APPENDIX F

TRANSMUTATION CONCEPTS

ADVANCED LIQUID-METAL REACTOR

Introduction

Liquid-metal reactor technology has been under development for over 40 years in the United States and several other nations. Its principal potential application would be as an advanced nuclear power reactor, capable of breeding new fuel from natural or depleted uranium. It has generally been assumed that the advanced liquid metal reactor (ALMR) will be needed in some future era when low-cost resources of uranium are depleted, so a breeder could avoid the rising fuel costs of light-water reactors. Although natural uranium is abundant and readily available on the world market, some nations, such as France, the United Kingdom, and Japan, have stated their intent to develop breeders to reduce their dependence on imports of natural uranium.

Although some of the early fast-spectrum reactors ran into serious problems, the more recent experience in the United States presents a very positive picture of fast-reactor technology. The performance of the EBR-II, in operation regularly since the early 1960s, and the 400 MWt (megawatt thermal) Fast Flux Test Facility, commissioned in 1979, have demonstrated that a medium-size liquid-metal-cooled fast reactor can be highly reliable.

The fast spectrum that makes an ALMR an efficient producer of fissile plutonium can also be used to transmute plutonium and minor actinides as an aid to waste disposal. Studies of fast reactors for transmutation were carried out in the late 1970s and early 1980s. In the late 1980s, the Department of Energy (DOE) project to develop the ALMR as an advanced power reactor focused also on applying the ALMR as a transuranic burner. France and Japan have shown similar interest. In the United States, this work has been conducted by the Argonne National Laboratory (ANL) and General Electric (GE), under DOE funding. For this application, core configurations that would operate at breeding ratios varying from 1.25 to 0.22 have been studied.1 The reactor technology for transuranic transmutation is similar to, but more demanding than, that for the more familiar breeder application. Consequently, there is a large body of experience to aid the development of the ALMR as a burner of transuranic waste.

In this section, the ALMR work of ANL and GE is summarized, including the ANL proposal for an integral fast reactor (IFR), an ALMR with integrated fuel reprocessing, for power generation and waste transmutation.

Reference ALMR Designs

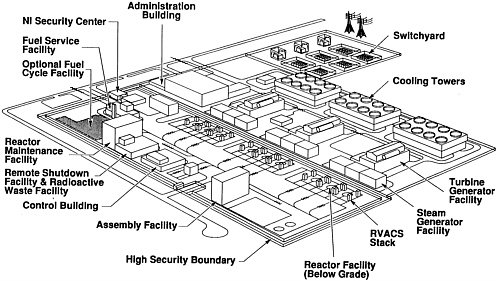

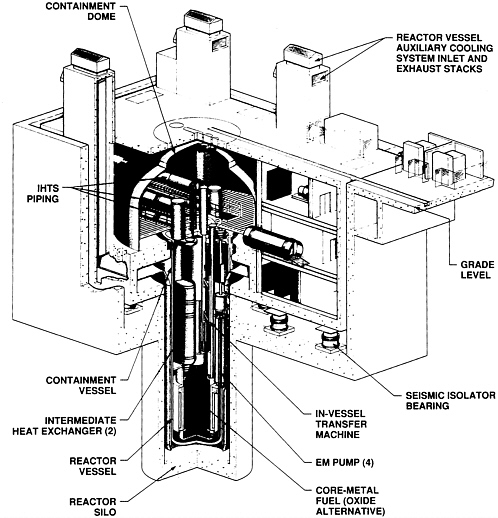

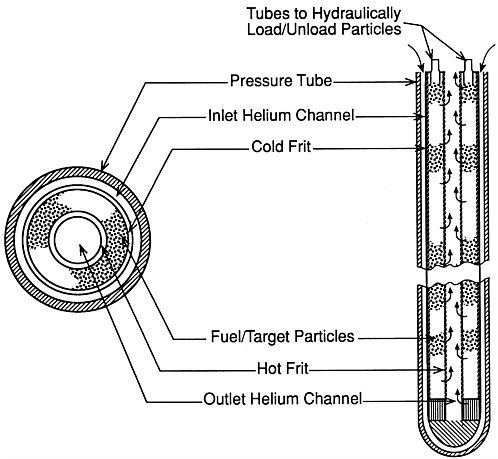

GE has the responsibility for reactor design for the ALMR project. GE's power reactor, innovative, small module (PRISM) concept is a modular ALMR generating 1,395 MWe (megawatts electric), comprising nine reactor modules arranged in three power blocks of 465 MWe each. As shown in Figure F-1, each power block in turn comprises three compact, sodium-cooled, pool-type fast reactor modules of 471 MWt with its own steam generator that is heated by secondary sodium piped from the intermediate heat exchangers in the reactor module. The design goals emphasize passive shutdown heat removal for loss-of-cooling accidents and passive reactivity reduction to a safe, stable state for undercooling or overpower events with failure-to-scram. The current PRISM-type ALMR uses a metal-alloy fuel that is being developed concurrently by ANL.

An ALMR can be designed as a breeder, such that the rate of production of new fissile material (plutonium and other transuranics) by neutron absorption in uranium equals or exceeds the rate of destruction of fissile material by fission and neutron capture. Such a breeder could be started in one of four ways: (1) with transuranic elements (TRUs) recovered from reprocessing spent light-water reactor (LWR) fuel, (2) with 25-35% enriched uranium, (3) with surplus military plutonium made available from the disarmament program, or (4) with excess plutonium produced by breeders of earlier generations. By reducing the amount of neutron absorption in uranium in the core and blankets, an ALMR can be designed to operate at a breeding ratio less than unity. This would require a continuous make-up of TRUs (e.g., from spent LWR fuel) as well as the start-up inventory, thereby increasing the mass rate of consumption of TRUs recovered from spent LWR fuel.

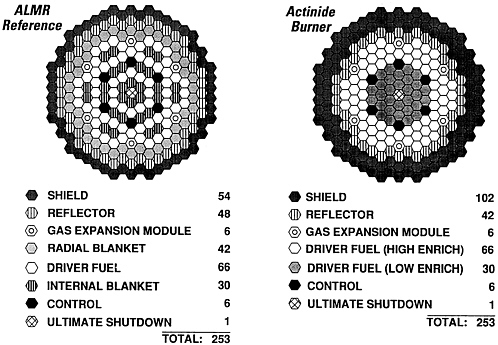

Two core configurations for the PRISM-breeder application and proposed TRU burner are shown in Figure F-2. The ''actinide burner" core contains no radial and internal blanket assemblies to reduce the generation of new 239Pu by neutron absorption in 238U, resulting in a lower breeding ratio. The amount of TRU start-up inventory required depends somewhat on the breeding ratio at which an ALMR is operating. For a 1.4 GWe PRISM-type ALMR, the TRUs for a start-up core plus two reloads ranges from 27.2 Mg for a breeding ratio of 1.11 to about 14.6 Mg for a breeding ratio of 0.65.

ALMR designs with a wide variation of breeding ratios, over the range of 1.25 to 0.22, have been considered as part of the overall ALMR design study. Variations (Thompson et al., 1991) of the reference ALMR breeder design involve elimination of external blankets containing fertile material to reduce the conversion of uranium to TRUs. To increase neutron leakage, and thereby to reduce fissile breeding in the core, these burner designs require shortening the core height, with minor adjustment in fuel composition but without changes in fuel-rod diameter or in the number of fuel rods. This approach to enhance TRU depletion is based on the key constraint that the diameter of the reactor vessel remain constant, and it is obviously limited by

the maximum allowable power density or by the linear heat generation rate of the fuel rods, so that safety characteristics are not compromised.

With reduced fissile breeding and reduced heavy metal inventory, the burner designs also result in increased reactivity swing over a fuel cycle. This then requires larger control rod worths and hence entails potentially larger positive reactivity insertions and degraded performance in transient overpower events. As the breeding ratio decreases, there is less reactivity insertion resulting from sodium voiding in a power excursion. However, with decreasing breeding ratio, less negative reactivity is available from Doppler broadening of the neutron absorption resonances that occurs when the fuel is heated in a power excursion.

Based on these considerations, GE concludes that a TRU burner with a breeding ratio of 0.60 and a core height of 0.76 m (30 in.) is the lowest possible breeding ratio configuration that would have acceptable safety features.

Designs with breeding ratios varying from 0.22 to 1.25 appear in the ALMR/IFR project literature (Chang, 1992b; M.L. Thompson, 1991 and private communication, 1991; K. Wu, private communication, 1991).

Recycle of minor actinides (MA) in an ALMR results in greater decay heat and radioactivity in discharge fuel assemblies. The ALMR project anticipates that the fuel handling equipment, including transport casks, can accommodate the higher levels of decay heat and radioactivity without major design modifications (Thompson et al., 1991).

The ALMR project (Johnson et al., 1990; M.L. Thompson, private communication, 1991) reports preliminary designs for ALMRs fueled entirely with TRUs, with no 238U for breeding or internal conversion. One design is fueled with a mixture of plutonium and separated MAs, with a breeding ratio of 0.22. Another is fueled with MAs, with a breeding ratio of 0.85.2 Such an MA burner could be useful if separated plutonium were to be recycled to LWRs as mixed-oxide (MOX) fuel—as is being done in Europe and planned in Japan, and if it were found desirable to construct a separate fast-spectrum reactor to transmute the minor TRUs separated in chemical reprocessing of discharge MOX fuel. These designs obviously indicate higher mass depletion rates of TRUs supplied to the liquid-metal reactor (LMR) fuel cycle for start-up and make-up, per unit of thermal power generated, compared with those of the designs of transmutation devices without internal breeding from 238U or 232Th fertile material (e.g., the designs for the accelerator transmutation of waste [ATW] without thorium) considered in the Los Alamos Concepts of accelerator-driven transmutation systems.

However, eliminating internal breeding from fertile material results in shorter fuel residence time in the reactor and lower fuel burn-up in an irradiation cycle. Consequently, the TRU inventories in the external fuel cycle increase, resulting in larger inventories required for start-up before steady-state recycle is achieved.

Effects of the start-up inventories and TRU make-up rates on overall transmutation performance are discussed under Transmutation Performance.

Transmutation Performance Requirements

Performance requirements for TRU-burning ALMRs have changed markedly in recent years and have not been clearly defined. Varying lines of objectives and arguments have been presented during recent years by DOE and its contractors, ANL and GE. To illustrate the varying lines of argument, in January 1990, DOE (Griffith, 1990) outlined the objectives of the ALMR project with regard to improving waste disposal of spent LWR fuel, stating that the ALMR project expects to develop a new pyrochemical process that will remove 99.9 to 99.999% of the actinides from waste streams, corresponding to process decontamination factors of 103 to 105.3 This expectation was said to result in a thousandfold reduction in the quantity of actinide waste going to a geologic repository.

The principal benefit claimed for this reduction in the quantity of TRUs is that the resulting wastes would be expected to be "benign after 200 to 300 years," when the 90Sr and 137Cs fission products will have decayed, reducing the risks from geologic disposal (ANL, 1991; Berglund et al., 1990; Hannum, 1992). ANL (Till, 1990) has stated that the waste from actinide-burning ALMRs "… will not have any actinides in it such as uranium, plutonium or any of the minor actinides such that, after 200 years, the cancer risk to man will be no greater than the original form, i.e., natural uranium." Indeed, if the risks from a given quantity of TRUs in a geologic repository over a given period of time are considered to be serious, one must also consider the risks from significant quantities of TRUs that would remain as yet untransmuted in the ALMR's above-ground fuel cycle—in storage, in reactors, and in reprocessing and fuel refabrication facilities—during the long time period that the transmutation would have to be accomplished.4

Apparently, the objective of such a large reduction in TRU inventory in repository waste is based on the ALMR project's desire to reduce the "radiological risk" of the TRUs (Till and Chang, 1989) in a repository to the "cancer risk level" (Berglund et al., 1990) of the original uranium ore mined to fuel the LWRs that generated the spent fuel. The ALMR project apparently assumes that these "risks" are measured by toxicities. The errors in using toxicities and uranium ore comparisons are discussed in Chapter 4.

DOE has clarified some important consequences of the ANL claims. In testimony to Congress in April 1990, DOE stated that the TRU-burning fast reactor "… would reduce the life of the remaining waste to about 200 years, instead 10,000 years, and the waste could then

|

3 |

Although the transmutation by ALMRs is said to deal with "actinides," the DOE ALMR project actually limits the calculation to transmutation of TRUs. Transmutation of the considerable quantities of uranium recovered from LWR spent fuel is not considered. Because TRU transmutation is spoken of popularly as "actinide burning" within reactor programs in this country and abroad, that terminology is occasionally used herein. |

|

4 |

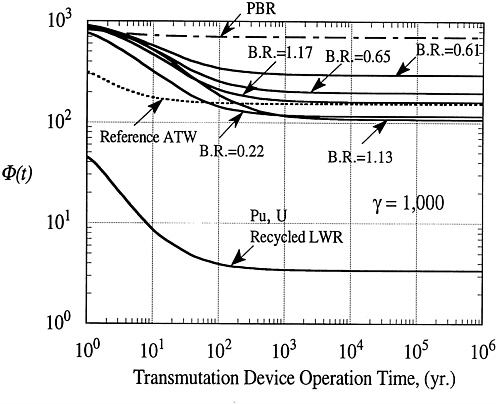

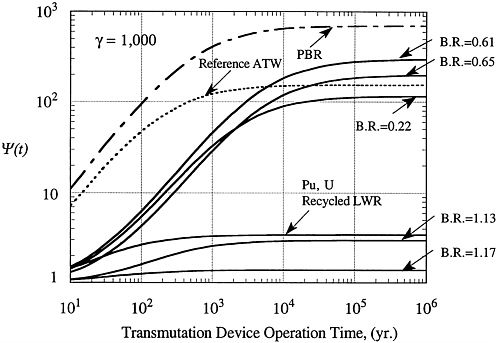

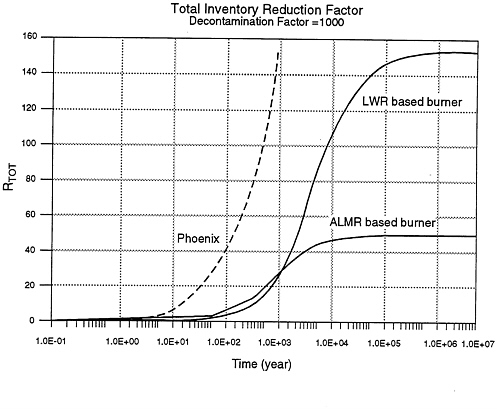

Estimates presented in Chapter 5 show that the time to achieve only a hundredfold reduction in total TRU inventory by the proposed ALMRs would be about 2,800 years for a series of ALMRs of a breeding ratio of 0.65, operating at constant power, assuming sufficient production of TRUs from LWRs to furnish TRU make-up during this period, or about 200 years in a declining-power scenario in which TRU inventory at the end of each reactor life is used to start and fuel a smaller number of subsequent ALMRs. The times for inventory reduction are even longer for other breeding ratios reported by the ALMR project. |

be stored above ground until it dies out" (Watkins, 1990). More recently, ALMR proponents have stated that a geologic repository will still be needed for some of the waste streams from the reprocessing cycles, because the process decontamination factor is not sufficiently high to qualify the waste as Class C "non-TRU" waste (i.e., with an alpha activity of less than 100 nanocuries per gram [Till and Chang, 1989]).

Another way of approaching performance requirements is in terms of the DOE schedule (Griffith, 1990) that showed the introduction of 1.4 GWe of new TRU-burning ALMRs in the year 2005, followed by the introduction of an additional 1.4 GWe ALMR per year for the next 40 years. All of the 62,000 Mg of LWR spent fuel accumulated by 2011—the time of opening the first repository—could be reprocessed and used to fuel these ALMRs, together with the yearly discharge of additional spent fuel from LWRs assumed to operate during this 40-year period. By the year 2045, there would be no inventory of LWR spent fuel. However, a geologic repository would still be needed for defense wastes and for the radioactive wastes produced in ALMR operation. The ALMR project does not propose to develop separation processes with decontamination factors sufficiently high that TRU-containing wastes could be disposed of as low-level waste, nor does it propose to transmute fission products present in LWR spent fuel and generated by ALMR operation.5

The Department of Energy's 1991 National Energy Strategy (DOE, 1991) assumed a similar rate of introduction of TRU-burning ALMRs, beginning in 2012 (Goldner et al., 1991), achieving a level of 19 ALMR power plants by 2030. Each ALMR was assumed to generate 1,395 MWe and to operate at a breeding ratio of 0.6 or 1.01. The National Energy Strategy also assumed a growth of total U.S.-installed nuclear capacity from the present installed capacity of about 110 to 195 GWe by 2030, primarily with advanced LWRs, introduced at a rate much greater than that assumed by Griffith (1990). The cases analyzed show that with such ALMR growth, all spent fuel discharged from LWRs from 2012 to 2030 could be processed to fuel the ALMRs, and a portion of the stockpile of LWR spent fuel could also be processed and transmuted during this period.

The new ALMRs would be primarily to treat new spent fuel emerging from LWRs after the first spent-fuel processing plant is built, around 2010 or earlier (Goldner et al., 1991). However, if the ALMRs are available and economically competitive, they could be applied to process and transmute LWR spent fuel that would otherwise be emplaced in the first U.S. geologic repository for high-level waste (HLW). Therefore, if the TRU-burning ALMR program were successful on the schedule expected by DOE and its contractors, there would be no need to load the first U.S. HLW repository with spent fuel (Griffith, 1991). This would call for considerable change in the repository design, in repository safety analysis, in the qualification of waste forms, and in licensing.

Although DOE has not defined performance requirements for the ALMR, the committee finds that the ALMR fuel reprocessing development underway at ANL is aimed at achieving decontamination factors of about 1,000. Therefore, for the purpose of the current study, a

decontamination factor is adopted as a performance goal, and evaluations are made of what overall system performance can be achieved with the various ALMR designs.

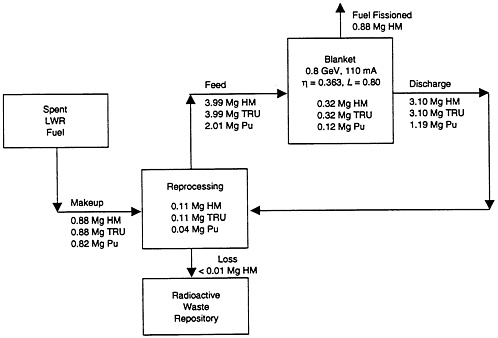

Transmutation Performance

While the reactor is transmuting the various isotopes in the fuel assemblies, it is producing higher mass TRUs and fission products in the fuel and blanket assemblies. Calculated annual production and destruction rates of various TRUs in the ALMR are calculated by GE (Thompson et al., 1991) assuming an average fuel burn-up of 150,000 MW·d/Mg, corresponding to a fuel residence time of about 6.5 years.6

At the end of the life of an ALMR at constant power, the core and reprocessing inventory would be essentially intact. These could be transferred to subsequent replacement ALMRs to continue power generation and the transmutation. In assessing the performance of the ALMR concept to consume TRUs that would otherwise appear in a geologic repository, it is important to consider the untransmuted inventory in the reactor and in reprocessing. It is also important to compare the total inventory of TRUs in the waste and in the fuel cycle to the amount that would be present for the same power generation from alternative sources, such as from additional LWRs. Calculations presented in the later section, Comparison of Reactor and Accelerator Approaches show that several hundred years would be required to reduce the total inventory of TRUs by even a factor of 10 by deploying ALMRs, and thousands of years would be required for a hundredfold reduction, assuming a constant level of nuclear power in the future. The time for a hundredfold reduction could be reduced to a few hundred years if nuclear power were to be terminated as rapidly as possible, consistent with operating a progressively smaller number of ALMRs at constant neutron flux as the reactor and fuel-cycle inventories of the system of several initial ALMRs become transmuted.

Facilities and Support Requirements

To implement the TRU-burning program as described by DOE (Griffith, 1990; Goldner et al., 1991), commercial-scale facilities to reprocess LWR spent fuel would be required. According to the GE ALMR reports, this facility could be an aqueous PUREX/TRUEX process or could be based on ANL's proposal to develop a pyrochemical separation process for LWR spent fuel. GE specifies a reprocessing capacity of 2,700 Mg of LWR spent fuel, more than twice the capacity of any single commercial reprocessing facility. Currently the largest worldwide commercial facility, near completion in the United Kingdom, is the THORP plant, with a throughput of 900 Mg heavy metal. Based on reprocessing/fabrication times estimated by the ALMR project (Taylor et al., 1991), the new commercial-scale LWR fuel reprocessing facility would have to be operational for about 2 years before the commercial ALMRs are

introduced. Thus, the new large-scale reprocessing facility would have to commence operation by 2003 according to one DOE schedule (Griffith, 1991) or 2010 according to another (Thompson and Gonzaga, 1994).

Argonne National Laboratory's IFR concept of the ALMR specifies that each ALMR power-generating facility would have its own integrated facility for reprocessing discharged ALMR fuel and for fabricating recycle fuel. For a breeding ALMR, the throughput of driver and blanket fuel discharged from an ALMR would be about 21 Mg/yr of uranium and TRUs for each 1,395 GWe ALMR (Johnson et al., 1990). The throughput of ALMR discharge fuel would decrease to about 13 Mg/yr for an ALMR with no uranium blanket. The reprocessing capacity quoted here is that necessary to process the backlog, following DOE's proposed schedule of deployment. Without large-scale reprocessing deployment in the United States, separation and transmutation is an impossible venture.

There must also be facilities for converting the reprocessing waste streams into waste solids suitable for emplacement in a geologic repository or suitable for other waste disposal sites. Necessary processes and facilities, in addition to those described by the ALMR program, include:

-

a process to remove actinides and soluble fission products from the inner surfaces of cladding hulls from LWR fuel and a process to produce a suitable waste solid from the cladding hulls;

-

a process to remove noble-metal fission products from the uranium stream from pyrochemical reprocessing of LWR spent fuel if that uranium is to be sent to surface storage as now specified by the ALMR program, and a process to produce a suitable waste solid from the separated fission products;

-

processes for high-yield (greater than 99.9%) recovery of radioiodine, 14carbon, and technetium if LWR spent fuel is to undergo aqueous reprocessing and processes to produce suitable waste solids from these separated radioelements; and

-

processes to separate radioactive cesium and strontium, and to produce suitable waste forms for these separated radioelements, and processes and facilities for storage of these separated radioelements for 200 to 300 years before disposal as radioactive waste (this is a possible additional separation proposed by ANL [Chang, 1992b] and by DOE [Young, 1991] to reduce heat generation in a geologic repository and to increase the amount of waste that could be emplaced in a given repository area).

Qualifying the several different fuel types and compositions that will arise from TRU recycling in the ALMR will be a formidable task.

The ALMR project points out that removing most of the actinides from the HLW would result in a lower rate of heat generation by radioactive decay. This would allow an increase in the total waste loading of a geologic repository of a given area, if that waste loading is limited by the total rate of heat generation. The ALMR program also proposes that the heat-generating fission products 90Sr and 137Cs be separated when spent fuel is reprocessed. By storing the separated strontium and cesium on the surface for about 300 years, the first repository could accommodate more waste than now planned and could defer the time when a second repository

is needed (Till and Chang, 1989; Young, 1991). However, Ramspott et al. (1992) point out that the current limits on waste loading in the proposed first repository are not based on heat generation rate. They point out that if the loading were limited by heat generation rate, other techniques could increase waste loading without the complexity of reprocessing and transmutation. If this option is to be pursued, it will be necessary to develop additional separations processes, means of storing the strontium and cesium for hundreds of years, and new waste forms for satisfactory containment of the strontium and cesium for later emplacement in a geologic repository. Containment of the 3-million-year 135Cs is particularly challenging.

Development of the ALMR concept, the new technology for reprocessing LWR spent fuel and for reprocessing and fabricating ALMR fuel, and the additional processes for separating fission products and for preparing special waste forms would require extensive facilities for research, development, testing, and operational demonstration, including prototypes.

Risk and Safety Issues

The National Research Council's (1992) study of nuclear power options for the future summarizes safety features of the ALMR, which is designed only for power generation, and also summarizes risk and safety issues that must be resolved. Two transient safety tests at the EBR-II with metal fuel successfully demonstrated the safety potential of the ALMR concept. The study notes that:

The properties of the metallic fuel and the large thermal inertia of the sodium pool are key to achieving reactor shutdown passively (i.e., without relying on operation intervention, active components such as control rods, pumps, valves, or the use of balance-of-plant for heat removal) while keeping temperatures low.

However, the report cautions that the presence of a positive sodium void coefficient of reactivity in the ALMR/PRISM design is a continuing concern. It may require revisions to the present design such as a larger diameter core with a lower height.

For ALMRs as TRU burners, GE's approach to eliminating 238U blankets in the ALMR designs of lower breeding ratio requires shortening the core height, with minor adjustment in fuel composition but without changes in fuel-rod diameter or in the number of fuel rods. The diameter of the reactor vessel would remain constant and is limited by the maximum allowable power density or by the linear heat generation rate of the fuel rods so that safety characteristics are not compromised.

With reduced fissile breeding and reduced heavy metal inventory, the burner designs also result in increased reactivity swing over a fuel cycle. This then requires larger control rod worths and hence entails potentially larger positive reactivity insertions and degraded performance in transient overpower events. As the breeding ratio decreases, the positive sodium void coefficient of reactivity decreases, and the Doppler coefficient of reactivity remains negative but becomes smaller in magnitude.

From this approach, GE concludes that a TRU burner with a breeding ratio of 0.60 and a core height of 30 in. is the configuration that would have acceptable safety features and the lowest breeding ratio.

Additional risk and safety issues relevant to the actinide burning, which are identified in the present study, are summarized below. Among the more important issues of reactor and fuel-cycle safety are the following:

-

the effect of reducing the breeding ratio to increase consumption rate of TRUs from an LWR spent fuel, thereby compromising passive safety features;

-

the effect of more favorable neutronic properties of MAs, such as 237Np, on reactivity transients and reactor safety;

-

the effect of the higher specific activity and neutron emission from the decay of higher mass actinides, and from other species resulting from multiple recycle, on radiation exposures and risks from reprocessing, fabrication, and handling of recycle fuel; and

-

the effect on reactor transients and safety if the ALMR is started on enriched 235U instead of starting it with plutonium and other TRUs from LWR spent fuel. The analysis of fuel-cycle economics in Chapter 4 indicates that start-up on 235U would be economically favored if reprocessing costs are comparable to contemporary costs in other countries.7 The decision as to whether to start ALMRs from LWR fuel transuranics could be further affected if there are important differences in safety features for ALMRs started with transuranics as compared with starting with 235U.

Even though a breeding ratio of 0.60 is said to be the lowest breeding ratio that would result in acceptable safety features, ANL has explored designs with even lower breeding ratio designs, limited to single-batch fueling, with thin fuel pins and loose fuel lattices. The reactivity swing over a cycle can be large, as is especially the case for the burner design fueled with plutonium and MAs, with a breeding ratio of 0.22. For this design, unless the cycle length is substantially shortened, transient overpower events would likely result in unacceptable consequences. The fuel composition is well outside the EBR-II metallic-fuel database. Also, MAs cannot be separated from plutonium in the current pyrochemical processing. Even though the low breeding ratio results in a greater make-up rate of TRUs per unit of thermal power, the large out-of-core inventory for this fuel cycle results in a much lower inventory reduction factor in a given operating time than can be achieved for the PRISM design with a breeding ratio of 0.65.

Fuel consisting primarily of MAs will generate a larger amount of decay heat and may present additional problems in processing and handling. Although the sodium void reactivity worth and Doppler coefficient of reactivity do not appear acceptable for the MA-burner design, there is not sufficient information available for this design to evaluate the reactivity characteristics. Thus, considerable research and design effort appears necessary to develop an

LMR core that is fueled entirely with TRUs without compromising safety characteristics of current ALMR designs.

The operation of a system using ALMRs can impact the occupational safety and environmental issues associated with the mining and milling of uranium ore, because breeding ALMRs started and fueled with TRUs from LWR spent fuel would require no more fresh uranium ore for the electrical energy generated by these ALMRs. However, if the ALMRs were to operate at a breeding ratio less than unity to increase the amount of TRU burning during a reactor lifetime, then continuing LWRs to supply make-up TRUs, as envisioned in DOE's energy strategy, would require additional fresh uranium ore. Thus, the mixed power system of LWRs and nonbreeding ALMRs would result only in a few-fold decrease in the amount of ore mined per unit of energy produced.

As an alternative to start-up on plutonium, the TRU-burning ALMRs could be started on enriched 235U. If so and if the breeding ratio were unity so that no further make-up 235U were required, the 40-year lifetime requirements of uranium ore for the ALMR would be about the same as for an LWR of the same electrical generation. There would be no significant savings in mining and milling of uranium ore for 235U start-up. However, if the first-generation ALMRs were to operate with a sufficient breeding gain, then the excess plutonium they produce could be used to start next-generation ALMRs, so that no further uranium mining and milling would be required.

A reduction in ore mining and milling from ALMR operation may have only a limited effect on the occupational health and safety of the U.S. nuclear industry within U.S. territory because of two fundamental changes that took place in the industry during the preceding two decades: (1) the adoption of solution mining of uranium in the United States, with an accompanying decrease, compared with conventional mining techniques in the potential for accidents and irradiation; and (2) the large increase in the fraction of uranium ore imported from Australia and Canada, which is projected to range from 72 to 82% of the domestic utility requirements in 1992 through 2002. Indeed, U.S. uranium ore production has dropped by a factor of about 8 since the production peak in 1980, and the drop in employment in the U.S. uranium industry is about a factor of 20 lower than the peak employment in 1979.8

TRU-burning ALMRs that are started and refueled with TRUs recovered from LWR spent fuel otherwise destined for a geologic repository would be a means of producing nuclear-generated electric energy without further mining and milling of uranium ore, but this TRU-burning fuel cycle would create a new waste that would be a long-term environmental issue. The proposed flowsheets for reprocessing LWR spent fuel show that uranium recovered from LWR spent fuel would be stored on the earth's surface instead of going to geologic disposal.9

About one-sixth of the uranium originally mined to fuel the LWRs that produced that spent fuel would thus become a potential surface contaminant, a contaminant that would present a greater potential risk to future people than if it were buried as a HLW.10 If this separated uranium, containing about 0.8% 235U, were returned to isotope separation for reenrichment, the amount that would be left for long-term surface storage would be reduced by 20%.

State of the Technology

More than a dozen liquid-metal-cooled fast reactors have been constructed and operated in the United States, in several states in Europe, and in the former Soviet Union. Although some of the reactors have operated extremely well, the overall performance record is mixed. In the United States, two early fast reactors had serious difficulties. The Fermi-I reactor suffered a serious structural failure of certain core components that led to a local flow blockage and fuel melting. The EBR-I test reactor suffered a partial core melt during a dynamics experiment.

The more recent experience in the United States is much more favorable. EBR-II has operated successfully for over 30 years. The larger Fast Flux Test Facility (400 MWt) has had an outstanding record since starting operations in the late 1970s. However, in the United Kingdom, the Prototype Fast Reactor suffered cracking of primary system components as a result of cyclic thermal stresses. France's Rapsodie and the Superphénix liquid metal reactors, as well as the BN-350 reactor in the former Soviet Union, have experienced steam generator leaks. Repair of Rapsodie was considered too expensive to justify keeping the reactor in service after 15 years of operation. The 250 MWe demonstration plant Phénix, which started regular operation in 1974, is shut down pending study and evaluation of transient negative reactivity pulses that were observed in 1989 and 1990 while the reactor was operating at full power. Operation of the Superphénix 1,200 MWe plant has been curtailed for an extended period by a sodium leak, discovered in 1987, in an auxiliary vessel for the storage of discharged fuel (National Research Council, 1992). Future plans for Superphénix appear to be uncertain at present.

The lesson that can be drawn from the experience to date is that sodium-cooled fast reactors can be designed, built, and operated reliably. However, there is a much smaller base of experience, particularly with large LMRs, than with LWRs. There remain sensitive design issues. Proceeding with a program of large-scale TRU burning with an ALMR would require substantial development, testing, and large-scale demonstration under Nuclear Regulatory Commission (NRC) safety review and licensing before one could proceed with confidence. These issues are exacerbated when the proposed new processing technologies are included, particularly if they are included as processes in the IFR concept.

ALMR FUEL

The ALMR is designed to utilize metallic fuel. Its high thermal conductivity affords much smaller temperature swings during reactivity and loss-of-coolant transients. Metal fuel seems better adapted to ANL's proposed pyrochemical processes. Although there is a substantial body of experience with metallic fuel for fast breeders, relatively little of that experience is at high burn-up, and essentially none is with actual recycle fuel containing minor TRUs and the recycled fission products, particularly the lanthanides. The ALMR fuel performance is highly sensitive to the in-reactor microstructure that develops, which is in turn highly sensitive to the phases that precipitate, which are in turn highly sensitive to the chemistry of the fuel. Hence, the in-reactor behavior of a fuel with a significantly large concentration of MAs will need to be extensively characterized. Significant irradiation experience with such fuel will be needed under actual design conditions.

MOX fuel is a possible alternative that has been demonstrated satisfactorily to very high burn-up (greater than 150,000 MW·days/Mg). It seems better adapted to aqueous processing. However, there is essentially no experience with such fuel containing significant amounts of MAs. Also, an oxide-fueled reactor would not have the inherent safety advantage that has been demonstrated for metal fuel. Thus, even with oxide fuel, significant fuel development and irradiation testing would be required. Application of conventional aqueous reprocessing to multiply recycled MOX fuel could increase the necessary cooling time between reactor discharge and reprocessing, further increasing the time to obtain a given reduction in TRU inventory.

REACTOR DYNAMICS AND SAFETY PARAMETERS

Although fast reactors have been operated with mixed plutonium-uranium fuel, there is essentially no operating experience with significant quantities of MAs. Also, there is little experience with recycle fuels containing the lanthanides that would be recycled from pyrochemical reprocessing. In order to provide an adequate basis for licensing, it would be necessary to confirm cross sections, reactivity coefficients, and reactor dynamics over a range of fuel compositions. A representative operating prototype designed and operated under NRC licensing would be required and might also aid in verifying satisfactory operation and design margins at low breeding ratios.

FUEL FABRICATION FACILITIES

The fabrication of fuel containing TRUs will require automated, remotely maintained, and remotely operated fuel production facilities. Such facilities designed for recycle of TRUs recovered from LWR spent fuel and for recycle of TRUs recovered from ALMR spent fuel must be of significant capacity, whether constructed as fabrication facilities colocated with one or more ALMRs, as in the IFR concept, or whether constructed as centrally located facilities with larger throughput. Although there is substantial experience with the fabrication of mixed

plutonium-uranium fuels, there are no high-capacity facilities with remote operation and maintenance.11 The fuel fabrication facilities themselves are likely to require significant development and prototype testing, possibly in support of a research, testing, or demonstration reactor.

If 14C is not removed in reprocessing and made into a suitably insoluble waste form, it can be a troublesome radionuclide in a geologic disposal system. If so, the fuel fabrication processes must maintain a low enough concentration of residual nitrogen in the fabricated fuel to avoid production of significant quantities of 14C.

REPROCESSING

Reprocessing would be required to separate the TRUs and fission products from spent LWR fuel as well as from ALMR recycle fuel. As discussed in Chapter 2, there is substantial experience at production scale with the aqueous PUREX process for separating uranium, plutonium, and fission products from spent fuel, including LWR spent fuel. PUREX separation facilities of smaller scale have operated on discharge fuel from LMRs. However, the recoveries are not high enough to meet the process decontamination factor of 1,000 that has evidently been adopted as a requirement by the ALMR program. Also, MAs are usually not separated, except for limited amounts of separations of neptunium. To recover MAs and to achieve high recoveries of all these separated species, the TRUEX process has been studied as an addition to PUREX. TRUEX development has progressed little beyond the laboratory scale. However, the PUREX/TRUEX reprocessing system may be in a more advanced stage of development than the pyrochemical processes proposed for the IFR, including pyrochemical processing of LWR spent fuel.

The ALMR project has proposed pyrochemical reprocessing of discharged metal fuel from an ALMR. Development at ANL is focused toward reprocessing integrated with a reactor complex. Significant experience has been gained on simulated ALMR fuel at a laboratory scale. ANL has also proposed to develop pyrochemical processing technology for high-yield recovery of TRUs from LWR spent fuel, but that technology has not been demonstrated even at laboratory scale (see Chapter 2).

Whatever process or processes are chosen, they will require significant further development and demonstration in a pilot-scale plant of reasonable size, designed and operated under NRC licensing.

It may also be desirable to develop one or more additional reprocessing steps for separation of the long-lived fission products (e.g., 99Tc and 129I) that can significantly affect the calculated risk from geologic disposal. Indeed, the ANL annual report for 1991 (ANL, 1991) states that

The long-lived fission products are returned to the (IFR) reactor to be consumed. … Long-lived wastes are consumed with reactor fuel, leaving only a small amount of shorter-lived radioisotopes to be disposed of as nuclear waste.

However, the ALMR program has not yet addressed the recycle and possible transmutation of these troublesome long-lived fission products.

STEAM GENERATORS

Steam generators have proved to be the most troublesome major component in the pressurized water reactor system. Leaks have been a frequent occurrence; many generator tubes have required plugging. At several reactors, it was necessary to replace the entire set of steam generators. The experience with steam generators in liquid-metal-cooled reactors has been generally better, but the consequences of a leak of high-pressure hot water or steam into sodium are also much more severe. The experience with the EBR-II steam generators has been excellent, with only one leak over their 30-year life. On the other hand, most of the other sodium-cooled reactors around the world have experienced some problems with steam generator leaks.

In the United States, it was envisioned that the Clinch River project would provide experience with large steam generators in a utility operating environment. That program was canceled. Subsequently, DOE maintained a steam generator program for several years, but the program has withered for lack of funding. Because steam generator performance is so important to maintaining reactor availability and capacity factor, pursuit of an ALMR TRU-burning program will require a program for development of large LMR steam generators, with extensive test and demonstration.

DEMONSTRATION

To deploy an ALMR system for TRU burning would require reactors, large-scale reprocessing facilities, and fuel fabrication facilities that can operate reliably as a system at high capacity. Because multiple facilities would be required, a TRU-burning program would require predictability of licensing. All of these factors strongly suggest the prudence of prototype or near-prototype demonstration facilities at which the necessary fine tuning of design, the experience base for licensing, and operating experience can be gained. It is not likely, for example, that successful demonstration of pyrochemical processing at EBR-II, as planned by DOE, would provide sufficient basis for reliable design and cost estimating of a large-scale (2,700 Mg/yr) facility for pyrochemical processing of LWR spent fuel, to be funded by risk capital and to be regulated by the NRC. Not only is the process new and unproven even at the laboratory scale, but the capacity is several-fold greater than even the largest commercial reprocessing facility based on the well-developed PUREX process. It is unlikely that the design

and safety review for the EBR-II IFR would be sufficient to provide a reliable basis for an industrial design under NRC licensing.

Cost Information

SYSTEM COSTS

Reports of cost estimates made by the ALMR project have been reviewed by the committee. However, the validity of the estimates is uncertain, particularly in the area of capital costs and costs of reprocessing LWR and ALMR spent fuel. For the purpose of this study, the committee relied on the Electric Power Research Institute's (EPRI's) independent estimate of the costs of LWRs and the long-range LMR, as did a recent report on nuclear power by the National Research Council (1992). However, relative costs can be better estimated. It is the cost of the ALMR and its fuel cycle relative to that of the LWR or of an advanced light-water reactor (ALWR) that can reveal the circumstances wherein the ALMR might be competitive as an alternative source of nuclear power and as a means of transmuting TRUs for waste disposal.

The National Research Council (1992) report notes that EPRI has independently evaluated some overnight capital costs and operations and maintenance costs (EPRI, 1989). The estimates are more general than those of the vendors, but they are based on clear definitions. Uncertainties are estimated as -30 to +80%. EPRI's estimates of overnight capital costs are somewhat higher than those of the vendors (National Research Council, 1992). The results for LWRs and ALMRs are shown in Table F-1.

With regard to the relative economic potential of the ALMR, ALMR plants (e.g., PRISM) may be able to compete economically with water reactors if fuel reprocessing turns out to be technically and economically feasible, and if the overnight capital costs of these plants are as low as the vendors indicate (National Research Council, 1992). EPRI costs estimates (Table F-1) suggest that these capital costs will be higher than the vendor estimates.

The economic projections are highly uncertain, first, because past experience suggests higher costs, longer construction times, and lower availabilities than projected and, second, because of different assumptions and levels of maturity among the designs. The EPRI data, which the National Research Council believed to be more reliable than that of the vendors, indicate that the large evolutionary LWRs are likely to be the least costly to build and operate on a cost per kilowatt-electric or kilowatt-hour basis. EPRI puts the midsized LWRs with passive safety features between the two extremes.

However, neither the PRISM design nor the PRISM technology are sufficiently developed to provide a reasonable degree of confidence in cost estimates. Finally, different institutional arrangements may be required for utility involvement in a PRISM plant because of reprocessing, concerns about diversion of sensitive nuclear materials, and lack of utility experience with the technology (National Research Council, 1992).

TABLE F-1 EPRI-Estimated Overnight Capital and Operations and Maintenance Costs (in December 1988 dollars).

|

|

|

Operations and Maintenance Costs |

|

|

Advanced Reactor Type |

Overnight Capital Costs (per rated kW) |

Fixeda ($/kWe-yr) |

Incrementalb (cents/kWh) |

|

Large evolutionary LWRs |

$1,300 |

61.1 |

0.11 |

|

Mid-sized passive LWRs |

$1,475 |

72.7 |

0.11 |

|

Liquid metal reactors |

$1,725 |

75.5 |

0.15 |

|

a These operating costs are essentially independent of actual capacity factor, number of hours of operation, or of kilowatts produced. They include labor charges for plant staff. b These variable operating costs and consumables are directly proportional to the amount of kilowatts produced. They include chemicals consumed during plant operation. SOURCES: EPRI (1989); National Research Council (1992). |

|||

The LMR might be commercially competitive if uranium fuel shortages limit the use of LWRs. The LMR's safety features and ability to recycle TRUs are not considered important positive factors for its early market potential. Any strategy requiring fuel reprocessing introduces significant technical, economic, and nonproliferation policy considerations, some of which would complicate licensing.

The TRU-burning ALMR reactor and fuel cycle are expected to be more expensive than an ALMR optimized only for power generation (Chang, 1992; Taylor et al., 1991). Expected contributors to the higher cost for TRU burning are the likely higher cost for high-yield chemical recovery of actinides and fission products; the expense of additional LWR reprocessing for reactors with degraded breeding ratio to increase TRU consumption, and the expense of additional development, testing, and safety issues associated with recycle of MAs and fission products. Therefore, the era of competitiveness of the TRU-burning ALMR with the LWR will be even later than that of economical introduction of ALMRs designed only for power generation.

For the present study, it is important to estimate the time in which the LMR optimized for power generation (and not for TRU burning) could be economically competitive with LWRs. Calculations of the relative economics of ALMR deployment scenarios, involving both ALMRs

and LWRs, have been made by Delene, Fuller, and Hudson at Oak Ridge National Laboratory (ORNL) (Delene et al., 1993). At the request of this committee, that analysis has been extended to estimate the future time at which rising ore costs from LWR operation result in a cost of electrical generation from an ALMR that equals that from an ALWR.

The analysis, prepared by C.R. Hudson (private communication, 1993), compared constant-dollar-levelized plant busbar generating cost, including capital, operations and maintenance, fuel, and decommissioning. Relative costs of the power plants were based on the relative overnight capital costs and operating and maintenance costs for large evolutionary LWRs and for LMRs similar to data in Table F-1.12 All costs except that of uranium ore were assumed to remain constant through time on a real-dollar basis. The ALMR busbar costs were calculated at several different assumed costs of LWR spent fuel reprocessing. Plutonium from LWR spent fuel was assumed to provide the fissile material for the initial core of the ALMR and for the first two reloads. Thereafter, the ALMR was assumed to sustain its own fuel cycle (i.e., unity breeding ratio). Other assumptions used in developing this analysis are

-

after-tax cost of money = 9.57%/yr;

-

waste fee for ALMR and ALWR = 1 mill/kW·h;

-

decommissioning sinking fund charge = 1 mill/kW·h; and

-

facilities financed at 70% equity, 17%/yr return on equity, typical of low-risk investment.

ALMR costs are based on recent studies by General Electric (Hutchins et al., 1991) and by ORNL (1992), that adopt ANL's estimates of the cost of pyrochemical processing and fabrication of recycle ALMR fuel.

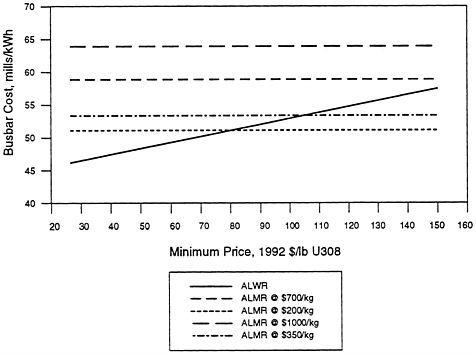

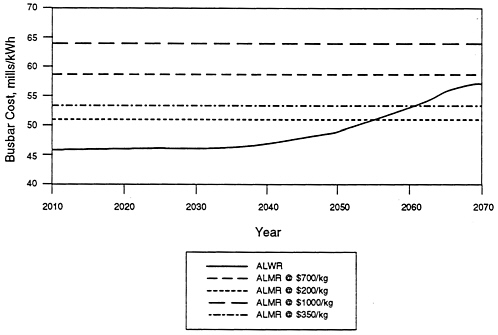

Figure F-3 shows the calculated levelized busbar cost of electricity from ALWRs and ALMRs as a function of the unit price of natural uranium (dollars per pound of U3O8) for various values of the price for reprocessing LWR spent fuel. The busbar costs for the ALWR do not depend on reprocessing cost but increase linearly with the cost of natural uranium. Because the ALMR uses no natural uranium, its busbar cost is insensitive to the ore price but increases with the price of reprocessing LWR spent fuel to obtain plutonium for start-up. LWR spent fuel was assumed to be free. No credit was taken for the value of uranium recovered from LWR spent fuel. The curves do not extend beyond a price of uranium ore of $150/lb, which ORNL estimates to be the cost of uranium from seawater, a resource of large magnitude.

For ore prices as high as $150/lb, the ALMR would be competitive with the ALWR if LWR spent fuel can be reprocessed for about $680/kg. If LWR spent fuel can be reprocessed for $350/kg, the ALMR busbar cost will be greater than that of the ALWR unless the price of natural uranium becomes greater than $105/lb. This is more than fivefold greater than the present price of natural uranium.

A goal of the ALMR project is to develop pyroprocessing LWR spent fuel to cost $350/kg or less, in order to justify starting the ALMR on TRUs from LWR spent fuel instead

of starting on uranium enriched from natural uranium at an ore cost of $29/lb. From the data in Figure F-3, in an era of low price for uranium ore, as may well occur into the next century, a reprocessing cost even as low as $200/kg would justify starting an ALMR on LWR TURs instead of with enriched uranium, but it would not justify building ALMRs instead of LWRs.

Hudson has estimated the depletion of U.S. uranium resources, assuming only LWRs are added at 1.4 GWe per year during the next century, to be operated in once-through fueling. From data of cost of uranium ore as a function of amount consumed, Hudson then calculated the busbar cost from once-through ALWRs as a function of time, shown in Figure F-4. For a given reprocessing cost, the intersection of this ALWR curve with the corresponding horizontal lines for the ALMR provides the estimated time at which a first-generation breeding ALMR could become as economical as a LWR. If the reprocessing cost is as low as $350/kg (the target value identified for the ALMR project) the time for competitiveness with the LWR is the year 2060. For a reprocessing cost of $1,000/kg or greater, near the estimates for contemporary foreign PUREX plants corrected for U.S. industrial financing, the time of intersection with the ALWR curve would be beyond the year 2070. It may not occur for a far longer time if a large quantity of natural uranium from seawater is available at $150/lb.

These calculations are based on an ALMR plant with a generating capacity of 1,395 MWe, consisting of three power blocks and nine reactors. The fuel cycle is designed to be a break-even cycle requiring fissile material recovered from LWR spent fuel for the initial core and first two reloads. Costs are based on studies by GE (1991) and ORNL (1992). The ALWR plant is a 600 MWe single reactor with a once-through fuel cycle. Capital and operation and maintenance costs are based on vendor input to a U.S. Council for Energy Awareness (1992) study. These cost assumptions are similar to those found in the earlier EPRI Technical Assessment Guide (1989). Unit fuel costs are those used in the ORNL ALMR Deployment Economic Analysis (1993).

Busbar costs of electricity include a 1 mill/kWh waste fee and a 1 mill/kWh decommissioning sinking fund charge. All costs are expressed as 1992 constant-dollar levelized values. Constant-dollar levelization is calculated as described by DOE (1988).

A greater capital and operation and maintenance cost for the ALMR will result in even later dates of economical competitiveness, or even lower necessary reprocessing cost. Delene et al. (1993) estimate that if the capital costs of the ALWR and ALMR are equal, the time for equal generation costs would be about the year 2060, assuming a reprocessing cost of $1,000/kg.

The TRU-burning ALMR reactor and fuel cycle are expected to be more expensive than for an ALMR optimized only for power generation (Chang, 1992b; Taylor et al., 1991). Expected contributors to the higher cost for TRU burning are the likely higher cost for high-yield chemical recovery of actinides and fission products, the expense of additional LWR reprocessing for reactors with degraded breeding ratio to increase TRU consumption, and the expense of additional development, testing, and safety issues associated with recycle of MAs and fission products. Therefore, the era of competitiveness of the TRU-burning ALMR with the LWR will be even later than that of economical introduction of ALMRs designed only for power generation, unless the TRU-burning operation is subsidized by possible improvements in performance of a geologic repository. In the absence of considerable subsidy for possible

waste-disposal benefits, the TRU-burning ALMR is not likely to be an economic choice for power generation until well into the second half of the next century or later.

THE LIGHT-WATER REACTOR

Plutonium Recycle in LWRs

Light-water reactors are by far the most mature of any of the proposed burners of nuclear waste. Over 100 LWRs are operating in the United States and about 400 total worldwide. LWRs have over 4,000 reactor-years of operation and supply about 70% of the electricity consumed in France and some parts of the United States. Fresh fuel for an LWR normally uses low-enriched uranium (LEU) as the fissile component. However, operation is also possible with MOX fuel, which combines plutonium, recovered from reprocessing, with natural or LEU oxide as a PuO2-UO2 mixture. This section discusses an extension of the experience with such plutonium-uranium MOX fuel in LWRs to the more complex requirements for refabricating and burning MOX fuel that contains radionuclides recovered from reprocessed LWR spent fuel (i.e., plutonium, the MAs, and selected fission products 99Tc and radioiodine).

The U.S. Plutonium Utilization Program began in 1956 and stimulated related work in several European nations and Japan. This development effort was motivated by the potential for fuel-cycle economies through the recycle of plutonium recovered from LWR spent fuel in anticipation of the rising costs of LEU in the future. In the mid-1960s, the United States conducted a commercial recycle demonstration at San Onofre including a full core load of MOX fuel. Several U.S. reactors conducted tests with partial core loadings of MOX fuel.13

Other nations have also successfully operated commercial LWRs with MOX fuel on a limited scale for several decades (Bairiot, 1984; Bairiot and Vandenberg, 1989). Beginning in 1963, Belgium used MOX fuel in their BR3 pressurized water reactor (PWR), achieving a proportion of 70% MOX fuel in 1986. Germany started the commercial use of MOX fuel in 1981, following extensive test and demonstration from 1968 to 1977, and licensed a large MOX fuel fabrication plant at Hanau, although construction was cancelled in 1992 after design was completed. Switzerland began using MOX fuel in the Beznau reactor in 1984, and Electricity de France began loading MOX on a commercial basis in 16 plants in 1985. Japan launched a MOX demonstration program in 1986 and currently is considering the use of MOX fuel in 12 PWRs and several boiling water reactors (BWRs) in the 1,000 MWe range. Indeed, France, Germany, and Japan have the capability for extensive MOX fuel programs in the future, depending whether planned or projected MOX fuel fabrication facilities are actually constructed and put into operation.

Work on reprocessing and plutonium recycle came to an end in the United States in the mid-1970s, as a result of both economic and public policy considerations that are discussed in

Chapter 1 and 4. The increased availability of enrichment capability and low-cost uranium ore eliminated the economic incentive for plutonium recycle in LWRs and postponed breeder commercialization. Also, the concerns about the possible stimulus that widespread commercial plutonium recycle might give to the proliferation of nuclear weapons played a significant role in the decision of the United States and several other nations to forego recycle. However, several nations—notably, France, the United Kingdom, Russia, and Japan—continue to pursue reprocessing for limited recycle of plutonium into LWRs and for support of their ongoing breeder development programs.

To meet the objective of transmuting the TRU and long-lived fission product inventories as a part of reducing waste disposal risks, the LWR with aqueous reprocessing is the most mature option technologically, requiring the least development time and effort. Present-day LWR designs are readily adaptable for the task. In contrast, fuel-cycle economics with reprocessing is far less certain. For fresh fuel containing radionuclides, the fuel development and the fuel and system performance verification would require time to obtain a database sufficient for licensing, as discussed below. Time also would be needed to construct and license the necessary fuel reprocessing and refabrication facilities in the United States. Thus, advanced LWR designs, which are currently under development and regulatory review, could be alternative candidates to present-day LWR designs to adapt for waste transmutation. In particular, the designs might be useful as the dedicated TRU burners discussed in the next subsection.

Reference Designs

SELF-GENERATED RECYCLE WITH TRANSURANICS

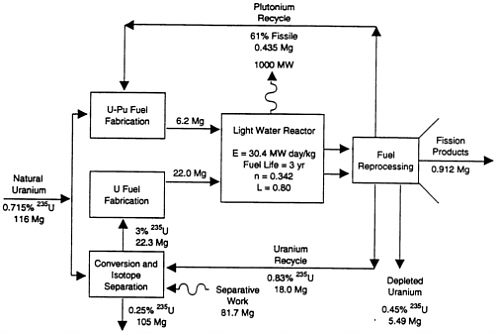

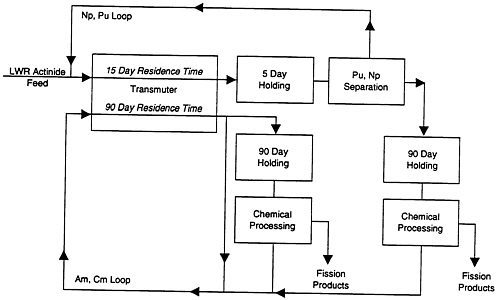

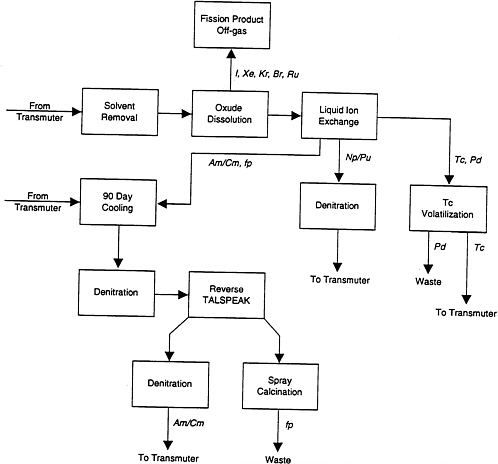

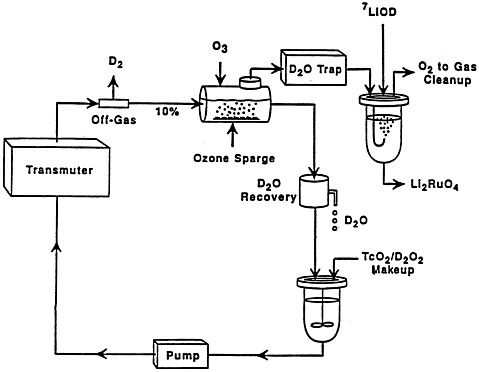

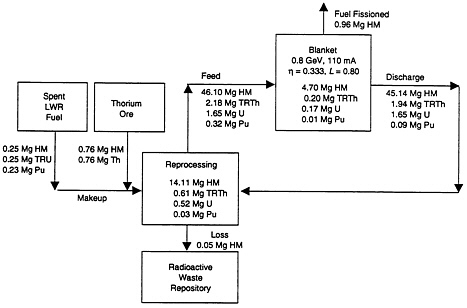

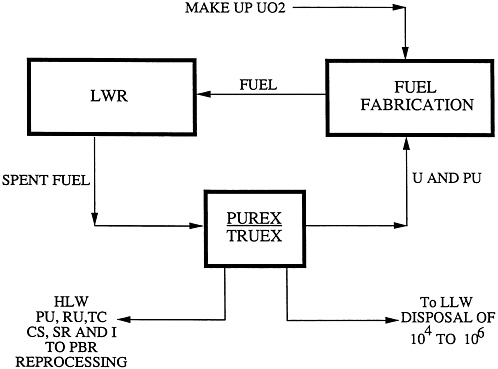

In the mid-1960s to the mid-1970s, the U.S. nuclear industry adapted the PWR and BWR designs for ''self-generated uranium-plutonium recycle" in which the fissile material recovered from reprocessed LWR spent fuel would be recycled back to the same reactors. Figure F-5 shows a representative material flowsheet for a commercial 1,000 MWe PWR based on a design of mid-1970s vintage by Combustion Engineering14 (Pigford and Yang, 1977; Hebel et al., 1978). Other LWR designs would have comparable flowsheets for self-generated recycle.

Self-generated recycle schemes typically use heterogeneous cores that contain both rods with normal LEU (about 3.3% 235U) fuel and rods with MOX fuel, so that the reactor characteristics are very similar to those for normal fueling. Two arrangements have been used to accommodate the two types of fuel materials and maintain a suitably flat power distribution in the core. Fuel rods are packaged in "fuel assemblies" that contain arrays of 14 × 14 to 18 × 18 fuel rods for a typical large PWR. In the first arrangement, each assembly may have both

|

14 |

Now Asea Brown Boveri Combustion Engineering Nuclear Power. The data for self-generated recycle is published in Shapiro et al. (1977). The material balance of Figure F-5 would need to be altered for the material flows required in a system to accommodate the already existing LWR spent fuel. |

normal rods and MOX rods. In the second arrangement, each assembly contains rods only of one type or the other. Both arrangements have advantages and disadvantages.

The use of plutonium introduces new issues of reactivity control and power distribution in the reactor because of the higher neutron-absorption cross section for 239Pu compared with 235U. Thus, the distribution of neutron flux and the concentration of plutonium in MOX rods are critical design issues that establish how the two types of fuel rods are distributed in the fuel assemblies. In the first arrangement, a MOX fuel rod near normal fuel rods, exposed to nearly the same neutron flux, may generate more thermal power. Thus, the proportion of the two types of rods may be varied depending on where an assembly is to be placed in the reactor (at the interior, periphery, or corners of the core).

The first arrangement gives a good match to the local power generation and simplifies the reactor operator's task but complicates fuel assembly production and testing. The second arrangement, in which an assembly contains rods of only one type, simplifies the task of the fuel producer. However, in a MOX assembly there may be considerable variation in flux from the assembly surface to its interior, which requires attention to the concentration of plutonium in the various rods. Thus, the second arrangement complicates the task of the reactor designer and operator to ensure that all fuel rods operate at the desired power within safety limits.

Moreover, the higher absorption cross section in 239Pu reduces the effectiveness of the usual reactor control absorbers. For self-generated recycle of plutonium containing mainly 239Pu, designers concluded that the existing control absorbers could be used if no more than about one-third of the core were fueled with MOX fuel. A larger loading would require modification of the pressure vessel head in a PWR (or the bottom-mounted control structure in a BWR) to accommodate more control rods.

Adapting the self-generated recycle approach to the transmutation of the MAs and selected fission products could proceed by mixing these constituents with the plutonium in the MOX fuel rods. The addition of MAs and 238Pu, 240Pu, and 242Pu complicates somewhat the issues of reactivity control and core power distribution, due to the changing composition and reactivity of the waste material to be burned as the transmutation proceeds over many fuel cycles. In particular, the isotopes 241Am and 240Pu have large cross sections for thermal neutrons and significantly affect the reactivity. However, recent work (Lee and Du, 1994) confirms earlier studies that show that self-generated recycle with MAs and TRUs is could be feasible with one-third core loading. Moreover, the changing fuel composition and the presence of very high actinide radioactivity in discharged and recycled fuel complicates fuel reprocessing and fabrication, quality assurance, and fuel-performance testing and verification that are required for licensing. These reactivity control and fuel issues are discussed more fully under State of the Technology below.

DEDICATED LWR TRANSURANIC BURNERS

The U.S. nuclear industry also envisioned an alternative approach to self-generated recycle with one-third core loading. Some of the PWRs were designed with the flexibility of adding enough control absorbers so that these reactors could be fueled entirely with MOX fuel

containing natural uranium rather than LEU. These LWRs would operate as dedicated "plutonium-burner" reactors while the other LWRs would be fueled entirely with normal LEU. This would avoid the problems arising from two types of fuel rods with different neutronic characteristics. To flatten the power distribution in the core, the concentration of plutonium in the rods may be varied depending on where an assembly is to be placed in the reactor. Thus, the division into plutonium burners and normal LWRs would simplify the issues of control-absorber design, reactivity control, and local heat generation rate in the MOX fuel rods. Such plutonium burners could serve as devices for transmuting the MAs and fission products.

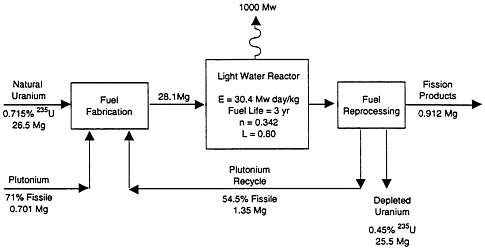

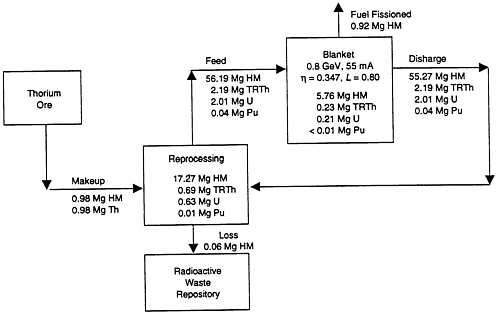

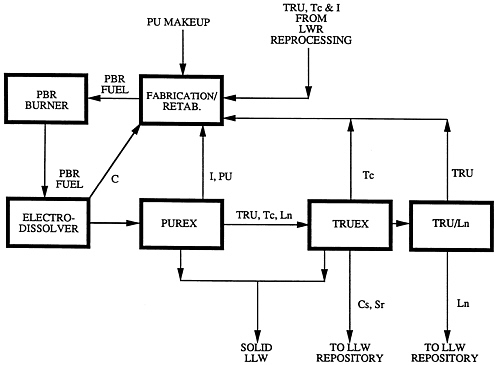

Any of the current or advanced LWR designs could be adapted for such a purpose. Figure F-6 shows a representative material flowsheet of a plutonium-burner PWR based on the same commercial 1,000 MWe PWR design by Combustion Engineering as for self-generated recycle in Figure F-515 (Pigford and Yang, 1977; Hebel et al., 1978). An LWR is an efficient alternative for dedicated plutonium burning because it can take advantage of the high fissile specific power of a thermal reactor that results in a high fractional burn-up in the target fuel.

However, the changing composition and the radioactivity from the MAs and the various plutonium isotopes in the target fuel material raise similar issues—concerning fuel refabrication, quality assurance, and fuel performance testing and verification—for an LWR TRU burner as is discussed above for LWR self-generated recycle. The recent study of Lee and Du (1994) indicates that the neutron absorption by the 241Am and 240Pu isotopes may build up to levels in dedicated burner operation that requires addition of uranium of moderate enrichment (a few percent) to maintain reactivity. This would also enhance the capabilities for burning the long-lived fission products.

ADVANCED LWR DESIGNS

In recent years, the EPRI has conducted a program for U.S. utilities to reconceptualize LWR designs based on the extensive LWR experience in the United States and abroad. The overall objective is to achieve greater engineering and physics margins and reduced complexity of construction and operation, compared with previous LWRs. Two classes of designs are in the process of being certified for standardized licensing by the NRC. The goals are at least a factor of 10 reduction in the potential for any core-damaging accident and an even greater reduction in the potential for public harm. Additional goals address better economics.

Specific designs for "large evolutionary LWRs," all rated about 1,300 MWe, have been proposed by Westinghouse for the advanced PWR-1300, by GE for the advanced BWR, and by Asea Brown Boveri Combustion Engineering Nuclear Power for the System 80+ PWR. These systems generally conform to requirements set forth in the Utility Requirements Document (EPRI, 1990), summarized in Table F-2 and serve as benchmarks

|

15 |

The data for the plutonium burner is published in Shapiro et al. (1977). The flowsheet and material balance of Figure F-6 would need to be altered to include the MA and fission product feeds. |

TABLE F-2 Key Utility Design Requirements for Advanced Light-Water Reactorsa

|

Plant size |

Reference size 1,200–1,300 MWe for evolutionary designs; reference size 600 MWe for passive safety designs |

||

|

Design life |

60 years |

||

|

Design philosophy |

Simple, rugged, no prototype required |

||

|

Accident resistance |

≥ 15% fuel thermal margin, increased time for response to upsets |

||

|

Core damage frequency |

< 10-5/yr by probabilistic risk analysis |

||

|

Loss of coolant accident |

No fuel damage for 6° pipe break |

||

|

Severe accident mitigation |

<25 rem at site boundary for accidents with > 10-4/yr cumulative frequency |

||

|

Emergency planning zone |

For passive plant provide technical basis for simplification of offsite emergency plan |

||

|

Design availability |

87% |

||

|

Refueling interval |

24 months capability |

||

|

Maneuvering |

Daily load follow |

||

|

Worker radiation exposure |

< 100 person rem/yr |

||

|

Construction time |

1,300 MWe: ≦ 54 months (first concrete to commercial operation); 600 MWe: ≦ 42 months |

||

|

Design status |

90% complete at construction initiation |

||

|

Economic goals |

10% cost advantage over alternative (nonnuclear) after 10 years and 20% advantage after 30 years |

||

|

Resulting cost goals (1989 dollars) |

|

1,200 MWeb |

600 MWeb |

|

|

Overnight capital 30-year levelized total generation |

1,300 $/kWe 6.3 cents/kW·h |

1,475 $/kWe 7.2 cents/kW·h |

|

SOURCE: Electric Power Research Institute (1990). a These requirements apply to both the large evolutionary LWRs and to the mid-sized LWRs with passive safety features. b 1,200 MWe commercial operation in 1998; 600 MWe in 2000. |

|||

for the near-and mid-term future. The design improvements cover every facet of the systems—reactor core design, fluid systems, steam generators, control and instrumentation, and containment.

In addition to the evolutionary improvements in design, GE and Westinghouse have proposed LWRs of 600 MWe that would employ primarily passive means—gravity, natural circulation, and stored energy—for the main safety functions. Known as "mid-size LWRs with passive safety features," such reactors could be attractive because of the simplification in system components (tanks, valves, pipes, cabling, ducting, etc.) with accompanying reduction in cost and improvement in operability, maintainability, and reliability (National Research Council, 1992:102–110). Also, such reactors may reduce the reliance on active components and human operators, relative to present-day designs, to cope with the wide variety of abnormal conditions. The passive safety features may even eliminate the need for special safety systems, such as the emergency core cooling system in present-day designs.

The Westinghouse AP-600 design and GE's simplified boiling water reactor design presumably require more development before commercial deployment than would the large evolutionary LWR designs. Nonetheless, the passive safety designs potentially could be available for start of construction by the end of this decade, and the evolutionary designs by the mid-1990s, depending on the pace of licensing and utility interest. Indeed, an AP-600 has been proposed recently as a weapons plutonium burner (Buckner and Parks, 1992). However, the critical issues raised above for the current designs—concerning reactivity control and local heat generation rate in the MOX fuel rods, as well as radioactivity in the refabricated fuel—would impact transmutation with either class of advanced LWR designs.

Transmutation Performance Requirements

The MAs could be burned in a thermal spectrum. Also, LWRs could transmute the technetium and iodine fission products. The estimated fractional burn-up rates are 11 and 3%/yr, respectively (Croff et al., 1980, 1990). In addition, the LWRs could furnish make-up plutonium if a transmutation system has other reactors that act as waste burners and are net plutonium consumers.

However, the higher capture-to-fission ratio for a thermal spectrum results in a greater build-up of high mass MAs. Successive neutron captures would produce several curium isotopes that decay by spontaneous fission and produce fast neutrons. Some will decay by alpha emission and produce enough heat to produce a cooling problem (see Chapter 4). Much of the curium alpha and neutron activity would come from 242Cm and 244Cm with contributions from 246Cm and 248Cm as these isotopes build up in later fuel cycles of the transmutation period. Further capture of neutrons together with beta decay would produce some 252Cf, which is an intense emitter of neutrons from spontaneous fission. In addition, unburned 238Pu would be a significant neutron source and heat producer. Thus, the build-up of high mass TRUs over many fuel cycles poses an issue for fuel reprocessing, target fuel refabrication, quality assurance, and fuel performance verification (see State of the Technology below).

In the residual high-level waste (HLW) after LWR transmutation, the curium isotopes and 238Pu may build up to very high activities, sufficient to dominate the short-term risks from a geologic repository. The 234U and 226Ra decay daughters of 238Pu would add to the long-term risk. Transmuting 237Np would not necessarily reduce its long-term risk appreciably if neptunium is solubility limited. Transmutation of 129I and 99Tc, or deploying better repository waste forms for these radionuclides after chemical separation, could significantly decrease the calculated individual dose and risk from a repository. However, using transmutation as a means to add more waste from future nuclear power systems to the proposed Yucca Mountain repository, as DOE has proposed, could increase the individual doses and risks from that repository, even for radionuclides that have been reduced in inventory by transmutation. Predicting the resulting effect on repository performance would depend on detailed calculations that have not yet been performed.

The comparative transmutation performance is discussed in Chapter 4, where inventory reduction factors are calculated for the Combustion Engineering PWR design as a plutonium burner, assuming a process decontamination factor of 1,000. By comparison with an ALMR of similar reactor breeding ratio (i.e., 0.65), a higher asymptotic inventory reduction factor seems possible with the LWR—about 4,800:1 versus about 3,000:1. Similarly, the time required to attain a given inventory reduction would be less than for an ALMR.

The superior performance of the LWR plutonium burner results from the higher fissile specific power of an LWR reactor, which should prevail even when MAs are included. The comparative performance is similar, but time scales are shorter by a factor of about 5 for a declining power scenario in which nuclear power is phased out as rapidly as possible consistent with transmuting the maximum amounts of TRUs and key fission products in the HLW.

Facilities and Support Requirements

REPROCESSING REQUIREMENTS

Transmutation with LWRs requires facilities of high reliability and capacity factor to reprocess the LWR spent fuel. Although the reprocessing of commercial reactor fuel was discontinued in the United States in the mid-1970s, a facility for reprocessing commercial reactor fuel had operated at West Valley, New York, for a short period, and two large commercial reprocessing facilities had been constructed at Barnwell, South Carolina and Morris, Illinois, but not operated. These plants were based on aqueous PUREX technology to separate uranium and plutonium from HLW and were designed for contact maintenance after the PUREX initial separations stage. Also, they were not constructed with international safeguards in mind. Thus, their design experience is relevant, but their costs would not fully reflect present-day requirements.

With aqueous-based technology, the facility could use a TRUEX process stage after the basic PUREX process for better separation of the MAs and reduction of the TRUs in the various waste streams to as low a level as possible. Additional processing might be employed after the TRUEX stage to separate the technetium and possibly other fission products. Also, radioiodine

would be recovered from the off-gases. TRUEX has been demonstrated on actual reactor waste at laboratory scale, but a process scale-up and pilot-scale test/demonstration would be necessary with waste containing MAs. It may become possible to use pyroprocessing technology for LWR waste, but its feasibility has yet to be demonstrated for oxide fuels, even at laboratory scale (see Chapter 2).

Based on trends in the United States and overseas for increased protection of operational personnel as well as the general public, one could assume the requirement for a fully automated, remotely maintained type of reprocessing facility (i.e., with heavy shielding and equipped with sufficient automation and redundancy to avoid the need for human access even for maintenance). Such a facility presumably would include automated materials accountability and advanced surveillance capability for safeguards.

Around 1980, a detailed study was conducted by Bechtel and Oak Ridge National Laboratory (ORNL) for a plant with all-remote operation and maintenance for reprocessing oxide breeder reactor fuel, including provision for safeguards (Jones, 1981). In addition, the experience of foreign commercial reprocessors using aqueous-based separations is highly relevant. A large reprocessing facility (UP2) at La Hague, France, with a dual defense/commercial mission has operated for over a decade, and a commercial facility (UP3) with a nominal operating capacity of 800 MgHM/yr has recently been constructed. The United Kingdom operated a small reprocessing facility at Dounreay, Scotland, and is constructing a commercial plant (THORP) of 800-MgHM/yr nominal operating capacity at Sellafield. Japan has operated a small reprocessing facility at Tokaimura and is planning for a facility at Rokkashomura of 800-MgHM/yr nominal operating capacity (see Chapter 4 and Chapter 6, Cost of Fuel Reprocessing). However, the European plants are not designed for totally remote maintenance. The design of the planned Japanese facility at Rokkashomura may be closer to the anticipated requirements for a U.S. facility.

Thus, a considerable base of experience exists on which a commercial-scale reprocessing facility could be designed and operated in the United States to meet present-day requirements. A plant the size of UP3 or the planned Japanese reprocessing facility (nominally 800 MgHM/yr operating capacity) could support many LWR TRU burners. In addition to technical issues such as TRUEX development, however, there are difficult issues of proliferation policy, public acceptability, licensing, high capital costs, and overall fuel-cycle economics. The development and system costs are estimated below. For other issues, see Chapter 6.

FUEL FABRICATION REQUIREMENTS