2

New Materials And Their Commercialization

DEFINITION OF ADVANCED MATERIALS

The term advanced materials encompasses a wide range–from composites with very high strength/weight ratios to silicon wafers with feature sizes approaching atomic dimensions. For example, metal-matrix composites are combinations of materials possessing unprecedented strength/weight ratios and requiring entirely novel processing. In addition, advanced materials can have unique combinations of properties (e.g., high strength combined with a specific coefficient of expansion), or they can be tailored to a specific requirement (e.g., graded seals).

One of the best, concise definitions of “advanced materials” is given in the Advanced Materials and Processing Program plan (AMPP), a document that supplemented the President's budget submission for fiscal year 1993 (FCCSET, 1992). The report states that “.advanced means the most recent evolutionary developments within a materials class” The meaning of advanced thus encompasses traditional materials that have been improved as well as new materials recently invented. A few specific examples given by the workshop participants include materials that exhibit:

-

unprecedented composition, such as YBa2Cu307, a high-temperature superconducting ceramic;

-

unusual purity, such as silica-based optical fibers for optical communication;

-

novel structure and/or combinations, such as carbon fiber-reinforced thermoplastic polymeric composites;

-

novel processing, such as molecular beam epitaxy, casting of single-crystal turbine blades, or steel sheet made by continuous strip casting and cold rolling (advanced processing methods may add value to the material by improving performance or reducing cost);

-

to two or more components (examples include high-temperature stability and strength in ceramic composites for aircraft engine exhaust components);

-

commercialization of a next-generation product or component, sometimes at lower cost.

Some advanced materials represent evolutionary advances, because they provide incremental improvements in performance and utilize existing materials and processes. Others are revolutionary–that is, they require substantial additions to the knowledge base. Evolutionary materials are usually producible with existing plant and equipment, whereas revolutionary materials most often require major new facilities. Revolutionary advances generally involve greater risk and cost, and usually represent discontinuous change–that is, to fully exploit their properties often requires developing entirely new compositions or processes. Evolutionary advances are pursued on a more or less continuous basis and, as a rule, are easier to achieve.

All advancements in materials enable new products and systems to be produced that are unachievable with existing materials. In many cases, current-generation materials will be supplemented with advanced materials in next-generation products and systems, because they offer improved performance and, often, lower cost over the service lifetime of the component or system. Other situations require product redesign to capture the full benefits of the advanced material.

Both evolutionary and revolutionary advances are very important in the materials sector. Because commercialization of the

revolutionary class of advanced materials usually requires major new facilities and involves the achievement of discrete advances in knowledge, compositions, and processes, the suggestions in this report may be more germane to this class of advanced materials.

At present, the five most critical classes of advanced materials are metals, ceramics, polymers, semiconductors, and composites. Many of the materials in each class are used as structural materials for load-bearing functions; others (often referred to collectively as functional materials) are grouped according to their application for functional purposes. Table 2-1 lists the types of materials in each class.

DEFINITION OF COMMERCIALIZATION

“Materials commercialization” as used in this report is defined as: “the cost-effective production and application of advanced materials to meet global market needs.” The objective of this activity is to introduce into commercial use materials that are, or ultimately will be, producible, of high-quality, reliable, durable, and economically rewarding to producers and users.

NATURE OF THE COMMERCIALIZATION PROCESS

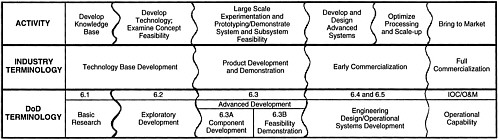

The process of fundamental and applied research, technology development, and the use of that technology in designing and manufacturing products can be described in a general way. Workshop participants examined the phases of the commercialization process in terms of function or activity that is performed at each step. They compared these activities with regard to the terminology for commercialization used by industry and the DOD and found that the phases in the commercialization process shown in Figure 2-1 were roughly the same regardless of whether government or industrial

TABLE 2-1 Classes of Advanced Materials (It should be noted that the universe of advanced materials is constantly evolving as new materials appear and existing ones become considered conventional).

|

FUNCTIONAL CLASS |

STRUCTURAL |

MAGNETIC |

ELECTRONIC |

PHOTONIC |

BIOMATERIALS |

OTHER |

|

CLASS OF MATERIALS |

||||||

|

METALS |

Aluminum alloys Nickel-base alloys Iron-base alloys Titanium alloys Amorphous metals Intermetallic compounds Copper alloys |

Neodymium-iron-boron Cobalt-based |

Interconnects Superconductors |

Biocompatible metals |

Metallic coatings |

|

|

CERAMICS (including glasses) |

Structural ceramics |

Ceramic-based |

Piezoelectrics Ferroelectrics Superconductors |

Optical fibers Optical waveguides |

Biocompatible ceramics |

Ceramic membranes Ceramic coatings |

|

POLYMERS |

High-temperature polymers Liquid crystal polymers Polymer blends |

Conductive polymers Insulators Resist polymers Connectors Dielectric polymers |

Nonlinear optical polymers |

Biocompatible polymers |

Polymeric membranes Polymeric coatings Adhesives |

|

|

SEMICONDUCTORS |

Silicon Gallium arsenide Mercury-cadmium-telluride |

III-V compounds II-VI compounds IV-IV compounds |

||||

|

COMPOSITES |

Polymer-matrix composites Metal-matrix composites Carbon-carbon composites |

Polymer-matrix composites Metal-matrix composites Ceramic-matrix composites |

Biocompatible composites |

Transparent materials |

terminology was used. Moreover, each phase, rather than being distinct, often overlaps with the next phase.

The process of developing and commercializing materials is a lengthy one, often requiring 10 years or even longer. A primary reason is that progressing through each phase of the development process requires increasing amounts of material to be processed and fabricated, followed by extensive testing to demonstrate that the properties that make the material desirable have not changed. Before full-scale application, it must be shown that the performance of the material is indeed reproducible, meets all of the necessary standards, and has the necessary life-cycle properties and integrity for the intended application. This process takes time and large capital investments, which is why automotive or airplane manufacturers, for instance, are reluctant to change from a known to a newly developed advanced material. Economics is a large driver in the process as development proceeds from laboratory to commercial quantities. In the final analysis, the materials supplier, component manufacturer, and final product manufacturer or assembler all must make returns on their investments, so materials commercialization ultimately must stand the test of profitability of the final manufactured product.

Workshop participants examined and discussed case studies of four materials–Kevlar, metal-matrix composites, carbon-fiber composites, and carbon-carbon composites–presented at the workshop. They determined that the case studies provided a number of lessons regarding factors that affect the nature and length of the commercialization process –especially for materials commercialization. These lessons follow:

Early Market Assessment. Accurate, early, and realistic market assessment–of application areas as well as estimated sales volume–is important for providing the incentive to make continuing investments in research and development (R&D). Estimating market size and determining the “return threshold” are critical determinants of commercial success.

Risk Versus Payoff. Risk and cost must be balanced by the prospective payoff. If a company does not view the potential profits of the commercialization activity as being sufficiently attractive (weighed against other business opportunities) to warrant the required investment, there will be no motivation to proceed. The developer's business culture and experience must be suited to the demands and risks of commercialization.

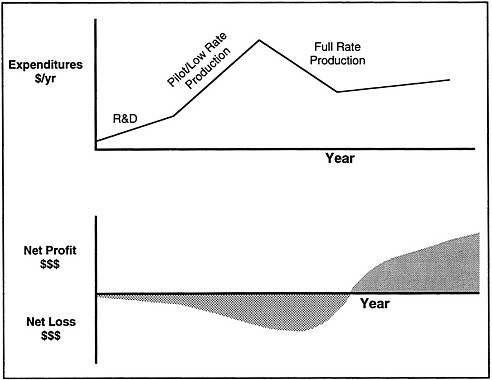

R&D Costs Versus Total Costs. It is generally assumed, even by research managers, that R&D represents a very large portion of the total cost of commercializing a new material. However, the bulk of the cost of technological innovation is in pilot-scale manufacture and product introduction. In most instances of commercialization, R&D accounts for a relatively small share of the overall cost of product development. This is illustrated in Figure 2-2, which shows the relatively modest costs for R&D compared with those for pilot development and production. This generic chart is based on the experience of the workshop participants. Thus, processing cost and the ability to scale up efficiently are crucial determinants of the ability to commercialize a new material.

The Need for “Champions.” In-house “champions” willing to argue enthusiastically for the commercialization effort for a particular material are essential, and ideally they should exist at both the technical and executive levels. However, overenthusiastic promotion can mislead by generating unwarranted optimism about the technical problems and the prospective market. This excess enthusiasm can be guarded against by frequent verification of technical progress and market projections.

End Users Often Are Not the Customer. There is a kind of “food chain” with respect to materials suppliers and users. The user of a material should provide feedback on performance to the supplier. End users should ultimately drive requirements, but the end user of a

Figure 2-2 Expenditures and cumulative profit and loss in a typical commercialization process.

material is often not the material supplier's customer; the customer is the parts manufacturer. In such cases, direct supplier-user interaction does not occur, and the supplier may not receive necessary feedback on operational experience with the material.

User-Supplier Interaction. Feedback from the prospective end user to the material supplier is necessary for improving the material. Prospective users should be given small amounts of the material to evaluate. The most fruitful situation is a continuing partnership between the supplier and the user, involving two-way communication of requirements, capabilities, and experience with the material. User-supplier communication between those engaged in a particular commercialization effort is most effective on a specific, in-depth, technical level.

Business Integration Decisions. The economic benefits of integrating downstream (into semifabricated or finished parts/components) and upstream (into raw materials, in the case of composites) can be considerable. Integration permits companies to control the quality, price, and availability of raw materials and allows them to participate in the more profitable end of the commercialization cycle (manufacturing). It also provides them with direct access to the design and fabrication process. Decisions about whether to consolidate operations or integrate the business operations (both vertically and horizontally) are critical, however. The wrong decision can easily be fatal; yet these decisions are difficult to make with confidence in an arena of rapidly changing technology and shifting or small markets.

The Need to Diversify Applications. Major single markets for a material are rare today. More common are multiple smaller markets. While developing a new material to serve more than one customer or application demands more time and money, it actually broadens a company's experience base, allows it to spread costs, and protects it from unforeseen market/technology shifts.

Value of the Entrepreneurial Environment. It is clear that the conventional entrepreneurial environment–characterized by a small, highly motivated team; clear corporate ownership of the technology; and a strong commitment of resources to the specific development effort at the right time–is a superior environment for producing innovations and seeing them to market. However, entrepreneurs often do not have the funding available to sustain an extended R&D and product development effort, particularly if an early market collapses or an adverse decision about adopting the new material is made.

A part of the difficulty the United States has had in competing over the past decade or longer has been the apparent, but not well documented, fact that other nations (notably Japan) have been able to shorten the commercialization process. An examination of several

reports dealing with Japanese industry shows a number of lessons that can be learned; however, these apply to the manufacture of such end products as automobiles and electronics rather than the commercialization of materials per se (NMAB, 1986; Clark et al., 1987; Reich, 1989). Nevertheless, these lessons are important, since a material must be incorporated into a product to be useful. These lessons suggest the need for:

-

a clear, strong product concept developed early on and maintained consistently by the project team;

-

a high degree of cross-functional coordination within the company and with suppliers, including a free flow of information and plans;

-

functional integration embodied in a cross-functional project team;

-

a strong project manager who has overall responsibility for the timeliness and quality of the product and the authority to pursue it aggressively;

-

an emphasis on continuous improvement of products, rather than abrupt discontinuity between successive products;

-

a willingness to use off-the-shelf components wherever possible, rather than designing every component from scratch;

-

a consumer public eager to purchase and try technological innovations and supported by rigid distribution and dealer networks that demand rapid matching by competitors' products;

-

a large and highly skilled engineering work force with a strong product orientation and low turnover rate among companies.

Some of the above lessons undoubtedly are culturally embedded and difficult to emulate in the United States. However, U.S. industry is studying and adopting those features that are compatible with American business culture.

GOVERNMENT STAKE IN THE COMMERCIALIZATION PROCESS

Historically in the United States, most advanced materials have originated primarily in the defense and aerospace sectors. Certainly those were the sectors in which government had a large stake, with national security R&D funded by DOD and space R&D funded by the National Aeronautics and Space Administration (NASA) and DOD. Advanced military and space systems often relied on new materials, and DOD, for instance, was the customer for buying materials first developed under its basic and exploratory research program. This meant that DOD also funded the far more expensive stages of development referred to in Figure 2-1 as “Component Development,” “Feasibility Demonstration,” and “Engineering Development.” The importance of this fact cannot be overemphasized, since the government thereby assumed the risk and expense of moving the material to the commercial stage, which might never have been done otherwise because of the heavy investment required. The initial development of composites for use in military aviation is a good example of this pattern (Chou et al., 1986).

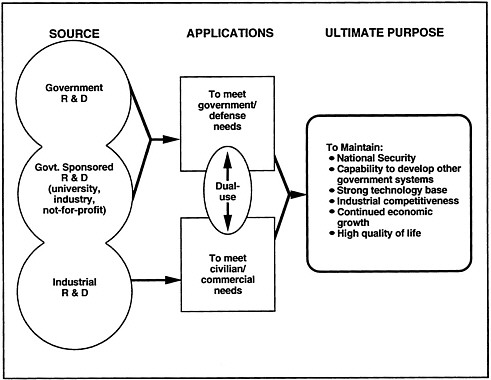

Faster commercialization of new materials is of importance to the government for two reasons: (1) to ensure the government's ability to specify and procure advanced military and space systems that depend on new materials, while obtaining maximum benefits from available materials technologies at costs that represent commercial production, and (2) to enhance the competitiveness of U.S. industries while extending the nation's technological leadership. This dovetailing of military/government and global industrial competitiveness drivers is illustrated in Figure 2-3, and the technologies in question (i.e., those technologies useful to the military as well as the commercial sector) are usually referred to as “dual-use.”

Ideally, government agencies should be able to draw upon commercial materials R&D and products, just as civilian industries should be able to draw upon technology developed in government

laboratories. The same holds true in all areas of technology, as is detailed in a report of the Center for Strategic and International Studies (CSIS, 1991). Reducing acquisition costs and ensuring the availability of desirable new materials requires developing a commercial market for the material and then meeting that demand with domestic production.

The increasing concern with U.S. competitiveness in the past few years, together with the recent cessation of the Cold War, has led to a different view of the government's role in materials development and commercialization. This view is formally expressed in Advanced Materials and Processing: The Fiscal Year 1993 Program, a document that supplemented the President's budget submission for fiscal year 1993 (FCCSET, 1992). The goal of the program is to “.improve the manufacture and performance of materials to enhance the U.S. quality of life, national security, and industrial productivity and economic growth.” Four strategic objectives are defined as follows:

-

Establish and maintain the U.S. scientific and technological leadership position in advanced materials and processing.

-

Bridge the gap between innovation and application of advanced materials technologies.

-

Support agencies' mission objectives to meet national needs with improvements in advanced materials and processing.

-

Encourage university and private sector R&D activities in materials technologies, their applications, and their implementation.

These objectives and the accompanying program were one of several presidential initiatives for the fiscal year 1993 federal budget.

For the first time, the government's materials program, funded at $1.658 billion in fiscal year 1992, has, in part, been defined as supporting productivity and economic growth. While the mechanisms for implementation are not well explored as yet, this initiative represents a profound change from previous justifications for the materials program.

Figure 2-3 Drivers for dual-use technology.

The economics of the defense and aerospace markets have been characterized by high cost, high performance, high risk, and relatively low volume. Commercial applications, by comparison, generally are driven by low cost, resulting in speed, consistent quality, and large volumes. While the defense market is declining, the opportunities in some commercial sectors such as transportation, communication, and infrastructure will be growing over the next few years. Advanced materials applications will be characterized by greater price sensitivity and speed to market. Whereas at one time the defense sector was looked upon as the leader in technological development, it is increasingly becoming a follower, as more complex technologies are developed in a growing commercial sector. The concept of dual-use technologies has become accepted in today's R&D climate to the point