The Greening of Industrial Ecosystems. 1994.

Pp. 171-177. Washington, DC:

National Academy Press.

Greening the Telephone: A Case Study

JANINE C. SEKUTOWSKI

AT&T is currently conducting a demonstration project called Green Product Realization to provide a basis for a more comprehensive "green" design program. The demonstration project will be used as a learning experience to generate feedback about the relevancy and utility of potential design for environment (DFE) guidelines and tools and to explore all elements of a system for delivering "green" products to customers.

The DFE effort at AT&T represents one of the first attempts to link industrial ecology concepts to specific industrial practices. The challenge of implementing DFE lies in the extreme difficulty of quantifying environmental attributes in a way that permits comparison among environmental effects and life cycle stages. Moreover, there are many data to which AT&T lacks access, such as information about the environmental effect resulting from the mining or processing of materials purchased by the firm.

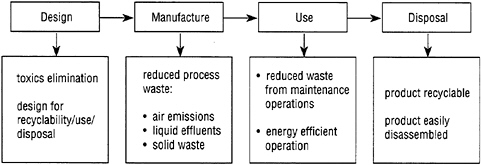

At AT&T, "Green Product Realization" is the designation of a program for developing the full-stream capability for minimizing the adverse life cycle environmental impacts of manufactured products throughout their entire life cycle (see Figure 1). It builds on a concurrent engineering program used by AT&T and many other companies. This system is called DFX, where DF stands for "design for" and X stands for downstream (from design) considerations such as manufacturability, installability, reliability, or testability. DFE, therefore, is any product or process design activity that minimizes the adverse environmental effects of the manufacture, use, and eventual disposal of products (see Figure 2).

However, although DFE principles may be applied to produce a "green" product, if, at the end of its life, the product ends up in a landfill, can it still be consid-

FIGURE 1

Simplified product life cycle.

ered "green"? It is important to extend our concern for minimizing the environmental impact of products beyond the traditional boundaries of design and manufacture to include such downstream considerations as use and end-of-life. It is in part to understand the implications of this paradigm shift that AT&T began a study to investigate what makes a product "green" from a life cycle perspective.

To speed the development and application of "green" design principles, and to investigate the environmental implications of the entire life cycle of a product, a single product was selected for the demonstration project. The criteria used to select the product were its size, number of components used, and length of production cycle. The obvious small product, with a minimum number of components and with a short product delivery cycle, given AT&T's product mix, was a telephone. This led to the Green Phone Feasibility Study Project.

DEFINING "GREEN"

For this feasibility study, a narrow view of environmentally preferable options, or "greenness," was selected. One reason for this is that the applicable methodologies, such as life cycle analysis (or LCA), are not very rigorous at this time. AT&T felt that it could not wait to begin developing "green" product principles until methodological questions were settled. For purposes of this project, for example, if a recyclable plastic is used, this is viewed as "green," even though, if a rigorous life cycle analysis were done, it might not be truly ''green" when balanced against the energy consumed and the waste produced to manufacture and recycle the plastic.

FIGURE 2

DFE product/process design activities.

Another attribute defined as "green" is the use of options that make for easy recycling of materials, such as

-

Applying the rules of design for assembly, because it implies design for disassembly (i.e., a product that is designed for assembly is generally easier to disassemble into component pieces for recycling).

-

Labeling plastic parts to facilitate separation after disassembly.

-

Using no metalized plastics.

-

Avoiding use of different plastics in the same separable component.

Other practices defined as environmentally preferable included the following: (1) waste from manufacturing is not simply landfilled, and (2) the product is not landfilled at the end of its life.

ORGANIZING THE GREEN TEAM

AT&T assembled a cross-functional team for this feasibility study. The team includes representation from product management and marketing, design and manufacture, R&D, and the corporate environmental organization. One of the first activities was a "green" product special interest group breakout session at a users group conference. In general, the "green" product concept was well received by customers. When asked if they would purchase a "green" product rather than another product, price and function being the same, all but one customer responded yes. All of the customers said that they would consider purchasing a product with refurbished or remanufactured components, provided the quality was as good as a "new'' product, although the majority expected the price to be lower. Ninety percent of those polled said they would participate in a recycling program, and all of those polled said they would accept biodegradable packaging and documentation printed on recycled paper.

With such a favorable response from customers, the team decided to determine how "environmentally preferable" AT&T's current processes are, that is, to establish a baseline for telephones currently being manufactured. The baselining task was divided into the four product phases: design, manufacture, use, and end-of-life.

GREEN BASELINE

Design

To help evaluate the environmental aspects of the design of the telephone, the AT&T team is developing a "green" scoring system, which assigns numerical points for various environmentally preferable attributes. The design is evaluated on how well it meets these attributes. For example, if the design possesses a particular "green" attribute, it would get a score of five, whereas it might get a

score of three for partial attributes. The final "green" rating is then calculated from the ratio of the actual scores and the maximum possible score; a perfectly · "green" product—based on the selected attributes—would receive a rating of 100. This calculation is a convenient method for comparing design options.

A software-based tool to calculate the "green" score of a product design is being developed. Such a tool would provide an easy, uniform way to assign numerical points to various environmentally desirable attributes. It would be a useful way of evaluating the environmental effect of potential design changes. It would also allow evaluation of the "greenness" of a product family and could be used to track progress in each successive generation of product.

The scoring system for "greenness" of design includes the following product attributes:

-

Can the material variety be minimized?

-

Can components be reused or recycled?

-

Are recyclable plastics used?

-

Can metal parts be detached and recycled?

-

Are plastics identified with established standard ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization) marks for recycling?

-

Can the product be easily disassembled?

-

Are screws used?

-

Are there any hazardous elements?

-

Are heavy metal pigments used?

-

Are brominated flame retardants used?

-

Are adhesives used?

Based on these attributes, the score for the design of the telephone was quite good; in fact, the existing design of the telephone already incorporates a number of environmentally desirable elements. Apparently, this is mostly due to the fact that a rigorous DFA (design for assembly) analysis was done on the design of this telephone. There are, however, some improvements that can be made to make the design of the telephone "greener":

-

Materials in components and housings can be identified with ASTM or ISO markings for easier recycling.

-

It is possible to reduce somewhat the variety of materials used; for example, the same grade of ABS plastic should be used throughout.

Going forward, AT&T hopes to incorporate these findings in the next generation of products to make them even more environmentally preferable. This will be aided by improvement to the scoring system as LCA and DFE methodologies are developed further.

Manufacture

Another stage of the life cycle of the telephone for which a baseline must be established is, obviously, the manufacturing stage. For purposes of the initial analysis, an initial boundary condition of considering only those components manufactured in AT&T factories for the "green" evaluation was established. This somewhat arbitrary restriction was necessary for practical reasons: data from hundreds of suppliers simply were not available and would in many cases be proprietary. Although it is difficult, at this time, to conceive whether or how suppliers (original equipment manufacturers, or OEMs) should be evaluated for "greenness," it may be appropriate to consider them at a later date. In the interim, AT&T has used generic tools, such as contract and purchase order provisions, to impose clearly desirable baseline environmental standards on suppliers (such as not using packaging made with chlorofluorocarbons).

The following qualitative statements can be made about the "greenness" of the manufacturing process for a telephone:

-

A significant quantity of waste is generated in the packaging of components that are assembled into the telephone.

-

Similar waste streams are treated differently at various factories.

-

Some of these waste treatments are environmentally preferable to others (why these preferable methods have not been adopted throughout the firm will be analyzed in the future).

The next task is to analyze quantitatively the manufacturing of the telephone. The entire manufacturing sequence will be characterized with an objective of identifying and quantifying all wastes (air, liquid, and solid) and all the associated costs and waste handling options. A scoring system, similar to that developed for the design phase, may then be developed for manufacturing to calculate "greenness" and track progress. Because of the complexity of the manufacturing process, this task will be extremely difficult. For example, frequently several products are made on the same manufacturing line using the same inputs, making it difficult to quantify wastes for any one product type.

Use

For purposes of this initial investigation, the AT&T team is assuming that the "greenness" of the use phase is good and no further characterization is necessary for two reasons. First, the energy consumption of the telephone is minimal. Second, the environmental impact of the design and manufacturing, and perhaps end-of-life, phases is many times greater. It is also possible that some telephone use substitutes for energy-intensive transportation, making the telephone as it functions within our economy an environmentally preferable product. Thus, the use phase will be examined for "greenness" at a later stage of the project.

End-of-Life

Work on evaluating the end-of-life phase of a telephone for "greenness" has not yet begun. However, there are several observations that can be made.

A recycling infrastructure for AT&T telephones is available. This infrastructure is a legacy from the Bell System and has existed for many years. It used to be that the Bell System leased telephones to customers. These telephones were designed to last for 40 years and it was only after this length of time, or if the customer moved, that the telephones were returned to the Bell System. These telephones were then refurbished and leased to different customers, or AT&T factories "mined" the returned telephones to recycle or reuse various materials. In essence, AT&T had a "take-back" policy long before such policies became popular with environmental regulators.

This AT&T recycling infrastructure is still in use for leased products. However, the percentage of leased telephones is declining for two reasons. First, customers are now buying telephones rather than leasing, and these telephones are only sporadically returned to AT&T. Second, because technology is changing rapidly and new features are continually designed into telephones, customers are buying telephones more frequently to take advantage of these new features.

For leased products, the "green" score for the end-of-life stage would be high; it is unclear what the score would be for products that are sold, because it is not known what happens to them. AT&T will investigate an integrated return policy for its telephones. Unlike the Bell System return policy, this one must be economical to support the reality of being in an unregulated, highly competitive business.

THE NEXT STEPS

As the demonstration project proceeds, several tasks require further effort. For example, as a result of the project several technological options for designing a "greener" telephone have been uncovered. These options need to be considered in the design of the next generation product. DFE guidelines for telephones must be developed and implemented to ensure a uniform approach to environmentally preferable design. The "green" design scoring system needs to be further developed and extended to other life cycle stages. An economical, realistic take-back program for telephones needs to be explored.

AT&T hopes to apply the lessons gained from the demonstration project to other products as well. In addition, as "greener" materials and process technologies become available, they need to be implemented. An example is the development of lead-free interconnection technologies, such as conductive adhesives or lead-free solder alloys. There are, however, substantial data and methodological gaps that AT&T, acting independently or with a few other progressive companies, cannot bridge. Development of international or national priorities and standards

for material selection would be useful (if done in an open process free of the temptation to craft trade advantages out of environmental standards).

The development of environmentally preferable products is an evolving process, and it might now be said that work on a "greener" telephone has begun. A truly environmentally preferable telephone is the ultimate goal.