Appendix I

Energy Technologies and

Applications for the Soldier

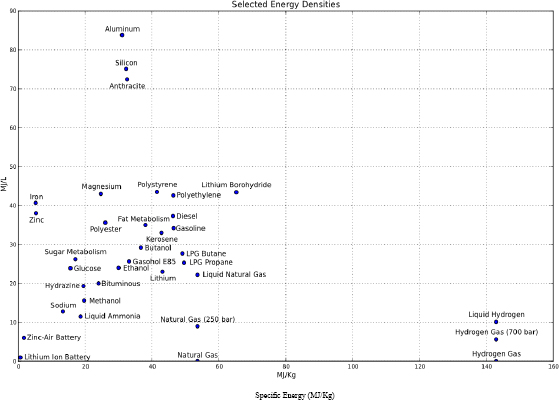

With the exception of harvested solar and wind energy, almost all of the Soldier’s energy supply comes from the energy stored in chemical bonds. That energy is accessed by the Soldier in the form of food, explosives/propellants, and electricity from batteries, fuel cells, and fueled systems, such as internal and external combustion engine/generator combinations. Figure I-1 shows common energy sources in terms of both specific energy and energy density.

FIGURE I-1. Selected energy densities. SOURCE: http://en.wikipedia.org/wiki/ File:Energydensity.svg.

While the energy content of these sources may be quite high, the amount of that energy that can be efficiently extracted is only a fraction of what is theoretically possible for most applications. Table I-1 is a compilation of the most relevant technologies and current states of the art.

TABLE I-1 State of the Art for Technologies Most Relevant to the Dismounted Soldier

| Battery Chemistry | Specific Energy Theoretical | (Whr/kg) Battery | Comments/State of the Art |

| Primary batteries | |||

| LiSO2 | 1,175 | 190 | Inventory item BA5590 |

| LiMnO2 | 1,000 | 220 | Inventory item BA5390 |

| Li(CF)x | 2,180 | 370 - 600 | Inventory: low specific power version; in half BA5590 size at TRL 5–6 |

| Secondary batteries | |||

| Lithium polymer | 750 | 130–200 | Commercial product. Widely used in cell phones. |

| Lithium ion | 750 | 108 | Inventory BB5590 |

| LiCoO2 | 140 | Inventory LI-145 | |

| 158 | Inventory LI-80 | ||

| Zinc-air | 1,370 | 280–300 | Inventory BA-8140, BA 8180 |

| Lithium-air | 5,210 (including oxygen) | 800 cell demo; | TRL 4–5 experimental. |

| 400 half battery | Rechargeable possible at TRL 4 | ||

The Communications-Electronics Research, Development, and Engineering Center (CERDEC), the Natick Soldier Research, Development, and Engineering Center and the Army Research Laboratory have research and development programs to overcome current shortcomings of energy sources for the Soldier.

BATTERY TECHNOLOGIES

The trend in batteries, partially driven by commercial applications and the potential for high specific energy, is with a few exceptions, toward lithium chemistry (both disposable and rechargeable batteries). The two notable are exceptions (1) the zinc-air system, which is a primary disposable battery, is an “air breather” (as are fueled systems), and is fielded in a variety of versions and (2) the lithium-air battery, which is currently in the early stages of development and can function as a primary or secondary battery.

Prototypic systems that will undergo field evaluation in the near term include the following:

• A high-power, high-specific-energy conformal centralized primary lithium battery system.

• Primary lithium batteries based on LiMnO2.

• Primary batteries based on Li(CF)x (half size and low specific power).

• The Net Warrior rechargeable Li 145 lithium ion battery.

In the near term, the specific energy and energy density of these batteries are still far removed from what is theoretically possible. The wide disparity between what is theoretically possible for batteries based on lithium chemistry and what is practical shows that there is much room for improvement. The technical challenges to packing more energy into smaller size are always further complicated by practical considerations such as safety, life, charge/discharge rates, and cost.

Ideally, one would like the rechargeable batteries to be as energetic as the primary single-use batteries. Rechargeable batteries are about 75 percent as energetic as primary batteries. Battery technologies such as lithium polymer, lithium ion polymer, and lithium ion batteries can be improved substantially through the development of new electrolytes. In addition, the engineering of more active electrode materials and innovative packaging can result in major improvements in stored energy without sacrificing the other characteristics demanded by users. For both primary and secondary batteries, cell-level tests indicate that batteries can be improved by a factor of 2 or more to approach 300 Whr/kg in the near to mid term (5-10 year time frame), thereby reducing weight and volume.

For the far term (10-20 years), the development of both primary and secondary versions of Li-air energy sources will be revolutionary and offer performance on a par with that of fueled systems. The basic chemistry of Li-air has been demonstrated in both battery formats (see, for example, Laoire et al., 2011; Zheng et al., 2008). A survey of the technical literature identifies the following research and engineering issues that must be resolved to reduce the technology to practical embodiments:

• Detailed quantitative understanding of the electrochemical kinetics of charge/discharge cycling since these determine chemical reversibility and the level of coulombic efficiency in cycling.

• Development of appropriate electrolytes and cathode structures that can function in the presence of O2.

• Development of electrocatalysts.

• Development of high-porosity air cathodes that maximize transport of reactants to the catalyst surface.

• Development of a suitable lithium metal or lithium composite electrode that minimizes dendritic growth and environmental contamination.

• Development of air separator membranes that allow oxygen to pass while excluding environmental contaminants and water.

As a measure of progress, CERDEC-sponsored programs in lithium-air batteries have achieved impressive results in a nonrechargeable format. Energy densities of 800 Whr/kg were achieved for individual cells, and in a “first packaged” technology readiness level (TRL) 4 demonstration, a multicell lithium air battery in a half -90 configuration achieved 450 Whr/kg (Laoire et al., 2011). Forty charge/discharge cycles with 100 percent coulombic efficiency have been reported.

FUEL CELL TECHNOLOGIES

Fuel cells have been researched for about as long as batteries. Their primary attributes are high conversion efficiency, low acoustic and thermal signatures (some embodiments), and favorable scaling over a wide range of sizes. They lag behind batteries in practical embodiments, however, primarily because they require fuels that are not currently in the military logistics chain. In its Appendix D, the NRC study Meeting the Energy Needs of Future Warriors, provides a comprehensive comparison of the basic technologies and performance parameters for relevant fuel cell technologies (NRC, 2004). Like zinc-air and lithium-air batteries, fuel cells are “air breathers,” which places restrictions on immersion and necessitates filtering in extremely dusty environments.

Direct Methanol Fuel Cells

Direct methanol fuel cells (DMFCs) are proton-exchange fuel cells in which methanol, CH3OH is used directly as the fuel. Their main advantages are as follows:

• Methanol is a commonly available fuel.

• Methanol is stable over a wide range of environmental conditions.

• It is easy to transport.

• The nonpolluting waste is mostly water vapor with carbon dioxide.

The main disadvantages are these:

• Methanol has a low specific energy compared to aviation fuel and gasoline.

• It has a low conversion efficiency (thermodynamic efficiency ~40 percent).

• Complex balance of plant.

• Its introduction into the military inventory would require a new and separate fuel infrastructure.

Reformed Methanol Fuel Cell

Reformed methanol fuel cells (RMFCs), are proton-exchange fuel cells, where the methanol is reformed into a hydrogen gas stream before entering the fuel cell. The advantages of RMFC over DMFC systems are as follows:

• Higher efficiency.

• Better low-temperature performance.

• Simplified stack management (no water).

• Higher specific power.

Their main disadvantages are these:

• Waste heat must be managed.

• Methanol reformers are complex.

Solid Oxide Fuel Cells

Solid oxide fuel cells (SOFCs) operate at temperatures high enough to function on a wide range of hydrocarbon fuels without external reforming. This is due to the high internal temperatures that allow fuel oxidation at the anode and largely negate the need for catalyst. The electrolyte in a solid oxide fuel cell is a hard, nonporous ceramic compound that allows versatility in stack construction. SOFC advantages are these:

• High-temperature operation allows internal reforming.

• They are highly resistant to poisoning by sulfur and carbon monoxide.

• Versatile geometry.

• High efficiency.

• Multifuel capable.

Its basic disadvantages are these:

• The high temperature calls for special materials.

• Slow start-up times.

• High temperatures require special thermal management techniques.

• Reliability and robustness are issues.

Comparison of Fuel-Cell Types

Table I-2 lists the fuel-cell-driven technologies that have been developed for military applications. The last column in the table provides current TRL and status.

TABLE I-2. Fuel Cell State of the Art

| Type and Fuel Dry Weight | Power level (Watts) | Efficiency % | Dry System Specific power (W/kg) | Start up time (min) | Mass for a 72-hr mission (kg) | Comments |

| DMFC Methanol Water/methanol mix at T>40C 1.18 | 20–25 | 22.4 | 21 | 10 | 2.6 | TRL 7 Soldier power source (field evaluation) |

| RDMFC Methanol 1.6 kg | 50 | 31 | 30 | 18 | TRL 6–7 Hybrid or stand-alone energy source (field evaluation) | |

| SOFC Propane fuel 2.6 kg | 50 | 50 | 19. | 30 | 6.2 | TRL 6–7 Hybrid or stand-alone power source (field evaluation) |

| DMFC Methanol/water mix 15 kg | 300 | 22.4 | 20 | 10 | Ops specific–would not be required to run continuously | TRL 6–7 Squad battery charger and stand-alone power supply |

| RMFC Methanol 16.3 kg | 300 | 18 | 30 | Ops specific–would not be required to run continuously | TRL 6–7 Squad battery charger and stand-alone power supply | |

| SOFC Propane 16 kg | 300 | 50 | 19 | 15 | Ops specific–would not be required to run continuously | TRL 6–7 Squad battery charger and stand-alone power supply |

In the mid-term (5-10 years), the basic technologies associated with the fuel-cell types in Table I-2 have already undergone extensive development and aside from reducing the cost of manufacturing, the biggest single gain that can be expected is to develop a reliable, sulfur-tolerant jet propellant (JP) fuel reforming capability that could be integrated into these fuel cells. Note that both liquid propane and JP fuels have approximately the same specific energy but that liquid propane has about half the energy density in Whr/liter that JP has. Both have roughly 2.25 times the specific energy of methanol, a difference that increases when it is necessary to use a methanol/water mixture for operation at higher temperatures.

As with any of the fueled systems, there are two issues associated with warm-up time and with operation of the small fuel cells as part of a hybrid system that the Soldier can carry: immersion in water and contaminant ingestion. DMFC and RMFC are currently being built for limited deployment in Afghanistan and in other active military operations. All three of the main types discussed above are at a TRL of 6-7 and are in various stages of testing. As mentioned, their widespread introduction into the inventory will also require the introduction of a new “logistics fuel,” which does not seem to be practical at this time.

In the far term (10-20 years), the technology using hydrocarbon fuels will continue to mature and to achieve marginal increases in performance. However, given that hydrogen has a specific energy of about 40,000 Whr/kg, roughly 3.25 times that of JP and liquid propane gas, major technological advances in a highly competitive civilian hydrogen economy could drive increases in system-specific energy greater than JP fuel systems. Note that the energy density in Whr/liter is extremely poor, forcing trade-off between mass and volume for specific hydrogen storage technologies.

COMBUSTION SYSTEMS

In two earlier studies, Energy-Efficient Technologies for the Dismounted Soldier, (NRC,1997) and Meeting the Energy Needs of Future Warriors, (NRC, 2004), fueled electrical energy sources were considered in the size range relevant to the dismounted Soldier. In general, the conclusions from those studies show that fueled sources have significant potential for providing a reliable source of energy for the Soldier. In both studies, conversion efficiencies in the 10-50 percent range (fuel heat value to usable energy) were possible, but the level of technical development for suitable fuels was at a low TRL.

The Army is rapidly moving to implement rechargeable battery technology as the Army standard as the specific energy of rechargeable batteries improves and the costs of primary batteries and of their delivery to theater falls. While delivery of a single battery to theater is approximately the same no matter what the type, rechargeable batteries will cost about 5 times as much to manufacture. Given that they can undergo the charge/discharge cycle 200 times or more—a primary battery is used only once—it is obvious that the basic cost and delivery cost savings are

enormous. However, this scheme necessitates having battery chargers at several points, down to the level of vehicles and the individual Soldiers themselves.

The Army has begun development on a recharger technology in limited production using fuel-cell prototypes. Unfortunately, the fuel cell alternatives use hydrogen, propane, or methanol fuels, and the Army would much prefer not to have a new battlefield fuel in the inventory. As an alternative to fuel cells, CERDEC funded research on two types of systems that could use standard battlefield fuels—small external combustion Stirling energy systems and small internal combustion engine converter systems.

External Combustion—Stirling

External combustion engines such as steam engines and Stirling cycle engines have been in use since about 1800 but seem, except in a few embodiments, to have mostly been relegated to history, because internal combustion engines and electrical power from an ever-expanding grid were more efficient. Their primary advantage lies on the fact that the thermal process is steady state, which allows combustion optimization and energy recuperation. Further, steady-state combustion inherently has a lower acoustic signature than internal impulsive combustion. It is possible to operate two separate free-piston versions of Stirling engines such that all vibration is canceled, resulting in an extremely quiet system.

Early versions of Stirling engines employed exotic materials and had low specific power even though they were efficient converters of thermal energy to electricity. In recent years, however, advances in materials have led to the development of components with sufficient high-temperature properties that interest in Stirling technology has emerged as a viable energy converter for some applications. It is currently a viable candidate for deep space exploration1 and shows promise for battlefield (NRC, 2004) and commercial applications such as co-generation.2 Since the Stirling converter requires only a heat source, it is inherently multifuel-capable and has been demonstrated with a range of energy sources, from nuclear to heavy distillates. The Stirling engine can be made in a range of sizes with no loss of efficiency. For example, since about 1990, free-piston Stirling engines have been successfully demonstrated over power levels from 40 W to 25 kW. Stirling engine technology offers the potential for unique military systems that have extremely long life ( >10 years) of continuous operation, unprecedented reliability in a military environment, and extremely simple and elegant mechanical functionality—the motor alternator comprises only one or two moving parts, neither of which is in contact with the other. Since 2005, there has been steady progress in taking the NASA investment in Stirling technology for deep space missions and adapting it for use as a battlefield energy source (CERDEC-funded Defense Advanced Research Project Agency (DARPA)

____________________

1Additional information available at http://www.grc.nasa.gov.

2Additional information available at http://www.stirling-tech.com/cogeneration.

Palm Power program). Proof-of-principle prototypes at a TRL of 5-6 were built and tested.

The Army has been funding the development of small Stirling converter technology for a number of years based on its desirable characteristics and the fact that it could be made man portable and multifuel capable. The Stirling engine ultimately promises to deliver:

• A basic motor alternator with >20,000 hrs of continuous life.

• Mean time between failure of balance of plant items >5,000 hrs.

• Replacement needed only in the case of extreme abuse or battle damage.

• Most spare parts would be black boxes such as controllers.

• Logistic fuel powered and can work on any heat source.

• High efficiency minimizes battlefield fuel requirement.

• May use waste heat in combined heat and power applications >80 percent efficiency.

• Battery charger makes rechargeable batteries a real possibility.

• Silent watch applications for long duration.

• Acoustic signature of less than 50 dBA at 7 m.

• Can operate in any orientation.

• Operates on the move.

Small Internal Combustion Engines

Soldiers in Iraq and Afghanistan purchased commercial Honda generators in the 1-3 kW range to augment their energy sources. These units use gasoline but can be modified easily to function with propane. They have a limited format for the electrical output: 12 V DC and 120 V AC. Noting that commercial Honda generators cost less than $1.00/W, there have been numerous efforts in the past 10 years to modify commercially available engines, both two cycle and four cycle, to run on heavy distillates.

CERDEC’s small internal combustion engine development efforts use standard gasoline fueled-engines. The first approach to converting small gasoline engines to heavy fuel use is to purchase a standard, hand pull-start commercial Honda generator and modify the carburetor to accept vaporized heavy distillate. There are three overriding problems with this approach: (1) the fuel, although vaporized, still consists of long-chain hydrocarbon molecules that are hard to ignite, (2) partial combustion leads to coke formation and gumming of the engine—wet stacking—and (3) the engine is difficult to start.

The alternative CERDEC approach is to develop a fuel “gassifier/cracker” that breaks up the large molecules in heavy distillate fuels at the expense of a few percent decrease in energy density. Such a fuel cracker was developed initially for Honda by Precision Combustion, Inc. (PCI). Basically, the output from the gassifier contains a high percentage of molecular hydrogen (H2), CO, and CO2, as

well as molecules like C3H6, in various proportions. The focus of the PCI effort is to miniaturize the “gassifier/cracker” to suit a small engine rather than an engine like the Honda one, which produced many kilowatts of thermal power. This device is essentially the first stage of a conventional reformer and the basic physics is understood. The hydrogen in the gas stream should aid starting; the smaller molecules should limit coking; and the technology will build on previous successful efforts for Honda.

Combustion Systems State of the Art

The near-term state of the art for combustion technology developments is depicted in Table I-3. The last column lists the levels of development in terms of TRL with remarks on the applicability to TSU operations.

TABLE I-3 Near-term State of the Art for Relevant Combustion Technologies

| Type and Fuel Dry Weight | Power level (Watts) | Efficiency % | Dry System Specific power (W/kg) | Start up time (min) | Mass for a 72-hr mission (kg) | Comments |

| Stirlinga JP fuel 1.7 kg | 35 | 21 fuel to electric | 20.5 | 4.6 | TRL 4–5. No advanced development. DARPA Palm Power. | |

| Stirling JP fuel 12.6 kg | 160 | 16 fuel to electric | 12.7 | 3 | 19 | TRL 6 demonstrated configured as hybrid source. |

| IC engine Gasoline 3.1 kg | 400 | ~18 fuel to electric | 129 | 1 | TRL 5 integrated into robot in hybrid configuration. | |

| IC engine Gasoline 13.1 kg | 1,000 | ~25 fuel to electric | 76.3 | 1 | TRL 9 typical Honda commercial product in limited field use by military | |

| IC engine JP fueled | ~1,000 | TRL 5–6 Honda engine modified to use JP fuel directly. | ||||

| Type and Fuel Dry Weight | Power level (Watts) | Efficiency % | Dry System Specific power (W/kg) | Start up time (min) | Mass for a 72-hr mission (kg) | Comments |

| IC engine JP fueled | ~1,000 | TRL 4–5 Honda engine operating from reformed JP fuel. | ||||

a James Huth and Josh Collins, Diesel Fuel-to-Electric Energy Conversion Using Compact, Portable, Stirling Engine-Based Systems,” 13th International Stirling Engine Conference, Japan Society of Mechanical Engineers.

In the mid-term (3-5 years), the primary impediment to the further development of Stirling technology for military applications is cost. If sufficient funding is available, mass-produced engines producing 100-500 W and having thermal conversion efficiencies of 30 percent or greater should be available. System specific power in the range of 20-30 W/kg appear feasible. The far term is not clear at this time.

HARVESTED ENERGY

There are many small-scale energy conversion technologies that might form the basis for energy harvesting, but they generally cannot be scaled up to industrial size. Several technologies can be applied to harvesting:

• Piezoelectric materials generate a small voltage whenever they are mechanically deformed. Vibration/pressure from any source can stimulate piezoelectric materials to convert some of that mechanical energy to electrical energy potentially useful to the Soldier. Harvesting of Soldier motion has been demonstrated in the laboratory.

• Some wristwatches are already powered by the kinetic pendulum energy that can be harvested from the movement of a human arm. The conversion mechanism is the movement of a coil in a magnetic field of a permanent magnet, generating usable electrical energy. This is a practical application at low power for watches.

• Photovoltaics convert the energy in optical radiation, primarily from the Sun, to usable electrical energy using semiconducting materials that are photovoltaic. Many practical applications exist at the Soldier level and are currently employed in theater.

• Thermoelectric generators consist of the junction of two dissimilar materials and the presence of a thermal gradient. Such generators are

highly developed for space applications. They require large thermal gradients at high temperature to attain reasonable conversion efficiency.

• Micro wind turbines convert the kinetic energy in winds to usable electrical energy. The technology in large sizes is commercially available but applications at the individual Soldier level are limited by mass and the need to elevate the turbine.

• In areas of dense radio frequency such as large urban areas, it is possible to use special antennas to harvest the local radio frequency waves across a wide spectral range and convert them into usable energy. Laboratory-scale demonstrations have been conducted, but usable energy requires large antenna structures unless the device can be placed close to a powerful transmitter.

Solar Energy

The solar flux at Earth’s surface is on the order of 1,400 W/m2. At first glance, that constitutes an enormous amount of energy available for harvesting for Soldier use. However, three factors govern our ability to use this energy. First, it only works when the Sun shines and, second, the efficiency of the conversion mechanism determines the amount of solar energy that is harvestable. Thirdly, in current embodiments, it is difficult to use when a Soldier or a squad is on the move.

Moreover, even under the best of conditions, solar energy is available only during daylight hours and is further constrained by local weather and atmospheric conditions. While these factors are limiting, the energy is there for the taking, has minimal exploitable signature, and, in current embodiments, is robust, flexible and lightweight. Theoretical efficiencies can be calculated as a function of the material energy band gap and the junction type for exposure to the solar spectrum.

There is a great disparity between what is theoretically possible and what is achievable in practical embodiments. The state of the art in photovoltaic cells for harvesting solar energy was driven initially by NASA for powering spacecraft and has been applied to operations as far away as Mars, where the insolation is much less than that available at Earth orbit. Since NASA strives to minimize the mass being put into orbit, its research has focused on cell efficiency.

Cost, robustness, and low mass have driven the first field application of photovoltaic energy harvesting to use thin-film amorphous silicon cell technology. The Army currently deploys solar converters that generate up to 60 W and weigh about 10 lb with forces in Iraq and Afghanistan. The solar cells are made from highly flexible, amorphous thin film that can be optimally folded or rolled into a compact package. Amorphous thin-film cells are only about 10 percent efficient and need somewhat less than 0.5 m2 of active cell area to generate 60 W in full sun conditions.

There are many vendors of this technology. Typical solar converter units that have military potential are available from OkSolar (OkSolar.com), which advertises off-the-shelf systems ranging in power output from 5.0 W to 60 W and varying in weight from 0.17 kg to 1.18 kg for the cell array alone. Under full sun, the 5 W system has a specific energy of 29.4 Whr/kg normalized to 1 hr and the 60 W unit has 51 Whr/kg for the same normalizing condition. Figure I-2 shows a deployable portable solar array.

Near-Term Solar Solutions

Since the solar flux is fixed, improvements in energy conversion efficiency is the only way to increase the energy available to be harvested. Crystalline silicon solar cells have been developed for many years, and the technology is very mature for applications where the cells can be rigidly mounted and where cost is not an issue. Along with the increased efficiency of single-crystal silicon cells comes the fact that these cells can be bent, folded, or otherwise mutilated and still function. However, they cost much more than the amorphous thin-film cells. An increase in efficiency from 10 percent to 25 percent would decrease the area needed for a 60 W charger to about 0.17 m2. It is still unclear how a solar unit would be packaged for military use and what its performance parameters in finished format would be.

FIGURE I-2. Deployable portable solar array. SOURCE: Deanna Tyler and George Au, Army Power Division, “Assessment of the Army’s Need for Portable Energy,” presented at the DARPA Limits on Thermodynamic Storage (LOTS) of Energy Proposers’ Day Workshop, December 4, 2009.

It is, however, now possible to have 60 W output from a 10 cm × 17 cm (4.0 inches × 6.5 inches) flat panel that could be integrated into the Soldier’s outer

garments if robustness issues can be overcome. In this way, it could become a source of energy for the Soldier that is always on when the Sun shines and in a hybrid configuration can keep his or her primary energy source, a lithium-based rechargeable battery, in a state of full charge.

Mid- to far-term solar solutions

In the mid term, advances in photovoltaic converter technology will reduce the size of arrays by a factor of two or more, with concomitant reductions in mass. There is considerable room for improvement in the engineering of high-efficiency photocells through multibandgap engineering. GaInP/GaAs/Ge multijunction devices have demonstrated 32 percent efficient cells without concentration. Also, the application of nanotechnology in the form of quantum wells and quantum dots promises further increases in efficiencies, so that a 60 W array will approach the physical dimensions of a playing card, allowing ready integration into the Soldier’s outer garments with redundancy.

Biomechanical Energy

Biomechanical energy is harvested by a mechanism that can extract energy from the motion of legs, arms, and other body types to drive a generator that converts some of the kinetic energy into usable electrical energy. For the most part, biomechanical energy harvesting has concentrated on leg motion since legs are used repetitively and repeatedly for locomotion, whereas arm motion is highly variable, and arms often do not move substantially when they are involved in load carrying. Biomechanical energy harvesting is not new; in fact, hand-cranked generators predate the Second World War. There are also commercially available flashlights that are driven by shaking a spring loaded magnetic mass through a linear alternator to produce “minutes” of light. These devices require a conscious effort on the part of the Soldier to harvest energy.

Because Soldiers walk a lot, the challenge is how to harvest energy from this motion. Robert Kunzig has described human locomotion as somewhat like an “imperfect pendulum” (Kunzig, 2001). In a pendulum energetic, energy cycles between potential energy, stored in the vertical lift of the pendulum, and the kinetic kind, as the pendulum passes through the point of lowest potential energy. If walking were ideally pendulum-like, energy use would be minimal, since the center of mass of a walking human passes through the same cycle. The actual walking process is only about 65percent efficient at most, with the remainder of the energy coming from the energy content of the food eaten by the individual. In any case, the energy harvested from locomotion is ultimately provided by energy intake from food.

A survey of the literature shows two efforts that have reached the level of sophistication needed for serious consideration. The first of these, based on initial work at the Simon Frazier University in Canada and further developed and

marketed by Bionic Power, headquartered in British Columbia, Canada, harvests energy from knee motion, which is a source of “negative work” as the “pendulum” process involved in walking cycles energy between potential and kinetic. Figure I-3 shows a Bionic Power system intended for military use. By carefully controlling the point in the walking cycle where energy is harvested, the manufacturer claims that its technology has minimal effect on locomotion and fatigue of the wearer.

The performance of the Bionic Power system is as follows:

• Nominal power output: 8-14 W (1.5 m/s walking speed, level ground).

• Maximum power output: 25 W (15 degree down slope).

• Effort setting: 10 levels.

• Output voltage: 5 V to 16.8 V (2 to 4 Li ion cells).

• Maximum output current: 5 A

• Battery chemistries supported: lithium ion (others available upon request).

• LCD indicator: charge complete, charging, fault, output power.

• Connections: left leg, right Leg, battery.

• Fault Protection: Reverse polarity, open/short circuit, over/under voltage, temperature faults.

• External power input: 8 V to 24 V: Solar, vehicle, fuel cell.

• Operational speed: 0.5 to 3 m/s (slow walk to fast jog).

FIGURE I-3. Harvest of biomechanical energy. SOURCE: Reprinted with permission from BionicPower™. Available online at http://bionic-power.com/powerwalk_photos.html.

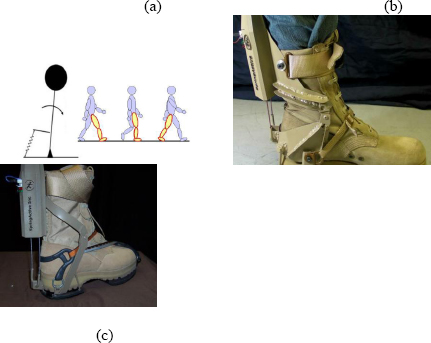

The second technique was described by Hitt et al.3 This harvesting is similar in base concept to the harvesting described above in that it takes into account the mechanics of locomotion to harvest energy associated with the rotary motion of the leg-foot interface during the normal walking or running process. Figure I-4a shows the biomechanics of the walking process.

FIGURE I-4 Soldier Power Regeneration Kit (SPaRK): (a) illustration of the biomechanics; (b) side view of device attached to combat boot; and (c) back view of device attached to combat boot. SOURCE: LTC Joseph Hitt, et al., Program Manager, DARPA, “Dismounted Soldier Biomechanical Power Regeneration,” presented at the Proceedings of the 27th Army Science Conference, Orlando, Fla., November 29 – December 2, 2010.

The mechanics of the Soldier Power Regeneration Kit (SPaRK) device, which is based on an inverted pendulum model, is described by Hitt et al. as follows.

Soldier Power Regeneration Kit (SPaRK) will harvest energy during mid-stance of walking gait. The tibia rotates over the stance foot as the contralateral limb swings and positions for heel strike. During this time, the energy in the stance foot ankle joint is negative as the muscles

____________________

3LTC Joseph Hitt, et al., Program Manager, DARPA, “Dismounted Soldier Biomechanical Power Regeneration,” presented at the Proceedings of the 27th Army Science Conference, Orlando, Fla., November 29 – December 2, 2010.

work to slow the falling body. This mechanical energy was transferred to a small DC motor via a highly efficient ball-screw and burned off across a resistor to determine output power. A uniquely tuned spring was placed in series with the ball screw to reset the starting position during the swing phase. This method allowed the production of 3.5 watts of continuous power output from one ankle device while walking at 6.4 km/hr (4 mph.)

The work by Hitt et al. was intended as proof of principle; typical performance parameters for each ankle are given in Table I-4. The authors conclude that the results provide confidence that biomechanical energy harvesting may be a viable “augmentative and emergency power supply for the future network-centric dismounted Soldier.”4

TABLE I-4. Energy and Weight of Biomechanical Prototype.

| Speed 4.8 | (km/hr) 6.4 | Knee Bends | |

| Average power (W) | 2.5 | 3.5 | 9.2 |

| Average energy/step (J) | 2.7 | 3.2 | 7.7 |

| Total device weight (kg) | 1.4 | 1.4 | 1.4 |

| Average W/kg | 1.8 | 2.5 | 6.6 |

| Generator-only weight (kg) | 0.3 | 0.3 | 0.3 |

| Average W/kg | 8.3 | 11.7 | 30.7 |

SOURCE: LTC Joseph Hitt, et al., Program Manager, DARPA, “Dismounted Soldier Biomechanical Power Regeneration,” presented at the Proceedings of the 27th Army Science Conference, Orlando, Fla., November 29 – December 2, 2010.

Biomechanical harvesting of energy from a Soldier’s locomotion will continue to mature in the near to mid term, with systems increasing in efficiency and decreasing in mass. This technology will become even more important as parallel efforts to reduce the demand for energy for a Soldier’s electronics suite are successful.

Other harvesting mechanisms that have been investigated and may have far-term potential:

____________________

4LTC Joseph Hitt, et al., Program Manager, DARPA, “Dismounted Soldier Biomechanical Power Regeneration,” presented at the Proceedings of the 27th Army Science Conference, Orlando, Fla., November 29 – December 2, 2010.

• Pyroelectric energy harvesting,

• Electrostatic (capacitive) energy harvesting,

• Blood sugar energy harvesting, and

• Tree metabolic energy harvesting.

HYBRID ENERGY TECHNOLOGY

Hybrid systems consist of a primary high-energy-density element, an intermediate rechargeable energy storage unit usually capable of higher specific power, and an energy management system that allows the unit to interface with any load. In most embodiments, the high-energy-density element is a fueled system. Fueled systems derive oxygen for combustion from the air arrangement that has both good and bad features. First, the mass of the oxygen used in the energy production process is not carried by the Soldier and second, the energy content of the fuels is large compared to that of batteries, which both store and deliver energy. On the downside, the fuel’s need to ingest air for combustion in turn necessitates the ability to shut the fueled system off when there is a potential for clogging or contaminating the unit. Doing so renders the fueled system unusable until it can “inhale” clean air again. To mitigate these problems, fueled source-rechargeable battery hybrids are being researched, and a few have been introduced on a limited basis to the Soldier. The state of the art for hybrid systems is depicted in Table I-5. The data assume a 72-hr mission.

TABLE I-5. State of the art in hybrid systems

| Power Train | Weight (lb/kg) | Volume (in3/cm3) | Energy (Whr) | Average Power Capability (W) | Specific Energy (Whr/kg) | Comments |

| Six Li-145 batteries (all- battery baseline) | 13.2/6.0 | 216/3,540 | 870 | 12.0 | 145 | Inventory |

| 4G Zn-air fuel cell/Li-145 battery | 9.4/4.3 | 218/3,572 | 1,145 | 16.0 | 266 | Inventory |

| Methanol fuel cell/Li- 145 battery | 6.1/2.8 | 94/1,540 | 895 | 12.4 | 319 | Experimental limited rate initial production |

REFERENCES

Kunzig, R. 2001. The physics of … walking: Why humans move like an imperfect pendulum. Discover Magazine. Available online http://discovermagazine.com/2001/jul/featphysics. Accessed March 29, 2013.

Laoire, C.O., S. Mukerjee, E. Plichta, M.A. Hendirckson, and K.M. Abraham. 2011. Rechargeable Lithium/TEGDME-LIPF6/O2 Battery. Journal of the Electrochemical Society 158(3): A302-A308.

NRC (National Research Council). 1997. Energy-Efficient Technologies for the Dismounted Soldier. Washington, D.C.: National Academy Press.

NRC. 2004. Meeting the Energy Needs of Future Warriors. Washington, D.C.: The National Academies Press.

Zheng, J.P., R. Y. Liang, M. Henderickson, and E.J. Plichta. 2008. Theoretical Energy Density of Li-Air Batteries. Journal of the Electrochemical Society 155(6): A432-A437.