As a way of providing context to the study, Chapter 2 gives a brief overview of wind turbines and wind farms and presents a short outline of the wind farm development process. It compares tasks common to land-based and offshore development and indicates those that are unique to offshore. The chapter also examines general similarities and differences between offshore oil and gas and offshore wind energy hazards. In addressing Task 1 (see Box 1-2) of the committee’s charge, this chapter briefly describes the hazards involved with the phases of wind farm development and provides background for the more in-depth discussion of offshore hazards in Chapter 4. In addition, Chapter 2 provides an introductory comparison of the relative risk of hazards associated with offshore oil and gas operations that are relevant to offshore wind farms and that will be discussed further in Chapter 4.

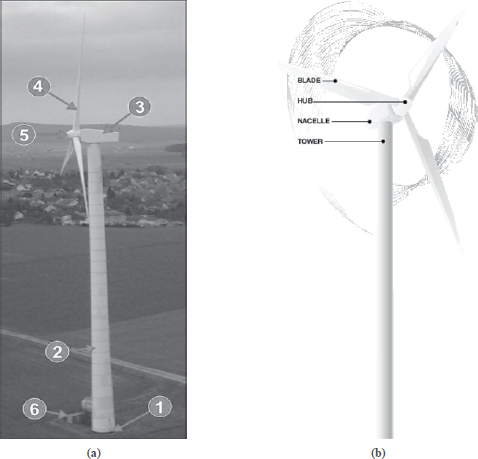

Whether located onshore or offshore, wind turbines1 are characterized as machines or devices that convert wind energy into electricity. They consist of similar components, including a tower that rests on a substructure (or foundation), a nacelle that sits on top of the tower, and a rotor assembly that connects to the nacelle and includes a hub to which

_____________

1 Wind turbines consist of two basic designs, horizontal axis and vertical axis. Horizontal axis (or propeller-style) wind turbines, the more common of the two, are configured with rotor blades perpendicular to the wind direction and with the main axis of rotation in the horizontal plane. Vertical axis turbines have a vertical main axis of rotation (see http://www.awea.org/learnabout/faq/windturbine.cfm, accessed March 1, 2013). This study will focus on horizontal axis turbines, which represent nearly all larger, “utility-scale” turbines.

the blades are attached (see Figure 2-1). For offshore wind turbines and land-based wind turbines, once the technician is inside the wind turbine, most tasks are exactly the same. Thus, for a majority of the tasks inside a wind turbine, the hazards and risks are similar.

The tower usually consists of two to four tubular steel sections that are joined together and coated with a variety of sealants and paints. Resting

FIGURE 2-1 Common components of a land-based wind turbine: (a) photo indicating ![]() foundation,

foundation, ![]() tower,

tower, ![]() nacelle,

nacelle, ![]() rotor blade,

rotor blade, ![]() hub, and

hub, and ![]() transformer; (b) diagram indicating blade, hub, nacelle, and tower.

transformer; (b) diagram indicating blade, hub, nacelle, and tower.

(SOURCE: Figure 2-1a, World Wind Energy Association, http://www.wwindea.org/technology/ch01/estructura-en.htm; Figure 2-1b, American Wind Energy Association, http://www.awea.org/issues/supply_chain/upload/Supplier-Handbook.pdf.)

on a foundation, towers vary in height, depending on site and available wind speeds, and will narrow slightly from the base to the opening in the top. Although towers are still equipped with ladders, most modern towers are also equipped with lifts. The foundation is a structural support system that stabilizes the wind turbine by transferring the vertical and horizontal forces acting on it to the surrounding ground. For land-based turbines, foundations are generally some type of reinforced concrete slab, monopile, or multipile solution and are determined by the geotechnical conditions of the site (AWEA n.d.).

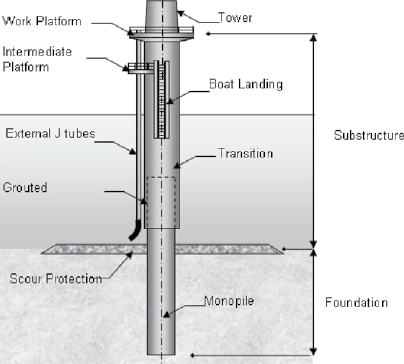

Substructures for offshore turbines are also designed according to site conditions, including water depth, currents, wave height, wind speed, and seabed conditions. The European wind industry has relied on monopile and gravity-based substructures for water shallower than 25 meters. For water deeper than 25 meters, the industry is researching the use of other types of substructures, including jacket, tripod, triple, suction bucket, and floating.2 The focus of this study is on the monopile substructure.

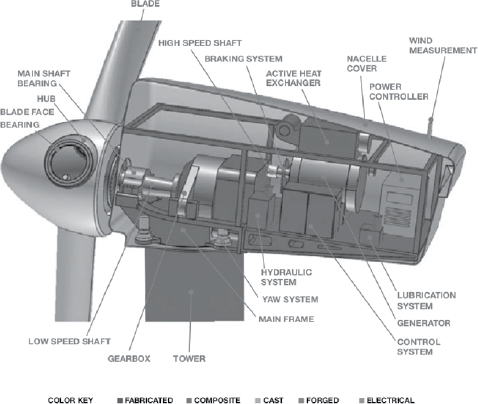

The nacelle is the boxlike compartment resting on top of the tower and containing most of the equipment required to convert wind energy into electricity. This equipment (see Figure 2-2) includes the drivetrain components—rotor shaft, gearbox (unless the design incorporates a direct drive turbine, which does not have a gearbox), and generator. Also included are remote sensors and systems for monitoring and controlling the turbine, such as an anemometer, brake system, cooling system, and yaw drive, which keeps the rotor hub facing the wind (AWEA 2009). The rotor assembly for a geared turbine connects to the nacelle and consists of the hub, covered by a nose cone, blades, and pitch drive (for a sense of overall turbine size, see Figure 2-3). The typical utility-scale turbine has three blades that range in length from 35 to 60 meters, but manufacturers are testing larger blades. Each blade is bolted onto the hub along with the pitch drive, which allows the blade to rotate on its axis, controls the amount of wind captured, and ensures that the turbine can be stopped either locally or remotely by pitching the blades completely out

_____________

2 For a more detailed review of substructure and foundation types, see TRB 2011, AWS Truewind 2009, and Tveiten et al. 2011.

FIGURE 2-2 Nacelle components. (SOURCE: http://www.awea.org/issues/supply_chain/upload/Supplier-Handbook.pdf.)

FIGURE 2-3 Offshore 5-MW wind turbine with wind technicians on board. (SOURCE: http://www.areva.com.)

FIGURE 2-4 Transition piece and substructure for monopile foundation. (SOURCE: EWEA 2009.)

of the wind. The hub connects the rotor assembly to the driveshaft and is heavy and rigid to absorb excessive amounts of vibration (AWEA n.d.). Because an offshore turbine is exposed to a more demanding environment than is a land-based turbine, it requires several design modifications. They include a strengthened tower to handle the added force from waves, a pressurized and climate-controlled nacelle compartment to protect internal components from the corrosive marine environment, a place within the tower to provide emergency accommodation for workers, and an external access platform or transition piece (see Figure 2-4) to facilitate access and maintenance (TRB 2011).

As mentioned in Chapter 1, the National Renewable Energy Laboratory (NREL) estimates the potential for generating wind energy in the United States at more than 12 million megawatts (MW) (NREL 2011), with

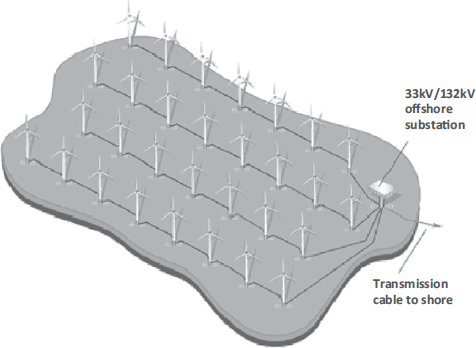

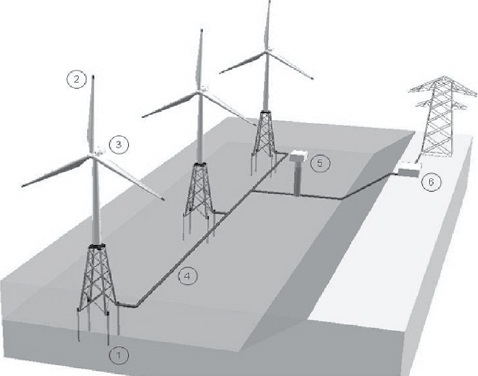

FIGURE 2-5 Sample layout of offshore wind farm (kV kilovolt). (SOURCE: Barrow Offshore Wind Project: http://www.bowind.co.uk/popup1.htm.)

most of this potential coming from areas located offshore or in the central part of the country.3 As of the end of December 2012, all 60,007 MW of installed capacity in the United States was from land-based wind farms (AWEA 2013). Wind farms consist of one or more independently operating wind turbines that generate power, are connected together with electric cables, and are connected to an electrical substation. The electrical substation or, when offshore, an electric service platform (ESP) collects the power output from the wind farm and transmits it to the grid (see Figures 2-5 and 2-6).

Compared with land-based wind farms, offshore wind farms can be larger both in size and in the amount of power generated because the wind resources are more abundant. The size of turbines for land-based

_____________

3 For a detailed map of U.S. land-based and offshore wind resources, see http://www1.eere.energy.gov/wind/resource_assessment_characterization.html, accessed March 1, 2013.

FIGURE 2-6 Simple layout of offshore wind farm: ![]() foundation,

foundation, ![]() wind turbine generator,

wind turbine generator, ![]() nacelle,

nacelle, ![]() interturbine cables,

interturbine cables, ![]() offshore substation and export cable, and

offshore substation and export cable, and ![]() onshore grid connection. (SOURCE: Presentation by Bill Wall at the Offshore Energy Knowledge Exchange Workshop, April 11, 2012, Washington, D.C. http://www.wind.energy.gov/pdfs/offshore_energy_knowledge_exchange_workshop_report.pdf.)

onshore grid connection. (SOURCE: Presentation by Bill Wall at the Offshore Energy Knowledge Exchange Workshop, April 11, 2012, Washington, D.C. http://www.wind.energy.gov/pdfs/offshore_energy_knowledge_exchange_workshop_report.pdf.)

wind farms is subject to the constraints of vehicles and installation equipment. Trucks hauling components and installation equipment must travel over existing roads, often to remote areas, which limits access to areas and ultimately the size and capacity of land-based turbines. In contrast, marine transportation and installation equipment can accommodate larger and heavier turbine components for offshore wind farms. Electricity from land-based wind farms must be transmitted over greater distances. The strongest onshore wind resources are located in more rural and less populated states, away from the major coastal population centers where, despite high demand for electricity, land is less available and has more competing uses. However, offshore

wind resources are located closer to the densely populated urban centers and would allow shorter transmission distances (Musial and Ram 2010).

Developing a Wind Farm

Describing the process of developing and operating a wind farm in detail is beyond the scope of this study. However, the process is much longer for offshore than for onshore wind farms, involves multiple steps, and is logistically complex. Outlining these steps and planning the entire project thoroughly, from start to finish, are necessary for any successful wind project.

Developers of land-based wind farms must consider many issues.4 The preinstallation phase involves identifying a potential wind farm site and understanding the suitability of its wind resources—important factors for any developer. NREL provides some information on existing wind resources for the United States.5 More detailed wind resource data are collected through meteorological towers installed at or near the potential site, a process that can take up to 3 years but that can provide data useful in optimizing turbine location. Wind farm developers must also understand the transmission system and how far the power that will be generated must travel to reach the grid. Building an extended transmission infrastructure to join a wind facility’s substation to the grid can add complexity to the project. Electrical cables connecting each turbine will also need to be installed, and developers will need to consult topographical information in preparing the land at a site. This information will help in placing turbines, since each tower foundation will need to be prepared and leveled, and in designing access roads to the site. How the installation equipment, wind energy components, and work crews get to the project site to construct and service the wind farm must also be considered. Building new roads to each turbine and updating or expanding the transportation infrastructure will add to a project’s cost and complexity.

_____________

4 More information concerning the development and siting of land-based wind energy projects in the United States is given by http://www.awea.org/sitinghandbook/downloads/AWEA_Siting_Handbook_Feb2008.pdf.

5 See also http://www.windpoweringamerica.gov/.

Developers of offshore wind projects face similar issues, including extensive planning and a costly process that can take years. Once acceptable sites are identified6 and developers obtain the appropriate leases and permits for state or federal waters, their work has just started. All the decisions that the developer makes before installation have consequences and affect all future outcomes. This is especially true of design decisions and health and safety considerations, both of which are discussed in more detail in Chapter 5. Consideration of health and safety should begin during the initial planning stages and continue throughout the life of the project. Decisions must therefore be made with as much detailed information as possible, including data from site assessment activities and guidance from experienced individuals. Like their land-based counterparts, offshore wind farm developers must understand available wind resources and collect data from meteorological towers. Developers must survey the potential site, collect metocean (wind, wave, and current) data, and understand meteorological conditions such as wind levels and wave conditions. Developers must also understand the seabed conditions at the site, including currents and the subsea terrain, both of which are important in predicting and protecting against scour—erosion of the seabed adjacent to the support structure. Next, the developer will need to choose the type and size of the turbines to be installed at the wind farm. All these decisions will influence the detailed design and planning of the wind farm—for example, the type of foundation to be used, how the installation will occur, the number of qualified personnel needed, the need for and availability of various types of equipment (including vessels), how cabling between turbines will be done and the electrical power exported to shore, what port facilities will be needed, the overall operations and maintenance strategy, and the decommissioning plan. The developer is constantly aware that work on the wind farm occurs in a marine environment and that all access to the site is by boat or by helicopter; workers cannot just drive up to the work site and get out of their truck, nor can they easily evacuate a wind turbine in an emergency.

_____________

6 See also http://www.nrel.gov/gis/wind.html.

Phases of Offshore Wind Farm Development

The major phases of wind farm development include installation of the components of the wind turbine, installation of cables connecting the turbine together and to the electrical grid, the commissioning of the turbine into service, the operations and routine maintenance stage, and the eventual decommissioning of the wind farm. At the start of installation, the layout site and staging port cover a large area and are important for the overall success of the project. The port must be able to accommodate the large freight vessels that deliver the foundations, transition pieces, and turbine components and must allow for component offloading, storage, and preassembly as well as loading onto repurposed installation vessels as needed. The layout site also must be able to handle the weight of all the delivered equipment; otherwise, the quay could buckle under the total load.

Installation

This phase involves the installation of major components, among them the foundation and transition piece, and the assembly of the wind turbine. It includes most of the heavy lifting of turbine components. Although the number of workers involved in the installation phase will depend on the size of the wind farm, this is the most personnel-intensive phase in its development and operation.

Foundation or Substructure and Transition Pieces Once the appropriate foundation and substructure components are fabricated, installation can begin. If a monopile is being installed, for example, a specialized jack-up vessel equipped with a crane and pile-driving ram could be used. Monopiles are loaded onto one or more vessels and transported to the installation site. The monopile would be lifted into place and driven into the seabed to a depth of 20 to 30 meters, depending on seabed conditions and design requirements. After foundations or substructures are installed, the transition piece is placed on top of the monopile at a specific height and grouted into place (Thomsen 2012). Transition pieces (see Figure 2-4) are of standard sizes and include an external work platform, a boat landing, ladders, a diesel generator to provide power for lighting and for other purposes when the turbine is not running, a crane for lifting

components, decks, J-tube supports, and other cable connections. Work platforms are used during all phases of operations and provide access to the wind turbine (Melnyk and Andersen 2009). To prevent erosion, rock armoring or another type of scour control may be added around the turbine foundation after installation (McNeilan and Smith 2011). Installation of the foundations or substructures for a wind farm will be complete or well under way before that of the wind turbines themselves begins.

Once these structures are in place, the components needed for assembling a specific number of wind turbines are loaded onto vessels or transport barges at the staging area and are moved to the installation site. An installation vessel or crane barge accompanies transport barges to the site, where the jack-up vessel deploys next to the foundation and begins the installation of the turbine components.

Wind Turbine Components A common assembly technique is to lift the base tower from the transport vessel; place it on the transition piece; bolt it down; and then lift, place, and bolt the next tower section on the previous tower section. Once the two to four tower sections are in place, the nacelle is lifted and secured to the top of the tower. The hub is lifted and bolted onto the nacelle if it is not already secured there, and then individual turbine blades are bolted onto the hub. In some instances, the hub with all three turbine blades is lifted and attached to the nacelle. This is referred to as a rotor lift. The process is repeated until all wind turbines of the wind farm are assembled.

Cable Installation and Electrical Substation

Each wind turbine in a wind farm generates power independently and sends its power to a transformer located at the base of the tower. Sub marine cable interconnects each turbine with up to a dozen other turbines to create an array. Specialized cable installation vessels and underwater cable installation equipment connect the turbines and embed the electrical cable up to 2 meters below the seabed.7 Each array is then connected to the central substation or an ESP. The power

_____________

7 Presentation at the Offshore Energy Knowledge Exchange Workshop, Washington, D.C., April 11, 2012, by J. Whitman. http://www.wind.energy.gov/pdfs/offshore_energy_knowledge_exchange_workshop_report.pdf.

generated from each turbine is sent to the transformer, where it is increased and sent to the ESP.

The voltage generated in an individual turbine is classified as low voltage, usually below 1,000 volts, although some larger turbines can generate voltages of up to 3,000 volts. Turbines are interconnected and use individual transformers to step up power to medium voltage, from 10 to 36 kilovolts, and to send to the ESP. ESPs typically step up voltage from under 36 kilovolts to 100 to 220 kilovolts and send the electricity to shore (EWEA 2009).

The ESP is a multistory offshore substation and is the central point for all interconnected wind turbines. All power generated from the turbines is transmitted via the underwater cable system to the ESP, where additional transformers increase the voltage level again to minimize electrical losses and then send the electricity to a land-based substation and ultimately to the grid through another undersea cable that can handle the higher voltage. Structurally, ESPs are similar to a typical offshore oil and gas platform. Generally, they are braced-frame structural systems that extend from the seabed to roughly 20 feet above the waterline, with three or more support legs and driven pile foundations. An above-water frame and deck system is then connected to the jacket structure serving as a platform for the electrical equipment.

Installation of an ESP involves transporting the jacket structure and support piles to the site on a barge. The jacket is set on the seabed, and the support piles are driven to hold it in place. The deck structure is then transported to the site via a barge and is lifted into place atop the jacket, where it is welded to the jacket legs. Typically, the deck is transported to the site fully outfitted with the equipment necessary for the ESP operations. In larger wind farms and those farther offshore, the ESP is sometimes a manned structure providing living quarters for turbine technicians, medical personnel, and personnel watching the wind farm’s remote monitoring systems. It is also provided with advanced rescue equipment and has a helicopter landing platform.

Specialized cable installation vessels and underwater cable installation equipment are also used to bury cable from the ESP to the onshore connection point. Once the installation process is complete and before normal operations of the wind farm can begin, the turbine must be commissioned. For financial reasons, on larger wind farms the turbines are

handed over individually or in smaller groups to start producing electricity as soon as possible.

Commissioning of a Wind Turbine

Once a wind turbine is assembled, teams of workers begin the steps necessary for making it operational. This is referred to as the commissioning phase and includes the inspection and testing of turbine functionality and electrical infrastructure, including substation. This phase can be work-intensive and may require a team of three to six people and more than 1,000 person-hours for each wind turbine.8 During commissioning, the work team performs quality control activities and tests the internal systems, including the turbine control systems, the remote monitoring and access systems, and all electrical systems. The rotor blades are set in slow rotation to test the drivetrain, along with the overspeed protection system. Once the turbine is connected to the grid, it is further tested in sequences and finally put into operation. This phase is of particular interest because the risk of electrical incidents is now present.9

Operations and Maintenance

Once they are operational, wind farms are essentially unmanned offshore facilities with personnel accessing them only to perform maintenance and repairs. Scheduled maintenance ensures ongoing functionality of the equipment and system, and scheduled inspections evaluate condition; maintain safety systems; and satisfy lease, permit, and regulatory requirements. Such routine access is often accomplished with smaller vessels that do not have cranes or large carrying capacity. Unscheduled maintenance, which can include major repairs such as replacing a major wind turbine component, may require the use of larger jack-up installation vessels that can carry replacement components and more personnel (Thomsen 2012). If the manufacturer supplies a warranty period for the wind turbines, the work crews supplied during the operations and maintenance period will consist of a team of two or more people for every 20 to 30 turbines. Routine or scheduled maintenance requires

_____________

8 J. Nielsen, Siemens, presentation to the committee, April 2012.

9 J. Nielsen, Siemens, presentation to the committee, April 2012.

approximately 40 hours per year; unscheduled maintenance requires a similar or a smaller amount of time.10

Several presentations to the committee indicated that manufacturers are integrating automated systems with their wind turbines more often, so that the need for traveling to offshore facilities has decreased.11 These systems allow for the remote monitoring of operational status and controlling of individual turbine performance characteristics such as rotor speed, blade pitch, and yaw. Other centralized software systems are often used to gather, transmit, and analyze indicators and the operational status of an entire wind farm. These systems, referred to as supervisory control and data acquisition (SCADA) systems, can collect data on meteorological conditions and power output from individual turbines or the entire wind farm. The data from a SCADA system are useful in remote supervisory and control actions, such as monitoring for safe operation and operating at an optimal state, diagnosing and repairing turbines, and starting and stopping turbines as needed for routine maintenance and in emergency situations (Lynn 2011, 151–152). Although the need for on-site visits will not be eliminated, wind farm operators can use remote monitoring and control systems to decrease the number of on-site visits and ultimately to reduce the exposure of their workers to hazards.

Decommissioning

Current regulations require wind farm operators to decommission or remove all facilities and wind farm components at some point in the future.12 The committee is unaware of any offshore wind projects that have been decommissioned anywhere in the world, but the process is understood to be the reverse of the installation process and could be more hazardous and difficult than the installation phase. This process would include the removal of all underwater cables, wind turbines, towers, ESP, transition pieces, and foundations and would require equipment and vessels similar to those used during installation.

_____________

10 J. Nielsen, Siemens, presentation to the committee, April 2012.

11 J. Nielsen, Siemens, presentation to the committee, April 2012.

12 See 76 FR 64776, Subpart I—Decommissioning. https://federalregister.gov/a/2011-22675.

Wind Farm Development Tasks Common to Land-Based and Offshore Facilities

As mentioned earlier, the development of land-based and offshore wind facilities requires extensive planning and thorough knowledge of site conditions. The two types of operations need a staging area for storing large components before installation. Cranes are used in both land-based and offshore projects. During land-based operations, cranes in the staging area or warehouse area will load components onto trucks or trains for transport to the installation site. For offshore projects, cranes load the components onto transport vessels before floating them to a project site. Large cranes are also used for lifting the individual components during assembly for both land-based and offshore wind facilities. The installation of electric cables between turbines and to a substation and then to the grid is interconnected in a similar pattern in land-based and offshore wind farms, but the introduction of water in the offshore environment adds another dimension, since cable installation is accomplished with remotely controlled vehicles. Likewise, the manual handling of components, for example bolts and cables, in a wind turbine is similar for land-based and offshore facilities, as are most of the tools and equipment. Once inside the turbine, the difference is not noticeable.

Wind Farm Development Tasks Unique to Offshore Facilities

The marine environment differentiates offshore work from that done onshore. Work is done on the water, in or with a boat; under the water in diving operations; or above the water, in or on a wind turbine. Weather is a factor for land-based work, but in the offshore environment, the weather and sea state (wind speed, wave height, visibility, etc.) are deciding factors. A typical offshore wind project will plan for significant downtime due to bad weather conditions. Unlike workers onshore, offshore technicians do not drive themselves to the work site but are transported by a vessel, which has its own crew. Offshore technicians are dependent on a complex logistical arrangement that includes transfer to and from a vessel or helicopter, coordination with other marine vessels, and extra marine rescue equipment (for example, an immersion suit). Training,

if applicable, may be required, such as in Standards of Training, Certification, and Watchkeeping or Helicopter Underwater Egress Training.

In an offshore environment, the transfer to the wind turbine is not a matter of a few steps on a normal staircase but an operation that may require the use of fall protection equipment, coordination between the technician and the vessel crew, and additional climbing of ladders of 5 to 20 meters while exposed to the given weather conditions. On land, technicians rely on a well-stocked truck parked near the wind turbine that they can use to drive away. Offshore technicians rely on the transfer vessel for transportation and emergency evacuation, for spare components or missing tools, and for breaks. Logistical coordination with the transport vessel is critical for successful offshore work. Offshore communication and logistics are also critical as more work teams are shuttled by transfer vessels and work simultaneously in more wind turbines. Typically, a wind project will have to provide its own communication network. Often, very high frequency radios are used, but in some cases signals cannot cover the span of the wind farm, and repeaters are needed. In some cases the vessels are also used to relay the communication signals.

Advanced weather monitoring is crucial for offshore work, especially in severe weather situations and when lightning is a threat. In cases of sudden severe weather when transfer vessels are unable to collect all offshore work teams, technicians remaining in a wind turbine are supplied with enough provisions for up to 3 days but must stay in designated areas and observe special rules and procedures. Although diving operations are kept to a minimum, they are sometimes required for offshore work, for example to position a foundation, prepare for cable laying, or inspect the turbine.

Offshore wind workers live onshore and are transported back and forth on a daily basis, although accommodations aboard an ESP or similar offshore platform could be utilized. However, if the wind farm is far offshore, a hotel vessel (or floatel) is sometimes provided to minimize travel time. Living conditions on offshore platforms and floatels are normally good, but technicians without offshore work experience will need time to acclimate to the new living environment related to life at sea.

Similarities and Differences Between Offshore Oil and Gas Facilities and Offshore Wind Farms

The oil and gas industry has operated offshore for decades and has developed many best practices and standards that can be used as a foundation for offshore wind development. Oil and gas developers started with practices and equipment for land-based applications and adapted them to the marine environment, as offshore wind developers have started to do. The oil and gas industry’s understanding of seabed geology and meteorological conditions and their effects on design and operations is proving beneficial to the offshore wind industry. The wind industry is using innovations such as jack-up vessels and different foundation types, which were first developed by the oil and gas industry (Melnyk and Andersen 2009).

One difference between an oil and gas industry facility and a wind farm is the way the workers get to work. Oil and gas employees travel to and from offshore structures by crew boat. The workers transfer from a boat to a small landing platform on the structure by using a rope attached to the structure to swing to and from the boat, or they transfer between boat and platform by using a Billy Pugh basket and the platform’s crane. As offshore platforms became larger and moved farther from shore, the transfer of workers by helicopter became more routine. On some European offshore wind farms workers are lowered from a helicopter to a platform on the nacelle, but for the most part offshore wind farm workers will continue to rely on transfers from a boat to the ladder and the transition piece on the wind turbine. Although technical solutions providing a more stable transfer walkway between the vessel and the wind turbine are available, moving people from a vessel to a wind tower presents more potential for individual injuries than landing them by helicopter on an offshore oil and gas structure.

A second difference between an offshore oil and gas platform and an offshore wind turbine is the inherent unknown of the geological structure underneath an oil and gas platform, such as an undetected high-pressure gas pocket or unexpected subsidence of the earth’s surface, neither of which is a likely source of an emergency on an offshore wind turbine.

A third difference is that during the exploration phase many oil and gas platforms are often manned by personnel who not only travel back

and forth between shore and platform by helicopter or boat but also live on the platform and service and operate the facilities for an extended period of time, usually ranging from 7 to 30 days straight on a 12-hour-per-day work schedule. Depending on the size of the facility and the ongoing operations, up to 250 people may be on board at any given time, which may result in much activity in a small area. An error by one employee, therefore, can have a far-reaching impact on the entire platform. An offshore wind farm will have fewer workers on or near the wind turbine at any one time, so the consequences of an error by an employee are less than those on an oil and gas facility.

A fourth difference is the nature of the product with which oil and gas personnel are working—hydrocarbons under pressure—which makes an offshore oil and gas platform a more likely and varied source of hazards than an offshore wind turbine. In addition, the various types of dangerous equipment used to work with the hazardous product on an offshore oil and gas platform do not exist on a wind turbine. Such equipment can include “pigs,” gas compressors, and pipeline pumps, which work at high pressure. A “pig” is a maintenance tool that is forced through the oil and gas pipeline by using a “pig launcher” either for clearing the pipeline or for inspecting it. A gas compressor is a mechanical device that is capable of compressing gas by reducing the volume of the container enclosing the gas. This is done by placing the gas in a container with a mechanical wall that is able to push forward. The process puts the gas under extreme pressure and allows it to be transported through pipes. Crane accidents are also frequent causes of injuries and fatalities on an oil and gas platform. Although cranes are used on wind turbines, they are used less frequently and involve fewer personnel.

Hazards Involved in Wind Farm Development

Hazards to worker health and safety related to wind farm development can occur during the major phases of the project: installation, commissioning, operations and maintenance, and decommissioning. Many common hazards of these phases are summarized in Box 2-1.

• Weather conditions such as high winds, extreme cold and heat, and icy or wet surfaces can expose workers to environmental and slip hazards.

BOX 2-1

Common Hazards for Offshore Wind Farms

The following list of hazards is not comprehensive and is not a substitute for a formal hazard analysis that is part of the safety management system development process.

Assembly and fit-up (installation only)

Chemical exposure

Confined space entry

Crane and lifting

Demolition (decommissioning only)

Diving

Dropped objects

Electrocution and arc flash Emergency evacuation Electric and magnetic field exposure (operations only, once power is being generated)

Falls from height

Fire

Human factors health issues (climbing, awkward postures)

Human factors safety issues (pinch points, rotating equipment)

Noise exposure

Personnel transfers (falls into the water); access by boat; access by helicopter

Slips and trips

Vibration

Weather exposure

SOURCE: Generated by the committee.

• Loading materials during transport can lead to dropped objects and uncontrolled lifts.

• During development, crane operations occur in windy areas and introduce lifting and crush hazards while large components or heavy pieces of equipment are moved.

• Personnel working in the tower or the nacelle are at heights and climb ladders multiple times per day, and they face fall hazards or exposure to dropped objects.

• In a wind turbine, workers encounter confined spaces and are exposed to fumes, dust, and toxic chemicals and materials.

• Electrical hazards, such as electrical burns and electrocution, are a concern.

• Workers confront awkward postures, prolonged kneeling, and repetitive upper body movements, often in cramped spaces, which can lead to short-term sprains and fatigue as well as long-term injuries.

• Workers face stress and occupational safety and health risks from work organization—often resulting from the way jobs are designed and from organizational policies that shape how the jobs are designed.

While land-based and offshore wind farms share many hazards, the offshore work environment presents some hazards not encountered on a land-based facility. Among them are personnel transfers between vessels and wind turbines; helicopter access to offshore facilities; allisions between vessel and wind turbines; collisions between two or more vessels operating in the same area; falls into water by personnel; diving hazards during foundation installation, cable laying, and regular turbine inspections; evacuation from a wind turbine during a fire, explosion, or severe weather event; and the travel distance to and from shore during emergencies.

Hazards of Offshore Oil and Gas Facilities Relevant to Offshore Wind Farms

Many offshore oil and gas hazards and their associated risks are similar to those of offshore wind farms. Table 2-1 outlines some specific hazards with an indication of whether the overall risk from those hazards to an offshore wind farm worker is similar to, higher than, or lower

TABLE 2-1 Risks from Typical Hazards for an Offshore Wind Farm Worker Compared with Those for an Offshore Oil and Gas Worker

| Hazard | Relative Risk (Wind Versus Oil and Gas) | Comment |

|

Electrical injury |

Higher |

Higher-voltage equipment and all activities related to this equipment. |

|

Personnel transfers |

Higher |

More boat transfers expected for a worker on offshore wind turbines. Oil and gas platform boat landings and helipads are larger than those for wind monopiles. Helicopters are used more often for oil and gas. |

|

Awkward postures |

Higher |

Generally, more room to perform tasks is available on oil and gas platforms. |

|

Confined space entry |

Similar |

Wind turbines have more confined spaces and must be entered more frequently; regardless, confined space entry for both oil and gas and offshore wind carries inherent risk and can have serious consequences. |

|

Falls into water |

Similar |

Activities in locations where falls into water are likely are similar. |

|

Diving |

Similar |

Similar activities and frequencies. |

|

Manual material handling |

Similar |

Similar needs for upgrades or maintenance requiring manual handling of equipment and materials. |

|

Long-term physical wear and tear |

Similar |

Relatively little climbing is required for offshore oil and gas workers, but shifts and work schedule may be longer. |

|

Mechanical hazards (e.g., pinch points) |

Similar |

Both installations require work on machines that pose dangers to workers. |

|

Slips and trips |

Similar |

Common hazards in all workplaces. |

|

Exposure to heat and cold |

Similar |

Both wind and oil and gas facilities have limited climate-controlled spaces. |

|

Falls from heights |

Similar |

More climbing and higher climbing is required for activities on wind turbines; however, a higher exposure rate for personnel on oil and gas platforms may exist. |

|

Fire |

Lower |

Oil and gas facilities process flammable materials. |

|

Explosion |

Lower |

Oil and gas facilities process flammable materials. |

|

Crane lifts |

Lower |

Oil and gas facilities generally have permanent cranes that are used more frequently than those that may exist on wind turbines. |

| Hazard | Relative Risk (Wind Versus Oil and Gas) | Comment |

|

Noise exposure |

Lower |

Turbines will be shut down when workers are present, but most equipment is not shut down during oil and gas operations. |

|

Chemical exposure |

Lower |

Oil and gas facilities process material containing a variety of potentially harmful chemicals. |

|

Exposure to weather |

Lower |

More work in outdoor spaces on oil and gas platforms. |

NOTE: Table 2-1 is not intended to be a direct comparison between the two industries, but only an approximation of relative risk. The hazards and risks between offshore wind and offshore oil and gas are not always directly comparable. After installation, offshore wind farms are more like oil and gas production platforms and less like oil and gas drilling rigs.

SOURCE: Generated by the committee.

than the risk to an offshore oil and gas worker. The table represents the committee’s judgment on the basis of its experience and provides a comment column with some background to support its conclusion of relative risk.13

Certain hazards—chemical exposure, fire, and explosion—associated with the volatile products involved in offshore oil and gas work are less likely with offshore wind. And, because the number of people on a wind turbine at any one time is much smaller than on a drilling platform, the likelihood of a worker being exposed to these hazards is smaller. Common hazards for the oil and gas industry may include falls (particularly down stairs); injuries from cranes and heavy lifts; injuries from being struck by objects; and musculoskeletal injuries from lifting, which may occur less frequently on wind turbines but have similar consequences. Other typical worker injuries including slips and trips and exposure to the weather elements may occur with a similar frequency, but the overall risk of a catastrophic event on an oil and gas platform is higher than what can be expected on a wind farm. For wind farms, the likelihood of a catastrophic event is lower with respect to personnel and environmental

_____________

13 The committee was unable to collect reliable injury statistics across the different industries to compare and illustrate common or unique hazards.

hazards. The risk of a hazardous materials spill on wind farms is lower because the amounts of such materials (usually lubricating oils and hydraulic fluids) within each wind turbine are small compared with the volume of oil or gas being produced from an offshore platform. In addition, the wind facilities are unmanned, and even when they are occupied, wind turbines are maintained by fewer workers, typically fewer than five.

Although land-based and offshore wind turbines follow similar designs and share many characteristics, offshore wind turbines require additional features and modifications for operation in a marine environment. The towers of offshore wind turbines are strengthened to handle the increased forces from waves, and an offshore nacelle is usually pressurized and climate-controlled to protect the internal components from the corrosive marine environment. Working with large installation equipment and moving large turbine components present many challenges. While land-based and offshore operations share development steps, marine and land-based environments present different hazards and risks. As mentioned above, the weather is the deciding factor for offshore work. Since personnel must use a vessel (or possibly a helicopter) to access wind turbines, weather conditions and sea state will determine the accessibility of the wind farm. The dependence on a vessel to access offshore wind turbines creates issues not only when the technician transfers back and forth between the vessel and turbine but also when the worker needs to evacuate or requires spare tools or components. Such dependence does not occur to the same degree during land-based development. Offshore logistics are critical, since vessels must avoid collisions with other vessels and with turbines. Diving operations are sometimes necessary during installation or inspection of wind turbines, which creates additional risk that does not occur onshore. On the basis of this initial comparison, the hazards and associated risks of offshore wind development are likely to be greater than those of land-based wind development. Offshore wind development shares most of the same hazards as land-based wind development but adds those resulting from the marine environment. Chapter 4 discusses potential offshore wind

hazards in more detail and presents relevant regulations, standards, and best practices that might be appropriate.

The oil and gas industry has worked in an offshore environment for decades and has many best practices and standards that would be useful for the offshore wind industry. Chapter 3 introduces regulations and standards that are followed by the oil and gas industry and discusses their relevance to the offshore wind industry. While the oil and gas and wind industries share many offshore hazards, the overall associated risk for oil and gas hazards is greater than for the offshore wind industry. The oil and gas industry works with a more volatile product, and the risk of an explosion or fire on an offshore oil and gas platform is greater than on an offshore wind turbine. Furthermore, offshore drilling platforms are manned and thus pose a greater risk to human life than does the unmanned wind turbine. Chapter 5 discusses the associated risks of the oil and gas industry and the wind industry in more detail.

REFERENCES

| Abbreviations | ||

| AWEA | American Wind Energy Association | |

| EWEA | European Wind Energy Association | |

| NREL | National Renewable Energy Laboratory | |

| TRB | Transportation Research Board | |

AWEA. 2009. AWEA Wind Power Value Chain: Building Links to a Cleaner Energy Future. Washington, D.C. http://www.awea.org/_cs_upload/learnabout/publications/4144_1.pdf. Accessed March 1, 2013.

AWEA. 2013. AWEA U.S. Wind Industry Fourth Quarter 2012 Market Report. http://www.awea.org/learnabout/publications/reports/AWEA-US-Wind-Industry-Market-Reports.cfm. Accessed Feb. 4, 2013.

AWEA. n.d. Anatomy of a Wind Turbine. Fact sheet. http://www.awea.org/issues/supply_chain/Anatomy-of-a-Wind-Turbine.cfm. Accessed Feb. 1, 2013.

AWS Truewind. 2009. Offshore Wind Technology Overview. Prepared for the Long Island–New York City Offshore Wind Collaborative. Albany, N.Y. http://www.linycoffshorewind.com/PDF/AWS%20Truewind%20Offshore%20Wind%20Technology%20Final%20Report.pdf.

EWEA. 2009. Wind Energy—The Facts: A Guide to the Technology, Economics and Future of Wind Power. http://www.wind-energy-the-facts.org.

Lynn, P. A. 2011. Onshore and Offshore Wind Energy: An Introduction. Wiley and Sons, West Sussex, United Kingdom.

McNeilan, T., and K. R. Smith. 2011. Seabed Scour Considerations for Offshore Wind Development on the Atlantic OCS. www.bsee.gov/Research-and-Training/Technology-Assessment-and-Research/Project-656.aspx.

Melnyk, M., and R. Andersen. 2009. Offshore Power: Building Renewable Energy Projects in U.S. Waters. PennWell Corp., Tulsa, Okla.

Musial, W., and B. Ram. 2010. Large-Scale Offshore Wind Power in the United States: Assessment of Opportunities and Barriers. Report TP-500-40745. National Renewable Energy Laboratory, Golden, Colo.

NREL. 2011. NREL Highlights: NREL Study Finds U.S. Wind Energy Potential Triples Previous Estimates. http://www.nrel.gov/docs/fy11osti/50860.pdf. Accessed Feb. 19, 2013.

Thomsen, K. E. 2012. Offshore Wind: A Comprehensive Guide to Successful Offshore Wind Farm Installation. Academic Press, Waltham, Mass.

TRB. 2011. Special Report 305: Structural Integrity of Offshore Wind Turbines: Oversight of Design, Fabrication, and Installation. Transportation Research Board of the National Academies, Washington, D.C. http://www.trb.org/Publications/Blurbs/165263.aspx.

Tveiten, C. K., E. Albrechtsen, J. Heggset, M. Hofmann, E. Jersin, B. Leira, and P. K. Norddal. 2011. HSE Challenges Related to Offshore Renewable Energy: A Study of HSE Issues Related to Current and Future Offshore Wind Power Concepts. SINTEF A18107. SINTEF Technology and Society, Trondheim, Norway.