The second session of the workshop focused on methods for managing and disposing of wastewater from the production of unconventional hydrocarbons, the potential impacts of hydraulic fracturing and other production processes on water quality, and regulations aimed at minimizing the risk of adverse effects from unconventional hydrocarbon production on water and the environment. Following three plenary talks, workshop participants broke into working groups to discuss these topics and to identify priorities for future research, as summarized below.

Water Issues Relating to Unconventional Oil and Gas Production

John Veil, Veil Environmental, LLC

Veil gave a brief review of the shale gas production process (see Chapter 1), noting that water plays a role in several steps, including drilling the well (e.g., lubricating the drill bit with drilling fluid or mud), preparing a well for production (e.g., hydraulic fracturing, collecting flowback water), and producing gas (e.g., collecting, treating, or disposing of fluids). Each hydraulic fracturing job requires about 5 million gallons of water, which comes from local ponds or streams, constructed reservoirs, the public water supply (e.g., used municipal water, groundwater), or wastewater from gas wells.

The amount of water used in shale gas production receives significant public attention. Veil calculated that about 6 percent of the wastewater generated by oil and gas production in the United States (1 million active wells) comes from shale gas production (20,000 wells). Veil also compared the amount of water required for hydraulic fracturing of the Marcellus Shale with the amount of water used for other purposes. He calculated that a high production year for the Marcellus may

require 80 million gallons of water per day in New York, Pennsylvania, and West Virginia,1 compared with 17,120 million gallons per day withdrawn by the thermoelectric industry and 24,577 million gallons per day for all purposes in the three states (Kenny et al., 2009).

The management of wastewater is complicated by rapid changes in water quality and water quantity over time. The volume of flowback water declines sharply after the first few hours to days while concentrations of total dissolved solids and other constituents in flowback and produced water increase rapidly. The most common way to manage wastewater is to inject it into a disposal well. Other management methods include removing metals and other contaminants to create clean brine; desalinizing clean brine to create clean freshwater; evaporating the water to dryness or crystalline form; and filtering flowback water to remove suspended solids and blending it with freshwater for use in a subsequent fracturing job. Because only 10–20 percent of the volume of fracture fluid returns to the surface, 80–90 percent freshwater must be added to the flowback water for recycling.

In Pennsylvania, a substantial amount of the flowback and produced water is being reused, in part because options for nearby injection wells are limited. At some point in the future, the number of new wells being drilled will decline while all the old wells continue to produce water. When more water is produced than can be recycled, additional water management facilities will be needed in the region.

Veil closed by identifying some water-related practices that are relatively environmentally friendly, including siting wells away from streams and water wells, collecting water samples before drilling to have a baseline for assessing contamination, constructing wells using appropriate materials, testing to ensure well integrity, air drilling the top section of wells to reduce water needs, using lined reserve pits or tanks for drilling wastes, reusing wastewater, and emphasizing piping over trucking of water.

Questions. A workshop participant asked why so much fluid stays underground, and Veil answered that the fracture process creates significant surface area, which attracts moisture. The rock actually imbibes some of the water. Shales like the Barnett return more water than is put in the well, whereas shales like the Marcellus return only a small fraction of water that is put in.

Identifying and Assessing Potential Impacts of Unconventional Hydrocarbon Production on Surface and Groundwater Quality

Rosemary Capo, University of Pittsburgh

Capo noted that the risks to groundwater quality vary with the production activity. For example, a loss of well integrity when surface casing is being set can allow fluids to migrate from the open hole, and chemicals stored at the surface for well completion and hydraulic fracturing can spill or leak. Many of these risks can be managed through due diligence in the shale gas development process.

The primary water quality issues related to unconventional gas production in the Appalachian Basin include high concentrations of total dissolved solids in the produced water, the migration of stray gas into the water supply, and the potential migration of water from deep formations into shallow aquifers. Produced water from the Marcellus Shale is high in total dissolved solids, typically 180,000 milligrams per liter after a few weeks of production, posing challenges for recycling and

___________________

1 This hypothetical maximum was estimated by doubling the highest number of wells drilled in Pennsylvania, West Virginia, and New York and multiplying by 5 million gallons of water per well. The number of wells in Pennsylvania and West Virginia were based on state records. For this calculation, the number of wells in New York (currently zero) was assumed to be the same as the number of wells in West Virginia (922).

for wastewater treatment. Before the produced water can be used in subsequent fracture jobs, the fracture fluid mix must be adjusted substantially to avoid degrading well performance.

In addition, high concentrations of particular chemical constituents can be problematic. For example, barium can combine with sulfate in the water used for recycling and cause sediment to build up in the wells. Potentially hazardous species such as uranium and radium can mobilize from drill cuttings under acidic conditions. Although uranium is low in water produced from the Marcellus Shale, the concentrations of radium and strontium tend to be high and to increase over time.

Marcellus-produced water is also high in bromine, which can react with organic compounds in surface water to produce trihalomethanes, a possible health risk. Elevated levels of bromine have been detected in surface water near Pittsburgh, and studies are under way to determine whether the source is industrial wastewater treatment plants, which treat fluids from oil and natural gas production, or coal-fired power plants.

Combustible gas such as methane is common in water supply wells in the Appalachian Basin. Potential sources include naturally occurring gas seeps; abandoned or operating gas wells, coal mines, or landfills; coalbed methane wells; natural gas storage fields and pipelines; shallow formations and aquifers; buried organic matter; drift gas deposits; or other sources. Some sources of methane (natural gas or coal beds, landfills, and drift gas deposits) can be distinguished using stable isotope measurements, although the data can be difficult to interpret if the gas is a mixture from multiple sources. Better techniques for analyzing methane isotopes and more baseline measurements of water quality before and after drilling would improve identification of the source(s) of stray combustible gas.

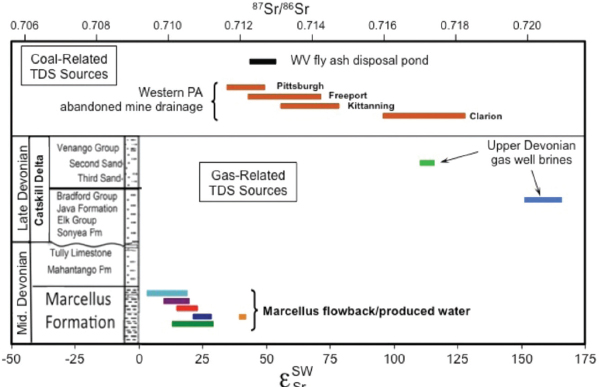

The extent to which water from deep formations can migrate into shallow aquifers is unclear. The high total dissolved solid content of some artesian water suggests that water from deep formations can migrate along natural fractures into shallow aquifers, although this interpretation has been questioned. Some model simulations have suggested that hydraulic fracturing can create conduits for brine migration above the target formation, although the modeling methodology has been challenged. Strontium isotopes may prove useful for tracing the movement of fluids in the environment because Marcellus-produced waters have a different isotopic composition than other sources, including conventional Upper Devonian gas reservoirs, abandoned coal mine draining, fly ash impoundments, and coal-fired power plant discharges (Figure 3.1). Early results (Capo et al., in press) show that even small amounts (<0.1 percent) of Marcellus-produced water in groundwater or surface water would significantly shift strontium isotope ratios.

Capo concluded that water quality studies in the Appalachian Basin are complicated by the geologic variability and the legacy of coal and mineral mining, oil and gas production, and industrial activities, all of which can contribute contaminants. Developing the baselines needed to track these sources will take significant time and effort.

Questions. A workshop participant said that the Pennsylvania Department of Environmental Protection seems unwilling to disclose whether bromide levels in the Allegheny River have changed. If they have not changed, then perhaps shale gas production is not the source. Capo said that daily sampling results published recently show spikes in bromide levels, some of which exceed levels recorded over the past 5 years. It appears that only one nearby centralized wastewater treatment facility has treated Marcellus-type fluids, but coal-fired power plants in the area use brominated solvents. Her group is sampling individual creeks and streams near these treatment centers and power plants to try to resolve the source(s).

Another participant asked how uranium and radium are removed from water and what is done with the residual material. Capo said that uranium tends to stick to particles, so the uranium content of produced water is low even if the uranium content of organic-rich black shale is high. Some people have proposed trying to recover uranium from drill cuttings before the cuttings are disposed

FIGURE 3.1 Strontium isotopic signature of water from shale gas production (bottom) compared with the isotopic signatures of coal-related sources (top). SOURCE: Reprinted from Capo et al. (in press), with permission from Elsevier.

in landfills. Wiseman said that regulatory changes would be required to make that happen. If a regulation specifies disposal of waste in a particular manner, then it generally has to be modified to allow for reuse or recycling.

State Shale Gas Regulation in the Appalachian Basin:

Recent Enhancements, Remaining Gaps, and Opportunities for Change

Hannah Wiseman, Florida State University

Wiseman noted that a large number of government regulations and enforcement strategies are aimed at protecting soil, surface water, and groundwater quality during well site activities. Relevant federal laws include the Clean Water Act, which prohibits the discharge of wastewater into streams and requires erosion control measures to prevent contaminated runoff from leaving the site during storms. In addition, most states have regulations governing the storage of flowback and produced water (e.g., requirements for pit lining and freeboard, well and site setbacks), well construction (e.g., well casing standards, blowout prevention equipment), and spills of onsite material (e.g., prevention and control plans, secondary containment requirements, erosion and sediment control plans). More states are beginning to require baseline testing, and West Virginia and Pennsylvania provide additional incentives for testing by presuming that contamination of water wells within a certain time and distance from hydrocarbon production is caused by the oil and gas operator.

The impact of wastewater disposal on soil, surface water, and groundwater quality is regulated by the federal Safe Drinking Water Act, which requires that disposal wells not endanger underground sources of drinking water. States implement this act for underground injection control wells, and Ohio also requires seismic testing and monitoring of the wells. Pennsylvania has few underground injection control wells and requires a waste management plan and reuse strategies. The Environmental Protection Agency is drafting standards for treating wastewater.

Some states regulate the quantity of surface water withdrawn for fracturing by requiring permits or water management plans showing that aquatic resources will not be adversely affected. For example, West Virginia requires operators to demonstrate that streamflow will be sufficient downstream of the withdrawal and that adverse impacts on aquatic life will be minimized. Some multistate compacts require water withdrawal permits or set minimum flow requirements across watersheds.

Compared with the number of regulations focused on water, relatively few regulations focus on air quality or ecosystems. Air quality regulation is dominantly at the federal level. The Clean Air Act sets emission standards and covers some equipment for controlling conventional and hazardous air pollutants and for capturing volatile organic compounds and methane. Some states also require minor source permitting for conventional pollutants from wells, storage tanks, or equipment at sites, and some states have rules limiting venting, flaring, and gas leaks.

Only a few regulations cover habitat fragmentation or impacts to wildlife and landscapes. For example, the U.S. Fish and Wildlife Service has listed the diamond darter, a freshwater fish, as an endangered species and has designated West Virginia’s Elk River as critical habitat. Maryland is proposing comprehensive drilling plans to minimize the area of surface disturbance and to prohibit well pads in certain sensitive areas.

In recent years, environmental protections have grown stronger, with states such as West Virginia, Pennsylvania, and Ohio expanding setbacks. Ohio has also added a baseline water testing requirement. Casing requirements are also being updated or expanded. In Ohio, for example, casing material must now comply with industry standards, and the casing must be installed in a manner that isolates underground sources of drinking water and hydrogen sulfide gas. Air quality protections have been strengthened in West Virginia, which is encouraging green completion technologies,2 and in Pennsylvania, which is trying to reduce air emissions through leak detection, equipment repair, and other measures.

Of course, regulations are useful only if they are enforced. Enforcement requires qualified inspectors who know how drilling and fracturing work and what to look for at a site, and who are capable of identifying problems and violations in the many regulations governing unconventional hydrocarbon production. A number of states have established minimum qualifications for inspectors to encourage good enforcement and minimum salaries to encourage retention. For example, West Virginia recently set minimum salaries for inspectors ($35,000) and supervising inspectors ($40,000). Other approaches for improving inspection and enforcement include focusing on the highest-priority regulatory problems, establishing uniform inspection reporting to produce consistent information about problems (Pennsylvania), and disclosing violations and enforcement actions to the public (Pennsylvania and Ohio).

To fund enforcement, some states are increasing fees and penalties. For example, both West Virginia and Ohio have increased well permit fees and Ohio has increased waste injection well fees, particularly for waste produced in other states. West Virginia and Pennsylvania have increased penalties for violating oil and gas rules.

Wiseman concluded by identifying gaps in regulation and enforcement, including uniform collection and reporting of baseline testing data, bonds set high enough to cover site restoration,

___________________

2 See Department of Environmental Protection New Source Performance Standard 0000.

environmental liability insurance, training of inspectors, and consideration of how biological and other processes may change contaminants in flowback water being stored for recycling.

Questions. One workshop participant asked Wiseman to comment on the validity of using the State Review of Oil & Natural Gas Environmental Regulations (STRONGER)3 process to review state regulations as well as the direction the program is taking. Wiseman noted that STRONGER is a collaboration of industry, environmental groups, and state regulators. It arose in part because the Environmental Protection Agency decided against regulating most oil and gas exploration and production waste under the Resource Conservation and Recovery Act, and left it to the states to address any potential gaps in the management, handling, and disposal of waste. STRONGER has developed guidelines for good regulation, not only for handling waste, but also for other aspects of oil and gas development, including hydraulic fracturing. It reviews state regulatory programs for compliance with these guidelines, looking at both the substance of state regulations and enforcement (e.g., number of staff members). Wiseman thought that this process is crucial and that efforts to compare state programs and find gaps should be expanded. The primary weaknesses are that state participation is voluntary and that the extent to which states have implemented the STRONGER recommendations varies.

Each working group was asked to consider the following themes:

• Potential effects on surface water and groundwater quality and quantity—Connections between hydraulic fracturing and other production technologies and processes, and water systems, including scientific data and methods in assessing impacts;

• Technical and engineering processes—Use of water in producing hydrocarbons from unconventional resources and methods for managing and disposing wastewater; and

• Research priorities—Scientific and engineering research needed to narrow or characterize uncertainties.

Issues that were directly related to these themes or that were raised by more than one working group, including working groups in other sessions, are summarized below. The complete working group reports appear in Appendix D.

Research and Data on Surface Water and Groundwater Quality

The working group discussions covered water use, reuse, treatment, disposal, geochemistry, and their linkages. Research priorities identified by the working groups included assessments of the impact of chemicals or materials used in the preproduction or production stages on water quality, the variability of stray methane in well water, the fate of fluids that remain in the subsurface, and potential problems with naturally occurring radioactive material in wastewater and solid waste. Longitudinal studies on long-term processes and the impacts of shale gas production on water quality would yield information that could help the public differentiate between perceived and actual risk.

Every working group identified the importance of baseline data and ongoing measurements to assess and monitor water quality and fluid migration. Establishing a baseline would require decisions on what constitutes the baseline, which parameters to measure, and protocols for measuring

___________________

these parameters in consistent ways. Data collected for monitoring could be gathered into a public database or library to support research and communication with the public. Citizens could also be enlisted in collecting data for monitoring.

Engineering Practices to Reduce Water Volume and Impacts to Water Quality

Several working groups pointed out that the shale gas industry has developed best practices (related to casings, cement, and well completion) to minimize surface water and shallow groundwater contamination. In addition, the working groups had several suggestions for improving wellbore integrity, such as developing better cements, identifying methods for detecting leaks, and agreeing on standards, tools, and protocols for testing wellbore integrity. Maintaining the integrity of old and abandoned wells is a challenge, and one working group suggested developing sensors to monitor the infrastructure and, if possible, fluid composition at different depths.

Other technical and engineering issues raised in the working groups included reducing the volume of water for hydraulic fracturing and developing advanced water treatments, such as high-rate, in situ treatment techniques for flowback and produced water, and desalination procedures to improve water quality and to recover valuable compounds. Disposal of produced water and cuttings, some of which contain radioactive materials, remains an issue. Simply keeping up with numerous and changing practices in wastewater treatment, disposal, transport, reuse, injection, and subsurface transport is a challenge.

Regulations

The working groups observed that regulations and standards as well as their application and enforcement vary across jurisdictional boundaries. As a result, it can be a challenge for companies to operate and for regulators to share data across jurisdictions. Another issue is that resources and inspectors are insufficient to guarantee regulatory compliance. Some suggested developing a process for updating state and multistate regulations and standards, and some suggested developing standards, criteria, and metrics for inspectors.

Working group participants disagreed on whether there are too many or too few regulations. Regulations generally cover specific practices, and rapid changes in water management practices mean that new regulations are continually being written. Some suggested targeting any new regulations to address vulnerable points and gaps in water management. Others suggested finding ways to develop a few good regulations that address the major environmental concerns.