Electromagnetic Field Manipulation of Properties—Session Summary

Gerard Ludtka, Distinguished Research Staff, Materials Processing and Manufacturing Group, Materials Science and Technology Division, Oak Ridge National Laboratory

Gerard Ludtka began his presentation by noting that high-magnetic-field processing affects all materials. While people think of iron and steel when they think about magnetic fields, magnetic fields can impact all metallic systems, covalently bonded systems, and polymeric systems. He mentioned examples as diverse as graphite, copper, and chocolate. He said one advantage to being at Oak Ridge National Laboratory (ORNL) is the access to supercomputing capabilities that allow sophisticated modeling to explain some of the physics being observed. ORNL also has a spallation neutron source, allowing for in situ, real-time materials characterization.

Dr. Ludtka then discussed how high and thermomagnetic processing (H&TMP) can improve the performance of materials. The approach used at ORNL couples induction heating within a superconducting magnet, with H&TMP for rapid throughput, part-by-part heat treatment processing. ORNL also has experimented with applying this process without the induction heating for a “heat-free” heat-treating method. The processing technique provides accelerated kinetics, novel

microstructures within the material, and the possibility for enhancing material performance. This technique is a new synthesis-catalysis tool for overcoming reaction-activation barriers, and it has the potential to reduce processing energy and costs.

Dr. Ludtka then went on to describe numerous material properties that strong magnetic fields affect, including these:

• Phase stability;

• Diffusion barriers;

• Dislocation cores;

• Fault energies;

• Phonons and magnons;

• Kinetics, by raising temperatures and by affecting the critical stable nucleus for precipitate formation; and

• Catalysis and synthesis, by affecting activation energy barriers.

Dr. Ludtka described a workshop conducted in 2005 by the National High Magnetic Field Laboratory to understand the needs of industry in X-ray and neutron effects. The workshop, Probing Matter at High Magnetic Fields with X-rays and Neutrons, resulted in a long list of material families and impact areas, including biological materials, synthesis of proteins, composite systems, and many, many others (Granroth et al., 2005). ORNL researchers are working to extend and realize some of these ideas.

Dr. Ludtka then very briefly described magnetic field processing at ORNL as a commercial-scale, synthesis-catalysis processing tool designed to impact phase equilibria and accelerate phase transformation kinetics. It is designed to simultaneously impact material properties such as strength, toughness, and phase equilibrium. The magnetic field processing facility at ORNL uses 9 T superconducting magnets with a vertical, 8 in. diameter bore.

Dr. Ludtka then explained why a high magnetic field shifts the phase boundaries of a material. There is a term in the free energy equation that is correlated with the external magnetic field (the integral expression in the equation below), although it is not traditionally considered to play a significant role:

![]()

∆G represents the change in free energy, α represents the ferrite fraction, and γ represents the austenite fraction in the Fe phase diagram, where a is the free energy for either ferrite or austenite. R is the gas constant and T is the temperature. In the integral H is the magnetic field and M the magnetization. Contrary to the assumption that the magnetic field term is unimportant, research at ORNL has shown that high-magnetic-field processing does have an impact on microstructure,

phase transformation kinetics, and materials performance. The effect of the magnetic processing on any of these parameters scales with the applied magnetic field.

Dr. Ludtka showed that H&TMP processing provides typical improvements of 10-15 percent in strength, ductility, and/or toughness, with maximum gains of 30 percent in these parameters. H&TMP also provides shorter tempering times (by up to 80 percent) and lower tempering temperatures (by up to 30 percent) while still achieving performance gains of 20-30 percent in yield strength and ultimate tensile strength with no loss of ductility. He also described how inexpensive alloys that do not contain cobalt can be used in steel to improve toughness. The sample sizes processed to date range up to 75 mm in diameter by 200 mm in length. Dr. Ludtka also pointed out that it is important to think about scaling up to commercial applications; this processing has been successfully demonstrated on several commercial prototype systems. He emphasized that the H&TMP technology is a transformational breakthrough that has the ability to significantly impact phase equilibria and kinetics, and it is a new synthesis and catalysis tool that can influence the behavior and performance of all materials.

Dr. Ludtka then said that understanding creep life remains an important unresolved question. Creep life improves significantly—up to 600 percent—in some alumina-forming austenitic steel alloys (Brady et al., 2008) after magnetic field annealing as compared to as-processed alloys that have not undergone magnetic field annealing. In experiments, however, when titanium and zirconium were added, creep life did not change or became worse after magnetic field annealing compared to as-processed samples, and the mechanism for this is not well understood. This is something ORNL is trying to understand through modeling. Dr. Ludtka also discussed the need to understand the impact of the interaction of the magnetic field, temperature, and alloying elements. In particular, he described a collaborative effort with Toyota Motor Engineering & Manufacturing North America to increase the strength of magnesium alloys. It seems like magnetic processing during aging increases the strength of the alloy.

Dr. Ludtka then addressed another set of experiments with high-temperature superconductors. The goal of this project is to develop processing technologies for rare-earth-element-free superconductors using high magnetic fields to increase the critical current density by two orders of magnitude while also improving material strength by 30 percent over conventionally processed material. The approach incorporates H&TMP techniques along with carbon nanomaterials and powder metallurgy processing to develop the superconductor. The high-magnetic-field processing allows the critical current of the Josephson junctions to increase without decreasing the size of the devices. Superconductor synthesis using high-magnetic-field reaction sintering has yielded microstructural features typical of a high-pressure phase fabrication process.

Dr. Ludtka then described a project in compaction and sintering of commercial

magnet materials under high magnetic fields. The goal of this project is to reduce the rare earth content and improve the performance of rare-earth-element permanent magnets. The research uses cold powder compaction in a high magnetic field, followed by high-magnetic-field sintering, to process materials for maximum efficiency by aligning their microstructure. The expectation is a reduction of more than 30 percent in rare earth element usage using the magnetic field assisted powder consolidation and sintering techniques without loss of magnet performance.

Dr. Ludtka then described research in the next generation of composites. Using techniques based on H&TMP, the next generation of carbon fibers is expected to yield 100 percent improvements in strength and a 50 percent increase in stiffness modulus. Polymeric matrix (epoxy) materials are expected to gain improvements in tensile stiffness of 300 percent in the direction of the applied magnetic field. These changes to strength and stiffness would allow for revolutionary changes in the weight of aircraft and other vehicles.

Dr. Ludtka then very briefly described three additional applications of magnetic fields. The first application is defects, where the defect interacts with the magnetic field and effectively acts as a localized magnetic field source, producing a pseudo-field of up to 300 T at the point defect location. The next application is oxidation, where magnetic fields can accelerate a radical oxidation reaction. The third example was polymeric and organic materials, where magnetic fields have the potential to impact the orientation of polymeric and organic materials.1

Dr. Ludtka spent some time discussing the benefits of magnetoplasticity and the reduction of residual stress. Magnetic fields afford the ability to improve fatigue life and deformation behavior, thus extending component life by up to 30 percent. The assumption is that magnetic fields can be used to break main domain walls, preventing (or delaying) the formation of persistent shear bands and their migration, as well as crack formation. Similarly, residual stress reduction via magnetic processing during or after component fabrication also extends component lifetimes and allows for design stresses to be higher, enabling smaller, lighter-weight, more-energy-efficient components.

Dr. Ludtka then mentioned potential functional material applications of magnetic field processing to produce. The functional materials research topics included nanomaterials for magnetic storage, nanostructures, superconducting materials, and magnetic control of hydrogen storage.

He also described the electromagnetic acoustic transducer (EMAT) solidification/ casting technology. The goal of this project is to achieve wrought-like microstructure and properties in as-cast materials. This would mean the elimination of micro- and macrosegregation, a reduction in grain size, an overall increase in strength, and improved creep performance. Dr. Ludtka showed examples of cast

______________________

1 Including, for example, controlling the solidification and crystallization of sugar and chocolate.

iron successfully processed using this technology, with a 51 percent improvement in hardness.

Dr. Ludtka then showed some results of single crystal growth of an iron-nickel-cobalt alloy, where the molten alloy is subjected to a high magnetic field and then solidified. This allows for single crystal growth in a low-energy process. He also described crystallizing biological macromolecules in a high magnetic field; the magnetic field can control the growth kinetics and structure.

Dr. Ludtka then showed the magnet capabilities at ORNL, where there are four separate superconducting magnet processing facilities:

• A commercial-scale superconducting 9 T magnet with a vertical 8 in. bore and 9 in. uniform field strength, designed for large-scale experiments;

• Two continuous-feed H&TMP systems with two horizontal 5 in. bore superconducting magnets with a 9 in. uniform field; and

• A 9 T, 5 in. vertical bore superconducting magnet with a 9 in. uniform field, designed for solidification processing.

All systems have a cryogen recondensing cooler, eliminating the need for replenishing the cryogens.

During the question-and-answer session, Dr. Ludtka was asked if anisotropy could be causing local strain, causing strain hardening when a sample is put into the magnet. Dr. Ludtka said that while magnetostrictive forces can be significant, the dislocation dynamics tend to be normal. A participant suggested that the sample be removed and put in again with the opposite orientation as a test.

A questioner noted that the potential improvements reported by Dr. Ludtka (100 percent in tensile strength and 50 percent in stiffness modulus in carbon fibers) are amazing increases and asked if this information had drawn the attention of carbon fiber producers. Dr. Ludtka responded that today’s economy is such that industry is discouraged from funding this type of research, but that DARPA might be interested.

Another questioner asked if ORNL has conducted any research in carbon nanotube growth in a magnetic field. Dr. Ludtka responded that several years ago researchers at the laboratory took carbon precursors and made graphene sheets and nanotubes in a magnetic field.

In response to a question about research in China, Dr. Ludtka said that Chinese researchers are publishing aggressively in many areas related to high-magnetic-field processing. The government of China hired Bruce Brandt, former director of the National High Magnetic Field Laboratory DC Magnet User Program, to help build a high-magnetic-field facility in China. In general, China lags about 5 years behind the United States in developing high-magnetic-field processing.

Dr. Ludtka was asked what was on his wish list. He responded that he wished

for sustained funding. DOD is more apt to fund an industry-led proposal; however, developments made possible by DOD may not be shared outside DOD. He would like to see a situation where research is sustained and the information is publicly available. From the perspective of funding agencies, there are also challenges in finding the right balance between modeling and application.

MATERIALS PROCESSING AT THE NATIONAL HIGH MAGNETIC FIELD LABORATORY

Gregory Boebinger, Director, National High Magnetic Field Laboratory, and Ke Han, Scholar/Scientist, National High Magnetic Field Laboratory

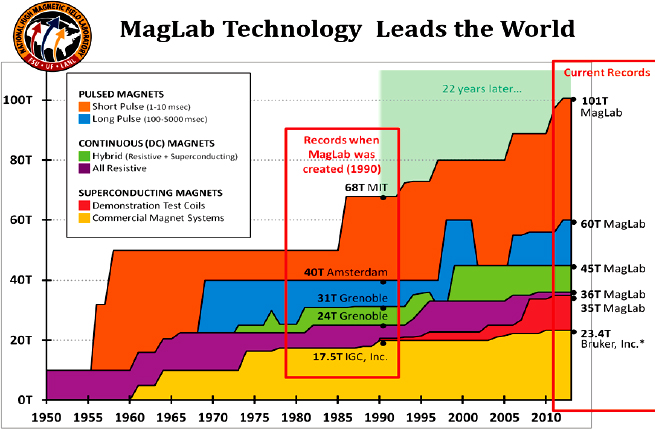

Dr. Boebinger began the presentation by describing the National High Magnetic Field Laboratory (MagLab). Most of the facility resides at the Florida State University campus site, with smaller campuses at Los Alamos National Laboratory and the University of Florida. The laboratory was formed in 1990 as the result of an NRC study and the ensuing national competition. It is recompeted periodically, and the next recompetition is in 5 years. It is funded primarily by the National Science Foundation (NSF), with substantial contributions from the state of Florida as well. Since 1990, NSF has contributed roughly $500 million and the state of Florida has contributed roughly $350 million, which is a unique national-state financial partnership. The Department of Energy also supports the laboratory, especially the Los Alamos site. In 2011, the MagLab’s user program hosted over 1,200 scientists from more than 200 institutions in the United States and around the world. The user community is ever changing, as every year roughly 20 percent of the principal investigators on proposals to use the facility are first-timers. To use MagLab facilities, there is a competitive proposal process for magnet time. Successful proposals receive no-cost access to magnet facilities and time. Experimental results obtained using the facility must be published. MagLab usage results in approximately 400 journal publications per year; about half of the research activity at the laboratory is concentrated in condensed matter physics and materials science, and the remainder is distributed across geochemistry, chemistry, biology, biochemistry, and other engineering. MagLab currently holds the world records in magnet strengths in all categories and also holds records in short-pulse magnets (101 T), long-pulse magnets (60 T), hybrid magnets (45 T), resistive magnets (36 T), and superconducting magnets (35 T in a demonstration test coil). Figure 3.1 shows how magnet strength has evolved over time for the various types of magnets.

Dr. Boebinger described the status of the 35 T all-superconducting magnet project. At the MagLab, researchers have taken a wide-bore resistive magnet and dropped a high-temperature superconducting magnet into it to create a proof-of-

FIGURE 3.1 Maximum magnetic field strength as a function of year for different types of magnets. SOURCE: Presentation by Gregory Boebinger and Ke Han, National High Magnetic Field Laboratory, presentation to the Standing Committee on Defense Materials, Manufacturing and Infrastructure on December 5, 2012, slide 6.

principle 35 T demonstration. In superconducting magnets, the superconducting materials used constrain the magnet. Because of the current-carrying capacity limitations of the material, niobium-3 tin (Nb-3 Sn) will never allow for a superconducting magnet larger than 25 T. Yttrium barium copper oxide (YBCO) has good current-carrying capacity, allowing for a higher magnet strength, but the material is highly anisotropic, which introduces complications for magnet production. Isotropic round wire is easier to incorporate into a magnet design, is easier to wind, and makes it easier to achieve high levels of homogeneity. MagLab researchers recently discovered that round-wire bismuth strontium calcium copper oxide (BSCCO) can be processed in high-pressure oxygen, eliminating the formation of voids that plagued earlier round wire and allowing for the material to be used for magnet production with a high magnetic field strength.

Dr. Boebinger then discussed resistive pulsed magnets and continuous magnets. Once again, the materials constrain the magnets. He pointed out that the

pressures inside the MagLab 100 T pulsed magnet are on the order of 200,000 psi (1.4 GPa), thus exceeding the strength of most steels. To ameliorate the huge explosive pressures inside the magnets, copper/niobium and copper/silver nanocomposite materials are used in wire form for pulsed magnets and in sheet form for continuous magnets to increase the material strength.

Dr. Boebinger pointed out the uniqueness of magnetic fields, particularly when compared to techniques used at other facilities: Magnetic fields are a flexible thermodynamic parameter (as opposed to X-rays or neutrons, which are probes) and can be used in situ, rapidly, reversibly, and with infinite tunability. In this sense, magnetic field experiments are often more flexible than experiments that change other thermodynamic variables such as pressure or carrier densities. In addition, unlike temperature, pressure, and carrier concentration, magnetic fields are a vector, so an experiment can be designed to probe anisotropies or impose new anisotropies.

Dr. Han then described how high magnetic fields can be used to improve the properties of a material. By changing the phase transformation behavior (such as the solidification and the solid-phase transformations), the microstructure can be refined and improved. By altering the texture of a material, the anisotropy of the material can be tailored to suit a particular purpose. Examples of magnetic field processing include improving the mechanical properties of structural materials or the magnetic properties of magnetic materials. Dr. Han included several examples where magnetic fields were used to alter material properties.

The first example Dr. Han showed used a 33 T high magnetic field to change the mechanical properties of high-strength steels. The application of the 33 T field increased the martensitic transformation and pearlite transformation temperatures.

Dr. Han then showed a second example in which high-magnetic-field processing was used to align nanotubes in making buckypaper.2 Alignment was created by filtering the nanotubes in a high magnetic field (up to 17 T), creating unique anisotropic properties in the material suitable for use as actuators. The strain magnitude increased by 15 percent, and the material acquired anisotropic properties suitable for an actuator. The asymmetry is a new feature generated by processing in a high magnetic field.

A third example was the influence of high-magnetic-field processing on the critical current density of Bi2Sr2CaCu2Ox/AgMg round wire. Dr. Han showed that heat treatment of superconducting wires can impact the critical current density in particular orientations when the treatment is conducted in the presence of a high (8 T) magnetic field.

A fourth example was improving rare earth magnets using high magnetic

______________________

2 Buckypaper is a material made from carbon nanotubes that is 10 times lighter than steel and 250 times stronger than steel.

fields. The rare earth metal neodymium is critical today in the production of permanent magnets. However, the volatility of its price poses a challenge to magnet manufacturers. Neodymium cost $10/kg in 2006, $450/kg in 2011, and $140/kg in the summer of 2012. There exists approximately 250 g of permanent magnets in a standard automobile and 1 kg of permanent magnets in a Toyota Prius, so its price is a significant concern in industry. The goal of the project Dr. Han described is to reduce the use of rare earth metals for magnets, replacing them with anisotropic nanocomposite magnets. To date, the theoretical maximum energy product for isotropic material is between 50 and 120 megagauss oersted (MGOe) for anisotropic nanocomposites. (The energy product measures the performance of the permanent magnet.) However, the highest experimental result to date is approximately 24 MGOe for isotropic, nonuniform nanostructures, which is well below the theoretical result. To reduce rare earth content, researchers have investigated using exchange-coupled hard and soft phase nanocomposite magnets.

Dr. Han provided a final example, one of high-magnetic-field annealing related to exchange-coupled nanocomposites. In this experiment, iron and palladium foils are annealed at a constant temperature for several hours in a high magnetic field (19 T) to change the material’s magnetic properties. The high magnetic field introduces texture and affects the phase transition behavior. Different annealing temperatures provide different critical magnetic fields and energy products, and an optimal annealing temperature can be selected to give the largest increase in energy product.

Dr. Han summarized by saying that processing in a high magnetic field can improve material properties by changing a material’s texture and/or microstructure. The improvement can occur through changes to the phase transformation temperatures. Alignment can occur in materials that are both ferromagnetic and nonferromagnetic. He pointed out that these improvements benefit structural materials (for instance, by improving strength) and functional materials (improving magnetic properties).

In response to a question about how experimenters determine processing field strength, Dr. Boebinger said that the peak field strength was chosen for the bore size that was needed; the larger the bore, the smaller the magnetic field. He said that field studies were also conducted to make certain that field strengths would be sufficient.

The presenters were asked how much consideration was given to microstructural alignment versus texture and how the two variables could be separated. Dr. Han responded that the MagLab measures texture. Understanding the detailed correlation between microstructural alignment and crystallographic texture remains for future work.

The presenters were also asked if the material property changes in the experiments were permanent. Dr. Han responded that at ambient temperatures, changes

are permanent in the selected examples presented. However, the materials would reanneal at different temperatures, which could further change material properties. Another participant stated that high-temperature solution treatments tend to be stable, but it is important to understand what has changed and what has been manipulated in the microstructure.

FIELD-ASSISTED SINTERING TECHNOLOGY

Robert Dowding, Materials Engineer, U.S. Army Research Laboratory

Mr. Dowding began his talk by noting that his presentation was about electric-field-assisted sintering technology. This is not the first time the Army has been interested in this type of technology, he said. In one form or another, spark sintering apparatus has been in existence for quite a while. Approximately 20 years ago, the Army became interested in nanomaterials, and as a consequence became interested in rapid sintering technologies and developed a system called plasma pressure compaction. Plasma pressure compaction is one of many similar technologies, including electric-current-assisted sintering (ECAS), spark plasma sintering (SPS), field-assisted sintering technology (FAST), pulsed electric current sintering (PECS), plasma pressure compaction (PPC), and plasma-assisted sintering. Mr. Dowding said that although SPS is the most common name, it is not accurate because the technique has little to do with plasmas, sparks, or sintering. He suggested that FAST is the most accurate terminology of all the choices. For that reason, the FAST acronym will be used throughout the remainder of the presentation to describe the general category of electric-field-assisted sintering techniques.

Mr. Dowding stated that a rapid FAST system has several characteristics:

• One-step processing,

• Preservation and control of microstructure/nanostructure and metastable structures,

• High consolidated density (100 percent),

• Net and near-net shape processing,

• Potential cost savings,

• Potential energy savings (60-70 percent), and

• Novel joining of materials.

A FAST system uses conductive graphite tooling typically having a cylindrical shape. Metallic or ceramic powder goes in as loose powder or as a preconsolidated form, and energy is applied. The process is characterized by rapid heating and short dwell times. One problem associated with such a system is where to take

pyrometer or other temperature measurements; the temperature inside the powder bed is observed to be higher than anywhere else in the system. The process is not well scaled and as currently practiced is good for fairly simple components such as low-aspect-ratio shapes with rotational symmetry. It works well for sputter targets and thermal management applications. The production of body armor breastplates using a FAST system would push the process too close to its current limits.

FAST is similar to hot pressing in that both processes use indirect heating. FAST uses conduction heating at up to 106 K/min, while hot pressing uses conduction/ convection heating at about 80 K/min. In a FAST system, the components are in physical contact, enabling joule heating if the powder being used is conductive. (If the powder is an insulator, the heating comes from around the powder bed, creating a miniature graphite furnace around the powder bed from the graphite tooling.) FAST techniques offer a number of distinct advantages compared to hot pressing, including shorter sintering times and lower temperatures, increased production rates, and lower energy costs. They also have shorter processing cycles and are easy to use. However, FAST techniques have a number of drawbacks. The physics involved are not well understood, and models describing the processes are lacking. Thermal gradients are a problem, causing gradients and variations in consolidation in certain materials. Typically, the overall specimen size is small: The thickness is most often smaller than the diameter, and the diameter is currently limited to around 8-12 in. Scaling up is also very uncertain.

Mr. Dowding explained that the mechanisms that describe FAST are not well understood but that it does appear clear that “there is no plasma generation, sparking, or arcing present during the SPS process and during neither the initial nor the final stage of sintering” (Hulbert et al., 2008). He described, and discounted, a number of explanations in the literature, including spark impact pressure, plasma cleaning of particle surfaces, joule rapid heating, local melting and evaporation, surface activation on the particles, electron wind force, field-assisted diffusion, and plastic deformation. Despite the poor understanding of the underlying physics, Mr. Dowding pointed out, the process is still a very useful one, and there is a growing interest in FAST technology; the number of publications and the number of pieces of equipment are both increasing.

Mr. Dowding then described the FAST devices made at the Army Research Laboratory. The first-generation devices, called PPC machines, were developed through an award from the Small Business Innovation Research (SBIR) program. They are “open air processing” machines. The second-generation devices were constructed in an atmosphere-controlled chamber. A graphite furnace was added to increase the overall temperature to avoid thermal gradients. These machines are used to process a variety of materials. The first example Mr. Dowding described was the processing of tungsten. Tungsten powder, which is sensitive to the amount of oxygen present, sinters better in the atmosphere-controlled environment. The

goal of the project was to process tungsten so that it would undergo a specific, required deformation transformation that can result in very fine grain sizes. The key measurement is adiabatic shear band susceptibility, which is related to strength and inversely related to the strain rate sensitivity, both of which vary with grain size. FAST-based processing of pure nanocrystalline tungsten resulted in either fine grain sizes or high consolidated densities, but it was not able to achieve both simultaneously.

Mr. Dowding then provided an example of processing ceramic powder. The goal was to create improved ceramic armor materials. In this case, the key performance indicator is the ductility parameter. The ductility parameter is inversely related to flaw size, which is again related to the size of the grain. When grain size is reduced, flaw size is also reduced and ductility increases. Using FAST techniques, processing times can be reduced to 10 percent of those used in commercial processing and temperatures are lowered by about 400°C to produce dense, fine grain sizes. Mr. Dowding also described how his laboratory is attempting to increase the toughness of boron carbide ceramic. In collaboration with Zhifeng Ren and his group at Boston College, Mr. Dowding and his group have modified carbon nanotubes with boron carbide and added them to boron carbide powder prior to FAST processing. To their surprise, the carbon nanotubes survived the sintering process but failed to provide enhanced reinforcement to the final processed ceramic.

Mr. Dowding then pointed out that there are no good models for FAST and FAST-like processing. He showed data for temperature contours for a punch-die-compact assembly of a rectangular compact. For a rectangular compact made of tungsten, the temperature contours showed significant thermal gradients across punch length, die height, and die diameter—gradients of 400-600°C. This is a significant problem that must be resolved before scaling up production rate and volume. Although a specimen can be processed in seconds, the chamber takes hours to cool down. Companies are investigating ways to speed up the throughput.

Mr. Dowding then described other materials under investigation. An aluminum nickel composition can be processed in different ways and yields very different structures. The results differ markedly when the aluminum is coated with nickel compared to when elemental powders are blended. He also presented an example of processing magnesium/nanodiamond. Because FAST processing allows for processing at lower temperatures, the nanodiamond structure is able to survive the processing.

Mr. Dowding was asked about manufacturers of FAST processing machines in this country. He replied that his machines were made under an SBIR contract in a partnership with Materials Modification Inc. of Fairfax, Virginia, and that they are commercial products. State-of-the-art machines are also made in Germany by FCT and in this country by Thermal Technologies of California.

In response to a question, Mr. Dowding said that diameter effects have been

noted during processing; homogeneity is more difficult to attain for larger pieces. He was also asked about microwave sintering, particularly for tungsten. He said that in that instance, owing to surface area/volume ratio considerations, the inverse is true: The bigger the piece processed, the more successful it is.

OPEN DISCUSSION: ELECTROMAGNETIC MANIPULATION OF PROPERTIES

Discussion Leaders: Rosario Gerhardt, Professor, School of Materials Science and Engineering, Georgia Institute of Technology, and George T. (Rusty) Gray III, Laboratory Fellow, Los Alamos National Laboratory

Dr. Gerhardt began by noting that the physics behind all these effects is not well understood. She also said that there had been many examples but not many details in the presentations of this session. She said that clearly the presenters were sold on the ability to change the material microstructure at will. She asked which research area(s) would have the highest priority if only one or two areas of research were possible. Dr. Ludtka said that while industry would not be interested in high-temperature superconductors, it would be most interested in changing the mechanical properties of materials. DOD would want to push the envelope for performance and therefore might be more interested in the high-temperature superconducting magnet technologies. Dr. Han noted that industry would be likely to look for where they could get the most value for the least investment. For instance, if manufacturers could achieve a 20-30 percent improvement in the key performance properties of a less-expensive low-performance material, they would be very pleased. For example, a 1 T magnet is inexpensive and can be large, and one could put an entire truck rail into it. That might be useful to industry.

Dr. Gerhardt also asked if once a magnetic field has been used to induce a particular change, the treated material would be in a metastable state. Would the material revert to its original state at different temperatures or change its properties in some way? Dr. Han responded that it depends on what material property has been changed. If the material’s texture is changed and the material is in a solid state, the texture will not be lost. If the solubility is affected at a high temperature, that effect will not be lost. But if the material is processed at a certain temperature and then raised to a higher temperature, the effect that had been added could be lost.

Dr. Gray asked if the surface properties of a material could be impacted without affecting the bulk material. A participant responded that if a continuous magnetic field is used, it will permeate everywhere. If an induction coil is used, it is a function of frequency. A 400 kHz coil will provide shallow penetration, while a 10 kHz coil will provide deeper penetration. As far as the respondent knew, however, no one had shown this.

A participant asked about miniaturizing. The response was that if the superconducting material in a magnet is improved, the diameter of the magnet system can be smaller. The cost will increase, however. With respect to miniaturizing, one must also consider that the bore is an aluminum tube, which is a perfect microwave tube. If a large field is needed, however, either current or area must be increased, as field size equals current multiplied by area, with miniaturizing then becoming difficult. However, if a large force is needed, because force is related to the gradient, miniaturizing is not a problem.

A participant noted that aside from defense applications, there are applications in building and architecture where aligning crystals in a particular way would give a strong elastic modulus longitudinally, potentially enabling novel construction ideas.

Someone asked if there are any synergies between additive manufacturing and electromagnetic field manipulation. The general response was yes, particularly in high stress materials and in large-scale structures like bridges and beams. Electromagnetic manipulation after additive manufacturing may offer a way to provide a more homogeneous material and a lower temperature for annealing.