PROTOCOL FOR FIRST ARTICLE TESTING,

SEPTEMBER 20, 2011

MEMORANDUM FOR: SEE DISTRIBUTION

SUBJECT: Standardization of Combat Helmet Testing

All Department of Defense (DoD) combat helmet acquisition programs under DOT&E oversight will execute, at a minimum, the attached protocol for testing that results in a decision to qualify a design for full-rate production (i.e., First Article Testing). Likewise, First Article Testing conducted for sustainment contracts such as those executed for the Services by the Defense Supply Center Philadelphia will follow this protocol.

This protocol updates and supersedes the protocol for combat helmets published in December 2010. It includes changes necessary due to differences in the construction and material properties of aramid-based helmets such as the Advanced Combat Helmet (ACH) and Lightweight Helmet (LWH), and ultra-high molecular polyethylene-based helmets such as the Enhanced Combat Helmet (ECH). Specific changes include specifying, based on helmet material, the number of shots per helmet for penetration testing. In addition, the ballistic transient deformation upper tolerance limit will be calculated independently for each shot location; shot locations will not be combined as before. User input to this standard remains essential, not only in identifying the ballistic threats that combat helmets are expected to defeat, but especially as changes in helmet design and capabilities influence changes in test methods and procedures.

As testing of combat helmets continues and additional data are obtained, DOT&E will publish, as necessary, updates and changes to the attached protocol. Additionally, DOT&E will work with the Services, USSOCOM and Defense Agencies to incorporate this protocol, and future changes to it, into existing test operating procedures and military standards.

Attachment:

As stated

DISTRIBUTION:

ASSISTANT SECRETARY OF THE ARMY (ACQUISITION, LOGISTICS AND TECHNOLOGY)

ASSISTANT SECRETARY OF THE NAVY (RESEARCH, DEVELOPMENT AND ACQUISITION)

ASSISTANT SECRETARY OF THE AIR FORCE FOR ACQUISITION AND MANAGEMENT

SPECIAL OPERATIONS ACQUISITION EXECUTIVE, UNITED STATES SPECIAL OPERATIONS COMMAND

DIRECTOR, DEFENSE LOGISTICS AGENCY

COMMANDER, DEFENSE SUPPLY CENTER PHILADELPHIA

COMMANDER, U.S. ARMY TEST AND EVALUATION COMMAND

COMMANDER, OPERATIONAL TEST AND EVALUATION FORCE

COMMANDER, AIR FORCE OPERATIONAL TEST AND EVALUATION CENTER

DIRECTOR, MARINE CORPS OPERATIONAL TEST AND EVALUATION ACTIVITY

COMMANDER, MARINE CORPS SYSTEMS COMMAND

DIRECTOR, OPERATIONAL TEST & EVALUATION, UNITED STATES SPECIAL OPERATIONS COMMAND

PROGRAM EXECUTIVE OFFICE SOLDIER

PROGRAM EXECUTIVE OFFICE SPECIAL OPERATIONS FORCES WARRIOR

PROGRAM EXECUTIVE OFFICE LITTORAL AND MINE WARFARE

COMMANDER, NAVAL SEA SYSTEMS COMMAND, SHIP INTEGRITY AND PERFORMANCE

FEDERAL BUREAU OF INVESTIGATION, BALLISTIC RESEARCH FACILITY, FBI ACADEMY (ATTN: SSA J. BUFORD BOONE III)

NATIONAL INSTITUTE OF STANDARDS AND TECHNOLOGY, PROGRAM MANAGER WEAPONS AND PROTECTIVE SYSTEMS (ATTN: MR. KIRK RICE)

Military Combat Helmet

Standard for Ballistic Testing

The objective of this protocol is to establish DoD-wide, statistically-derived test methods for combat helmets that will provide increased confidence in the performance of personal protective equipment. This protocol also establishes standard testing references, protocols, procedures, and analytical processes for combat helmet testing.

As necessary, the Services will use the standards and information in this protocol to update or develop Test Operating Procedures (TOPs), Military-Standards (MIL-STDs), Purchase Descriptions (PDs), Internal Operating Procedures, and other documents relevant to this commodity area.

DOT&E will work in coordination with the Services, United States Special Operations Command (USSOCOM), and the Defense Logistics Agency to update this protocol at least annually. As this protocol is codified into the aforementioned documents, updates to this protocol may be directly addressed via updates to those documents.

Protocols established in this standard supplement those currently in practice across the DoD. However, this protocol does not address all issues associated with testing combat helmets. Test agencies, contracting officials, and material developers should therefore continue to use and reference TOPs, MIL- STDs, Internal Operating Procedures (IOPs), and other guiding documents currently in use to fully explain test setup and execution procedures. This protocol is not intended to be applied against already qualified designs.

Elements of Standardization

Table 1 establishes standard reference documents, precedence, and source information related to this standard. The list is not meant to be all encompassing. For elements referenced to this standard, those elements are found later in this document. Elements referenced to Service requirements documents reflect that this is a testing standard and not a requirements document. Service user representatives and the USSOCOM establish Service- and USSOCOM-unique requirements. This includes, for example the requirements of threat munitions and respective velocities to be applied against this testing protocol.

The Services have adopted a Ballistic Transient Deformation (BTD) standard that the BTD cannot exceed 16.0 mm for impacts by a 9 mm projectile on the right, left, and crown of the helmet, and 25.4 mm for impacts at either the front or back of the helmet. USSOCOM is developing a headform that may enable USSOCOM to achieve a BTD result that is better than the current Service BTD standard with the current headform. With the adoption of the laser scanning methodology for BTD measurement, and with the analysis completed by the National Institute of Standards and Technology1, the DoD adopted the rounding methodology described in ASTM E29-082 for rounding the BTD measurement to 0.1 mm. Therefore, for uniformity with this standard, and unless changed by formal requirements documents (a Service-generated, Joint Capabilities Integration and Development System (ICIDS) compliant capability production document, for example), the DoD adopts as the BTD requirement a maximum of 16.0 mm for impacts by a 9 mm projectile on the right side, left side, and helmet crown, and a maximum of 25.4 mm

__________________

1 National Institute of Standards and Technology, Dimensional Metrology Issues of Army Body Armor Testing, February 17,2010.

2 ASTM E29-08, Standard Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications.

for 9 mm projectile impacts at either the helmet front or back. The DoD requirement that these BTD standards are not exceeded is based on the specified upper tolerance limit calculated from the data set.

Table 1. Elements of Standardization

|

Element |

Reference |

|

Range Setup (physical layout of test range, instrumentation, measurement devices, recording devices, etc.) & Test Conduct |

Service Requirements Documents |

|

Backing Material/Clay Calibration |

IOP PED-003 |

|

Fair Hit/No Test Criteria |

This Standard |

|

Definition of Complete/Partial Penetrations |

This Standard |

|

Ballistic Transient Deformation (BTD) Measurement |

IOP PED-003 w/current revisions |

|

Shot Patterns/Shot Order/Distribution of Test Article Size in Test Matrix |

Service Requirements Documents |

|

Sample Size/Statistical Confidence in Test Results/Analysis Methodologies |

This Standard |

|

Threat Munitions |

Service Requirements Documents |

Range Setup and Test Conduct. Test range setup will be in accordance with Protective Equipment IOP PED-003, Procedures for Head Protection Testing. Test conduct will be in accordance with Service Requirements documents, IOP PED-003 (including revisions), and this standard. Testing will include both ballistic characterization testing (“V50” testing) and resistance to penetration/ballistic transient deformation (RTP/BTD) testing (“V0” testing). If these documents do not meet the needs of test agencies, test agencies may adopt procedures not defined within the documents. When such an event arises, DOT&E requests those agencies provide to the approving officials for those documents a written explanation of the deficiency and the range setup procedures used that were outside the scope of the documents. Subsequently, the approving officials should consider adoption of the provided information. Likewise, if a test agency deviates from these standards, they should provide a written explanation to the approving officials describing the necessity of doing so. Any changes to IOP PED-003 must be documented in individual test plans and concurred with by program offices prior to test execution. Revisions to IOP PED-003 must also be coordinated with the Services and USSOCOM prior to implementation. Any conflicts between Services and test organizations will be referred to the Integrated Product Team for resolution. Requirements or governing Service documents may specify the use of a headform other than the modified NIJ headform used in IOP PED-003. If a requirements document specifies a different (non-NIJ modified) headform, the responsible test agency will provide DOT&E with the range setup and test conduct procedures for use with the headform specified by the requirements document. Any Service, USSOCOM, or test organization that encounters helmet-related situations or circumstances not addressed in this protocol (e.g., first article testing of a single size) will coordinate the resolution of that situation with DOT&E.

Backing Material/Clay Calibration. Backing material (clay) preparation, cold working, temperature conditioning, monitoring, life-cycle management, and calibration will be in accordance with IOP PED-003.

Fair Hit/No Test Criteria. An impact is considered FAIR if:

(1) The yaw is within acceptable limits (less than or equal to 5.0 degrees for 9 mm full metal jacket projectiles and fragments or less than or equal to 3.0 degrees for rifle threats)

(2) The shot location is within acceptable limits (as specified in the requirements document or IOP PED-003)

(3) The obliquity is within acceptable limits

(4) The velocity is within acceptable limits. For RTP/BTD testing, a shot with a high velocity (except for the final shot), regardless of the results of the test (partial or complete penetration), will be declared “inconclusive” and repeated with a new (untested) helmet. For an impact with a low velocity that is not a complete penetration, the shot will be declared “inconclusive” and repeated with a new (untested) helmet. For an impact with a low velocity that is a complete penetration, the shot is valid and a retest is not required. If the final impact is a high velocity shot that generated a partial penetration, the shot is valid.

Complete Penetration (V0 RTP/BTD). A complete penetration shall be defined as complete perforation of the shell by the projectile or fragment of the projectile as evidenced by the presence of that projectile, projectile fragment, or spall in the clay, or by a hole which passes thru the shell. In the case of the fastener test, any evidence of the projectile, fragment of the projectile, or fastener in the clay shall be considered a complete penetration. Non-metallic material such as paint, fibrous materials, edging, or edging adhesion resin that are emitted from the test specimen and rest on the outer surface of the clay impression are not considered a complete penetration.

Complete Penetration – Witness Headform (RTP). A complete penetration occurs when the impacting projectile or any fragment thereof, or any fragment of the retention system hardware perforates the witness plate resulting in a crack or hole which permits light passage.

Complete Penetration (V50). A complete penetration occurs when the impacting projectile or any fragment thereof, or any fragment of the test specimen perforates the witness plate resulting in a crack or hole which permits light passage. A break in the witness plate by the helmet deformation is not scored as a complete penetration.

Partial Penetration. A partial penetration is any fair impact that is not a complete penetration.

If these definitions do not meet the needs of the material developer, the material developer must document deviations from these definitions and provide them to DOT&E. DOT&E will coordinate such information with the Services and USSOCOM to determine if changes are warranted to this standard.

Ballistic Transient Deformation (BTD) Measurements. Transient deformation, or BTD, values shall be determined for each impact location. BTD values will be determined by comparing differences in the elevation of the pre-shot clay surface at the intended impact location to the surface of the clay after the impact has been made. For BTD measurements:

(1) The laser scanning device will be used in accordance with (IAW) IOP PED-003.

(2) The method used to determine BTD values shall be IAW IOP 002 Rev D (or updated revision), Measurement of Back-Face Deformation using Faro Quantum Laser Scan Arm and Geomagic Qualify for Helmets (RPS Alignment).

(3) The pre- and post-shot scans will then be analyzed using IAW IOP 002 Rev D (or updated revision) to determine the maximum BTD of depression made by the impact. In making this determination, any clay surrounding the impression that has been raised above the original level of the surface (cratering) will be ignored. The BTD value will be recorded as the number of digits reported out by the software, but reported in millimeters to the nearest tenth digit following standard ASTM E29 “Standard Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications” (Rounding Method paragraph 6).

Shot Pattern/Shot Order/Distribution of Test Article Size. Appendix A defines the distribution of helmets in this protocol for V50, V0, and hardware testing. Shots against hardware are conducted against hardware on helmets separate from those helmets shot to determine resistance to penetration and ballistic transient deformation. For aramid-based helmets such as the Advanced Combat Helmet (ACH) and Lightweight Helmet (LWH), Appendix A provides five shots per helmet in each of the five impact locations described in IOP PED-003 for V0 9 mm RTP/BTD testing, two shots per helmet for RTP hardware testing, and one shot per helmet for small arms RTP testing (if a requirements document calls for small arms testing). Shot sequence for 9 mm RTP/BTD testing is specified in Appendix A. For ultrahigh molecular polyethylene-based helmets such as the Enhanced Combat Helmet (ECH), Appendix A provides two (instead of five) shots per helmet for V0 9 mm RTP/BTD testing. For small arms RTP testing, test plans will ensure shots will be distributed between all helmet locations and will randomize shot sequence and sizes. All shots will be at 0° obliquity.

Sample Size/Statistical Confidence in Test Results. Table 2 displays the RTP/BTD statistical analysis required for this protocol. The standard is established to provide a high level of statistical confidence in the test results. For resistance to penetration tests (small arms, hardware, and 9 mm shell), the lower confidence level for the probability of no penetration, P(nP), is the statistic of interest and the result compared against a 90 percent probability of no penetration. For BTD, the Upper Tolerance Limit (UTL) will be computed and the result compared against the requirement.

Table 2. Statistical Analysis Methodologies

|

Resistance to Penetration |

|

| Analysis Methodology |

90% Lower Confidence Level |

|

Ballistic Transient Deformation |

|

| Analysis Methodology |

90% Upper Tolerance Limit with 90% Confidence |

Analysis Methodologies. The Lower Confidence Level (LCL) of the P(nP) is calculated using the Clopper-Pearson method. The LCL for P(nP) is calculated by combining shot locations, helmet sizes, and environmental conditions.

For BTD, the arithmetic mean of the BTD measurements is calculated as well as the indicated UTL. The 90 percent UTL at 90 percent confidence provides the estimated BTD measurement below which 90 percent of BTD measurements will occur, with 90 percent confidence. The BTD UTL will be calculated independently each for the crown, front, and back locations by combining all helmet sizes and environmental conditions at those locations. A fourth BTD UTL will be calculated by combining the right and left shot locations for all helmet sizes and environmental conditions after verifying the data from

the side locations can be combined for analysis. If the BTD measurements from the side locations form two distinct distributions, then a separate BTD UTL must be calculated for each side location.

Threat Munitions. The Services and USSOCOM will generate requirements documents that identify the threat munitions and associated velocities that will be applied against this protocol. As noted previously, the BTD requirement of a maximum 16.0 mm for the 9 mm projectile on the right, left, and crown regions, and 25.4 mm for the 9 mm projectile on the front and back regions, will be the DoD standard until superseded by a validated capabilities document.

This protocol does not prevent the Services or USSOCOM from conducting testing with additional threats that may not be applied against this testing protocol.

Conclusion. The Services and USSOCOM will document adherence to this protocol in formal test plans and reports.

Appendix A

Helmet Test Matrix

(Advanced Combat Helmet and Lightweight Helmet)

|

V50 |

Ambient |

Hot |

Cold |

Seawater |

Weatherometer |

Accelerated Aging |

| 2-grain |

1 V50 |

1 V50 |

1 V50 |

1 V50 |

||

|

Size: Small |

Size: Medium |

Size: Large |

Size: XL |

|||

| 4-grain |

1 V50 |

1 V50 |

1 V50 |

1 V50 |

||

|

Size: XL |

Size: Small |

Size: Medium |

Size: Large |

|||

| 16-grain |

1 V50 |

1 V50 |

1 V50 |

1 V50 |

||

|

Size: Large |

Size: XL |

Size: Small |

Size: Medium |

|||

| 17-grain |

1 V50 |

1 V50 |

1 V50 |

1 V50 |

1 V50 |

1 V50 |

|

Size: Medium |

Size: Large |

Size: XL |

Size: Small |

Size: Large |

Size: Medium |

|

| 64-grain |

1 V50 |

1 V50 |

1 V50 |

1 V50 |

||

|

Size: Large |

Size: XL |

Size: Medium |

Size: Small |

|||

| Small Arms |

1 V50 |

1 V50 |

1 V50 |

1 V50 |

1 V50 |

|

|

Size: Medium |

Size: Small |

Size: XL |

Size: Large |

Size: Medium |

||

|

9 mm RTP/BTD Shell |

60 shots |

60 shots |

60 shots |

60 shots |

||

|

12 helmets |

12 helmets |

12 helmets |

12 helmets |

|||

|

Sizes: |

Sizes: |

Sizes: |

Sizes: |

|||

|

Small: 3 |

Small: 3 |

Small: 3 |

Small: 3 |

|||

|

Medium: 3 |

Medium: 3 |

Medium: 3 |

Medium: 3 |

|||

|

Large: 3 |

Large: 3 |

Large: 3 |

Large: 3 |

|||

|

9 mm RTP Hardware1 |

17 shots |

16 shots |

16 shots |

16 shots |

||

|

9 helmets |

8 helmets |

8 helmets |

8 helmets |

|||

|

Sizes: |

Sizes: |

Sizes: |

Sizes: |

|||

|

Small: 2 |

Small: 2 |

Small: 2 |

Small: 2 |

|||

|

Medium: 3 |

Medium: 2 |

Medium: 2 |

Medium: 2 |

|||

|

Large: 2 |

Large: 2 |

Large: 2 |

Large: 2 |

|||

|

Small Arms RTP1,2 |

17 shots |

16 shots |

16 shots |

16 shots |

||

|

17 helmets |

16 helmets |

16 helmets |

16 helmets |

|||

|

Sizes: |

Sizes: |

Sizes: |

Sizes: |

|||

|

Small: 4 |

Small: 4 |

Small: 4 |

Small: 4 |

|||

|

Medium: 5 |

Medium: 4 |

Medium: 4 |

Medium: 4 |

|||

|

Large: 4 |

Large: 4 |

Large: 4 |

Large: 4 |

1This matrix provides for a total of 65 shots for both the 9 mm RTP hardware and the small arms RTP tests and allows up to three complete penetrations to achieve the lower limit of 0.90 for RTP with 90% confidence. For the 9 mm RTP hardware testing in ambient conditions, the third medium helmet will be shot once to obtain the 65th data point for this test.

2Applicable only if the requirements document specifies a small arms requirement.

Helmet Test Matrix

9 mm Resistance to Penetration/Ballistic Transient Deformation

(Advanced Combat Helmet and Lightweight Helmet)

| Ambient | Hot | Cold | Seawater | ||||||||||||||||||||||||

| Size | Helmet | Order | Size | Helmet | Order | Size | Helmet | Order | Size | Helmet | Order | ||||||||||||||||

| S | #1 | F | B | Cr | R | L | S | #1 | L | F | B | R | Cr | S | #1 | Cr | F | B | R | L | S | #1 | B | L | F | R | Cr |

| #2 | L | R | Cr | B | F | #2 | Cr | R | B | F | L | #2 | L | R | B | F | Cr | #2 | Cr | R | F | L | B | ||||

| #3 | B | R | F | L | Cr | #3 | F | R | L | Cr | B | #3 | F | B | R | L | Cr | #3 | L | F | R | Cr | B | ||||

| M | #1 | Cr | L | F | R | B | M | #1 | B | Cr | L | R | F | M | #1 | Cr | L | R | B | F | M | #1 | B | Cr | R | F | L |

| #2 | R | L | B | Cr | F | #2 | R | Cr | F | B | L | #2 | B | R | L | Cr | F | #2 | R | B | Cr | L | F | ||||

| #3 | F | Cr | B | L | R | #3 | L | B | F | Cr | R | #3 | F | Cr | L | R | B | #3 | F | L | Cr | B | R | ||||

| L | #1 | L | Cr | R | F | B | L | #1 | Cr | B | R | L | F | L | #1 | F | R | Cr | B | L | L | #1 | L | R | F | Cr | B |

| #2 | B | F | R | Cr | L | #2 | F | L | R | B | Cr | #2 | L | B | Cr | R | F | #2 | B | Cr | F | R | L | ||||

| #3 | Cr | F | L | B | R | #3 | R | L | Cr | F | B | #3 | R | Cr | B | L | F | #3 | Cr | L | B | F | R | ||||

| XL | #1 | R | B | L | F | Cr | XL | #1 | B | F | Cr | L | R | XL | #1 | F | L | B | Cr | R | XL | #1 | R | F | B | L | Cr |

| #2 | B | L | Cr | F | R | #2 | L | Cr | F | B | R | #2 | Cr | B | L | F | R | #2 | L | Cr | R | B | F | ||||

| #3 | R | F | Cr | L | B | #3 | R | B | F | Cr | L | #3 | R | F | L | B | Cr | #3 | F | B | R | Cr | L | ||||

Key:

F=Front

B=Back

R=Right

L=Left

Cr=Crown

All shots at 0° obliquity

Helmet Test Matrix

(Enhanced Combat Helmet)

|

V50 |

Ambient |

Hot |

Cold |

Seawater |

Weatherometer |

Accelerated Aging |

| 2-grain |

1 V50 |

1 V50 |

1 V50 |

1 V50 |

||

|

Size: Small |

Size: Medium |

Size: Large |

Size: XL |

|||

| 4-grain |

1 V50 |

1 V50 |

1 V50 |

1 V50 |

||

|

Size: XL |

Size: Small |

Size: Medium |

Size: Large |

|||

| 16-grain |

1 V50 |

1 V50 |

1 V50 |

1 V50 |

||

|

Size: Large |

Size: XL |

Size: Small |

Size: Medium |

|||

| 17-grain |

1 V50 |

1 V50 |

1 V50 |

1 V50 |

1 V50 |

1 V50 |

|

Size: Medium |

Size: Large |

Size: XL |

Size: Small |

Size: Large |

Size: Medium |

|

| 64-grain |

1 V50 |

1 V50 |

1 V50 |

1 V50 |

||

|

Size: Large |

Size: XL |

Size: Medium |

Size: Small |

|||

| Small Arms |

1 V50 |

1 V50 |

1 V50 |

1 V50 |

1 V50 |

|

|

Size: Medium |

Size: Small |

Size: XL |

Size: Large |

Size: Medium |

||

|

9 mm RTP/BTD Shell |

24 shots |

24 shots |

24 shots |

24 shots |

||

|

12 helmets |

12 helmets |

12 helmets |

12 helmets |

|||

|

Sizes: |

Sizes: |

Sizes: |

Sizes: |

|||

|

Small: 3 |

Small: 3 |

Small: 3 |

Small: 3 |

|||

|

Medium: 3 |

Medium: 3 |

Medium: 3 |

Medium: 3 |

|||

|

Large: 3 |

Large: 3 |

Large: 3 |

Large: 3 |

|||

|

9 mm RTP Hardware1 |

17 shots |

16 shots |

16 shots |

16 shots |

||

|

9 helmets |

8 helmets |

8 helmets |

8 helmets |

|||

|

Sizes: |

Sizes: |

Sizes: |

Sizes: |

|||

|

Small: 2 |

Small: 2 |

Small: 2 |

Small: 2 |

|||

|

Medium: 3 |

Medium: 2 |

Medium: 2 |

Medium: 2 |

|||

|

Large: 2 |

Large: 2 |

Large: 2 |

Large: 2 |

|||

|

Small Arms RTP1,2 |

17 shots |

16 shots |

16 shots |

16 shots |

||

|

17 helmets |

16 helmets |

16 helmets |

16 helmets |

|||

|

Sizes: |

Sizes: |

Sizes: |

Sizes: |

|||

|

Small: 4 |

Small: 4 |

Small: 4 |

Small: 4 |

|||

|

Medium: 5 |

Medium: 4 |

Medium: 4 |

Medium: 4 |

|||

|

Large: 4 |

Large: 4 |

Large: 4 |

Large: 4 |

1This matrix provides for a total of 65 shots for both the 9 mm RTP hardware and the small arms RTP tests and allows up to three complete penetrations to achieve the lower limit of 0.90 for RTP with 90% confidence. For the 9 mm RTP hardware testing in ambient conditions, the third medium helmet will be shot once to obtain the 65th data point for this test.

2Applicable only if the requirements document specifies a small arms requirement.

Helmet Test Matrix

9 mm Resistance to Penetration/Ballistic Transient Deformation

(Enhanced Combat Helmet)

| Size | Helmet | Ambient | Hot | Cold | Seawater | ||||

| Shot 1 | Shot 2 | Shot 1 | Shot 2 | Shot 1 | Shot 2 | Shot 1 | Shot 2 | ||

| #1 | Cr | B | L | F | Cr | B | L | F | |

| Small | #2 | L | F | Cr | B | R | F | Cr | B |

| #3 | Cr | B | R | F | Cr | B | R | F | |

| #1 | R | F | Cr | B | R | F | Cr | B | |

| Medium | #2 | Cr | B | R | F | Cr | B | L | F |

| #3 | L | F | Cr | B | L | F | Cr | B | |

| #1 | Cr | B | R | F | Cr | B | R | F | |

| Large | #2 | R | F | Cr | B | L | F | Cr | B |

| #3 | Cr | B | L | F | Cr | B | L | F | |

| #1 | L | F | Cr | B | L | F | Cr | B | |

| X-Large | #2 | Cr | B | L | F | Cr | B | R | F |

| #3 | R | F | Cr | B | R | F | Cr | B | |

Key:

F=Front

B=Back

R= Right

L=Left

Cr=Crown

All shots at 0° obliquity

PROTOCOL FOR LOT ACCEPTANCE TESTING,

MAY 4, 2012

MEMORANDUM FOR: SEE DISTRIBUTION

SUBJECT: Standard for Lot Acceptance Ballistic Testing of Military Combat Helmets

Department of Defense (DoD) combat helmet acquisition programs under DOT&E oversight are required to execute, at a minimum, the attached protocol for testing that results in a decision to accept a production lot from a vendor (Lot Acceptance Testing). Lot Acceptance Testing conducted for sustainment contracts such as those executed for the Services by the Defense Supply Center Philadelphia must also follow this protocol.

This protocol updates and supersedes the combat helmet lot acceptance protocol published in January 2012. It revises the aramid-based LAT matrix in appendix A to conform with the acceptable quality level for resistance to penetration specified in the protocol. There is no change to the acceptable quality level for resistance to penetration.

As testing of combat helmets continues and additional data are obtained, DOT&E will publish, as necessary, updates and changes to the attached protocol. Additionally, DOT&E will work with the Services, USSOCOM, and Defense Agencies to incorporate this protocol, and future changes to it, into existing test operating procedures and military standards.

Attachment:

As stated

DISTRIBUTION:

ASSISTANT SECRETARY OF THE ARMY (ACQUISITION, LOGISTICS AND TECHNOLOGY)

ASSISTANT SECRETARY OF THE NAVY (RESEARCH, DEVELOPMENT AND ACQUISITION)

ASSISTANT SECRETARY OF THE AIR FORCE FOR ACQUISITION AND MANAGEMENT

SPECIAL OPERATIONS ACQUISITION EXECUTIVE, UNITED STATES SPECIAL OPERATIONS COMMAND

DIRECTOR, DEFENSE LOGISTICS AGENCY

COMMANDER, DEFENSE SUPPLY CENTER PHILADELPHIA

COMMANDER, U.S. ARMY TEST AND EVALUATION COMMAND

COMMANDER, OPERATIONAL TEST AND EVALUATION FORCE

COMMANDER, AIR FORCE OPERATIONAL TEST AND EVALUATION CENTER

DIRECTOR, MARINE CORPS OPERATIONAL TEST AND EVALUATION ACTIVITY

COMMANDER, MARINE CORPS SYSTEMS COMMAND

DIRECTOR, OPERATIONAL TEST & EVALUATION, UNITED STATES SPECIAL OPERATIONS COMMAND

PROGRAM EXECUTIVE OFFICE SOLDIER

PROGRAM EXECUTIVE OFFICE SPECIAL OPERATIONS FORCES WARRIOR

PROGRAM EXECUTIVE OFFICE LITTORAL AND MINE WARFARE

COMMANDER, NAVAL SEA SYSTEMS COMMAND, SHIP INTEGRITY AND PERFORMANCE

FEDERAL BUREAU OF INVESTIGATION, BALLISTIC RESEARCH FACILITY, FBI ACADEMY (ATTN: SSA J. BUFORD BOONE III)

NATIONAL INSTITUTE OF STANDARDS AND TECHNOLOGY, PROGRAM MANAGER WEAPONS AND PROTECTIVE SYSTEMS (ATTN: MR. KIRK RICE)

Military Combat Helmet

Standard for Ballistic Lot Acceptance Testing

The objective of this protocol is to establish DoD-wide, statistically-derived test methods for combat helmet lot acceptance tests that will provide increased confidence in the ballistic performance of personal protective equipment. This protocol also establishes standard testing references, protocols, procedures, and analytical processes for combat helmet testing against ballistic requirements. This protocol will be used for testing conducted at government facilities and at commercial test facilities conducting lot acceptance testing (LAT) on behalf of the DoD.

As necessary, the Services will use the standards and information in this protocol to update or develop Test Operating Procedures (TOPs), Military-Standards (MIL-STDs), Purchase Descriptions (PDs), Internal Operating Procedures (IOPs), and other documents relevant to this commodity area.

DOT&E will work in coordination with the Services, United States Special Operations Command (USSOCOM), and the Defense Logistics Agency (DLA) to update this protocol at least annually. As this protocol is codified into the aforementioned documents, updates to this protocol may be directly addressed via updates to those documents.

Protocols established in this standard supplement those currently in practice across the DoD. However, this protocol does not address all issues associated with testing combat helmets. Test agencies, contracting officials, and material developers should therefore continue to use and reference TOPs, MIL-STDs, IOPs, and other guiding documents currently in use to fully explain test setup and execution procedures. This protocol is not intended to be applied against already accepted lots, or against lots produced from designs not qualified using the September 20,2011, Military Combat Helmet test protocol for First Article Testing.

Elements of Standardization

Table 1 establishes standard reference documents, precedence, and source information related to this standard. The list is not meant to be all encompassing. The elements referenced to this standard are described later in this document. Elements referenced to Service requirements documents reflect that this is a testing standard and not a requirements document. Service user representatives and the USSOCOM establish Service- and USSOCOM-unique requirements. This includes, for example, the requirements of threat munitions and respective velocities to be applied against this testing protocol.

The Services have adopted a Ballistic Transient Deformation (BTD) standard that the BTD cannot exceed 16,0 mm for impacts by a 9 mm projectile (velocity 1400 +50 feet per second) on the right, left, and crown of the helmet, and 25.4 mm for impacts at either the front or back of the helmet. USSOCOM is developing an alternate headform that may enable USSOCOM to achieve a different BTD result as compared to the current Service BTD standard with the current headform. With the adoption of the laser scanning methodology for BTD measurement, and with the analysis completed by the National Institute of Standards and Technology, the DoD adopted the rounding methodology described in ASTM E29-08 for

rounding the BTD measurement to 0.1 mm.1,2 Therefore, for uniformity with this standard, and unless changed by formal requirements documents (a Service-generated, Joint Capabilities Integration and Development System (JCIDS) compliant capability production document, for example), the DoD adopts as the BTD requirement a maximum of 16.0 mm for impacts by a 9 mm projectile on the right side, left side, and helmet crown, and a maximum of 25.4 mm for 9 mm projectile impacts at either the helmet front or back. The DoD requirement that these BTD standards are not exceeded is based on the one-sided upper tolerance limit calculated from the data set.

Table 1. Elements of Standardization

|

Element |

Reference |

| Range Setup (physical layout of test range, instrumentation, measurement devices, recording devices, etc.) and Test Conduct |

Service Requirements Documents |

| Backing Material/Clay Calibration |

IOP PED-003 w/current revisions |

| Fair Hit/No Test Criteria |

This Standard |

| Definition of Complete/Partial Penetrations |

This Standard |

| Ballistic Transient Deformation (BTD) Measurement |

IOP PED-003 |

| Shot Patterns/Shot Order/Distribution of Test Article Size in Test Matrix |

Service Requirements Documents |

| Sample Size/Statistical Confidence in Test Results |

This Standard |

| Threat Munitions |

Service Requirements Documents |

Range Setup and Test Conduct. Test range setup will be in accordance with Protective Equipment IOP PED-003, Procedures for Head Protection Testing. Test conduct will be in accordance with Service Requirements documents, (Purchase Descriptions / Product Specifications), IOP PED-003 (including revisions), and this standard. Testing will include both ballistic characterization testing (“V50” testing) and resistance to penetration/ballistic transient deformation (RTP/BTD) testing (“V0” testing). If these documents do not meet the needs of test agencies, test agencies may adopt procedures not defined within the documents. When such an event arises, DOT&E requests those agencies provide to the approving officials for those documents (a specification owner, program office, etc) and the affected program offices a written explanation of the deficiency and the range setup procedures to be used that were outside the scope of the documents. Subsequently, the approving officials should consider adoption of the provided information. Likewise, if a test agency deviates from these standards, they should provide a written explanation to the approving officials describing the necessity of doing so.

__________________

1 National Institute of Standards and Technology, Dimensional Metrology Issues of Army Body Armor Testing, February 17,2010.

2 ASTM E29-08, Standard Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications.

Any proposed changes must be coordinated with program managers from the Services, USSOCOM, and DLA prior to implementation to preclude an adverse impact on existing contracts or specifications. Any changes to IOP PED-003 must be documented in individual test plans and concurred with by program offices prior to test execution. Revisions to IOP PED-003 must also be coordinated with the Services and USSOCOM prior to implementation. Any conflicts between Services and test organizations will be referred to the Integrated Product Team for resolution. Requirements or governing Service documents may specify the use of a headform other than the modified NIJ 0106.01 headform used in IOP PED-003. If a requirements document specifies a different (non-NIJ modified) headform, the responsible test agency will provide DOT&E with the range setup and test conduct procedures for use with the headform specified by the requirements document. Any Service, USSOCOM, or test organization that encounters helmet-related situations or circumstances not addressed in this protocol will coordinate the resolution of that situation with the responsible program office or specification owner and the Deputy for Live Fire Test and Evaluation, DOT&E.

Backing Material/Clay Calibration. Backing material (clay) preparation, cold working, temperature conditioning, monitoring, life-cycle management, and calibration will be in accordance with IOP PED-003; exceptions will be coordinated in the detailed test plan.

Fair Hit/No Test Criteria. An impact is considered FAIR if:

(1) The yaw is within acceptable limits (less than or equal to 5.0 degrees for handgun / pistol and fragment simulating projectiles or less than or equal to 3.0 degrees for rifle threats).

(2) The shot location is within acceptable limits (as specified in the requirements document or IOP PED-003).

(3) The obliquity is within acceptable limits.

(4) The velocity is within acceptable limits (as specified in the detailed test plan). For RTP/BTD testing, a shot with a high velocity (except for the final shot), regardless of the results of the test (partial or complete penetration), will be declared “inconclusive” and repeated with a new (untested) helmet. For an impact with a low velocity that is not a complete penetration, the shot will be declared “inconclusive” and repeated with a new (untested) helmet. For an impact with a low velocity that is a complete penetration, the shot is valid and a retest is not required. If the final impact is a high velocity shot that generated a partial penetration, the shot is valid for calculating penetration results but not for BTD. The shot sequence from that sub-test will be repeated on a new, untested helmet. All valid BTD and penetration data will be used for calculations.

(5) For RTP/BTD testing, a complete penetration on any shot that is otherwise fair is valid for calculating penetration results and a new (untested) helmet will be tested using the full 9 mm Vo shot sequence to complete the test matrix. Valid penetration and BTD data from both helmets will be used for analysis.

Complete Penetration (V0 RTP/BTD). A complete penetration shall be defined as complete perforation of the shell by the projectile or fragment of the projectile as evidenced by the presence of that projectile, projectile fragment, or spall in the clay, or by a hole which passes

thru the shell. In the case of the fastener test (when specified in the detailed test plan), any evidence of the projectile, fragment of the projectile, or fastener in the clay shall be considered a complete penetration. Non-metallic material such as paint, fibrous materials, edging, or edging adhesion resin that are emitted from the test specimen and rests on the outer surface of the clay impression are not considered a complete penetration.

Complete Penetration – Witness Headform (RTP). A complete penetration occurs when the impacting projectile or any fragment thereof, or any fragment of the retention system hardware perforates the witness plate resulting in a crack or hole that permits light passage. This applies only when the use of this headform is required by the requirements document and specified in the detailed test plan.

Complete Penetration (V50). A complete penetration occurs when the impacting projectile or any fragment thereof, or any fragment of the test specimen perforates the witness plate resulting in a crack or hole that permits light passage. A break in the witness plate by the helmet deformation is not scored as a complete penetration.

Partial Penetration. A partial penetration is any fair impact that is not a complete penetration.

If these definitions do not meet the needs of the material developer, the material developer must document deviations from these definitions and provide them to DOT&E. DOT&E will coordinate such information with the Services and USSOCOM to determine if changes are warranted to this standard.

Ballistic Transient Deformation (BTD) Measurements. Transient deformation, or BTD, values shall be determined for each impact location. BTD values will be determined by comparing differences in the elevation of the pre-shot clay surface at the intended impact location to the surface of the clay after the impact has been made. For BTD measurements:

(1) The laser scanning device will be used in accordance with (IAW) IOP PED-003.

(2) The method used to determine BTD values shall be JAW IOP 002 Rev D (or updated revision), Measurement of Back-Face Deformation using Faro Quantum Laser Scan Arm and Geomagic Qualify for Helmets (RPS Alignment),

(3) The pre- and post-shot scans will then be analyzed IAW IOP 002 Rev D (or updated revision) to determine the maximum BTD of depression made by the impact. In making this determination, any clay surrounding the impression that has been raised above the original level of the surface (cratering) will be ignored. The BTD value will be recorded as the number of digits reported out by the software, but reported in millimeters to the nearest tenth digit following standard ASTM E29 “Standard Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications” (Rounding Method paragraph 6).

Shot Pattern/Shot Order/Distribution of Test Article Size. Appendix A defines the distribution of helmets in this protocol for V0 and hardware testing. Shots against hardware are conducted against hardware on helmets separate from those helmets shot to determine resistance

to penetration and ballistic transient deformation. For aramid-based helmets, such as the current Advanced Combat Helmet (ACH) and Lightweight Helmet (LWH), Appendix A provides five shots per helmet in each of the five impact locations described in IOP PED-003 for V0 9 mm RTP/BTD testing, two shots per helmet for RTP hardware testing, and one shot per helmet for small arms RTP testing (if a requirements document calls for small arms testing). Shot sequence for 9 mm RTP/BTD testing is specified in Appendix B. For ultra-high molecular weight polyethylene-based (UHMWPE) helmets such as the Enhanced Combat Helmet (ECH), Appendix A provides two (instead of five) shots per helmet for V0 9 mm RTP/BTD testing. For small arms RTP testing, test plans will ensure shots will be distributed between all helmet locations and will randomize shot sequence. For hardware RTP testing, test plans will ensure the first shot location alternates between the right and left sides. All shots will be at 0 degrees intended obliquity (checked prior to firing the test shot per IOP PED-003). Impacts within 5 degrees of intended obliquity are considered to meet the fair hit obliquity requirement (per IOP PED-003).

Helmet testing is unique in that two to three disparate destructive tests axe required for each lot. Each test stresses the helmets in a particular way; presenting a challenging threat, exploiting a potential structural weakness, or imposing a BTD requirement; and each requires a different number of shots taken on an individual helmet. Each must therefore be treated as a distinct subtest. It is desirable to maintain reasonable LAT sampling levels (e.g. S-4); therefore, the total number of helmets allocated to penetration and BTD tests closely reflects the quantities required for the S-4 sampling level and consists of sub-tests sampled at either the S-2 or S-3 levels. The sampling levels reflect the perceived challenge imposed by each subtest, with more resources assigned to more challenging subtests.

For RTP/BTD testing, a complete penetration on any shot that is otherwise fair is valid for calculating penetration results. If a perforation occurs, no additional shots will be taken on the perforated helmet. The perforated helmet will count against the accept/reject criteria in Appendix A. To complete the test matrix, a new (untested) helmet will be tested using the full 9mm V0 shot sequence for the helmet that was perforated. Valid penetration and BTD data from both helmets will be used for analysis. Testing is complete when a complete set of valid BTD measurements have been taken. It is not necessary to complete BTD testing if the helmet fails the RTP portion of the test.

Sample Size/Statistical Confidence in Test Results. Table 2 displays the resistance to penetration and ballistic transient deformation analysis required for this protocol. The standard is established to provide a high level of statistical confidence in the test results. It also is intended to indicate the vendor is consistently producing helmets capable of meeting the First Article Testing standards. For resistance to penetration tests (small arms, hardware, and 9 mm shell) the equivalent acceptable quality level is 4 percent; the corresponding accept/reject numbers are provided in Appendix A. Accept / reject numbers are in terms of helmets tested. For the BTD test (9 mm shell), the Upper Tolerance Limit (UTL) will be computed using BTD as a continuous variable and the result compared against the requirement. The BTD UTL (with 90 percent confidence) will be calculated independently each for the crown, front, and back locations. A fourth BTD UTL (at 90 percent confidence) will be calculated by combining the

right and left shot locations if the data from the qualifying First Article Test indicates the data from the side locations can be combined for analysis. (Conduct both a t-test on the means and the Brown-Forsyth test for equal variances on the standard deviations using a significance level of 0.1 in both tests.) If the data from the side locations cannot be combined, the side locations must be calculated separately. Appendix A provides UTL proportions based on helmet type and number of 9 mm shell RTP/BTD subtests. Appendix C discusses UTL calculations. Lots that fail either the resistance to penetration or BTD criteria will be rejected.

Table 2. Statistical Analysis Methodologies

|

Resistance to Penetration |

|

|

Analysis Methodology |

4% Acceptable Quality Level |

|

Ballistic Transient Deformation |

|

| Analysis Methodology |

Upper Tolerance Limit with 90% Confidence |

Threat Munitions. The Services and USSOCOM will identify the threat munitions and associated velocities that will be applied against this protocol. As noted previously, the BTD requirement of a maximum 16.0 mm for the 9 mm projectile on the right, left, and crown regions, and 25.4 mm for the 9 mm projectile on the front and back regions, will be the DoD standard until superseded by a validated capabilities document.

This protocol does not prevent the Services or USSOCOM from conducting testing with additional threats that may not be applied against this testing protocol.

Conclusion. The Services and USSOCOM will document adherence to this protocol in formal test plans and reports. This protocol does not preclude program offices from conducting additional testing of combat helmets to ensure compliance with other contractual requirements.

Appendix A

Helmet LAT Test Matrix

UHMWPE-based LAT Matrix

| Lot Size | Sub-Test | RTP Accept |

RTP Reject |

||

| 91-ISO | Small Arms Shell RTP | Shots | 3 | 0 | 1 |

| Helmets | 3 | ||||

| 9 mm Hardware RTP | Shots | 6 | 0 | 1 | |

| Helmets | 3 | ||||

| 9 mm Shell RTP/BTD | Shots | 16 | 1 | 2 | |

| Helmets | 8 | ||||

| 151-500 | Small Arms Shell RTP | Shots | 5 | 0 | 1 |

| Helmets | 5 | ||||

| 9 mm Hardware RTP | Shots | 10 | 1 | 1 | |

| Helmets | 5 | ||||

| 9 mm Shell RTP/BTD | Shots | 16 | 1 | 2 | |

| Helmets | 8 | ||||

| 501-1200 | Small Arms Shell RTP | Shots | 5 | o | 1 |

| Helmets | 5 | ||||

| 9 mm Hardware RTP | Shots | 10 | 0 | 1 | |

| Helmets | 5 | ||||

| 9 mm Shell RTP/BTD | Shots | 26 | 1 | 2 | |

| Helmets | 13 | ||||

| 1201-3200 | Small Arms Shell RTP | Shots | 8 | 1 | 2 |

| Helmets | 8 | ||||

| 9 mm Hardware RTP | Shots | 16 | 1 | 2 | |

| Helmets | 8 | ||||

| 9 mm Shell RTP/BTD | Shots | 26 | 1 | 2 | |

| Helmets | 13 |

Aramid-based LAT Matrix*

| Lot Size | Sub-Test | RTP Accept |

RTP Reject |

||

| 91-150 | 9 mm Hardware RTP | Shots | 6 | 0 | 1 |

| Helmets | 3 | ||||

| 9 mm Shell RTP/BTD | Shots | 25 | 0 | 1 | |

| Helmets | 5 | ||||

| 151-500 | 9 mm Hardware RTP | Shots | 10 | 0 | 1 |

| Helmets | 5 | ||||

| 9 mm Shell RTP/BTD | Shots | 40 | 1 | 2 | |

| Helmets | 8 | ||||

| 501-1200 | 9 mm Hardware RTP | Shots | 10 | 0 | 1 |

| Helmets | 5 | ||||

| 9 mm Shell RTP/BTD | Shots | 65 | 1 | 2 | |

| Helmets | 13 | ||||

| 1201-3200 | 9 mm Hardware RTP | Shots | 16 | 1 | 2 |

| Helmets | 8 | ||||

| 9 mm Shell RTP/BTD | Shots | 65 | 1 | 2 | |

| Helmets | 13 |

*Current ACH and LWH have no small arms penetration requirement.

Appendix A

Helmet LAT Test Matrix Criteria

UHMWPE-Based Helmet:

For UHMWPE-based Lots Smaller Than 500 (only):

Calculate a 85/90 BTD UTL for every location using the four shots.

If the 85/90 UTL is below the limit for that location, the helmet passes for that location.

If all locations pass for BTD UTL, the lot passes.

If the location UTL is above the limit, calculate a 60/90 UTL using the four shots.

If the 60/90 UTL is above the limit, the helmet (and the lot) fails.

If the 60/90 UTL is below the limit, shoot an additional three helmets in that shot location. If the additional shots are needed from either the back or front, repeat the full 9 mm V0 shot sequence (crown/back or side/front) on each of the three helmets. If the additional shots are needed from either the side or crown, shoot only those locations on each helmet. AH valid BTD and penetration data will be used for calculations.

Calculate a 80/90 UTL using all seven shots for that location.

If the 80/90 UTL is below the limit, the helmet (and lot) passes. If it is above the limit, the helmet and lot fail.

For UHMWPE-based Lots Larger Than 500 (only):

Calculate a 80/90 BTD UTL for every location.

If the 80/90 UTL is below the limit for that location, the helmet passes for that location.

If all locations pass for BTD UTL, the lot passes; if not, the lot fails.

For UHMWPE-based Helmet Penetration Accept / Reject:

The accept / reject criteria for 9 mm shots are the number of helmets that fail to stop any of the hardware or the shell 9 mm shots. For 9 mm shell RTP/BTD shots, if a perforation occurs on the first shot, then no second shot will be taken on that helmet. Instead, a new helmet will be shot using the full 9 mm V0 shot sequence (two shots) to measure the BTD to complete the test matrix. A complete perforation on any shot that is otherwise fair is valid for calculating penetration results and a new (untested) helmet will be tested using the full 9 mmV0 shot sequence to complete the test matrix. All valid BTD and penetration data will be used for calculations.

Aramid-based Helmets:

9 mm BTD UTL:

|

Helmets Tested |

UTL |

|

13 |

80/90 |

|

8 |

75/90 |

|

5 |

2-Stage (see below) |

For Aramid-based Lots Smaller Than 150 (only):

Calculate a 85/90 BTD UTL for every location.

If the 85/90 UTL is below the limit for that location, the helmet passes for that location.

If all locations pass for BTD UTL, the lot passes.

If the location UTL is above the limit, calculate a 60/90 UTL for that location.

If the 60/90 UTL is above the limit, the helmet (and the lot) fails.

If the 60/90 UTL is below the limit, shoot an additional three helmets beginning with the shot sequence for LAT Helmet #6 (from the Aramid 9 mm shot order table on page B-l) to obtain the data for the required shot location(s) (for sides, shoot both sides for a total of 6 more side shots). All valid BTD and penetration data will be used for calculations.

Calculate a 75/90 UTL using shots from all 8 helmets.

If the 75/90 UTL is below the limit, the helmet (and lot) passes. If it is above the limit, the helmet and lot fail.

For Aramid-Based Helmet Penetration Accept / Reject:

The accept / reject criteria for 9 mm shots are the number of helmets that fail to stop any of the hardware or the shell 9 mm shots. For 9 mm shell RTP/BTD shots, if a perforation occurs then no following shots will be taken on that helmet. A complete perforation on any shot that is otherwise

Appendix B

Helmet Test Matrix

9 mm Resistance to Penetration / Ballistic Transient Deformation Shot Order

| UHMWPE 9 mm Shot Order | ||

| Shot 1 | Shot 2 | |

| LAT Helmet #1 | Cr | B |

| LAT Helmet #2 | R | F |

| LAT Helmet #3 | Cr | B |

| LAT Helmet #4 | L | F |

| LAT Helmet #5 | Cr | B |

| LAT Helmet #6 | R | F |

| LAT Helmet #7 | Cr | B |

| LAT Helmet #8 | L | F |

| LAT Helmet #9 | Cr | B |

| LAT Helmet #10 | R | F |

| LAT Helmet #11 | Cr | B |

| LAT Helmet #12 | L | F |

| LAT Helmet #13 | Cr | B |

| Aramid 9 mm Shot Order | |||||

| Helmet | Order | ||||

| LAT Helmet #1 | B | L | Cr | F | R |

| LAT Helmet #2 | Cr | R | B | L | F |

| LAT Helmet #3 | R | B | Cr | L | F |

| LAT Helmet #4 | B | F | L | R | Cr |

| LAT Helmet #5 | B | R | F | L | Cr |

| LAT Helmet #6 | Cr | B | L | F | R |

| LAT Helmet #7 | L | B | Cr | F | R |

| LAT Helmet #8 | Cr | B | R | F | L |

| LAT Helmet #9 | L | F | R | B | Cr |

| LAT Helmet #10 | F | Cr | B | L | R |

| LAT Helmet #11 | Cr | L | R | B | F |

| LAT Helmet #12 | R | F | B | L | Cr |

| LAT Helmet #13 | Cr | F | L | B | R |

Key:

F=Front

B=Back

R=Right

L=Left

Cr=Crown

All shots at 0 degrees obliquity. Shooting should start at a random point (row) in this list. Test progression is row by row, so each row is one helmet.

Appendix C

Upper Tolerance Limit

The BTD Upper Tolerance Limit (UTL) will be calculated independently each for the crown, front, and back locations. A fourth BTD UTL will be calculated by combining the right and left shot locations for all helmet sizes (combining all helmet sizes if more than one size per lot is tested) after verifying the data from the side locations can be combined for analysis. If the BTD measurements from the side locations form two distinct distributions, then a separate BTD UTL must be calculated for each side location.

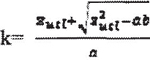

For BTD, the metric of merit is an UTL based on the assumption of normally distributed BFD data – a specified UTL at 90 percent confidence. Validated one-decimal place BTD measurements, for tested combat helmet articles that did not experience complete penetrations, are the basis for any UTL calculation. The UTL is defined as Yu = Ῡ + ks, where Ῡ is the mean of all valid BTD measurements, k is a look-up constant (varying with the sample size, UTL percentage, and confidence percentage), and s is the sample standard deviation.1,2 The UTL is reported to one decimal place accuracy after adjusting upwards via the “ceiling function” – ensuring that a conservative UTL is reported. For example, calculated results of 24.1349 mm and 24.1999 mm are each reported as 24.2 mm. Compliance with the BTD requirement is achieved only if the associated reported UTL is less than or equal to 16.0 mm (for left side, right side, and crown), and 25.4 mm (for front and back) (or a superseding threshold prescribed by a validated capabilities document).

__________________

1http://www.itl.nist.gov/div898/handbook/prc/section2/prc263.htm

2 where

where ![]() and zutl is the critical value from the standard normal distribution associated with the UTL percentage. zconf is the critical value from the standard normal distribution associated with the confidence percentage and N is the total sample size for the data of interest.

and zutl is the critical value from the standard normal distribution associated with the UTL percentage. zconf is the critical value from the standard normal distribution associated with the confidence percentage and N is the total sample size for the data of interest.