2

Standards Development

Standards serve many different purposes, as noted in the previous chapter. There are also many ways of developing standards. Figure 2-1 defines the three principal types of standards by development process. The first comprises consensus-building activities among private firms, technical experts, customers, and other interested parties. These groups write standards through a formal process of discussion, drafting, and review. Group members attempt to form consensus on the best technical specifications to meet customer, industry, and public needs. The resulting standards are published for voluntary use throughout industry. Standards arising from these processes are termed voluntary consensus standards. Examples range from dimensions of valve fittings in household plumbing to performance characteristics of automotive structural materials. A variety of private organizations produce voluntary consensus standards, including industry and trade associations; professional societies; nonprofit, standards-setting membership organizations, and industry consortia.

No single organization, public or private, controls the U.S. standards development system. The efforts of many U.S. voluntary consensus standards organizations, however, are coordinated by the private, nonprofit American National Standards Institute (ANSI). This organization sets guidelines for groups to follow in managing the consensus-seeking process in a fair and open manner. ANSI reviews and accredits many U.S. standards-setting organizations for compliance with these guidelines. It also approves many of the standards these organizations produce, designating them as American National Standards. These and other central roles that ANSI plays in the U.S. standards system, including representing

|

DE FACTO STANDARD |

A standard arising from uncoordinated processes in the competitive marketplace. When a particular set of product or process specifications gains market share such that it acquires authority or influence, the set of specifications is then considered a de facto standard. Example: IBM-compatible personal computer architecture |

|

VOLUNTARY CONSENSUS STANDARD |

A standard arising from a formal, coordinated process in which key participants in a market seek consensus. Use of the resulting standard is voluntary. Key participants may include not only designers and producers, but also consumers, corporate and government purchasing officials, and regulatory authorities. Example: photographic film speed--ISO 100, 200, 400, etc., set by International Organization for Standardization (ISO) |

|

MANDATORY STANDARD |

A standard set by government. A procurement standard specifies requirements that must be met by suppliers to government. A regulatory standard may set safety, health, environmental, or related criteria. Voluntary standards developed for private use often become mandatory when referenced within government regulation or procurement. Example: automobile crash protection—air bag and/or passive seat restraint mandated by National Highway and Traffic Safety Administration |

FIGURE 2-1 Types of standards.

U.S. positions in international standards organizations, are discussed in this chapter.

Not all private-sector standards are set through consensus. Many arise through competition in the commercial marketplace. When one firm's product becomes sufficiently widespread that its unique specifications guide the decisions and actions of other market participants, those specifications become a de facto market standard. De facto standards are sometimes called industry standards. A de facto standard is usually promoted by a firm or organization in pursuit of commercial benefits. These benefits include gaining economies of scale, protecting or increasing market share, and obtaining revenues from licensing of intellectual property, among others. The IBM personal computer architecture, established and promoted by IBM beginning in 1981, is an example of a de facto industry standard.1

De facto standards may arise without formal sponsorship, simply through widespread, common usage. Cultural norms and customs, including informal business practices, are unsponsored standards. The arrangement of keys on a typewriter or computer keyboard—the QWERTY keyboard, so named because of the placement of those letters in one row—is an example of an unsponsored, de facto technology standard. Although no firm or group of firms actively promotes the QWERTY standard, it remains the standard arrangement of most keyboards.2 Most standards of interest in the context of this report, however, are actively sponsored by one or more organizations or individuals.

Mandatory standards are standards set by government with which compliance is required, either by regulation or in order to sell products or services to government agencies. Public-sector standardization encompasses many levels of government. Federal, state, regional, and local government agencies set regulatory standards on products and processes in order to protect health, safety, and the environment. They also produce specifications for public procurement of goods and services. Some of these standards are written by government agencies, whereas others are developed in the private sector and adopted by agencies. Even in the case of standards written by government, the process of development is not without private input or participation. For example, laws governing administrative processes—such as the Administrative Procedures Act—require public review and comment on proposed regulations. The Federal Register regularly publishes requests for comments on standards drafted by federal agencies. Technical requirements for safety devices on machinery, developed by the U.S. Department of Labor's Occupational Safety and Health Administration, are an example of mandatory standardization.

The boundary between voluntary and mandatory standards is not always distinct. Government standards writers frequently refer to privately developed, voluntary standards within the text of regulations and procurement specifications. Mandatory standards may cite voluntary standards in whole or in part, with or without additional criteria beyond those set in the referenced standard. For example, many of the regulations applied in state and local building codes require that electrical materials, such as wiring, meet portions of the National Electrical Code, a consensus standard developed by the private, nonprofit National Fire Prevention Association.3 In addition, procurement specifications set by major manufacturers are, from the perspective of their suppliers, mandatory for doing business in the same way that government procurement standards are mandatory.

The mechanisms by which standards are developed are extremely diverse. There is no single process in the United States or worldwide for creating and adopting standards. There is great variability among different standards in such attributes as purpose, scope, specificity of requirements, relative technological sophistication, and speed of development. Many different types of organizations, companies, government agencies, and consumers are users of standards. The variables that affect the pattern of standards development in an industry or market sector include, among others, (1) industry size and concentration; (2) dominance of specific suppliers or buyers; (3) level and speed of technological advance; and (4) public interests such as safety, health, and environmental protection.4

Despite the diversity of U.S. standards development processes, however, some generalizations can be made that are useful in assessing the performance of the U.S. standards development system and providing guidance to policymakers. This chapter examines the major components of the U.S. system, turning first to the private-sector and then the public-sector components. Implications of the decentralized, market-oriented structure of U.S. voluntary standards development

processes are highlighted, as well as interactions between voluntary and mandatory standards-setting mechanisms in the United States.

Scope Of The U.S. System

Standards exist for virtually all industries and product sectors. The 20 leading nongovernment standards developers in number of standards produced, for example, encompass a spectrum of industry sectors: aerospace; electronics; automotive and mechanical engineering; petroleum products; chemicals; pulp and paper; and cosmetics. This group also includes developers of safety-related standards such as those for fire protection, industrial hygiene, consumer product safety, and product testing.5 Government standards at the federal, state, and local levels, including privately developed standards adopted by government, are similarly diverse. These encompass manufacturing, transportation, and communications equipment; environmental protection and public health; food, drugs, and consumer products; construction materials, such as electrical wiring, plumbing, wood, stone, and concrete; and the broad range of products procured for government use such as office equipment, vehicles, communications systems, and military hardware.6

The number of U.S. standards at a given point in time is difficult to identify. Table 2-1 details the approximate number of formal standards maintained in a current, active status by the main categories of public and private standards developers. The public sector list begins with the Department of Defense (DoD), which develops and maintains more formal standards than any other organization in the United States. The number of DoD standards was estimated by the National Institute of Standards and Technology (NIST, a branch of the Department of Commerce) at 38,000 in 1991. The number has begun to shrink, however, because DoD now decommissions more standards than it develops each year. Remaining federal procurement and regulatory standards bring the total of U.S. government standards to 52,000.7

The number of private-sector, voluntary consensus standards in the United States is 41,500.8 Table 2-2 lists the 10 leading standards-developing organizations (SDOs) in the United States, by number of standards produced. There are three types of private standards-developing organizations. First are technical and professional societies that engage in technical standards development. These consist of organizations of individuals who practice a profession or discipline, frequently a branch of engineering. Second are industry associations, whose membership consists of firms in a specific industry or trade. The third group has the more generic designation of standards-developing membership organizations, whose membership is open to individuals interested in standardization. Unlike professional societies for which standards development is one among many functions, these organizations' primary focus is standards development and standards-related activities.

TABLE 2-1 —U.S. Standards, by Developer (active standards as of 1991)

|

FEDERAL GOVERNMENT |

NUMBER OF STANDARDS |

|

Department of Defense |

38,000 |

|

General Services Administration (nondefense procurement) |

6,000 |

|

Other federal (primarily regulatory) |

8,500 |

|

Examples: Environmental Protection Agency, Occupational Safety and Health Administration, Federal Communications Commission |

|

|

Total |

52,000 |

|

PRIVATE SECTORa |

NUMBER OF STANDARDS |

|

Scientific and Professional Societies |

13,000 |

|

Examples: American Society of Mechanical Engineers (ASME), Institute of Electrical and Electronics Engineers (IEEE) |

|

|

Trade Associations |

14,500 |

|

Examples: National Electrical Manufacturers Association (NEMA), Computer and Business Equipment Manufacturers Association (CBEMA) |

|

|

Standards-Developing Membership Organizations |

14,000 |

|

Examples: American Society for Testing and Materials (ASTM), National Fire Protection Association (NFPA) |

|

|

Total |

41,500 |

|

Overall Total (Federal Government and Private Sector) |

93,500 |

|

a Not including de facto industry standards. SOURCE: Toth, Robert B., ed. Standards Activities of Organizations in the United States. NIST Special Publication 806. P. 4. National Institute of Standards and Technology. U.S. Department of Commerce. Washington, DC: U.S. Government Printing Office, 1991. |

|

Data on numbers of standards must be treated with caution, for several reasons. First, the definition of what constitutes a standard is not exact. There may be uncertainty in whether to consider a product description, specification, definition of a term, or description of a procedure to be a standard. Different agencies and organizations may vary in their interpretation of such cases. The context of the discussion is also significant. Given this report's primary focus on the links among standards, conformity assessment, and domestic and international

TABLE 2-2 —Top 10 Private Standards-Developing Organizations (active standards as of 1991)

|

TOP 10 DEVELOPING ORGANIZATIONS IN THE U.S. |

NUMBER OF STANDARDS |

|

American Society for Testing and Materials |

8,500 |

|

Society of Automotive Engineers |

5,100 |

|

U.S. Pharmacopeia |

4,450 |

|

Aerospace Industries Association |

3,000 |

|

Association of Official Analytical Chemists |

1,900 |

|

Association of American Railroads |

1,350 |

|

American Association of State Highway & Transportation Officials |

1,100 |

|

American Petroleum Institute |

880 |

|

Cosmetic, Toiletry & Fragrance Association |

800 |

|

American Society of Mechanical Engineers |

745 |

performance of U.S. manufacturers, the discussion here is limited to product and process standards. Professional certification, for example, such as that required of accountants, lawyers, and health care providers, is a type of standard that is not considered in this report.

Second, the distinction between a single standard with many sections and a series of separate, but related, standards may be arbitrary. The American Society of Mechanical Engineers (ASME) produced and regularly updates the Boiler and Pressure Vessel Code, a single standard running into thousands of pages. The code currently has 11 major sections covering design, fabrication, inspection, and safe operation of boilers, pressure vessels, and nuclear power plant components.9 The choice of writing a set of specifications as a single standard or a series of standards is made by each developing organization or agency, according to its own guidelines.

Third, not all published standards have equal influence in the economy. Some voluntary standards fail to achieve widespread acceptance or use in the marketplace. The most widely used 15 to 20 percent of standards developed by private organizations accounts for 80 percent of those organizations' orders for printed copies of standards.10 These standards may be presumed to have greater economic and technological significance than those that are rarely used. A standard applied at a critical point in a system, market, or industry, however, could have an impact far greater than the number of copies ordered from its publisher would indicate.

Both voluntary and mandatory standards may become technologically obsolete, yet remain in a technically active status. For example, an organization may

choose to maintain an outdated standard for the benefit of persons who own or acquire a piece of old equipment and need access to technical information in order to operate or maintain it. Alternatively, a standard may remain in existence simply for lack of incentive to unlist it. As many as 25 to 30 percent of U.S. government and private standards have been estimated to be obsolete.11

Finally, two groups of product and process standards are omitted from the data in Figure 2-1. First, information on numbers of state and local government standards is extremely limited and fragmentary. These standards are concentrated in such areas as building and construction materials, workplace safety, environmental protection, agriculture, and foods.12 Second, de facto standards are also excluded from the table. The same difficulties in enumerating public and private formal standards apply in the case of de facto standards set by firms through market competition. In addition, the distinction between a product that sets a standard, influencing the design of others, and a product that is simply one among many is highly subjective. The absence of a formal, institutional process for designating de facto standards compounds the difficulty of identifying, much less quantifying, the output of de facto standards development efforts.

These factors, among others, make it clear that neither a determination of the economic impact of standards activities in the United States nor an overall assessment of the U.S. system should focus closely on the quantities of standards produced. Valid assessments depend, instead, on examination of the efficiency and effectiveness of standards development in relation to the needs of industry, government, and society; the economic and technological implications of the U.S. system's characteristics; and the efficacy of existing mechanisms for strengthening and improving the system.

Private-Sector Standards

Efforts to coordinate standards development in the United States began to develop momentum early in this century. One factor spurring these efforts was the realization that technical standards were needed to ensure the safety of many new products of the industrial age. The first version of the American Society of Mechanical Engineers Boiler Code was written in 1914, in response to serious hazards posed by poor-quality boilers, which were prone to explode. The code—today, the Boiler and Pressure Vessel Code—performs several of the functions of standards outlined in the previous chapter. Most significant is its role in protecting safety by providing a standard against which unsafe boilers, components, and manufacturing methods can be identified and rejected. Large portions of the code have become mandatory through reference in government regulation in the United States and many other countries.13 The code also acts as a guide for manufacturers in the techniques of producing and maintaining safe boilers, pressure vessels, and nuclear reactors. In this way, the code fosters the diffusion of best practices throughout the industry.14

A large fire in downtown Baltimore in 1904 was another impetus to standardization. Fire engines from other cities that came to assist the Baltimore fire department were unable to connect their hoses to the local hydrants. The disaster, which included the loss of 1,526 buildings, could have been prevented if hose connections had been standardized, as they are today.15

Safety concerns were not the only factor that fostered industrial standardization in the United States. The economies of scale afforded by mass production are driven by standardization of parts and processes, as discussed in Chapter 1. The automotive industry was an early proponent of standardization, not only within each manufacturer's own plants, but industry wide. There were several incentives for standardization across the industry: It enabled parts suppliers to produce large quantities for multiple customers, such that suppliers could gain economies of scale and lower their costs. Suppliers passed these savings on as lower prices to automobile manufacturers. In addition, standardization meant that if one supplier went out of business (a frequent occurrence in the early years of the industry), shortfalls of parts could be made up by other suppliers without a delay for reconfiguring their machinery to new specifications. Standards also allowed manufacturers to impose minimum quality criteria on their suppliers, particularly for steel. In general, standardization benefited both suppliers and manufacturers throughout the industry.16

Coordinating standards development among different automotive firms became the responsibility of the Society of Automotive Engineers (SAE). SAE was (and remains) a professional society whose membership spanned the industry, including both manufacturers and suppliers; was independent of any one firm or set of interests; and had the technical competence for the required work. Its success in reducing the variety of parts and in promoting interchangeability and quality was such that the National Automobile Chamber of Commerce, an industry trade association, estimated in 1916 that SAE standards yielded cost reductions of 30 percent in ball bearings and electrical equipment and 20 percent in steel.17

Economic Rationale for Consensus Standardization

These examples from the history of standardization illustrate one of the most important economic aspects of standards. Uncoordinated market mechanisms alone do not ensure that necessary standards are set. Firms acting in isolation are not as effective at setting an industry standard as producers, customers, and other interested parties acting in coordination. Even in situations in which all participants in an industry sector would benefit from standardization, cooperation and communication among them are usually necessary for a standard to emerge.18

A primary reason cooperation is necessary is that standardization requires gathering information and developing compromises among the needs, interests, and capabilities of many different interested parties. It is not impossible for a

single firm to accomplish this task by marketing a product that meets the needs of diverse parties. In some cases, there are economic incentives to make the attempt. If a firm is successful in promoting its own, proprietary solution to a technological need and sets an industry-wide de facto standard, it may reap large benefits from dominating the resulting market. Microsoft Corporation's MS-DOS operating system is an example of success in this area. However, the costs of coordinating and accommodating multiple interests can be high. In addition, if a rival firm simultaneously attempts to set a competing standard, the companies can become caught in a winner-take-all game of investment and price cutting. In this case the benefits of success are outweighed by the costs of competing to set the standard.19

Another important reason the uncoordinated market can sometimes produce too few standards derives from the public nature of standards. When a standard has been set, everyone may use and benefit from it. This is true whether or not they participated in its development. The potential thus exists for free riders to benefit from standards-setting work done by others. In economics terminology, standardization is a public good.20 A standard can be used any number of times without depleting its utility. The more widely a standard is used, in fact, the more valuable it becomes—not only to those who originally developed it, but to all users. Communication, compatibility, economies of scale, and other benefits of standards all increase as those standards become more widespread. Conversely, if a standard is little used, its value is limited. Although coordination among participants in an industry takes time and effort, it increases the likelihood that the standard will become widely used and thus acquire value.

These theoretical examples are not meant to show that the free market is unable to produce standards. They demonstrate that individual firms acting alone may be unable to justify the cost of developing and promoting their own proprietary standards against the risk that their efforts will fail to establish a de facto standard. A firm that bears the costs of developing a standard by itself cannot generally capture rewards equal to the overall social and economic benefit that accrues from standardization. (An exception is noted in the next paragraph.) As a result, market incentives alone are not sufficient to encourage firms, acting in isolation, to produce as great a degree of standardization as would be most economically beneficial to the industry or to society at large.21

An exception, applicable particularly in the communications and information technology industries, is the establishment of network compatibility standards. A detailed body of recent economics literature examines the incentives facing firms to establish compatibility standards, such as telecommunication system interfaces and computer operating systems.22 These standards have unique economic properties, because they exhibit unusually strong returns to scale. Specifically, the more widespread a given network standard becomes, the greater does the incentive become for additional users to adopt that standard rather than be left as ''orphans," incompatible with other systems. A firm that builds momentum

behind its standard can benefit from a bandwagon effect in which users rush to adopt that standard. IBM Corporation in the 1960s, with System 360, and Microsoft Corporation's MS-DOS operating system in the 1980s are familiar examples of proprietary, de facto standards that conferred enormous economic benefits on their sponsors as computer users adopted them.23 Responses of consensus standards-developing organizations to the challenges posed by compatibility standards are discussed later in this chapter.

In most cases, as noted above, uncoordinated market competition among firms promoting their own, proprietary solutions to particular market needs will not lead to as much standardization as is theoretically desirable for the economy as a whole. Voluntary consensus standards are an effective, rational response to this economic dilemma of standardization in the free market. As the example of the early automobile industry and the Society of Automotive Engineers illustrates, industry participants working together can share the effort of developing standards and gain mutual benefits from the results. Most of the formal standards used in the U.S. private sector are developed by private standards-developing organizations, such as SAE. These organizations have developed procedures to foster communication, coordination, and consensus in order to overcome the limitations of the uncoordinated marketplace and achieve industry-wide standardization.

Many foreign countries, including key U.S. trading partners in Europe and Asia, have a central, primary national standards-developing body. This is usually a government-chartered private organization or a quasi-public agency, rather than a direct agency of the government. Examples include Germany's Deutches Institute fur Normung (DIN), the British Standards Institute (BSI), and France's Association Francaise de Normalisation (AFNOR).24 It is important to note, however, that even in countries in which a government agency sets national industrial standards, private-sector input plays a vital, pervasive role. It is impossible, given the breadth of technical and commercial expertise required to write standards, for all industry sectors to reside in any one organization. The resources of a national standards organization must always be supplemented with private-sector manpower, technical knowledge, and understanding of marketplace needs in order to develop useful standards. At the level of the technical committees—the volunteers who write the standards—the differences between foreign, relatively centralized standards systems and the U.S. system are negligible.25

It is important to note that issues related to ownership of private standards can influence the role they play in particular markets. Many standards developers, for example, offset expenses and generate income through sales of standards documents, to which they hold the copyright. For many SDOs, publishing is a significant source of operating revenue.26 In addition, license fees and royalties are often paid to owners of patented innovations incorporated into standards. These fees can be a significant incentive for firms to innovate and develop new

technologies and to permit their incorporation into standards. As previously noted, some firms gain substantial benefits from owning the rights to a proprietary technology that becomes a de facto industry standard. Prohibitively high payments to the owner of technology in a given standard, however, will deter its spread and motivate other parties to develop an alternative standard.27 In most consensus standards organizations, owners of intellectual property incorporated into a formal standard agree to license proprietary technology at reasonable terms.28

Voluntary Consensus Standardization Processes

In comparison to most foreign systems, the institutional structure of the U.S. voluntary consensus standards system is highly decentralized. The United States has more than 400 private standards developers. Most are organized around a given industry, profession, or academic discipline. About 275 engage in ongoing standards-setting activities. The remainder have developed standards in the past—usually few in number—and occasionally update them.29 There are three main types of U.S. standards-developing organizations: professional and technical societies, industry associations, and standards-developing membership organizations, discussed later in this chapter.30

All standards-developing organizations, to varying degrees, seek to overcome economic obstacles to standardization. The typical method for achieving this goal is to coordinate participation of volunteer technical experts in standards-writing committees. Each technical committee is responsible for standards in a particular area of product, process, or technology, although overlap does sometimes exist among different committees' scope of work. Committee membership is generally selected to represent a diversity of interests and viewpoints. Committees—or, in some cases, working groups that are subsets of a committee—meet on a semiregular basis over a period ranging from weeks to years. The first step in developing a standard is to identify an area of marketplace need requiring a standardized technical solution. Once a scope of work is set, draft technical standards are proposed, discussed, revised, and voted on. Consensus is, in most organizations, a key goal. Although negative votes do not prevent a standard's adoption, they must generally be considered and responded to in writing.31

Participants in a technical committee may propose, as foundations for a standard, technologies developed by their respective firms. Success in this effort may yield a marketing advantage or a technological head start over other companies whose technologies are not chosen. Alternatively, the committee may develop a compromise standard incorporating aspects of multiple proposals.32

After review, comment, and approval by the SDO's oversight board and membership at large, the organization publishes the standard. If the organization uses ANSI-accredited procedures, it may choose to have the standard approved and distributed by ANSI as an American National Standard. ANSI does not

review the standard for technical merit but, rather, certifies that it was developed through open, consensus-oriented procedures and does not unduly duplicate or conflict with existing standards. The standard's usefulness to interested parties in the relevant market sector—manufacturers, purchasers, regulators, testing laboratories, certifiers, and others—largely determines whether it gains widespread acceptance. A technologically obsolete, commercially nonviable, or otherwise unsatisfactory standard will be neglected. Such a standard will eventually be discontinued by the SDO. Broad dissemination and use of the standard, however, are presumably in the interest of those who participated in writing and approving it. These individuals and the firms or associations they represent are therefore likely to use and promote the standard.

There is ample opportunity for U.S. industry to participate in voluntary consensus standards development and ensure that it meets U.S. economic needs. Both manufacturers and their customers take part in standards setting through industry associations such as the Computer and Business Equipment Manufacturers Association (CBEMA); the Gas Appliances Manufacturers Association; and the Alliance for Telecommunications Industry Solutions, consisting of telecommunications service and equipment companies. Firms also pay salary and travel expenses for employees who serve as individuals in the work of professional societies and standards-developing membership organizations such as SAE, the American Society for Testing and Materials (ASTM), and the Institute of Electrical and Electronics Engineers (IEEE). Small firms may not have sufficient resources to devote personnel to technical committees. They can, however, monitor and submit technical inputs to the process through industry and trade associations. Firms are often active in developing standards within all three types of organizations and through de facto marketplace competition at the same time.

Standards-developing organizations vary widely in size, number of standards produced, breadth of industries and technologies covered, profile of membership, and geographic scope, among other factors. Nearly all, nevertheless, share two important features.33 First, they operate on the basis of consensus. Simple majority vote among participants in a standards-writing project is almost never sufficient to establish a standard. The consensus principle makes good sense in the context of the standards developer's mission. To produce standards that will achieve economies of scale, consumer safety, advancement of technology, compatibility, and other benefits of standardization, the standards must be accepted and used by as many firms and individuals as possible. Unless the standard is subsequently mandated as part of a government regulation or procurement specification, its acceptance by potential users is voluntary. Standards adopted as mandatory by government, moreover, are usually more effective if they reflect consensus among affected parties. A consensus among interested parties during the design of a standard clearly increases its prospects for broad acceptability.

The second feature common to most standards-developing organizations is administrative due process. These groups have formal policies governing such facets of standards development as technical committee membership; setting the scope of proposed standards; drafting and revising standards; voting within committees; review of draft standards by higher authority within the SDO; and balloting and approval by the membership at large.34 Due process in SDOs bears many resemblances to public administrative procedures law. Laws governing public agency decisionmaking processes have such aims as representation of multiple interests; objectivity and fairness of procedures; public access to information about agency actions; and accountability of the agency through formal appeals. Analogous features—public notice and comment, appeals, multiple interest group representation, and democratic procedures—are all to be found in the policies of most formal standards-developing organizations as well.35 These procedures increase the likelihood that a technical committee will reach a broad-based consensus, enhancing the value of the resulting standard.

Formal procedures, such as open participation and review, also serve as protection against allegations of collusive behavior for participants from competing firms. Consensus standards development is, in fact, well tolerated by U.S. antitrust law and precedent.36 There have been few successful antitrust lawsuits related to U.S. voluntary product standards. In each case where the suit was successful, it was the subsequent interpretation of the standard by some other party, such as a certifier, that was deemed anticompetitive. One example is American Society of Mechanical Engineers v. Hydrolevel Corporation, a 1982 case in which a standards developer, ASME, was defeated in an antitrust suit. It was the actions of a committee interpreting product compliance with the ASME Boiler Code that was found to be anticompetitive—not the code itself or the process by which it was written.37

The principles underlying consensus standards development evolved over a period of many years, within many different SDOs. Each organization applies the principles in different ways, with procedures and objectives specific to the needs of its industry sector or professional competence. Authority in the U.S. standards-developing system, consequently, is highly decentralized and linked to specific industry sectors. Adherence to the basic principles, however, is actively promoted through the central, coordinating function of the American National Standards Institute. ANSI is not a standards developer but, rather, a nonprofit organization that coordinates and supports the U.S. consensus standards development system. U.S. standards developers desiring ANSI accreditation of their procedures and standards must follow ANSI guidelines for consensus, open participation, and due process. Through accreditation, ANSI seeks to promote and perpetuate core principles of the U.S. voluntary standards system.38 Other ANSI functions in the U.S. system are discussed later in this chapter.

Standards-Developing Organizations

As previously noted, there are more than 400 standards developers in the U.S. private sector. Most of these belong to one of three main categories: industry associations, professional societies, and standards-developing membership organizations. In addition, consortia are playing an increasingly important standards development role, particularly in industries characterized by rapid advance of technology. Testing and certification organizations, such as Underwriters Laboratories, NSF International, and the American Gas Association, are discussed in Chapter 3. They represent a specialized category of organization responsible both for developing standards in certain sectors—typically related to health and safety—and for providing associated testing and certification services.39

Professional Societies Professional societies are individual membership organizations that support the practice and advancement of a particular profession. Several such societies, particularly in the engineering disciplines, develop technical standards. The goal of these SDOs is generally to find the best technical solution to meet an identified need. Participants in standards committees serve as individual professionals, not as representatives of the firm they work for. If more than one employee of a single firm serves in a committee, each still has a full vote in committee deliberations. Marketing considerations, however—such as securing commercial advantage for participants' firms—are in many cases secondary to technical factors in committee deliberations.40 Funding for these SDOs is principally from publication and sales of standards, as well as direct services to industry.

Institute of Electrical and Electronics Engineers Standards. IEEE Standards is a division of IEEE, Inc., an engineering professional society, founding member of ANSI, and ANSI-accredited standards-developing organization. The IEEE has a membership of more than 300,000 engineering professionals worldwide. IEEE Standards publishes more than 600 standards. Its area of expertise is electrotechnology, which ranges from electrical circuitry to artificial intelligence to aerospace. A Standards Board composed of voluntary industry and government representatives and 10 committees review requests from technical groups to initiate standards projects. After a consensus process, standards are approved by the Board and published as IEEE standards. IEEE participates in the United States National Committee (USNC) of the International Electrotechnical Commission (IEC), and the U.S. Technical Advisory Group (TAG) to the ISO and IEC Joint Technical Committee on Information Technology (JTC1).41

American Society of Mechanical Engineers. A founding member of ANSI, ASME is a professional society with an international membership of more than 100,000. It publishes 745 standards. In addition to standards development, ASME is involved in publishing, technical conferences and exhibits, engineering education, government relations, and public education. The ASME Council on Codes and Standards oversees 10 boards that supervise more than 700 committees. Drafts of standards are approved by committees and opened up to public comment after which, if necessary, they are redrafted and published as ASME standards. ASME is well known for its Boiler Code first published in 1914, and most recently revised and published as the Boiler and Pressure Vessel Code in 1992.42

Industry Associations Industry associations, also known as trade associations, are organizations of manufacturers, suppliers, customers, service providers, and other firms active in a given industry sector. Their mission is to further the interests of their industry sector, including the development of technical standards. Many industry associations develop standards or sponsor their development through a subsidiary or associated SDO. Funding is primarily through members' dues. Members of technical committees typically serve as representatives of their firm. Each firm carries equal weight in committee voting, regardless of the number of experts it sends to participate in the committee's standards development work. Industry association SDOs are likely to be more openly responsive to commercial market concerns in their technical decisionmaking than other types of SDOs.

Computer and Business Equipment Manufacturers Association. Accredited Standards Committee X3, Information Processing Systems (ASC X3). Created in 1916, the CBEMA is a professional trade association involved in the information processing, communications, and business products industry sectors. It maintains an ANSI-approved voluntary consensus program and sponsors the ASC X3 Secretariat, which oversees the legal, financial, and procedural work of the committee. The ASC X3 has 41 members including producers and consumers in the information technology industry, and it manages more than 500 projects. ASC X3's Operational Management Committee (formerly, the Standards Planning and Requirements Committee, SPARC) reviews submitted standards proposals and reports on its activities to the ASC X3. A proposal, after receiving X3 approval, is assigned to a technical committee for development into a standard. To complete the consensus process, the draft standard is redrafted, voted on again, and then sent to ANSI for final approval. The Strategic Planning Committee (SPC) manages the standards process and

helps to define the role of information technology standards in the industry.43

Association for the Advancement of Medical Instrumentation (AAMI). AAMI is a voluntary membership organization of about 5,000 health care professionals from industry, health care facilities, academia, research centers, and government agencies such as the Food and Drug Administration (FDA).44 AAMI works to advance patient care and medical technology through certification of biomedical engineers, education, technical publications, and development of medical device standards. AAMI is active in the development of international standards through sponsorship and representation on ISO and IEC committees and U.S. and ISO technical advisory groups (TAGs). It also maintains relationships with European counterpart organizations involved in standards development.45 In 1994, AAMI became the international secretariat for a new ISO committee developing standards for quality management systems in the health care equipment industry.

Membership Organizations Unlike industry associations and professional societies, standards-developing membership organizations have standards development as their central activity and mission. They do not limit their membership to an industry or profession, and they tend to have the most diverse membership among all SDOs. Their procedures tend to have the strictest due process requirements. Publishing and selling standards documentation accounts for the majority of their revenues. Membership fees are generally relatively low, facilitating participation by individuals not sponsored by an employer.

American Society for Testing and Materials. Established in 1898, ASTM is one of the world's largest voluntary consensus SDOs. It has an international membership of more than 35,000 and maintains 132 technical standards-writing committees. ASTM publishes standard test methods, specifications, practices, guides, classifications, and terminology for materials, products, systems, and services. Approximately 33 percent of ASTM's sales of standards are to international users, and many of its standards become de facto international standards. It produces an annual 70-volume set of more than 9,000 ASTM standards that are used worldwide.46

National Fire Protection Association (NFPA). The NFPA was established in 1896 in response to the need for uniform installation of sprinkler systems. NFPA publishes 280 specific fire safety standards.47 NFPA is an independent, nonprofit, voluntary membership organization with an international membership of more than 60,000 individuals and 115 national trade and professional societies. It maintains some 235 consensus

standards committees. After public comments are reviewed and committees reach consensus, the NFPA membership votes as a whole on adoption of standards as voluntary national standards. NFPA is also actively involved in public fire protection, fire analysis and research, government relations, and public education. Its standards are used in the fields of aviation, chemicals, engineering, hazardous materials, health care, marine fire protection, and signaling systems, among others. It also publishes the National Fire Codes and National Electrical Code, which are referenced in many state and local building regulations.48

Consortia Standards consortia are a response to the rate of technological advance outpacing consensus standards development in some industry sectors.49 They focus particularly on compatibility standards. Examples include the Corporation for Open Systems (COS) and the Manufacturing Automation Protocol (MAP) user group. COS, a vendor consortium, was established to promote the Open Systems Interconnection (OSI) suite of computer interconnection protocols. Currently, COS is active in testing OSI products for conformance to the standards. By contrast, MAP is a user consortium, created to pressure vendors of manufacturing automation systems to develop compatible products.

Participation in standards-setting is generally limited to consortium members. Requirements for openness, consensus, and due process are less strict than in other standards-developing organizations, primarily to speed the development process. In fact, standards produced by consortia represent a hybrid stage between de facto industry standards and full consensus standards. To gain acceptance of their standards in the marketplace, consortia may seek after-the-fact accreditation of the standards through ANSI procedures. This is particularly the case, for example, for consortia wishing to promote international acceptance of their standards through ISO and IEC.

American National Standards Institute

The American Engineering Standards Committee was formed in 1918 as a federation of several prominent SDOs. In the 1960s, after several name changes, it became the American National Standards Institute (ANSI). Its principal missions are to coordinate and strengthen the U.S. voluntary consensus standards development system; to promote awareness and use of voluntary standards; and to represent U.S. interests in international standardization bodies.50 ANSI is a nonprofit organization with annual revenues in 1993 of $16.7 million.51 ANSI membership includes approximately 1,300 companies; 35 government agencies; and more than 260 technical, trade, labor and consumer groups.52

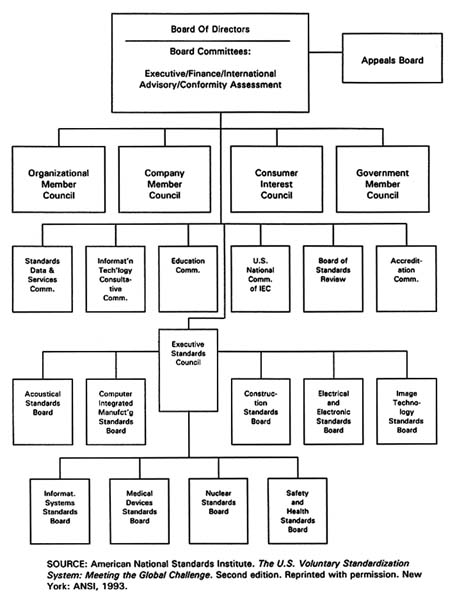

ANSI's organizational structure is decentralized (see Figure 2-2). ANSI's intent is for standards developers and users in different industry and technology sectors to be able to manage the development of standards at the level and

direction appropriate for each sector. For example, ANSI members in the information technology industry emphasize international standardization, whereas consumer and workplace safety and health standards are developed with a focus on U.S. national standards. Four member councils discuss issues from their constituents' perspectives, bringing them before the ANSI Board of Directors as needed. These are the Company, Consumer Interest, Government, and Organization Member Councils.53

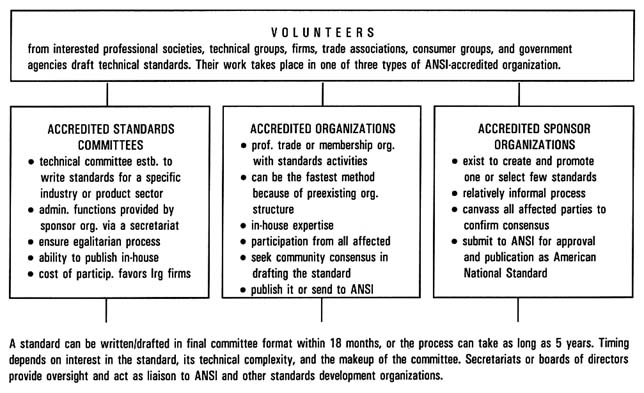

As noted earlier, one of ANSI's key means of carrying out its mission is to accredit U.S. standards developers. ANSI accredits both the organizations that develop standards and the standards themselves. (See Figure 2-3 for an overview of ANSI-accredited standards processes.) Accreditation is based not on the technical merits of standards but, rather, on the procedures used to develop them. Adherence to open participation, due process, and consensus procedures is necessary for an SDO to become an ANSI-accredited standards developer. ANSI accepts three different types of standards developers. Accredited organizations include most of the largest U.S. SDOs. Accredited standards committees (ASCs) write standards for a specific industry or technology sector, with administrative support provided by an interested host organization. An example is ASC X3 for Information Processing, whose secretariat is provided by CBEMA. Accredited sponsors are smaller groups that seek comment on and approval of their standards through a ballot of interested parties. These groups are usually formed to write one or a select few standards for a narrowly focused application.54

ANSI-accredited organizations may submit standards they have developed for ANSI approval as American National Standards. ANSI publishes American National Standards developed by some, mainly smaller, standards developers. Larger SDOs, such as ASTM, ASME, IEEE, and NFPA, publish standards under their own organizational name, even if they have been accredited as American National Standards. For example, more than half of the standards listed in the IEEE Standards Catalog are indicated, by footnote, as "recognized by the American National Standards Institute."55 The National Electrical Code, published by NFPA, is approved and identified by ANSI with the designation ANSI/NFPA 70; NFPA's own publications, however, refer to it simply as NFPA 70.56

Although ANSI is not a standards developer, as noted above, it publishes American National Standards developed by some of the groups it accredits. This activity has been a source of conflict between ANSI and some of the larger SDOs. Approximately 65 percent of ANSI's $16.7 million gross income (based on 1993 data) is generated from sales of standards and other publications. Net income from publication sales provides for 34 percent of ANSI's core (nonpublishing) expenses, which are not fully funded by membership dues.57 The SDOs' main objection is to ANSI's accrediting and providing publication services to smaller trade and professional associations to produce standards by the canvass method, rather than through a committee process.58 (Some standards developers rely on both canvass and committee methods at different times.) These groups can

obtain ANSI recognition for a standard by submitting it to an open ballot—a canvass—to verify agreement among parties who would be directly affected by the proposed standard. ANSI accreditation and publication of these standards as American National Standards enables them to achieve similar status and distribution—and thus compete for influence and sales—with those of SDOs that use a more thorough, committee-based consensus process. ANSI currently accredits 112 canvass sponsors, 42 organizations, and 199 standards committees.59

It is difficult to quantify either the extent of competition or the relative merits of canvass and committee standards. Such a determination is beyond the direct scope of this report. The circumstances of each case vary widely by industry, product, and type of standard. In the committee's judgment, nevertheless, this conflict is not a threat to the viability of the U.S. private standards development system. Whereas the leading SDOs develop and maintain hundreds of standards, most canvass developers are responsible for fewer than five standards.60 In addition, recent progress in resolving this and other conflicts between ANSI and leading SDOs appears to provide a basis for optimism that the private-sector, voluntary standardization system is capable of settling internal disagreements and continuing to meet the nation's need for standards.

A second challenge to ANSI, and to the U.S. consensus standardization system as a whole, has been the rapid advance of technology in some industry sectors. Slowness of consensus standards processes is a widely cited problem.61 Agreement among competing firms on the best technical standard for a given purpose can be difficult to achieve. Basic communication about technical questions may be costly and time-consuming, requiring numerous technical committee meetings and frequent correspondence. Due process requirements may add delay. Legitimate differences of technical opinion may be compounded, moreover, by participants' competition for marketing advantage. For example, a firm may have an overall interest in standardization, but seek delay in an effort to ensure that no standard is adopted, rather than allowing a competitor's technology to become the standard.62

Technological uncertainty compounds the difficulty of writing standards. To keep up with technological change, technical committees increasingly must set anticipatory standards. These are standards that describe technologies and products not yet completely developed. Recent economics research, moreover, suggests that setting compatibility standards for rapidly evolving information and telecommunications technologies presents a unique challenge to consensus standards developers. The challenge of compatibility standards arises from two phenomena. The first is the potential for significant economic rewards to firms that succeed in setting a proprietary, de facto compatibility standard, such as a computer operating system. The second is the possibility of a technology bandwagon, in which users rush to adopt a standard once it appears that most other users will adopt that standard. The corollary of the bandwagon is technology lock-in. Once most users have committed to a compatibility standard, there are

significant costs to switching to a new standard—even if it represents a more advanced or useful technology.63

Bandwagon and lock-in effects can reward some technologies with large market shares and hinder the success of others, irrespective of their technical merits. Lock-in of inferior technologies through standards can, in some instances, retard innovation and technological advance. These phenomena can occur faster than the typical development cycle of consensus standardization. The rise of standards consortia in the information technology and telecommunications industries is one response to this challenge. The limited due process, consensus, and open participation requirements of these organizations enable them to develop standards rapidly in many instances. Their procedures and restricted membership, however, may limit the acceptability of these standards outside the consortia that develop them.64 Consensus standards developers are responding to this challenge with such measures as streamlined due process and a tighter focus on customer needs in setting the scope for standards writing. In the past five years, for example, the international consensus standards developer for information technology, ISO/IEC Joint Technical Committee 1 (JTC1), has reduced the time needed to produce an international standard from more than 50 months to less than 36 months.65

The best means to achieve standardization, in the committee's judgment, is a flexible, sector-specific approach. Issues such as appropriate speed, technological sophistication, openness of participation, and degree of consensus for standards should be determined by participants in each industry sector. Standards development cycles that are too slow for the telecommunications industry, for example, might be too fast for building materials or consumer appliances. No single set of SDO procedures or performance criteria is likely to meet the needs of manufacturers and users across technologically and economically diverse industry sectors.

Common to all industry sectors, however, is the need for greater accessibility of information about standards and standardization processes. As noted previously, coordination costs are a significant hurdle for achieving standardization. Numerous SDOs with formal procedures for convening technical experts have come into existence in order to overcome this hurdle. Modern communications technologies, however, present additional opportunities to reduce the barriers to participation in standards development, particularly for small firms with limited resources. The National Standards Systems Network (NSSN), a pilot program administered by ANSI under a $2 million cooperative agreement with NIST, is intended to foster links among existing sources of standards information. Electronic dissemination is a key element of NSSN.66 Additional efforts of this type hold significant potential for facilitating participation, particularly for small enterprises and consumer interests. Other benefits will include lowering costs and increasing the speed and efficiency of the U.S. standards development system.

A third area in which ANSI's role has evolved through periods of both

tension and cooperation is its relationship with standards developers and users in the U.S. government.67 As a matter of policy, federal agencies are committed to adopt voluntary consensus standards to the greatest possible extent, rather than developing new, government-unique standards. In the final section of the chapter, cooperation and sources of tension between ANSI and the U.S. government related to federal participation in the voluntary standards system are discussed. In the next section, however, U.S. participation in international standards development through ANSI and other avenues is examined.

International Standards Development

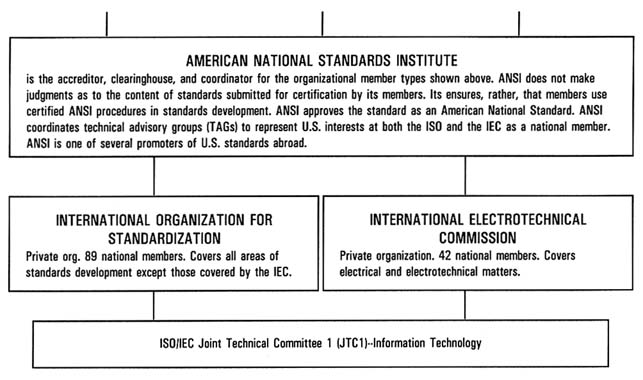

The two predominant international standards-setting bodies in the world are the International Organization for Standardization and the International Electrotechnical Commission. ISO and IEC are private organizations that develop standards in nearly all sectors of industry and technology. The largest exception to their coverage is international telecommunication standardization, which is the domain of the International Telecommunications Union (ITU). ITU is a treaty organization with membership comprised of government representatives from 160 countries. U.S. representation at ITU is coordinated by the Department of State.68 As private agencies, ISO and IEC accept as members the national standards organizations, whether public or private, of their member countries. ANSI is the U.S. national member of ISO and IEC, the latter through the ANSI-coordinated U.S. National Committee. (See Box 2-1 for additional background information and comparisons of ISO, IEC, and ITU).

International standards development processes resemble those of U.S. private SDOs in many respects.69 ISO and IEC prepare standards within a decentralized technical committee structure, drawing on volunteer technical experts from various member countries. Administrative support for technical committees is provided by a secretariat, from one of the participating countries. Standards are drafted through consensus. Voting within committees and in the organization at large, unlike many national SDOs, is by national delegation. As a result, a large country such as the United States has the same vote as a small country.

U.S. positions for international standardization activities are developed by volunteer experts within technical advisory groups (TAGs). ANSI coordinates the formation of U.S. TAGs corresponding to technical committees at the international level. In addition, on issues that the U.S. standards community considers of particular importance—such as standards affecting large shares of U.S. exports—ANSI and the U.S. standards community make efforts to obtain ISO and IEC designation of the United States as the secretariat for particular international technical committees.

The United States is a participant or observer in 95 percent of ISO, and nearly all IEC, technical committees and subcommittees.70 The United States

held 13.7 percent of ISO and IEC technical committee and subcommittee secretariats in 1992, an increase from 10.9 percent in 1988.71 These committees and subcommittees are concentrated in especially active areas of standards activity, producing in 1991 more than 38 percent of all ISO and IEC standards and 31 percent (measured in pages of text) of Draft International Standards. (The latter represents a significant increase over a 6.8 percent share in 1988.72)

In addition, the United States has had significant success in obtaining secretariats of ISO and IEC technical committees and subcommittees in industry sectors with high volumes of exports. For example, the United States holds the secretariats of ISO/IEC JTC1 for Information Technology; ISO Technical Committee (TC) 20, covering aircraft and space vehicles; ISO TC 61, plastics; and ISO TC 67, petroleum industry materials and equipment, among others. All of these committees set international standards in industry sectors that are among the top 10 U.S. export industry sectors.73

Cooperation between the U.S. public and private sectors—which is discussed in depth in the next section of this chapter—was instrumental in gaining a strong U.S. role in the recent establishment of an ISO technical committee on sterilization of health care products, an area of interest to U.S. exporters in the medical devices industry. Coordination among the AAMI, the FDA, and the Health Industry Manufacturers Association (HIMA) was instrumental in ANSI's developing a successful proposal and gaining ISO approval for a new committee, ISO TC 198. The international secretariat was assigned to the United States, where it is sponsored and staffed by the AAMI. A key goal of AAMI in pursuing this outcome, according to its staff, was to be able to cooperate with European standards developers to ensure harmonization of U.S., European, and international regulations.74

The scope of international standardization is broader than ISO and IEC alone. U.S. participation in ITU is significant to international standards development in the telecommunications equipment and services industries. In addition, standards produced by some U.S. standards developers take on the authority of international standards without going through a process of consensus building at ISO and IEC. For example, ASTM standards are used throughout the world, and 33 percent of ASTM's sales of publications are outside the United States.75 About 20 percent of ASME's sales of codes and standards are non-U.S. sales.76

The significance of both international standards and conformity assessment is growing in conjunction with the increasing importance of international trade to U.S. economic performance. Expansion and strengthening of international trading system rules concerning standards and conformity assessment provide additional incentives to U.S. industry, government, technical, and other participants in the standards system to focus increased attention on international activities. These and related factors are examined in detail in Chapter 4.

Government Role In Standardization

The public sector plays a major part in the U.S. standards system. Federal, state, and local government agencies are all active in developing and using standards. Standards written by federal agencies for regulatory and procurement purposes comprise more than half of the total number of U.S. national standards, as shown in Table 2-1. These are categorized as mandatory standards, reflecting their imposition through legislation and regulation or through contractual requirements for sale to government purchasers. Although these standards are developed outside the ANSI-coordinated voluntary consensus system, the mandatory and voluntary standards categories overlap. Many government standards

|

BOX 2-1 INTERNATIONAL STANDARDS DEVELOPERS International Organization for Standardization The ISO is a private international agency, established in 1946 with headquarters in Geneva, Switzerland. It is dedicated to voluntary standardization. Its membership consists of recognized national standards organizations of 89 countries. ISO covers work in all areas of standards development except those in the fields of electrical and electrotechnical standards, the domain of the IEC, and telecommunications, the expertise of the ITU. ISO has more than 160 technical committees, some 600 subcommittees, and a host of working groups that are supported by secretariats in 32 countries. The development process is lengthy and ultimately requires the majority consensus of technical committee members and 75 percent of the ISO voting membership. Only after consensus has been reached is it published by the ISO Council as an International Standard. The American National Standards Institute is the U.S. representative to ISO. ISO has published more than 6,700 international standards since its inception. International Electrotechnical Commission The IEC, an international voluntary organization headquartered in Geneva, Switzerland, specializes in standards development for electrical and electronic engineering. IEC is concerned mostly with creating specification standards for products and devices. It has a membership of presidents from the national committees of 42 countries. The development process is a lengthy one. The technical work is done by about 200 technical committees, which are managed by the Committee for Action. This committee has three advisory committees; an Advisory Committee on Electronics and Telecommunications, an Advisory Committee on Safety, and the Information Technology Coordinating Group. IEC issues publications and recommendations for international standards, as well as promoting safety, compatibility, interchangeability, and acceptability. To keep nonmember countries informed of the process and development of its standards, IEC created the Registered Subscriber Service. ANSI is the U.S. representative to the IEC. A major difference between ISO and IEC is that in the IEC each member nation has membership on every technical committee not just on those it chooses to join. International Telecommunication Union The ITU is the only international standards development organization that is nonvoluntary. It is a treaty organization run under the auspices of the United Nations. Governments, not industry, administer and enforce the regulatory telecommunications standards that come out of the ITU. It has a membership of 160 nations. The U.S. representative to the ITU is the State Department. A Plenipotentiary Conference acts as the authority and sets policy, while the council, composed of 43 members elected by the conference, deals with administrative matters. ITU maintains five permanent activities. They are the General Secretariat, the organization of World Conferences on International Telecommunications, the Radiocommunication Sector, the Telecommunications Standardization Sector, and the Telecommunications Development Sector. The ITU typically develops recommendations that are implemented as national standards by national telecommunications authorities. ISO, IEC, and the ITU are alike in two important ways. They all have similar administrative structures with committees, subcommittees, and working groups directing the standards-setting process, with varying levels of complexity. Also, they all rely on some from of consensus as the ultimate decisionmaking mechanism. None of the three organizations demands or expects participation from all nations; participation is voluntary at all levels. However, once a nation becomes a member it is expected to be actively involved. The focus on consensus is aimed at preventing a decentralization at the international level of standards development and encouraging broad-based compliance and harmonization. SOURCES: ''International Standards: It's a Small World After All." In Quality , Wheaton, IL: Hitchcock Publishing Co., August 1986. Cargill, Carl F. Information Technology Standardization: Theory, Process, and Organizations. Pps. 126-145. Bedford, MA: Digital Press, 1989. International Telecommunications Union informational brochure. Geneva: ITU Public Relations, 1993. |

Complete box on previous page.

make reference to consensus standards in whole or in part. This process has the effect of making many voluntary consensus standards, in effect, mandatory.

The Department of Defense and the General Services Administration (GSA), with 38,000 and 6,000 procurement standards, respectively, represent the bulk of federal standards development. The remaining 8,500 standards, mainly technical regulations, are produced by a wide range of departments and agencies (see Table 2-3). Regulatory standards center on the protection of public health and safety. Examples include regulations set by the Food and Drug Administration, Occupational Safety and Health Administration (OSHA), Consumer Product Safety Commission (CPSC), and Federal Aviation Administration, among other agencies. The Environmental Protection Agency (EPA) regulates products and processes

TABLE 2-3 —U.S. Government Standards Developers

|

Agriculture, Department of Agricultural Marketing Service Federal Grain Inspection Service Field Management Division Standards and Procedures Branch Food Safety and Inspection Service Foreign Agricultural Service Forest Service Engineering Staff Information Resources Management Planning, Review, and Standards Division Packers and Stockyards Administration Livestock Marketing Division Rural Electrification Administration |

|

Commerce, Department of Bureau of the Census Federal Coordinator for Meteorology National Institute of Standards and Technology National Computer Systems Laboratory National Engineering Laboratory and Law Enforcement Standards Laboratory Technology Services - Voluntary Product Standards National Oceanic and Atmospheric Administration National Marine Fisheries Service National Environmental Satellite, Data, and Information Service National Weather Service National Telecommunications and Information Administration Institute for Telecommunications Sciences U.S. Patent and Trademark Office Assistant Commissioner for Information Systems Assistant Commissioner for Patents International Patent Documentation Trademark Examining Operation |

|

Consumer Product Safety Commission Directorate for Engineering Sciences Directorate for Health Sciences |

|

Defense, Department of Office of the Assistant Secretary of Defense, Acquisition Defense Industrial Supply Center |

|

Energy, Department of Assistant Secretary for Defense Programs Building Technologies Building Systems and Materials Division Building Equipment Division Energy Information Administration Statistical Standards Environment, Safety, and Health Safety and Quality Assurance |

|

Environmental Protection Agency |

|

Federal Communications Commission Office of Engineering and Technology |

|

General Services Administration Information Resources Management Federal Supply Service Commodity Management Public Building Service |

|

Health and Human Services, Department of Centers for Disease Control National Institute for Occupational Safety and Health Food and Drug Administration Regulatory Affairs Health Care Financing Administration |

|

Housing and Urban Development, Department of Assistant Secretary for Housing - Federal Housing Commissioner Manufactured Housing and Construction Standards Division |

|

Interior, Department of the Minerals Management Service Rules, Orders, and Standards U.S. Geological Survey Information Systems Division National Mapping Division Water Resources Division |

|

Labor, Department of Mine Safety and Health Administration Standards, Regulations and Variances Occupational Safety and Health Administration Directorate of Safety Standards Programs |

|

National Aeronautics and Space Administration Occupational Health Safety, Reliability, Maintainability, and Quality Assurance Division |

|

National Archives and Records Administration Archival Research and Evaluation Staff |

|

Nuclear Regulatory Commission Nuclear Regulatory Research |

|

State, Department of U.S. National Committee for the International Telecommunications Union-Telecommunication Standardization Sector |

|

Transportation, Department of Federal Aviation Administration Federal Highway Administration Maritime Administration National Highway and Traffic Safety Administration Research and Special Programs Administration Standards Division United States Coast Guard Marine Safety, Security, and Environmental Protection Auxiliary, Boating, and Consumer Affairs Division |

|

Treasury, Department of Bureau of Alcohol, Tobacco, and Firearms National Laboratory Center Internal Revenue Service Standards and Data Administration U.S. Customs Service Commercial Operations Research Division - Laboratories and Scientific Services |

|

Veterans Affairs, Department of Acquisition and Material Management |

|

SOURCE: Toth, Robert B. Standards Activities of Organizations in the United States. NIST Special Publication 806. U.S. Department of Commerce. Gaithersburg, Md.: NIST, 1991. |

that affect the environment. The Federal Communications Commission (FCC) sets telecommunications equipment standards to ensure compatibility and to protect the security and integrity of the public communications network. The Department of Agriculture produces standards both to promote food safety and to ensure accurate grading and marketing of agricultural products. The Department of Commerce's National Institute of Standards and Technology, among other standards-related activities, develops and maintains standards for physical measurement, known as reference standards.77

Standards-writing activities of state and local governments are less easily identified than those of the federal government. These levels of government are very active in the areas of product certification and laboratory accreditation. Such programs, however, largely make assessments against standards originally written by other authorities—for example, private building codes organizations for construction standards and the NFPA's ANSI-approved National Electrical Code.78 (The automobile emissions standards written by the State of California are a well-known exception.) The impact of state and local standards-related activities, as discussed in Chapter 3, is reflected primarily in conformity assessment rather than in standards development. In a recent pilot project performed by NIST's National Center for Standards and Certification Information, for example, the official gazettes of California, Texas, and New Mexico were monitored for announcements of new standards development activity that might affect trade

within the North American Free Trade Agreement region. Only one standard was identified during several months of 1994.79

National Institute of Standards and Technology

The U.S. government agency with leading expertise in the area of technology standards and industry standardization issues is the Department of Commerce's National Institute of Standards and Technology (NIST). Although NIST is not a regulatory or a procurement agency, it is active in many aspects of both public and private standards setting. NIST was established in 1901 as the National Bureau of Standards, with responsibility for developing and coordinating reference standards—standards of weights and measures. In 1988, the bureau was reconstituted as NIST and given the explicit mission of assisting U.S. industry to advance its performance in the development and application of technology. Scientists at NIST's internal laboratories conduct basic and applied research in a wide range of physical sciences. One central goal of this research is to advance the science of measurement and testing and to apply these advances to standardization.80

For fiscal year (FY) 1994, NIST's overall budget was $520.2 million.81 Its FY 1995 appropriation request increased to $935.0 million (see Table 2-4). Most of the increase was in NIST's extramural industry assistance programs, including the Advanced Technology Program, the Manufacturing Extension Partnership, and the Quality Program. Appropriations for intramural programs, consisting primarily of the eight NIST laboratories, grew from $226.2 million to $316.0 million. The Office of Standards Services—which leads NIST's interactions with the voluntary consensus standards community and other federal agencies with standards activities—is part of NIST's Technology Assistance activity. The appropriation for Technology Assistance, of which the Office of Standards Services accounts for about half,82 grew from $11.0 million in FY 1994 to $14.9 million in FY 1995. The Office of Standards Services therefore represents approximately one-half of 1 percent of NIST's overall budget.