The final session of the workshop focused on the federal government’s present and future projects and plans related to data in materials and manufacturing. Presentations were made in Session 4 by Julie Christodoulou, Office of Naval Research, and Michael Stebbins, Office of Science and Technology Policy.

Julie Christodoulou, Director, Naval Materials Division, Office of Naval Research

Dr. Christodoulou began her presentation by describing the Lightweight and Modern Metals Manufacturing Innovation Institute, known as the LM3I Institute (LM3II). The LM3II provides an opportunity to integrate materials into emerging manufacturing technologies in a meaningful way to ultimately produce better-performing systems and components for military and civilian applications, and to do so faster and more affordably. LM3II is part of a national network of institutes that focus on topics of national import and benefit. It will have many partners, and DOD is leading the effort. Dr. Christodoulou said that metals are uniquely dual-use. There is no conflict between military applications and commercial value; DOD welcomes commercial applications of materials technologies, because a

broader marketplace will help reduce costs for the military. The goal of the LM3II is to demonstrate advanced manufacturing capabilities to enable systems that are lightweight, reliable, survivable, fuel efficient, affordable, and flexible while designing lightweight metals and applications that use them. Lightweighting has a near-term impact on fuel efficiency, flexibility, and overall costs for naval systems and platforms, and Dr. Christodoulou pointed out that many of these benefits were discussed in the National Research Council’s report on lightweighting (NRC, 2012). She said that LM3II focuses on aluminum, titanium, magnesium, and other modern metals and on manufacturing readiness levels (MRLs) 4-7.1 It is interested in incorporating ICME to shorten the design–production cycle. The goal is to have the program be self-sufficient in 5 years, with no dedicated funding after that time. Achieving this goal will require the identification of transition partners.

Dr. Christodoulou then briefly described the ICME process (see Box 2 in Dr. Ward’s summary for more information about ICME). She argued that ICME is an important driver in the acceleration of development times.

Next, she briefly discussed DARPA’s Accelerated Insertion of Materials (AIM) program. The AIM program was established to apply ICME to specific applications in the aircraft engine industry so as to reduce development time and costs. The AIM program focused on the designer’s toolbox, including knowledge, heuristics, and collections of data sets. Dr. Christodoulou stressed the importance of being able to use that set of knowledge and heuristics to exert greater control over a material’s structure and properties. She pointed out that ICME can help materials scientists communicate better with part designers, enabling them to take advantage of the complexity of a material’s microstructure to design a better component.

Dr. Christodoulou then provided an example of a project with exceptionally complex data. The example related to grain growth in a titanium alloy. The project, led by Lauridsen and Voorhees, used high-fidelity three-dimensional synchrotron imaging techniques and phase field modeling to capture anisotropy effects. The project used successive images to study the progression of grain boundaries to understand the microstructure. While the data collection process took about a week, the data analysis took over 2 years because of the exceedingly complex data (Poulsen, Voorhees, and Lauridsen, 2013).

Dr. Christodoulou also stressed the importance of mixing models at multiple length scales to predict microstructural evolution and resultant localized properties. She pointed to the work of Li and Wang in phase field models of microstructure evolution. Phase field models developed at different length scales provide a useful

_________________

1 MRL is a scale on which to assess manufacturing maturity and risk using a standard set of criteria. MRLs range from 0 (basic manufacturing implications identified) to 10 (full-rate production demonstrated). See http://www.dodmrl.com for more information about MRL definitions. Accessed February 27, 2014.

means to capture fundamental insights into phase transformation and deformation mechanisms and to establish physics-based models for engineering applications. Again, in order to do this, large and realistic volume elements must be explored. Materials naturally have a large amount of heterogeneity associated with them, and that space needs to be examined. The data need to be very rich in detail in order to be able to create an accurate model. These systems also require powerful analysis tools to acquire the data and develop models that are correspondingly rich in detail.

Dr. Christodoulou then discussed the Advanced Manufacturing Partnership and the MGI. The two initiatives were announced jointly in June 2011 and are synergistic. (See Box 1 in Dr. Ward’s presentation, above, for more information about MGI.) Dr. Christodoulou pointed out that ICME is the primary tool to address the challenges presented in the MGI, and MGI is therefore the entity to enable widespread adoption of ICME—to make best practice become common practice. She also reminded the audience that there is a continuum in materials development: The phases of materials development (discovery, development, property optimization, systems design and integration, certification, manufacturing, and deployment) are all synergistic, and researchers in each phase need to be able to interact using a common language.

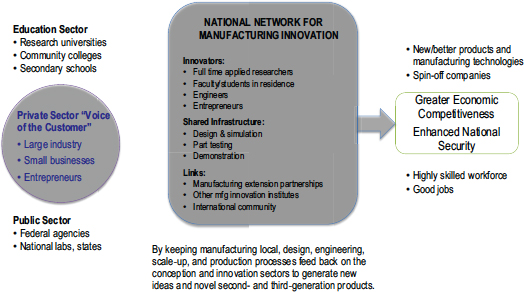

Dr. Christodoulou then discussed the National Network for Manufacturing Innovation (NNMI), a program that is designed to look at the interfaces among industry, academia, and government partners to identify gaps and provide the missing physical and intellectual middle ground. NNMI is a technology incubator for small organizations or multiagency groups. A schematic of the vision for NNMI is shown in Figure 6. Dr. Christodoulou described the NNMI as an incubator space, to which smaller or multicomponent groups can bring a problem or idea and test its viability. She noted that the NNMI seeks to provide opportunities for education at all levels, including sabbaticals, student co-ops, and internships.

Returning to the goals of the LM3II, Dr. Christodoulou emphasized the importance of bringing in industrial counterparts early in the design and development process; she noted that this is one of the central requirements for ICME. The transition pathways will then be established from the very onset of a project. She reminded the audience that LM3II is looking for self-sustainment—that is, independence from dedicated federal funding—in 5 years, so transition opportunities must be explored now. She believes that the LM3II will be formalized in the near future.

Dr. McGrath asked about the LM3II’s expectations and whether it anticipates becoming like the open platform of Open Manufacturing. Dr. Christodoulou responded that LM3II would be a complex, public–private partnership for the next 5 years, with $70 million total investment from the government over that time and with expectations of more than that in matching funds. The institute is currently sorting through issues related to levels of engagement and intellectual property. She said that each project would likely have its own unique intellectual property

FIGURE 6 Elements of the NNMI. SOURCE: Julie Christodoulou, Office of Naval Research, presentation to the committee on February 6, 2014, Slide 28.

arrangements, although the approach to developing those arrangements can be established early. The LM3II is working toward common data formats while making sure to understand the different architectures under development.

Dr. Schafrik asked about the GE example, which consisted of a project in solid-state welding in titanium. He noted that there are unusual phases at the interface zone. He asked if those were under investigation in this project, or whether the project was considering only the monolithic material. Dr. Christodoulou responded that they hope to look broadly at manufacturing technologies, including joining.

A participant asked if Dr. Christodoulou has considered cartography to represent microstructure. Dr. Christodoulou said that some element of mapping has to be undertaken to represent microstructure. There is a need for standards to capture the properties. Another participant pointed out that the materials and manufacturing community borrows from the medical community in imaging. Dr. Christodoulou agreed and noted that the digital data set is not simply a digital image. Material properties, performance, and structure evolution must be quantified, along with any changes to those variables. Still another participant said that collections of microstructures tend to focus on small-scale changes but that it is important to simultaneously capture changes on longer scales.

Michael Stebbins, Assistant Director for Biotechnology, Science Division, White House Office of Science and Technology Policy

Dr. Stebbins explained that he is the White House lead on openness and access to scientific data. The White House activity encompasses all fields of scientific study, and it has direct relevance to the materials community. He pointed out that many workshop participants noted that materials science does not have what is generally considered a “big data” problem.” However, he would like for there to be one: He would prefer to see that the materials science community has too much data rather than not enough. Dr. Stebbins pointed out that, looking broadly across all scientific disciplines, it is difficult, if not impossible, to access the data that underpin figures in scientific journals. There are historical reasons for this, he argued, not practical limitations, as data storage is now inexpensive and widely available. The obstacles that prevent data access include cultural mindset, lack of suitable storage locations, lack of data standards, and insufficient funding for managing data sets. Dr. Stebbins pointed out that the biomedical research community has been approaching a crisis in that it has become virtually impossible to reproduce biomedical results. This is not because of widespread fraud, but because of a lack of access to protocols, underlying data, and process information. The biomedical community has developed good monotypic databases, with analytic tools superimposed on them. As a result, the community is able to share insights and accelerate development. Dr. Stebbins argued that genomics is a good example of a field in which data sharing is particularly critical. He added that, while monotypic databases are important and should continue to be used, something more may be necessary for a large corpus of data and said that a 3-4 PB per year database is a good prototype starting size. The White House is in the process of working with scientific journals to require that any article published in them have referenced data with a persistent identifier, including metadata and proper credit.

Dr. Stebbins pointed out that the only “currency” available today to a research scientist is the scientific publication in a journal. It may be possible to add a new currency: the actual data. He said that frequently a single paper may have many coauthors, and the individual contribution of each author is unclear. This is particularly true in certain fields, such as high-energy physics. Published data may be able to clarify the individual’s role. In some fields, publishing the data may not be feasible or useful; in others, such as biology, it will dramatically accelerate development and allow for reproducibility. He asked the workshop participants if materials science would find the publication of data useful. Any potential advances, unintended consequences, or possible hazards in materials science should be explored now, before engaging the relevant publishers.

Dr. Stebbins pointed out that the government has had relatively little impact on increasing data sharing. By contrast, federal laws tend to focus on preventing the government from forcing the sharing of results. The Bayh-Dole Act,2 for instance, encourages researchers to retain their discoveries for the purpose of commercialization. However, the government has not had much experience in the promotion of data sharing. The most successful instances of data sharing have been driven by publishers, who seek to ensure data quality in their publications.

A participant pointed out that the National Nanotechnology Initiative (NNI) has a focus area in informatics and is working with relevant journals on data access as well. Dr. Stebbins said that it would be important for conversations to be coordinated with White House policy and with the bigger picture surrounding information sharing.

Another participant pointed out that universities are struggling with open publishing vs. licensed publishing. Universities must pay to access journals. These costs may be amplified if the access suddenly includes additional costs for data access as well. Dr. Stebbins said that the initial pilot programs OSTP is considering will be free. The researchers (not the publishers) will deposit their data with a registered third party. In time, standards will develop for the database, and publishers may require a specific data management solution that costs additional money. As an example, the journal Nature has an agreement with the company FigShare. Participants worried that this additional cost for having FigShare manage the data is likely to be passed on to the authors, and publishing in Nature is already quite expensive. A high-end journal such as Nature is likely to succeed with this model, but other journals may find that additional data costs will discourage article submissions. Dr. Stebbins pointed out that other private sector entities will likely become more engaged in data storage and management, including the nonprofit community. A participant asked who would select the data storage site. Dr. Stebbins replied that the journal could say that it has a preferred database or a partnership with a particular data-sharing site. Alternatively, the journal could establish the data standard. Data longevity will need to be part of the standard; longevity would need to be guaranteed. Self-storage is unlikely to meet any longevity standard.

Various participants discussed questions about access to data that still needed to be addressed, which data set(s) needed to be provided, and data standards. Someone argued that it would not be sufficient to upload a data set; authors must upload models as well. Dr. Stebbins agreed that models should be part of the metadata, including specific algorithms and software versions. Someone else pointed out that publishers are a good point of leverage in the academic community. In

_________________

2 The Bayh-Dole Act of 1980 amended patent and trademark law to permit universities and small businesses to retain intellectual property rights to work conducted using federal funding (Public Law 96-517).

communities such as pharmaceuticals and other industries, however, publication is not a high priority. The data in those instances are used to build business and are considered proprietary. It becomes difficult, if not impossible, for the outside community to gauge the quality of those data. The participant supposed that it would be very challenging to try to move into the commercial space with this proposal.

Wayne Ziegler and Chuck Ward both said that this open data initiative is consistent with and complementary to the activities in ARL and AFRL. Dr. Ward said that both their initiatives have been in communication with NIST and the relevant journals. He said that they are working to develop standards for CALPHAD data. They will next work with issues related to more complex data. He noted that it is fairly easy to come to a set of data standards for crystallography and CALPHAD, but other more complex data sets, such as three-dimensional data, will be more difficult.

A participant voiced concern that materials research has a lot of associated information or metadata, including sample preparation, and tracking the amount of metadata associated with an individual sample may be onerous. Dr. Stebbins pointed out that while this could be true it was still his belief that it is tractable.