Advancing Sustainable Manufacturing with the Use of Cognitive Agents

STEVEN J. SKERLOS

University of Michigan

The emerging field of “cognitive” manufacturing is characterized by capabilities and visions for moving beyond “smart” manufacturing toward systems that have the capacity to monitor and evaluate manufacturing performance and then propose process and operations improvements based on sensor and multifaceted data, optimization techniques, and advances in machine learning. In this paper I consider how cognitive systems can advance the state of the art in sustainable manufacturing.

After providing a definition of sustainable and cognitive manufacturing, I explain the importance of an optimization framework for sustainable manufacturing, discuss research needed using different knowledge systems to assess sustainability impacts, and illustrate several applications of cognitive agents to advance sustainable manufacturing.

DEFINING SUSTAINABLE AND COGNITIVE MANUFACTURING

Sustainable manufacturing has been defined by the US Department of Commerce as the creation of manufactured products using processes that minimize negative environmental impacts, conserve energy and natural resources, are safe for employees, communities, and consumers, and are economically sound (Haapala et al. 2013). Implicit in this definition is the support of sustainable development, which is defined as meeting the needs of humanity today without compromising the ability of future generations to meet their own needs (WCED 1987).

Sustainable manufacturing efforts are viewed as incomplete unless they address concerns in three core dimensions: economic, environmental, and social. These dimensions are now commonly referred to as the triple bottom line. Sus-

tainable manufacturing can thus be thought of as a multidimensional challenge with components that must be evaluated in a temporal, geographical, and cultural context.

But sustainable manufacturing is challenged by incomplete data, knowledge, metrics, and supporting systems. It must therefore increasingly rely on cognitive manufacturing, which involves the implementation and interaction of a variety of sensors and machine learning techniques that not only provide real-time monitoring but also can perceive performance and suggest alternatives to reduce cost and environmental impacts. These machine-based interpretive systems, called cognitive agents, are embedded in the processes of design, supply, production, control, and procurement, to name a few.

The application of cognitive agents can help identify and navigate sustainability tradeoffs in manufacturing decision making. Toward this end, I review research advances needed to help manufacturers establish their sustainability targets. I then suggest that cognitive agents, inspired by early advances in carbon/ energy management, can help a manufacturer maximize its profit while coordinating achievement of the company’s sustainability targets across its forward/reverse supply chains, manufacturing processes and systems, facility operations, product designs, and, potentially, the influence of future regulations.

OPTIMIZATION FRAMEWORK FOR SUSTAINABLE MANUFACTURING

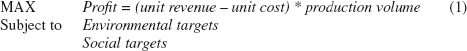

Translated into an optimization statement, the Department of Commerce definition of sustainable manufacturing would aim to simultaneously maximize economic, environmental, and social performance. But such an approach is inconsistent with how most firms operate. A more realistic formulation would pose economic performance as the objective with the environmental and social dimensions posed as constraints, which could be conceptually written as follows:

Equation 1 is a corporationwide execution system problem based on setting environmental and social improvement targets as constraints. The distinction between targets within the objective function and constraints is important because the introduction of environmental and social targets alongside economic targets would require the inherently arbitrary task of monetizing sustainability targets against the firm’s primary objective of profit. The inclusion of environmental and social targets in the constraint set is a more transparent expression of what is valued by the firm and makes clear what steps are being taken to address sustainability issues beyond compliance with applicable legislation.

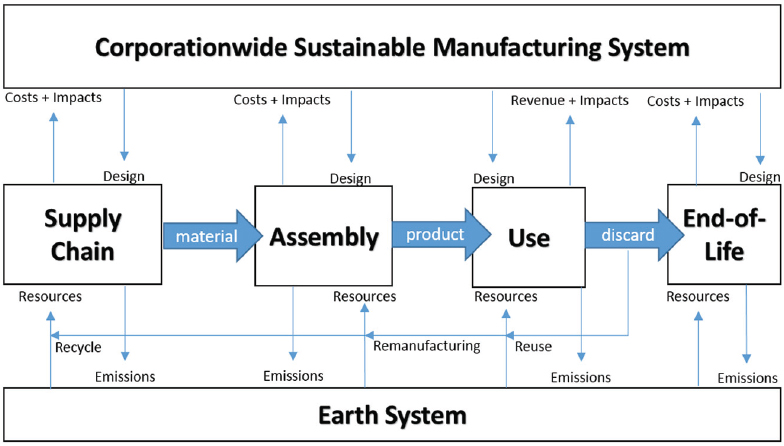

The embodiment of Equation 1 as a design driver for the life cycle influence of manufacturing firms is represented in Figure 1. At the highest level, the manufacturing system would not only optimize product design to maximize profit but also predict environmental and social impacts across the product life cycle to meet environmental and social constraints, using deviations between predictions and data to improve subsequent predictions. The master system would coordinate subsystems at the factory level, and these subsystems would select manufacturing processes and orchestrate facility operations in concert with firm objectives to minimize costs, waste, and negative impacts on workers, communities, and the environment.

Given the complexity of Figure 1 it is appropriate to ponder the development of cognitive agents to support the achievement of sustainable manufacturing objectives. However, as discussed in the next section, the challenges are manifold. Nonetheless, real-world applications of optimization-driven sustainable manufacturing are emerging in narrower contexts, such as factory operations, supply chain design, and manufacturing process planning, as discussed below.

KNOWLEDGE SYSTEMS TO ENABLE SUSTAINABLE MANUFACTURING: RESEARCH NEEDS

The first challenge in achieving the vision of Figure 1 is establishing the link between manufacturing systems and their life cycle environmental and social consequences. Research in environmental and social impact assessment methods is needed to understand these consequences and then, based on the results, set meaningful targets for social and environmental improvement of manufacturing systems.

I discuss below research advances needed in the areas of environmental impact assessment, consequential life cycle assessment, and social life cycle assessment to achieve these ends. Then I conclude this section with a discussion of how firm-level targets can be met with the assistance of coordinated cognitive agents.

Environmental Impact Assessment Methods

Because not all reductions in air/water emissions are equivalent, emissions constraints in Equation 1 cannot be set rationally without some understanding of their real consequences. The need for such knowledge has prompted research to understand the transport, fate, and damages caused by specific product and manufacturing emissions. There is also a need to understand where and when pollutants are emitted throughout the supply chain to connect manufacturing system decisions to their real environmental impacts. As a result researchers in the life cycle assessment (LCA) community are working to resolve LCA data spatially and temporally as well as to interpret the impacts of emissions in terms of ecology and toxicology (e.g., Pennington et al. 2006; Reap et al. 2008). This research

FIGURE 1 Scope of consideration for cognitive agents advancing sustainable manufacturing systems. The top-level system coordinates operational subsystem agents and product/supply chain design choices toward the achievement of corporationwide sustainability targets.

is important to help manufacturing firms provide their stakeholders with relevant and unbiased data as sustainability targets are established.

Consequential Life Cycle Assessment (cLCA)

Life cycle assessment entails holistic consideration of the environmental impacts of a product or process, starting from material acquisition and continuing to the product’s end of life, accounting for all the unit processes in the product system (Curran 2006; ISO 2006). cLCA developed from the need to expand the system boundaries of LCA beyond a single product to the interactions between one life cycle and another (Ekvall and Weidema 2004; Finnveden et al. 2009; Hertwich 2005).

cLCA is a technique that can identify expected changes to the environmental performance of interacting manufacturing systems when new technologies are proposed to advance sustainability in factories. Because sustainable manufacturing exists at the nexus of multiple product and process life cycles, advances in cLCA methods and data are necessary to help make decisions that may be counter-intuitive but are actually better for the environment and society. For instance, carbon dioxide may be viewed either as a greenhouse gas pollutant to be avoided in manufacturing or, less intuitively and more correctly, as an environmentally conscious process fluid that is a waste from other industrial processes and that should be recovered for use in manufacturing to eliminate health hazards and water pollution while reducing life cycle greenhouse gas emissions. cLCA methods can distinguish between surface-level rules of thumb and the deeper causalities that actually drive environmental impact.

Social Life Cycle Assessment (sLCA)

sLCA is an effort to fold social aspects of a product or system into environmental life cycle assessment. Jørgensen and colleagues (2008) reviewed sLCA methods and summarized many midpoint indicators (e.g., in the areas of human rights, working conditions, labor practices, job creation, community communication, corruption) and endpoint indicators (e.g., mortality, morbidity, autonomy, safety, security, opportunity, influence) that manufacturers and their stakeholders can consider in establishing sustainability targets. sLCA is an emerging field, and accelerated efforts to develop datasets, metrics, and interpretation methods are needed to advance it for seamless use with other LCA tools in the context of sustainable manufacturing.

From Targets to Action

Advances in LCA will help firms establish targets that are well aligned with the ecological and societal sustainability requirements most relevant to the firms’

activities. Once targets are set, they need to be rationally distributed among products and operations. For instance, a firm may set a goal to reduce its carbon footprint in addition to reducing water pollution and improving workplace health and safety. Today it is common for such goals to be applied uniformly across the firm’s business units or factories. But such an approach is not cost optimal and could limit opportunities for breakthrough improvements. For instance, it might be more practical and advantageous to increase the carbon footprint in one factory if it means eliminating worker health risks and water pollution at that factory. In such a case the firm’s other factories might reduce their carbon footprint so that the firm can meet its overall sustainability goals.

Given the complexity of operations and the multidimensional nature of sustainability, a quantitative approach consistent with the goals of cognitive manufacturing can be useful to coordinate activities in a manner that achieves all firm-level sustainability goals at least cost.

Analytical target cascading is an optimization method that decomposes a system into a hierarchy of subsystems and coordinates their optimization problems such that the solutions are consistent with the overall optimization solution for the top-level system (e.g., Kim 2001; Nyström et al. 2003). Sustainability applications of target cascading can help firms determine sustainability targets for specific products and manufacturing processes to ensure that the firm meets all its goals without unintentionally compromising some (e.g., worker exposure to process chemicals) while pursuing others (e.g., reductions in carbon footprint).

TOWARD COGNITIVE AGENTS TO ADVANCE SUSTAINABLE MANUFACTURING

Advanced optimization techniques are now being applied in supply chains to minimize fuel costs and carbon emissions by proposing alternative transportation modes and routes. Such efforts are being encouraged by the US Environmental Protection Agency (EPA) SmartWay program1 and adopted by large corporations such as Walmart. These supply chain design tools can be easily modified to include additional metrics. A top priority should be to minimize the harm caused by other air pollutants emitted alongside carbon dioxide, because air emissions from transportation systems are a significant cause of disability and premature mortality (e.g., Caiazzo et al. 2013).

In factories, systems are emerging to help reduce energy consumption and carbon emissions from manufacturing operations. These systems range from control systems for lighting and HVAC based on occupancy to the timing of machine warm-up and standby assignments based on production schedules. More advanced

__________________

1 According to the SmartWay website (www.epa.gov/smartway/), “SmartWay® is an EPA program that reduces transportation-related emissions by creating incentives to improve supply chain fuel efficiency.”

systems are being applied to optimize production schedules based on time of day and peak demand electricity charges.

As automated systems “learn about” their own energy consumption relative to alternatives available in the marketplace, they will be able to generate suggestions for capital purchases of equipment such as motors and pumps to increase manufacturing process efficiency and eliminate waste. This takes the “energy treasure hunt” concept2 and embeds it in the factory’s cognitive control.

Cognitive agents applied to sustainable manufacturing would extend energy/ carbon considerations to material and water consumption, air and water pollutant emissions, and long-term health impacts on workers. These metrics can be constantly evaluated relative to firm-level sustainability objectives to yield suggestions generated by cognitive agents for changes to facility operation or manufacturing process selection.

Two hypothetical examples below illustrate how cognitive agents could begin to influence manufacturing process selection.

Energy Consumption of Alternative Manufacturing Pathways

In the first case a cognitive agent is endowed with models of energy consumption for alternative processes to make dies and molds, with both additive and subtractive manufacturing pathways. The cognitive agent considers the following conceptual problem:

![]()

Morrow and colleagues (2007) built energy consumption models for tool and die production based on subtractive and additive pathways, establishing criteria for the selection of additive manufacturing in Equation 2 over conventional milling. They found that products with high cavity percentage in the total volume were viable candidates for sustainable manufacturing via an additive pathway and that additive manufacturing created the possibility of new mold and die systems with lower life cycle energy consumption (e.g., in systems with conformal cooling channels, heat sinks, protective coatings, and remanufacturing).

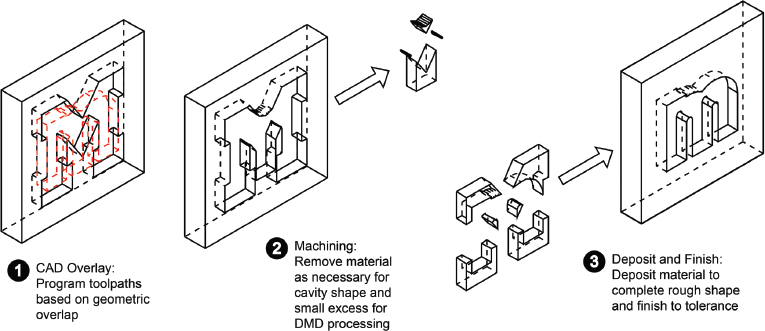

In this case the cognitive agent facilitates process selection to include additive, subtractive, and combination pathways that minimize production cost while reducing life cycle energy consumption. This concept is illustrated in Figure 2, which shows the modification of a mold die from a capital M to a lowercase m using the combination of milling (subtractive process) and direct metal deposition (DMD; additive process).

__________________

2 Energy treasure hunts, developed by Toyota, are an extension of the concept of lean manufacturing, aiming to eliminate energy waste.

FIGURE 2 A hypothetical application of combining additive and subtractive manufacturing to convert mold tooling with minimal material investment and environmental emissions. CAD = computer-aided design; DMD = direct metal deposition.

Gas-Based vs. Water-Based Cutting and Grinding Fluids

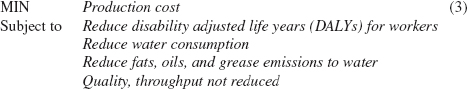

Aqueous metalworking fluids are significant polluters of water and cause long-term health risks for workers (e.g., Skerlos et al. 2008). In this case we suppose that a cognitive system is aware of alternative metalworking fluids, such as gas-based minimum quantity lubrication systems, and considers the following variant on Equation 1.

Based on the materials being machined and on process operating parameters, cognitive agents could advise on the availability of more sustainable metalworking fluid alternatives. They also could adjust process parameters and process operations to enable the accommodation of environmental and health constraints while minimizing cost. Using productivity and quality metrics fed back to the system, the cognitive system can make decisions about metalworking fluid applications that maximize productivity while minimizing the generation of waste and health hazards. To maximize their effectiveness, the agents would be connected to complementary agents in the wastewater treatment system, occupational health system, tool/fluid/material procurement system, and others such that total system costs to the firm are factored into the decision.

Cognitive Agents Beyond the Factory Walls

Future generations of cognitive systems may link decisions made within the firm to its forward and reverse supply chains. The efforts of large manufacturing firms to understand upstream carbon emissions have already led to Internet-based systems to provide information about supplier carbon performance to centralized databases. Networks of cognitive agents could perform this task in an automated manner while offering, for instance, recommendations to procurement regarding supply chain design (Seuring and Müller 2008) and recommendations to product design for enabling “reverse” supply chains through targeted design for remanufacturing actions (Hatcher et al. 2011).

The notion of cognitive agents working collaboratively to achieve sustainability objectives is fundamentally different from simply linking data systems containing environmental performance metrics. The linked cognitive agents would automatically generate opportunities for firms to collaborate toward reducing emissions via strategies that would yield greater profit for both firms than they could achieve if they acted alone.

This concept would not need to stop at communication between firm-level cognitive agents: these could connect with similar agents at the community and national levels to explore new opportunities for mutual gain. For instance, where regulators aim to reduce the environmental impact of manufacturing firms, cognitive agents at the policy level could connect with those at the firm level to inspire novel solutions such as funding mechanisms for clean technology that could benefit manufacturers by overcoming financial hurdles and benefit society by achieving environmental improvements at less cost than traditional “command and control” regulation.

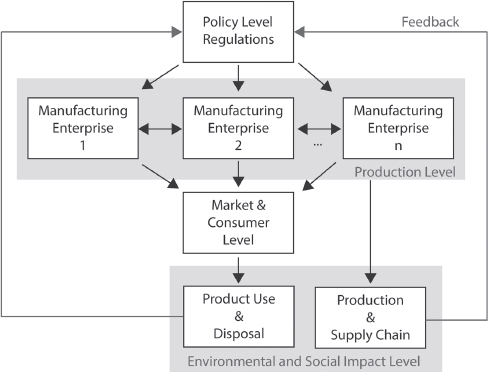

Research has already begun to demonstrate how cLCA frameworks could support efforts to tackle such challenges by enhancing understanding of the interactions shown in Figure 3 that lead from regulation to production/consumption and ultimately to social and environmental impact (Whitefoot and Skerlos 2012).

SUMMARY

The complexity of sustainable manufacturing demands the creation of new knowledge and systems to set targets for social and environmental improvement and achieve them at least cost. This effort can start with today’s nascent

FIGURE 3 Interaction of systems that influence environmental and social impacts.

systems for energy and carbon management and can be extended to a broader set of environmental and health metrics. As cognitive manufacturing systems emerge and gain access to LCA data from the supply chain, they can influence the design of forward/reverse supply chains, factory siting decisions, and broader aspects of manufacturing process selection.

Cooperation between cognitive agents that influence both product design and manufacturing creates opportunities to improve product environmental performance and expand remanufacturing activity. In addition, the cooperation of firm- and government-level cognitive systems can lead to new strategies for achieving sustainability objectives at lower societal cost than permitted by legacy regulatory frameworks.

ACKNOWLEDGMENTS

The author is grateful for the substantial contributions to the concepts described in this paper that were made by J. Rhett Mayor (associate professor of mechanical engineering at Georgia Institute of Technology), W. Ross Morrow (assistant professor of mechanical engineering and economics at Iowa State University), Katie Whitefoot (senior program officer for manufacturing, design, and innovation at the National Academy of Engineering), Panos Papalambros (Donald C. Graham Professor of Mechanical Engineering at the University of Michigan), and Jyoti Mazumder (Robert H. Lurie Professor of Mechanical Engineering at the University of Michigan).

REFERENCES

Caiazzo F, Ashok A, Waitz I, Yim S, Barrett SRH. 2013. Air pollution and early deaths in the United States. Part I: Quantifying the impact of major sectors in 2005. Atmospheric Environment 179:198–208.

Curran MA. 2006. Life Cycle Assessment: Principles and Practice, EPA/600/R-06/060. Cincinnati: US Environmental Protection Agency.

Ekvall T, Weidema B. 2004. System boundaries and input data in consequential life cycle inventory analysis. International Journal of LCA 9(3):161–171.

Finnveden G, Hauschild M, Ekvall T, Guinee J, Heijungs R, Hellweg S, Koehler A, Pennington D, Suh S. 2009. Recent developments in life cycle assessment. Journal of Environmental Management 91:1–21.

Haapala KR, Zhao F, Camelio J, Sutherland JW, Skerlos SJ, Dornfeld DA, Jawahir IS, Zhang HC, Clarens AF. 2013. A review of engineering research in sustainable manufacturing. Journal of Manufacturing Science and Engineering, Transactions of the ASME 135(4):041013-1-041013-16.

Hatcher GD, Ijomaha WL, Windmill JFC. 2011. Design for remanufacture: A literature review and future research needs. Journal of Cleaner Production 19(17):2004–2014.

Hertwich EG. 2005. Life cycle approaches to sustainable consumption: A critical review. Environmental Science and Technology 39(13):4673–4684.

ISO (International Organization for Standardization). 2006. ISO 14040, Environmental Management-Life Cycle Assessment-Principles and Framework. Geneva.

Jørgensen A, Le Bocq A, Nazarkina L, Hauschild M. 2008. Methodologies for social life cycle assessment. International Journal of LCA 13(2):96–103.

Kim HM. 2001. Target Cascading in Optimal System Design. PhD thesis, Department of Mechanical Engineering, University of Michigan, Ann Arbor.

Morrow WM, Qi H, Kim I, Mazumder J, Skerlos SJ. 2007. Environmental aspects of laser-based and conventional tool and die manufacturing. Journal of Cleaner Production 15(10):932–943.

Nyström M, Larsson T, Karlsson L, Kokkolaras M, Papalambros PY. 2003. Linking analytical target cascading to engineering information systems for simulation-based optimal vehicle design. International Conference on Engineering Design, Stockholm, Sweden, August 19–21.

Pennington DW, Margni M, Payet J, Jolliet O. 2006. Risk and regulatory hazard-based toxicological effect indicators in life-cycle assessment (LCA). Human and Ecological Risk Assessment 12(3):450–475.

Reap J, Roman F, Duncan S, Bras B. 2008. A survey of unresolved problems in life cycle assessment, Part 2: Impact assessment and interpretation. International Journal of LCA 13(5):374–388.

Seuring S, Müller M. 2008. From a literature review to a conceptual framework for sustainable supply chain management. Journal of Cleaner Production 16(15):1699–1710.

Skerlos SJ, Hayes KF, Clarens AF, Zhao F. 2008. Current advances in sustainable metalworking fluids research. International Journal of Sustainable Manufacturing 1(1):180–202.

WCED (UN World Commission on Environment and Development). 1987. Our Common Future. Oxford: Oxford University Press.

Whitefoot KS, Skerlos SJ. 2012. Design incentives to increase vehicle size created from the US footprint-based fuel economy standards. Energy Policy 41:402–411.