to implosion;

• The implosion velocity V;

• The amount of capsule material involved in mixing across the single interface characteristic of this class of capsule designs, M; and

• The overall shape of the implosion, which is characterized by a dimensionless parameter S.

These tuning campaigns are expected to use what are termed “keyhole” targets, backlit gas capsules, “symcap” capsules, and reemission capsules. Ignition is neither expected nor desired in these types of capsules, although tritium-hydrogen-deuterium (THD) capsules, which are intended for use in many of the preignition integrated experiments, utilize the ignition design but incorporate less DT thermonuclear fuel in favor of the less reactive HD. The use of THD capsules is expected to allow collection of data with which to confirm or calibrate calculations of the nuclear performance of the optimized implosion system (laser pulse + hohlraum + capsule design). Calibration of the nuclear diagnostics is planned using capsules of the so-called “exploding pusher” design.

The work mentioned thus far has all been accomplished at the NIF facility at LLNL. Additional preparations for optimization and testing of ignition capsules have been carried out at other laser facilities, notably the OMEGA laser at the University of Rochester’s (LLE). One aspect of this work has investigated some of the problematic aspects of LPI. Experiments at LLE have also facilitated the development and porting of diagnostics to the NIF and have provided data on the operation of noncylindrical “rugby” hohlraums;2 experiments are

__________________

2 Rugby hohlraums are shaped not like a cylinder but like a rugby ball, with a wall having a tapered curve.

planned to provide similar data on the efficacy of “P2” laser entrance hole (LEH) shields.3

If ignition can be achieved on the NIF, target simulations presented to the panel suggest that optimization of the tuning parameters and increases in the driver energy could result in gains of between 50 and 100 at some future facility.

Evaluation and Discussion of Remaining R&D Challenges

It is too early in the experimental campaign to evaluate the performance of the NIC ignition target design. However, information already in hand does indicate some potential problem areas, which could become showstoppers. They are discussed individually below.

Implosion Velocity

Perhaps the most critical discrepancy is that the measured implosion velocity of nonoptimized capsules is ~10 percent lower than the calculated velocity, even early in the implosion. The fact that related quantities, such as capsule bang time, are likewise delayed compared to expectations confirms the interpretation of the velocity measurements. Possible explanations offered at the time the panel received its briefings are that the calibration of the hohlraum temperature measurement (Dante X-ray flux diagnostic) was incorrect, or that the opacity of the Ge dopant in the capsule wall (to reduce early-time heating of the interior portions of the capsule) was higher than expected. Plans are in place to explore these hypotheses by checking the calibration in question and testing capsules without that dopant for comparison.

The principal means available to increase the implosion velocity is to increase the laser drive energy. Greater drive energy would, however, also increase the preheating from LPI, which, as discussed below, does not appear to be well understood. A path forward is thus not guaranteed.

Implosion Symmetry

The panel was told that there are some concerns about early-time imprinting of drive asymmetries based on observations of reemission targets. Furthermore, the overall implosion symmetry of baseline targets was routinely more prolate

__________________

3 P2 refers to the type of departure from sphericity that the shields are intended to reduce. A nearly spherical shape with azimuthal symmetry is often represented mathematically using Legendre polynomials, and P2 is the standard means of referring to the second Legendre polynomial, which is needed to describe a shape that has been described as a “sausage.”

than predicted. Acceptable symmetry was obtained using interbeam energy transfer between outer and inner laser cones, but at present this process has not been successfully incorporated into the design simulations used to predict target performance. The consensus of the panel is that this situation may be a further indication of unknown LPI processes in the hohlraum or of other predictive inadequacies.

Mix

The prediction of mix across shocked interfaces and during convergent implosions has been a very active and controversial area of research in many technical communities for many years. Approximate simulations of mix are possible and are routinely included in some target simulations, but the calculated mix—and therefore its calculated effects—is recognized to be unreliable. Moreover, data to validate calculations of the consequences of mix are thus far unavailable. It is therefore planned to compensate for the effects of mix empirically—that is, it is planned to design and engineer for sufficient margin in ignition conditions and gain to compensate for whatever degradation the mix may cause.

The lack of a definitive, quantitative understanding of the origins and evolution of mixing has raised concerns that isolated bumps and defects in the capsule shell could give rise to spikes of wall material that would penetrate into the central fuel region. The potential for such an occurrence clearly is related to the precision of target fabrication; some target fabrication technology issues are discussed below.

Implosion Adiabat

Measurements indicate the existence of disparities between the calculated and actual adiabats on which NIF capsules implode. Some workers have postulated that the disparities are due to inaccuracies in tabulated plastic ablator (CH) release isentropes, but there appears to be no technical evidence to support this hypothesis.

LLNL briefings to the panel conveyed conviction that hot electron preheat from LPI in the NIF target has been adequately anticipated and that the implosion adiabat of the fuel can be managed by controlling shock heating. Nevertheless, the uncertainties concerning LPI processes within a target hohlraum (discussed below) and the strong sensitivity of a capsule’s gain to preheat make the understanding and management of a capsule’s implosion adiabat an area of concern to the panel.

Laser-Plasma Interactions

LPI diagnostics on an ID target assembly can only sample the small solid angle of light that is backscattered out of a hohlraum’s laser entrance holes. The processes occurring inside the hohlraum, including those that can produce hot electrons, are

difficult to observe. These circumstances significantly decrease the effectiveness of efforts to ascertain the adequacy of simulations of LPI.

Initial experiments on the OMEGA laser have shown disparities between modeling for both vacuum and gas-filled rugby hohlraums. Scattering of the inner beams entering a hohlraum is reported to be greater than predicted, providing specific evidence of simulation inadequacies.

Current simulations approximate LPI using inverse Bremsstrahlung energy deposition models in which the power balance of the beams is input by the user, although rad-hydro modeling has apparently been improved through the use of nonlocal electron transport models and detailed configuration analysis (DCA). Cross-beam transfer is estimated via analytic models. There is a fluid model for LPI, called PF3D, which includes approximate models of kinetic effects; the use of similar models might improve LPI simulations for laser fusion applications.

It appears to the panel that the current state of understanding and simulation capability of LPI presents a significant risk to both the NIC and the credibility of any indirect-drive IFE design concept, such as the Laser Inertial Fusion Energy (LIFE) initiative. The effects of LPI may be a central issue, contributing to observed disparities between measured and calculated implosion entropy, velocity, and shape in the NIC.

Capsule Fabrication

There is extensive experience in fabrication of NIC-style targets, and there is a high likelihood that the capsule and hohlraum system can be made to the desired specifications.

CONCLUSION 4-1: The national program to achieve ignition using indirect laser drive has several physics issues that must be resolved if it is to achieve ignition. At the time of this writing, the capsule/hohlraum performance in the experimental program, which is carried out at the NIF, has not achieved the compressions and neutron yields expected based on computer simulations. At present, these disparities are not well understood. While a number of hypotheses concerning the origins of the disparities have been put forth, it is apparent to the panel that the treatments of the detrimental effects of LPI in the target performance predictions are poorly validated and may be very inadequate. A much better understanding of LPI will be required of the ICF community.

CONCLUSION 4-2: Based on its analysis of the gaps in current understanding of target physics and the remaining disparities between simulations and experimental results, the panel assesses that ignition using laser indirect drive is not likely in the next several years.

The NIC plan—as the panel understands it—suggests that ignition is planned after the completion of a tuning program lasting 1-2 years that is presently under way and scheduled to conclude at the end of FY2012. While this success-oriented schedule remains possible, resolving the present issues and addressing any new challenges that might arise are likely to push the timetable for ignition to 2013-2014 or beyond.

CONCLUSION 4-3: Ignition of a laser-driven, indirect-drive capsule will provide opportunities for follow-up work to improve understanding of the potential for IFE.

• If ignition is achieved with indirect drive at the NIF, then an energy gain of 50-100 should be possible at a future facility. How high the gain at the NIF could be will be better understood by follow-on experiments once ignition is demonstrated. At this writing, there are too many unknowns to project a potential gain.

• Achieving ignition will validate the assumptions underlying theoretical predictions and simulations. This may allow a better appreciation of the sensitivities to parameters important to ignition.

USE OF LASER-DRIVEN, INDIRECT-DRIVE TARGETS IN A PROPOSED IFE SYSTEM

The proposed—and de facto—baseline model for a laser ID power plant is the LIFE initiative of LLNL. The discussions in this section are therefore based on that design as presented to the panel.

The current target design for LIFE was derived from the current baseline NIC design, with subtle but distinct differences. Modification was necessary to increase the calculated gain for IFE. Other modifications were to enable rapid, affordable fabrication in bulk, because the current plan for LIFE envisions firing approximately 1 million targets per day. The developers of LIFE plan to accommodate errors in the calculated target performance by adopting a design that is calculated to produce 125 percent of the gain for which LIFE was designed. The 25 percent surplus gain is viewed as a margin that would be eroded by the combined effects of inaccuracies in target design, fabrication, insertion, drive (shape, intensity, smoothing, and aiming), and LPI.

As discussed above, in evaluating the current NIC target, issues relating to the target implosion velocity, implosion symmetry, mix, the implosion adiabat, and LPI must be addressed. In spite of the modifications to the NIC target design that adapt it for use in LIFE, sufficient similarities persist that the preceding issues apply fully, unless and until optimization and other research conducted under

the NIC program lead to a favorable resolution of the underlying uncertainties. The differences between the NIC and LIFE targets also raise additional issues, as discussed below.

Modifications to Increase Gain

The design approach to increasing the gain of the IFE capsule stems from an approximate analytical expression in which capsule yield is proportional to Ecapsule5/3, where Ecapsule is the energy absorbed by the capsule. The strategy is to increase the implosion energy primarily by increasing the drive temperature in the target hohlraum. The drive temperature is increased by increasing the laser driver energy and decreasing losses. The laser energy is to be increased from a maximum energy of 1.8 MJ at the NIF to 2.2 MJ for LIFE.

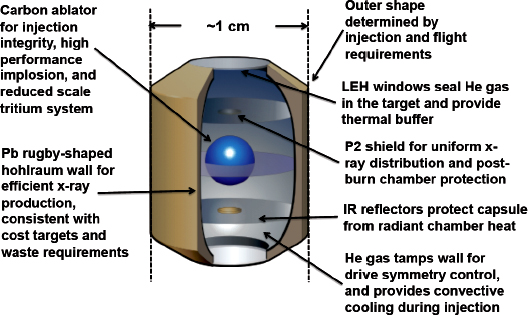

A hohlraum shaped like a rugby ball has been designed to more efficiently partition the drive energy; the redesign includes reducing the case-to-capsule diameter ratio to 2.0-2.4. The energy lost by reradiation from the hohlraum is to be reduced by the use of P2 LEH shields, and the conversion of absorbed energy to implosion energy is to be increased by using a high-density carbon (HDC) shell to increase the ablation efficiency. An illustration of the LIFE target design is shown in Figure 4-1.

FIGURE 4-1 The LIFE target design. Modifications from the NIC target design include the curved (“rugby”) inner wall of the hohlraum, the high-density carbon ablator, the LEH shields, and the P2 shine shields. SOURCE: M. Dunne, LLNL, presentation to the panel on July 7, 2011.

Modifications for Production Operation

The proposed manufacturing process of the LIFE target is a significant extension of the well-proven process for manufacturing targets for the NIC.

Capsule Fabrication

There is extensive experience in capsule fabrication, and it appears likely that the capsule can be made to the desired specifications. The technical challenges are (1) to demonstrate the formation of a uniformly thick, low-density (20 mg/cc) foam wall inside the diamond shell using a technique that is suitable for mass production and (2) to develop a cost-effective manufacturing process that can process more than 1 million targets per day through multiple steps where each target is individually handled. Proponents assert that automation can achieve the required throughput for an indeterminate capital and development cost; the bigger issue is whether the manufacturing can be done for the required per-item cost (estimated to be in the range of 20-40 cents).4

The method proposed for forming a uniformly thick fuel layer is a radical departure from the method used for making targets for the NIF. The reason for this new concept is to reduce the time required to form the fuel layer and thereby reduce the tritium inventory for the power plant. The design is for the fuel layer to be maintained as a supercooled liquid at a temperature sufficiently below the freezing point to achieve the required vapor pressure. The thickness uniformity of the fuel layer is expected to be provided by the 20 mg/cc CH foam wall, the interfacial liquid surface tension, and a controlled thermal profile along the surface of the hohlraum. This process has to be demonstrated. A critical technical milestone is to demonstrate that the DT liquid can be supercooled sufficiently to achieve the required vapor pressure, a property that has not been observed in cryogenic fluids.5 A second technical challenge will be to preserve the uniformity of the liquid fuel when the capsule is accelerated to a velocity of 250 m/s into the target chamber. The low mechanical stiffness of the low-density foam and the low viscosity of the liquid will make the uniformity of the fuel layer thickness susceptible to the high acceleration loads.

Neither of the traditional methods of introducing fuel into the capsule—a capsule fill tube or diffusion filling—is feasible for power plant targets. A method would have to be developed to seal the capsules with a plug of some appropriate material after filling them with DT.

__________________

4 D.T. Goodin, General Atomics, presentation to the main IFE committee on January 29, 2011.

5 Different IFE target designs exist for different methods of achieving compression. Only one target design proposes supercooled DT liquid. If this step turns out to be physically impossible, then alternative designs will be explored.

Hohlraum

The rapid capsule insertion necessary for a power plant will require structurally rigid support for the capsule and the LEH shields. The hohlraum-capsule structure is a delicate and intricate design with tight assembly tolerances on how precisely the capsule needs to be positioned inside the hohlraum. In addition, there are two internal shine shields that need to be positioned precisely inside the hohlraum using a low-mass support structure so that neither the thermal profile nor the X-ray radiation flux within the hohlraum is excessively perturbed. Further work is required to define a construction that meets these requirements and will also survive the high acceleration loads experienced when the assembly is injected into the target chamber.

The hohlraum walls in the LIFE design are to be of a lead alloy that is optimized for high opacity at the capsule drive temperature. Current hohlraums are constructed either entirely of gold, or of gold-plated uranium. The latter are impractical for a high production rate. As an example, a firing rate of 10 Hz translates to 8.6 × 105 capsules fired per day. With a hohlraum mass of 3 g, 2.6 metric tons of lead must be collected and recycled per day. Using lead rather than solid gold will reduce both the start-up cost and the security requirements for the crucial processes of hohlraum material recycling and target fabrication.

Evaluation

In evaluating the current NIC target, issues relating to the target implosion velocity, implosion symmetry, mix, the implosion adiabat, and LPI were discussed above. The modifications to the NIC target design that adapt it for use in LIFE leave it fully vulnerable to the issues surrounding the performance of the NIC capsule, unless and until optimization and other research conducted under the NIC program lead to a favorable resolution of the underlying issues. The differences between the NIC and LIFE targets and drives also raise additional issues, which are discussed below. This section on the LIFE design concludes with an evaluation of the robustness of the LIFE target design.

Modifications to Increase Gain

The credibility of the effectiveness of the target design changes from NIC to LIFE is directly related to obtaining and understanding the desired performance of the NIC Rev 5.0 design and understanding its operation. The seriousness of the issues discussed in this section can be expected to become more apparent as the ignition campaign unfolds. Many of these changes are scheduled for study on OMEGA, the NIF, or both.

Capsule Implosion

The system modifications to increase the capsule drive are primarily intended to increase the energy of the imploding capsule; the implosion velocity is one indicator of this energy. The planned increase in the energy of the LIFE lasers should provide the most direct means of increasing the energy of an imploded capsule. The outlook for carrying out this plan is clearly independent of the target design, but any compromise in achieving this energy goal could severely reduce the likelihood of achieving sufficient gain for a power plant to be feasible.

Calculations indicate that a redesign of the target hohlraum from the cylinder shape used thus far at the NIF to a rugby shape can increase the drive temperatures for the enclosed capsule. However, initial experiments on the OMEGA laser using this hohlraum shape have shown disparities between the expected and measured temperatures. This trend was observed for both evacuated and gas-filled hohlraums. The disparities are not well understood and could be caused by increased importance of missing models of laser-plasma interactions or by something as simple as inadequate zone resolution. Although independent codes are used at the various laboratories, they tend to have similar models. Until a better understanding of the disparities between modeling and experiments on rugby hohlraums is achieved, there will be concerns that the needed drive temperatures might not be obtained.

Data appropriate for validating calculations of the temperature distribution and history in a rugby hohlraum are not yet in hand. Aspects of the calculations needing validation include the behavior of hohlraums with Pb walls, the radiation flow and hydrodynamic effects of P2 LEH shields, and the radiation hydrodynamics of a target utilizing a case diameter:capsule diameter ratio between 2.0 and 2.4. Such data must be acquired to attain confidence in predictions of target operation for LIFE.

Mix

The HDC to be used in the LIFE outer shell is a more complex material than the CH it is replacing; it exhibits a microcrystalline structure and is described by a complicated phase diagram. Because three-dimensional, directional irregularities are intrinsic to a microcrystalline structure, the potential for HDC to affect the hydrodynamic stability of the capsule requires further study.

LPI

The modifications of the LEH and the addition of the P2 shields to the NIC hohlraum create the potential for the LPI issues discussed above to be exacerbated by the use of a rugby hohlraum. Some increased effect could also be expected from

the approximately 20 percent increase in laser power. The introduction of LEH shields with the rugby hohlraum may increase the mass of blown-off material in which LPI occur. Resulting changes in LPI phenomena may also change the implosion adiabat for the capsule.

Modifications for Production Operation

Target Fabrication

A target of this design has not yet been made, and new technologies will be required to make it. Only once the target is demonstrated to meet the specifications can the feasibility of mass-producing these targets for the desired cost be accurately assessed.

The plan to form the outer fuel layer of a LIFE target capsule by wicking liquid DT into a layer of nanoporous foam is a radical departure from the method used for making targets for the NIF. It will be necessary to demonstrate the formation of a uniformly thick, low-density (20 mg/cc) foam wall inside the HDC shell using a technique that is suitable for mass production. The efficacy of the planned smoothing mechanisms, as well as the ability to create and maintain the required thermal profile on the hohlraum through target insertion must also be demonstrated.

Other specific issues of concern include the need to eliminate the polishing step for the HDC shell and the significant length of time (approximately 2 days) involved for crucial manufacturing steps (chemical vapor deposition of the HDC and etching to remove the silicon mandrel) (Biener et al., 2009). The hohlraum-capsule structure is a delicate and intricate design with tight assembly tolerances on how precisely the capsule and two P2 LEH shields need to be positioned inside the hohlraum using low-mass support structures so that neither the thermal profile nor the X-ray radiation flux within the hohlraum is excessively perturbed. A construction method that meets these requirements is not yet available.

It would be important to the successful operation of the targets that the original specifications for the composition and uniformity of the lead mixture used to make the hohlraum walls be consistently maintained. The use of a “salted” Pb solution or alloy for the body of the target hohlraum would probably complicate the recycling process for that material. When it exits the reaction chamber, this material will have to be cycled through a full sequence of phases, proceeding rapidly from a solid to a plasma and then somewhat more slowly to a gas and a liquid. The composition of this liquid Pb mixture is unlikely to be uniform on the micron scale, and some portion of the other target components would also be present.

Whether fabrication to sufficiently tight specifications can be done for an acceptable per-item cost is an important question. It should be apparent from the discussion above that there are numerous technical challenges associated with

developing an effective fabrication technology. However, the fuel costs for an inertial fusion power plant are much larger than is typical for the power industry,6 so there is, financially, very little room for compromise. As currently envisioned, a viable technology must be capable of producing approximately 1 million targets a day through multiple steps in which each target is individually handled. Automation might achieve the required throughput by eliminating individual handling, but the associated capital and development costs are not known. The critical point from the standpoint of target design is that a compromise on any target specification or other aspect of fabrication quality would be likely to significantly reduce target gain.

Additional Considerations

The combination of extreme conditions that exist in a power plant reaction chamber and the very tight specifications that must be maintained for an IFE power plant to function result in an unusually tight coupling between the target design and some of what would typically be considered the separable engineering aspects of a power plant design. For the LIFE concept, the target insertion mechanism and the protection of the reaction chamber’s laser windows fall into this category.

Target Insertion

The target must be positioned precisely at the desired location and in the desired alignment at the specified instant in time to uniformly drive the implosion. Positioning tolerance within approximately 1 cm of the optimum position was demonstrated as part of the High Average Power Laser (HAPL) program (see Box 4-2) using a smaller target than the proposed LIFE target. However, the conditions of the HAPL demonstration did not include transport through hot Xe gas, which will be present in the LIFE chamber to help protect the walls. Turbulence in this gas due to the ~10 Hz firing rate is inevitable, and its effect on target positioning is currently unknown. The LIFE targets are to be inserted into the reaction chamber in a manner that is most reminiscent of a bullet, requiring an acceleration of 400-500 g to reach the required 250 m/s velocity. This acceleration places very great demands on the technology for target fabrication.

The nominally low-mass supports for the P2 LEH shields and for the capsule itself must survive target acceleration with a sufficiently predictable geometry that their position satisfies tight specifications. It is even more important that the geometry of the capsule layers be as designed at shot time. The low mechanical stiffness

__________________

6 The LIFE point design puts fuel costs at nearly 28 percent of the cost of electricity, about the same as the laser costs. From T. Anklam, LLNL, presention to the main IFE committee on January 31, 2011.

Box 4-2

Highlights of the High Average Power Laser Program

The goal of the HAPL program (FY1999-2009) was to pursue integrated development of science and technology for IFE that would be, to the extent possible, simple, durable, and affordable without sacrificing performance. The program featured parallel efforts on KrF and diode-pumped, solid-state lasers (DPSSLs). A high priority was placed on acquiring experimental data for both laser systems and technology concepts. The Sombrero Power Plant study (Sviatoslavsky et al., 1992) was used as a starting point.1

The HAPL program was based on laser-driven, direct-drive targets because of their potential for higher drive efficiency, simpler target fabrication, lower estimated cost, and smaller inventory for material recycling. Both conventional hot-spot ignition and shock ignition concepts were investigated. Predictions indicated that the drivers were equivalent for the conventional ignition and that the shorter-wavelength target produced higher gains for shock ignition. At the program goal of no more than 25 percent recirculating power, a combined driver target gain (hG) of 10 was needed, corresponding to a minimum target gain of 140 for a 7 percent efficient laser system (e.g., KrF). The HAPL program made significant progress in repetitive laser technologies for both diode-pumped Nd:glass and electron-beam-pumped KrF, demonstrating multihour runs at pulse rates from 5 to 10 Hz.

Research and development supported by the HAPL program included (1) calculations of neutron damage to optical ports and optics trains; (2) the development and successful testing of a new dielectric grazing incidence multilayer mirror for the first optical element of the laser system; (3) the development and demonstration of a method to mass-produce foam shells for target capsules; and (4) the development and demonstration of a cryogenic fluidized bed to make DT layers economically (the estimated cost of production was less than $0.17 each).

Target injection by both light-gas gun and magnetic slingshot was developed and tested. A method to improve capsule illumination accuracy detected the reflection (“glint”), from the moving capsule, of the light of a small laser to determine the target’s trajectory. Real-time adjustment of the laser mirrors enabled illumination that was within 28 µ of the ideal to be demonstrated.

_________________

1 An overview of the HAPL results is in Sethian et al., 2010.

of the low-density foam and the low viscosity of the DT liquid wicked into it may make it difficult to ensure a uniform thickness at shot time. These capabilities have not yet been demonstrated.

The HAPL program demonstrated active aiming of the drive laser that reduced its equivalent positioning error to 28 µ. The “glint” technique, in which the target capsule was illuminated during its trajectory through the essentially evacuated reaction chamber by a separate laser, utilized optical sensor location of the target by reflected laser light to determine the appropriate aim point. The firing rate in HAPL-sponsored tests was 5 Hz.

Successful translation of the glint technique to LIFE-style IFE would require that the target trajectory be sufficiently predictable to allow enough time to adjust

the directions of the laser beam cones. Should perturbations of the target trajectory increase to problematic levels as it neared its aim point (the center of the turbulent region), very rapid detection and aiming adjustments would be needed to meet the 100 µ-equivalent error requirement for the LIFE design. Orientation of an ID target is also important, unlike the spherical HAPL target capsule. The target insertion technique includes inducing a spin along the LEH axis to stabilize its orientation. Successful irradiation would require that a target’s angular momentum sufficiently overwhelm the effects of its hydrodynamic interaction with vorticity in the Xe fill of the reaction chamber that its orientation remains within acceptable bounds. Any second-order effects from also adjusting the aim of the laser beams are assumed here to be negligible. The difficulty of the other half of the glint technique—the illumination and detection of the target entering the reaction chamber—will be increased by the Xe fill. An assessment of this effect has not been presented to the panel.

Some unspecified portion of the gain margin calculated for the LIFE target has been allocated to compensating for nonoptimum insertion, but turbulence or other irregularities in the Xe gas through which the targets must pass could lead to sufficient inaccuracy not only to overwhelm that margin, but also to preclude capsule ignition. A key issue here is the repeatability of any phenomena that significantly perturb the target’s trajectory.

The LEH shields are themselves inside LEH windows that are needed in the LIFE concept to separate the reaction chamber Xe from the He inside the hohlraum. The LEH windows also represent an interface between the cold interior of the target and the prevailing conditions of the reaction chamber. Some fraction of any Pb plasma or vapor from previous capsules through which a target travels might be expected to condense on the LEH windows during insertion and could affect the irradiation of the hohlraum interior.

Lastly, the accelerations must not cause any portion of the supercooled DT to change phase. Significant solidification would break the HDC ablator shell, and isolated solidification would create density nonuniformities that would spoil the implosion, either directly or by seeding hydrodynamic instabilities.

Target Robustness

The Merriam-Webster online dictionary7 has several meanings for “robust,” one of which is pertinent to the current discussion: “capable of performing without failure under a wide range of conditions.” Robustness will be used in what follows to mean the quality of being robust according to this definition, with the regrettable caveat that the current state of the art limits an assessment’s tie to reality to relatively indirect data. A result of this limitation is that degrees of robustness

__________________

7 Available at www.merriam-webster.com.

actually indicate the assessed likelihood that a system can be made robust by actions and processes that are anticipated, proposed, or otherwise foreseeable, and, more fundamentally, the assessed likelihood that a system can be made to work at all.

Based on evaluations of the associated issues, the panel assesses the robustness of the physics design for the LIFE target concept to be low. The main factors leading to this assessment are the following:

• Ignition of a fusion target operating in the physics regime of laser-driven ICF has never been observed, but a robust design would have to reliably produce a large gain under much less controlled conditions than are normal in laboratory experiments. Moreover, the parameter space over which simulations predict adequate gain for the LIFE target capsule is relatively small, and the optimization of several parameters, an integral part of NIC, can be expected to further narrow the parameter space over which sufficient gain might be obtained;

• Significant departures from predicted operation have been observed on implosion experiments pertinent to the LIFE target design. These disparities, which were observed at both the NIF and the OMEGA lasers, relate directly to important aspects of target operation (e.g., implosion velocity), and the targets in which they were observed are the closest available analogues to the LIFE target. The discrepant data are important to the calibration or validation of the simulations on which predictions of the operation of the LIFE target are based, but tentative explanations of the disparities are at this time unsupported;

• To achieve the gain required for the LIFE plan to be viable, its target design incorporates modifications that are likely to further reduce the predictability of the target performance; and

• The outer, dense thermonuclear fuel region of the LIFE target is planned to be constructed of liquid DT wicked into low-density foam, but obtaining the gas pressure believed to be required for successful operation would require cooling the target capsule below the thermodynamic triple point for DT. The ability to create a LIFE target as currently designed therefore requires the existence of a physical phenomenon—the stabilization of a supercooled DT liquid in a low-density foam for an extended period of time—that has never been observed and for which there is no theoretical prediction.8

__________________

8 There are studies that suggest it is possible to supercool hydrogen isotopes and other fluids (see, for example, Beaudoin et al., 1996). It remains unclear whether this effect can be achieved in the nanoporous hydrocarbon foam material, and if the corresponding vapor pressure is the desired value.

CONCLUSION 4-4: The target design for a proposed indirect-drive inertial fusion energy system (the Laser Inertial Fusion Energy, or LIFE, program developed by LLNL) incorporates plausible solutions to many technical problems, but the panel assesses that the robustness of the physics design for the LIFE target concept is low.

• The proposed LIFE target presented to the panel has several modifications relative to the target currently used in the NIC (e.g., rugby hohlraums, shine shields, and HDC ablators), and the effects of these modifications may not be trivial. For this reason, R&D and validation steps would still be needed.

• There is no evidence to indicate that the margin in the calculated target gain ensures either its ignition or sufficient gain for the LIFE target. If ignition is assumed, then the gain margin briefed to the panel, which ranged from 25 percent to almost 60 percent when based on a calculation that used hohlraum and fuel materials characteristic of the NIC rather than the LIFE target, is unlikely to compensate for the phenomena relegated to it—for example, the effects of mix—under any but the most extremely favorable eventuality. In addition, the tight coupling of LIFE to what can be tested on the NIF constrains the potential design space for laser-driven, indirect-drive IFE.

SOLID-STATE-LASER-DRIVEN, DIRECT-DRIVE FUSION

Current Status

The leader in direct-drive inertial confinement fusion with solid-state lasers is the Laboratory for Laser Energetics (LLE) at the University of Rochester, which operates the OMEGA Laser Facility (OMEGA and OMEGA EP) for the National Nuclear Security Administration (NNSA). LLE is conducting research into direct-drive ICF targets that utilize either the hot-spot ignition concept used by the NIC capsule or one of the more recent two-step ignition concepts (fast or shock ignition). The 60-beam OMEGA laser system, which delivers >30 kJ of 3ω light on target with 1-2 percent irradiation nonuniformity, has been operating since 1995, is fully instrumented, and is capable of up to 1,500 shots/year. The OMEGA EP laser system, which adds four NIF-like beamlines (6.5 kJ at 3ω), was completed in April 2008 and can propagate to either the OMEGA or OMEGA EP target chamber. Two EP beams can be operated as a high-energy petawatt (2.6 kJ in the infrared in 10 ps) system.

The current ICF program is aimed at exploring, understanding, and quantifying the physics issues of direct-drive laser targets at OMEGA drive energies and

extrapolating the target performance to ignition and high-yield regimes. LLE has been routinely fielding cryogenic capsules since 2001 and has seen a steady improvement in implosion experiments as the quality of the ice layer and the centering of the target in the chamber have been improved. The flexible pulse-shaping capability of OMEGA enables the generation of multiple-picket pulse shapes that can drive ignition-scaled cryogenic DT implosions to ignition-relevant implosion velocities (3 × 107 cm/s) on a low adiabat (α ~ 2-39). The energies and relative timings of the three pickets and main pulse are adjusted to optimize the coalescence of four shocks to create a central hot spot, the same implosion strategy used at the NIF. Areal densities (ρr) up to 300 mg/cm2 have been measured using a magnetic recoil spectrometer in cryogenic DT implosions on OMEGA drive at ~8 × 1014 W/cm2 (Goncharov et al., 2010). The measured areal density in these experiments is larger than 88 percent of the predicted one-dimensional (1-D) value. The measured area mass density, ion temperature, and neutron yield can be combined with computed 1-D neutron yield to estimate the overall ignition parameter (![]() )10 for these experiments. These OMEGA cryogenic implosions have achieved an appreciable fraction (~3 percent) of the overall ignition parameter. The low inferred adiabats of these targets suggest that hot electron production from LPI and deposition into the fuel are within acceptable limits.

)10 for these experiments. These OMEGA cryogenic implosions have achieved an appreciable fraction (~3 percent) of the overall ignition parameter. The low inferred adiabats of these targets suggest that hot electron production from LPI and deposition into the fuel are within acceptable limits.

LLE has developed a 1 MJ symmetric, direct-drive NIF ignition design using a triple-picket pulse scaled to NIF laser parameters11 that has a 1-D gain of ~50. Because direct drive has higher implosion efficiency than indirect drive, it is calculated to produce higher target gains, which should lead to lower laser cost.

No existing solid-state laser system in a direct-drive configuration presently has sufficient energy to demonstrate ignition. A multilaboratory workshop was held in 2001 whose purpose was not to preclude direct drive on the NIF (Meyerhofer, 2001). It was also agreed that the change board process would be used to ensure that future modifications did not preclude direct drive on the NIF. However, it is not clear that the final assembly procedure strictly adhered to this principle.

Reconfiguring the NIF to symmetric direct drive geometry represents the lowest target physics risk but the highest facility cost, and it would disrupt weapons physics experiments using hohlraums. As an alternative, LLE has identified a so-called “polar drive” (PD) geometry that allows direct-drive target performance to be studied at lower facility cost and minimal disruption of other experiments but

__________________

9 α is a measure of the degree to which the actual adiabat of the implosion exceeds the ideal Fermi-degenerate adiabat (for which α = 1).

10 The ignition parameter is the energy that would have had to be absorbed by the target to produce ignition based on the other parameters achieved in the implosion—symmetry, density, and so on, as calculated in simulations.

11 This involves targets whose dimensions are scaled down from the ignition design due to the reduced energy on OMEGA relative to the NIF.

at the price of higher target physics risk. Calculations predict that by repointing the beams from the existing laser ports, a uniform target drive can be achieved with PD irradiation, assuming that the irradiation at the equator is compensated by increased laser intensity. The risk is that the oblique irradiation at the equator occurs at lower densities, which reduces laser absorption and hydroefficiency and requires lateral heat flow to the equator from nonradial beams (Skupsky et al., 2004). The NIF triple-picket PD design with expected nonuniformities and multiple phase-modulation frequencies (multi-FM) beam smoothing achieves a calculated two-dimensional (2-D) gain of 32.

LLE has identified five changes on the NIF that would implement a PD capability for an ignition demonstration. OMEGA EP can be used to test many of the modifications, including multi-FM 1-D SSD beam smoothing,12 and to validate laser performance. Advanced two-step ignition concepts such as shock ignition (SI) or fast ignition (FI) provide alternatives to conventional hot-spot ignition. If successful, these ignition options will open the path to high-gain ICF (G ~ 150) for ~1 MJ laser drivers (Perkins et al., 2009; Betti et al., 2006).

Fast ignition requires a combination of long-pulse (implosion) and short-pulse (FI) lasers. Aspects of FI both by electrons13 and protons14 were briefed to the panel. Integrated FI experiments have begun on OMEGA as part of the program of the Department of Energy (DOE) Office of Fusion Energy Sciences, which is studying the fast-electron coupling into a compressed core. The inferred laser-to-target heat coupling of ~3.5 percent needs to be increased significantly for FI to be a viable concept. Integrated simulations of electron-driven FI experiments are challenging and do not presently suggest ways of improving the target coupling. In principle, FI can also be achieved with protons accelerated by ultrashort-pulse lasers, which has the advantage of ballistic ion transport and sharper energy deposition. However, proton FI is hindered by lower laser conversion efficiency (~10 percent experimentally), a high intensity requirement (~1020 W/cm2), and a high proton-dose requirement (~1016 protons) that complicates target fabrication. Further, a more complicated capsule design is required if a reentrant cone is used to protect the proton-generation foil. Although there is international interest in FI (e.g., the Fast Ignition Realization Experiment (FIRE) project at ILE/Osaka and HiPER in the United Kingdom), funding is presently insufficient for FI to challenge the mainline

__________________

12 One-dimensional smoothing by spectral dispersion (SSD) with multiple phase-modulation frequencies (multi-FM) requires preconditioning the laser pulse with three high-frequency modulators to increase the bandwidth and is followed by a dispersion grating to increase the temporal skew. Multi-FM 1-D SSD has been optimized to provide the required beam smoothing to enable PD ignition. See Marozas et al., 2010.

13 D. Meyerhofer, LLE, “Fast and Shock Ignition Research,” presentation to the panel on July 6, 2011.

14 J. Fernandez, LANL, “Inertial Confinement Fusion (ICF) Targets at Los Alamos National Laboratory,” presentation to the panel on May 10, 2011.

programs on the NIF or the Laser Megajoule Facility (LMJ), which is under construction in France. Furthermore, the recently proposed concept of SI appears to be an easier and more attractive alternative to standard hot-spot ignition. SI utilizes a standard long-pulse laser beam with a pulse shape that provides a high-intensity spike at the end of the main drive pulse. The SI concept has been tested using CH shells on OMEGA. Higher areal densities (30 percent) and significantly higher neutron yields (~4×) were achieved with SI pulse shapes (Theobald et al., 2008).

Continued fundamental research into FI theory and experiments, the acceleration of electrons and ions by ultrashort-pulse lasers, and related high-intensity laser science is justified. However, issues related to low laser-target energy coupling, a complicated target design, and the existence of more promising concepts (such as SI), led the panel to the next conclusion on the relative priority of FI for fusion energy.

CONCLUSION 4-5: At this time, fast ignition appears to be a less promising approach for IFE than other ignition concepts.

Recent and Upcoming Work

The in-flight shell adiabat has been tuned by means of shock-velocity measurements using a variant of the NIF “key-hole target” (Boehly et al., 2011). Cross-beam energy transfer (CBET) has been identified as an issue that may be reducing laser energy absorption on OMEGA by 20 percent. Near-term experiments are planned to study mitigation strategies using modified phase-plate designs. Initial shock ignition designs for the NIF have 1-D gains of 70 at 680 kJ, with about half of that total energy in the shock generation pulse. PD diagnostic commissioning targets using existing ID phase plates are being imploded on the NIF (Cok et al., 2008).

LLE continues to demonstrate hydroequivalent scaling experiments on OMEGA to validate design codes that are then used for PD ignition calculations for the NIF. Upcoming experiments using targets with improved quality and reduced offset from the target chamber center are predicted to increase the ÷ from 3 percent of ignition to 5-6 percent, achieving the maximum credible performance for a 30-kJ driver.

LLE is developing a project execution plan (PEP) to demonstrate PD ignition on the NIF in 2017.

Evaluation and Discussion of Remaining R&D Challenges

Direct-drive, capsule-implosion data exist only at the 30 kJ level. The predicted hydroequivalent scaling requires validation at the MJ energy level, including issues of LPI, shock ignition at MJ energies, and symmetry. The modifications of the NIF for PD need to be developed and tested on OMEGA and deployed on the NIF. There

are target physics risks for polar drive that need to be studied. Further, there are target fabrication, injection, and survival issues that are specific to the direct-drive approach. Specific issues are discussed individually below.

LPI

The larger energies for ignition targets are achieved through longer laser pulses, which result in long-scale-length plasmas that are more susceptible to LPI. There is a need to study and demonstrate acceptable laser energy deposition and hot electron production for ignition-scale plasmas. Relevant experiments can be done on OMEGA EP, which has NIF long-pulse beam lines. In particular, planar two-plasmon decay (TPD) experiments can quantify the hot electron production by collecting all electrons.

There are critical uncertainties in extrapolating TPD physics in planar geometry to the oblique irradiation geometry of the equatorial beams for NIF PD. Integrated TPD experiments on OMEGA will be very important in quantifying the production and deposition of hot-electron energy.

The plasma physics community requires a better understanding of CBET, including better theory and modeling, additional measurements, and tests of potential mitigation techniques.

The ability to model underdense plasma conditions is important for understanding LPI, since most LPI depend exponentially on electron density and temperature. Continued development of these models—including the effects of nonlocal transport—is important, especially for PD beam geometries.

Shock Ignition

Fully integrated 2-D point designs for the NIF PD shock ignition targets are required in order to plan for experimental campaigns on the NIF. Experiments need to continue on OMEGA to identify whether there are any LPI issues that are unique to the SI approach, especially in PD geometries. Experiments need to be done on OMEGA and later on the NIF to determine whether the hot-electron production by the high-intensity spike is acceptable for high-gain target performance. Calculations and experiments need to be performed to study the implementation of shock ignition pulses, including the trade-offs among laser beam parameters, illumination symmetry, and SI performance.

Symmetry

It remains to be seen whether sufficiently smooth laser beams can be created on the NIF to allow direct drive experiments, particularly in the PD geometry. Pointing errors and nonradial deposition geometries could lead to low-mode symmetry errors. Insufficient beam smoothing could lead to high-mode asymmetries. Symmetry issues related to providing both normal and high-intensity beams to illuminate SI targets need to be investigated, including calculations and experiments in PD geometry.

Reconfiguring the NIF for Polar Drive

These steps need to be taken to enable polar drive experiments on the NIF:

• Demonstrate new multi-FM 1-D SSD beam smoothing technique and validate on OMEGA EP.

• Design and demonstrate tailored phase plates to increase equatorial beam coupling.

• Design and demonstrate polarization smoothing for OMEGA EP to reduce focal-spot irradiance modulation. Design and demonstrate distributed polarization rotators (DPRs) that are sufficient to achieve polar-drive ignition on the NIF.

• Demonstrate integrated NIF PD beam smoothing on OMEGA EP.

• Complete development of a NIF fill-tube target that meets polar-drive ice layer specifications.

• Complete development of concepts for a PD ignition target insertion cryostat.

Polar-Drive Physics

Understanding of the following areas of polar-drive target physics need to be improved:

• Deposition in low-density plasma by oblique beams at equator, including three-dimensional (3-D) laser ray trace algorithms that are compatible with PD geometry.

• Ability of laser to deliver increased intensity to equatorial beams.

• Nonlocal transport and heat conduction for nonradial beams; this may require extensions to existing theory and algorithms.

• Possible LPI issues unique to PD illumination geometry; e.g., CBET between overlapping beams.

CONCLUSION 4-6: The prospects for ignition using laser direct drive have improved enough that it is now a plausible alternative to laser indirect drive for achieving ignition and for generating energy.

• The main concern with laser direct drive has been the difficulty of achieving the symmetry required to drive such targets. Advances in beam-smoothing and pulse-shaping appear to have lessened the risks of asymmetries. This assessment is supported by data from capsule implosions (performed at the University of Rochester’s OMEGA laser), but it is limited by the relatively low drive energy of the implosion experiments that have thus far been possible. Because of this, the panel’s assessment of laser-driven, direct drive targets is not qualitatively equivalent to that of laser-driven, indirect-drive targets.

• Further evaluation of the potential of laser direct-drive targets for IFE will require experiments at drive energies much closer to the ignition scale.

• Capsule implosions on OMEGA have established an initial scaling point that indicates the potential of direct-drive laser targets for ignition and high yield.

• Polar direct-drive targets will require testing on the NIF.

• Demonstration of polar-drive ignition on the NIF will be an important step toward an IFE program.

• If a program existed to reconfigure the NIF for polar drive, direct-drive experiments that address the ignition scale could be performed as early as 2017.

Potential for Use in an IFE System

If ignition and high yield can be demonstrated for DD targets, the higher target gain translates into greater system efficiency and lower laser energy (size). The even higher predicted gains of shock ignition targets make this DD concept very attractive. Shock ignition is not an option for ID targets because of the inherent integrating nature of the hohlraum, which limits the ability to spike the temperature drive.

Demonstrating PD ignition on the NIF is an important step toward an IFE program. This should include experiments to explore the performance of shock ignition targets on the NIF.

To date, the LLE ICF program has been focused on the development of laser-beam-smoothing technologies and single-shot ICF target physics experiments, which is the appropriate scope of the NNSA program. With the exception of some work in developing mass-production techniques for fabricating cryogenic DD targets and studying their survival in IFE-relevant thermal environments, LLE has not conducted research into either repetitive solid-state laser technologies or the host of issues associated with an IFE power plant. Through the HAPL program, LLNL has

been the lead laboratory in developing repetitive solid-state lasers (DPSSL technology). Similarly, through the HAPL program, the Naval Research Laboratory (NRL) has supported the study of many of the technology and material issues related to the operation of a DD power plant. This suggests that there are opportunities for teaming among LLE, LLNL, and NRL if an IFE program is established to explore the potential of a DD fusion power plant with solid-state lasers. Further, LLE has much to contribute in target physics and target fabrication if KrF lasers prove more attractive as the laser driver in a DD power plant.

Additional Considerations

Target Injection

A key issue here is the repeatability of any phenomena that significantly perturb the target’s trajectory.

Survival of Cryogenic Target

LLE has been studying the survival of cryogenic DD targets via complete Monte Carlo and computational fluid dynamics modeling of heat load to the target and its effect on the ice during injection into the chamber. These calculations will be supplemented by experiments in a surrogate IFE chamber. This issue was also addressed in the HAPL program, but more study is needed.

Reactor Chamber Issues

Most direct-drive IFE schemes are predicated on a dry-wall concept and an evacuated chamber. A host of structural and material issues need to be addressed. The HAPL program supported initial research in most of these areas, but much more work will be required before a power plant design can be completed. The HAPL final optic train was designed to meet the requirements for illumination uniformity, adequate tritium breeding, the threshold for damage to the grazing incidence metal mirror, and neutron damage to the conventional DD target. This design was applicable to both DPSSLs at 351 nm and KrF at 248 nm (Sethian et al., 2010).

CONCLUSION 4-7: In general, the science and engineering of manufacturing fusion targets for laser-based ICF are well advanced and meet the needs of those experiments, although additional technologies may be needed for IFE. Extrapolating this status to predict the success of manufacturing IFE targets is reasonable if the target is only slightly larger than the ICF target and the process is scalable.

However, subtle additions to the design of the ICF target to improve its performance (greater yield) and survivability in an IFE power plant may significantly affect the manufacturing paradigm.

CONCLUSION 4-8: There are important differences between the direct-drive and indirect-drive based targets. The direct-drive target is simpler to build than is the indirect-drive target, and it is more vulnerable to the environment when it is injected into the target chamber. Understanding these nuances and demonstrating a viable manufacturing process would likely be an important early priority for an IFE program because the quality and variability in the target’s specifications can strongly affect the target’s gain.

CONCLUSION 4-9: One major area where the IFE laser-driven target differs from the ICF target is the method of delivering the target to the target chamber at a high frequency. The high-velocity projectile techniques proposed for laser-based fusion show promise, but there has been little quantification of the degree to which the target will be compromised during the process and what effect any degradation may have on the target’s gain. Also, changes that need to be made to the ICF target to improve its survivability in the IFE target chamber environment have been identified, but the consequence of these changes for the manufacturing process is not known. These are issues that need to be thoroughly addressed early in any future IFE program.

KRYPTON FLUORIDE LASER-DRIVEN, DIRECT-DRIVE FUSION

The leader in DD inertial confinement fusion with KrF lasers is NRL in Washington, D.C., which operates the Nike and Electra lasers. Nike is the world’s largest KrF laser. Its amplifier with 60-cm aperture delivers a pulse of between 3 and 5 kJ at 248 nm to planar geometry targets using a smoothing technology called “induced spatial incoherence” (ISI). Nike has demonstrated “focal zooming,” which allows the laser to more efficiently deliver late-time energy to the imploding spherical ICF pellet.

Electra is a repetitive KrF laser that was developed as part of the HAPL program to study the technology issues of repetition rate, durability, efficiency, and cost for inertial fusion energy. The HAPL program is discussed in Box 4-2. NRL has also developed the FAST (Gardner et al., 1998; Zalesak et al., 2005) radiation-hydrocode, which has several unique features that make it complementary to the ICF codes used at other laboratories.

The current ICF program on the Nike laser is focused on studying the hydrodynamic performance of planar targets accelerated by very smooth laser beams at 248 nm. LPI theories predict higher intensity thresholds for shorter wavelength

lasers, proportional to the square of the wavelength. Further, shorter wavelengths enable higher absorption efficiency, larger drive pressure, and higher hydrodynamic efficiency. Experiments to quantify the growth of Richtmyer-Meshkov and Rayleigh-Taylor instabilities in planar cryogenic (deuterium wicked into foam) targets with thicknesses close to that of a high-gain target have been published (Pawley et al., 1999) and found to be in good agreement with theoretical predictions by the FAST3D code. The use of a thin high-Z layer to mitigate the imprinting of nonuniformities in the low-intensity laser foot was proposed and validated on Nike (Obenschain et al., 2002).

Further collaborative validation experiments on OMEGA demonstrated “significant and absolute (2X) improvements in neutron yield when the shells are coated with a very thin layer (~200–400 angstrom) of high-Z material such as palladium” (Mostovych et al., 2008). Thus, this imprint mitigation technique has been shown to work in both planar and spherical geometries at 248 and 351 nm. The utility of the high uniformity and higher ablation pressure generated by the Nike KrF laser was recently demonstrated in experiments on hypervelocity acceleration of planar targets in collaboration with researchers at the Institute of Laser Engineering at Osaka University in Japan. Whereas the Gekko XII/HiPER glass laser (351 nm) achieved a 700 km/s velocity, the KrF laser was able to achieve a 1,000 km/s foil velocity (Karasik et al., 2010). Extrapolating this performance to spherical DD implosions, ISI and zooming with a KrF laser offer the potential to use targets having lower aspect ratios and to reduce hydroinstability growth, thereby achieving higher target gain for less laser energy.

In 2008, Nike was upgraded to enable high-intensity LPI target experiments. The 2ωpe instability at quarter-critical density is of greatest concern in DD targets, where measurement of ωo/2, 3ωo/2, and hard X-ray (>20 keV) emissions indicate the onset of the instability. The quarter-critical instability thresholds observed in Nike experiments with ISI-smoothed beams are in approximate agreement with planar beam 2ωpe theory, which does not account for the effects of beam smoothing, beam overlap, or saturated levels. This agreement includes an attempt to study the scaling with plasma scale length by varying the laser pulse length. OMEGA experiments with beams smoothed by SSD show similar agreement, and the predicted wavelength scaling appears to have been obtained. The OMEGA experiments have been modeled using the FAST and LILAC codes, both of which are in agreement with respect to the onset of LPI (Seka et al., 2009). However, DD ignition targets will likely need to operate above this theoretical threshold, and further research to understand, model, and measure LPI is required. This includes utilizing the NIF-equivalent OMEGA EP beam parameters to study LPI at plasma scale lengths that are relevant to ignition high-yield DD IFE targets.

A series of DD IFE target designs have been studied with the goal of maximizing target gain while minimizing laser energy. A conventional DD design provided

IFE-relevant 1-D gains (G ~ 100) at laser energies of ~1.3 MJ (Bodner et al., 2002). Later designs gave 1-D gains of order 50 with 500 kJ of KrF laser light by going to higher implosion velocities and using early-time spikes in the pulse shape to tailor the implosion adiabat and diminish Rayleigh-Taylor instability growth (Colombant et al., 2007).

The shock ignition concept proposed by Betti (Betti et al., 2007) and discussed in more detail in the preceding section, is now the baseline for KrF designs because of the higher predicted gains. An initial step in validating these designs was obtaining the agreement of FAST simulations of neutron yields with LLE simulations and experiments (Theobald et al., 2008). At IFE energies, FAST simulations of ISI-smoothed KrF beams using focal zooming give shock-ignition 1-D gains that are roughly twice as high as the best conventional designs (Schmitt et al., 2009). High-resolution, 2-D FAST simulations (for Legendre modes l = 1-256), which include the effects of inner and outer surface finishes and laser imprint, predict that these targets are robust to such perturbations.

The KrF research program would benefit from further 3-D implosion studies, improved LPI simulations, and experimental validation from LPI and implosion experiments on both OMEGA and the NIF in PD configuration. However, in PD geometry, the oblique irradiation near the equator occurs at lower densities, which reduces absorption and hydroefficiency and introduces nonradial beam illumination geometries and lateral heat flow. These are the remaining R&D challenges.

Recent and Upcoming Work

Having adequate numerical models for nonlocal thermal and hot-electron transport has been a challenge for several decades. Of special concern for DD, electron thermal transport in a laser-produced plasma cannot be described with a local approximation in many regions because the electron mean free path is longer than the temperature gradient scale length. NRL researchers have found that a Krook model provides reasonable descriptions of both preheat and flux limitation and have developed a computationally tractable algorithm; they are now verifying the accuracy of the model. This improved model will soon be available to apply to the analysis and design of ongoing experiments, as well as to the design of PD experiments on the NIF. These models are also relevant to the uncertainties in NIF hohlraum modeling.15

NRL has recently begun to simulate polar, DD implosions on the NIF using the FAST code. This will complement ongoing work by LLE in defining DD experiments for a polar-drive platform on the NIF. The growing collaboration will allow

__________________

15 M. Rosen, LLNL, “Understanding of LPI and Its Impact on Indirect Drive,” presentation to the panel on September 21, 2011.

development of conventional and shock ignition designs for the NIF and will enable use of the new Krook model to study the effect of nonlocal transport in the PD geometry.

Evaluation and Discussion of Remaining R&D Challenges

NRL presented a path forward to IFE DD target physics that included implosion experiments on OMEGA, LPI experiments on both Nike and OMEGA EP, and polar DD experiments on the NIF. The theory and simulation efforts included the development of better physics models for the FAST code, improved two- and three-dimensional hydroimplosion simulations, and improved ability to perform LPI simulations. NRL also proposed the development of one KrF IFE beam line that was capable of delivering ~20 kJ on target to study target interaction and LPI physics at IFE-relevant intensity and plasma scale lengths. The goal of this program, to be carried out in collaboration with LLE, would be to validate the fundamental physics of DD, to determine whether sufficient gains are feasible for IFE, and to validate the physics models for comparing DD target performance at 248 nm and at 351 nm.

The fundamental issues for DD capsules are the same at these two wavelengths, and the plans discussed in the solid-state laser DD section are all relevant and necessary. The importance of extending the OMEGA target performance database to NIF energies cannot be overemphasized. Specific issues relevant to the NRL program are discussed individually below.

Direct-Drive Theory and Physics Models

There is a continued need to develop improved physics models for DD in FAST, especially for potential megajoule-class experiments on the NIF, but in a nonradial, PD geometry. This includes continued development of nonlocal thermal and hot-electron transport models, improved nonlocal thermodynamic equilibrium (non-LTE) radiation modeling (particularly for thin, high-Z layers) and improved laser ray tracking for NIF PD geometries. There is also a need for improved LPI modeling, perhaps by teaming with other groups that have developed this capability and applying it at KrF wavelengths.

Laser-Plasma Interactions

As part of an increased effort toward understanding LPI, data on thresholds at KrF wavelengths will be useful. If a 20-kJ KrF laser was developed, it would provide the capability to study LPI at 248 nm in relevant scale-length plasmas and compare the results with OMEGA EP data. LLE is currently studying the role of CBET in DD

experiments on OMEGA. KrF IFE designs may need to account for this physics, including the trade-off between CBET and illumination symmetry.

Polar-Drive Physics, Symmetry, and Shock Ignition

All of the issues listed under the solid-state DD section are relevant to the KrF DD program. Research into the physics issues of PD geometries, illumination symmetry in all DD geometries, and exploration of the potential of shock ignition as a high-gain target concept might best be pursued as a collaborative ICF/IFE program with both OMEGA and the NIF.

Capsule Fabrication, Injection, and Survival

These issues are similar to those already described for solid-state laser-driven targets.

Potential for Use in an IFE System