The Greening of Industrial Ecosystems. 1994.

Pp. 1-19. Washington, DC:

National Academy Press.

The Greening of Industrial Ecosystems: Overview and Perspective

DEANNA J. RICHARDS, BRADEN R. ALLENBY, and ROBERT A. FROSCH

"Paper or plastic?" is rapidly becoming the commonest query of our day. In selecting a desirable bag at the grocery store check-out stand, the environmentally concerned base their decision not just on which is better at carrying groceries, but which is "greener." Making a rational choice on environmental preferability of even simple options, however, is not simple. A comparison of beverage cups— plastic vs. paper vs. ceramic—illustrates the difficulty. The intuitive choice, based on disposability, is that ceramic is preferable, followed at a considerable distance by paper and then perhaps plastic, which is less biodegradable than paper. The most comprehensive study to date indicates, however, that ceramic cups are the preferable option only if each cup is reused at least hundreds of times; a conclusion dependent heavily on assumptions about washing patterns (van Eijk et al., 1992). As multiple reuse is unlikely in many cases (think of the logo-stamped coffee mugs that populate trade fairs), the counterintuitive conclusion is that both paper and plastic cups can be preferable to ceramic cups, depending On consumption practices. This raises interesting systems questions: Are long-lasting multi-use products always environmentally preferable? Should complex products such as automobiles or computers always be manufactured for multiple reuse? What are the effects—on the economy, on technological choices, on company operations, on consumer options—of what seem to be environmentally beneficial changes in existing products or the introduction of ''green" products and processes?

As with all systems work or analysis, definition of the systems boundaries is critical. This is the case both in biological ecology and in the analysis of engineering systems such as computer networks, transportation systems, or chemical processing facilities. The same challenge exists in trying to understand industrial

ecosystems. For example, an industrial ecosystem may be defined by a single product. Any product, at a certain time, has a unique ecosystem characterized by raw material suppliers or component manufacturers, delivery, maintenance and collection systems, waste handlers, recyclers, and consumers. The various actors in industrial systems—raw material supplier or component manufacturer, consumer, waste handler, or recycler—are analogous to biological organisms. In these complex spatial and temporal webs of human production and consumption activities, individual materials may be traced through several different industrial ecosystems, and each industrial sector (and even company) may be characterized as playing a role in several industrial ecosystems. Alternatively, an industrial ecosystem may be bounded by geography (such as an urban area), an industry (such as agriculture), or a material (such as lead). Finally, just as from a global perspective, it is possible to think of the earth as made up of numerous interrelated natural ecosubsystems, so we may speak of the industrial ecosystem in terms of the whole network of industrial ecosubsystems.

Industrial ecology recognizes the unique role of humans in creating complex artifacts and institutions that force changes in materials and energy flows in both industrial and natural systems. Natural ecosystems, which provide the raw materials for economic activity, also serve as sinks for wastes from producers and consumers in industrial activities. The full, intricate, and complex set of interactions between industrial and natural ecosystems, however, is beyond the scope of this book, the subject of which is the value of using concepts derived from the study of natural ecological systems to understand interwoven natural and industrial systems. Thinking in this way—about industrial ecosystems—provides opportunities to examine and inform the ways in which producer and consumer practices in the economy may be altered to create environmentally compatible industrial ecosystems. Industrial ecology system boundaries may be drawn to include interacting industrial and natural processes. This book focuses primarily on the industrial components of these complex ecosystem extensions.

This volume of papers, drawn from those presented at a July 1992 National Academy of Engineering Workshop on Industrial Ecology and Design for Environment (DFE), represents an effort to advance the understanding of industrial ecology and to explore how companies can improve the environmental performance of their products, processes, and operations based on that understanding. In doing so, it builds on earlier efforts by the Academy, including Technology and Environment (Ausubel and Sladovich, 1989), Energy: Production, Consumption, and Consequences (Helm, 1990), and Keeping Pace with Science and Engineering: Case Studies in Environmental Regulation (Uman, 1993). Industrial ecology is still a young and evolving concept, and its ability to provide the theoretical or empirical underpinnings for action in companies, or by regulators or customers, is growing rapidly. However, what is known about the current ecology of industrial systems and their transformation suggests strategies and research efforts worth considering.

INDUSTRIAL ECOLOGY-A SYSTEMS APPROACH

Industrial ecology offers a unique systems approach within which environmental issues can be comprehensively addressed. It is based on an analogy of industrial systems to natural ecological systems.

The idea of an industrial ecology is based upon a straightforward analogy with natural ecological systems. In nature an ecological system operates through a web of connections in which organisms live and consume each other and each other's waste. The system has evolved so that the characteristic of communities of living organisms seems to be that nothing that contains available energy or useful material will be lost. There will evolve some organism that will manage to make its living by dealing with any waste product that provides available energy or usable material. Ecologists talk of a food web: an interconnection of uses of both organisms and their wastes. In the industrial context we may think of this as being use of products and waste products. The system structure of a natural ecology and the structure of an industrial system, or an economic system, are extremely similar (Frosch, 1992, p. 800).

There are obviously limits to this analogy, but it can help illuminate useful directions in which the system might be changed. Consider, for instance, waste minimization at a scale larger than that of a single unit or facility in light of the biological analogue. A mature natural ecological community operates as a waste minimization system. In general, the waste produced by one organism, or by one part of the community, is not disposed of as waste by the total system so long as it is a source of useful material and energy. Some organism, some part of the ecological system, tends to evolve or adjust to make a living out of any particular waste. Microorganisms themselves are often turned into food for some other organism, and so the materials and the energy embedded in them (within the constraints of the second law of thermodynamics and given solar insolation) tend to circulate in a large, complex web of interrelated organisms.

In an industrial ecology, unit processes and industries are interacting systems rather than isolated components. This view provides the basis for thinking about ways to connect different waste-producing processes, plants, or industries into an operating web that minimizes the total amount of industrial material that goes to disposal sinks or is lost in intermediate processes. The focus changes from merely minimizing waste from a particular process or facility, commonly known as "pollution prevention," to minimizing waste produced by the larger system as a whole. It is not a new idea that waste should be considered a potentially useful material. A number of industries and industrial systems and processes are noted for using the waste Of one process as feedstock for another. For example, steel scrap recycling is almost as old as the steel industry itself. The chemical and petrochemical industries characteristically attempt to convert as much of their raw material as possible into valuable products by finding uses for materials that were previously

discarded, or making chemical production process changes so that waste materials can become products.

There are several barriers to finding new uses for waste, or changing processes so that waste generated has some value to a customer elsewhere in the industrial system. First, the data available to begin assessing the potential for recovery of useful by-products from waste are scanty and of poor quality, and need improvement. Current data do, however, illustrate the potential of prospecting in waste streams for highly concentrated, high-value material. In some instances, materials occur at higher concentration in waste streams than in natural ores. Moreover, because the potential value of recoverable material in the waste stream increases with concentration, it is often feasible to design waste streams for reuse and recycling (Allen and Behmanesh, in this volume).

Second, the incentive to find resources in waste streams depends in part on there being a reliable market for the waste by-product. Materials that have a high economic value are highly conserved. The automobile industry has long recycled components, such as starters and alternators, that would otherwise be waste. This use of potential waste occurs because there is a market for what would otherwise be disposed of as waste. The role of markets in promoting recycling is highlighted by the fact that 75 percent, by weight, of a car is currently recycled (Klimisch, in this volume). This is not the result of any mandate to recycle automobiles, but rather occurs because there is a market for the recycled material and for refurbished components and parts. The auto recycling infrastructure is one among many environmentally sound recycling systems that exist today. Care should be taken to ensure that public policy initiatives to encourage resource recovery do not throw such existing systems of materials recovery and reuse into disarray. New policy initiatives should focus on stimulating markets for material currently being disposed of as waste.

Past experience with recycling in the United States may provide insights into current recycling programs. In the 1930s and 1940s there was an economically viable paper recycling industry that was not motivated by environmental concerns. An investigation into its decline might prove instructive. The experience of the 1980s, when old newspapers collected for recycling were warehoused for lack of a market for the used paper, shows the futility of programs organized solely for the sake of recycling, independent of demand. An apparent, gradual market adjustment in the 1990s may eliminate the need for warehousing newsprint, but if this adjustment is inadequate, consideration will have to be given to other possible changes in paper recycling.

Third, there are clearly information deficiencies that hinder the operation of markets for waste and recycled material. Frequently lacking, for example, is information identifying who has what (supply), who needs what (market), who could use what (potential market), or who could produce something if somebody else wanted it (potential supply). These data are not available, because companies are frequently secretive about the composition of their waste streams (for fear that

knowledge about waste streams can lead to deductions about proprietary processes), because different sectors are not familiar enough with each others' operations to know what opportunities are available, and because materials derived from waste streams are often considered inferior to virgin material.

Finally, the current regulatory structure can also prevent the linking of industries or industrial processes for more efficient use of waste materials (or recycled material). Some current regulations thwart rather than facilitate recovery and use of waste. As a result regulations often increase rather than decrease the amount of waste produced. Pfahl (in this volume) provides an example of how the ecologically beneficial recycling of lead dross would have been halted had a U.S. Environmental Protection Agency ruling labeling solder dross as hazardous waste been maintained. Recycling would have ceased because most of the secondary smelters involved in recycling lead from solder dross were not licensed to handle a material defined as hazardous waste under the Resource Conservation and Recovery Act, although it is not clear that any real hazard would have been posed by their handling of the dross. This type of problem arises not because anybody intended the outcome. Rather, the current media-specific environmental regulatory system focuses on the disposal and treatment of waste, not on minimizing waste. Thus, it can discourage attempts to reuse waste rather than provide incentives to do so.

Impediments to implementing environmentally preferable alternatives, however, are not restricted to environmental laws and regulations. For instance, antitrust laws, especially in the United States, can hinder industry cooperation that would be critical to developing comprehensive product and material recycling systems (Anderson, in this volume); inappropriate standards and specifications by large customers, such as the federal government, can also stifle the diffusion of environmentally preferable technologies (Morehouse, in this volume); and consumer protection laws that classify "remanufactured" products as "used" (secondhand) discourage product-life extension activities such as refurbishment and component reuse.

A broader, systems-based approach to industrial activity thus begins to illustrate the deficiencies in current understanding of industrial ecologies and the consequences and effects of changing production and consumption processes. It also exposes the impact of fiscal and regulatory policies in shaping the structure and operation of industrial ecosystems. There is clearly a need to better understand current industrial ecosystems and to tap points of leverage within them to improve the environmental performance of these systems.

Several papers in this volume refer to sustainable development. Sustainable development represents the quest for an economy that exists in equilibrium with the earth's resources and its natural ecosystems. Sustainable development brings environmental quality and economic growth into harmony, not conflict. It is a concept that recognizes that economic activities and environmental considerations need to be integrated for humanity's long-term well-being. Sustainable develop-

ment, however, is framed in broad and vague terms of restructuring social, economic, technological, and industrial policies and practices, of building new institutions, and of controlling population. Industrial ecology hints at concrete steps that lead to continuous environmental improvement that is also economically beneficial.

The current ecology of industrial systems suggests several environmentally desirable changes in industrial production and practices. These changes include improving the efficiency and productivity of industrial systems, minimizing waste in the use of raw materials, substituting abundant and environmentally benign materials for those that are less so, developing uses for waste products, and reusing manufactured products at the end of their first life. The goal of efficient materials and energy use suggests exploring ways in which the web of waste recycling and reuse found in natural systems may be imitated in the industrial context. Moving toward such a system, as illustrated earlier, involves changing a complex mix of interacting factors. To do so it may be necessary to improve current information systems or create new ones, remove regulatory barriers, and devise economic incentives.

INDUSTRIAL ECOLOGY AND ITS CONTEXT

Understanding Industrial Ecology

To chart a course toward environmentally preferable industrial systems and practices, it is necessary to consider the current state of industrial ecosystems and to set goals for the use of materials and energy to achieve the ideal state. In addition it is necessary to explore policies and incentives that will reorient production and consumption systems through natural market forces.

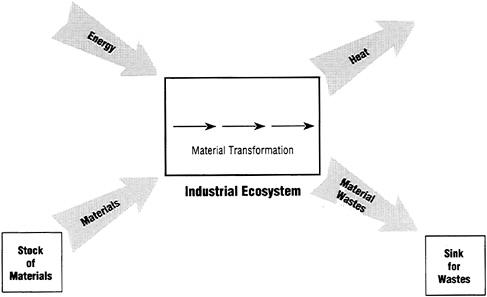

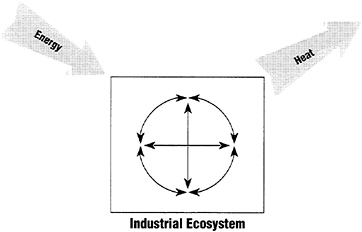

It is useful to consider three possible stages in the evolution of an industrial ecosystem. Type I industrial ecosystems (Figure 1), are characterized by linear, one-way flows of materials and energy where the production, use, and disposal of products occur without reuse, or recovery, of energy or materials. In Type II industrial eco-systems (Figure 2), some internal cycling of materials occurs, but there is still a need for virgin material input, and wastes continue to be generated and disposed of outside the economic system (i.e., as emissions to air or water). Hypothetical Type III industrial ecosystems (Figure 3) would be characterized by complete or nearly complete internal cycling of materials. Material is highly conserved, no waste material is released, and heat escapes. Type III industrial ecosystems are most similar to natural systems. The energy and materials flows provide some fundamental insights.

Like the earth's biota, all three industrial ecosystems models depend on continuous inputs of energy. This raises two questions: What are the prospects for meeting energy needs in the long term? and Can the environmental impacts of energy conversion be minimized? Linden (in this volume) suggests that fossil

FIGURE 3

Type III industrial ecosystem.

energy reserves are adequate to support a rational and planned transition to sustainability. However, emissions from the use of such resources—particularly heavy metals and carbon dioxide—will have to be controlled if this potential is to be exploited in environmentally acceptable ways.

Probing deeper we find that this is but part of the answer. Duchin (in this volume) suggests that the geographic locus of emissions of carbon dioxide and oxides of sulfur and nitrogen will continue shifting from the rich to the poor economies, even if only moderate economic growth is achieved in developing countries over the next several decades. At the same time, there will be a significant increase in the total emissions of carbon dioxide. These shifts are likely to occur even under optimistic scenarios of accelerated adoption of modem, commercially proven technologies to reduce and control pollution in both rich and poor nations. Therefore, if emissions are to be held at current levels, significant changes in production and consumption practices will be required. In addition, strategies to improve industrial ecosystems in industrialized countries are likely to differ from those in developing nations.

Current industrial ecosystems can be characterized by a mix of Type I and Type II materials flows. Industrial cycles tend to be open, with little recycling. The Type III industrial ecology model, which most closely resembles natural ecosystems, is a "no waste" ecology. It is in keeping with the limiting goal of "zero discharge" adopted by several major companies. Yet, the elimination of manufacturing wastes, or zero discharge, is beyond the capability of modem technology and would require the full participation of consumers. It is probably an unattainable goal, but in pursuing that objective it is important to recognize that there are only two possible long-run fates for materials—dissipative loss and recycling or reuse. Recycle and reuse will therefore have to be a part of any quest for a zero-discharge industrial ecology.

Ayres (in this volume) suggests two metrics that can be used to measure the extent to which materials cycles have been closed. The first, a surrogate measure of "distance" from a steady-state condition, is the fraction of current metal supply needed to replace dissipative losses (i.e., production from virgin ores needed to maintain a stable level of consumption). The second is a measure of materials productivity, which is the economic output per unit of material. Materials productivity can be measured at various scales—for the economy as a whole, for each sector, or for each firm—as well as for each major element, such as carbon, oxygen, hydrogen, sulfur, chlorine, iron, or phosphorus. These types of metrics can be useful in gauging the environmental efficiency of production and consumption practices based on the flow of materials.

The study of the flow of materials within and among industrial systems can also reveal opportunities for material recovery and reuse. Allen and Behmanesh (in this volume) give a simplified model of lead circulation through the economy. Using data on production, consumption, and waste flows, they find (not surprisingly) that waste streams with high concentrations of lead are more likely to be recycled than dilute waste streams. One would also expect to find other raw materials of high value in waste streams. Yet, even though the concentrations of metal resources in many waste streams are higher than for typical virgin resources, much of this waste material is now being discarded. Reductions in the quantity of material being jettisoned may be achieved through improvements in information about these hidden opportunities, more extensive trading in waste, appropriate regulatory reform, and advancements in separation and recovery technologies.

The Context of Industrial Ecology

The flow of materials, the use of energy, and the development and application of technology to produce and use goods and services do not occur in a vacuum. Each of these interrelated aspects of economic activity is influenced by a complex mix of dynamic economic forces, business practices, technological options, regulations, scientific understanding, and public opinion. Social values, and public perceptions and demands, often shape strategies to address public interest concerns such as the environment. Regulations, for example, reflect public values and are crafted to address societal concerns. Their structure, however, can be more or less efficient in achieving the desired social end. Currently, the majority of environmental regulations are rigid and prescribe methods of controlling emissions rather than encouraging desired outcomes. Housman (in this volume) argues that command-and-control regulations may have reached the limits of their effectiveness and must be replaced by more market-oriented strategies that provide the same or a higher level of environmental protection. Such a movement, however, will require that market-oriented regulations still protect the values society places on the possible outcomes or results.

The value society places on natural resources, however, is difficult to gauge

and is not static. It changes as a result of economic and cultural factors. For example, in both rich and poor nations, expenditures to achieve environmental gains must be justified against the need for resources to fight poverty, disease, and ignorance. Richer nations are likely, however, to have more resources to spend on environmental protection than poorer countries. Societal values can also be altered by the availability of management and technological solutions. Social costs associated with the environment, therefore, can be influenced by the substitutability of technology and knowledge for natural resources.

Crosson and Toman (in this volume) present four limiting scenarios relating substitutability and social costs: (1) complete substitutability among resources and zero social costs; (2) complete lack of substitutability and zero social costs; (3) complete lack of substitutability and catastrophic social costs; and (4) complete substitutability and catastrophic social costs. Markets may be effective for selecting among available options where there are many substitutes that can be exploited with low social cost trade-offs among resources. However, where there are few substitutes for resources and the social cost of exploitation is high, direct government intervention may be needed. Decisions to limit free market forces to address environmental solutions occur when a particular situation is judged to be too risky to leave to market forces. Such judgments, however, may vary widely among the individuals and groups involved, and the challenge is in employing a mix of regulations and incentive mechanisms to achieve desired outcomes. The newer initiatives such as pollution prevention and the precautionary principle (Housman, in this volume) seek to avoid environmental harms before they occur. By setting targets instead of dictating solutions, they allow the regulated community to compete to meet the goals. They are examples of ways to encourage internalization of environmental costs into the market. Environmental quality is often considered to be free or underpriced by the marketplace. The aim of these initiatives is to have the market prices for goods and services reflect a proper valuation of environmental impacts associated with their production, use, and disposal.

The internalization of environmental costs through public policy decisions currently occurs through direct regulation or (to a lesser extent) through economic instruments. Each approach has advantages and disadvantages. Properly designed regulations can produce swift and relatively predictable results (as was the case with the mandatory phaseout of leaded gasoline), but they can also impose unnecessary costs on industry and stifle environmentally innovative designs; for example, they can discriminate against new technologies by prescribing specific technologies as rigid standards (such as so-called best available emissions-control technology) (Weinberg et al., in this volume). In addition, prescriptive environmental regulations are unfortunately too often written as if the world were static,1 and do not consider the risks to society of not innovating.

Economic instruments, including surcharges on industrial emissions and taxes on undesirable compounds such as ozone-depleting substances, can provide

flexibility by providing direction toward desired outcomes rather than dictating methods to achieve them. They are suited to addressing dissipative environmental problems, such as groundwater contamination or heavy metal dispersion into the atmosphere. These environmental problems are not linked to large point sources of pollution and therefore are not amenable to being contained by command-and-control methods. Economic instruments are also better suited to influencing product design for environmental benefits. The proliferation of design and materials technology choices, the global nature of production and consumption (with materials, parts, and components frequently crossing many borders in both the assembly and the sale of a product), and the multidimensional nature of product impacts require flexible policies. While economic instruments offer several advantages, they can be expensive to administer and are often politically unpopular. The challenge for policymakers is to employ a mixture of regulations and economic instruments that encourage designers to take account of rapid technological change while simultaneously safeguarding environmental quality (Weinberg et al., in this volume).

EMERGING COMPANY PRACTICES

Even as policymakers grapple with ways to encourage environmentally sound production and consumption practices, private firms are changing practices in response to competitive and environmental pressures. World-class manufacturing practices that have emerged in recent years call for a systems approach to managing the complex manufacturing enterprise.2 Because the environment is a critical operating component in manufacturing, environmental issues are beginning to be considered in the product realization processes and operations of companies together with traditional criteria such as cost, quality, and performance.

Two manufacturing practices that facilitate the integration of environmental factors in industrial production are concurrent engineering and total quality management (TQM). First, environmental factors can be considered as an element of the concurrent engineering ''Design for X" (DFX) process, where "X" represents a product characteristic such as reliability or manufacturability that the company wants to maximize in its product design (Allenby, in this volume). Second, the adoption of TQM programs has made quality the responsibility of everyone in the company, not just the organization's internal quality group. By using existing or developing TQM programs, it is possible to translate environmental responsibilities across the board in a similar manner (Pfahl, in this volume). Both concurrent engineering practices and TQM techniques seek to integrate as many external factors as possible into initial design activities and thereby avoid problems that may occur after the fact. As environmental considerations are cast as critical components of concurrent engineering practices or as important quality issues, they are more easily accepted as standard practice within companies.

Several features common to world-class manufacturing practices and to integrating environmental factors in companywide operations are worth noting.

-

Senior management commitment to change

In the larger firms prominent in advancing environmentally preferable practices (or at least in publicizing them), there typically is a commitment of senior management to environmental progress (Dillon, in this volume). Such commitment is necessary to achieve fundamental changes in culture, organization, and procedures.

-

Goals, priorities and strategies

Corporate goals, priorities, and clear strategies to achieve goals are the basis of good project planning and, not surprisingly, are critical in efforts to effect change in corporations.

-

Use of cross-functional teams

Both concurrent engineering and TQM make use of cross-functional teams to ensure sensitivity to changes in the external climate (customer needs, and regulatory, technical, legal, social, as well as environmental requirements). Product development teams include the traditional product managers, design engineers, and individuals with expertise in manufacturing, marketing, sales, law, and the environment.

-

Learning from current product lines

An examination of current product lines and production practices can reveal opportunities for environmental improvement. Baselining can be a useful exercise to determine how well a product meets certain environmental criteria and to evaluate the environmental effects associated with the raw materials chosen by the design team. It can also reveal ways to reduce those effects (Sekutowski, in this volume). Cross-functional teams can be effective in evaluating products, processes, and operations and identifying opportunities for continuous improvement, including environmental improvement.

-

Partnering to achieve common goals

There are several ways in which companies and other organizations can work together to meet common goals, including environmental goals. Partnerships may be formed horizontally between companies within the same industry to achieve common noncompetitive alms or vertically with suppliers, vendors, and recyclers to ensure that environmental impacts of a product's production, delivery, sale, use, maintenance, recycle, reuse and disposal are handled appropriately (Klimisch, in this volume). Alliances can also be formed with universities and government laboratories to support related studies and to tap expertise not necessarily available within companies. Productive alliances can also be forged with environmental advocacy groups.

-

Managing the supplier chain

The information found in supplier management systems is an indirect systems component that can affect design decisions in a firm. Suppliers can be

asked to meet specifications that are environmentally appropriate while still maintaining necessary quality, cost, and performance standards. For instance, military specifications and standards have an extensive influence on global manufacturing practices and component selection practices (Morehouse, in this volume). A change in these specifications, therefore, can have a profound effect on practices of companies that supply the military.

A private firm's standards and specifications can have a similar effect on the design of its products and operations, as well as on the environmental performance of its suppliers. Private firms can, therefore, ensure that their products are environmentally superior by reviewing their standard components lists, which identify stock components to be used in design where possible, and ensuring that all recommended components are as environmentally acceptable as possible. These firms can also use their purchasing contracts to influence suppliers' behavior by requiring environmentally preferable practices.

In addition to these practices, the environmental life cycle approach (Allenby, in this volume), total environmental cost accounting (Todd, in this volume), and the selling function of the product (Stahel, in this volume) raise issues regarding the reorientation occurring in firms that respond to environmental concerns.

Taking a Life Cycle Approach

The most far-reaching implication of integrating environmental concerns in the economic decisions of companies and society is the need to take a life cycle approach to environmental analyses. This approach requires that environmental impacts—with "environmental" taken broadly to include relevant safety, health, and social factors—be understood and summed up across the lifetime of the product, process, material, technology, or service being evaluated. The goal is to reduce to a minimum the overall environmental impact of a product or process, and not simply address one aspect of that impact. This goal becomes important because minimizing the impacts of subsystems does not ensure that the impacts of the entire system are minimized, or even reduced.

Most judgments of environmental preferability hinge on life cycle assessments (LCA) of products, material, and processes and on the actions taken.3 These assessments provide a comprehensive profile of energy and material inputs to, and environmental impacts of, making, using, and retiring products. However, LCAs are seldom able to provide a clear-cut answer on environmental preferability or to provide a definitive measure of product "greenness." Studies of fairly simple consumer items, such as reusable vs. disposable diapers, have come to opposite conclusions depending on the assumptions made. The assumptions have to do with the types and modes of pollution and energy use considered in the analysis. If it is difficult to make an environmental distinction between different

types of diapers, cups, or bags (products of simple design, minimal material diversity, but high material density), the challenge the United States Air Force faces in defining "green weapons," (which are of complex design, contain a complex mix of materials, and have a comparatively low material density) is clearly beyond the current state of the art.

The notion of "green" weaponry (discussed by Morehouse, in this volume) is often greeted initially with bemusement. However, it raises some challenging questions: what are the environmental implications of maintaining aircraft, ships, and other weapons platforms over many years (frequently beyond design lifetimes), and how can the environmental impacts be reduced through more appropriate design? More fundamentally, if all aspects of a life cycle are to be considered, and consistent answers are not possible in the comparison of "simple" articles such as cups, what does it mean to designate a more complex product—an aircraft, a ship, an automobile, a computer—as environmentally superior?

If the environmental preferability of products cannot be determined unambiguously—and it is doubtful that the methodologies and sufficient data to identify environmentally preferable options do generally exist—regulators, design teams, and product and process engineers face a serious conundrum. They are being asked to promote and develop environmentally desirable materials, technologies, processes, and products with little valid guidance on what "environmentally preferable" means in practice, how these choices can be identified, or how their choices may affect other parts of industrial ecosystems, including raw material suppliers or component manufacturers, delivery, maintenance and collection systems, waste handlers, recyclers, and consumers.

The comprehensive life cycle assessment is data intensive and can vary depending on the quality of data available, the biases of the assessor, and the assumptions made. The need, however, is for simple methodologies that are inexpensive to use. As a corollary, no one has yet developed a methodology that easily identifies first-order environmental effects and separates them from the innumerable second-and third-order effects that any design choice entails. There is, therefore, much work to be done in refining life cycle methodologies and in bridging the gaps in information. In the final analysis, it is a question of choosing from among several alternatives—one or another design emerges from among different designs. If a selection is to be made among several alternatives that equally meet the traditional criteria of cost, quality, function, and customer acceptance, better environmental life cycle information may tip the balance in favor of an environmentally preferable design.

Most LCA methodologies have been developed in the context of chemical substance risk assessment, and some of the proposed methodologies appear better suited to relatively simple products, such as consumer personal care products or plastic packaging, rather than complex manufactured durable goods. The Design for Environment (DFE) methodologies, proposed by Allenby (in this volume) illustrate practical applications of life cycle approaches to environmental decision

making in complex manufacturing operations, and ways to apply them to subassemblies or completed products. The DFE methodologies can be developed as a module of concurrent engineering practices or the product realization process that can facilitate the integration of environmental objectives and constraints in the design process directly. At the same time, there is a need to improve tangential systems, such as the accounting or supplier management systems, which affect design decisions indirectly.

Getting at the "Total Environmental Costs" in a Firm

Existing accounting systems can prevent modern firms from internalizing environmental costs and considerations and can compound difficulties encountered in effecting environmentally preferable changes. Environmental costs that are buried in overhead accounts are hidden from managers. As a result, these costs are not seen and cannot be controlled. The need to improve accounting systems is no trivial matter. Incentives (and disincentives) must be fed back to the appropriate decision makers.

Accounting systems must capture currently hidden and unaccountable costs, such as product-related legal expenses, regulatory costs, public relations expenses, and the opportunity costs of failing to adopt clean technologies (Todd, in this volume). There are, however, severe institutional barriers that prevent managers from getting the information necessary to pursue optimal environmental waste-reduction strategies. First, current accounting systems were not designed to capture much of the engineering and accounting data required for environmental decision making. Second, data that are collected and processed are usually aggregated in such a way that they lose their environmental information content (as well as managerial control). Finally, line managers are rarely made responsible for environmental costs.

If accounting practices are to be changed, important institutional barriers must be removed, and incentives must be provided to motivate aggressive and creative development of solutions to reduce or eliminate wasteful processes and practices. These steps are important because the compensation of managers is frequently based in part on profitability that results from reducing controllable costs. Managers, therefore, have strong disincentives to seek "full environmental costing" within the firm, because this would bring additional costs under their accountability. The paradox is that managers cannot act without adequate information, and yet they will not act voluntarily if the result is not recognized and may in fact hurt the measure of their performance.

Shifting to Selling the Function of the Product

From a sustainable development perspective, industrial ecology suggests that the flow rate of materials in the economy may have to be slowed. Stahel (in this

volume) advocates a shift to an economy that sells the functionality of products rather than the products themselves to decelerate materials flow. This concept implies, for example, offering pesticide control instead of pesticides, communication services instead of phones, computing power instead of computers, refrigeration instead of refrigerators, and transportation instead of automobiles. It suggests valuing products not by the cost of their production but by the value the customer derives from using the products. An economy based on providing "functionality" would encourage reuse of products over recycling of products.

This idea in fact reflects both a past practice and a growing trend. For instance, it was not long ago that the Bell Telephone System in the United States owned the phones its customers used and then recycled or reused the phones as customers turned them back in. There is also evidence of some companies experimenting with providing functionality of products in their marketing efforts. For example, a new business group at Dow Chemical, Advanced Cleaning Systems, intends to maintain and increase the sales and profitability of the company's chlorinated solvents business, which is threatened by increased regulation of ozone-depleting chemicals and federal and state programs to control toxic air emissions (Dillon, in this volume). The group is developing not only alternative chemicals and processes but a range of customer services as well—improved process controls and the recycling of spent chemical solvents. It offers delivery of new chemicals to its customers in conjunction with "take-back" of the used chemical in reusable containers (Dillon, in this volume). The spent chemical can then be cleaned or reprocessed and be either returned to service or disposed of appropriately. This practice is an example of asserting control over the product life cycle while providing the customer with the functions of the product.

In the longer term, the possibility of a "functionality economy" raises truly revolutionary implications, not just for manufacturing firms and their customers but for society and regulators as well. One obvious implication is that products would be built to last long. Yet, because older, less efficient products such as automobiles may pollute more, manufacturers may have to design them to be easily upgradable. The more difficult issues of a functionality economy involve figuring out how to handle the impact of extended manufacturer liability for products and how to evaluate the costs of providing the service as well as the associated value Of the service provided.

EDUCATION NEEDS AND RESEARCH DIRECTIONS

Universities have a unique role to play in influencing the evolution of industrial ecosystems. In education, there is a need to base concepts such as pollution prevention, waste minimization and reuse, as well as product and material recycling and reuse considerations on broad engineering science principles, and to introduce them into engineering education. This can be accomplished by showing how environmental considerations of key design features can be balanced with

other design factors such as cost, aesthetics, functional performance, reliability, and quality. Friedlander (in this volume) suggests that this is one of the greatest challenges currently facing the engineering profession.

New engineering curricula may have to be developed to educate the next generation of engineers so that they can incorporate environmental factors into design decisions. New courses may be needed, but it may be more effective to integrate some of the lessons learned from industry case studies (and joint university-industry research) into existing design classes across the various engineering disciplines. In addition, engineers also need a good understanding of the interaction between the technological and environmental systems at various scales— macro (level of the economy), meso (level of the firm or plant), and micro (the level of the process)—of industrial organization. Finally, environmental considerations must be integrated into the curricula of other disciplines, such as business, law, economics, and public policy. Changes needed in education can be accelerated if industry clearly articulates the qualifications it seeks in the graduates it hires.

In research and policy, academic research institutions can tackle many of the pressing questions about industrial ecology and ways to create sustainable industrial ecologies. Examples of research needs include work on engineering and economic systems analyses and forecasts of industrial metabolism, input-output models of the economic and environmental implications of alternative strategies, development and analysis of waste stream composition data to target waste recovery and reuse, technologies to recover material from waste streams, tools to aid environmentally based material selection in design, management strategies for life cycle product management, and management studies of corporate cultural change. Universities are also in a unique position to play the role of broker in contentious policy debates and to convene groups with diverse views and opinions to shape policy on neutral grounds (Ehrenfeld, in this volume).

SUMMARY

The flow and embodiment of materials and energy in production and consumption activities of the economy underlie both economic growth and environmental perturbations. The familiar remedy for environmental ills has been to address the symptoms of pollution—in the air or water and on land—at the end of production and consumption processes. Command and control at the end of such processes has had little effect in altering their internal workings or the composition of products and did not consider the operation of industrial ecosystems or the influence of economic, social, and political pressures. As the shift is made from controlling pollution to preventing it and, beyond that, to achieving sustainable development, comprehensive approaches that focus on economic systems and the flow of materials and energy are needed to address the complex mix of issues raised about energy use, material choices, product and process design, interfirm

relations, material and waste management, market responses, information needs, and public policy choices.

Industrial ecology provides a systems perspective based on its analogy to biological ecosystems. This analogy illustrates the points of leverage for, and barriers to, improving the environmental characteristics of industrial ecosystems at the macro-level (the global economy), meso-level (the firm), and the micro-level (the industrial process). At the macro-scale the barriers include the inadequacy of current data about wastes and their potential recovery, the absence of reliable markets for waste by-products, the piecemeal environmental and fiscal regulatory approaches that inadvertently discourage environmentally sound practices, divergent values held by stakeholders, population growth, and significant income disparities among countries. A variety of structural and stakeholder factors affect industrial ecology at the macro-levels, but industrial ecology offers a framework within which all may be evaluated.

Taken together, the authors in this volume offer substantial evidence that change is beginning to occur in the understanding of industrial ecology and that changes in practice are occurring in industry, the military, academia, and government to reduce the environmental impacts of economic development. Nonetheless, there are barriers to change in the structures of both government and private firms such that change will be neither quick nor easy. At the theoretical and applied level, it is apparent that a great deal of research is necessary to inform the decisions being made by governments, the actions being taken by companies, and the education of engineers, lawyers, business managers, sociologists, and economists. This book provides a basis for intensifying that effort.

NOTES

REFERENCES

Ausubel, J. H., and H. E. Sladovich, eds. 1989. Technology and Environment. Washington, D.C.: National Academy Press.

Centre for Environmental Science. 1992. Methodology for Environmental Life cycle Analysis: International Developments. Paper prepared as a part of the National Research Programme for Recycling of Waste Products, J. A. Assies, investigator. University of Leiden, Netherlands.

Frosch, R. A. 1992. Industrial ecology: A philosophical introduction. Proceedings of the National Academy of Sciences 89(February):800-803.

Heim, J. A., and W. D. Compton, eds. 1992. Manufacturing Systems: Foundations of World-Class Practice. Washington, D.C.: National Academy Press.

Helm, J. L., ed. 1990. Energy: Production, Consumption, and Consequences. Washington, D.C.: National Academy Press.

Society for Environmental Toxicology and Chemistry (SETAC). 1991. A Technical Framework for Life Cycle Assessments. Washington, D.C.: The SETAC Foundation.

Uman, M. F., ed. 1993. Keeping Pace with Science and Engineering: Case Studies in Environmental Regulation. Washington, D.C.: National Academy Press.

van Eijk, J., J. W. Neiuwenhuis, C. W. Post, and J. H. de Zeeuw. 1992. Reusable Versus Disposable: A Comparison of the Environmental Impact of Polystyrene, Paper/Cardboard and Porcelain Crockery. Ministry of Housing, Physical Planning and Environment , Deventer, Netherlands.