3

Factors Affecting Materials Commercialization

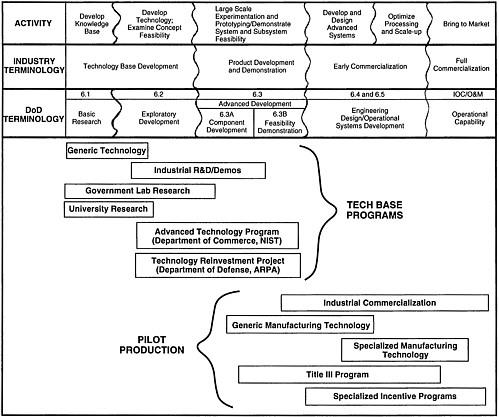

It is generally recognized that one of the key problems in the commercialization of new materials is the difficulty of moving from R&D to the point of commercial production. This transition centers around that part of Figure 2-1 marked “Component Development and Feasibility Demonstration” (DOD Terminology) or “Product Development and Demonstration” (Industry Terminology). It is here that feasibility for commercialization and confidence have to be established before proceeding. Findings on this point are explicit and come from varied sources. For example, the Defense Science Board said in 1987 that:

. . . both the Defense Department and commercial industry are seriously deficient in rapidly moving technology from R&D to systems and products. The greatest opportunity to improve the rate and effectiveness of this transition process is by increasing focus on the early advanced development phase of the S&T [science and technology] program, that is, Budget Category 6.3A.

(DSB, 1987)

Similarly, the Carnegie Commission addressed the problem of “Stimulating the Diffusion of High-Leverage Technologies from the Laboratory to the Field:”

The armed services, like industrial companies, have difficulty transferring their best technologies from the laboratory to new products in a timely way. The DOD's 6.3A program is intended to facilitate such transfer by funding the building and testing of “breadboard” prototypes that, while inexpensive and quickly assembled, still allow for demonstrating the feasibility of a technology in the military application foreseen for it.

(CCSTG, 1990)

As part of the DOD-wide response to such concerns, the U.S. Air Force Materiel Command has initiated a Materials Transition Program that focuses on what it terms the “transition gap” between the latter stages of 6.2 (Exploratory Materials Development) and the early stage of 6.3 (6.3A, Component Development). Figure 3-1 describes the objectives of this program.

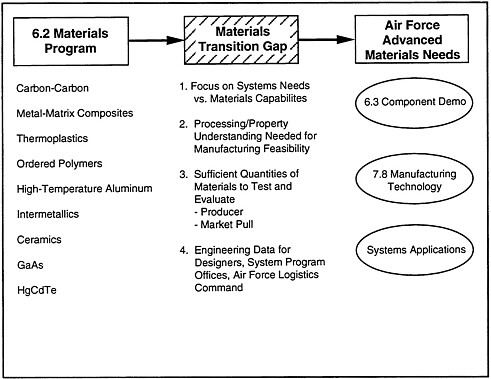

There are similar initiatives on the industry side. For example, the U.S. Advanced Ceramics Association launched a “Bridging the Gap Initiative” in late 1990 aimed at shortening the time between R&D and commercialization of advanced ceramic technology. The association identified the “bridge problem” in a somewhat broader area than the DOD (Figure 3-2), but the formulation of the problem and the objective of the initiative are the same (USACA, 1991).

A multitude of barriers need to be overcome to lead to successful commercialization of a material. In general, these barriers can be categorized as technical, such as the availability of test procedures and property data, processing and manufacturing technologies, and sensitivity to flaws in materials and processes; regulatory/legal, such as government procurement policies, intellectual property rights, environmental protection, and health and safety; and economic, such as R&D costs, market size, interest rates, cost of capital facilities, and profit goals. These barriers are described in greater detail in the balance of this chapter–with emphasis on the

Figure 3-1 U.S. Air Force Materials Transition Program (Source: R. L. Rapson, Materials Laboratories, Wright Laboratories, Wright-Patterson Air Force Base).

technical factors, since these represent the expertise of the workshop participants and the National Materials Advisory Board (NMAB).

TECHNICAL FACTORS

Definition of Technical Goals

The developer of a new material often fails to clearly establish the goals that a new material should meet. Since materials development driven by theory and computer simulation is still in its infancy, most materials development is conducted empirically. Goals are often chosen on the basis of experimental observation rather than

Figure 3-2 U.S. Advanced Ceramics Association “Bridging the Gap” Initiative (Source: USACA, 1991).

application needs. Developers sometimes fail to distinguish between the search for revolutionary developments to achieve major breakthroughs in properties, and evolutionary development to achieve incremental improvements in existing materials and performance levels. In his article, “Turning Ideas into Products,” Gomory describes these different approaches for the electronics industry by defining “cyclic development” as contrasted with “ladder advances” (Gomory, 1988). He defines the “ladder” process as a step-by-step reduction to practice of a new idea. In his terminology, the invention of the

transistor is an example of the “ladder” process. “Cyclic development,” by comparison, is a more common process of repeated incremental improvement. In this type of improvement process, an existing product gets better and develops new features year after year. The cumulative result of these incremental changes can indeed be profound. A good example, as he points out, is that 20 years of incremental improvement has resulted in advancing from one bit on a chip to one million bits.

Too often, revolutionary development efforts set overambitious goals for materials performance, which in turn creates an all-or-nothing approach, resulting in failure. In general, a balance must be achieved by the developer between high-risk, high-return goals and incremental improvements with well identified objectives.

One of the problems with defense-stimulated or space-stimulated materials developments has been a mission-oriented agency that often sets goals or specifications relating to narrow mission objectives, thereby ignoring potential commercial requirements or existing commercial products. This practice can severely limit the market for a material and drive up production costs. A recent report by the Carnegie Commission addresses this question in detail (CCSTG, 1991), while the use of commercially developed technologies for defense purposes is treated in an Office of Technology Assessment report (OTA, 1989).

Difficulty of Scale-Up

Scaling-up a new material from laboratory quantities to precommercial, and eventually commercial quantities, often results in unforeseen obstacles, thus posing formidable risk to the industrial developer. The cost of scaling-up is especially severe for small entrepreneurial companies whose resources often are too limited to invest in new process and manufacturing equipment. In addition, such equipment may not be able to reproduce the material and its properties quite like the samples produced in the laboratory. Pilot

demonstrations are the most important part of materials development in transitioning from invention in the laboratory to commercial applications. Process modeling is a powerful technique to minimize these difficulties, but it requires skills and resources not available to everyone.

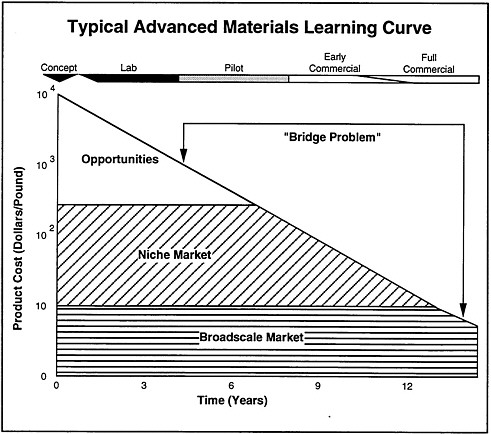

The DOD has supported some pilot production programs (as shown in Figure 3-3) through activities like the Industrial Modernization Incentives Program. This program was originated by the Air Force to encourage companies that make up the defense industrial base to modernize their facilities. The goal of these modernization efforts has typically included increased production efficiency, improved product quality and durability, lower product life-cycle costs, and reduced lead times (Schafrik & Fiorino, 1992).

Another DOD program addressing pilot production is Title III of the Defense Production Act, which deals with guaranteed sales and other incentives to meet strategic goals for defense (Defense Production Act, 1950). Title III has provided for guaranteed purchases of specific new materials, thus creating a sufficient market to meet strategic goals for defense and, in some cases, stimulate other applications. Section 302 of Title III also authorized “loans to private business enterprises (including research corporations not organized for profit) for the expansion of capacity, the development of technological processes, or the production of essential materials” High-purity silicon, discontinuous reinforced aluminum composites, and synthetic rubber are all examples of materials whose development was stimulated by Title III–which expired in October 1990. Fortunately, Title III was reauthorized by Congress in November 1992 and, in fact, has been amended to include several new features related to commercialization. Among these is language that allows Title III support to expand capacity to meet defense and nondefense combined needs and a statement to the effect that an important purpose of Title III is the creation of an economically viable production capacity.

A third program is the Manufacturing Technology program, established by DOD and designed to translate materials into

components and systems. Despite their usefulness, however, the Manufacturing Technology program has undergone funding reductions in the last couple of years, and the Industrial Modernization Incentives Program has been eliminated by DOD.

A program established by Congress in the Technology Competitiveness Act of 1988 provides technology development grants to single businesses, independent research institutions, or joint ventures (NIST, 1991). Awards are made for generic technology development and precompetitive technology, the latter being defined as “R&D activities up to the stage where technical uncertainties are sufficiently reduced to permit assessment of commercial potential and prior to development of application-specific commercial prototypes.” One of the awards relating to materials development in 1992, for instance, was to the Nanophase Technologies Corporation to “develop the technology to produce commercial quantities of new nanocrystalline ceramics” (New Technology Week, 1992).

Design, Processing, and Data Bases

Detailed design methodologies based on conventional materials are often not valid for new materials. For example, polymeric and composite parts are designed to net shape, while metal parts often are designed to be machined. There are major differences in deformation behavior; metals yield and strain-harden, while composites are stiffer, and ceramics do not yield. There are also significant differences in joinability–metals can usually be welded and mechanically fastened easily, while non-metallic materials cannot. Finally, there are differences in the directionality of properties–metals can usually be processed to have isotropic properties, while composites are anisotropic. These differences, and others, require fundamental changes in design approaches.

To achieve the low-cost materials and processing necessary to satisfy commercial markets requires widespread application of concurrent engineering. This will permit real-time exchange of

information regarding design needs and materials capability. Concurrent engineering, which makes the interfaces between design and manufacturing more transparent, has the potential to reduce the time required to design and produce a product that incorporates new materials.

Materials-design data bases are usually very costly and take a long time to develop. There are too few data bases available, and they are not standardized. Yet reliable data bases are essential to the identification of realistic application opportunities. To make matters worse, materials test requirements and the associated standards are often inadequate or lacking.

Knowledge of how most materials perform over their life cycle in a given component application is incomplete. In the case of composites, for example, deformation and failure mechanisms are difficult to define and measure, making life prediction problematic. Accelerated tests to predict expected long-term performance are difficult to develop. This lack of life-cycle data inevitably leads to conservative design, using larger margins of safety than would otherwise be necessary. It also makes it difficult to fairly compare materials on the basis of lowest life-cycle cost, since initial acquisition cost and life-cycle cost are usually very different.

Standards and International Standardization

A number of private sector standards-writing organizations exist in the United States to develop domestic standards; they include the American National Standards Institute; the American Society for Testing and Materials; and several activities under specific technical societies, such as the Institute of Electrical and Electronics Engineers and the Society of Automotive Engineers. The American National Standards Institute is not only the coordinator of standards writing but also the member body in the International Organization for Standardization. U.S. industry appears to be reluctant to pay for and participate in international standard-setting activities, while by

contrast, Japanese and European participants are fully subsidized by their respective industries–to the extent that Europeans and Japanese are beginning to dominate the chairmanship and membership of the International Organization for Standardization and other technical standards committees. The result is that other countries' market and product requirements are gaining prominence in the standards, while U.S. manufacturers are increasingly becoming followers in the standards development process.

The National Institute of Standards and Technology held a workshop in April 1990 to examine the role of the government in standards-related activities. A major topic of discussion was whether there is a need for a coordinating function to facilitate the timely development of standards by existing standards organizations. (A potential model for such a coordinating role is the Standards Council in Canada, in which the government plays the coordinating role.) No strong consensus was reached. However, in a summary report the institute set forth a number of conclusions dealing with standardization and conformity assessment (Leight, 1990). Several of the conclusions related to the need for closer interactions between government and industry and the need for more effort by industry to support, participate in, and monitor standard-setting activities. The report called specifically for the government to “intensify negotiating efforts to ensure foreign acceptance of products based on testing and certification performed within the United States,” and to:

. . . sponsor or co-sponsor with interested parties from the private sector a series of workshops with various industry sectors to specify more precisely the needs for coordination and representation of U.S. conformity assessment interests abroad. Then, appropriate systems should be developed to meet those needs and to promote effective application of these mechanisms in behalf of U.S. manufacturers and exporters. Particular consideration should be focused on the division of

responsibilities between Government and the private sector in a cooperative mode of operation.

The danger in not maintaining leadership and full participation in international standards development is that U.S. industry will eventually be forced to accept the standards promulgated by other international or quasi-international groups such as the Community of European Nations. U.S. industry must be able to market its products within the world market without restrictive standardization barriers. Greater support and coordinated action by U.S. industry are essential to industry 's competitive future.

Inflexibility in Manufacturing

The resistance to change on the part of design engineers, materials manufacturers, and system developers is considerable–and understandable. This resistance is partly due to the fixed design concepts for systems and the high cost of requalifying materials when specifications are changed.

Inflexibility in manufacturing is an impediment to the introduction of new materials. The lack of involvement of materials experts in designing products and manufacturing operations often means that the selection of materials is frozen very early in the product development cycle. As a consequence, new materials and processes cannot be used to enhance products and improve manufacturing or to solve manufacturing problems. Once the product is manufactured, the process is frozen. Insertion programs to replace specific components with an improved material after a thorough design analysis are one way to break this impasse and allow improvements through incremental application of new materials technology. An example of such a program is the ceramic insertion program initiated by the Advanced Research Projects Agency in early 1991.

For companies to take advantage of newly developed materials, their products and their associated manufacturing systems should be considered concurrently and with as much versatility as the particular application allows. System developers should be made aware of new materials that would provide superior performance. They should incorporate into their design and manufacturing scheme the potential to quickly insert improved materials technology at any point in the lifetime of the product family, not just during the initial design. This will allow the fairly rapid accumulation of realistic service experience. If low-risk opportunities are selected, the cost of these demonstrations can be minimized. It must be recognized, however, that the narrow focus of insertion programs, while important for building confidence, will limit the full performance potential of the material.

Another mechanism necessary to improve the manufacturing process is a closer working relationship between materials suppliers, parts fabricators, and end users. In commercializing the use of a new material, process, or product, industry is increasingly turning to consortia that offer the opportunity for shared technical development, shared risk and cost, and enhanced communications. The Automotive Composites Consortium is a good example in the structural materials area, while the Semiconductor Manufacturing Technology Corporation is a good example in the electronic materials and components area. Such consortia may or may not include government funding. Likewise, federal laboratories may be involved in such consortia if their expertise is applicable to the overall good.

Engineering Education

During the 1970s and 1980s, engineering schools concentrated on teaching engineering science rather than engineering design (MSB, 1991). As a result, there is currently a shortage of the talent needed to take advantage of advanced materials through cost-effective design and new-product application.

Industries such as the automobile manufacturers are designing to engineering requirements derived from customer requirements that are established from market surveys and clinics. New concepts such as “design for manufacturability” and “design for assembly” are being used. In addition, the concept of recyclability of materials and components is becoming important. All of these approaches must be taught to materials engineers who will interface with, or in some cases practice, the engineering design of products.

It is essential that U.S. industry have an adequate supply of engineers who understand materials processing and manufacturing. Because government funding of university research primarily emphasizes basic research, students tend to be educated in those areas in which the research faculty are proficient–fundamental theory, analysis, and discovery –rather than in making things and making them work economically. The emphasis in university engineering education on materials design, materials processing, and manufacturing needs to be increased (NRC, 1989).

A valuable adjunct to academic programs would be some form of “practice school.” In this model, the student works on actual professional assignments in the field, with real responsibility, for several months at a time. This model could be adopted by materials and engineering departments for educating students in materials processing and manufacturing. The National Science Foundation's Engineering Research Centers and Science and Technology Centers Program are a step toward this concept. Germany's Fraunhofer Institutes, with their employment of doctoral students in research and their apprentice programs for masters and undergraduate students, are an even stronger embodiment of this approach.

The best known example in the United States is the Chemical Engineering Practice School at the Massachusetts Institute of Technology, first established in 1916. Students spend up to eight weeks at each of two plants working in teams on specific problems. They design the problem-solving approach, gather the necessary data,

and make oral as well as written reports with recommendations (Gushee & Margolin, 1992).

The success of these concepts critically depends on a commitment by industry to make positions for individuals trained in processing and manufacturing more attractive. Such a strategy would be in industry 's best interest, since better trained employees will contribute to a company's competitiveness.

Equally important are continuing education programs for engineering designers and manufacturing engineers already in practice, so that conventional paradigms of design and manufacture, based on metals, can be resynthesized to take advantage of advanced materials. Technical personnel without degrees who are involved in engineering and manufacturing also should have access to additional training, especially with respect to new materials.

REGULATORY/LEGAL FACTORS

Intellectual Properties

Two primary issues that relate to intellectual property rights were identified by workshop participants: patent rights under government contracts and process-intensive patents.

Rights Under Government Contracts

There is both a perceived and a real issue concerning the use of patented technology in the performance of government contracts. The basis for both concerns is the Authorization and Consent clause that is included in most contracts with the U.S. government, at least those in which production of hardware is concerned.

Under one form of this clause, the infringement of third party patents is allowed because the government assumes the liability for this action. If the owner of the patent pursues an infringement to

recover damages, either in the form of lost royalties or any other form, the suit is ultimately maintained against the government. For example, Company A owns the Composition of Matter patent for a material, but Company B needs to use the material to make hardware for the U.S. government in fulfillment of a contract that includes the proper form of the Authorization and Consent clause. Company B can use the patented alloy for this purpose. If Company A then brings suit against Company B, Company A has the Authorization and Consent clause as a defense, and the suit is ultimately maintained against the government for damages. Moreover, Company A cannot prevent Company B from using the patented material, so exclusive access to the material by Company A is breached. Thus, there is a real loss to Company A, because the right to exclusively practice its patented technology is abridged, and, for most companies, there is a perceived difficulty in bringing suit against the government with its vast resources. The loss presumably is compensated by the recovery of damages against the government in the U.S. Court of Claims.

There is a related situation that often is confused with the Authorization and Consent clause. That is the case of patented technology that is owned by a company but was developed in whole or in part by the company as part of a government-funded R&D effort. In such cases, the government retains the right to a royalty-free license for use in all government-purchased hardware. This seems reasonable, since part or all of the development expense was borne by the government. The company that owns the patent has the exclusive right to control the practice of the technology in all commercial situations, however.

There is also a concern related to proprietary data (i.e., data that is not patented) rights. The Center for Strategic and International Studies committee, chaired by Senator Jeff Bingaman, addressed this problem and its effects:

DOD's emphasis on obtaining unlimited rights in technical data, including the right to distribute

proprietary information to competitors, has created a major barrier to commercial and military integration. Under current regulations, a company could well lose its proprietary rights. This makes firms extremely reluctant to incorporate commercial technologies into a DOD contract. The emphasis on unlimited rights also discourages companies from exploiting the commercial opportunities of defense-supported technologies. Experience has shown that technologies that are potentially available to all companies will be exploited by none.

(CSIS, 1991)

Better protection of proprietary property rights of government contractors would encourage expansion of the pool of qualified vendors. The Center for Strategic and International Studies committee recommended that “All technology developed under contract, even if developed with public funds, should be the property of the contractor, subject to limited Government Purchase License Rights.”

Process Intensive Patents

International differences in the patent process and patent enforcement often inhibit commercialization by U.S. industry of new materials that tend to be more process intensive. Process patents are especially difficult to enforce, because it is difficult to demonstrate infringement. This is especially important in engineered materials, where materials performance is integrally tied to processing technology. The use of neutral third parties to confirm or deny the occurrence of process patent infringement could be helpful in resolving process patent disputes quickly and possibly in deterring infringement.

Antitrust Concerns

Antitrust concerns are improving for precompetitive cooperation among companies but are still formidable for production activities. Joint ventures ease this difficulty but are an expensive legal solution to the fundamental need for easier cooperation. The United States is still at a competitive disadvantage in this area with respect to other industrialized countries. If antitrust restraints on cooperation in production were to be relaxed, pilot plant facilities, for instance, needed for scaling new materials from the research to the production stage, could be used by more than one company. A relaxation of antitrust laws with regard to pilot operations would not only help to overcome technical difficulties but would also reduce the risk (both actual and perceived) that industry faces in the materials commercialization process.

Export Restrictions

Export controls, imposed by the Department of State or the Department of Commerce in the interest of national security, in many cases restrict the ability of U.S. materials producers to expand their markets. A byproduct of restricted access is closed technical meetings, which reduce the flow of knowledge among American companies, restrict the peer review process, and inhibit open publication. These controls appear to be easing somewhat at present. However, the State, Commerce, and Defense departments need a better method for determining precisely how far to go in balancing commercial interests against national security considerations in their application of the International Trade and Arms Regulation and export control legislation. A recommendation made by a National Research Council panel is that the United States and other members of the Coordinating Committee for Multilateral Export Controls change the basis of their technology transfer restrictions from a policy of general denial of dual-use (military and commercial) controlled items to a policy of

presumed approval to export, based on verified end-use of the product (COSEPUP, 1991). This issue is currently being addressed by the coordinating committee, especially with regard to trading with the former Soviet Union, and early indications are that export control regulations may become liberalized.

Environmental, Safety, and Health Regulations

Regulations concerning environmental impact of materials processing and manufacturing add to the cost and risks of commercializing new materials. In the U.S. steel industry, for example, the commonly quoted assertion is that environmental compliance costs represent $10–$20/ton, or 2.5–5.0 percent of the price of steel. The percentage may seem small, but for most U.S. steel companies this cost is equal to or greater than the profit margin in today's market. In the aluminum industry, one major domestic producer estimates that its environmental costs amount to roughly 1 percent of total sales (accounting for various offsets reduces the figure to about 0.75 percent). The added cost is reported to be $0.09–$0.15/lb for copper and $0.06/lb for lead (NMAB, 1990).

Environmental regulations and controls in most developed nations, such as Japan and the European Economic Community, now equal or exceed those in the United States. But in the developing world and the nations now emerging from behind the former Iron Curtain, environmental regulations and controls are much less stringent. Many of these nations, while not competitors now, will be competitors in the future. The relatively low costs they incur in addressing environmental concerns will be a factor in that competition.

As environmental concerns evolve, there often are conflicts between federal, state, and local laws that magnify paperwork and hamper compliance. A recent Office of Science and Technology Policy report states that an integrated approach to energy and

environmental issues is necessary in the utilization of emerging technologies.

It is important that environmental, health, and safety requirements should be well defined and the process for compliance should be streamlined. There must be a common ground that provides for both preservation of the environment and the competitiveness of U.S. industry.

(OSTP, 1990)

ECONOMIC FACTORS

Cost Versus Risks

The high cost of materials R&D, along with the even higher costs of testing, pilot-scale manufacture, and technology demonstration, represent a substantial up-front investment. At the same time, the return on that investment is unknown and will not become known until long after most of those funds have been spent. In today's turbulent business environment, taking such risks is hazardous. This is as true for many other technologies as it is for materials.

Market Size

Where the government is the prospective customer for a new material, actual demand in terms of volume can be quite small. For example, specialty materials being developed for the National Aerospace Plane would initially find application in very few vehicles. From the perspective of industry management, the potential risk is offset by the possible benefits–a larger demand may develop downstream, or new applications may be found for materials

developed for this project. However, some materials developed for government purposes may never achieve dual use.

Short-Term Management Goals

Given the substantial commitment of dollars and time required for materials technology development, the often noted short-term profit outlook of corporate management is a barrier to long-term innovation. There are some emerging examples of American companies that have enhanced their competitive posture by deemphasizing traditional short-term financial management measures and focused on product quality, employee involvement, and speed to market. These examples include Nucor (rapid incorporation of innovative, high-risk steelmaking technologies), Ford Motor Company (fundamental engineering and manufacturing changes that resulted in significant quality improvements), Boeing Airplane Company (reducing 777 development time through reliance on “paperless ” CAD/CAM tools), and 3M Company (active encouragement of entrepreneurially minded employees to exploit new technologies). Over time, corporate cultural transformation in the United States will make focusing on the correct measurements “second nature.” History suggests that such a transformation must start at the top of the organization and work its way down.

High Cost of Capital Facilities

Companies are often constrained to the use of installed or existing capital facilities, because the perception of small markets makes it hard to justify new investment. Yet new materials often require costly new facilities for production and to guarantee reproducibility. At those times when the cost of capital is high in the United States relative to other countries, U.S. companies are less competitive, and funding for commercialization becomes more difficult.

Government Procurement and Funding Policies

Several of the most significant financial impediments to commercialization are those imposed by government procurement practices. Some of the barriers to commercialization of new materials derive from restrictions imposed by government. Some examples are given below.

Least-Cost Procurement

The policy of least-cost procurement has apparent budgetary advantages but can be detrimental to the quality of materials and systems procured. This policy is now beginning to shift toward permitting the use of “best value supplier” rating systems for government subcontracts. These rating systems permit government and contractor procurement personnel, in selecting vendors, to balance considerations of cost with considerations of timely delivery, quality, and technical performance.

Overabundance of Suppliers

The practice of encouraging a large pool of suppliers may be detrimental to materials advancement, because, in an environment of small markets, circumstances often dictate the need for only two or three vendors. A large number of suppliers can mean that the business is profitable for none.

Cost Accounting Rules

The government's cost accounting system fails to take adequate account of the technology development cycle. Its perspective of basing allowable profit as a fixed percentage of material or product cost is foreign to commercial practice. It tends to reward high-cost suppliers who do not invest in improving their technology. It inhibits

its innovative suppliers by restricting gains from employing risk capital that could be used to advance the materials and process technology. For prime contractors, the Independent Research and Development cost recovery system provides some help in countering this problem.

First Cost Versus Life-Cycle Cost

The practice of selecting materials according only to initial cost ignores the importance of life-cycle cost, which is often substantially lower for advanced materials than for the conventional materials they replace (NMAB, 1991). Acquisition and finance managers should understand and promote the importance of life-cycle cost thinking, including environmental and recycling costs.

Funding Uncertainties

Funding uncertainties engendered by the annual budget cycle and lack of follow-through on approved programs create a lack of confidence in the ability of government to maintain progress toward planned programs and goals. This can act as a disincentive to commercialization of a new material if the market for that material is largely tied to a prospective government-funded system that can be radically changed or cancelled with very short notice.