The Greening of Industrial Ecosystems. 1994.

Pp. 137-148. Washington, DC:

National Academy Press.

Integrating Environment and Technology: Design for Environment

BRADEN R. ALLENBY

Twenty years ago, environmental problems appeared simple and obvious: the Potomac and Hudson Rivers were so polluted that they could not be fished; the air in Los Angeles was foul; Love Canal and other sites were poisoned by toxic chemicals. Remedies were equally direct: the Clean Water Act, the Clean Air Act, Superfund, and the Resource Conservation and Recovery Act.

Now, with several decades of research and experience behind us, we have begun to recognize that we are treating the symptoms, not the disease. The problem is not individual rivers, airsheds, or hazardous waste sites, although they must be addressed. The problem is the relationship between human economic activity and the environment. It is a systems problem, arising from fundamental changes in the scale of human activity in relationship to supporting biological, physical, and chemical systems. Regional and global environmental perturbations cannot be adequately mitigated until this relationship is understood and regulatory and industrial practices are modified to reflect such an understanding.

A basis for developing a broad understanding of these issues, frequently termed ''industrial ecology," is being established, albeit the effort is still in its infancy (Allenby, 1992a; Ayres, 1989; Frosch and Gallopoulos, 1989). Nonetheless, five fundamental principles upon which we may base development of improved methodologies for integrating technological and environmental systems can already be identified:

-

Methodologies should be comprehensive and systems-based.

-

Methodologies should be multidisciplinary, including technical, legal, economic, political, and cultural dimensions to the extent possible.

-

Mitigation of environmental perturbations can only be achieved by focusing on technology, and developing policies and practices that encourage the evolution of environmentally preferable process and product technologies.

-

Economic actors, including private firms, must internalize environmental considerations and constraints to the extent possible, given existing exogenous constraints on firm behavior (e.g., laws such as the antitrust statutes or the prices of inputs and competitive products).

-

Policies and regulations must reflect the need for experimentation and research as different paths and methodologies are tried (rigid micromanagement through command-and-control regulation will in many cases be incompatible with systems-based approaches embodied in methodologies such as Design for Environment (DFE), as the unfortunate negative impact of the Resource Conservation and Recovery Act on industrial recycling practices demonstrates (see the paper by Pfahl in this volume and, more generally, Office of Technology Assessment [OTA], 1992).

Obviously, a great deal of work remains to be done before we begin to fully understand industrial ecology and apply it to current industrial ecosystems (see the discussion by Ehrenfeld in this volume). In the interim, however, there can be no excuse for evading the application of the approaches we do understand to ongoing regulatory and industrial behavior. Although just emerging and still generally untested at this point, DFE is one potential methodology for accomplishing this. Design for Environment should be regarded more as an approach, than as an existing, implemented system.

Before introducing DFE, it is important to recognize that our current unsophisticated approaches tend not to recognize important differences among classes of products and materials. Thus, for example, it is useful to differentiate between two classes of manufactured items: low-design/high-material items, such as packaging, consumer personal care items (e.g., soaps and shampoos), and bulk chemicals; and high-design/low-material products such as automobiles, electronic and communications equipment, and airplanes.

These product streams generally have different life cycles within the economy. For example, the former tend to be used up and dispersed into the environment rather than discarded (packaging being an obvious exception). Materials use in the two cases also implies different recycling and disposal requirements. Materials use in a low-design/high-material product stream tends to be relatively simple, and, in many cases, few materials are incorporated into individual items (this need not be the case, however; a snack chip bag only 0.002 inch thick consists of nine separate layers of material [OTA, 1992]). Thus, recycling is fairly straightforward. On the other hand, the structure and materials use of a high-design/low-material product such as a printed wiring board are highly complex, and many materials, including different plastics, ceramics, alloys, frits, and glass-

es, are often present in a single product. Recycling of materials for such a product is thus much more complicated and difficult.

Moreover, as implied by the designation, the design function is far less important for a low-design/high-material product than for a high-design/low-material product. This reflects a fundamental difference: the design of a complex high-design/low material product requires consideration of an additional, highly complex, system that low design/high-material products do not—that is, the product itself. Associated upstream and downstream product and manufacturing process implications of changes to such a product or its associated manufacturing systems make the analysis far more complex than in the case of a low-design/high-material item. Moreover, the supplier/customer networks for high-design/ low-material products tend to be far more complex than those for low-design/high-material products.

This has a number of policy implications, the primary one being that regulatory tools that may be effective in encouraging environmentally appropriate technology for high-design/low-material items may be dysfunctional or at least inefficient when applied to many low-design/high-material products. Thus, for example, post-consumer take-back requirements for high-design/low material articles will drive firms (and thus designers) to produce products more easily disassembled and recycled. On the other hand, postconsumer take-back requirements imposed on low-design/high-material products such as consumer packaging, which generally require significant transportation of used product, may not be economically efficient.

DESIGN FOR ENVIRONMENT

As a practical matter, the only way the five principles enumerated above can be implemented by industry in practice, at least for high-design/low-material products and associated manufacturing processes, is by driving environmental considerations and constraints into the design process. Implementation of DFE practices is intended to accomplish this.

The idea behind DFE is to ensure that all relevant and ascertainable environmental considerations and constraints are integrated into a firm's product realization (design) process. The goal is to achieve environmentally preferable manufacturing processes and products while maintaining desirable product price/ performance characteristics (Allenby, 1991).

DFE is intended as a module of an existing design system known as "Design for X," or DFX, where "X" is a desirable product characteristic such as testability, manufacturability, or safety (Gatenby and Foo, 1990). This has at least two critical advantages. For one, linking implementation of DFE to an existing process reduces the culture shock of integrating environmental considerations into product and process design and makes the entire package far more acceptable and easier to implement. For another, the need to create DFE to fit into an existing

design procedure imposes a necessary discipline on DFE development that helps make DFE practical in a real operating environment.

Implementing DFE has a number of benefits for the firm. The major benefit is that it provides a mechanism for the firm to manage environmental issues as they evolve from simply overhead, "end-of-pipe," considerations to strategic and competitively critical. Thus, compliance with increasingly complex, sometimes contradictory, environmental regimes can be eased by designing to avoid emissions. Costs arising from taxes, fees, or burdensome regulations directed at inputs such as energy or virgin materials, or from wastes or carbon produced during manufacturing, can be identified and managed only through such a comprehensive approach.

Another important reason firms are adopting DFE is the need to meet increasing environmental concerns on the part of customers. There are two major components to this challenge for manufacturing firms.

The first is the much-discussed growing interest that consumers exhibit in "green" products. At this point, determining environmental preferability, or "greenness," over the life cycle of a product is frequently beyond the state of the art. Moreover, determining the depth and importance of environmental consumerism is somewhat problematic and depends to a great extent on the product and its market, as well as overall economic conditions. It is, however, clear that such preferences exist to some degree.

The second is more subtle and much harder to address ad hoc: the demands of sophisticated customers for products that reduce their potential environmental costs. Thus, for example, the U.S. Air Force may be concerned about a weapons system that requires chlorofluorocarbons (CFCs) for routine maintenance, or that produces significant used oil or chlorinated solvent waste streams. Sophisticated business customers may pressure component or subassembly suppliers to reduce their use of toxic substances such as lead solders or batteries containing cadmium, or to use environmentally preferable packaging. State and national laws require recycling of batteries and elimination of heavy metals in packaging or plastics. Such requirements frequently require design changes: they clearly cannot be addressed by traditional "end-of-pipe" means.

Comparing DFE with other environmental management and regulatory concepts helps demonstrate the comprehensive nature of the methodology. Perhaps the most familiar of these concepts is "pollution prevention" and such associated terms as "waste minimization" and "toxics use reduction." DFE incorporates these concepts, but as elements in a more complex multidimensional analysis. To a large extent, these concepts still reflect the ''end-of-pipe" mind-set, in that they do not comprehend the need for a comprehensive, systems-based, technologically sophisticated approach to environmental management in a high-technology economy.

Other concepts involve aspects of the comprehensive DFE system as well. These include, for example, practices such as "Design for Disassembly," "Design

for Refurbishment," "Design for Component Recyclability," and "Design for Materials Recyclability." Like pollution prevention, these are obviously necessary dimensions of a DFE system.

These single dimensions are important not just in themselves but because they offer firms a relatively easy path to begin implementing DFE. No firm has yet implemented a comprehensive DFE system, and, indeed, fully implementing DFE practices will in all likelihood require that most firms develop new competencies, organizations, and information systems. This will take time and, in many cases, changes in organizational cultures as well. Accordingly, the most practical path for firms to follow may be to concentrate on implementing a few of these concepts initially, such as pollution prevention and Design for Disassembly, and then move on to other aspects of DFE as experience is gained.

Life cycle analysis, or LCA, incorporates into DFE the concept that all environmental impacts of an item—from those attributable to inputs, to manufacture, to consumer use, to disposal—should be considered in evaluating the environmental preferability of the product (Society of Environmental Toxicology and Chemistry [SETAC], 1991). LCA is a means by which data on environmental impacts, an important component of a DFE approach, can be generated. LCA can thus be equated to the DFE Matrix System discussed below. While it is probable that both LCA and the DFE Matrix System will continue to evolve in similar directions, at present LCA appears to apply more to low-design/high-material products, in that proposed methodologies do not reflect the systems implications of manufacturing complex articles. Perhaps for similar reasons, LCA also is essentially an analytical method; it does not provide a mechanism by which identified environmental considerations and constraints can be introduced into product and process design, as DFE does.

A number of other generic terms, such as "green engineering" and "environmentally conscious manufacturing," are also in use. Although these efforts have generated useful ideas and specific technical practices, as currently defined they tend to follow a rather ad hoe approach to meeting environmental goals. The lack of a systems-based approach makes it difficult for firms, and designers, to implement these concepts in a comprehensive manner.

IMPLEMENTING DESIGN FOR ENVIRONMENT

The implementation of DFE practices involves two categories of activities: (a) global, comprehensive projects whose effect extends across all design functions; and (b) specific individual evaluations of products, processes, or inputs.

In the first category are projects that can be undertaken at any time and will help result in environmentally preferable products across the board. Such activities include review of all internal specification documents to determine whether unnecessary environmentally harmful processes (such as cleaning with chlorinated solvents) or components (lead solder where conductive epoxy systems might

be used) are being required. Similarly, manufacturing firms should evaluate specifications and requests for proposals from their customers to determine whether unnecessary environmental impacts are being explicitly or implicitly required.

Using generic contract clauses to change supplier behavior can also be effective. For example, several years ago AT&T began by contract to require that all suppliers use non-CFC packaging. Those who were unable to comply contacted AT&T, which then directed them to preferable alternatives. A general improvement of all packaging used by both AT&T and its suppliers was achieved.

Identifying unnecessary process steps can also be an effective way of reducing environmental impact across many operations. Thus, many electronics companies found they could reduce their use and emissions of CFCs and chlorinated solvents by eliminating some cleaning steps or by doubling-up cleaning operations. This activity can be driven back into the design process by identifying design decisions that require environmentally harmful processing activities, and selecting alternatives. Thus, for example, use of an open relay switch on a printed wiring board requires that the board be cleaned with a chlorinated solvent, since such relays "can't swim"; that is, they cannot be exposed to water. Substituting a sealed relay permits the use of environmentally preferable aqueous cleaning systems.

More specific DIE activities involve an analysis of options for specific design choices. Here, a particular product, process, or input would be evaluated using several basic steps.

1. Scoping. The target product, process, or input is chosen, and options are identified. This is a critical step, particularly because the process of identifying options also generates a set of potential competitive surprises.

A second important component of the scoping process is to determine the depth of analysis required. For a fundamental design decision—such as moving · away from lead solder technologies in printed wiring board assembly—a fairly rigorous analysis would be appropriate. However, where incremental changes to an existing product or process are under consideration, there are relatively few options open to the designer, and a DIE analysis can be correspondingly limited.

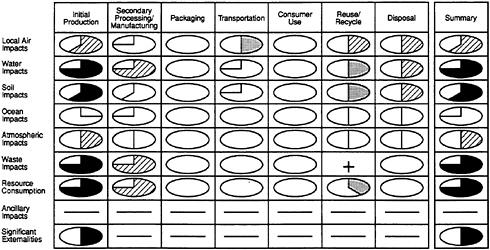

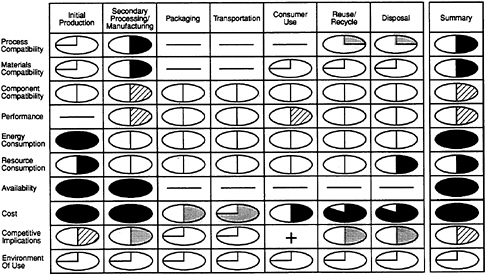

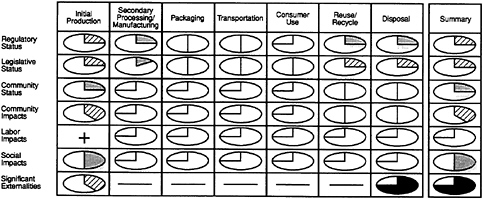

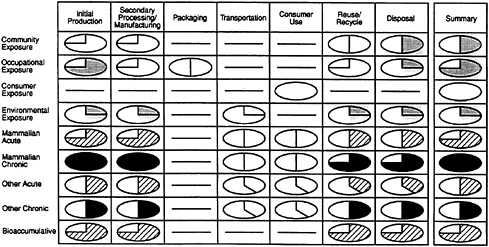

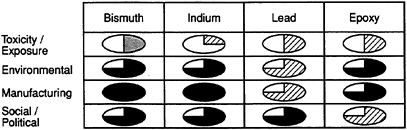

2. Data Gathering. The next step is to gather and evaluate all relevant data. This may be done using LCA methodologies or, alternatively, by completing a data collection effort aimed specifically at DIE information needs. Such an effort revolves around collecting information in at least four areas, illustrated by the data collection matrices in Figures 1-5: environmental primary, manufacturing primary, social/political primary, and toxicity/exposure primary. A summary matrix then captures the most severe concern for each ranking. The data in the matrices shown in Figures 1-5 are drawn from an example developed by the author and described later in this chapter.

There are three possible entries for each matrix cell (Figure 6). One or two pluses in a cell means the option has positive environmental effects for that cate-

FIGURE 1

Environmental primary matrix for bismuth.

FIGURE 2

Manufacturing primary matrix for indium.

gory and indicates the relative degree of benefit. A straight line means the cell is inapplicable to the option. An oval indicates some degree of concern: an open, or blank, oval indicates minimal concern; dots indicate some concern; diagonal lines indicate moderate concern; and solid black indicates serious concern.

An important feature of this graphical approach is the ability to indicate relative degrees of uncertainty. Thus, the amount by which each oval is filled in

FIGURE 3

Social/political primary matrix for indium.

FIGURE 4

Toxicity/exposure primary matrix for lead.

(going clockwise from 12 o'clock, as illustrated in Figure 6) with the appropriate pattern indicates the relative degree of uncertainty. For example, a solvent with potentially serious health effects, such as methylene chloride (a suspected carcinogen), would receive a solid black rating in the appropriate cell but, as those effects are quite uncertain, the oval might be only be half filled.

3. Data Translation. Once an analysis is completed, the information must be digested and turned into tools with which the design engineer or team can work. It is not very helpful, for example, to tell a designer that methylene chloride is a possible human carcinogen if the designer is unaware of alternatives. It is far more effective to create design tools, such as standardized components lists; design procedures, such as checklists that can be reviewed by environmental ex-

FIGURE 5

Summary matrix of the analysis.

FIGURE 6

DFE Information System (DFEIS) symbols.

perts; and software systems that incorporate these data into the design process without requiring further knowledge on the part of the designer.

These design tools can take many forms. For example, as AT&T phased out its use of CFCs in manufacturing, it created two useful tools. One, a handbook, listed all common solvents and, among other things, provided a color flag to indicate whether use of the material was acceptable from an environmental and regulatory perspective (for example, benzene would be red, or not acceptable, while water would be green, or acceptable under all circumstances). The other was a heuristic hierarchy of process choices (implementation of which frequently entailed changes in design process or product design). The preferable choice was to eliminate the cleaning step entirely; the second was to use an aqueous system; the

third was to use a semiaqueous system (water/hydrocarbon); the fourth, temporary and least preferred, was to use a chlorinated solvent.

Another "design tool" is simply to require that all components be labeled to ease postconsumer recycling. Thus, for example, plastic casings for computers or copiers increasingly have a label embossed on the inside giving the type of plastic, which facilitates material recycling. This need not concern the designer directly; it merely needs to be incorporated into the standard components list or required of the supplier through specifications.

DESIGN FOR ENVIRONMENT: TESTING THE SYSTEM

An experimental test of a formal DFE Information System (DFEIS) methodology was carried out by the author on a fairly controversial problem that AT&T confronted regarding the desirability of substituting indium alloys, bismuth alloys, or isotropic conductive epoxy technologies (using silver as the filler) for the lead solder currently used in assembly of printed wiring boards in electronics manufacturing (Allenby, 1992b). The results, presented in Figure 5, were counterintuitive, supporting a conclusion that significant substitution of indium, bismuth, or isotropic conductive epoxy technologies for lead solder would not be environmentally preferable.

None of the environmental effects that led to this conclusion occurred during the manufacturing or consumer use life cycle stages, the only ones that would have been considered in most standard industrial evaluations. Rather, they reflected basic characteristics of indium and bismuth ores (and, to a lesser degree, silver); namely, the low concentrations of indium and bismuth in virtually all ores, and the low world reserves of the metals taken as a whole. Under these circumstances, extraction would be very energy-intensive, and substantial environmental impacts, at least locally, could be anticipated (see Figure 1). Moreover, this raises obvious cost and availability concerns that should be addressed before relying on these options for a critical manufacturing function (see Figure 2).

Additionally, it was noteworthy that even this relatively limited, real world test of the DFEIS raised several unresolved ethical issues. For example, if indium or bismuth were to be substituted for lead solder, much of the environmental impact (and associated social and community impacts as well) would fall on localities where the mining and processing occurred, including some outside the United States. The potential environmental benefits, a reduction in the amount of lead solder from printed wiring boards in waste streams, would accrue primarily to localities near landfills or incinerators in the United States, where the electronic items would be disposed of. The asymmetrical geographic distribution of risk and benefit raises clear equity concerns, but I am aware of no generally accepted methods for resolving them.

A second issue, that of intergenerational resource allocation, is an extremely difficult equity problem. Since there is little indium in the world, is it appropriate

to consume much of this limited stock in the manufacture of televisions and VCRs, where it will eventually end up in sinks from which it is virtually unrecoverable? Is this acceptable given that the risks posed by alternatives, such as lead solder, are probably minimal for this use? In essence, this amounts to buying little or no risk reduction for U.S. inhabitants today by loading potentially substantial costs on future generations. If other materials can substitute for indium completely, the answer might still be yes, but we have no way of knowing this: indium might have some unique value in the future. (This is the rationale behind the ranking of "serious concern" in the disposal life cycle stage/significant externalities category in Figure 3.)

At this point, at least, there are no generally accepted legal or economic answers to this conundrum. What is perhaps more interesting, however, is that this very difficult issue arose in a relatively simple analysis of a serious existing design decision. Companies are deciding now whether to begin the difficult task of shifting to alternative joining technologies for printed wiring boards, so they will implicitly answer the ethical questions in any event. By failing to implement DFE practices, we are not avoiding problems; we are just ignoring them.

The toxicity/exposure primary matrix, containing the most familiar material, completes the matrix set, but even here there were important implications. Thus, as Figure 4 indicates, even for lead, a material whose toxic effects have been known since Roman times, considerable uncertainty over nonmammalian toxicity remains. Also it should be noted that data on exposure and on acute toxicity are integrated to provide the rankings captured in the summary matrix. This reflects the well-known toxicological principle that the hazard posed by any agent is a function of both the inherent toxicity of the agent and the concomitant exposure of the target population. Either exposure or toxicity alone does not generate hazard.

CONCLUSION

We are now at a stage where we are beginning to understand the multidisciplinary, systemic nature of the interrelationship between technology and environment. Current regulatory and industrial practices, however, are still predicated on an increasingly dysfunctional symptoms-oriented approach. Design for Environment practices provide a means by which industry—and regulators—can move beyond current single-dimensional, ad hoc approaches in the short term and evolve a systems-based, comprehensive set of practices over the long term. Both the environment and industrial competitiveness will benefit as a result.

REFERENCES

Allenby, B. R. 1991. Design for environment: A tool whose time has come. SSA Journal September:5-9.

Allenby, B. R. 1992a. Industrial ecology: The materials scientist in an environmentally constrained world. MRS Bulletin 17(3):46-51.

Allenby, B. R. 1992b. Design for Environment: Implementing Industrial Ecology. Ph.D. dissertation, Rutgers University.

Ayers, R. U. 1989. Industrial metabolism. Pp. 23-49 in Technology and Environment, J. H. Ausubel and H. E. Sladovich, eds. Washington, D.C.: National Academy Press.

Frosch, R. A., and N. E. Gallopoulos. 1989. Strategies for manufacturing. Scientific American 261(3): 144-152.

Gatenby, D. A., and G. Foo. 1990. Design for X: Key to competitive, profitable markets. AT&T Technical Journal 63(3):2-13.

Office of Technology Assessment. 1992. Green Products by Design: Choices for a Cleaner Environment. Washington, D.C.: U.S. Government Printing Office.

Society of Environmental Toxicology and Chemistry. 1991. A Technical Frame-work for Life Cycle Assessment. Washington, D.C.: SETAC Foundation.