Appendix C

Potential Breakthroughs in Convenience Foods

Most people have never considered (or perhaps have abandoned) the idea of sorghum, millet, and the other African grains becoming prestigious foods for up-scale mass consumption. Everyone accepts that wheat is sold as bread, pastries, and baked goods; rice comes in all sorts of precooked forms; and maize is routinely available in convenient flour or grits. However, almost no one thinks of sorghum and millets in the same light. These African cereals are relegated to the limbo of foods suited only for personal use in rural regions by individual families who have to prepare their own food from raw grain.

But possible ways to upgrade Africa's own grains are on the horizon, and these deserve thorough investigation and development. Such processing breakthroughs can break the malicious mind-set, diversify the uses, improve the nutritive value, and boost the acceptability among consumers. Their success will create convenient-to-use foods, open vast new markets for Africa's farmers, and improve both rural economies and the balance of payments of many nations. In this particular sense, food technologists hold the key to the future of the lost grains of Africa.

This topic is far too broad to be covered adequately here. (It actually deserves a major international research endeavor.) Nonetheless, a few possible innovations—encountered while compiling this report—are mentioned below, just to provide perspective on some opportunities that are now languishing through lack of initiative.

POPPING

Popping is a simple technique that produces light, attractive, ready-to-eat products. It improves taste and flavor and it yields a crunchy, convenient food. Most people think of it as a process only for maize, and no wonder: popcorn is wildly popular among Americans and

others who know it well. What has hardly been appreciated, however, is that most of Africa's grains also pop. While less spectacular than popcorn, they do expand dramatically and they, too, take on an agreeable toasty flavor. In the future, popped forms of sorghum, pearl millet, finger millet, fonio, and perhaps other grains could find extensive usage.

As has been mentioned previously (pages 43 and 177), people in India already pop sorghum and finger millet on a large, and sometimes commercial, scale. They often mix together milk, brown sugar (jaggery), and popped finger millet to create a very pleasant dessert. Popped finger millet is also used in brewing.

For finger millet, as well as for Africa's other cereals, popping seems to offer many benefits. It is a promising way to increase the grain size, create ready-to-eat foods, and add flavor to what are often bland dishes. Something similar is happening in the United States with amaranth. This former staple of the Aztecs and Incas is making a comeback, largely as a popped snack food. Recently, a continuous popper designed to handle amaranth's extremely small seeds was patented.1 Such a device may well be the key to commercially popping Africa's small-grain cereals as well.

Once the popped grains are available, many new foods are likely to be created. Indian food scientists have blended popped finger millet with legumes such as puffed chick pea or toasted green gram to form nutritious and very tasty new foods.2 In Africa, something similar might be done using legumes such as peanut, cowpea, or bambara groundnut.

PUFFING

The process of puffing, a variant on popping, was discovered almost a century ago. Since then, cereals made from puffed rice and puffed wheat have been breakfast staples worldwide. Puffed oats and maize are now also produced.

In the puffing process the grain is placed in a sealed chamber and heated until the pressure rises. Then the chamber, or puffing ''gun," is suddenly opened. Relieved of the pressure, the water vapor expands, blowing up the grains to many times their original size (for wheat, 8-16 times; for rice, 6-8 times). Finally, they are toasted and dried until crisp.

Puffing has probably never been attempted with African rice, fonio, tef, or the other African grains, but it is another possible way to

boost the size of these small grains, add flavor, and produce quality convenience foods with high consumer demand.

MALTING

Germination also upgrades the quality and taste of cereals. The sprouting process, known as malting, releases amylase enzymes that break starches down into more digestible forms including sugars. The result is to liquefy, sweeten, and raise the nutritional value.

Malting is particularly good for children because they can better assimilate the partially digested nutrients.3 During World War II, government authorities in Great Britain (to mention just one country) seized on malting as a way to prevent childhood malnutrition brought on by wartime food shortages. Malt extract was produced in large amounts and distributed for daily use by children. This thick, dark, pasty material may have looked awful, but children loved its sweet and pleasant taste. It is in fact still sold in parts of the world, not so much as a nutritional supplement but as an everyday food that people buy for its flavor. It is also the key flavoring ingredient in famous foods such as malted milk and Ovaltine®.

Why malting is not more widely used in these days of mass malnutrition is a puzzlement. Perhaps the process is so associated with barley that the two have become almost synonymous, and, because barley will not grow where malnutrition mostly occurs, it is never considered. What has been overlooked, however, is that finger millet and some sorghums are almost as good at malting as barley. Their amylase activity is also high. And they will grow where the malnutrition is rife.

It is perhaps the ultimate irony that malting is practiced every day in many African homes, but the fact that malted grains make fine foods is overlooked.4 Finger millet malt, for example, is great tasting, easily digested, rich in both calcium and sulfur-containing amino acids, and an ideal base for foods for everyone, from the very young to the very old.5 But most of what is made these days is used in fermentations that produce beer (see box, page 168).

|

3 |

For more on this topic, see Appendix D. where the use of malts in preparing weaning foods is discussed. |

|

4 |

Villagers are not the only ones who misunderstand malting. Missionaries in more than one country have preached against it in the mistaken belief that malted foods are alcoholic. |

|

5 |

Malleshi and Desikachar, 1986a. |

FERMENTING

Lactic acid fermentations are used worldwide to produce foods such as sour cream, yogurt, sauerkraut, kimchee, soy sauce, and pickled vegetables of all kinds. Except for making sourdough bread, it is so far not used widely to "sour" cereal products. But in Africa it is traditionally used to flavor and preserve porridges and to produce popular foods such as bogobe (sour sorghum porridge) in Botswana, nasha (sour sorghum and millet porridge) in the Sudan, and obusera (sour millet porridge) in Uganda. People in many parts of the continent prefer the sharp flavor of these fermented porridges.6

Despite its almost complete neglect by cereal science, acid fermentation is yet another process for upgrading a grain's taste and nutritive value. For the food supply of Africa, it is particularly promising. The lactic acid fermentation process is well known. It is generally inexpensive and requires little or no heating, making it fuel efficient. It yields highly acceptable and diversified flavors. And it usually improves nutritive value.

It is commonly used in households (at least throughout eastern and southern Africa) and remains one of the most practical ways to preserve food for hundreds of millions of hungry people who cannot obtain or afford canned or frozen foods.

Lactic acid fermentations make foods resistant to spoilage, thereby performing an essential role in preserving wholesomeness. The bacteria rapidly acidify the food to a pH so low that dangerous organisms are no longer able to grow. They also produce hydrogen peroxide, which kills organisms that cause food spoilage (the lactobacilli themselves are relatively resistant to hydrogen peroxide). Certain lactic bacteria (notably, Streptococcus lactis) produce the antibiotic nisin, active against gram-positive organisms. Others produce carbon dioxide, which also helps preserve foods, notably by displacing oxygen (if the substrate is properly protected).

The course of the fermentation can be controlled by adding salt. Salting limits the amount of pectinolytic and proteolytic hydrolysis that occurs, thereby controlling softening (as well as preventing putrefaction).

Although fermented porridges were once extremely popular in rural Africa and are still widely consumed, their popularity appears to be declining. Some consumers are turning to alien alternatives that are widely advertised, such as tea or carbonated drinks. In many districts, farmers (as we have noted earlier) are giving up sorghum and millet and are growing maize. And in others, people are said "to lack the will and the interest" to prepare traditional fermented porridges.

|

6 |

The use of such fermentations to make baby food is discussed in Appendix D. |

But for all that, fermentations have a future and deserve recognition and attention. For one thing, they are very promising for creating weaning foods that may overcome mass malnutrition (see next appendix). For another, lactic acid fermentations are promising as commercial methods of processing and preserving food as well as for creating business enterprises.

PRECOOKING

To help meet the demands of an ever hungrier Africa (not to mention the world), the partial cooking of grains looks particularly promising. When dropped into boiling water, most (perhaps all) of the grains described in the earlier chapters soften within 5 or 10 minutes. The hot water partially gelatinizes the starch so that the dough sticks together and can be rolled into sheets or squeezed into noodles.

Some food technologists have already begun applying such processes to sorghum and pearl millet.7 In the future, precooking might be applied to most of Africa's native cereals to produce top-quality, ready-to-cook foods that are stable, more nutritious, and easy to store.

Below we highlight three techniques—parboiling, flaking, and extruding.

Parboiling8

Parboiling is basically the process of partially cooking grain while it is still in the husk (that is, before any milling). The raw grain is briefly boiled or steamed. (Generally, it is merely soaked in water, drained, and then heated.) Only after the resulting product is dried is it dehusked and decorticated.

What results is very different from the normal milled grain. Sorghum kernels, for instance, come out looking like rice: light-colored, translucent, firm, and intact—attractive in both appearance and aroma and much less sticky than normal. Of course, they still must be cooked to become edible.

Parboiling not only gelatinizes the starch in the grains, it also does the following:

-

Makes the milling process more efficient. (In a recent trial

-

with soft-kernel sorghum, parboiling more than doubled the yield of decorticated grain.)

-

Inactivates enzymes and thereby greatly extends shelf life. (It even improves the storability of pearl-millet flour, a material notorious for turning smelly during storage.)

-

Kills insects and their eggs so that it reduces storage losses.

-

Improves the grain's cooking characteristics. (Boiling parboiled sorghum, for instance, doesn't produce mush; instead, the kernels remain separate, whole, and very much like pilaf or rice.)

-

Improves nutritional values. (This is notably because it helps retain water-soluble constituents—such as the B vitamins and certain minerals—that otherwise are thrown out with the cooking water.)

-

Upgrades certain grains that have poor processing characteristics (the soft endosperm in finger millet, for example).

Given its now widespread use in the rice industry, parboiling is a surprisingly recent newcomer to commerce. Until the 1930s, it was hardly known outside South Asia where it was a village technology employed by poor people in their cottages. In the last 60 years, however, parboiled rice has rocketed into extensive worldwide use, and parboiling is now done on a giant commercial scale in countries such as the United States.

Parboiling is still good for village-level use, however. For example, field trials in Mali, using local sorghum and pearl millet, showed that it was practical, satisfactory, and boosted the yields from milling. Malian families tested the parboiled grains in local dishes and condiments (such as peanut sauce) and rated them very acceptable.9

At first sight, the extra energy and effort needed to parboil grains would seem to be a major disadvantage. However, the increases in yield and quality provide both the processor and consumer with substantial benefits.10 Rice is already parboiled in the villages of some parts of Mali (not to mention half of India), which certainly suggests that the product is good enough so that people will find the fuel and put in the extra effort to prepare it.

Flaking

In this process, decorticated (pearled) grains are soaked, heated, partially dried (to about 18 percent moisture), pressed between rollers,

|

The Power of Processed Foods Despite the reliance on sorghum and millet in some countries, and despite consumer preference for flour made from them, the industrial production and commercialization of local flour has barely been established in Africa. Sorghum and millet flours are still mainly produced by each individual household. On the other hand, the introduced grains—wheat, rice, and maize—are more commonly milled at commercial facilities. This makes the foreign grains look superior and it holds back the local cereals. And the situation is worsening. Soon, the rural labor force could be insufficient. Thus, even if production is increased there won't be the people to process it. For example, in most regions it is the young women who process most of the grain, but increasingly they are going to school, getting jobs, or abandoning the countryside to seek opportunity in the cities. In a sense, then, it is imperative to find and develop good profitable uses for millet, sorghum, and the others. And the time is ripe. With increasing urbanization and rising disposable incomes, the demand for preprocessed and convenience foods is accelerating. This is one reason why commercially milled wheat and maize flour are increasingly preferred. Sorghum and millet are much cheaper, but they are unprocessed and therefore less convenient to use. As a result, markets for locally grown sorghum and millet are diminishing, incentives for local production are deteriorating, and foreign exchange reserves are dwindling to meet ever-rising demands for preprocessed flours.* In dry regions, processing facilities are particularly vital to the future of local cereal farming. There, sorghum and millet are essential for a viable agricultural community. Both crops are so drought tolerant they can grow where other cereals cannot. When imported flour crushes the demand for them, the farmers are left with no outlet for their grain in years of good rainfall when they have a surplus. And when market prices fall, farmers cannot afford the inputs, such as fertilizer, that can keep their yields up. If, as has been noted, markets for local flour and processed foods are developed, a large and healthy trade between a country's own sorghum, millet, and fonio farmers and its cities could operate to everyone's benefit. Success with processing would likely transform Africa's native cereals into big-time, high-value worldwide foods. |

and, finally, completely dried into flakes.11 The resulting product is a convenience food of many potential uses. The flakes store well and hydrate quickly when dropped into warm water or milk. They can be used in many types of sweet or savory dishes. When deep fried, they burst into light and crispy products.

African grains are particularly suitable for flaking because they are small and soak up water quickly. But although the process is simple, it is seldom used today. The holdup seems to be purely technological: grain-flaking machines are large, expensive, and inappropriate for Third World use. Now, however, a simple, inexpensive machine capable of flaking cereals in villages has been developed in India.12 A unit has been installed in a village near Bhopal, and the people took to it and were able to operate it without supervision.

This type of invention could open up a new world for sorghum, millet, fonio, and other grains. More than 30 years ago, South African researchers mixed sorghum flour with water, then passed the slurry through a hot roller that both cooked and dried it. The resulting ready-to-eat flour proved very palatable and would keep for at least 3 months without deteriorating. Whole milk or skim milk (used in place of the water) produced a similar flour that was not only tasty but rich in protein, calcium, and phosphorus. Processing costs were reportedly low.13

Extruding

Extruding is a variant of the flaking process. The moistened and half-cooked grains are squeezed out through small holes. It is how noodles and pastas of all kinds are prepared. It, too, improves water absorption and cooking quality. Noodlelike products can probably be made from all the grains highlighted in this report. The pearled grains are first soaked for a day or two, then drained, mashed, cooked, extruded, and dried.

Noodles prepared from blends of finger millet and legume flours are already being used in India to form nutritionally balanced foods that can be used as supplementary foods for malnourished children.14 When deep fried, they make excellent crispy products—said to equal those

|

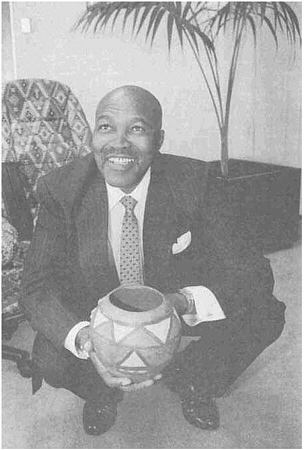

Success Brewing in South Africa* Mohale Mahanyele's story exemplifies the immense business opportunities to be found in commercializing the traditional foods made from African grains. In the late 1980s South Africa's government set out to privatize the sorghum-beer industry. For at least 20 years, sales had been dropping, as workers migrated to the cities and left the rural villages where the low-alcohol, high-protein drink is embedded in the culture. The government hired a management consultant, Mohale Mahanyele, to advise it on how to get rid of the business. His task seemed like a thankless one; the sales decline seemed inexorable. One analyst said the authorities were merely unloading "an old Third World product doomed to die." Mahanyele did not agree. "There were a lot of leaders in the African community who thought we were being set up to fail," he says. "But I thought differently. Here was a drink that had always been associated with our festive occasions, and it had been taken away from us and tainted. It was humiliating, degrading. I wanted to restore the dignity of sorghum." Armed with that vision, Mahanyele himself set out to buy the business from the government-run monopoly in 1990. It seemed like a foolish notion. He had to raise $20 million to purchase the corporation and its 21 factories, but he had no access to white capital. So he did something never before attempted in his country: he sold shares to fellow Africans, building on the centuries-old custom of stokvels— small, informal savings societies—in traditional communities. National Sorghum Breweries ended up with 10,000 shareholders, more than 90 percent of whom are black—a novel arrangement in a country where few blacks own the roof over their heads. But Mahanyale's problems were far from over. In addition to the dropping sales, he had to overcome sorghum beer's political stigma, created during the 80 years when the white-minority government ran the business. To his own people, "Kaffir beer,'' as it was known, had become a symbol of white oppression. But Mahanyele succeeded. Today, National Sorghum Breweries is by far South Africa's most successful black-owned business. It has nearly doubled its volume in the past three years, while |

|

paying annual dividends of 20 percent or better. "We understand the product," he says. "We have a color fit and a culture fit with our customers." Through the development of the sorghum-brewing business, Mohale Mahanyele has become South Africa's foremost apostle of black economic empowerment. The company's board and management team, once all white, is now nearly all black. Most of its contractors are black, including 500,000 small businessmen who distribute the beer to stores throughout the country. It employs a quarter of South Africa's black accountants, and is putting more than 100 of its executives through an MBA program that it runs on the premises. Today, National Sorghum Breweries is beginning to diversify into other products—food, soft drinks, computers and, most daunting of all, conventional beer, a market in which a giant white-owned brewery currently has a 98-percent share. Can more success be far behind? Sorghum beer has a rather thick consistency with a refreshing acid flavor; the alcohol content is only 3-4 percent by volume, but large amounts are apt to be consumed on festive occasions. Women have brewed it in Africa's villages for centuries (see page 168). No one has ever written a definitive work on African beers and their nutritional or social roles. This could be a major project for African scholars. These beers are more important than most people realize. A special quality is their safety. Because they are highly acidic (ranging between 3 and 4 on the pH level), they are free of bacterial contamination. So far, however, science has shied away from investigating such beers. Anthropologists and nutritionists refer to them, but that is about all. This is surprising because sorghum beers are an important part of life throughout most of Africa below the Sahara. |

prepared from rice. Noodles from finger millet and other African grains could probably be economically produced in small-scale industries, as the equipment needed is not overly complicated and the capital investment is modest.

LEAVENING LOAVES

Raised bread has become what is perhaps the world's premier food. Wherever it is introduced people eagerly adopt it and clamor for more. Unfortunately, however, leavened breads can be made only from wheat or rye, neither of which grows well in the tropical zone where the neediest people are concentrated.15

For at least 30 years scientists worldwide have searched for ways to make raised bread without using wheat and rye. Such work could have profound implications for Africa (see box, page 310) but, despite the theoretical promise, nowhere has there been much practical success so far. Local staples tend to make unattractive, short-lasting, poor-rising breads that the public shuns. Dough strengtheners and other modifiers (such as emulsifiers, pentosans, xanthan gum, and wheat gluten) can be added. They make acceptable breads, but usually they must be imported and are expensive.

Now, however, there is a possibility of a breakthrough: research has shown that it is possible to prepare loose-structured bread from local grains using a swelling and binding agent. Different types have been tested. Dried pregelatinized cereal or tuber starches have shown some success. Glyceryl monostearate is said to be effective. Locust bean gum, egg white, and lard are also fairly good. These compounds act to bind the starch granules together, making it possible for the dough to hold carbon dioxide gas and thereby to rise. Baked products obtained this way have greater volume, softer crumb, and a more regular texture.

FAO Bread

Although none of the techniques has yet yielded light, high breads like those from wheat, there has been partial success. Perhaps the most advanced is a project operated by the Food and Agricultural Organization of the United Nations (FAO). The FAO method involves

|

Avoiding the Wheat Trap Researchers in several southern African nations have banded together to produce a white sorghum that can be locally grown to make flour for bread and mealies (cornmeal). They seem to be already on the verge of success. If so, they will have developed the first truly African bread grain. The following is a recent announcement from PANOS, an international organization that specializes in disseminating Third World news. Fifty scientists from Angola, Botswana, Lesotho, Malawi, Mozambique, Namibia, Swaziland, Tanzania, Zambia, and Zimbabwe, the 10 countries grouped in the Southern African Development Coordination Conference (SADCC), are now being trained to breed and produce sorghum hybrids. Soon, that number of trainees is expected to double. Why all the excitement? To help reduce the region's dependence on imported wheat, researchers in Zimbabwe have developed hybrid strains of sorghum and millet that are designed for use in making flour and bread. The work at the Matopos Research Station near Bulawayo forms part of a drive to reduce food shortages in the SADCC countries. For most people in the region maize is the staple, but the crop does not grow well in the drier areas. Researchers are trying to develop substitutes that can be grown there and mixed with wheat for bread or maize for mealies. Any surplus could be sold to make high-quality malt. In farm tests, the new hybrids have produced bigger yields than existing varieties. The researchers expect to have white-grained hybrid sorghum for milling very soon. It is hoped that the white sorghum will satisfy a popular preference for white maize meal. A local milling company is already working with a nongovernmental organization called Enda-Zimbabwe to set up pilot mills in rural areas to grind the hybrid grains for bread. Before people in areas of low rainfall can be persuaded to abandon their often futile efforts to grow maize, good varieties of the new hybrids must be available in large quantities of the seed. |

boiling part of the flour from a local cereal (or root) until it thickens into a gel strong enough to hold the gas released during breadmaking. When added to local flour, yeast, sugar, and salt, this starchy substitute for gluten produces a puffy bread of acceptable texture, taste, and color.

Reportedly, this new technology is simple, inexpensive, and uses nothing but local ingredients. It can, for example, produce leavened loaves using sorghum, millets, and other African grains.

Leavening with Fungus

Recently, food scientists in India have found that fermenting a mixture of grain and pulse (legume seed) can produce a gum thick enough to act like gluten. This special process, locally known as idli or dosai fermentation, involves the microorganisms Leuonostoc mesenteroides, which is used in other parts of the world for producing dextran gums from sucrose. Using this fermentation, a mixture of rice and dahl (made with black gram or other legume) can be turned into a dough that will produce breadlike products without employing any gluten. Either the legume, the microorganisms, or the combination produces a gum that holds the carbon dioxide gas, thereby leavening the products. It is a fermentation that enables raised breads to be

|

The Wheat Trap Africa is finding itself more and more caught up in what is being termed the "wheat trap." During the past 20 or 30 years, certain governments as well as private companies have responded to consumer demand by establishing wheat mills. As a result, various countries now spend large amounts of foreign exchange importing wheat to feed those mills. The bulk of the flour produced is used to make bread for the working population, as well as for the small expatriate population living in the towns and cities. Bread is a convenient food because it is ready to eat, easily carried around, and not messy like porridges and gruels. Its taste is highly acceptable, it gives a feeling of bulk and fullness, and it is relatively cheap. With large numbers of people migrating from rural areas to the cities, the demand for bread has increased. However, the population is being fed on food the country does not grow, with scarce foreign exchange being used to import wheat to produce flour. More foreign exchange is also spent on spare parts and foreign managers to maintain and run the flour mills. The process not only damages the economy but the indigenous African cereals as well. They are being left in a state of underdevelopment and inadequate processing. J. Maud Kordylas |

made without any wheat or rye.16 Perhaps other fermentations or other substrates for this fermentation to do this job can also be found.

Biotechnology

With all the advances in biotechnology these days, it seems likely that the genes that cause gluten to form in wheat will soon be isolated. Inserting them into the chromosomes of Africa's native grains could bring profound changes. Suddenly, sorghum or pearl millet would (at least in theory) produce bread that rises without any extra help. This is not a far-fetched idea. Indeed, it will be surprising if it does not come about within the next decade or two.