2

Evolution of Combat Helmets based

Combat helmets have evolved considerably over the years. This chapter describes the changes in design and materials, from those used in World War I to today’s Advanced Combat Helmet (ACH). One of the key advances was the development of aramid fibers in the 1960s, which led to today’s Kevlar-based helmets. The Department of Defense (DoD) is continuing to invest in research to improve helmet performance, through better design and materials as well as better manufacturing processes.

In early usage, soldiers wore equipment made of leather or cloth in an attempt to protect their heads from sword cuts and other blows. When rifled firearms were introduced in the late 1700s, this equipment was found to be inadequate, and its use declined considerably. Over time, the equipment transitioned from providing protection to being an accessory worn for pageantry and unit recognition.

World War I saw a substantial increase in the effectiveness and lethality of artillery, resulting in a new focus on protective equipment, including helmets. The primary threat during this conflict was fragmenting projectiles, and helmets made with steel were introduced for protection in Europe in 1915. Even though stopping a rifle bullet was considered beyond the ability of the helmet materials at the time (due to weight considerations), there were enough benefits to warrant issuing a helmet to all ground troops.

Around this time, the governments in Europe started to invest considerable efforts on research dealing with helmet design, materials, and support systems (such as chin straps and liners). This research resulted, among other advances, in a new grade of metal known as Hadfield steel. Different variations of these steel helmets were used by forces in the United Kingdom and the British Commonwealth during World War I and later. The U.S. military adopted helmets based on Hadfield steel, called the M1 “steel pot,” in 1942. These helmets remained in service until the mid-1980s when they were replaced with helmets manufactured from a nonmetallic material. Small numbers of the M1 helmet are still used today in special missions such as shipboard firefighting.

The beginning of World War II also saw an escalation in the lethality of ballistic threats, resulting in higher fatalities and injuries. The bullets and shrapnel in World War II had greater mass and higher velocities. As was the case with World War I, soldiers initially resisted wearing helmets. They felt that the 3.5-lb helmet was too heavy, and that it limited hearing, vision, and mobility of the wearer. However, the troops quickly accepted the trade-off when they observed the lethality of the munitions on the battlefield and recognized the protection provided by the helmet.

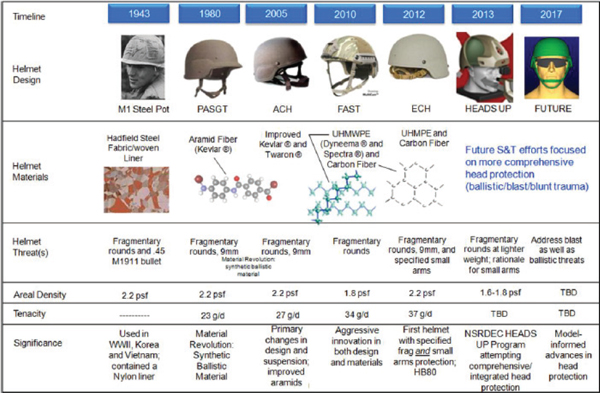

Figure 2-1 illustrates the evolution of U.S. military helmets since World War I. The rest of this chapter discusses the evolution and developments in some detail.

DuPont invented a new material called aramid fiber in the 1960s. This was a class of strong, heat-resistant synthetic fibers that had many desirable properties. It was eventually marketed under the trade name of Kevlar, and the name would become synonymous with “bulletproof material.” Kevlar represented a breakthrough, enabling a leap ahead in technology of synthetic composite materials. The U.S. government selected Kevlar over other materials that were available at the time, such as nylon, e-glass fiber, and stretched polypropylene. The government was already molding the M1 helmet liner with a similar matched-tool compression molding process, so that the same manufacturing process could be used to make Kevlar helmets.

The Personnel Armor System for Ground Troops (PASGT) was the first helmet to use Kevlar. PASGT refers to both vests and helmets made of Kevlar, and they were used by all military services from the mid-1980s to around the middle of

FIGURE 2-1 Evolution of helmets from World War I to present. SOURCE: Walsh et al. (2012).

the last decade. These helmets are still being used by some services but will be replaced in the future.

The U.S. Special Operations Command designed and developed the Modular Integrated Communications Helmet (MICH) as a replacement for PASGT. MICH had several changes, including improved Kevlar aramid-fiber reinforcement, leading to better protection. They also allowed better fit and integration of communication headsets. MICH was adopted by the U.S. Army in 2002 as its basic helmet and renamed the Advanced Combat Helmet. The Marine Corps decided to use a design profile that was similar to the PASGT and designated it the Light Weight Helmet (LWH).

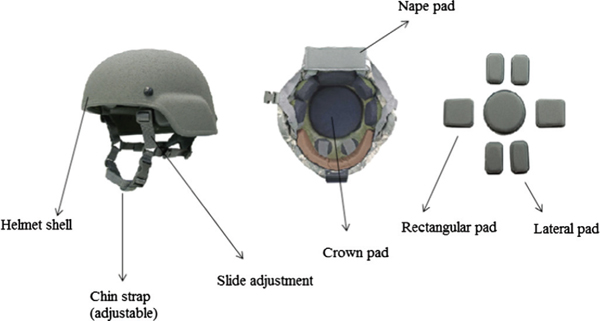

There were also developments in helmet retention systems. The M1 “steel pot” used a nylon cord suspension system, sweatband, and chinstrap, and the PASGT helmet and its variants also used similar retention systems. The MICH, ACH, and LWH helmets switched to a multi-pad and four-point retention system (Figure 2-2) that had better impact protection while providing increased comfort.

The next major advance in helmet technology resulted from a combination of advances in materials and manufacturing processes. A new generation of ultra-high-molecular-weight polyethylene fibers (UHMWPE) was developed in industry. In parallel, the government funded efforts to address technology gaps that had previously precluded manufacture of thermoplastic-based fibers and matrices for affordable soldier protection systems. The programs focused on developing new technologies, tooling, and hybridization techniques to enable commercially available and emerging grades of thermoplastic ballistic composite materials to be formed into complex helmet shapes. There was participation from the Marine Corps, U.S. Special Operations Command, and the industrial sector. These efforts enabled the development of the Future Assault Shell Technology (FAST) helmet, the Maritime helmet, and, ultimately, the U.S. Marine Corps Enhanced Combat Helmet (ECH). The FAST helmet is significant for its early use of UHMWPE material and its novel design.

To improve ballistic protection, the Army has initiated several developmental programs over the last decade. These include the Scorpion, Objective Force Warrior, and Future Force Warrior programs. The goal of the Scorpion program was to improve protection and performance through an integrated system. It tried to address the continuing problem of protection while also providing the soldier with capability, such as communications, hearing protection, and displays, needed in an evolving battlefield environment. The program also explored the use of materials with better ballistic performance and processing concepts to deliver increased structural performance. In addition, the program examined how to provide more options in helmet shaping, compat-

FIGURE 2-2 Helmet multi-pad and four-point retention systems. SOURCE: PEO Soldier, U.S. Army.

ibility, and ergonomics as well as device and accoutrement integration. These early efforts would ultimately result in an entirely new generation of helmet technologies, designs, and manufacturing processes.

2.3 RECENT DEVELOPMENTS AND DIRECTIONS

In 2009, the U.S. government launched the “Helmet Electronics and Display System–Upgradeable Protection” (HEaDS-UP) program, involving multiple organizations. As of 2012, it was the largest head-protection research and development project within the Army. It leverages multiple efforts—in the areas of ballistic materials (transparent and non-transparent), high-resolution miniature displays, and sensors—to design a modular-integrated headgear system that takes into account the relevant ergonomics considerations.

The HEaDS UP program is designed to include participation from a wide spectrum of Army organizations as well as other services and government agencies. The goal of the program is to provide two different and independently developed concepts of an integrated headgear system and packages of design options as well as guidelines based on manufacturing best practices, lessons learned, and technology maturation. The resulting insight will be used to develop an integrated head, face, and neck protection headgear system that incorporates modular, upgradeable protection.

The soldier-relevant goals are twofold: (1) reduced weight for equivalent protection and small increased weight for significantly increased capabilities; and (2) increased situational awareness in all environmental and obscurant conditions without sacrificing mobility and agility.

Unlike past considerations for fielded helmets, the HEaDS UP program also explicitly acknowledges that the helmet is no longer simply a device to prevent injury from fragments and blunt impact. It recognizes that the helmet has become a platform to provide the soldier with new capabilities to enhance their survivability. The consequence is further device integration and modularization of accoutrements in or attached to the helmet. It might mean even more ballistic protection from small arms threats and maxillofacial (mandible) systems that can be rapidly donned or doffed. But the advances are limited by the total amount of weight a soldier is able to carry for an extended period of time.

Continued improvement in materials is also leading to advances in helmet performance. For example, ECH delivers much better protection against fragments compared to ACH, due to a shift to unidirectional UHMWPE fiber in a thermoplastic matrix. The shift was also enabled by a new generation of preforms and manufacturing methods appropriate for UHMWPE. While other promising materials have been identified (e.g., copolymers, graphene, and high-tenacity UHMWPE), dramatic weight reduction without a significant loss in ballistic performance has been elusive.

Another factor in helmet protection is the way the constituent materials are assembled. Previous research results suggest that, in unidirectional UHMWPE panels, varying fiber orientation and fiber architecture can provide better balance between resistance-to-penetration and deformation

mitigation. Vargas-Gonzalez et al. (2011) have explored this issue for panels that had more architectural complexity.

New materials are also under evaluation for mitigating the effect of impacts to the head. Both recoverable and non-recoverable energy-absorbing materials are being considered for use as helmet pads. Concepts for decoupling the helmet into a ballistic and impact shell (and using energy-absorbing materials between shells) are also being explored.

Novel manufacturing equipment and methodologies also have a role to play in improving performance. The first generation Helmet Preform Assembly Machine is an example of a process that exploited the ability of thermoplastic composites to be locally consolidated, leading to a rapid, automated method of stabilizing and building up helmet preforms. The underlying lesson is that processing should also be explicitly considered as an asset in pursuit of incremental performance gains in head protection materials and systems.

DoD has undertaken extensive efforts to improve combat helmet designs. The design goal is to reduce injuries and injury severity, while achieving operational needs. However, the goal of this report is to evaluate test protocols. In the following chapters, the extent to which the above goal—of reducing injuries and injury severity—is achieved by the test programs is discussed.

Vargas-Gonzalez, L.R., S.M. Walsh, and J.C. Gurganus. 2011. Examining the Relationship Between Ballistic and Structural Properties of Lightweight Thermoplastic Unidirectional Composite Laminates. ARL-RP-0329. Army Research Laboratory, Aberdeen Proving Ground, Md.

Walsh, S.M., L.R. Vargas-Gonzalez, B.R. Scott, and D. Lee. 2012. Developing an Integrated Rationale for Future Head Protection in Materials and Design. U.S. Army Research Laboratory, Aberdeen Proving Ground, Md.