CHAPTER FOUR—

TRANSMUTATION SYSTEMS

The previous chapter focuses on the chemical technologies for separating radionuclides in spent fuel and defense high-level radioactive waste (HLW). This chapter considers proposals for attaining the neutron fluxes that could transmute such radionuclides, focusing on the prospects for benefiting the disposition of spent fuel from civilian reactors.1 For achieving transmutation, any practical system must integrate transmutation with separations of radionuclides to be transmuted by reprocessing of spent light-water reactor (LWR) fuel assemblies. In addition, all the proposed transmutation processes have a complex fuel cycle and would involve not one new facility but an interdependent system of many. Such systems require many components: spent-fuel reprocessing plants, waste transmutation facilities with systems to remove heat and (optionally) convert it into electricity, fuel fabrication plants, processing plants for the wastes from the separations and transmutation processes, sites for eventual disposal of the low-level radioactive waste (LLW) and any remaining HLW, as well as transportation systems for moving fuel and radioactive material between sites.

This chapter assesses the basis for transmutation by taking a systems point of view on the following proposals made by various organizations to the U.S. Department of Energy (DOE).

-

Advanced liquid-metal reactor (ALMR) as part of an integral fast reactor (IFR) system, proposed by General Electric (GE) and the Argonne National Laboratory (ANL).

-

Particle bed reactor (PBR), proposed by the Brookhaven National Laboratory (BNL).

-

Accelerator transmutation of waste (ATW) system, proposed by the Los Alamos National Laboratory (LANL).

-

Phoenix accelerator-driven fast reactor concept, proposed by the Brookhaven National Laboratory.

-

Clean Use of Reactor Energy (CURE), a study2 by Westinghouse Hanford Co. and Battelle Pacific Northwest Laboratories, involving modified liquid-metal fast reactors (LMFR) as waste transmuters in a system with LWRs.

In addition to these systems, the LWR is evaluated as a transmuter of transuranics (TRUs) and selected fission products from reprocessed LWR spent fuel. An LWR transmuter is a feasible approach in its own right, assuming the development of a fuel cycle to support such transmutation. In the analysis presented in this chapter, an LWR transmuter system serves as a reference for evaluating the advantages, disadvantages, and development requirements of the other proposals.

The chapter presents some judgments on the current level of technological maturity of the proposed systems and the prospects for their further development, using information from foreign programs for perspective. The fuel cycle required to support transmutation is considered, including separations, waste treatment, technical issues, and costs. The impacts on the repository are covered. Proposal-specific aspects of crosscutting issues from fuel-cycle economics, impacts on the repository, health and safety, licensing, and the institutional context are reviewed, but a comprehensive discussion of such issues, and of nuclear proliferation, is deferred to Chapter 6. A detailed evaluation of the concepts is provided in the appendices to this report.

The sections listed below summarize the evaluation of the three primary transmutation concepts, namely, the ALMR/IFR, ATW, and LWR systems, plus an initial assessment of the PBR and Phoenix systems, on which less information is available. The evaluation that follows in the sections to this chapter covers the following topics:

-

transmutation processes and concepts;

-

reduction of transuranic inventories;

-

reduction of key fission product inventories;

-

safety issues for the reactor, fuel materials, and supporting fuel cycle;

-

development time, cost, feasibility, and risk through system demonstration;

-

time scale and costs for complete system deployment; and

-

comparative thermal and electrical efficiencies.

TRANSMUTATION PROCESSES AND CONCEPTS

The subsection below, Transmutation Processes, reviews the principal nuclear processes for transmuting the key fission products and transuranics (TRUs). The subsections Transmutation Reactor Approaches, Overview of Critical Reactor Concepts, and Overview of Accelerator-Driven Reactor Concepts introduce the transmutation proposals and the LWR as a waste transmuter and reference system for the proposals. The subsection Separations with Transmutation of Plutonium (Only) introduces a simplified transmutation concept in which the only TRU burned is plutonium, possibly with key long-lived fission products.

Transmutation Processes

Transmutation of Key Fission Products

The main transmutation processes for fission products are neutron capture (producing a higher mass nuclide) and beta decay. For many fission products the neutron capture cross sections in a thermal (or epithermal) spectrum can give substantial transmutation rates. The corresponding capture cross sections in a fast neutron spectrum are typically orders of magnitude smaller.

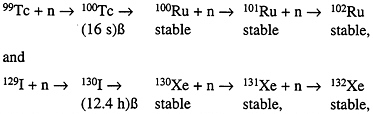

Transmutation of the long-lived fission products 99Tc and 129I is feasible in a thermal reactor. The ruthenium and xenon transmutation products are stable under neutron capture processes; that is,

and

The 129I is produced with stable 127I, which also transmutes to stable isotopes. For a thermal neutron spectrum typical of a uranium-fueled PWR, the spectrum-averaged capture cross sections for dilute 99Tc and 129I from the ORIGEN-2 code library are 13.8 barns and 3.2 barns, respectively (Wachter and Croff, 1980).3 An ORIGEN-2 calculation for a PWR gives in-reactor transmutation rates of about 11 percent per year for 99Tc and 3 percent per year for 129I (Wachter and Croff, 1980). Practical transmutation rates will be low because the external inventory of 99Tc and 129I in reprocessing and target fabrication must be taken into account.

Transmutation of 90Sr (29 yr) and 137Cs (30 yr) is possible in principle but not in practice. Their transmutation would make little improvement in the calculated radiological risk for a geologic repository because of the relatively short-term nature of their radioactivity, although the reduction in repository heat loading might be marginally advantageous.

Transmutation of the long-lived radionuclide 135Cs would also be possible in principle but not in practice. This radionuclide would be transmuted to stable 136Ba through short-lived 136Cs. Unfortunately, 135Cs is produced with a larger quantity of stable 133Cs, which would undergo neutron capture to 134Cs and to more 135Cs. To remove the stable 133Cs beforehand by isotopic separation would be formidable in the presence of the intense 137Cs gamma radiation field. Rather than attempting to transmute 135Cs, its radiological risk in a geologic repository could be reduced by separating cesium in the reprocessing operation and incorporating it into waste form in which cesium would have a significantly reduced solubility in groundwater.

Transmutation of Transuranics

Characteristics of Thermal and Fast Neutron Processes. Transmuting the TRUs is more complex (Benedict at al., 1981). In a neutron flux, several competing processes determine the concentrations of the transmuted isotopes as a function of time. Three processes are important here: (1) neutron-induced fission, (2) neutron capture to produce a higher-mass nuclide, and (3) radioactive decay. Table 4-1 lists the half-lives of selected uranium and TRU isotopes that occur during transmutation and the ratios of their spectral-averaged capture and fission cross sections for several kinds of thermal and fast neutron spectra. A number of characteristic features may be seen by a study of the properties.

First, the "capture-to-fission" ratios for thermal neutron spectra show marked differences for odd-versus even-neutron isotopes. Odd-neutron isotopes fission well in a thermal spectrum; in fact, such fission is favored over capture by factors of 2 to 10. In contrast, most even-neutron isotopes are not fissioned by neutrons below several hundred kilovolts in energy, due largely to the extra nuclear stability conferred by neutron pairing. Hence, in a thermal reactor, such nuclei are fissioned only by the fission spectrum neutrons.

Second, the thermal neutron "capture-to-fission" ratios are typically higher than those for fast spectra. This effect is exaggerated for even-neutron isotopes; indeed, 240Pu and 241Am have large thermal neutron capture cross sections and are parasitic absorbers in thermal reactors. However, odd-neutron isotopes also show the effect by factors of 1.5 to 3, mainly because capture cross sections are typically higher for thermal spectra. Most importantly, the high thermal capture-to-fission ratio of 239Pu and its capture products result in relatively large amounts of higher-mass actinides in a thermal-neutron transmuter, as compared to a fast reactor.

Transuranic Production and Transmutation. The main source of the principal TRU, 239Pu, is neutron capture in 238U followed by two beta decays (i.e., in the initial spent fuel plus possible additional production during transmutation). The 239Pu fissions well with neutrons of any energy. Alternatively, it produces 240Pu by neutron capture. Table 4-1 lists a capture-to-fission ratio of 0.55 in a thermal spectrum compared to 0.17 and 0.26 in a fast spectrum with metallic and oxide fuel, respectively. Successive neutron captures, starting with 239 Pu, produce higher mass isotopes of Pu, Am, and Cm.

The minor actinides and other plutonium isotopes, in particular 240Pu and 242Pu, fission well in a fast spectrum. That isotope 237Np could undergo neutron capture and furnish additional 239Pu. That is,

However, in a very high neutron flux, the intermediate nucleus 238Np could attain a high probability of capturing a second neutron and fissioning before the beta decay could take place. Thus, in principle, a high-flux transmutation scheme could achieve a higher fissioning rate of various isotopes than a scheme that operates at ordinary thermal flux levels.

Two even-neutron isotopes in the plutonium chain, 240Pu and 242Pu, are key precursors of higher-mass actinides by neutron capture to 241Pu and 243Pu, which can undergo beta decay to 241Am and 243Am, respectively (see Table 4-1). The two americium isotopes fission well in a fast spectrum, but can produce 242Cm (163 d) and 244Cm (18.1 yr) by neutron capture in a fast or thermal spectrum. However, the higher capture-to-fission ratio characteristic of a thermal spectrum, discussed above, results in a build-up of higher-mass actinides during thermal neutron transmutation. A chain of long-lived curium isotopesis produced by successive neutron captures—245Cm (8,500 yr), 246Cm (4,820 yr), 247Cm (1.56 × 107 yr), and 248Cm (3.7 × 105 yr), even some 250Cm (9.7 × 103 y). The chain branches at 249Cm with the 64-minute beta decay to 249Bk, which leads in steps to production of californium isotopes, in particular 252Cf. Even higher-mass actinides can be produced in a thermal flux >1015 neutrons/cm2-s, such as in the high-flux isotope reactor (HFIR). Thus, a range of higher-mass isotopes is produced in either a fast or thermal spectrum, although the relative proportions are quite different. The possible effects of the higher actinides are discussed in the sections on several of the transmutation options. In target waste material, 252Cf would be a potent source of neutrons by spontaneous fission. In addition to alpha emission, spontaneous fission also occurs in curium isotopes, becoming more probable with increasing curium mass, i.e., 242Cm (8 × 10-6%), 244Cm (1.3 × 10-4%), 246Cm (0.027%), 248Cm (0.83%), and 250Cm (~99%) (Hoffman et al., 1992). In addition, unburned 238Pu can be an important source of neutrons by (α, n) processes. Hence, for thermal neutron transmutation concepts, significant neutron emission could present problems during fuel reprocessing and refabrication, quality assurance, and performance verification. To a lesser extent, the issue could arise with fuel rods for transmutation in a fast reactor.

Transmutation Reactor Approaches

Classes of Reactor Concepts

To take possible advantage of nuclear processes for transmutation, two quite different classes of reactors have been studied for neutron generation. The work to date consists primarily of a conceptual analysis of the effects of the neutrons generated in either approach in order to estimate the benefits and hazards that would result from changing the character of the waste to be disposed. The two classes of reactor concepts are:

-

Critical nuclear reactors: The nuclear assembly, containing the waste and possibly additional fissile material, operates with a net neutron multiplication factor of unity. This class includes thermal reactors, such as the LWR and PBR, and fast reactors, such as the ALMR.

-

Accelerator-driven nuclear reactors: The nuclear assembly operates with a neutron multiplication factor less than unity, i.e., subcritical, so that neutrons must be added from a source external to the nuclear assembly. Intense

TABLE 4-1 One Group Capture-to-Fission Cross-Section Ratios of Transmutation Isotopes for Thermal and Fast Neutron Spectra in Various Reactor Cores

|

Isotope |

Half-Life |

U-PWRa |

Pu-PWRb |

LMFBRc |

ALMRd |

Main Source |

|

235U |

7.04 × 108 yr |

0.22 |

0.28 |

0.27 |

0.25 |

natural uranium |

|

236U |

2.34 × 107 yr |

— |

— |

— |

— |

neutron capture by 235U |

|

237U |

6.75 d |

— |

— |

— |

— |

neutron capture by 236U & 238U |

|

238U |

4.47 × 109 yr |

9.02 |

7.93 |

5.44 |

4.34 |

natural uranium |

|

239U |

23.5 min |

— |

— |

— |

— |

neutron capture by 238U |

|

237Np |

2.14 × 106 yr |

61.3 |

42.43 |

4.22 |

2.71 |

6.8 d beta decay of 237U |

|

238Np |

2.1 d |

0.10 |

0.10 |

— |

— |

neutron capture by 237Np |

|

239Np |

2.35 d |

— |

— |

— |

— |

23.5 min beta decay of 239U |

|

238Pu |

87.7 yr |

14.06 |

7.51 |

0.60 |

0.44 |

2.1 d beta decay of 238Np |

|

239Pu |

2.44 × 104 yr |

0.55 |

0.56 |

0.26 |

0.17 |

2.35 d beta decay of 239Np |

|

240Pu |

6,560 yr |

178.1 |

70.55 |

1.25 |

0.82 |

neutron capture by 239Pu |

|

241Pu |

14.4 yr |

0.33 |

0.31 |

0.18 |

0.15 |

neutron capture by 240Pu |

|

242Pu |

3.75 × 105 yr |

76.43 |

47.78 |

1.42 |

0.93 |

neutron capture by 241Pu |

|

243Pu |

4.98 h |

0.49 |

0.49 |

— |

— |

neutron capture by 242Pu |

|

241Am |

433 yr |

94.2 |

63.96 |

4.95 |

3.56 |

14.4 yr beta decay of 241Pu |

|

242Am |

16 h |

— |

— |

— |

— |

neutron capture by 241Am |

|

242Am |

141 yr |

0.21 |

0.20 |

0.10 |

0.07 |

neutron capture by 241Am |

|

243Am |

7,370 yr |

106 |

78 |

3.84 |

2.29 |

4.98 h beta decay of 243Pu and neutron capture by 242Am |

|

242Cm |

163 d |

10.38 |

11.4 |

1.59 |

0.85 |

16 h beta decay of 242Am |

|

243Cm |

28.5 yr |

0.12 |

0.13 |

0.09 |

0.07 |

neutron capture by 242Cm |

|

244Cm |

18.1 yr |

15.79 |

14.83 |

1.71 |

1.21 |

10 h beta decay of 244Am |

|

245Cm |

8,500 y |

0.17 |

0.17 |

0.12 |

0.10 |

neutron capture by 244Cm |

|

246Cm |

4,820 y |

5.04 |

4.71 |

0.72 |

0.47 |

neutron capture by 245Cm |

|

247Cm |

1.56 × 107 yr |

0.65 |

0.63 |

0.16 |

0.12 |

neutron capture by 246Cm |

|

248Cm |

3.4 × 105 yr |

8.36 |

7.88 |

0.68 |

0.44 |

neutron capture by 247Cm |

|

249Cm |

64 min |

0.03 |

0.03 |

— |

— |

neutron capture by 248Cm |

|

250Cm |

9,700 yr |

— |

— |

— |

— |

neutron capture by 249Cm |

|

249Bk |

523 d |

807.0 |

460.3 |

4.63 |

1.92 |

64 min beta decay of 249Cm |

|

250Cf |

13.1 yr |

513.6 |

292.8 |

0.37 |

0.20 |

fast beta decay of 250Cf |

|

251Cf |

800 yr |

0.48 |

0.45 |

0.12 |

0.10 |

neutron capture by 250Cf |

|

252Cf |

2.65 yr |

0.47 |

0.41 |

0.39 |

0.32 |

neutron capture by 251Cf |

|

a Normal low-enriched uranium in a pressurized water reactor. b Self-generated plutonium recycle in a pressurized water reactor. c Mixed oxide fuel in a liquid-metal fast reactor. d Metallic fuel in an advanced liquid-metal (fast) reactor. SOURCES: U-PWR and Pu-PWR from ORIGEN 2.1 (1991). LMRBR and ALMR from GEFR-00898 (1991).4 |

||||||

-

beams of very high-energy protons would be focused on targets such as lithium, tungsten, molten lead, or even the fuel itself. This would generate large numbers of spallation neutrons that would be multiplied by the subcritical assembly to transmute waste material surrounding the target.

The various transmutation concepts differ widely in the many technical, programmatic, economic, and other dimensions by which they may be characterized. However, there are no universal figures of merit for the evaluation of the different transmutation approaches. The remaining sections of this chapter summarize the results of the evaluation using a variety of "measures" for comparison:

-

the rate and time for various percentage reductions in the TRU inventory:

-

the flexibility and rate for reducing key fission product inventories:

-

the safety issues for the reactor, fuel materials, and supporting fuel cycle;

-

the development time, cost, feasibility, and risk through complete demonstration;

-

the estimated time scale and costs for complete deployment, including overall fuel cycle economics; and

-

the comparative thermal and electrical efficiencies per net amount of waste transmuted.

The first type of measure, the reduction in TRU inventory, raises a methodological issue. Over the life cycle of a reactor, approximately 30 years, most of its initial load of TRUs is transmuted; however, additional TRUs are generated. Thus, only a partial net reduction occurs over each reactor life cycle, the untransmuted TRUs being passed to the next generation of reactors for further reduction. Some groups and authors emphasize the time to reprocess and burn the TRUs originally in the LWR spent fuel, which is much shorter than the time required for a net reduction including the TRUs created during transmutation. Others emphasize the TRUs in waste sent to a repository from reprocessing, discounting surface-stored waste at fuel-cycle facilities on the grounds that the fuel-cycle material still contains fissionable resources. However, for the major part of the transmutation period, most of the inventory is in surface facilities. This results in increased risk to nearby populations, compared to the direct disposal of spent fuel in the repository, due to the additional operations to burn the waste.

As one figure of merit for each type of transmutation system, therefore, this report evaluates the net decrease in total TRUs versus time for multiple reactor life cycles of that system, compared to an untransmuted reference case. That is, the net TRU ratio as a function of time is defined to be the TRUs from a once-through, uranium-fueled LWR cycle for a given electrical power level, divided by the total TRUs for the system in question (in the reactor, the associated fuel-cycle facilities and the waste) for that power level. The time scale for achieving various percentage reductions, the asymptotic reduction factors, and the neutron efficiencies for the concepts are useful for comparisons.

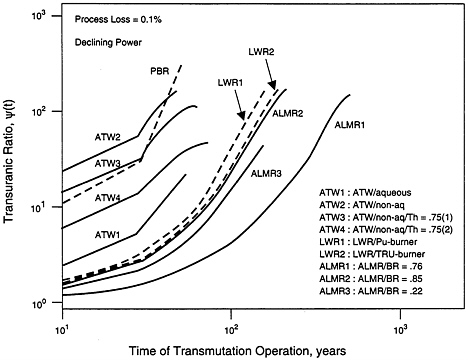

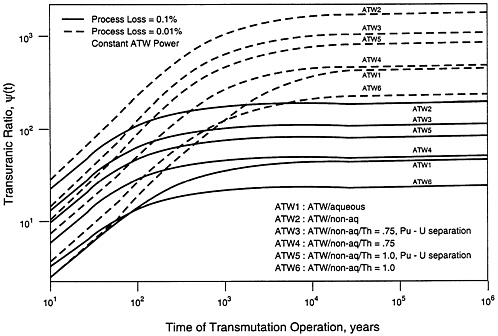

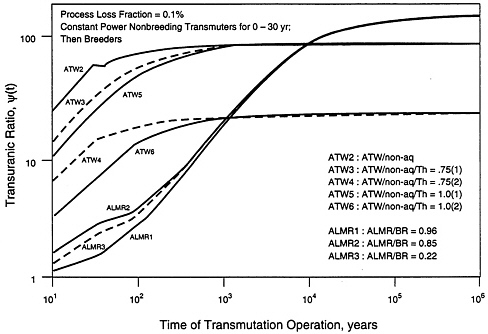

The calculated TRU ratios and the corresponding times for various fractional changes in net inventory range widely among the proposals. For evaluation purposes, this report considers two nuclear power scenarios, under the assumption that the transmutation systems would produce electrical power for distribution to the electrical grid. For example, for a continuing "steady nuclear power" scenario with a mix of breeding and nonbreeding transmuters, achieving a net TRU ratio of a factor of 100 requires from a few hundred years for some proposals to several thousand years for others. A TRU ratio of 10 requires from about 7 years to over 400 years for the various proposals at constant nuclear power. The time scales are significantly shorter for a "declining nuclear power" scenario, in which nuclear power is phased out as rapidly as possible consistent with transmuting the most nuclear waste. For this type of scenario, for example, the calculated time to achieve a TRU ratio of 100 ranges from about 40 years to several hundred years.

Engineering and Materials Issues

In both the critical reactor and accelerator-driven subcritical reactor approaches, there are variations in the chemical and physical properties of the fuel containing the waste to be transmuted. For this reason, all the proposals entail fuel development and verification issues. Moreover, even for the systems operating with subcritical reactors, the heat generation rates would require careful analysis of the provisions for safe removal of residual heat generated from the decay of fission products and minor actinides after the termination of the fission process. Also, the transmutation systems that employ a high fissile specific power (i.e., the thermal-reactor concepts) are likely to raise safety issues associated with the control of reactivity and power distributions in the reactor core. Detailed analysis of such issues is important for the licensability of the system designs. All the concepts require development and testing of at least some aspects in a pilot-scale system. Indeed, most of the systems will require demonstration at full-scale prototype before such systems could be implemented confidently for reliable operation at high-capacity factor.

Several proposals aim at producing and sustaining a very large fractional destruction rate—the product of neutron flux and cross section—since that determines the rate of transmutation of the waste. A large destruction rate, in turn, entails high heat generation rates from the high fission rate and decay heat of nuclei in the reactor proper and, in the accelerator-driven case, from proton deposition in the target. For these proposals the engineering designs pose difficult problems. In some proposals the materials must withstand conditions beyond engineering experience with present-day reactors. These conditions include neutron (and in the case of accelerator-based proposals, proton) fluxes and fluences, neutron spectra, temperatures, and chemical environments, singly or in combination. High-energy neutron and proton fluxes impart atomic displacement damage that generally degrades structural materials and affects basic properties (e.g., ductility, fracture toughness) and imparts dimensional instabilities (e.g., swelling and creep). Such flux levels would also increase the level of activation products in the nuclear waste.

Indeed, some of the proposed systems envision neutron fluences for certain components that are beyond the levels achieved for the corresponding components in existing systems,

e.g., more than 100 displacements per atom for some structural components or roughly an order of magnitude more than experienced in the Fast Flux Test Facility (FFTF). The displacement damage can be aggravated by nuclear transmutation that converts existing alloying elements to impurities. Two such processes are (1) transmutant gas production (e.g., helium from (n, α) production) arising from the high-energy portion of the neutron spectra in accelerator-based sources, and (2) transmutation of existing alloying elements to deleterious activation products by neutron absorption in approaches with a thermal spectrum. These types of induced impurities compound the difficulties imposed on structural materials required to operate at the high temperatures due to the high flux/power and density/thermal efficiency requirements of several of the transmuter concepts. Additional deterioration can be anticipated with those concepts that employ nonaqueous chemical environments (e.g., molten salts, liquid metals, aqueous slurries) to achieve the system performance requirements. Thus, several proposals entail considerable research and development before the chances of success can be ascertained.

Program Funding

As yet, there is no focused overall program in the United States for development of S&T technologies. The objectives and time table for such an effort are difficult to work out in the present climate of uncertainty about the future of nuclear power in the United States—in particular, uncertainty concerning the prospective geologic repository at Yucca Mountain and the possible future commercialization of a fast breeder reactor sometime in the next century. This committee, therefore, is able to estimate only an approximate total expenditure level for the U.S. effort.

For FY 1992, DOE's Office of Nuclear Energy (DOE/NE) identified direct expenditures of about $19 million specifically for transmutation objectives: about $15 million for the LANL's ATW effort and about $4 million for transmutation applications of the ALMR and IFR concept. In addition, the national laboratories used discretionary funding to extend their efforts. A few million dollars was spent at LANL and BNL in FY 1992 on accelerator-based concepts for transmutation. Smaller efforts were conducted by Westinghouse Hanford and Oak Ridge National Laboratory (ORNL).

However, DOE was spending a much larger amount for research and development indirectly related to transmutation objectives. For example, the ALMR effort at GE and the IFR at ANL were aimed primarily at breeder reactor development for future power production which are both adaptable to transmutation. This support included the support for ANL-West located at the Idaho National Engineering Laboratory. In addition, the development of accelerators for tritium production and other military objectives was indirectly relevant. For FY 1992 then, the efforts directly or indirectly applicable to transmutation systems amounted to about $75 million.

The total funding allocated to separation and transmutation in FY 1993 was is $133.5 million. DOE/NE identified direct expenditures of $41.4 million specifically for transmutation objectives: $8.9 million for ALMR development at GE, $26 million for metal fuel and IFR development at ANL, and $6.5 million for LWR actinide burning. The related ANL-West supporting facilities would add $76.1 million to the FY 1993 transmutation commitment. In addition, the DOE defense budget includes $4 million for ATW-related efforts at LANL, and the waste management budget includes $12 million for efficient separations and processing.

In FY1994 the administration began a phase-down or phase-out policy of the DOE/NE programs related to separations and transmutation.

In FY1995, a total of $104.8 million has been identified for these programs including IFR, but these funds are exclusively designated for close out and termination costs.

International Activities

International activities in S&T as a method of ameliorating high-level waste management are being conducted by individual countries as well as under the coordination of international organizations (the Organization for Economic Cooperation and Development's Nuclear Energy Agency, the International Atomic Energy Agency, and the Commission of the European Communities). Most of this activity is in Japan and Western Europe, with the majority of the European activity in France. Unlike the U.S. S&T program, however, the interest in Japan, France, and the United Kingdom stems from a larger interest in commercially reprocessing fuel, both in the near-term for LWRs using mixed-oxide (MOX) fuel and in the long-term for a breeder reactor economy. As a result, these countries are working on the technologies necessary for any S&T waste management scheme, including enhanced reprocessing techniques, remote fuel fabrication, and reprocessed waste packaging.

The interest in these countries in S&T for waste management has increased recently, largely as a result of increasing public resistance to high-level waste repository siting. Japan has perhaps the largest financial commitment to this effort through its OMEGA Project, which is a research and development effort aimed at partitioning actinides from HLW and transmuting actinides in either critical reactors or accelerator-driven subcritical assemblies. French and U.K. efforts have looked at actinide burning in fast reactors, but more from a perspective of controlling reactivity swings. Coordinated European programs have considered actinide

burning in fast reactor blankets, and preliminary work at the Paul Scherrer Institute in Switzerland has considered accelerator-driven spallation for actinide burning. Finally, both Japanese and European programs are examining nonaqueous separations techniques as well as enhanced aqueous reprocessing.

Overview of Critical Reactor Concepts

This subsection gives an overview of a fast reactor system and two types of thermal reactor systems that are proposed or are being considered for transmutation of nuclear waste, namely,

-

transmutation of TRUs in an ALMR as part of an IFR proposed by GE and ANL;

-

transmutation of TRUs and fission products in LWRs, either existing designs adapted for the purpose or more advanced designs currently in certification review by the Nuclear Regulatory Commission (NRC); and

-

transmutation of minor actinides with a PBR, as proposed by BNL.

The concept of transmutation using critical reactors has been studied for several decades; indeed, the United States was a leader in the field in the 1970s. Early in the commercialization of LWRs in the United States, the U.S. Atomic Energy Commission (AEC) and the nuclear industry expected that the cost of mining and enriching uranium would increase as high-grade uranium ore supplies were used up. In the 1960s and early 1970s, the AEC projected that this would occur by the 1980s and become increasingly serious in the 1990s. The parties visualized that spent LWR fuel would be reprocessed commercially and the plutonium and unburned uranium separated and recycled, first into LWRs and later into breeder reactors when they became commercialized. Thus, the total plutonium in the fuel cycle would be limited.

Fast Critical Reactor Concepts

The ALMR/IFR program had been sponsored by DOE/NE during the previous administration under joint development by GE and ANL.5 It emphasized the power reactor, innovative, small module (PRISM) fast reactor concept, which has been aimed primarily at the development of a breeder reactor for power production that would produce more fissile material than it consumes. It has long been recognized that a fast reactor can be modified to operate at a conversion (breeding) ratio, ß, less than 1.0 and thus could be configured to operate as a net burner of transuranics.6 For that matter, the neutron spectrum of a fast reactor can be softened, as proposed, for example, in the CURE concept, and gain capability to transmute fission products while retaining good characteristics for transmuting transuranics.7

This subsection discusses the GE and ANL proposal for an IFR for burning the TRUs. An IFR would comprise an ALMR for the purpose of burning TRUs together with its own self-contained capability for processing and fabricating the metallic fuel/waste alloy. For such reprocessing, ANL proposes to use pyrometallurgical technology. ANL is also exploring pyroprocessing of LWR spent fuel to provide the TRUs to start the ALMRs; this capability might be collocated with each IFR or configured in a larger, centralized facility to support many IFRs. As an alternative, GE has considered a centralized capability for LWR spent-fuel reprocessing based on aqueous plutonium and uranium extraction and recovery by transuranic extraction (PUREX-TRUEX) technologies.

More than a dozen fast breeder reactors have been operated in the United States, the Soviet Union, the United Kingdom, France, and Japan, although none are yet on-line as breeders for reliable power production. Further development would be needed to burn minor actinides (MA), including operation of a prototype integrated system. Designs with a breeding ratio, β, of 0.22 to 1.25 appear in the ALMR/IFR project literature (Chang, 1991a, 1991b; M.L. Thompson, private communication, 1991). Recent GE studies (Thompson, 1992) involve elimination of external blankets and shortening of core height, without changes in fuel rod diameter or number of fuel rods. Preliminary ANL designs (Johnson et al., 1990) include IFRs fueled entirely with TRUs. One design involves a mixture of plutonium and MA with β = 0.22; another involves mostly MA with β = 0.85. However, with reduced fissile breeding and heavy metal inventory in the core, the TRU burner designs entail increased specific power and higher reactivity swing over a fuel cycle.

GE suggests that for a TRU burner, β = 0.60 is the minimum

value with acceptable safety features. This limits the waste inventory reduction capability of the system. The consequences of this limitation for the inventory reduction factor, and the time required to burn various fractions of the actinides, are explored in detail later in this chapter (see Appendix F).

Thermal Critical Reactor Concepts

Several earlier studies of transmutation (Croff et al., 1977; Croff, 1980; Wachter and Croff, 1980) included LWRs as transmutation devices. Those studies focused on transmuting the MA, assuming that the recovered uranium and plutonium from LWR spent fuel would be recycled to the LWRs. Wachter and Croff also showed that an LWR could transmute 99Tc and 129I. However, the reprocessing of commercial reactor fuel did not go forward in the United States and is not currently considered viable for recycle to LWRs or breeder reactors, for both economic and public policy reasons. Consequently, transmutation schemes now proposed to assist the geologic disposal of LWR spent fuel (and/or accomplish other energy objectives) must deal with the transmutation of all the TRUs, the principal one being plutonium.

The section, The Light Water Reactor in Appendix F, discusses the LWR as a reference case for burning plutonium, the MAs, and the key fission products 99Tc and 129I.

The section, The Particle Bed Reactor Concept in Appendix F, evaluates the BNL proposal of a PBR for transmutation (Van Tuyle, 1992). The PBR is a thermal reactor concept based on a gas-cooled space reactor design. The PBR would have a compact core and operate with a power density of 5 MWt/liter, which is a factor of 102 greater than that of a typical LWR and even higher than the 1.13 MW/liter attained by the high flux isotope reactor (HFIR). The fuel material is embedded in small graphite particles (0.8 mm in diameter) packed in cylindrical pressure tubes. The tubes accommodate the packed particle bed within two coaxial porous plugs (frits) so that the particles could be cooled by forced circulation of helium. Heavy water and beryllium carbide moderators are being studied. The BNL proposal envisions burning the MAs, with the unburned plutonium and perhaps the unused fissile uranium to be directed for recycle to LWRs. A power reactor with such a high power density would be without precedent or experience as a commercial power reactor.

Overview of Accelerator-Driven Reactor Concepts

An alternative to using fast or thermal critical reactors is to generate a fraction of the neutrons by spallation with high-energy protons from an accelerator. LANL and BNL have made conceptual studies for achieving subcritical accelerator-based transmutation (see Appendix F). These concepts envision the production of electricity, part of it to power the accelerator and part available for sale to offset the costs of such an approach. The accelerator-based concepts are relatively new and are less well characterized and in a less mature state of technical development than the approaches using critical reactors. For these reasons, after introducing the specific proposals, the general features of accelerator-based approaches compared to those of the more familiar critical-reactor-based transmutation will be highlighted.

Appendix F treats four concepts for ATW under review by LANL for commercial LWR waste (Arthur, 1992a).8 Spallation neutrons are produced when the proton beam strikes a lithium (or heavy metal) target inside the assembly, which moderates the neutrons to a thermal spectrum and multiplies them by a large factor, namely, 20 in the current designs (corresponding to a neutron reproduction factor Keff = 0.95 for the subcritical assembly). The concepts differ in the type of fluidized waste/fuel (either a heavy-water slurry or a molten salt solution that circulates in a blanket), the type of processing used (aqueous or nonaqueous), the target material, and whether thorium is used in the molten-salt cases to provide production of fissile 233U. Each facility would have its own on-line fuel-processing capability, various storage and waste treatment facilities, and heat conversion and electrical power generation equipment. The four concepts are as follows:

-

transmutation of TRUs and some fission products recovered by aqueous reprocessing of LWR spent fuel, using an aqueous neutron multiplying system that generates electrical power (Case ATW-1);

-

transmutation of TRUs and some fission products recovered by nonaqueous reprocessing of LWR spent fuel, using a nonaqueous neutron multiplying system that generates electrical power (Case ATW-2);

-

transmutation of TRUs and more fission products recovered by nonaqueous reprocessing of LWR spent fuel, using a nonaqueous neutron multiplying system, fueled partly with thorium and generating electric power (Case ATW-3); and

-

transmutation of TRUs and some fission products in a nonaqueous thorium-breeder system for electrical power generation (Case ATW-4).

The LANL effort is in an early conceptual design stage. The baseline design, referred to as Case ATW-1 in this report, employs known technology to the extent possible and

furnishes a reference materials balance. LANL makes no claim that this design is optimized. LANL is also exploring three nonaqueous approaches with improved performance and economy. Referred to in this report as Cases ATW-2, ATW-3, and ATW-4, they attempt to optimize both the system neutron economy and overall system electric power production.

In contrast, the Phoenix concept proposed by BNL is envisioned to be part of a larger scheme for separating and transmuting waste from LWRs (Van Tuyle, 1992). As discussed in the section, The Accelerator-Based Phoenix Concept (see Appendix F), the Phoenix proposal would transmute the MAs and the radio-iodine from the reprocessed LWR spent fuel. The separated plutonium and uranium would be recycled to LWRs. Like the LANL ATW concept, Phoenix generates neutrons by spallation with a high-energy proton beam from an accelerator and multiplies the neutrons in a subcritical assembly that contains the waste to be transmuted. Unlike the LANL ATW, the proton target in Phoenix is composed of the MA waste itself. The neutrons have a hard spectrum, in contrast with the thermalized spectrum of the ATW. The Phoenix concept builds on existing oxide fuel technology developed under the FFTF program, together with aqueous separations technologies to reprocess both LWR and Phoenix spent fuel.

Since there is no plutonium in the Phoenix initial fuel charge, there is insufficient neutron generation for the MAs to burn both the radio-iodine and the technetium fission products. The discharged HLW containing technetium and the other fission products would be packaged for surface storage and, ultimately, geologic disposal. Thus, the scope of HLW transmutation would not be as extensive as in the ATW concept and is more like that of a fast spectrum, critical reactor approach, such as the ALMR.

The ATW and Phoenix concepts have several general features in common that can be contrasted with critical reactor-based concepts. Both laboratories point out that high fissile specific power can be attained that can result in fast burn-up rates of the actinides and certain fission products as well. BNL points out that the combination of high flux and hard spectrum in Phoenix results in shorter times to achieve given reductions in actinide inventories than possible with an ALMR.

Indeed, LANL believes that a neutron spallation source coupled to a fission blanket provides a fundamental enhancement in the effective number of neutrons per fission. Their calculations project a high-intensity thermal flux of 2 to 3 × 1015 neutrons/cm2-s, which is about an order of magnitude higher than is typical of thermal power reactor systems (Bowman et al., 1991). For such a system, LANL projects two key advantages (Arthur, 1992b).

First, a high neutron flux could provide more efficient destruction of certain actinides by enabling a nucleus to undergo two sequential (n, α) reactions, increasing the probability of the nucleus capturing a second neutron before the state created by capture of the first neutron would decay. Thus, an ATW system could, in principle, efficiently transmute some actinides that normally cannot be transmuted well with a thermal neutron flux but require fast neutrons.

However, the high thermal flux of the ATW would lead to a build-up of higher MAs in the residual inventory as transmutation proceeds, in particular, 242Cm, 244Cm, 246Cm, and 248Cm as well as 252Cf, all of which are significant neutron emitters. The level of radioactivity would be considerably higher than for the LWR and, of course, orders of magnitude higher than with a fast neutron spectrum. As discussed in Appendix F, the level of radioactivity may affect the quality assurance of the slurry/liquid target fuel during transmutation.

Second, the separation of accelerator and target/blanket assembly allows for rapid transmutation and entails relatively low inventories. Indeed, a main feature of the ATW, discussed in detail in Appendix F, is that it can transmute a given fraction of its TRU inventory far more rapidly than a fast reactor. This is a consequence of the lower critical concentrations characteristic of thermal reactors and the lower inventory in the on-line reprocessing system, as discussed later in this chapter.

Finally, both laboratories assert that an accelerator-based waste transmuter has potentially improved safety features vis-à-vis critical reactor concepts because, at least in theory, the assembly can be maintained subcritical, and shutdown can be accomplished rapidly by shutting off the accelerator. However, the discussion in Appendix F on the ATW and later in this chapter brings to light several types of transients that pose potentially significant safety issues for the accelerator-based concepts, in addition to the issues posed by decay-heat removal and target-heat dissipation.

Separations with Transmutation of Plutonium (only)9

An LWR or an ALMR would operate much more efficiently with 239Pu as the recycle fuel than with recycle of all the TRU isotopes contained in the LWR spent fuel. This suggests a waste management concept intermediate between the once-through LWR fuel cycle and the full transmutation of all TRUs and selected fission products. That is, the accumulated LWR spent fuel could be reprocessed and only the separated plutonium recycled to either an LWR or ALMR. In addition, 14C and 129I could be captured, e.g., as off-gasses, and packaged in low-solubility waste forms that

could be developed. The recovered uranium would be packaged for geologic disposal or possibly for recycle to an enrichment facility. An LWR could also transmute the long-lived 99Tc and 129I fission products if they were separated and recycled.

An ALMR could operate with the types of fuel previously developed for the fast breeder; the fast neutron spectrum would minimize higher plutonium build-up. With a LWR, the essential difference between this plutonium recycle concept and the "classic" thermal recycle of plutonium, demonstrated in the late 1960s, is that here the plutonium would be multiply recycled, resulting in a build-up of higher plutonium isotopes in the LWR thermal neutron spectrum. In particular, 240Pu and 242Pu are significant absorbers of thermal neutrons and reduce reactivity. Reactivity of the multiple recycle LWR fuel, however, can be maintained satisfactorily with make-up 239Pu or uranium of moderate enrichment.

For such plutonium-only transmutation, present-day separations technology using PUREX may be sufficient, having process losses on the order of 1% for plutonium (see Chapter 3). The other TRUs would go to the HLW for geologic disposal, although some of the neptunium might also be recycled if that proved easy to do. The PUREX process waste might be contained in a glass waste form, as planned for the defense HLW. As noted above, a waste form would need to be developed for the14C. By also separating certain long-lived fission products, one could possibly devise other improved waste forms, e.g., for 99Tc and 135 Cs. If pyroprocessing were used with an ALMR plutonium burner, additional new waste forms would be required. Of course, the big costs are those of LWR spent-fuel reprocessing and the all-remote fabrication of plutonium-bearing recycle fuel. Moreover, this waste management concept opens the door to the major public policy issues entailed in the commercial use of plutonium, in particular the relationship to U.S. nonproliferation policy (see Chapter 6).

The main benefits to waste management would come from (1) the improved waste forms and/or transmutation of the long-lived fission products and (2) waste form for 14C, which is an apparent issue at present for the special case of the Yucca Mountain repository. However, it is problematic whether plutonium-only transmutation could capture other prospective benefits to waste management claimed for the full transmutation of the TRUs. First, transmuting the plutonium could reduce somewhat the calculated repository hazards from human intrusion scenarios in which waste is brought directly to the surface. The effect would depend on the time after repository closure at which the human intrusion event occurred.

For postclosure times of a hundred years or so, 238Pu with an 87.7-year half-life is an important contributor to the TRU activity; this radionuclide would be transmuted. However, for postclosure times to several thousand years, the untransmuted 241Am with an 433-year half-life would dominate the TRU activity. This would be especially true for the older spent fuel in which the 241Pu had already decayed with a 14.4-year half-life to 241Am. For postclosure times of 10,000 years or more, 239Pu and 240Pu would dominate the TRU activity and would be transmuted. However, when the 239Pu is eliminated by transmutation, or has decayed, 237 Np would dominate the TRU activity.

In addition, plutonium is quite insoluble in groundwater under planned repository conditions. Thus, plutonium transmutation would have little direct effect on the dissolution-and-migration scenarios important for long-term repository risk (except by eliminating one of the precursors of 231Pa). Also, removal of the plutonium would reduce the long-term heat load on the repository, although the untransmuted 241Am would still be a major contributor. For the Yucca Mountain repository, however, decay heat is being considered as a means of keeping the waste containers dry while increasing the capacity of the repository, so that transmuting the plutonium (or other TRUs) may actually be a disadvantage for that site.

REDUCTION OF TRANSURANIC INVENTORIES

Introduction

This section examines the extent to which the amounts of TRUs in wastes from the various proposed transmuters can be made significantly smaller than the amount of TRUs in spent fuel in the reference once-through LWR fuel cycle. Inventories of TRUs in wastes from fuel reprocessing and TRU recycle are considered, together with inventories of untransmuted TRUs in the transmuter and in the associated facilities for reprocessing and fabrication of recycled material. To defray the cost of transmutation, all of the transmutation concepts propose generating and selling electrical energy resulting from the fission of TRUs. In this section the inventories of TRUs in the transmutation fuel cycle and in the reference once-through fuel cycle are compared for the same amount of electricity generated.

Typically, only a small fraction of the TRUs in a transmuter would be transmuted while exposed to reactor neutrons during an irradiation cycle. The fuel discharged from the reactor would be reprocessed to remove fission products and the recovered TRUs would be recycled. Special techniques for reprocessing are specified in order to reduce the amount of TRUs lost to the reprocessing wastes. Process-loss fractions of the order of 0.001 to 0.000110 or less have

been proposed. However, TRUs must be recycled many times through the reactor and its external fuel cycle before being transmuted, so the actual fraction lost to the reprocessing waste is greater than the fraction lost in each reprocessing cycle. Also, for safety and fuel-cycle economics, several of the transmutation concepts convert fertile 238U or 232Th to additional TRUs that must also be recycled and transmuted. Consequently, even with new separations that would reduce the losses to waste to 0.001 to 0.00001 of the amount processed, the inventories of TRUs in the waste would be far greater than what might be expected by multiplying the TRU inventories in LWR spent fuel by the process-loss fraction.

For many of the transmuter concepts, such as the ALMR, the inventories of TRUs in the reactor and its external reprocessing-refabrication fuel cycle are large. In some transmuter concepts much of the TRUs supplied to the transmuter during its life would remain in the reactor and its fuel cycle. This residual inventory must be accounted for as potential high-level waste. Consequently, as long as nuclear power from transmuters is to be continued, the TRU inventory at the end of life of each transmuter would be transferred to a succeeding transmuter. To achieve the transmutation goals, it would be necessary to operate the transmuters long enough so that the above-ground inventory in the transmuter and its fuel cycle is no longer much larger in magnitude than the inventory in the total waste produced. Therefore, the time-dependent inventories of TRUs in the transmuter and its fuel cycle should be included when analyzing the extent to which transmutation can reduce TRU inventories below the inventories in the reference once-through LWR fuel cycle.

For a given number of first-generation transmuters, constant electric power from transmuters would result if each succeeding transmuter were of the same electric power as the first-generation transmuter. Alternatively, each generation of follow-on nonbreeding transmuters11 could be of smaller electrical power as the total TRU inventory is consumed, resulting in the phase-out of nuclear power at a rate consistent with the necessary reduction in total TRUs that will become radioactive waste. For nonbreeding transmuters, additional LWRs could eventually be required to furnish make-up TRUs to fuel the transmuters, once the stockpile of stored LWR fuel has been exhausted.

Calculation for the various transmutation concepts of the time-dependent ratio of the amount of TRUs in waste from the reference LWR once-through fuel cycle to the amount of TRUs in the transmutation fuel cycle is the subject of this section.

The Transuranic (TRU) Ratio

The following analysis (Hebel et al., 1978; Pigford and Choi, 1991) describes the extent of TRU inventory reduction for the various transmuter concepts as a function of time. It is important to use an index that measures the extent to which TRU inventories in the transmuter, in its waste, and in its fuel cycle would be smaller than the inventory of TRUs for the reference fuel cycle of once-through LWRs. This index is called the "transuranic (TRU) ratio" ψ(t), defined as

total inventory of transuranics sent to waste disposal

in time for the reference once-through LWR fuel cycle, if no fuel

reprocessing, no recycle, and no transmutation

ψ (t) = ——————————————————————————

total inventory of transuranics at time t in the transmuter,

in its fuel cycle, and in process wastes

TRUs supplied to the transmuter system for start-up and for make-up fuel can be obtained by reprocessing existing LWR spent fuel and/or by reprocessing spent fuel from future LWRs. In calculating quantities for the equivalent reference fuel cycle, i.e., for the numerator of ψ(t), that same amount of TRUs must be assumed to go directly to waste disposal. Also, in the trnasmutation fuel cycle, transmuters generate a specified electric power P(t) and a specified total electrical energy by time t. To maintain equivalence, the TRU inventory in the nontransmutation fuel cycle considered in the numerator of ψ(t) must also include the TRUs that would be produced by reference LWRs producing the same electric power P(t) and the same electrical energy as the transmuters. All of these TRUs calculated for the non-transmutation fuel cycle are assumed to be sent to waste disposal.

A more direct measure of the extent of depletion of TRUs by transmutation is the ratio of the total amount of TRUs supplied to the transmuter to the inventory of TRUs in the transmuter system and in its waste. This ratio is defined as the "depletion ratio" χ(t). It is lower in magnitude than the TRU ratio ψ(t). To be meaningful, however, the comparison of waste-disposal benefits for alternative electric power systems must be made on the basis of the same electric power and the same electric energy. Therefore, the transmutation concepts should have the benefit incorporated into the TRU ratio ψ(t).

Scenarios for Constant Transmuter Power

Transmutation devices could replace some or all of the LWRs (or other reactors with a once-through fuel cycle) that provide continuous generation of electricity. A given initial amount of TRUs, such as the lifetime inventory from all current LWRs, could be used as the start-up inventory of "breeder" transmutation devices (i.e., breeding ratio of unity or greater). As an alternative, "nonbreeder" transmutation devices (i.e., breeding ratios less than unity) could be used for more rapid reduction of the TRU inventory, as suggested by DOE/NE (Young and U.S. Department of Energy, 1991). The nonbreeders would require make-up fissile material for ongoing operation, as well as start-up inventory.

A scenario of steady transmuter power has many options for deploying transmuters. Three options are treated in this subsection, corresponding to (1) continuous operation of breeder transmuters; (2) initial operation of transmuters as nonbreeders, later switching to breeders; and (3) continuous operation of nonbreeder transmuters and TRU-producing reactors, such as LWRs. Each of these options could involve an initial period in which the transmuters are started and fueled with TRUs recovered from the stockpile of LWR spent fuel. The desired goal would be to reduce the total TRU inventory well below that of the reference once-through LWR fuel cycle. The extent of that reduction would increase with time, until the option attains an asymptotic state in which the inventory of TRUs in the accumulated reprocessing waste becomes much larger than the inventory in the transmuter and its fuel cycle.

-

Breeder transmutation devices could be started utilizing the inventory of TRUs accumulated from reprocessing existing spent LWR fuel for breeder start-up. No new LWRs would be required. Even though the TRU inventory within the reactor and fuel cycle would remain constant with time, together with the inventory in reprocessing waste, it would be less than the inventory in unreprocessed fuel from the once-through fuel cycle if it delivered the same amount of electrical energy.

-

The new transmutation power plants could be operated as nonbreeders until all the accumulated inventory of TRUs from reprocessing existing LWR spent fuel has been utilized for start-up and refueling. These transmutation systems could then be converted to breeders. No new LWRs would be required. The ultimate degree of inventory reduction would be the same as that obtained in option (1).

-

The new transmutation power plants could be operated as nonbreeders. TRUs from the stockpiled LWR spent fuel would be used to start the first transmuters and to refuel these and subsequent transmuters. If the stockpile of spent LWR fuel is not sufficiently large, LWRs (or some equivalent nuclear power plant with a once-through fuel cycle) could be operated to supply make-up fissile material for the later-generation transmuters.

Declining Power Scenario

Nonbreeding transmutation devices could be constructed and operated to transmute as much as possible of a given initial inventory of TRUs. Each transmutation device, operating at a given thermal power, would require a certain inventory of TRUs in its critical or subcritical reactor and in its fuel cycle. If the desired inventory reduction is greater than can be achieved during the life of a given initial number of transmutation devices, the inventory remaining at the end of life of the first-generation transmuters can be used to start and fuel a smaller number of second-generation transmuters. In each subsequent generation there would be less total inventory, so that the total thermal power of the transmuters—i.e., the number of transmuters of a given thermal power in the system—would decrease with each generation until, finally, there would not be enough inventory and reactivity to operate a single transmuter module. This process would be realistic if it were planned to discontinue nuclear power after a desired inventory reduction was achieved.

Inventories and Transmutation Rates

The following results are presented for the TRU ratio ψ(t) for the many transmutation options and their variations described in detail in various appendices to this report. The numerical parameters used in the calculations are summarized in Table 4-3. The transmuters treated here are the following: (1) the ALMR/IFR for several values of the breeding ratio; (2) four ATW concepts, including the baseline aqueous system (ATW-1) and three advanced nonaqueous systems (ATW-2, ATW-3, and ATW-4); (3) the LWR with full TRU recycle; and (4) the PBR TRU burner. As discussed in the ALMR section of this report, there is not a uniform progression of inventories (I), specific burn-up rate (B/I), and other properties with decreasing breeding ratio. This is because some of the ALMR designs are the modular PRISM concept, others are more nearly homogenous cores, and one (BR = 0.22) specifies refueling the entire reactor core at the end of an irradiation cycle. Some differences in the six ATW concepts are explained in the table footnotes.

These data are used to illustrate the extent of long-term transmutation by ALMRs, for both steady and declining power. Similar calculations for other transmuters are presented to point out the differences in TRU transmutation by the various concepts.

A recent publication by J. C. Lee and J. Du (1994) suggests that the calculations for a LWR TRU burner may be

optimistic. If first-generation LWR TRU transmuters are fueled with TRUs recovered from stored and aged fuel discharged from once-through LWRs, the decay of 241Pu to 241Am during decades of storage of the once-through discharge fuel should be considered. This was not included in the calculations by Gorrell (1979) that were the basis for the data on LWR TRU transmuters in Table 4-2. Instead, Gorrell assumed recycle of actinides from contemporaneous LWRs, assuming two years from fuel discharge to recycle as MOX fuel.

Decades of storage prior to recycle could result in decay of most of the 241Pu in fuel at the time of reactor discharge. The decay product, 241Am, is thermally nonfissile and has a high cross section for absorbing thermal neutrons. Thus, the highly fissile 241Pu that would aid criticality in lessaged recycled TRUs would have been replaced by a strong neutron absorber. Consequently, greater concentrations of fissile actinides would have to be present in the MOX fuel for criticality. The inventory of TRUs would increase, and it would take longer to reach a near-equilibrium fuel-cycle inventory. Also, the calculations by Lee and Du indicate a lower net burn-up rate of TRUs than that calculated in Gorrell's data.

Lee and Du also assume that all uranium recovered from reprocessing discharged LWR fuel would also be recycled directly as MOX fuel. However, uranium recycle directly as MOX fuel in LWRs is not contemplated by those countries that are pursuing the option of fuel reprocessing. Instead, the recovered uranium would be recycled to a facility for uranium isotopic enrichment, or it could be stored. Recycling uranium directly to the reactor would increase the concentrations of neutron-absorbing 236U and of the neutron-capture products 237Np and 238Pu, all of which absorb thermal neutrons. For the LWR-plutonium and LWR-TRU transmuters considered in the present report, the recovered uranium would not be recycled directly as MOX fuel, regardless of the age of the fuel to be reprocessed for TRU recycle. Calculations for this fuel cycle are based on data of Gorrell, who did not assume recycle of uranium directly as MOX fuel. Therefore, the calculations by Lee and Du have overestimated the extent of neutron absorption from 236 U, 237Np, and 238Pu.

The calculations by Lee and Du indicate less net destruction of TRUs than do the calculations by Gorrell. Whether this would still be true for the LWR-TRU fuel cycle, without direct uranium recycle as MOX fuel, remains to be determined from further calculations.

If LWR TRU transmuters were to operate for the very long times considered in this study, the effects of fueling first-generation transmuters with TRUs from long-cooled LWR discharge must ultimately disappear. For example, in the following section, Constant-Power LWR Transmuters , times of the order of thousands of years to achieve a significant net reduction in total TRU inventory are calculated. The calculations by Gorrell would then describe the fuelcycle properties that would ultimately emerge. The inventories and burn-up rates calculated by Lee and Du, if corrected for no direct recycle of uranium, would better describe the characteristics of transmuters during the first few reactor generations.

Thus, the issues resulting from the recent calculations by Lee and Du cannot be resolved without further calculations. Such calculations would be lengthy and are not within the scope and schedule of the present study. Our illustrations herein of the possible features of LWR plutonium and LWR TRU transmuters are based necessarily on data from Gorrell's calculations.

Constant-Power ALMRs, Unlimited Supply of TRUs From Stockpile of LWR Spent Fuel

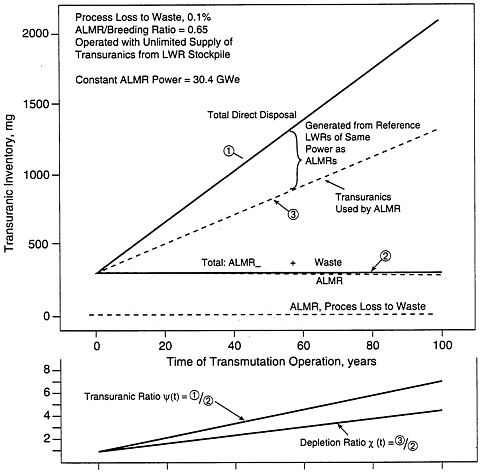

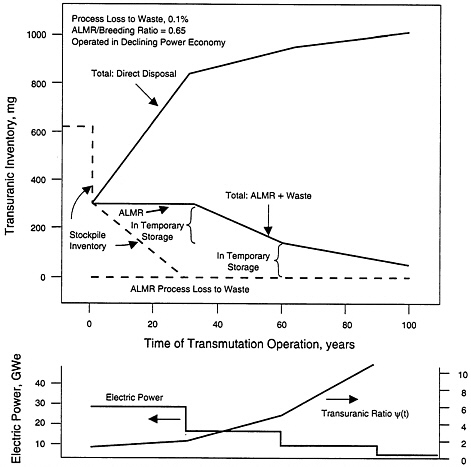

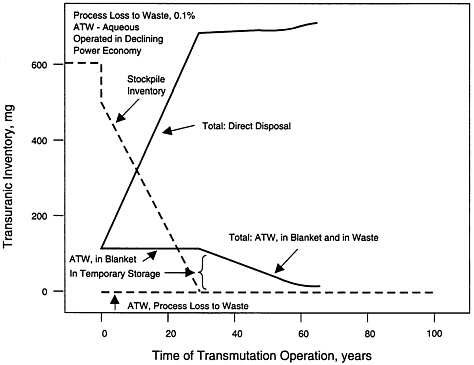

The TRU inventories for ALMR burners of 0.65 breeding ratio for the first 100 years for the simple case of constant power and an unlimited stockpile of spent fuel containing TRUs are shown in Figure 4-1. The scenario is conceptually simple and is presented to aid in understanding. Also, the resulting TRU ratio is identical to that of more realistic scenarios of a limited LWR-spent-fuel stockpile, as illustrated later in Figure 4-3. The total electrical power assumed to calculate inventories for Figure 4-1 is 30.4 GWe, to facilitate comparison with Figure 4-3. However, the value of the TRU ratio ψ(t) is independent of the power level. In this figure it is assumed that at end of life, each ALMR is replaced with an identical ALMR that receives the reactor and fuel-cycle inventory of TRUs from its predecessor. Calculations during the first 10 years are only approximate because steady-state fuel-cycle quantities are assumed.

Assuming, for simplicity, that all initial ALMRs begin operating at time zero, the total TRU inventory in the ALMRs and their fuel cycles is 305 Mg and is essentially constant with time. For a process loss to waste of only 0.1% per reprocessing cycle, the TRUs appearing in waste during the first 100 years would be relatively small, only about 8.3 Mg. The total TRU inventory for the ALMR option is given by line no. 2.

If there were no ALMR transmuters, the stockpile of spent LWR fuel withdrawn for reprocessing to start and fuel ALMRs would instead go directly to waste disposal. That amount is shown by the dashed line no. 3 of Figure 4-1, labeled "TRUs used by ALMRs." Further, with no ALMRs the reference once-through LWRs would produce the same constant electrical power as did the ALMRs. At any instant the inventory of TRUs in the spent fuel from those reference LWRs is the difference between line no. 1, labeled "Total direct disposal," and the dashed line.

FIGURE 4-1 TRU inventory, TRU ratio and depletion ratio versus time for constant-power ALMR, unlimited stockpile of LWR spent fuel. SOURCE: Choi and Pigford, 1994.

The ratio of the inventory of line no. 1 to the inventory of line no. 2 is the TRU ratio ψ(t), shown on the lower plot of Figure 4-1 for the same time scale. The TRU ratio reaches a value of 6.9 at 100 years. Reducing the TRU inventory by only a factor of 6.9 below that of the reference once-through fuel cycle is far from the goals proposed for transmutation, yet that would be the reduction if ALMRs were operated at constant power for 100 years and then terminated.

Line no. 3 of Figure 4-1 shows the total integrated quantity of TRUs supplied to the ALMR transmuters from time zero to time t. The ratio of line no. 3 to line no. 2 is the depletion ratio χ(t), shown in the lower plot of Figure 4-1. It is the factor by which TRUs supplied to the transmuter are depleted by transmutation. However, the depletion ratio does not reflect the additional benefit to the transmutation system that results from the reference once-through LWR reactors of the same electrical power producing additional TRUs that would also be sent to waste disposal. Therefore, it is the TRU ratio ψ( t) that is emphasized throughout this chapter.

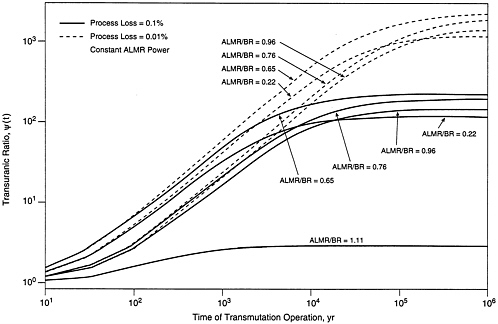

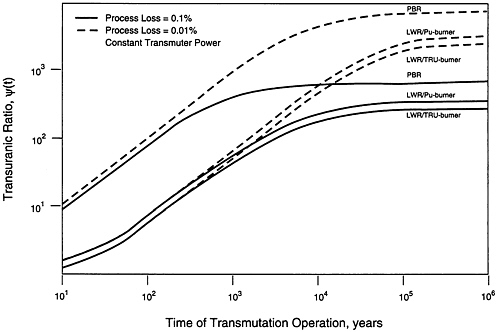

More extensive reduction below that of the reference fuel cycle would require much longer operation, as shown in Figure 4-2. Here the TRU ratios are plotted as a function of operating time for ALMRs of various breeding ratios (BR) and for two different values (0.001 and 0.0001) of the process-loss fraction. These curves also apply to other scenarios involving constant power of transmuters, such as simultaneous operation of LWRs to supply make-up TRUs to nonbreeding ALMRs, as discussed in the next section. The curves of Figure 4-2 are calculated to times that are probably unrealistic for any but the breeding ALMRs (BR = 0.96 and 1.1). Uranium resource12 limitations may prelude simultaneous operation of LWRs for such long times.

FIGURE 4-2 TRU ratio and depletion ratio versus time for ALMRs at constant power, effect of process loss. SOURCE: Choi, J. S., and T. H. Pigford. Reduction in Transuranic Inventory by Transmutation. Report UCB-NE-4177. Berkeley: University of California.

Figure 4-2 shows that for a given breeding ratio the TRU ratio approaches asymptotically a constant value. The values of this asymptotic ratio are given in Table 4-2. For each breeding ratio the constant-power time constant τ, given as the time for the TRU ratio to reach within a factor of (1 – 1/e) of the asymptotic value, is also listed in Table 4-2. The time constant is about 6,000 years for 0.65 breeding ratio and about 14,000 for a break-even breeder.13 The predicted TRU ratios at 100 years are listed in Table 4-3.

Both Figure 4-2 and Table 4-3 show that the attainable TRU ratio is affected little by the processing-loss fraction during the first few hundred years. Reducing the processing-loss fraction can affect the reduction factor appreciably only after many thousands of years.

Assuming that nuclear power is to continue in the future at a steady power level, and assuming that transmutation by ALMRs is desired to benefit ultimate waste by reducing TRU inventories by even as little as an order of magnitude, Figures 4-2 and 4-3 show that a commitment would have to be made to continue ALMRs and their progeny for many centuries.

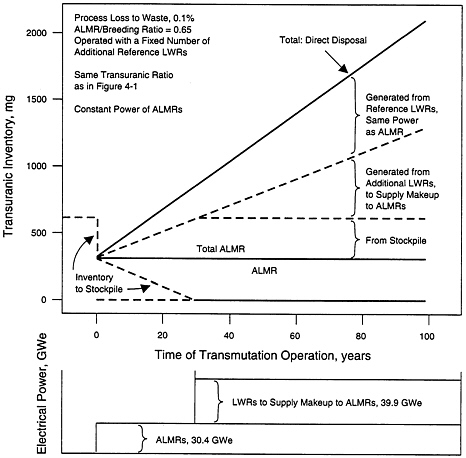

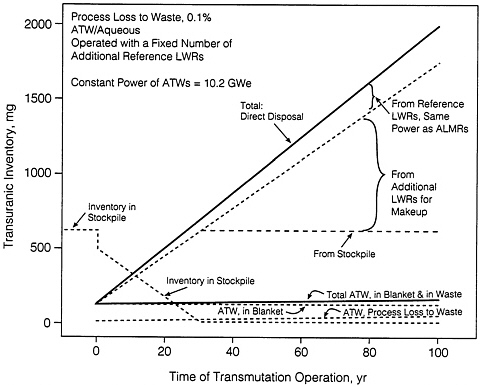

Constant-Power ALMRs, Limited Stockpile of LWR Spent Fuel, Additional LWRs

Figure 4-3 shows the time-dependent TRU inventories for the mixed ALMR-LWR fuel cycle. This is the fuel cycle proposed by DOE, except that here it is assumed that all first-generation ALMRs start operating simultaneously. The 612 Mg of TRUs that can be obtained by reprocessing the 62,000 Mg stockpile of LWR spent fuel is reduced at time zero when 305 Mg is withdrawn to start the ALMRs. The remaining 307 Mg is used as make-up fuel for the first-generation ALMRs during their operating life. Thereafter, 39.9 GWe of new LWRs begin operation to furnish make-up TRUs for the second-generation and later-generation

TABLE 4-2 Numerical Parameters Used in the Calculations for Inventory Reduction Factors for ALRMs, LWRs, ATWs, and PBR

|

Transmutorsa |

Ib (kg) |

Cyclec (yr) |

F/Id (yr-1) |

D/Ie (yr-1) |

B/If (yr-1) |

P/Ig (yr-1) |

ψinfh |

τi (yr) |

|

ALMRs |

|

|

|

|

|

|

|

|

|

β=1.1 1j |

27,200 |

1.88 |

0.100 |

0.104 |

-.00424 |

0.0132 |

3 |

190 |

|

0.98j |

19,400 |

1.61 |

0.121 |

0.121 |

0 |

0.0185 |

153 |

14,100 |

|

0.76k |

27,600 |

1.88 |

0.108 |

0.099 |

0.00904 |

0.0130 |

204 |

15,800 |

|

0.65j |

14,000 |

1.67 |

0.262 |

0.229 |

0.0336 |

0.0256 |

220 |

6,070 |

|

0.62k |

14,400 |

1.16 |

0.175 |

0.149 |

0.0259 |

0.0249 |

290 |

9,800 |

|

0.22l |

34,900 |

0.56 |

0.347 |

0.316 |

0.0313 |

0.0103 |

120 |

4,800 |

|

LWR, Pum |

17,200 |

1.00 |

0.200 |

0.152 |

0.0481 |

0.0208 |

345 |

8,560 |

|

LWR, TRUn |

21,600 |

1.00 |

0.200 |

0.162 |

0.0377 |

0.0166 |

272 |

8,530 |

|

ATWs |

|

|

|

|

|

|

|

|

|

Aqueouso |

15,550 |

0.146 |

7.00 |

6.85 |

0.1458 |

0.0231 |

24 |

230 |

|

Nonaqp |

600 |

0.083 |

14.1 |

12.0 |

2.05 |

0.598 |

188 |

120 |

|

Nonaq/Th 75%, Pap |

480 |

0.083 |

12.7 |

12.0 |

0.698 |

0.748 |

113 |

130 |

|

Nonaq/Th 75%p |

1,130 |

0.083 |

12.3 |

12.0 |

0.297 |

0.318 |

50 |

135 |

|

Nonaq/Th 100%, Pap |

340 |

0.083 |

12.0 |

12.0 |

0 |

1.06 |

88 |

110 |

|

Nonaq/Th 100%p |

1,280 |

0.083 |

12.0 |

12.0 |

0 |

0.280 |

23 |

130 |

|

PBRq |

1,425 |

— |

1.46 |

0.615 |

0.845 |

0.176 |

700 |

1,200 |

|

a β is the breeding ratio, defined as the ratio of thermally fissile 233U, 234U, 239Pu, 241Pu production to thermally fissile destruction. b Inventory of TRUs in transmutor and fuel cycle at steady state, scaled to the power level of 1,395 MWe. c For the solid-fuel ALMRs and LWR the cycle time is the chronological time between refuelings. For the fluid-fuel ATWs the cycle time is the time to process the blanket inventory. All times are for a capacity factor of 0.8. d F is the refueling rate of TRUs. e D is the discharge rate of TRUs from the core and blanket. f B is the rate that TRUs must be supplied from an external source. At steady state, F = D + B. g P is the rate of production of TRUs from a 1,395 MWe PWR, 33 MWd/kg, 0.80 capacity factor, equal to 359 kg/yr (Benedict et al., 1981; D.O.E., 1987). h ψinf is the asymptotic reduction factor, for the process-loss fraction of 0.001. iτ is the time to reach (1 - 1/e) of the asymptotic value, for γ = 1,000. j Data from General Electric for a PRISM ALMR with core and blanket. Includes inventory in 2-year external cycle for cooling and reprocessing discharged ALMR fuel (M.W. Thompson, private communication, 1991; K. Wu, private communication, 1991). k Data from General Electric for a PRISM ALMR with a homogenous core and no blanket. Includes inventory in 2-year external cycle for cooling and reprocessing discharged ALMR fuel. (M.W. Thompson, private communication, 1991). l Derived from ANL data for a 450 MWe ALMR with no blanket and core charged entirely with TRUs, scaled to 1,395 MWe and 80 percent capacity factor (Johnson et al., 1990). Includes inventory in 2-year external cycle for cooling and reprocessing discharged ALMR fuel. m From Pigford and Yang (1977). See also Hebel et al. (1978: Figure 8, p. 57). Based on data for total plutonium. Only plutonium is recycled. n Derived from data of Gorrell (1979). o Derived from equations and data given by Davidson (1992). p Derived from data of Bowman (C.D. Bowman, private communication, 1992). The notation "nonaqueous/Th, 75%, Pa" indicates that the fluid fuel is nonaqueous, 232Th is added as a fertile material to breed 233Pa and 233U, 75% of the thermal energy results from fissioning bred uranium, and protactinium is separated rapidly in the on-line coupled reprocessing system. For the systems using 232Th, computation of "TRUs" also includes the protactinium and uranium. q Derived from data of Kang and Kazimi (1993). |

||||||||

TABLE 4-3 TRU Ratios for Constant-Power ALMRs at 100 Years

|

TRU Ratio ψ(t) |

||

|

Breeding Ratio |

0.001 Loss Fraction |

0.0001 Loss Fraction |

|

0.22a |

4.98 |

5.14 |

|

0.65 |

6.74 |

6.90 |

|

0.96 |

2.81 |

2.85 |

|

a The ALMR with 0.22 breeding ratio contains negligible quantities of 238U, the usual fertile material to breed TRUs. In that sense, it does not breed from natural fertile material. The value of 0.22 results from the ALMR project's arbitrary definition of breeding ratio, i.e., it treats neutron absorption in 238Pu and 240Pu as "breeding." |

||

ALMRs. For the reference fuel cycle the total electric power is 70.3 GWe, the sum of the electrical power for the ALMRs and LWRs in the transmutation fuel cycle. The total inventory of TRUs to waste disposal for this mixed fuel cycle is identical to that in Figure 4-1, and the TRU ratios for the two scenarios (Figures 4-1 and 4-3) are identical. The long-term TRU ratios shown in Figure 4-2, and the discussion thereof, also apply here.

Declining-Power ALMRs

Figure 4-4 shows the time-dependent inventories and TRU ratio for a declining-power scenario, chosen to achieve

FIGURE 4-3 TRU inventory and ratio versus time for limited stockpile of LWR spent fuel, constant-power ALMR. SOURCE: Choi, J. S., and T. H. Pigford, 1994. Reduction in Transuranic Inventory by Transmutation. Report UCB-NE-4177. Berkeley: University of California.

FIGURE 4-4 TRU inventory and ratio versus time for declining-power ALMRs. SOURCE: Choi, J. S., and T. H. Pigford, 1994. Reduction in Transuranic Inventory by Transmutation. Report UCB-NE-4177. Berkeley: University of California.

FIGURE 4-5 TRU ratios versus time for declining-power ATWs, LWRs, and ALMRs. SOURCE: Choi, J. S., and T. H. Pigford, 1994. Reduction in Transuranic Inventory by Transmutation. Report UCB-NE-4177. Berkeley: University of California.

more rapid reduction in TRU inventories than is possible for the constant-power scenario. During the first 30 years, 30.4 GWe of ALMRs of 0.65 breeding ratio are assumed to operate, using the entire TRUs available from the 62,000 Mg stockpile of LWR spent fuel otherwise destined for the proposed Yucca Mountain repository. Rather than constructing additional LWRs to fuel the second-generation ALMRs, the inventory of TRUs from the first-generation ALMRs is committed to start and refuel 15.1 GWe of second-generation ALMRs. Similarly, only 7.5 GWe of third-generation ALMRs would be used, and so on, until only a single critical module of an ALMR is finally used. In this way the TRU ratio and the extent of TRU depletion increase more rapidly with time than with constant power. In 100 years a TRU ratio of 11 could be obtained, compared to only 6.9 for the constant-power scenario.

In the declining-power ALMRs illustrated in Figure 4-4 the actual inventory of TRUs in the ALMRs would be reduced by only a factor of 8.1 in 100 years. Thus, the depletion ratio ψ(t) would be 8.1, as compared to the TRU ratio ψ(t) of 11 in 100 years. However, as explained earlier, actual depletion is not the proper figure of merit. The ALMRs must be credited with generating electrical energy during the depletion period. In the reference scenario of LWRs of the same electrical energy, additional TRUs would be produced, in addition to the original 612 Mg present in the LWR spent-fuel stockpile. Therefore, the proper index to illustrate the effectiveness of ALMRs in depleting TRUs is the TRU ratio ψ(t), as adopted throughout this analysis.