3

Microwave System Integration

A considerable investment has been made over many years in the development of microwave processing systems for a wide range of products including food, rubber, ceramics, and a vast array of other highly specialized products. Most of these have been developed on a ''bootstrap'' basis by small, industrial microwave companies working with users in joint development arrangements in which the user gets a proprietary process and the microwave company gets an exclusive manufacturing agreement if the process succeeds. As a result, much of the technology that has been developed to date is not widely available, and the "wheel" has to get reinvented over and over again as others explore the potential benefits of microwave processing.

While the basic components of a microwave processing system——generator, applicator, and control systems——are simple, the interaction of materials with microwave fields and changes in fundamental material properties during processing make design and development of microwave processes very complex. This complexity may be dealt with using an integrated approach with a process design team consisting of the materials and process engineer, the microwave equipment manufacturer, and an electromagnetic specialist.

This chapter identifies key considerations in equipment selection and design, consistent measurement of sample temperature in a microwave field, measurement of critical properties, and numerical process simulation. Use of these tools and an interdisciplinary approach to system design will lead to more successful applications of microwave technology.

MICROWAVE APPLICATORS

Simply stated, microwave applicators are devices that are designed to heat a material by exposing it to a microwave field in a controlled environment. The objective is to cause a controlled interaction between the microwave energy and the material to occur under safe, reliable, repeatable, and economical operating conditions. Applicators may be conveyor operated; batch; or, as in the case of indexing systems, a combination of both. Microwave energy may also be combined inside the applicator with other energy sources, such as hot air, infrared, and steam, in order to achieve special results. Microwave applicators may also be designed to permit controlled interaction under a variety of ambient conditions, ranging from vacuum to high pressure and humidity.

Multimode Applicators

As described in Chapter 2, the two general classes of microwave applicators are multimode and single mode cavities. Key features of multimode ovens include:

-

suitability for bulk processing applications;

-

oven dimensions that are often determined by product dimensions;

-

moderate to high efficiency;

-

adaptability to batch or continuous product flow;

-

performance that is less sensitive to product position or geometry; and

-

good uniformity that may require motion of product or hybrid heating.

Multimode applicators are often used for processing bulk materials or arrays of discrete material, whose overall dimensions are too large (larger than the wavelength of the operating frequency) to permit consideration for use in a single-mode oven. These applicators, in their simplest configuration, take the form of a metal box that is excited (driven) at a frequency well above its fundamental cutoff frequency. For example, the common home microwave oven typically has internal dimensions on the order of 12 to 16 in., while the wavelength is 4.8 in. The larger dimension corresponds to a cutoff frequency of about 400 MHz as compared with the operating frequency of 2.450 GHz.

Because the dimensions of the enclosure are very large when expressed in terms of the free-space wavelength of the operating frequency, a large number of standing-wave modes can exist at or very near the operating frequency inside the cavity. To establish a reasonably uniform electric field strength throughout the cavity, it is desirable to excite as many of these modes as possible. When multiple modes are excited, heating nonuniformity is minimized even when the field perturbing effects of the materials being processed are present.

Multimode applicator design involves a number of basic design parameters. They include uniformity of heating, required microwave power, applicator size, leakage suppression, and required performance characteristics.

Heating Uniformity

Uniform heating is difficult to obtain in a multimode oven. This difficulty arises from the unpredictable way in which the parameters affecting uniformity change with time. As a result, a number of techniques, in addition to excitation of multiple standing-wave modes, are used to promote uniform heating. They include metallic mode stirrers to ensure that all the possible modes are excited; surface scanning to direct the energy at regions of interest; product motion; and, in some cases, hybrid heating using conventional heating to replace surface losses.

In conveyor applicators, product motion is inherent in the process. In batch applicators, product motion may be introduced in a variety of ways that include rotation, orbital motion, and linear (vertical or horizontal) translation.

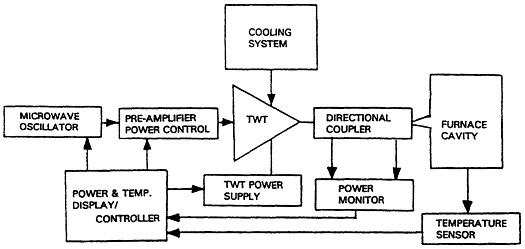

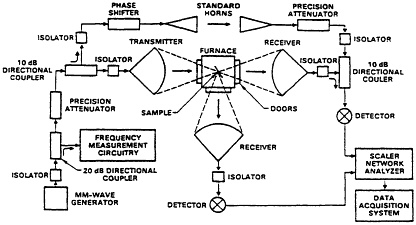

Another approach to improving heating uniformity is evident in the recently developed variable frequency microwave furnace. This furnace is a multimode cavity driven by high-power traveling wave tubes that produce up to 250 W continuous wave from 2.5 to 17.5 GHz and 500 W continuous wave from 0.9 to 8 GHz (Lauf et al., 1993). Earlier work showed capability to generate up to 2.5 kW from 4 to 8 GHz (Bible et al., 1992). As shown in Figure 3-1, the variable frequency microwave furnace consists of a traveling-wave-tube amplifier capable of sweeping approximately an octave frequency range and a signal control system that can adjust frequency or power to maximize absorption. Samples can be heated at fixed frequency, with adjustments for changes in sample characteristics, or subjected to continuously swept frequencies to achieve large-area uniformity by sequentially establishing several cavity modes.

Required Microwave Power

Required power is usually calculated based on an initial assessment of the proposed process and verified through actual testing once an initial oven concept, layout, and size have been established. Key parameters to be verified include heating-rate sensitivity, temperature uniformity, and process efficiency. Rate sensitivity, which can be a problem in some drying applications, may force the use of a longer cavity to increase process time at the expense of process efficiency.

Applicator Size

In many applications, applicator size is determined largely by the product size and compatibility with existing factory conveyor or batch production formats. Product size and rate sensitivity issues, mode number (uniformity requirement), and microwave-power handling capability under no-load conditions usually determine the minimum size of an oven. It is essential that an applicator be capable of operating under no-load conditions without electric field breakdown and without leakage for at least a sufficient time to let equipment and personnel safety devices shut the system down. Conveyorized ovens with large entrance and exit tunnels usually employ "lossy" (high  ") walls to suppress leakage. Under no-load conditions, the lossy walls act as parasitic loads that help reduce field strength in the cavity, thus reducing the risk of destructive arcing.

") walls to suppress leakage. Under no-load conditions, the lossy walls act as parasitic loads that help reduce field strength in the cavity, thus reducing the risk of destructive arcing.

Many batch ovens are designed to process a "disappearing load," which means that at the end of the process the cavity is effectively empty. A good example of this type of application is the drying of refractory materials. The microwave energy couples primarily to the water, since the refractory is relatively transparent to the microwaves. As drying proceeds, the amount of moisture in the cavity, and thus the microwave load, decreases. When no-load conditions are reached, extremely high fields can exist in the cavity and in waveguides feeding the cavity. Under these conditions, destructive arcing is a possibility unless special precautions

Figure 3-1 Schematic diagram of variable frequency microwave furnace (Courtesy of Microwave Laboratories, Inc.).

have been taken in the design m prevent it. Applicator design must allow for this possibility by allowing no-load operation or by providing means (e.g., arc detectors) to automatically shut down when safe operating conditions are exceeded.

Leakage Suppression

Suppression of microwave leakage from microwave oven doors and product openings is required for personnel safety and to reduce electromagnetic interference. Although these are two very different issues, they must be dealt with simultaneously by one choke or suppression runnel design. The current safety standard for microwave ovens is an emission specification that limits emissions at a distance of 5 cm from the surface of an oven to a maximum of 5 mW/cm2. Safety standards are discussed in more detail in a later section of this chapter.

Leakage can usually be suppressed by means of reactive chokes, provided that the other dimension of the opening is less than approximately one-half of a wavelength. Good examples of these types of openings are the door seals for industrial and conventional home microwave ovens and slot openings to permit ingress and egress of thin belt wed web materials processed in industrial microwave ovens.

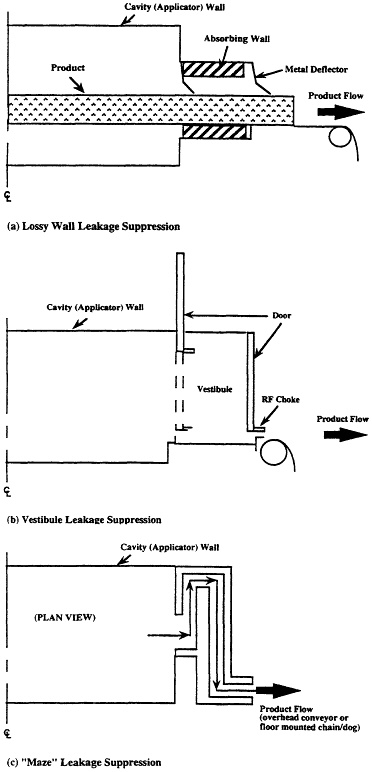

Reactive chokes are ineffective when the height of the opening is grater than about half a wavelength. In these cases, free radiation from the cavity can occur with the possibility of unacceptable levels of human exposure. There are three basic methods employed to deal with these situations. They are (1) leakage suppression runnels with absorbent walls, (2) vestibules with indexing conveyors and doors that open and close sequentially to admit product, and (3) "maze" openings that admit product by causing it to meander through a folded corridor lined with absorbing walls. These are illustrated schematically in Figure 3-2.

Required Performance Characteristics

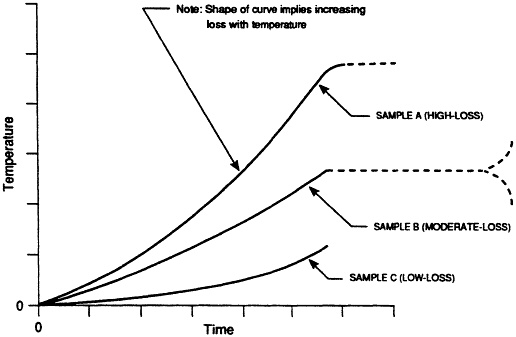

Figure 3-3 illustrates typical temperature versus heating time curves for most of the products processed in a multimode oven under constant microwave power input. Generally speaking, the slope of the heating curves, at low temperatures at least, will be linear provided that the change in material dielectric properties and heat loss mechanisms in the range of interest are negligible. The low-loss case (curve C) is typical for material such as natural rubber and other polymers that have low dielectric loss. Curve B is representative of a moderate-loss material or a low-loss material (curve C) doped to increase its loss. The plateau in curve B could represent the thermostating effect of a drying process that occurs when the moisture reaches the saturation temperature. The tail end of curve B represents what happens after all of the moisture is gone. If the base material is low-loss or transparent, the material will stop heating, and the temperature will gradually decrease. If the material is lossy, the heating process will continue upward until heat losses from the surface (radiative, conductive, and convective) occur at the same rate of the microwave energy is being delivered to the oven. This last effect is illustrated by curve A.

FIGURE 3-3 Typical temperature vs. heating time curves for multimode applicator with constant microwave power, sample weight and sample geometry.

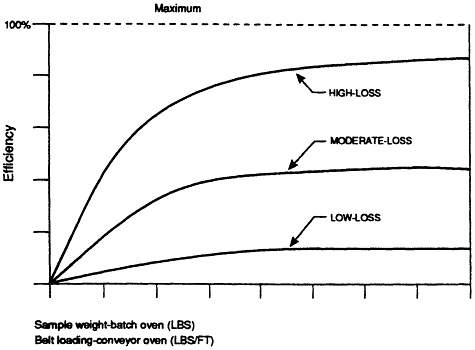

Figure 3-4 illustrates how the efficiency of a multimode cavity is affected by the amount of material in the cavity, and the dielectric loss properties of the material.

FIGURE 3-4 Schematic of multimode cavity efficiency vs. load size with constant power and variable sample weight.

Single-Mode Applicators

In their simplest form, single-mode applicators consist of a section of waveguide operating at a frequency near cutoff. They usually have had holes or slots cut in them to let product in or out. In more-demanding applications, they may consist of resonant, high Q cavities. Some advantages of single-mode applicators follow:

-

High fields are possible.

-

The applicators can operate in the standing or traveling wave configurations.

-

Fields are well defined.

-

Fields can be matched to product geometry.

-

The applicators are useful for heating both low-loss and high-loss materials.

-

The applicators are compatible with continuous product flow.

-

High efficiency is possible.

The use of single-mode applicators involves some penalties that must be weighed carefully. They are product specific rather than general purpose and in operation can be very sensitive (i.e., tuned off-resonance) to changes in product properties, geometry, and position.

As a result of these shortcomings, single-mode applicators tend to be more expensive to design. Their use may require automatic controls and feedback to ensure optimum performance.

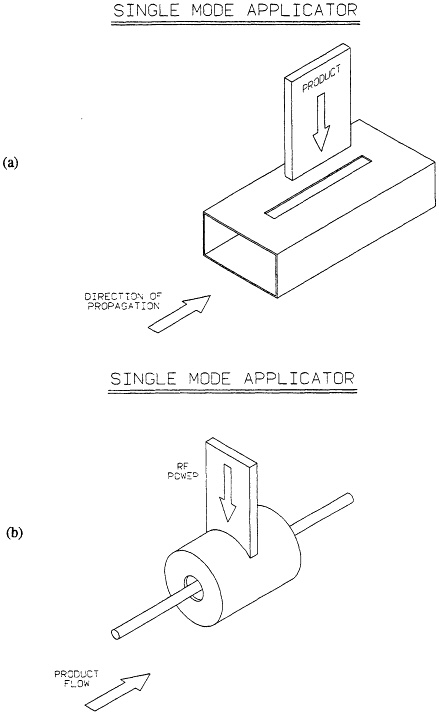

Figure 3-5 illustrates two examples of single-mode applicators. The first is a single-mode waveguide with a slot cut into the broad wall to permit passage of a thin material that is to be heated. Cutting the slot in the center of the broad wall of the cavity where the TE10 electric field is at a maximum ensures efficient coupling. The second is a cylindrical cavity operating in the TM01 mode, which puts the E-fields parallel to the longitudinal axis of the cylinder.

Periodic Structures

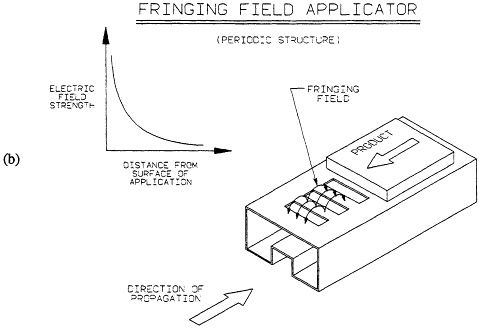

Periodic structures are microwave transmission lines that have been distorted or had discontinuities inserted into them at regular intervals. When microwave energy is fed through these structures, there are reflections caused by the discontinuities which result in the formation of pass bands and stop bands. These structures are important because field shaping to match product geometry is possible and because single-surface nonradiating devices can be built. As with single-mode applicators, periodic applicator design is involved and expensive, and the final design is very product specific.

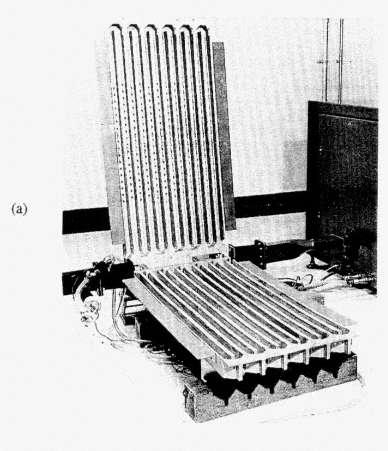

Two examples of these structures are shown in Figure 3-6. The first is the serpentine wave guide, which is similar to the slotted wave guide (Figure 3-5a) except that the structure has been folded back on itself to accommodate wide materials and to provide uniform heating and sufficient interaction length to ensure absorption of all of the microwave energy. The second is a single-surface applicator (Karp Line) formed by cutting slots in the broad wall of a rectangular wave guide. Microwave fields fringe out to the external surface, where they interact with a thin-film material to be heated. This structure has been used successfully to cure the glue used to bind the signatures in a book binding application.

MICROWAVE SAFETY STANDARDS

As microwave power levels for industrial processing systems increase, potential hazards associated with exposure to radiation become more important. Extensive work, as summarized in recent review articles (Michaelson and Lin, 1987; CRC, 1986), indicate that the effects on biological tissue from exposure at microwave frequencies are thermal in nature. Unlike the higher energy, ionizing region of the electromagnetic spectrum, including x rays and gamma rays, the nonionizing bands from DC to visible light do not carry enough energy to break chemical bonds (Redhead, 1992). The only effects of nonionizing radiation in the microwave region on human tissue are those derived from the energy—matter coupling mechanisms, particularly dielectric coupling, described in Chapter 2. At present, the only confirmed effect is warming, from the conversion of electromagnetic energy to heat. Thus, microwave exposure standards are based on the thermal effects of exposure.

Since, at microwave frequencies, sensation and pain thresholds are well before bums occur (Osepchuk, 1991), bums are most likely to occur due to contact with a heated conductor or opening, rather than through radiant exposure.

The currently accepted standard is the guidelines developed by the American National Standards Institute of 10 mW/cm2 power density for exposure (ANSI C95.1-1991). The power density guideline is based on a maximum permissible exposure of 0.4 W/kg specific absorption rate, which is a factor of 10 less severe than the determined threshold absorption level (Redhead, 1992). Standards based on the institute's guidelines include the Food and Drug Administration's emission standard of 5 mW/cm2 at 5 cm for microwave ovens (HHS, 1991) and the Occupational Safety and Health Administration's exposure standard of 10 mW/cm2 (Department of Labor, 1991).

To minimize exposure, the microwave system needs to be designed with effective leakage suppression, viewing or ventilation screens, and an interlock system on doors and access apertures to shut off power when doors are opened (Osepchuk, 1991).

TEMPERATURE MEASUREMENTS

One of the most difficult, yet important, parameters to measure in a microwave environment is temperature. Sample temperature is the most common process-control parameter in microwave processing. Inaccuracies in temperature measurement or perturbation of the microwave field by temperature sensors can lead to erroneous indications of process temperature and misleading representation of process efficiency.

The temperature of a body is its thermal state and is regarded as a measure of its ability to transfer heat to other bodies. The indication of how a numerical value may be associated with the temperature requires a review of the laws of thermodynamics, which is certainly beyond the scope of this document. To establish procedures for accurate temperature measurement, temperature may be defined as a quantity that takes the same value in two systems that are brought into thermal contact with one another and are allowed to come to thermal equilibrium . Based on this definition, it may be suggested that for accurate temperature measurements, both the body and the measuring device should make good thermal contact and both bodies should be in thermal equilibrium.

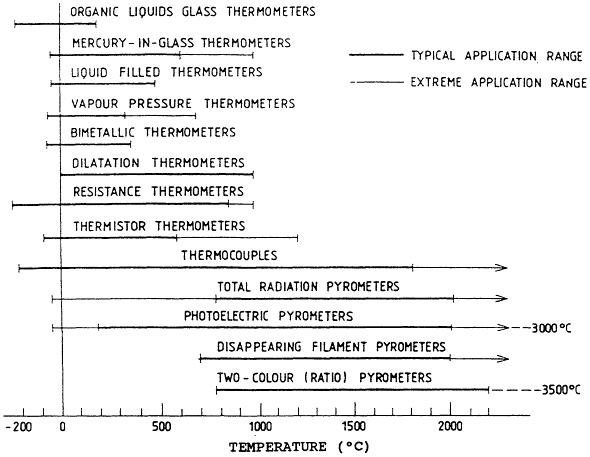

Figure 3-7 identifies various temperature-measuring instruments and their applicable temperature ranges. Thermocouples and optical measurement techniques are most often used in microwave processing.

Temperature Measurement in a Microwave Environment

Temperature measurements in a microwave environment present several difficulties:

-

Temperature measurement must be made directly within the sample and not in its vicinity. Microwaves heat the sample itself (heat from within) and not the surroundings, and hence temperature probes must maintain good contact with the sample to achieve accurate temperature measurements.

-

Thermal gradients developed during microwave heating make characterizing sample temperature using a single measurement difficult.

FIGURE 3-7 Classification of temperature-measuring instruments.

-

Maintaining good contact with the sample might be difficult because of the changes in sample size during processing or due to motion of the sample.

-

Conventional temperature-measurement procedures using thermocouples are not suitable for making these measurements in a microwave environment. The presence of a metallic temperature probe in a microwave environment can cause electromagnetic interference problems, causing distortion of the electrical field or affecting the electronics used for temperature measurement, as well as errors due to self heating; heat conduction; shielding; and excessive localized heating, particularly at the tip of the probe.

-

Optical measurement techniques such as pyrometers and optical fiber probes assume knowledge of emissivity.

-

The ''heating from within'' property of microwave heating results in a surface temperature that is different from the core value.

-

Depending on the optical properties and size of the sample, its emittance may make the optical radiation sensitive to the colder environment surrounding the sample.

Some of these measurement errors will be discussed in more detail in the following section.

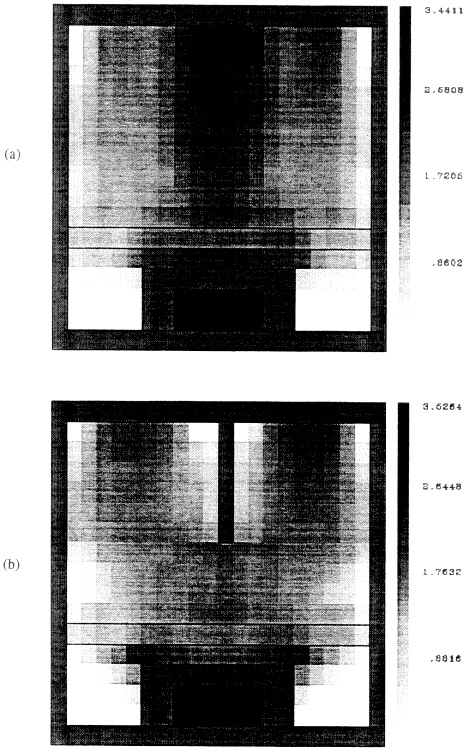

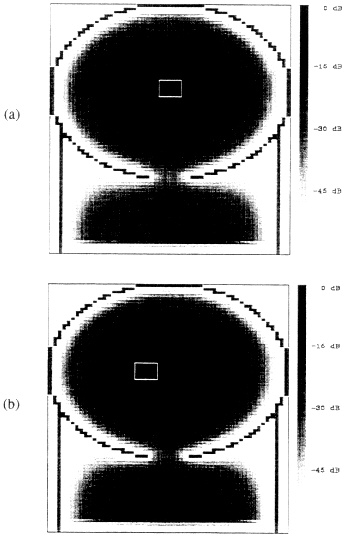

EMI Problems

When metallic temperature probes are used in the microwave environment, significant electromagnetic interference problems may occur. Electromagnetic boundary conditions require that the electric field be normal to conductors. Therefore, serious distortion of the electric field in the microwave environment will occur when a thermocouple is placed at a location where the electric field is parallel to the conductor. Figure 3-8a, shows results from numerical simulations, where it may be seen that placement of a conductor parallel to electric field vectors caused significant distortion in the field distribution in a multimode cavity. Figure 3-8b, on the other hand, shows that less distortion occurs when a metallic conductor is placed in a region of small electric field values, particularly since the conductor is perpendicular to the electric field vector. The only difference between parts (a) and (b) of Figure 3-8b is a noted concentration of the electric field lines at the tip of the conducting probe. This is the reason why it is often observed that using metallic temperature probes results in localized heating and possible thermal runaway in the sample.

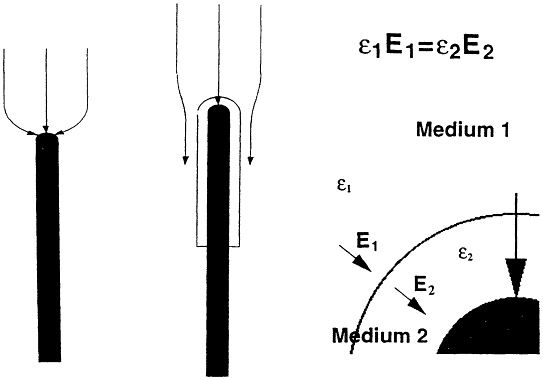

Alumina sheathed thermocouples have been used to reduce the effect of localized heating (Janney et al., 1991a). Figure 3-9 shows that, based on the boundary condition of the normal electric field component, such an arrangement will result in minimizing the local concentration of the electric field near the tip of the probe. However, such an arrangement is not expected to minimize the distortion of the electric-field distribution in the cavity, particularly when the probe is placed parallel to the electric field.

Although it may be acceptable to insert metallic temperature probes in multimode microwave cavities, placement of such probes perpendicular to electric field lines is crucial when measuring temperature in a single-mode cavity. Fortunately, electric field distributions are known in cavities, and hence it is possible to make such adjustments in certain modes.

Otherwise, serious distortions in the field configuration are expected, and performing a heating process under these conditions might be meaningless.

Errors in Optical Temperature Procedures

Although supplier specifications of accuracy may be as good as 2 ºC or less, there are many conditions that need to be satisfied before such accuracies may be achieved.

First, optical techniques measure surface temperature, which may be significantly different than internal temperatures due to microwave penetration and surface heat losses. Relationships between surface measurements and actual internal temperatures need to be understood.

FIGURE 3-9 Effect of ceramic sheath on electric field concentration at temperature probe tip (Kimrey and Iskander, 1992).

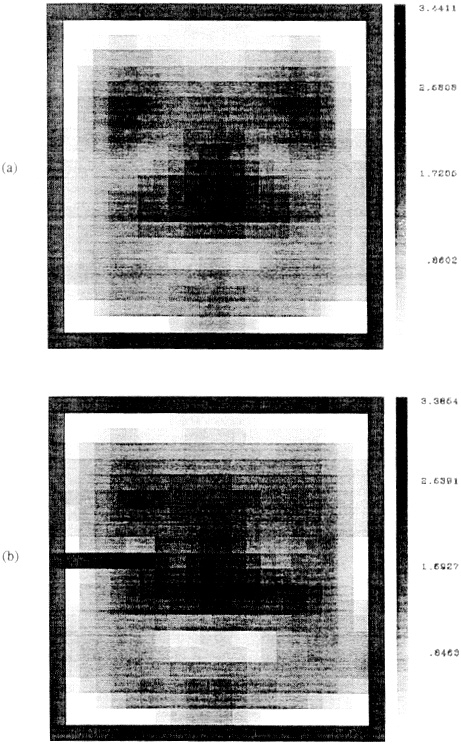

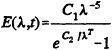

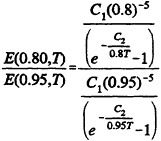

Second, accurate knowledge of the object's emissivity and its variation with temperature and frequency is possibly the most serious source of error in both pyrometric and optical-fiber thermometer measurement techniques. Emissivity is the ratio between the radiation energy of an object and the energy radiated by a perfect "blackbody" radiator at the same temperature. Although emitted radiation from a blackbody may be quantified in terms of Planck's blackbody radiation law, accurate knowledge of the emissivity of an object and its variation with temperature and frequency requires careful analysis. Emissivity depends on the object's surface state, homogeneity, and temperature. The error in measured temperature, dT, is related to an error in the emissivity values ![]() by

by

where ![]() is the new emissivity value,

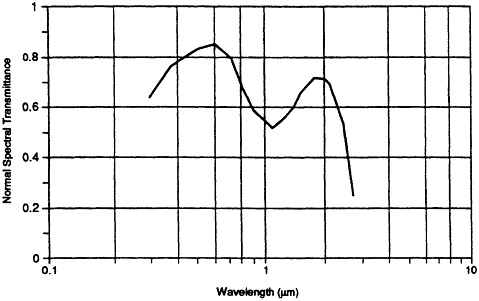

is the new emissivity value, ![]() is the original emissivity value, C2 = 1.4387 × 104 μm·K, and λ is the measurement wavelength in μm. Figure 3-10 shows the temperature-measurement error based on percent error in emissivity as a function of temperature. Figure 3-10, part a shows the case when temperature measurements were made at λ = 0.95 μm, while Figure 3-10, part b shows the expected errors when the measurements are made at λ = 3.5 μm,

is the original emissivity value, C2 = 1.4387 × 104 μm·K, and λ is the measurement wavelength in μm. Figure 3-10 shows the temperature-measurement error based on percent error in emissivity as a function of temperature. Figure 3-10, part a shows the case when temperature measurements were made at λ = 0.95 μm, while Figure 3-10, part b shows the expected errors when the measurements are made at λ = 3.5 μm,

which is conventionally used in these measurements. Errors as large as 200 ºC may occur if the emissivity estimate was in error by 20 to 25 percent at λ = 3.5 μm. Additional error may result from high sample transparency (emittance), which causes the temperature measurements using pyrometers or lightpipe to be sensitive to the cooler environment surrounding the heated sample.

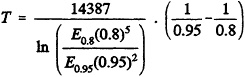

Finally, pyrometer temperature measurement in a single-mode cavity is often made through a Pyrex window. It is therefore important that the effect of the window be carefully calibrated, and fogging effect (if any) should be taken into account. Figure 3-11 shows the spectral transmittance of a 12.7-mm Pyrex window. The fact that the transmittance of the window depends on frequency adds another source of error when a dual-wavelength pyrometer is used in temperature measurement. To help quantify this error, consider Planck's equation for the radiated energy from a blackbody as a function of temperature and wavelength.

where λ is the wavelength, T is the temperature in Kelvins, C1 = 3.743 × 108 W.(μm)4/m2, and C2 = 1.4387 × 104 μm.K. If we consider a dual-wavelength pyrometer operating at 0.8 and 0.95 μm, then

FIGURE 3-11 Normal spectral transmittance of 12.7 mm Pyrex window.

Figure 3-12 shows the dual-wavelength temperature-measurement errors caused by 10- and 25- percent difference in signal strength between two wavelengths. It may also be noted from the Pyrex window transmission graph of Figure 3-9 that a 25 percent error in transmittance is a realistic value, since transmission is 0.69 at 0.8 μm and 0.57 at 0.95 μm. From Figure 3-12 it may be seen that at a temperature of 1500 ºC, a measurement error of ±270 ºC may easily be encountered without even taking into account errors due to uncertainty in emissivity values.

In the case of a blackbody optical sensor, an optical fiber with a thin metallic coating at the tip, the electromagnetic interference problems that may result from the metallization at the tip of the probe, as well as the routine problem of maintaining good thermal contact between the probe and the sample, are the dominant sources of error.

Summary

Based on a brief review of available temperature measurement techniques and the complications that may result when measuring temperature in a microwave environment, the committee made the following observations:

-

Temperature measurement in a microwave environment is a nontrivial procedure. Maintaining good thermal contact with the object being heated is crucial when hinting using microwaves, and it is important that temperature probes produce minimum perturbation to the existing fields in the microwave hinting chamber. This is particularly true when heating in single-mode cavities.

FIGURE 3-12 Temperature measurement errors for dual-wavelength optical pyrometer based on 10 and 25 percent difference in signal strength.

-

Problems with probe self-heating, perturbation of fields, changing the resonant frequency in the heating chamber, window fogging, and change of transmission with frequency must be quantified and included as part of the reporting of temperature measurements.

-

Procedures for estimating the effective value of the emissivity of the heated object and its variation with temperature and wavelength are important for verifying the accuracy of temperature-measurement results. These procedures should therefore be clearly described when reporting temperature measurements.

-

When optical pyrometers are used in surface-temperature measurements, the transmission properties of the viewing windows and their variation with the wavelength and during the heating process must also be quantified, and their impact on the accuracy of the temperature measurement must be reported.

The committee suggests that the scientific community set a higher standard and be more critical in accepting reports of temperature measurements. The validation of reported results must be required, and a detailed description of the level of interference with the microwave environment, procedures for estimating effective values of the emissivity, the effect of sample emittance versus temperature on the estimated value of emissivity, and observation-window-related issues must all be clearly described and carefully documented.

COMPUTER MODELING AND COMPUTER SIMULATION

Computer modeling and numerical simulation can provide valuable information involving various aspects of microwave processing, including:

-

microwave interaction with materials;

-

effects of hybrid heating;

-

heating multiple samples;

-

simulating and evaluating the performance of various microwave processing systems; and

-

expected magnitude and location of thermal gradients.

Valuable information regarding the uniformity of heating, the design and scale-up of a heating system, and process control parameters may be obtained from simulation results.

In spite of the many advantages of using computer modeling and numerical simulation in addressing many of the research and development and design aspects of the microwave heating process, examination of available literature reveals that reported activities in this area are rather limited (Iskander et al., 1991; Chaussecourte et al., 1992; Lorenson and Gallerneault, 1991). Other than some reported characterization of single-and multimode cavities using analytical (Manring and Asmussen, 1991; Barmatz and Jackson, 1992) and numerical (Iskander et al., 1993) procedures, most of the activities in this area were focused on laboratory experiments or empirical modeling of specific processes. Empirically simplified models and "microwave heating diagrams," based on measurements and on the data from numerical simulations conducted during development phases, can be important in the introduction of a new microwave process into a production environment. Computer simulation and numerical modeling and their use in developing and optimizing microwave processes and equipment are discussed in this section.

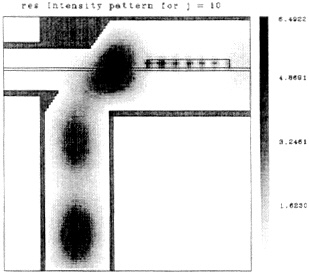

Numerical methods can be used to model a wide variety of microwave processing systems. For example, the finite-difference time-domain method has been used to model microwave sintering in rectangular and cylindrical single-mode cavities (Navarro et al., 1991; Chapman et al., 1992). The model used in the simulation of sintering in single-mode cylindrical cavities is shown in Figure 3-13. Model solutions allow the determination of the variation of the cavity fields with time, the time resonant frequency of the cavity, and the steady-state field and power distributions in the cavity and within the sample. Figure 3-14 shows a cross-sectional view of a calculated E-field distribution inside the cavity (with a ceramic sample inserted) and the feed waveguide at the resonant frequency. Calculations may also provide Qs of the empty and loaded cavities, and the electromagnetic fields and power distributions at the true resonant frequency (Iskander et al., 1993; Chapman et al., 1992).

Finite-difference time-domain modeling of multimode cavities to simulate heating processes, including hybrid heating, in multimode cavities can provide information about field distributions in the cavity and about the effects of sample insertion, insulations, susceptors, etc.

An example of a finite-difference time-domain model traveling-wave heating system is shown in Figure 3-15 (Metaxas and Meredith, 1983). The simulation places the sample on the conveyor belt translating through the center (peak) of a TE10 mode in a rectangular waveguide. It is often desirable to identify guidelines regarding suitable dimensions of samples, speed of conveyor belt, input power levels, etc., using available simulation capabilities. Results of the electric field distribution in the empty applicator are shown in Figure 3-16. Figure 3-17 shows the field distribution with a sample on the conveyor belt. The standing-wave pattern (distance between peaks) is significantly different from that in the empty waveguide.

Numerical simulations can also be used to predict sample temperature and to map temperature gradients. For example, temperature profiles within a spherical sample heated by microwaves have been modeled using a shell model (Barmatz and Jackson, 1992). Field strength and absorbed power were calculated using a total-absorption model (Jackson and Barmatz, 1991). Equilibrium temperature distributions were calculated by partitioning the sphere into shells. An example of model results for alumina is shown in Figure 3-18. The model was able to predict thermal runaway behavior observed for this material (as discussed in Chapter 2).

With the availability of high-performance computing systems, graphics tools, and suitable numerical techniques, computer modeling and numerical techniques can play an important role in designing realistic microwave-heating processes. However, there are several challenges that need to be met to improve the simulation results and increase the impact on microwave processing technology.

-

Results from numerical simulations need to be validated to show correlation with actual processes, including mapping of electric field and power-density distributions in microwave processing systems. As described earlier, one of the most important challenges facing the validation procedures is related to the accuracy of temperature measurements in a microwave environment.

-

Accurate knowledge of the thermophysical properties of samples and insulations, including the complex permittivity versus temperature and heat transfer characteristics, is crucial to numerical simulations. The currently available data are inadequate in many cases to perform accurate simulations.

-

Since large computational codes are expensive and require some expertise in computational electromagnetics, empirically simplified models and ''microwave heating diagrams'' should be developed based on measurements and on the extensive data collected from results of numerical simulation to make numerical techniques more accessible to processors.

Dielectric Properties Measurements

Dielectric properties measurement is an important component of the thermophysical characterization of materials. Physical interaction mechanisms between electromagnetic fields and materials can be inferred from the characteristic behavior of the complex permittivity of materials as a function of frequency and temperature. Knowledge of the dielectric properties

FIGURE 3-15 Model used for simulating continuous microwave heating in a traveling-wave-type applicator (Metaxas and Meredith, 1983).

FIGURE 3-16 Electric field distribution in the empty traveling-wave applicator. The calculated standing-wave ratio as a result of the miter bend is 1.6. The standing-wave palm in the feed waveguide is illustrated.

is also important in supporting numerical modeling and calculation of the absorbed power distribution pattern in samples and insulations heated using electromagnetic energy. Even with the availability of advanced simulation and modeling techniques and software that are discussed in the previous section, application of numerical simulations is hampered by incomplete or unreliable characterization of dielectric properties of materials and their variation of dielectric properties with temperature and frequency.

Measurement of complex permittivity over a broad frequency band is required to completely characterize the dielectric properties of materials and to identify and characterize the various relaxation processes. Since several review articles on dielectric property measurement are available (Von Hippel, 1954; Westphal and Sils, 1972; Westphal, 1975, 1977, 1980; Ho, 1988), a detailed description of test methods and evaluation of their accuracy and frequency limitations is not included in this report. Rather, broadband and high-temperature measurement techniques that have been used in conjunction with microwave processing of materials——specifically transmission line, resonant cavity, and free-space methods——will be described. Transmission-line methods are the most common in the microwave band, with coaxial-line methods used in the frequency range from 50 MHz to 10 GHz and waveguide methods used from 10 GHz to 100 GHz. Resonant cavity perturbation methods provide highly accurate measurements, especially for low-loss materials, but are single-frequency measurement techniques. Free-space quasi-optical techniques are usually the most accurate for measurements above 40 GHz. Automated, vector network analyzers have enhanced electromagnetic property testing though simplification, standardization and automation of testing techniques. A network analyzer serves as a generator of electromagnetic energy and a detector of the magnitude and relative phase of the incident, reflected, and transmitted waves (Blackham, 1992).

Transmission-Line Methods

The most popular measurement techniques for characterization of complex permittivity are transmission-line methods. They provide broad band data from a single test, are relatively simple to perform, and do not require large sample sizes. In transmission-line methods, complex scattering parameters (S-parameters) of a precisely machined sample placed in a coaxial line or rectangular waveguide are determined (Weil, 1992). Use of an automated network analyzer simplifies the measurements and the determination of S-parameters. Transmission-line methods are useful in that they show relaxation behavior and transitions in permittivity with changes in frequency for the material being tested. However, there are disadvantages in using these methods. First, precise sample fit is critical, with air gaps causing significant errors. Materials that are brittle or difficult to machine are especially troublesome. Second, elevated temperature measurements using transmission-line methods are very difficult (Tinga, 1992). The entire section of transmission line containing the test specimen must be contained in an oven or furnace. Differences in thermal expansion between the sample holder and the sample under test make it difficult to maintain precise sample fit as the temperature is increased. Also, changes in the electrical properties and dimensions of the transmission lines with increasing temperature must be accounted for to maintain reference calibration (Batt et al., 1992).

The open-ended coaxial-line method for the measurement of complex permittivity has been analyzed in detail by many authors for more than a decade (Stuchly and Stuchly, 1980; Burdette et al., 1980; Athey et al., 1982; Stuchly et al., 1982; Kraszweski et al., 1983; Kraszewski and Stuchly, 1983). The open-ended coaxial probe consists of a truncated section of a coaxial line and an optional extension of a ground plane to improve the contact with the sample under test. The input port of the sensor is connected to the measurement equipment through a coaxial cable. The parameter to be measured is the admittance (or the reflection coefficient) at the interface between sensor and sample. The use of an automatic network analyzer as the measuring instrument significantly simplifies and enhances the accuracy of the measurement procedure.

The design of an open-ended coaxial probe suitable for high-temperature measurement requires the selection of a probe material that has a very low thermal expansion coefficient. A Kovar coaxial-line probe (suitable up to 600 ºC), and a new probe made of metallized (silver) alumina have been utilized (Iskander and DuBow, 1983; Bringhurst et al., 1993). In the low-temperature-probe case, the calibration procedure involves the use of short and open circuits and of deionized water as standards. A modified calibration procedure, which uses short and open circuits and an alumina sample of known properties as standards, was developed to carry out calibration at temperatures as high as 1200 ºC. Otherwise, the measurement procedure and the calculation approach remain the same.

Cavity Perturbation Method

Cavity perturbation methods have been widely used to measure the complex permittivity of materials at microwave frequencies. The basic assumption of this method is that the sample must be very small compared with the cavity itself, so that a frequency shift that is small compared with the resonant frequency of the empty cavity is produced by the insertion of the sample (Altschuler, 1963). The resonant frequency and Q of the cavity are determined and compared with the empty cavity values. Cavity perturbation measurements can be highly accurate and are particularly advantageous in the determination of small loss tangents.

For purposes of measuring dielectric properties at high temperatures (up to 1200 ºC), the experimental setup requires the sample to be held in an adequate sample holder, which is to be heated in a conventional furnace and transferred into the cavity for test. In a typical measurement (Bringhurst et al., 1992), a thin-walled fused silica cylindrical tube was selected as a sample holder because of fused silica's temperature resistance and small variation of its dielectric properties with temperature (including low-loss). During the measurement, the tube is quickly moved from the furnace into the cavity when the desired temperature is reached. Initially, the empty sample holder is calibrated as a function of temperature (both resonance frequency and Q) to establish the "empty cavity" parameters in the perturbation expressions. Since sample and tube cooling rates are rapid after removal from the furnace and insertion into the cavity, special insulation blocks are often placed along the tube path from the furnace to the cavity to minimize cooling effects.

Free-Space Method

Free-space permittivity measurements are useful for accurate measurements at high frequency (above 40 GHz), for elevated temperature measurements, or for composite samples that have structural variations on a relatively large scale compared with sample sizes required for other measurement techniques. For this method, a plate of the sample material is placed between a high-directivity transmitter and receiver horns. When samples with relatively large dimensions are used, collimated, lens-corrected conical horns may be used to generate a near plane-wave beam over the area of interest. When sample sizes are restricted to less than the required dimensions or when spatial resolution is desired to test for sample homogeneity, spot-focusing lens antennas may be used to focus the microwave signal into a small spot on the sample. A schematic of the measurement apparatus is shown in Figure 3-19. Samples are positioned at a given angle in the path of the incident beam, and the transmission and reflection coefficients are measured by two identical receiver horns suitably aligned with respect to the incident beam and the sample. The dielectric properties are then determined from the observed transmission and reflection coefficients (Ho, 1988). Alternatively, if an automatic network analyzer is used in these measurements, either the complex transmission (magnitude and phase) or reflection coefficient may be used to determine the complex permittivity of the material under test. Measurement of the transmission coefficient is often preferred, because it avoids some measurement difficulties involved in the determination of reference planes in the reflection coefficient measurements.

FIGURE 3-19 Free-space method for dielectric properties measurements. The transmitter, receiver, furnace, and standard horn arrangement is typical, while the rest of the measurement equipment may be replaced with a modem automatic network analysis (Ho, 1988).