The Rise of Computer-Enabled Supply Chain Design

STEVE ELLET

Chainalytics

Engineers across all practices, industries, and applications are dealing with increasing system complexity, pushing the limits of engineering and human ability to grasp the large and complex. Whether it is designing an iPhone, a semi-autonomous rover to land on Mars, or a modern, fast, and efficient supply chain, an increasing level of sophistication is required. In supply chain design, this growth is being driven by increasing business complexity, access to “big data,” and Moore’s Law.

THE ROLE OF SUPPLY CHAIN DESIGN

Like all fields of design, engineers in supply chain design sift through a vast quantity of options to arrive at the best design—one that meets the needs of a business and its customers with minimal cost, risk, and environmental impact. Decisions about where to manufacture and stock products, which transportation modes to use, and what service levels to provide can either give a company a competitive advantage or leave it vulnerable to competitors and service disruptions.

Today’s supply chain designers increasingly use large-scale mathematical programming models (with the help of optimization- and simulation-based software tools) to evaluate tradeoffs between cost and performance. These tools enable the sophisticated modeling of end-to-end supply chains to evaluate a large number of alternatives, suggest new configurations, and test the robustness of the alternatives before proceeding with costly implementation.

Supply chain design has become a respected area of industrial engineering, with dedicated academics, practitioners, software vendors, and consultants. Over the past 20 years the field has transformed from spreadsheets and a few early

heuristic-based tools to modern tools and techniques that have become the standard for supporting critical design decisions in leading companies.

HISTORICAL OVERVIEW: LINEAR AND MIXED INTEGER PROGRAMMING

Mathematical historians credit Leonid Kantorovich, a Soviet economist, with developing linear programming (LP) in 1939, applying it first to the lumber industry and soon thereafter to the war effort. In 1947 an American, George Danzig, published the Simplex method for solving LP problems, leading to broader applications of the approach.

In supply chain design, the first LP models were used to answer network flow questions—for example, to determine the amount of volume for each node (i.e., facility) or arc (i.e., transportation lane) in a given network configuration. These analyses became commonplace in the 1980s and early 1990s and were typically used to identify the best locations for distribution centers. At this time, it was common to refer to this type of analysis as network optimization; the term supply chain design came much later once the design capabilities were more robust.

Linear programming led to the development of mixed integer programming (MIP), which has been substantially more useful in supply chain design. It allows for the direct consideration of on-off decisions and step functions (e.g., deciding whether a facility or manufacturing line should be active or inactive and how large it should be). MIP is highly effective, but it creates an enormous amount of mathematical complexity and can break down badly in real-world applications, as explained in Box 1.

Like an efficient searching algorithm, MIP looks across the millions of options and cuts off entire sections of the solution space that can be proven to be worse than the current best solution. This way, only a fraction of the network configurations actually have to be solved to determine a global optimum. But even then, MIP requires large amounts of memory and time, often more than can be accommodated with current hardware in a business-reasonable amount of time.

RECENT ADVANCES IN SUPPLY CHAIN DESIGN

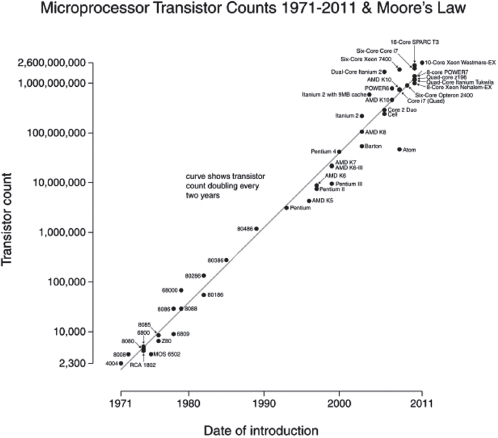

Over the past decade improvements in processor performance and the correlated drop in cost as described by Moore’s Law (see Figure 1) have supported a dramatic increase in the speed, complexity, and size of supply chain design models. The most important advances have allowed for the consideration of additional detail and accuracy, thus increasing confidence that the model represents the actual state. Like AutoCAD, the more detailed and accurate the model the better (to a point of diminishing returns, which is still pretty far off in supply chain design). Key recent advances have occurred in computer hardware, big data systems, and modeling tools.

BOX 1

MIP vs. Enumeration in the Real World

Mixed integer programming (MIP) involves a massive amount of mathematical complexity but is useful in solving otherwise intractable problems. Consider a small system of three warehouses (A, B, and C), in which each facility can be either active or inactive. The number of alternative network configurations to evaluate is 23 or 8 (A, B, C, AB, AC, BC, ABC, or none of these). If there were 10 warehouses, there would be 210 or 1,024 configurations. But, even then, it is still not impossible to simply test each one by running an LP 1,024 times and choosing the lowest cost (which is what mathematicians like to call enumeration). Now consider Coca-Cola’s US finished goods warehouse network, with more than 400 warehouses. The number of options—2400 or around 2.6 x 10120—is more than the estimated number of atoms in the universe (»1080). This single example vividly shows that enumeration has serious limitations in real-world applications.

Computer Hardware

Computer hardware moved to 64-bit Windows. Under a 32-bit system, the MIP solver was limited to 2 GB of memory (up to 3 GB in some configurations). The removal of this constraint, coupled with the low incremental price, has led to an explosion of model complexity in recent years. Also, the common availability of multicore and multiprocessor hardware in recent years has produced a step change in modeling capability. Solving an MIP model generates many sub-problems and is therefore well suited to a multithreaded approach.

Cloud-based solving technology is further removing barriers to large-scale modeling. Some vendors have built this capability directly into the software: the user can opt to connect to a remote solution-focused server maintained by the software vendor to solve one or more larger problems. Services like Amazon Cloud also enable users to push the limits of high-end hardware with a fraction of the hardware investment.

Big Data Systems

Big data systems make it possible to access and manipulate the large datasets that underlie supply chain design models. A company’s records of orders, shipments, and production, all at the transaction level, are the preferred inputs to the modeling process to ensure an accurate and unbiased model. The rise of business

FIGURE 1 The increasing availability of computing power as described by Moore’s Law has significantly enhanced the complexity, accuracy, and adoption of computer-enabled supply chain design. Source: WG Simon.

data warehouses, which provide easy access to these data, has increased the use of historical data for analytical purposes, in turn increasing the focus on data accuracy.

In addition to historical data, supply chain design models require what is called design data, information about options that did not exist in the historical network, such as candidate transportation lanes and potential facilities. Design data play an important role in supply chain design, and it is essential to guard against bias in such data. For example, consider a model in which all existing transportation lanes use actual costs (i.e., heavily negotiated rates) while new or potential lanes just have a carrier’s general estimate and are not negotiated at all. The model would choose all the existing lanes (because they are cheaper), incorrectly reinforcing the current state. The team members might be happy because the model says they are doing a great job and have an optimal supply chain, but this conclusion would be very wrong.

Accurate and unbiased “market data,” such as freight costs, are also critical to the success and credibility of the analysis. Big data systems empower large-scale, multicompany econometric models, such as Chainalytics’ Freight Market Intelligence Consortium, that produce the required inputs from the market.

Modeling Tools

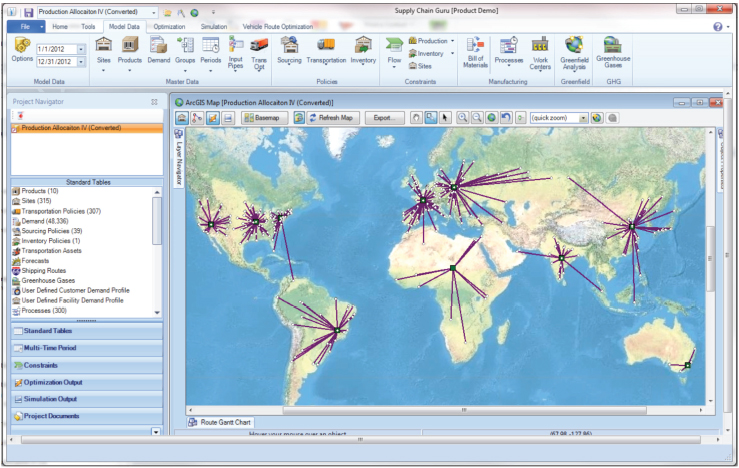

Modeling tools have become sophisticated but remain easy to use (Figure 2). Some of the important strides in this area are support for multiple objective functions, the coupling of optimization and simulation in a single application, automated sensitivity analysis, math formulation and solver improvements, and usability improvements that have reduced the barriers to entry for inexperienced users.

These advances have pushed the boundaries of supply chain design beyond network optimization into far more complex and valuable analyses of specific manufacturing lines, near-shoring or reshoring (i.e., whether to move production closer to the point of consumption), seasonal production plans, omnichannel distribution, the building of seasonal inventory, global tax strategies, item-specific flow path design, and the consideration of greenhouse gas emissions and other sustainability factors.

CONCLUSION

The world is becoming more complex. Change is accelerating. Companies need to be able to formulate strategies that deal with external factors such as changing oil prices, natural and man-made disasters, and customers’ increasing service expectations. Using sophisticated modeling techniques and tools such as MIP, companies are making better, faster, fact-based decisions that require fewer resources to make and move their products to market.

In the world of supply chain design, being more efficient means not only cheaper but also greener. The more accurate and detailed supply chain design models become, the easier it will be to reduce cost and waste.

And this is only the beginning. These tools and techniques have made tremendous strides in the past few decades, but they are still in their infancy. Software companies and practitioners are pushing the envelope on the size of model that can be solved, addressing more and more complexity.

FIGURE 2 Screen image of a modern supply chain design software depicting a global distribution network. Source: LLamasoft.