Fraunhofer-Gesellschaft: The German Model of Applied Research

The Fraunhofer-Gesellschaft (Fraunhofer Society) is a network of German institutes for applied research. The Fraunhofer’s primary mission is to perform contract research for German industry, particularly small and medium enterprises (SMEs), which translate basic research from universities and non-university research organizations into commercial products and industrial processes. The 60 Fraunhofer institutes in Germany, with an average staff of 400, perform research and test industrial processes on their premises which enjoy state of the art equipment and deep human competencies. Fraunhofer’s funding is derived from diverse sources, including federal, state, and European Union public funding, fees from contract research for industry and public organizations and foundations, and licensing fees for intellectual property. It has created roughly150 spin-off companies, with a very high rate of success.

Each Fraunhofer institute specializes in a particular technology or sector, and a Fraunhofer institute exists for virtually every sector of significance to a modern industrial economy, ranging from renewable energy, aerospace, automotive manufacturing, microelectronics and information technology. Each Fraunhofer institute is paired with a German university and can utilize the most promising students as part-time researchers, thereby giving students practical experience in commercially-oriented research and manufacturing environments. The institutes generate technology for commercial products and processes, enable companies to test equipment and industrial processes on pilot manufacturing lines, and foster a continual flow of trained engineers and technicians to the private sector.

The German model of innovation is widely credited as a major factor underlying Germany’s strong international competitive performance since the onset of the global financial crisis in 2008. German exports are at an all-time high and GDP growth outpaces the rest of the Euro zone and the United States. German competitive strength are often attributed to factors such as the country’s

highly-skilled work force; a longstanding “dual system” of education/apprenticeship, which marries academic learning and practical skills; the export prowess of Germany’s small and medium enterprise (Mittelstand), which dominates hundreds of world markets for niche technologies; a web of mutually-supporting networks of companies, associations, and research organizations that can address complex technological challenges and diffuse technology through collaboration; and the excellence of German engineering and manufacturing technology in companies of all sizes. The Fraunhofer plays a central role in supporting all of these aspects of German competitive strength.

Reflecting Germany’s international competitive performance, the Fraunhofer is probably the world’s most thoroughly studied applied research organization, with other countries examining the question of whether they could apply the “Fraunhofer model” wholly or partially and emulate Germany’s success. Of particular interest is Fraunhofer’s role in Germany’s abiding strength in “traditional” industries which have eroded in other developed economies, such as automobiles and machinery. Germany companies have remained competitive in these sectors through a continual process of incremental improvement in existing products and processes, an approach that may not yield technological breakthroughs but builds a competitive edge over a long timeframe. The Fraunhofer emphasizes performance of a large number of short-term research projects that have near-term commercial impact, an approach which reinforces the German method of incremental innovation. It continually diffuses competitively relevant innovation technology throughout the German economy and trains highly-skilled engineers, technicians and managers. Public funding of the Fraunhofer reflects a longstanding German national consensus that public investments must be made in research infrastructure that includes infrastructure for applied research with commercial relevance. 1

It is important, however, not to overrate the impact and the importance of Fraunhofer Gesellschaft for the German research and innovation system. While Fraunhofer Gesellschaft have contributed in significant ways to the recent success of German industry, this success has also rested on factors such as the high demand for capital goods/machinery by emerging economies and the match of this demand with Germany’s industry profile. Other factors supporting German competitiveness include a competitive currency, worker training programs, policies to subsidize the retention of skilled workers in economic downturns, and a dense network of supporting institutions, including localized banks with long-term relationships with Mittlestand firms.2

________________

1Dirk-Meints Polter, a former Fraunhofer deputy director, addressed this point in 1992, characterizing “subsidy,” as a misleading word: “we see ourselves as part of a scientific and technological infrastructure that is provided by the government, just as phones and roads are provided.” New Scientist. 1992. “German Innovation, British Imitation.” November 21.

2Additional instruments include innovation vouchers and Industrial Collective Research institutes. “In numerous Länder, including North Rhine-Westphalia, Baden-Württemberg and Bavaria,

INTRODUCTION

The Fraunhofer has an enviable reputation throughout Germany, Europe, and the world. A report by the U.K. House of Commons Science and Technology Committee commented in 2011 that “the name Fraunhofer resonates across the world and is widely associated with an impressive network of German technology and innovation centres.”3 In 2010, the United Kingdom’s Minister of State for Universities and Science, David Willetts, testified that the Fraunhofer Institutes “have been a key part of Germany’s success in advanced manufacturing and high grade engineering.4 In 2010, Fraunhofer was Germany’s second most popular employer for graduates in the natural sciences, fourth most popular for information and communications technology graduates, and seventh most popular for engineering graduates5. The amount of contract research business with industry—an accepted benchmark of Fraunhofer’s effectiveness in promoting industrial innovation—is at an all-time high and increased by 15 percent between 2010 and 2011.6

Recent German Economic Performance

A recent resurgence of interest in the Fraunhofer reflects the fact that Germany has weathered the financial crisis which began in 2008 far more

________________

innovation voucher programmes have been launched. Normally aimed at SMEs that conduct no R&D of their own, the programmes subsidise part of companies’ costs for consulting or external R&D services. The Federal Ministry of Economics and Technology (BMWi) launched a similar programme in 2010” <http://www.e-fi.de/fileadmin/EFI_2011_en_final.pdf>. The Industrielle Gemeinschaftsforschung, (IGF) is a “a mechanism enabling businesses to solve shared problems through shared projects. This kind of pre-competitive research closes the gap between basic research and industrial application. The results are available for everyone interested and the basis for individual adaptations within enterprises” <http://www.aif.de/en/collective-research.html>.

3House of Commons. 2011. Second Report: Technology and Innovation Centres. Committee on Science and Technology. February 9. p. 41.

4Ibid. pp. 7. German industrial leaders attribute their abiding success in export markets, in substantial part to Fraunhofer and other similar German research organizations. In 2008, Der Spiegel interviewed Ekkehard Shutz, the CEO of Germany’s biggest steel firm, ThyssenKrupp. Commenting on his firm’s success in a global market increasingly affected by low cost manufacturers based in Asia, he observed that despite Germany’s higher cost structure, it remained a “good place for production. You can tell by the fact that the lion’s share of our investment still flows into our German plants. We have exceedingly well-trained employees here, a good research environment, close cooperation with our customers and suppliers, our six partner universities, and non-university research institutions like the Fraunhofer Society and the Max Planck Institute.” Spiegel Online International. 2008. “We are not driving the Price Hike.” July 16.

5Reid, Benjamin et al. 2010. Technology Innovation Centres: Applying the Fraunhofer Model to Create an Effective Innovation Ecosystem in the U.K. Submission to the House of Commons Science and Technology Committee, December.

6Fraunhofer Magazine. 2012. “Boost in Earnings.” February.

successfully than most industrialized nations.7 German manufacturing as a share of GDP stood at 20.7 percent, versus 12.7 percent for the United States and 11.5 percent for the U.K.8 “[D]espite despite the onset of the financial and economic crisis in 2008, German research-intensive industry was able to develop a leading position among the established economies. Sectors which particularly profited from this development include the manufacture of road vehicles, machinery, electrical machinery, and chemicals.”9

This performance poses the obvious question of how a wealthy, high-wage country with a strong currency could compete so successfully in a global market where the terms of competition are increasingly driven by low-cost Asian firms.10

German Model of Innovation

The German model of innovation applies science, technology, and engineering to drive incremental but constant improvements in processes and technologies and aims at niche areas where competition is less intense than in large commodity markets.11 Although Germany has a vast array of research organizations capable of supporting such a strategy, the Fraunhofer is the foremost, and is most often cited as the driver of German competitiveness in export markets. The perception of Fraunhofer as a success story underpinning German competitive achievements in global markets has led other countries to study its methods and structure to determine whether part or all of the

________________

7Spiegel Online. 2011. “Stronger than Expected Growth: German Economy Defies Crisis.” November 15. German GDP grew 3.6 percent in 2010, with the rest of the Euro zone growing at 1 percent or less and the United States at 2.9 percent. German exports in 2011 reached 1 trillion Euros, an 11.4 percent increase over 2010 and the largest volume in German history. Spiegel Online. 2012. “News of Germany’s Strong Growth isn’t Welcome Everywhere.” February 9.

8Manufacturers Alliance for Productivity and Innovation.

9DIW Economic Bulletin. 2011. “German Manufacturing Withstands Rise of Emerging Economies.” June. The Christian Science Monitor observed in 2011 that Germans have looked around lately to find they have the preeminent world-class export economy in Europe. No one else comes close. German precision tools are coveted in Asia and Russia like Fabergé eggs. Germany is building much of the Summer Olympic and World Cup facilities in Brazil. The next generation of Eurostar trains linking the Continent and Britain will be made by Siemens of Germany, not, as they traditionally have been, by Alstom of France—a blow to French pride. The Christian Science Monitor. 2011. “Germany—the new mini-superpower.” January 30.

10Xinhua. 2012. “What’s Behind the Success Story of German Manufacturing Industry?” February 23; Spiegel Online. 2012. “How the German Economy Became a Model.” March 21.

11“Mass production has never been the norm in [Germany] to the degree that it has been in the United States (and Japan)…as a consequence, Germany’s factory work force shows a much stronger element of craftsmanship…this is also the result of the basic education that apprentices get in addition to their on-the-job training.” Junne, Gerd. 1989. “Competitiveness and the Impact of Change: Applications of ‘High Technologies’.” In Katzenstein, Peter J. (ed.) Industry and Politics in West Germany: Toward the Third Republic. Ithaca: Cornell University Press. pp. 256.

“Fraunhofer model” could be adopted domestically.12 The Fraunhofer model was extensively reviewed in 2010 and 2011 by the House of Commons Science and Technology Committee, and aspects of that model are now being adopted in the United Kingdom. 13 In the United States, the Fraunhofer was the subject of studies during the 1990s by the Council on Competitiveness and the Office of Technology Policy in the Department of Commerce.14 In 2005, French Research Minister Francois d’Aubert commented that his country needed to develop “Partnership research…on the model of the German Fraunhofer Institutes.”15 Other countries have demonstrated similar interest.16

Non-German observers tend to cite the Fraunhofer’s funding model as its strongest positive feature. That model, based on a formula of one-third core public funding, one third private contract research and one third publicly-funded contract research, ensures stable long-term funding. The model is particularly attractive to Anglo-American observers whose research institutions have suffered from erratic funding and a partisan political environment in which government support for science is controversial and uncertain. Fraunhofer staff acknowledge the success of the institute’s funding approach, but emphasize its relational aspects as the real basis for its success. Fraunhofer institutes operate in vast, multiple overlapping human and institutional networks embracing universities, companies, research organizations, trade associations, and foundations, organized by scientific field and areas of interest. Relevant units of these networks can be brought to bear on research projects, consortia, and development alliances to address specific tasks based on their particular competencies. Any private or public entity which enters into a research relationship with Fraunhofer gains entrée to these networks.

Fraunhofer is more than a networking organization. It possesses deep and broad organic competencies and institutional scientific memory, reflecting

________________

12In the run-up to the United Kingdom’s 1992 general election, each of Britain’s leading political parties vied to convince voters that their plan to apply the Fraunhofer model in the UK was the superior choice. Physics World. 1992. “Fraunhofer Fever Hits the UK.” March. New Scientist. 1992. “British Innovation, German Style.” March 21. New Scientist. 1992. “German Innovation, British Imitation.” November 21.

13Hauser, Hermann. The Current and Future Role of Technology and Innovation Centres in the U.K. Report for Lord Mandelson. The Daily Telegraph. 2011. “Follow the German Model and be Patient for Manufacturing to Thrive.” August 25. The Sunday Telegraph. 2010. “Welcome to Berlin, Peter. Is it the Future?” February 7.

14Mitchell, A. Duff. 1998. The Fraunhofer Society: A Unique German Contract Research Organization Comes to America. Burton, Daniel F. and Kathleen M. Hansen. 1993. German Technology Policy: Incentive for Industrial Innovation. Council on Competitiveness Occasional Paper, Challenge, January-February.

15Le Monde. 2005. “Research: The Key Points of the Law.” January 17.

16In 2008, the Dubai Institute of Technology (DIT) signed an agreement with Fraunhofer pursuant to which the institute agreed to help DIT develop a “comprehensive R&D and innovation model.” MENA Business Reports. 2008. “DIT, Fraunhofer Sign Agreement on Development of R&D Model.” September 22; Irish Times. “Bavaria or Bust.” June 8.

its permanent staff of scientists, technicians, and managers. Its institutes are extremely well-equipped and most of them operate multiple pilot manufacturing lines and other demonstration facilities.17 The Fraunhofer is a beneficiary of the “power and generosity of the…German machine tool industry,” which permits its labs to be equipped with state-of-the-art machines loaned on generous terms.18 The institute holds a massive patent portfolio which can be deployed on behalf of clients seeking to license cutting-edge technology. It is relentlessly focused on practical applications of technology.

Supporting the Mittelstand

The Fraunhofer is frequently cited in connection with the export strength of Germany’s small and medium enterprises. The best of these firms, the so-called Mittelstand, are typically family-owned, highly specialized, based in small cities and towns, and “build products that dominate obscure industrial subsectors”. “There is no doubt that the German Mittelstand were one of the main factors that generated economic success and prosperity in Germany after World War II.”19 Observing the slogan, “don’t dance where the elephants play,” the Mittelstand pursue niche markets, particularly at the high end of the product spectrum, and make continuous incremental improvements in their products to maintain leadership over their competitors.20 “It might be that their products will not be the cheapest, but they definitely have the best quality.”21 A 2007 study

________________

17Typically the Fraunhofer Institute for Molecular Biology and Applied Ecology IME in Aachen states in its 2011/2012 Annual Report that “The R&D activities in the various IME business areas involve certain platform technologies that need sophisticated apparatus and infrastructure as well as highly trained staff…The services provided include sequencing, chip technologies, proteomics, metabolomics, recombinant protein production, protein purification, protection structural and functional analysis, antibody manufacturing, and high throughput imaging technologies and are available to the working groups within the IME as well as the external clients.” Fraunhofer IME. 2012, Jahresbericht/Annual Report: 2011-2012. p. 15.

18The director of the Automation Department at the Fraunhofer Institute for Production Systems and Mechanical Constructions Technologies IPK, Gerare Dulen, commented in 1987 that in his department, “There are DM 50 million of machine tools in place. Most of them have been lent to us by industrialists. But we do developmental work for their account. Often, they turn prototypes over to us even before commercializing them. We then complete the development and programming of these prototypes. Afterwards they leave the machines with us at no charge for several months. The advantage of this arrangement is that we always have the most modern machines.” Industries et Techniques. 1987. “Applied Research: The Fraunhofer Method.” October 20. JPRS-ELS-88-006.

19Hamburg, Christian. 1999. Structure and Dynamic of the German Mittelstand. Heidelberg and New York: Physica-Verlag. pp. 1. Volker Treier, chief economist of the German Chamber of Commerce, characterizes the Mittelstand as the backbone of the German economy. Treier, Volker. 2011. “The Engine of Growth. Wall Street Journal. June 26. “If a particular job can be best done by a machine, then the chances are that the machine in question was built in a small town in Germany.” The Economist. 2011. “German Business: A Machine Running Smoothly.” February 3.

20Software Magazine. 2011. “Finding Hidden Gems in the German Mittelstand.” October.

21Boeing, Phillip. 2012. “What’s Behind the Success Story of German Manufacturing Industry?” Xinhua. February 23.

found that over 1,130 small and medium-sized German companies occupied the number one or two position in the world market for their products, or the number one position in the European market.22 According to one source, the Fraunhofer’s “main focus [is] on the Mittelstand companies,” and “the research facilities of Fraunhofer serve as external, very well equipped research departments of the Mittelstand companies.”23

The Skilled German Workforce

The Fraunhofer is cited in connection with another aspect of the German model, the country’s highly trained, technologically-adept work force, which has been a subject of foreign admiration and study for over a hundred years.24 To some extent this phenomenon is cultural—German blue collar workers draw on a tradition of craftsmanship with the attitude that “excellence on the shop floor is every bit as important as in the Nobel Prize caliber laboratory.”25 The pursuit of excellence in manufacturing is widely attributed to Germany’s longstanding “dual system” of vocational training, pursuant to which a course of academic study of a practical discipline is undertaken in parallel with apprenticeship at a company or a public vocational institute.26 The Fraunhofer applies the principle of the dual system at the highest educational levels, with masters and PhD candidates and postdocs simultaneously pursuing courses of study in science or engineering while performing work and acquiring practical experience in a Fraunhofer institute.27

________________

22The study was co-authored by Professor Bernd Venohr, a German management consultant generally regarded as one of the world’s leading experts on the Mittelstand and built on findings in earlier work by another expert, Hermann Simon, who coined the term “Hidden Champions” to describe the best of these companies. Venohr, Bernd and Klaus E. Meyer. 2007. The German Miracle Keeps Running: How Germany’s Hidden Champions Stay Ahead in the Global Economy. Berlin: Berlin School of Economics, May.

23Hamburg, Christian. 1999. Structure and Dynamic of the German Mittelstand. Heidelberg and New York: Physica-Verlag. pp. 58-59.

24 Thelen, Kathleen, 2004. How Institutions Evolve: The Political Economy of Skills in Germany, Britain, the United States, and Japan. Cambridge: Cambridge University Press. pp. 39.

25“This has much to do with the fact that the pursuit of excellence in Germany has not been limited to university-trained elites, but has occurred within each layer of German society…One relevant consequence is that managers trained in engineering or the sciences often feel they should be able to prove the mettle of their own skills in front of workers who have high standards against which to measure performance.” Beyerchen, Alan D. 1990. “Trends in the Twentieth Century German Enterprise.” In The Academic Research Enterprise within the Industrialized Nations: Comparative Perspectives. Washington, DC: The National Academies Press. pp. 80.

26In 2008, roughly 58 percent of Germany’s upper-secondary school students were also enrolled in vocation or technical programs, and many students combine apprenticeships with the pursuit of graduate degrees, entering the work force in their mid-20s with highly developed practical skills. Helper, Susan, Timothy Krueger, and Howard Wial. 2012. “Why Does Manufacturing Matter? Which Manufacturing Matters? A Policy Framework.” Brookings. February. p. 27.

27There is increasing overlap between the demand by industry for workers trained in vocational schools and universities. Professor Kathleen Thelen of Northwestern University, who has

Weaknesses of the German System

The German innovation system is by no means perfect. German innovation tends to build on established structures rather than creating entirely new ones; product and process improvements are slow, albeit continuous. “The resulting pattern of innovation is one that is more likely to generate improvements of existing products of existing firms and sectors than to give rise to new ones.”28 The postwar German system has not produced “radical, path-breaking innovations found, for example, in America.”29 Some observers believe that Germany’s “heavy concentration of R&D and innovation activities in the automotive sector…may lead to an unbalanced innovation system.”30 “Germany never came close to a computer industry that was able to compete with its U.S. counterpart.”31 Start-ups which become spectacular successes are rare, and would-be startups confront obstacles such as inadequate availability of venture and bank capital and legal and societal factors that punish market failure.32 As a

________________

extensively studied the German training system, notes that “firms (even small, medium-sized handicraft firms) are increasingly inclined to recruit new workers from among applicants holding university degrees…[there is] increasing competition between job applicants from the traditional vocational training track and those with technical college and university degrees. Thelen, Kathleen. 2004. How Institutions Evolve: The Political Economy of Skills in Germany, Britain, the United States, and Japan. Cambridge: Cambridge University Press. pp. 274.

28Streeck, Wolfgang. 1995. “German Capitalism: Does it Exist? Can it Survive? In Colin Crouch and Wolfgang Streeck, eds. Modern Capitalism or Modern Capitalisms? London: Francis Pinter. p. 14.

29Harding, Rebecca. 2000. “Resilience in German Technology Policy: Innovation Through Institutional Symbiotic Tension.” Industry and Innovation. December. p. 223.

30Astrom, Tomas, Marie Louis Eriksson and Lars Niklasson. 2008. International Comparison of Five Institute Systems. Copenhagen: Forsknings-og Innovationsstyreisen. December 23. p. 108. Numerous Fraunhofer institutes pursuing research themes with little apparent nexus with the automotive sector are in fact active in that sector. The Fraunhofer Institute for Experimental Software Engineering IESE is working with Audi on the development of software for electric vehicles, with BMW on a model for estimating the cost of software projects, and with “companies from the automotive domain” on software testing techniques. Fraunhofer IESE, “Automotive and Transportation Systems.” <http://www.iese.fraunhofer.de/en/customers_industries/automotive/referenzprojekt_mbtech.html>. The Fraunhofer Institute for Communications Systems ESK has a large “Business Unit Automotive” working on automotive software engineering, external communications from motor vehicles, and internal transmission and processing of data in vehicles. <http://www.esk.Fraunhofer.de/en/automotive.html>. The Fraunhofer Institute for Chemical Technology ICT is collaborating with Faurecia to develop advanced industrial processes for composites for application in the automotive field. Fraunhofer ICT, “Faurecia Signs R&D Agreement with the Fraunhofer ICT for Advanced Industrial Processes in the Field of Composites.”

<http://www.ict.fraunhofer.de/en/press_media/pressemitteilungen/2012/release4.html>.

31Wieland, Thomas. 2006. “Innovation and Culture, Technology Policy and the Uses of History.” Munich Centre for the History of Science and Technology. p. 7.

32Uwe Waltz, a professor at the Center for Financial Studies at the University of Frankfurt observed in 2011 that “entrepreneurship is not valued in Germany as it is in the United States. On top of that, U.S. business men are likely to go on the market at the first opportunity, while Germans like to perfect the final technical details before going into business.” Deutsche Welle. 2011. “Germany’s Venture Capital Market Starts to Take Off.” June 1.

result, with the notable exception of SAP, there is no German counterpart to Intel, Apple, Google, or Facebook. The former area of East Germany absorbs a substantial part of the federal research spending but generates comparatively little innovation.33

Dr. Stefan Kulhman, Director of the Fraunhofer Institute for Systems Innovation Research in Karlsruhe, told a National Academies symposium in 2007 that Germany’s education system, long considered quite strong, had declined to a point of crisis and required “and expensive restructuring.”34 The German university system is widely criticized and may prove incapable of supplying enough graduates with the skills required by German industry.35 In 2011, on any given month, Germany averaged 92,000 vacant engineering jobs. The director of the Köln Institute for Economic Research IW, Hans-Peter Kloes, commented that “if we cannot close the engineering gap, the continuing shortage of qualified employees will become a threat to the German business model.”36 Even the vaunted vocational training system is under strain; a 2010 study by Germany’s education ministry found that while there was an unmet need in German industry for 9-10,000 apprenticeships, one in five apprentices “did not stick out the apprenticeship,” the number of students entering apprenticeships was declining, and “businesses are facing a huge drop-off in apprentice numbers.”37

The Fraunhofer is implicated in at least some of these systemic weaknesses:

- Because the Fraunhofer business model is based on demand for research from industries that already exist, it has little economic

________________

33“East Germany and Berlin together eat up nearly one-quarter of the… federal research budget while employing only 11 percent of the country’s R&D personnel and accounting for 6 percent of its patent production.” Kuhlman, Stefan. 2007. “The Record and Challenge in Germany.” In National Research Council. Innovation Policies for the 21st Century. Charles W. Wessner (ed.) Washington, DC: The National Press. p. 70.

34Ibid. p. 70.

35National Research Council, Rising to the Challenge: U.S. Innovation Policy for the Global Economy. Wessner, Charles W and Alan Wm Wolff (eds.). Washington, DC: The National Academies Press. 2012. pp. 274. The Economist. 2009. “On Shaky Foundations.” June 25. The Times Higher Education World University Rankings 2011-12 place four German universities in the top 100 institutions worldwide. The highest ranked German university was Ludwig Maximillian University in Munich. The Economist. 2011. “German Universities: Mediocre but at least They’re Free.” June 30.

36Spiegel Online. 2012. “VDI Study—Lack of Engineers Costs German Economy Billions.” April 26. Bernd Rau, one of the founders of the Mittelstand company Roth and Rau, commented in 2010 that his company’s search for skilled workers was becoming acute. “It is more and more difficult, especially for the IT people, and also in engineering and mechanical engineering.” Deutsche Welle. 2010. “Labor Bottleneck Squeezes Germany’s Solar Sector.” November 23.

37Deutsche Welle. 2010. “Germany faces Youth Employability Crisis, Says New Report.” April 28.

-

incentive to incur the costs and risks associated with creating entirely new industries.

- The Fraunhofer and other non-university research institutions compete with German universities for funding and personnel, and may have contributed to the erosion over time of university-based scientific research in Germany.

- The Fraunhofer’s emphasis on research with relatively low risk, short time horizons, and early commercial payoff undermines its ability to support sectors such as biotechnology in which risks are substantial and the path to market is often many years long.

Although Fraunhofer centers have been established in the United States and other countries, they have not enjoyed the degree of success of their affiliates in Germany and it is questionable whether the Fraunhofer model is adaptable in its main aspects to a U.S. industrial innovation context:

- The full extent to which the Fraunhofer relies on government funding is frequently not appreciated. A widespread misimpression exists that the Fraunhofer’s primary funding source is the private sector. In fact, one-third of Fraunhofer’s funding consists of “core” money provided by the German federal and state governments, roughly another third comes from research contracts with government entities, and one third is provided through research contracts with the private sector—which are frequently supported by government grants and other financial assistance. While Germany as a nation tends to regard such public expenditures as a necessary form of infrastructural investment, it is unclear that such a high-level of government spending on commercially-related research could be reconciled with U.S. economic ideology or fiscal realities.

- A system of Fraunhofer-like research institutes could weaken U.S. university-based innovation. The U.S. Bayh-Dole Act of 1980 provided that U.S. universities conducting federally-funded research could own the patents for the technologies they developed, a policy shift that fostered an explosive growth of new companies commercializing university-based R&D. The Fraunhofer model interposes an intermediary organization between universities and industry, at that intermediary—not universities or companies—ends up as the owner of most of the intellectual property rights derived from government-funded research. While the Fraunhofer actively licenses its IP to industry, it is not clear that the German model is as dynamic as the current U.S. university-based system which—in contrast to the German—has given rise to entirely new technology-intensive industries. In addition, an intermediate research organization will

-

inevitably compete with universities for public and private funding as well as personnel.38

- The Fraunhofer model derives much of its strength from other elements of the German innovation system which are not present to the same degree in the U.S. The United States has no close parallels to the German system of stable government funding for commercially-relevant research; to the Mittelstand; to the “dual system” of vocational and training; or to the German tradition that competition should be subordinated to cooperative arrangements. These aspects of the German system reflect complex, multigenerational cultural and institutional evolution and cannot easily be replicated elsewhere. In this connection, an exchange which occurred in Britain’s House of Commons Science and Technology Committee in 2012 is worth noting. MP Sir Peter Williams commended the Fraunhofer model to his colleagues and urged that the country learn from it:

Williams: Down the decades everybody, from John Fairclough onwards, has said to the Government ‘Look at the Fraunhofer-Gesellschaft; there are lessons to be learned’. It is a fact that they do not have to debate the issues that we are debating today because they have been through the valley of death as a nation, as it were, and they prosper by valuing and backing engineering with their Lander, federal government, financial institutions, Mittelstand families, scientists, engineers, and business folk playing like a team, which is why they are going to win the European Championship as well…

MP Jim Dowd: So we could have all these benefits as well if all we did was change every single piece of our social structure.39

The Fraunhofer and the German innovation model are nevertheless of interest from an Anglo-American perspective because of Germany’s success in holding its leadership position in traditional manufacturing industries and in retaining a major manufacturing presence in Germany itself, with the implications which that holds for employment and regional economic development. Germany remains strong in industries like automobiles,

________________

38In the British Parliament’s recent deliberations over the establishment of intermediate research organization patterned on the Fraunhofer, concern was expressed by the Institute of Physics that the result “may well be to put further pressure on the universities which use research contracts as alternative sources of funding.” House of Commons Science and Technology Committee. Technology and Innovation Centres. Second Report of Session 2010-11. Volume I, Report, p. 27.

39House of Commons, Science and Technology Committee. “Bridging the Valley of Death: Improving the Commercialization of Research.” June 20 2012. Transcript of Oral Evidence.

machinery, metals, and chemicals—industries that have eroded, shed jobs, and begun to move offshore in the United States and the United Kingdom. For this reason, the German innovation system warrants study.

THE INSTITUTIONAL SETTING

The German innovation system is complex, featuring multiple levels of governance and interlocking responsibilities between different ministries and between authorities at different levels of the political system.40 Significantly, “in contrast to many other countries, [in Germany], there is an implicit consensus at the federal and state levels that funding should, by and large, be geared towards bridging the gap between knowledge creation and application.”41 The system is characterized by dispersion of authority and funding responsibility.42

Federal Ministries

At the federal level, the main responsibility for science and technology policy lies with the Federal Ministry of Education and Research (BMBF). The BMBF co-funds with the Länder Germany’s non-university research organizations, including Fraunhofer, and is the principal source of the institute’s basic public funding. The BMBF provides funding for a broad array of research programs and projects, generally aiming at collaborative R&D between public sector research and the private sector. Many BMBF programs are managed by semi-autonomous program agencies, a mechanism that has been characterized as “industry friendly”. The Federal Ministry of Economics and Technology (BMWi) promotes innovation-and-transfer projects through public-private R&D collaboration in topical areas which include energy, information technology, media, and aerospace. It operates a number of programs to support small and medium enterprises and to promote start-ups.43

________________

40“In Germany, science and technology planning, policy making, and funding take place on such a wide variety of different levels, and there are so many institutional structures, that it is difficult to avoid over-simplification when one tries to draw a coherent map of the present system…not only do we have a wide variety of institutional actors, but within each institution, we also find quite diversified structures funded by a multiplicity of sources and consisting of many sub-systems.” Krull, W. and F. Meyer-Kramer. 1996. Science and Technology in Germany. London: Cornell University Press.

41Edler, Jakob and Stefan Kuhlmann. 2008. “Coordination within Fragmentation: Governance in Knowledge Policy in the German Federal System.” Science and Public Policy. pp. 267.

42Throughout the German research system, “no performing actor is totally dependent upon only one policy actor for its resources,” so that all players can turn to more than one funding source for support, an arrangement which protects the autonomy of research actors from external direction and pressure. Winnes, Markus and Uwe Schimack. 1999. National Report: Federal Republic of Germany. Institute for the Study of Societies. TSER Project No. SOE1-CT96-1036. May.

43Edler and Kuhlmann. 2008. “Coordination within Fragmentation.” Op Cit. p. 268.

Federal-state Arrangements

Since 1975, federal-state funding of scientific research has been governed by the “Framework Agreement on Research Promotion” (RV-Bo) pursuant to which funding ratios are assigned to the federal government for universities and non-university research organizations. Under this arrangement, the Fraunhofer receives 90 percent of its core funding from the federal government and 10 percent from the Länder. The 90:10 funding ratio has endured for decades; it is one of many “organizational arrangements” in the German innovation system which “are very rigid because they are the result of complicated power balances which nobody can disturb because of possible incalculable consequences.”44 The rigidity of the German research funding arrangements arise out of a concordat between the federal government and the Länder that was negotiated in the early 1970s.45

“Research Cartel”

“Fraunhofer institutes occupy a specific role in a very elaborate division of labour within the German system of research.”46 The German non-university scientific research arrangements are widely characterized as a research promotion cartel. The lines of demarcation with respect to the responsibilities of each organization have been clearly established for many years, and no significant new research actor has entered this universe for decades.47 Competition within the institutes between internal subunits is

________________

44Winnes and Schimank. 1999. Federal Republic of Germany. Op. Cit. pp. 14.

45The “Bund-Länder Commission for Educational Planning and Research” (BLK) is a standing committee comprised of representatives of the federal government and each German state with a mandate to coordinate federal-state planning in research policy, and functions as the central clearing house for the financial aspects of governmental support for research. Since 1975, when the BLK was established, major decisions concerning the organization, operation, and funding of government-supported research have required joint action by the Länder and the federal government within the complex decision making structure of the BLK. That fact has placed the public funding of university and non-university research on a stable permanent basis, shielding research organizations from short-term budget gyrations and political meddling. Moreover, because of the difficulties associated with building the necessary consensus within the BLK, selection of research themes and the allocation of funds has largely been left to the scientific community to avoid politicizing decision making. These beneficial aspects of the German federal research system are partially offset by the stasis associated with the vertical interlocking organizational structure. Changes to the status quo can be vetoed by negatively-affected Länder, forcing a constant pursuit of consensus which “often allows only decisions on the lowest common denominator.” Winnes and Schimank. 1999. Federal Republic of Germany. Op. Cit. pp. 45.

46Written Evidence Submitted by Manchester Institute of Innovation Research, Manchester Business School, University of Manchester. (TIC 09). House of Commons Science and Technology Committee. February 17, 2011.

47The presidents of the research organizations meet on a regular basis among themselves and with the federal research ministry to discuss science policy, meetings which are dubbed “the holy

TABLE APP-A2-1 Germany’s Key Research Organizations

| Institution | Focus |

| Max Planck Society | Basic Research |

| Helmholtz Association | Basic Research (“big science”) |

| Fraunhofer Society | Applied Research |

| Leibnitz-Association | Various |

similarly constrained by the establishment of clear lines of demarcation between organizations and encouragement of collaboration when areas of overlap become apparent.48

The Max Planck organization, universities and public sector research organizations are responsible for basic research. The Helmholtz Association ensures infrastructure for large scale science projects of national importance.49 Fraunhofer and other institutes of applied research, such as the Steinbeis Foundation, are responsible for the transfer of technology from the science base to industrial end users.50 The Max-Planck and the Fraunhofer usually do not

________________

alliance”—a reference to the Nineteenth Century multilateral grouping of states that emerged from the Congress of Vienna and sought to preserve existing European frontiers and the balance of power. Winnes and Schimank. 1999. Federal Republic of Germany. Op. Cit. pp. 66.

48The German research minister reported in 1991 that “The increasing degree of overlapping of the acquisition fields of the individual Fraunhofer establishments, acting as profit-making centers, has triggered a process of debate in the FhG. It is conducted with the goal of supporting, by means of the proper organizational measures, the increasingly necessary processes of balance and demarcation between the individual institutes and facilities.” Thierbach, Dieter. 1991. Deutsche Einheit in Forschung und Technologie. Bonn: BMFT. Part. 2.6.

49The Helmholtz Society concentrates on long-term research which is either extremely costly or very risky and requires large research teams. Areas of focus have included high-energy physics, space technology, nuclear energy, medicine, environment technology, and biotechnology. Der Spiegel. 2008. “New Federal Funds. April 7. Wilhelm Leibniz (formerly known as the Blue List) is a designation for about 80 other large and medium-sized research organizations which engage in basic and applied research. Finally, 50 research institutes are directly organized under a federal ministry (Bundesforschungsinstitut) and similar organizations funded by the Länder.

50Harding. 2010. “German Technology Policy.” Op. cit. pp. 228. The Steinbeis Foundation operates technology transfer centers across Germany, and performs a networking function between basic research organizations and German industry. Unlike Fraunhofer, Steinbeis does not operate large-scale research infrastructure. Within the German research community, the research demand directed at Fraunhofer is usually regarded as less scientifically interesting than the demand directed at the basic-science oriented Max Planck institutes so that in Fraunhofer, “science curiosity is clearly subordinated to societal relevance.” Winnes and Shimank. 1999. Federal Republic of Germany. Op. Cit. pp. 211. At the same time, Fraunhofer scientists sometimes express a degree of disdain for basic research. One director in 1987 commented that “In the FRG we spend too much money on basic research. Currently everyone is concentrating on superconductors. That’s the problem of basic research. It is unable to escape the influence of what’s in vogue. Here, there is no such danger. We live on our results like a commercial firm…our job consists of demonstrating the feasibility and

compete for the same projects but will collaborate on specific projects that require the skill sets of both the basic and applied sciences.51

Federal High-Tech Strategy 2020

The German federal government is currently pursuing a “High-Tech Strategy 2020,” an effort to coordinate existing public support for research and innovation in a manner which improves the country’s international competitiveness and innovative capability. A target of this effort is to increase German R&D spending to 3 percent of GDP (it was about 2.8 percent in 2010). Reflecting the concern that German public funding of R&D is characterized as a “sprinkling can,” featuring large numbers of small grants for small projects, the High Tech Strategy seeks to concentrate public spending on targeted areas of cutting edge research. The strategy also targets perceived weaknesses in the German innovation system, including an inadequate market for venture capital and direct investment capital, inadequate participation by SME’s in R&D, and difficult conditions confronting technology-based start-ups and their financial backers.52

State Initiatives

Within the German federal system the Länder enjoy a degree of leeway for unilateral policy initiatives. They control the universities within their jurisdictions and can determine their funding level and strategic direction, and they can also provide non-university research organizations located in their territory with additional funding through research contracts and with a variety of other forms of support. Finally, they can use incentives to encourage new research institutes to choose them as sites and to attract research organizations and talented individuals from other Länder. Baden-Wurttemberg, North-Rhine-

________________

economic viability of technologies of the future.” Heuberger, Anton. 1988. “Applied Research the Fraunhofer Method.” Industries et Techniques. February 23. JPRS-ELS-88-006.

51Handelsblatt. 1991. “Joseph von Fraunhofer and Max Planck Can Feel Satisfied.” August 9. JPRS-EST-91-015. A recent example of Fraunhofer-Max Planck collaboration is a project involving the Fraunhofer Institute for Digital Media Technology, the Fraunhofer Institute for Integrated Circuits and the Max Planck Institute for Evolutionary Anthropology to develop a program that will recognize individual apes from photos, video, and audio footage, enabling biologists operating in the wild to track the number of individuals of a given species, to assess whether a given population is growing or declining, and to identify which factors affect the population. The Engineer. 2011. “Facial-Recognition Software Could Help to Save Great Apes.” August 1. Fraunhofer offers five-year, five million Euro research contracts to Max-Planck scientists who have ideas for applications for their basic research results. Comin, Trumbull, and Young. 2012. Fraunhofer: Innovation in Germany. Op. cit. p. 10.

52Federal Ministry of Education and Research. 2010. Ideas. Innovation. Prosperity. High Tech Strategy 2020 for Germany.

Westphalia and Bavaria have used such methods to develop technology-intensive economies.

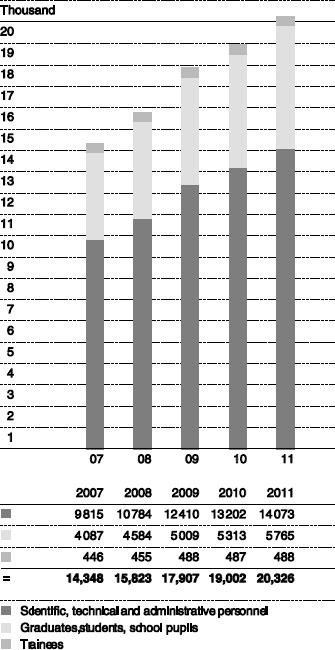

THE FRAUNHOFER GESELLSCHAFT TODAY

The Fraunhofer Gesellschaft is comprised of 60 research institutes active in over 250 business fields and core competencies. Its institutes are widely dispersed across Germany. Its legal form is a registered association under private law (eingetragener verein). Its annual budget is about 1.8 billion Euros. It has 20,000 employees.53 Each Fraunhofer institute is linked with a German research university and the Directors of Fraunhofer institutes usually also serve on university faculties. The Fraunhofer has established seven institutes in the United States and research subsidiaries in Chile, Austria, Portugal, and Italy. In strictly legal terms, the Fraunhofer is under no obligation to execute research programs drawn up by government entities but in practice its research orientation is closely aligned with that of the German government and the European Union.54

The Fraunhofer Mission

The core purpose of the Fraunhofer is the pursuit of knowledge with which has practical utility. It manages an annual business volume of about a billion Euros, most of it involving contract research.55 Characterizing itself as a “bridge” linking German universities and industry, the Fraunhofer is a formidable research organization in its own right, and generally owns the patents which are derived from joint university/Fraunhofer/industry collaboration. Fraunhofer institutes do not so much transfer knowledge from universities to industry as “generate relevant application-oriented knowledge themselves on demand from their clients. While this may often be strongly linked to research in universities…it nevertheless constitutes a knowledge creation sub-system of its

________________

53The 20,000 headcount was reported in Fraunhofer Magazine in February 2012.

54Germany’s research ministry has periodically assigned Fraunhofer clearly-defined missions in major national areas such as new materials, information technology, and the establishment of a research infrastructure in the former East Germany. Thierbach, Dieter. 1991. Deutsche Einheit in Forschung und Technologie. Bonn: BMFT. Part. 2.6. Technologie-Nachrichten Programm-Informationen. 1991. “Interim Report by the Federal Ministry of Research and Technology on the Implementation of the Unification Treaty Dated 31 August 1990 in the Area of Research and Technology. March 5; BMFT. 1986. Materialforschung JPRS-EST-86-036. November; BMFT. 1986. Forschung und Technik zum Whole Der Menschen: Jahresbericht 1984. JPRS-WST-86-015. March; “The Fraunhofer pays close attention to the research and technology policy of the European Community.” Frankfurter Allgemeine Zeitung. 1985. “Expose Chips with X-Rays.” JPRS-WST-86-018. October 24.

55Fraunhofer. 2010. Annual Report. p. 15.

own.”56 Because Fraunhofer is heavily dependent on revenue from contract research performed for industry, its research is closely correlated with the practical needs of companies. If a choice needs to be made between money from an industry project or the pursuit of cutting edge technology, the Fraunhofer institutes usually of necessity choose money.57 Although Fraunhofer R&D projects tend to be relatively small, short-term efforts seeking incremental improvements in products and processes, its institutes have achieved numerous noteworthy innovations.58

Governance

The Fraunhofer’s 60 research institutes in Germany are supervised by a headquarters organization based in Munich.59 Executive direction is provided by a President who is also Chairman of the Executive Board, comprised of three Senior Vice Presidents. The Executive Board manages the institutes’ business activities, develops science and research strategies, and negotiates with governmental organizations to raise funding. The Executive Board appoints the Directors of the individual Fraunhofer Institutes.60

________________

56Written Evidence Submitted by Manchester Institute of Innovation Research, Manchester Business School, University of Manchester. (TIC 09). House of Commons Science and Technology Committee. February 17, 2011. Dr. Hans Kunz, Director of the Fraunhofer Institute for Materials in Bremen, explained in the 1980s, that “we start where basic research stops. In the universities, research tries to produce a few micrograms of a new material. Here we try to scale this mark up to the level of the kilogram or the ton. Our idea is to offer industries a product together with its manufacturing process.” “Applied Research the Fraunhofer Method.” Industries et Techniques. February 23. JPRS-ELS-88-006.

57Interview with Fraunhofer Institute for Process Engineering and Packaging. Freising, Germany, June 13. 2012.

58Spiegel Online. 2009. “Solar Energy: German Research Strives to be a World Leader.” September 15; Spiegel Online. 2011. “A Stuttgart Lab’s Pioneering Effort to Cultivate Human Flesh.” April 15; Spiegel Online. 2007. “New Computer Program to Reassemble Shredded Stasi Files.” May 10; New York Times. 2005. “MP3 Developer Yields Royalty Riches.” March 10.

59Fraunhofer headquarters enjoys the organizational flexibility to redistribute resources among the research institutes. Prosperous institutes effectively cross-subsidize weak performers as long as the latter can be expected to prosper themselves in a reasonably foreseeable period of time. Fraunhofer headquarters is a service organization for the Fraunhofer institutes, and the institutes pay an annual service fee to headquarters.

60The Executive Board is supervised by a Senate comprised of roughly 30 eminent representatives of the fields of science, industry, and government. The Senate appoints the Executive Board, decides the Fraunhofer’s basic research policy, and makes decisions with respect to the establishment, merger, or dissolution of individual Fraunhofer institutes. The Senate is elected by the General Assembly, an entity which meets annually and is open to members of the Executive Board and Senate as well as individuals and legal entities interested in supporting the work of the institute. Fraunhofer. 2010 Statute of the Fraunhofer Gesellschaft. The Statue is not public legislation but a set of internally generated institutional by-laws. Fraunhofer. Structure and Organization of Fraunhofer-Gesellschaft: Scientific and Technical Council. Accessed at

<http://www.fraunhofer.de/en/about-fraunhofer/structure-organization/WTR.html>. The Executive Board is advised by the Scientific and Technical Council, an internal advisory organization. The Council is comprised of the Directors

Each Fraunhofer research institute is managed by a Director and Steering Committee. The Fraunhofer seeks Directors who combine scientific achievement and entrepreneurialism, and the Directors typically serve on boards of directors of German companies. The individual Fraunhofer institutes enjoy a high degree of autonomy and are allowed to choose their research fields and topics, their projects and the handling of project results. Individual institutes are free to determine their own internal organizational structure, set up separate profit centers, and distribute basic funding. The institutes are responsible for balancing their own budgets. If an institute experiences an operating loss in a given year, the shortfall is made good with funds from headquarters. Institutes that incur losses for a number of consecutive years risk closure.61 Each institute is advised by an Advisory Board comprised of representatives from industry, the scientific community, and the public sector. Each institute must review its strategic plan every five years, and, at five year intervals are subject to external audits.62

Growth in Contract Revenue

The Fraunhofer benchmarks its performance on the demand for its services from industry, manifested in revenue from research contracts. During the period 2007-2011, its annual industrial contract revenue grew by 78 million Euros, an increase of over 23 percent, and in 2011 hit an all time high of 406 million euros. Total contract revenue (public and industrially funded research) has grown steadily and reached 1.515 million Euros in 2011.

Relationships with Universities

Each Fraunhofer institute is linked with a German university with a research capability in the sciences and/or engineering which addresses the institutes’ area of focus. The Director of each institute usually is also a member of the faculty, and typically identifies the most promising university students to

________________

and Senior Managers of the FhG institutes and an elected representative of the research staff from each institute. The Council advises the Executive Board with respect to research and human resources policy, the appointment of directors, and the establishment or closure of institutes.

61Five Fraunhofer institutes were closed or turned over to other organizations in 1983. In general such closures are rare. VDI Nachrichten. 1984. “Between Science and Economics: Fraunhofer Presents 1983 Financial Statement.” November 16. JPRS-WST-85-01.

62Interview with Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB. 2012. Munich, Germany. Jun 15 2012. Establishment of new Fraunhofer institutes begins with a search for a university with a good reputation and strong capability in a given field. A Fraunhofer “project group” approaches the university about setting up a new institute in a collaboration. At present, a Fraunhofer project group is exploring the prospects for establishing a new institute in Mannheim in collaboration with medical schools in that city. If this project moves forward, a Fraunhofer medical institute will be operating with a staff of about 50 people within 5 years. Interview with Fraunhofer Institute for Production Technology and Automation IPA. 2012. Stuttgart, Germany. June 14.

steer to positions at Fraunhofer.63 Most Directors spend the majority of their time at the institute rather than in teaching activities.

The relationship between one of Germany’s leading universities of technology, RWTH Aachen, and Fraunhofer, illustrates the close interrelationship the institute develops with universities. RWTH Aachen, Germany’s oldest technology-oriented university, is co-located with four Fraunhofer institutes in the Aachen area, Fraunhofers ILT (lasers), FIT (applied information technology), IPT (production technology), and the Fraunhofer Institute for Molecular Biology and Applied Ecology IME. Adapting ideas from Stanford and Silicon Valley, RWTH Aachen allows companies to locate on campus, participate in university activities (including teaching) and enroll employees in university courses. A total of 18 chairs and institutes at RWTH Aachen and two Fraunhofer institutes (ILT and IPT) have established a “Cluster of Excellence…Integrative Production Technology for High Wage Countries,” the purpose of which is “to engage process engineers and materials scientists to develop new concepts and technologies for sustainable manufacturing.”64

Another example of the close Fraunhofer-university collaboration is the Dresden Innovation Center Energy Efficiency (DIZEEFF) which involves the Technical University of Dresden and the Fraunhofer-Gesellschaft. This involves a total of 13 collaborations between 8 university institutes and four Fraunhofer institutes in the area of energy efficiency. This effort “tightly connects basic research at [the University] with Fraunhofer’s competencies to transfer technologies and innovations to industry.”65

Funding

It is commonly said that one third of Fraunhofer’s revenues are contributed by the federal and Länder governments, one-third derived from

________________

63One Fraunhofer scientist who also serves on a university faculty observes that “my marketing effort is my lecture. I convince students to work [at Fraunhofer] 15-20 hours per week. I’m positioned to find the best. They can stay until they get their PhD (5-8 years), and use our excellent network to find jobs. We don’t pay a lot but the experience is good.” Interview with Fraunhofer Institute for Production Technology and Automation IPA. 2012. Stuttgart Germany. June 14.

64Fraunhofer ILT. 2010. Annual Report. pp. 33-34. Fraunhofer ILT, which specializes in laser technology, works closely with three RWTH Aachen University Chairs: Laser Technology (LLT), Technology of Optical Systems (TOS), and Nonlinear Dynamics of Laser Processing (NLD). The Fraunhofer ILTs’ “knowledge of current industrial and scientific requirements in the optical technologies flows directly into the planning of the curriculum.” Undergraduates and postgraduates “can put their theoretical knowledge into practice through project work at the three chairs and at the Fraunhofer ILT.” University courses are jointly dawn up by the university and the ILT institute. In addition to these collaborations, Professor Thomas Taubner, who oversees a working group at Fraunhofer ILT studying new nano-optic concepts using lasers, also holds a junior professorship at RWTH Aachen for “Nano-optics and Metamaterials,” where he supervises research by students in physics involving new imaging techniques with nanometric spatial resolution.

65Fraunhofer Institute for Material and Beam Technology. 2011. Annual report 2011. pp. 110.

industrial contracts, and one-third from public research contracts. This Drittelsung (literally, “third solution”) model has won extensive praise from foreign observers. “The Fraunhofers are quite safe in their funding, longer term, with those three separate pots of money to take.”66 While Fraunhofer spokesmen emphasize the revenue derived from contract research, the sine qua non of the Fraunhofer model is a major and sustained investment of “core” public funds at the national and state level.67 In Germany, the “Fraunhofer, for a long period, across different governments, have maintained a very significant chunk of public money in the structure,” a reflection of the relative stability of the German political system.68

The Fraunhofer’s one-third, one-third, one-third model is not, as sometimes believed, an indicator that the private sector accounts for two-thirds or even one third of the institute’s revenue. Governments substantially outspend private industry with respect to the contract research which the Fraunhofer institutes perform, accounting for over 45 percent of the total, versus 39 percent for private industry. Moreover, a substantial part of “industry” funds are comprised of government grants and other funding raised by companies and paid to Fraunhofer for contract research.69 Table APP-A2-2 depicts the Fraunhofer’s revenues by source for the year 2010, the most recent year for which such information is publicly available. The figures indicate that federal and state spending accounted for 1,080 million Euros out of total revenue of 1,727 million Euros, or 62.5 percent of the total revenues.70 Private industry contributes about 26.3 percent of total Fraunhofer revenues. Even these figures

________________

66Ridgway, Keith. 2010. Testimony to the House of Commons, Committee on Science and Technology. December 20.

67“The overriding lesson from Germany is that such centers must be funded consistently and at a significant scale over time if they are to deliver the economic impact of which they are capable.” Written Evidence Submitted by Rolls Royce (TIC 82). House of Commons Science and Technology Committee. January 12, 2011.

68Andrew Miller, the Chairman of the Science and Technology Committee commented with respect to the Fraunhofer’s funding model: “The other part of the Fraunhofer is, of course, longevity. Because the German political system doesn’t fluctuate like our system does, that is perhaps one of the reasons why there has been long-term continuity. Miller, Andrew. 2011. Formal Minutes. House of Commons, Ev. 28. January 12.

69In 1992, Rudolf Simon, the research director of Meissuer and Wurst, a Stuttgart-based producer of water and air filtration systems, commented on a contract research project performed by the Fraunhofer for his firm. “The Fraunhofer helped us—this is a very important point—to get the funding for our research activity from the government. Without this funding, I must say we would have been very reluctant to give subcontracts to the institute.” New Scientist. 1992. “German Innovation, British Imitation.” November 21. In the 1980s, the federal research ministry provided grants to small and medium companies to participate in contract research projects at Fraunhofer institutes to develop applications for hybrid integrated circuits in sensor systems. “Technologie Nachrichten—Management Informationen. 1987. “BMFT Subsidizes Thin Film Technology Research.” JPRS-ELS-87-015. March 2.

70A 2011 PowerPoint presentation by Anke Hellwig, a Fraunhofer Headquarters executive, the figure for 2010 for federal and Länder funding was 406 million Euros. Hellwig, Anke. 2011. “Fraunhofer: A Non-Profit Organization with Entrepreneurial Spirit.”

| TABLE APP-A2-2 Fraunhofer Gesellschaft Revenue by Source | ||

| 2010 (Millions of Euros) | ||

| Basic (Core) Funding | ||

| Federal Government | 490 | |

| Lander Government | 63 | |

| Revenue from FhG Activities | ||

| Federal Government | ||

| Project Funding | 323 | |

| Contracts | 11 | |

| Lander Government | ||

| Project Funding | 190 | |

| Contracts | 3 | |

| Revenue from the Private Sector | 454 | |

| Research Funding Organizations/Other | 111 | |

| Increase in work in progress | 36 | |

| Other operating income | 39 | |

| Interest and other income | 1 | |

| Total | 1,727 | |

| SOURCE: Fraunhofer Gesellschaft Annual Report 2010. | ||

probably understate the amount and proportion of public funding because they do not break out funding from the European Union programs as a separate line item.71

________________

71EU funding may be included in “research funding organizations and other funding sources”, it may be reflected in “revenue from the private sector, or both. One Fraunhofer Institute, Fraunhofer IGB in Stuttgart, reported in 2011-12 that 4.8 percent of its revenue from contract research are derived from the EU. However, FhG IGB staff indicate that other EU funding is provided to SMEs which use it to fund contract research at FhG IGB and it is counted under revenue from “industry and trade associations.” Interview with FhG IGB. 2012. Stuttgart, Germany. July 14. A 2011 Fraunhofer presentation set the EU contribution to the institutes’ revenues at 65 million Euros in 2010. Hellwig, Anke. 2011. “Fraunhofer: A Non-Profit Organization with Entrepreneurial Spirit.”

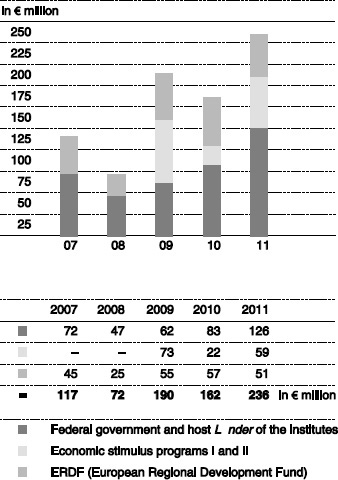

Basic or core funding is provided by the federal and Länder governments in the form of grants which are not tied to any particular activity or expenditure on a 90/10 federal/state ratio. The Fraunhofer headquarters allocates nearly two-thirds of its basic funding to individual FhG institutes pursuant to a formula which creates an incentive for institutes to raise additional funding from the EU and from industry—e.g. the more external funding raised by the individual institute, the more basic funding it will receive from headquarters. Another ten percent of the basic funding is awarded to institutes on the basis of competitive bids for proposals to enter new research fields. 10 percent of the basic fund is used to purchase new equipment.72 The remaining 15 percent is retained by the FhG Executive Board for use for special projects and the opening of new institutes.73 In recent years, the Fraunhofer has been able to establish new research units with public economic stimulus funds from the federal government and the Länder, as well as the European Regional Development Fund (ERDF).74 The Fraunhofer also derives income from donations, which are tax-deductible like charitable contributions.75

Infrastructure capital outlays are reported separately from Fraunhofer’s operating budget, which reports 143 million Euros in “current capital outlays.” This figure reflects investments in equipment and other fixed assets to maintain the operations of existing Fraunhofer units. Total capital outlays in 2011 were 379 million Euros (infrastructure capital outlays plus current capital outlays).

________________

72The Fraunhofer expenses its acquisitions at the time of purchase, so its books do not reflect depreciation expense.

73This funding formula was established by a former FhG director, Alexander Imbusch, in the 1970s. Comin, Diego, Gunnar Trumbull, and Kerry Young. 2012. Fraunhofer: Innovation in Germany. Harvard Business School Monograph 9-711-022. January 6. The basic funds are a powerful tool for attracting private money because partners benefit “from the investment capital which precedes work on any particular application.” Duff, Michael A. 1998. The Fraunhofer Society: A Unique German Contract Research Organization Comes to America. Office of Technology Policy, U.S. Department of Commerce. Washington, DC: U.S. Department of Commerce. October. pp. 23.

74The ERDF is a fund administered by the European Union which is intended to address regional disparities in Europe. Most of the ERDF funds allocated to Fraunhofer infrastructure projects in 2010 targeted at projects in the former East Germany. The German government portion of this funding is divided 50/50 between the federal and Länder governments. Major outlays have recently been made for a new research center in Dresden developing 3-D wafer level semiconductor packaging and interconnected technologies, expansion of the Fraunhofer Institute for Applied Polymer Research IAP’s Application Center Polymer Nanotechnologies in Potsdam-Golm, and expansion of the Fraunhofer Center for Silicon Photovoltaics CSP in Halle. The Fraunhofer IAP’s Application Center supports innovations such as flexible displays based on organic light-emitting diodes (OLEDs). The Application Center can support about 100 employees and has a usable floor space of 2600 square meters. Fraunhofer-Gesellschaft Annual Report 2011, pp. 19-20.

75Interview with Fraunhofer Institute for Process Engineering and Packaging IVV. 2012. Friesing, Germany. June 13.

FIGURE APP-A2-1 Major infrastructure capital expenditure and funding sources 2007-2011.

SOURCE: Fraunhofer Annual Report 2011, p. 20.

Contract Research for Industry

German and foreign firms contract with Fraunhofer institutes for research on specific themes. The standard form of collaboration is a one-off bilateral contract between a company and a Fraunhofer institute to achieve an agreed technological objective. The research is governed by signed contracts covering research activity and the ownership of intellectual property rights.76

________________

76Dr. Stefan Noken, an executive at Hilti AG, a German construction company and a Fraunhofer alumnus, offers some criticism of the institute’s contract procedures. “Sometimes it can take months to get a contract signed. I understand that Fraunhofer needs to stake out its claims and ensure it retains rights to the results of its work but it is also important to understand that companies want to

These projects frequently involve more than one Fraunhofer institute. Fraunhofer prices these contracts on the basis of the cost of running the project, plus a markup of about 15 percent, but the price does not include the historic costs incurred by the institutes to develop the knowledge used in the project. The price an individual institute charges for a working hour varies from institute to institute based on each organization’s cost structure, including infrastructure costs. The price is independent of the success or the failure of the final project. The Fraunhofer institutes are engaged in 6-8,000 industry contract research projects in any given year. The Fraunhofer institutes sign confidentiality agreements with its industry partners to protect their proprietary information.77 Some of these projects evolve into long-term strategic relationships between a company and a Fraunhofer institute, involving multi-stage collaborations over many years.

The Fraunhofer engages in collaborations with industry that extend beyond one-off contract research. Some technological challenges are sufficiently complex that they require multiple partners, and may engage numerous companies and Fraunhofer institutes. In some cases, Fraunhofer institutes perform contract research for industry associations.78 The Fraunhofer invests in and supports off-site R&D centers located on companies’ premises.79 It creates pilot manufacturing lines to permit the development and testing of processes in industry-relevant settings, reducing the risks associated with scaling-up of production.80 It forms joint ventures with companies.81 Pursuant to “special

________________

ring-fence a certain degree of exclusivity for themselves…[S]pending months honing the contractual agreements is neither in our interests, or indeed in Fraunhofer’s interests, so I would like to see a more pragmatic approach in that area.” “Pass Me the Hilti.” Fraunhofer website.

<http://www.fraunhofer.de/en/range-of-services/reference.html>.

77Comin, Diego, Gunnar Trumbull, and Kerry Young. 2012. Fraunhofer: Innovation in Germany. Harvard Business School Monograph 9-711-022. January 6. p. 10-11.

78In contract R&D for associations, the government contributes funding to the association, and companies that want to get access to the technology being developed must pay to join the association. Interview with Fraunhofer Institute for Process Engineering and Packaging IVV. Friesing, Germany, June 13, 2012.

79An example is Roth and Rau’s R&D center at the company’s headquarters in Hohenstein-Emsttal, Germany, an 11-million Euros project to develop products and processes to support more efficient solar cells. Fraunhofer-Gesellschaft contributed 3 million Euros to this project to equip the center with technology for research projects to be performed jointly by Roth & Rau and Fraunhofer institutes in Saxony. PVTech. 2009. “Roth & Rau Opens New R&D Centre to Boost Solar Cell Efficiencies.” May 11. “Fraunhofer research scientists and engineers are often to be found at this cutting-edge research facility.” Dr. Sylvia Roth, Roth and Rau Executive at <http://www.fraunhofer.de/en/range-of-services/reference.html>.

80The Fraunhofer Institute for Electron Beam and Plasma Technology FEP developed pilot lines to permit Biofilm SA to develop vacuum roll-to-roll production processes for polypropylene food packaging films. This project was co-funded by BMBF and the Saxon State Ministry for Economic Affairs, Labor, and Transport. Also involved in the project were Applied Materials (coating equipment), Vacuum Technologies Dresden (hollow cathode sources for plasma activation) and ISA GmbH (power supply system). Fraunhofer FEP, “Plasma Technology of the Fraunhofer FEP Becoming Established in the American Packaging Market.” Press release, April 20, 2012.

cooperation contracts,” companies can be given “guest” status at Fraunhofer institutes and operate their own laboratories and offices on the institutes’ premises.82 In 2005, the Fraunhofer entered into a public-private partnership with the U.S. semiconductor producer Advanced Micro Devices (AMD) and Germany’s semiconductor maker Infineon to open the Center for Nanoelectric Technology (CNT) near Dresden, with the two companies assuming responsibility for operating the site.83 The Fraunhofer Institute for Cell Therapy and Immunology IZI manufactures cell-based therapeutic products for pharmaceutical companies such as Northwest Biotherapeutics and Cognate BioServices Inc.84

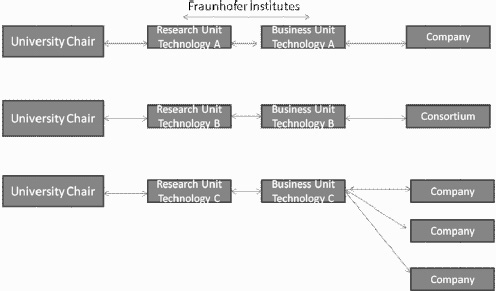

Fraunhofer institutes are organized in parallel structures of thematic “research units” and “business units.” Contacts with industry are made by the business units, which are the point of entry into the Fraunhofer system. The business units’ expertise tends to lie in the area of potential applications and market potential of the technologies in which they specialize. When a company asks a business unit for technical help, the unit assesses the potential cost of the project, its business feasibility, and the terms under which the parities will work. The business units draw up a list of Fraunhofer research units from which assistance will be required, e.g. materials, software, packaging, equipment, and other specialties. While the business unit maintains relations with the industrial client, the research units are the point of contact for the project with university faculty, students, and laboratories.85

Small and Medium Enterprises

The Fraunhofer’s core mission is to enable small and medium enterprises (SMEs) to gain timely access to scientific and technological innovation. Such companies typically have little or no internal research capability and must rely on external sources for such support. The Fraunhofer

________________

81In 2012 the Fraunhofer Institute for Ceramic Technologies and Systems IKTS and FuelCell Energy Inc., a manufacturer of fuel cell power plants announced an MOU to form a joint venture to develop the European market for Direct Fuel Cell stationary power plants. FuelCell Energy has established a legal entity in Germany for the joint venture and will be the majority owner. Fraunhofer IKTS will contribute research and development resources and use local resources and relationships to develop the market. FuelCell Energy, “FuelCell Energy Announces Cooperation with Fraunhofer IKTS to Develop the European Market for Stationary FuelCell Power Plants.” Press release, February 22, 2012.

82Fraunhofer ILT. 2010. Annual Report. pp. 20.

83Deutsch Press-Agentur. 2005. “Germany Opens Nanoelectrics Centre in Dresden.” May 31.

84Fraunhofer IZI, “Fraunhofer IZI Received Manufacturing Authorization for DCVax®-L Brain.” Press release, July 25, 2012; “Fraunhofer IZI Received Manufacturing Authorization for Tumor Vaccine CVacTM.” Press release, October 28, 2011.

85Interview with Fraunhofer Institute for Process Engineering and Packaging IVV. Freising Germany. June 13, 2012.