Appendix E: An Intelligent Knowledge System for Selection of Materials for Critical Aerospace Applications1

INTRODUCTION

A key requirement for the successful implementation of the unified life-cycle engineering concept for aerospace structures design is the availability of a well-developed intelligent knowledge system for the selection of materials for specific components (Burte and Harmsworth, 1989). There are two reasons for this: (1) the increasing complexity of the requirements for material performance for any components and (2) the wide range of candidate materials, particularly the newer and more-sophisticated, advance materials classes. There are two additional complicating aspects to this part of the problem. First, the newer, high-performance polymers, ceramics, and composites are difficult to identify and compare because of the lack of standard nomenclatures and test procedures. Second, data are becoming available so rapidly on so many materials that the task of keeping a database current is enormous.

A computerized diagnostic program to ensure that all of the important properties and characteristics of all logical candidate materials are considered and that they are analyzed with appropriate priorities would be of great value for reliable material selection. A study demonstrated the technical and economic feasibility of developing a computerized intelligent knowledge system for materials specialists and designers (IKSMAT) in the screening and selection of a wide range of materials for critical aerospace applications (Kaufman, 1988). Further it has been demonstrated that the IKSMAT has the potential to provide great flexibility in query, search, and analysis options, to be very easy for engineers and scientists to use, and to be easily and economically expanded to include many additional applications.

The program described below covered the production of a prototype IKSMAT that provided material-search capabilities for a wide variety of aircraft components.

VISION OF THE SYSTEM

The goal of the program was to develop and build a prototype version of IKSMAT. It was to provide vital guidance in the selection of alloys to meet sophisticated design requirements for spar applications and also form the basis of a system that could be expanded to encompass a broad range of materials (e.g., polymers, ceramics, and composites), components (e.g., engines and empennage), and applications (e.g., helicopters and missiles). The various elements undertaken were

-

knowledge base development, data qualification, and interface refinement for the following aerospace components: wingspar, bulkhead, upper wingskin, lower wingskin, fuselage, landing gear, and pivot/swivel fitting;

-

programming the system logic, query rules, and response options;

-

system design and assembly; and

-

establishment of a master database based primarily on MIL-HDBK-5F (DOD, 1986).

TECHNOLOGIES INCLUDED IN THE SYSTEM

Conceptual Model of an Intelligent-Knowledge-System

One generalized model of an IKSMAT applicable to the material selection problem defined above is illustrated in Figure E-1 (Kaufman, 1988). In this model, the knowledge base is the catalog of design and performance criteria for specific structures and the relative importance of the individual criteria in the performance of those structures, which interfaces with the material properties database covering the range of materials and properties of interest. This knowledge base is interfaced with programs permitting users to compile (knowledge acquisition) and utilize (inference engine) knowledge and data to solve problems. The system may be used independently to aid

Figure E-1 Model of an IKSMAT applicable to the material selection problem.

in the tracking and selection of materials for specific applications or interfaced directly with the early stages of the design process to illustrate the impact of the utilization of advanced materials on component/vehicle performance.

It is important to note that while the knowledge base itself is the foundation of the system, it is essential to have a well-developed database of reliable, well-documented information on which the inference engine can operate. No matter how sophisticated the logic incorporated into the system, it has little value unless users can have a high-level of confidence in the completeness and quality of the underlying knowledge base (Ambler, 1985; Kaufman, 1986a, Reynard, 1987).

IKSMAT Architecture and Operating Capabilities

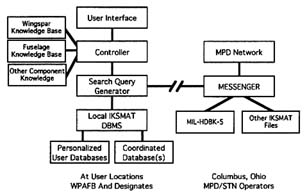

The specific system architecture required for the prototype is illustrated in Figure E-2. It is composed of two groups of components, one in the user's facility and the other in a ''master database facility." The user interface, controller, and supporting database and knowledge bases are maintained with their own database management system at the user's site. The "master" database facility contains the evaluated data prescribed by materials specialists from the Air Force and aerospace industry through activities such as the MIL-HDBK-5 Coordination Committee and maintained in MIL-HDBK-5 itself (DOD, 1986). It also contains other "external" sources of data, such as those made accessible by the National Materials Property Data Network and the Scientific and Technical Information Network (Kaufman, 1986b).

The user interface handles interactions with the user and provides the display screen control. The controller, the inference engine in the conceptual model discussed above, carries out the expert system functions, most of which will be broadly applicable to other components and other applications. The rules for material selection and design of specific components constitute the knowledge base in this model; extension of the system to handle additional components and applications involves adding to the logic in this knowledge base. Based on information in the knowledge base, the controller passes information to the user interface to determine what actions are required and then interprets the user input to generate queries in the search query generator.

The local database management system deals with the information in "temporary" data files supplied by the user in a manner completely compatible with the permanent databases, and the responses to the user are completely transparent in this respect (i.e., the user will not see the operation as two separate systems interacting), yet the integrity of the permanent databases is maintained. Two user files are kept: the personal database contains user-specific information and while the update database contains data agreed on by the entire user group as "pre-standard."

As noted above, the permanent databases containing evaluated data, such as those based on MIL-HDBK-5, and the principal search software would reside at a remote

Figure E-2 Specific system architecture for the prototype IKSMAT.

The system operates by applying rules based on application or component in the comparison and ranking of individual materials in prescribed sequences, gradually eliminating candidate materials based on their inability to meet stated criteria and the presentation in priority order of surviving candidates. The system must be flexible and dynamic in the sense that new material options may be incorporated at any time and the rules may be altered as necessary to reflect changing vehicular or structural performance requirements.

To be more specific, user approaches to IKSMAT must be of several general types of varying sophistication, including but not necessarily limited to the following:

-

user works within existing database and predefined material selection/design criteria and logic to identify optimum candidate materials for specific application;

-

user adds new materials to database and then performs analyses based on preset material selection/design criteria and logic to select optimum candidate materials;

-

user adds new properties for materials in the knowledge base and then performs analyses based on existing or new criteria involving those new properties to identify candidate materials;

-

user redefines priorities associated with existing properties and criteria for material selection and performs new analyses to determine the effect of the changes on the preferred candidate materials;

-

user inputs new criteria (specific properties or design-related parameters) and defines their priorities and then carries out analyses to determine candidate materials; or

-

user conducts general unstructured search with self-generated queries based on material, property, and parameter criteria.

Functionally, there are several additional features beyond those within the internal IKSMAT logic base and knowledge base that are considered important to a valuable materials information retrieval and analysis system. These are

-

ease of understanding for the occasional user who is not an information professional trained in the language and command structure of traditional on-line search systems like Dialogue;

-

flexibility with regard to the use of materials nomenclature and property terminology, permitting the user to use any technically correct names or terms (aliases) and still be able to locate the desired information; in addition, the user should have the ability to easily query the system about the meanings of the terms or abbreviations encountered in the process of searching; and

-

easy access to many other sources of materials property data, beyond those upon which the programmed materials selection process is based, so that newly generated corroborative or contrasting data may be located, retrieved, and analyzed quickly and efficiently.

The materials to be included in the prototype IKSMAT will include all steels, aluminum alloys, magnesium alloys, and high-temperature alloys included in MIL-HDBK-5. Among the set of candidate criteria for searching for aerospace materials are the following:

-

critical crack size index—square of ratio of plane strain fracture toughness to yield strength, an index of the critical crack size at the yield strength;

-

stress-corrosion cracking susceptibility—ratio of maximum tensile stress for resistance to tensile yield strength (as an alternative, the ratio of stress intensity threshold for stress-corrosion cracking to plane strain fracture toughness might be used);

-

stiffness efficiency—ratio of modulus of elasticity to density;

-

tensile or yield strength efficiency—ratio of ultimate tensile or tensile yield strength to density;

-

fatigue crack initiation resistance—fatigue strength at one million cycles of life, with stress ratio,

R= 0.0, with smooth (Kt =1.0) and notched (Kt =3.0) specimens;

-

rate of fatigue crack propagation—fatigue crack growth rate at an applied stress intensity (R= 0.0) of 10 ksi*in**0.5 (preferably based on spectrum loading, but no consistent standard exists); and

-

fabricability/cost index including factors such as initial cost per pound; special fabrication requirements like finishing or joining; or multiple sources (materials with high production costs or time lines would have low index numbers).

STATUS OF DEVELOPMENT AND BARRIERS TO IMPLEMENTATION

Knowledge Base/Database Content Development

The content of the knowledge base was established based on the information obtained from synthesis of the guidelines provided by several aerospace designers and finalized in discussions with General Dynamics, Fort Worth. While it was difficult to establish a consensus design approach, once the approach was present it was not difficult to build the associated rules to parallel the analytical process and map the related series of decision criteria.

Compilation of the content data needed for the master database proved to be a much more difficult task than anticipated because of the paucity of reliable, statistically meaningful property data available for any but the simplest of MIL-HDBK-5 design data. For example, even within MIL-HDBK-5, notably in the areas of fatigue, fracture toughness, and stress corrosion (key elements to critical aircraft design), there are very few consistent and statistically based data. This need could also not be satisfied from other sources; most are far less reliable than MIL-HDBK-5 insofar as quality and consistency of data are concerned.

IKSMAT Design

The overall IKSMAT design was satisfactorily completed. The knowledge base and controller designs were practical, and rule implementation was completed, including a strategy for programming ranking logic.

Programming

Programming of the IKSMAT was completed to the point where full-scale interactions with the master IKSMAT database assembled could be tested. Menu interface and presentation formats were also programmed, all to be operational within the National Materials Property Data Network and the Scientific and Technical Information Network, International, MESSENGER mainframe software.

Electronic Data Acquisition and Loading

This, like locating the original data, proved to be one of the most difficult and expensive tasks. Only a partially complete version of MIL-HDBK-5 could be created because of the complexity and variability of data and data formats, even within MIL-HDBK-5. In addition, developing machine-readable updates to MIL-HDBK-5 in a protocol needed to match the master database host in the MESSENGER language on Scientific and Technical Information Network, International, was necessary roughly every six months and proved so expensive as to be prohibitive, because the handbook was at the time produced as a hard-copy product, and the machine-readable updates were generated after the fact. Development of a machine-readable master version of MIL-HDBK-5 will solve this problem.

METHODS TO OVERCOMING BARRIERS

The barriers identified above prevented the production of a wholly satisfactory prototype IKSMAT and precluded any plans to commercialize IKSMAT at that time. The process demonstrated that while it may be possible to conceive, design, and create technically capable and logical artificial intelligence systems for concurrent engineering, the system may be of very limited value because of (1) the limitations of the available data, both in quantity and quality, and (2) the high cost of placing numeric data in useful machine-readable formats for the extensive manipulation needed in such systems.

The actions needed to eliminate these barriers include:

-

placement of much more emphasis by government and industry in building reliable, statistically meaningful material property databases that may serve as the foundation of intelligent materials selection and design software;

-

maintenance of master versions of materials databases in machine-readable form, readily updatable and readily duplicated and distributed for broad use; and

-

utilization of flexible software systems capable of rapid manipulation and varied presentation (e.g., graphical analysis and presentation of complex numeric data complemented with engineering-oriented, intuitive menu-driven interfaces).