2

Undersea Vehicle Capabilities and Technologies

This chapter describes the types and capabilities of undersea vehicles that will provide the functions necessary to serve as undersea tools for science and industry and respond to vital national needs in the oceans. When describing its capability, it is essential to conceive of an undersea vehicle as a system that encompasses: (1) a vehicle platform plus vessel and shore-based support; (2) a payload of task-performing devices and sensors; (3) a human in control, located either remotely or on site; and (4) the technology and hardware necessary to support, launch, and retrieve the vehicle. This system level vehicle concept must take explicit account of potential missions and objectives.

This chapter points out the importance of system integration—the "glue" binding the human-vehicle system into a single operational unit. The contribution of each subsystem to the overall technical performance capability of the vehicle assembly is assessed in the system context. Advances in the technology and capabilities of some subsystems may provide more overall system performance benefits than would improvements in other subsystems. Finally, and very importantly, each key vehicle subsystem is assessed in regard to the current state of practice and where significant improvements can be made.

In this systems context, an assessment of the state of practice is the starting point for assessing vehicle technology and capability for responding to the nation's needs. An understanding of development trends and influences within, and external to, the undersea vehicle industry is the next important step in determining research and development strategies and priorities. Indeed, some of the valuable aspects of vehicle development are driven largely by advances in other industries, both domestic and foreign. This relationship is a natural process induced by the intense competition among a few small vehicle engineering and manufacturing organizations that must focus their limited development capital on adapting technologies to the special requirements of the undersea environment and missions. The committee identified those technologies that are vital to advances in undersea vehicle capability and are not already being pursued in other arenas.

VEHICLE SYSTEMS

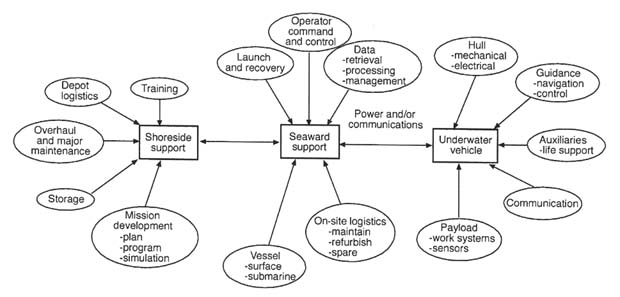

Vehicle systems designs are driven by mission requirements, available technology, and cost. A system must be an effective combination of human operators and vehicle subsystems and components that are integrated to achieve optimal performance (see system elements schematic shown in Figure 2-1). Consequently, the task for builders and designers of a vehicle system is to integrate this multiplicity of subsystems into a working whole. The attributes of each subsystem will be assessed and established by the committee based on the state of technology, relative cost, and mission requirements.

For a given mission or task, designers and engineers begin by considering its particular requirements. These vary according to mission requirements for maximum depth, endurance in range and in time, and sensors; the optimal human role in command and control; power available; cost; and a host of other factors. Depending on these criteria, a particular type of vehicle (DSV, ROV, or AUV) is selected and its subsystems chosen to best fulfill mission requirements. Subsystem capabilities improve with time as technology develops, so the optimum solution in the near future may be significantly better than what is optimal using today's technology.

Table 2-1 summarizes typical capabilities and examples of DSVs, ROVs, and AUVs. The characteristics listed are generic, and there are exceptions; but the table outlines the characteristics and relative strengths and limitations inherent to each type of system.

DSVs place the human in the environment and benefit from the human's high-resolution, three-dimensional observation capability and full visual depth of field that is still superior to the observational capabilities provided by remote sensors. This capability enhances the performance of inspection and imaging tasks as well as manipulation. In general, today's DSVs have relatively large payload capacities and good manipulation capabilities but do not provide real-time feedback to the surface. Moreover, they require costly

FIGURE 2-1 Schematic diagram of vehicle systems.

pressure housings and life support and safety systems for the human operators. DSV endurance at the work site is limited by prolonged surface periods for crew change and vehicle replenishment. The cost per operating hour is usually much greater than for other vehicle types because of the extra cost attributable to crew accommodation and life support, the larger surface support ship needed to handle the heavier human-occupied vehicle in launch and retrieval, and the more limited availability—therefore, the normally higher day rate—of support ships. In addition, the capital cost component of the day rate for DSVs is potentially higher than for unoccupied vehicles because they can be operated fewer hours due to human limitations.

In comparison to DSVs, ROVs provide greater endurance and greater range, including maneuverability of surface support vessels, at lower cost. Because life-safety support is not required, ROVs can operate in hazardous environments and provide simultaneous real-time observation and control to multiple remotely situated observers (Robison et al., 1992; Bowen and Walden, 1993).

AUVs are free from the tether restraint common to ROVs and can perform tasks with little or no operator input. However, AUVs must operate on a limited energy budget and can provide little real-time feedback to the operator, who is limited by the bandwidth available when using acoustic communication. However, new advances in task-level control architecture will enable the human to command tasks at high-level in real-time, and acoustical advances are continually expanding the available acoustic communication bandwidth.

DEEP SUBMERSIBLE VEHICLES

In the 1960s and 1970s many DSVs (with a human in situ) were in operation in a variety of different applications worldwide. Estimates indicate that more than 100 DSVs of all types were built during this time. DSVs have dominated ocean exploration, and some systems, such as Alvin, have been operational for the last three decades. DSVs continue to be used in support of certain military tasks and marine scientific research. However, few have been built recently (only four since 1990), and the number operating today is significantly less than it was 20 years ago. Since the 1970s, ROVs have replaced DSVs for most commercial work tasks, and the committee anticipates that ROVs will provide increasing support for marine science projects. However, there will continue to be certain vital exploration tasks that can be performed only by humans in situ.

Most contemporary DSVs require the on-site presence of a mother ship to provide logistical support for the vehicle and its personnel. The submersible's crew usually consists of a pilot and one or more observers. The observers are usually scientists, researchers, or technologists with an active part to play in conducting the mission. Due to limitations on human endurance and on-board power, mission times rarely exceed 8 hours, although some have extended to 16 hours or more. Emergency life support systems must be capable of operating for 72 hours beyond the maximum mission time.

The DSV places the crew directly at the site of interest. Visual observations are augmented for close-up inspections (less than 0.5-meter range) by video cameras, an important tool for direct observation (Robinson et al., 1992). Most DSVs are significantly larger than ROVs used in comparable missions. Its size makes the DSV a stable platform to support viewing and manipulative tasks, including biological and geological sampling. However, because it is essential for the DSV to be large enough to accommodate several persons, it is more difficult to handle at sea and more difficult to position when performing tasks in restricted work areas. Essentially, DSVs are vertical probes with limited horizontal range; therefore, they are less suitable for large-scale

TABLE 2-1 Comparative Undersea Vehicle Capabilities

|

|

DSVs |

ROVs |

AUVs |

|

DEFINITION |

Untethered, human-occupied, free-swimming, undersea vehicle |

Tethered, self-propelled vehicle with direct real-time control |

Untethered undersea vehicle, may be totally preprogrammed and equipped with decision aids to operate autonomously; or operation may be monitored and revised by control instructions transmitted by a data link. |

|

DEPTH |

Many to 1,000 m |

Very many to 500 m |

Several to 1,000 m |

|

|

Few to 3,000 m |

Many to 2,000 m |

Few to 3,000 m |

|

|

Very few to 6,000 m |

Few to 3,000 m |

Very few to 6,000 m |

|

|

One to 6,500 m |

Few to 6,000 m |

|

|

|

|

One to 11,000 m |

|

|

ENDURANCE |

|

|

|

|

Time |

Normally 8 hours, 24 to 72 hours max |

Indefinite, depending on reliability and operator endurance |

6 to 48 hours of propulsion May sit on bottom for extended periods |

|

Range |

< 50 km |

Limited in distance from host ship by tether |

350 km demonstrated; near-term potential 1,500 km, depending on energy source |

|

PAYLOAD |

1 to 3 people, 45 to 450 kg (100 to 1,000 lb); adaptable to tools and sensors |

45 to 1,590 kg (100 to 2,000 lb); adaptable to tools and sensors |

11 to 45 kg (25 to 100 lb); adaptable to measuring equipment, tools, and sensors |

|

SUPPORT |

|

|

|

|

Ship |

Most DSVs require large ship support; ship size varies with DSV size |

Depends on ROV size and mission requirements |

Medium—depends on AUV size and mission requirements |

|

Handling Systems |

Depend on DSV size |

Depends on ROV size |

Similar to ROVs, depending on AUV size |

|

Navigation Systems |

Relative to seafloor or surface vessel |

Relative to surface/seafloor |

Seafloor and inertial navigation |

|

STRENGTHS |

Direct human observation and manipulation |

Real-time feedback to operator, long endurance capability, low- cost per operating hour |

Potential for automated operations, ability to operate with or without human command and without tether; minimum surface support |

|

|

Real-time feedback to controller |

|

|

|

LIMITATIONS |

Large size, weight, and cost due to manned requirements |

Tether cable potentially limits maneuverability and range |

Energy supply |

|

|

|

|

Bandwidth of data link |

|

|

Limited mission time |

|

Capacity of internal recorders |

|

|

Potential personal hazards |

|

Limited work function complexity |

mapping and surveying operations. As with other systems, advances in propulsion, energy storage, and manipulators will contribute to DSV utility and may even reduce their cost. Developments incorporating innovative uses of materials have already reduced the size and weight of the next generation of DSVs, and a system designed to bring a single pilot to the deepest part of the ocean is in progress (Hawkes and Ballou, 1990; Broad, 1993).

REMOTELY OPERATED VEHICLES

ROVs are by far the most common type of undersea vehicle; more than 1,000 ROVs have been built since their introduction in the 1960s. ROVs connect to a surface vessel or platform by a tether that carries power and control signals and feedback data from the vehicle. Originally developed for the military, ROV technology was further developed by the civil sector in the early 1970s, when private firms developed ROVs in response to the needs of the offshore oil industry. ROVs were one factor that enabled the offshore industry to move beyond diver depth range. The results were reliable platforms serving a broad commercial market, with some technology transfer back to the military (McFarlane, 1987). ROVs continue to be used reliably in the offshore industry, and innovations in operational techniques and tool packages are expanding the scope of tasks these vehicles can perform (Langrock et al., 1992; Sucato, 1993). Nevertheless, ROVs are vertically operating systems that require significant surface support with attendant costs.

ROV manufacturing has been a highly competitive business. After attempts by several companies to compete in the rapidly growing offshore market of the 1970s, only one company, Perry Tritech, Inc., remains in the United States that builds full-size work platforms for the offshore industry. Worldwide, there probably are no more than five companies that have built more than one large ROV system. In the area of the smaller, low-cost ROV systems, a U.S. company, Deep Ocean Engineering, is the largest supplier among eight companies in the world that are in serial production of these vehicles.

Much of the commercial success gained by ROVs is due to the activities of service companies that operate vehicles under contract. Many of these companies began as commercial diving services, then gradually introduced ROVs as a lower cost alternative to many underwater tasks previously performed by divers. Other companies began as ROV service organizations only, following the pattern set by former successful commercial diving contractors. In the past two decades, the primary driver for ROV technology advancement has been commercial sector demand.

Light and medium-weight ROVs tend to have electrically powered thrusters. Heavy work-class ROV systems carry much larger payloads and tools, weigh up to 3,000 kilograms, and are fitted with hydraulic thrusters. These large ROVs found a niche in the offshore oil and gas industries and in the communication industry for underwater manipulation, cable burial, and inspection tasks. Large work-class ROVs are usually fitted with hydraulically powered manipulators, and some have protective cages that are used for launch and recovery. Nonmarine applications of ROVs, principally in nuclear and hydroelectric power plants and municipal water works, have evolved over the last two decades to provide small platforms for inspection of the radioactive, or potentially radioactive, components of nuclear power plants. The technical development and operational experience derived from the nuclear application has benefited the evolution and application of small vehicle designs for undersea application.

The mobility of ROVs is often restricted by tether drag, and their stability can be affected by wave action on the surface vessel, which is transferred down the tether. Despite the constraints to horizontal operations within the sea imposed by the tether, ROVs have provided a platform for conducting in situ observations within the water column with little disturbance of surrounding sea life. ROVs have also extended the horizontal search range for larger, more limited survey vehicles such as the DSV Alvin.

AUTONOMOUS UNDERWATER VEHICLES

Although AUV research has been under way for several decades, the technological challenges and applications are such that these vehicles have developed more slowly than ROVs. A few systems were in operation as testbeds in the 1970s, but it was not until the 1980s, with the advent of microprocessors and associated software architectures, that these systems began to approach truly autonomous operations (Walsh, 1994; Michel and Le Roux, 1981). AUVs have potential advantages over other vehicles types. Because they lack tethers and carry no human occupants, AUVs permit sensing in areas where humans cannot go, such as under ice, in militarily denied areas, or in missions to retrieve hazardous objects.

For the past two decades, more than 75 percent of AUV development has been funded by the military, so continued development of this technology may be vulnerable to reductions in defense research budgets (Walsh, 1994). Further, because most of this work has been experimental or directed at military objectives, experience with AUVs in support of scientific missions has been limited, and there has been virtually no experience in the commercial sector.1

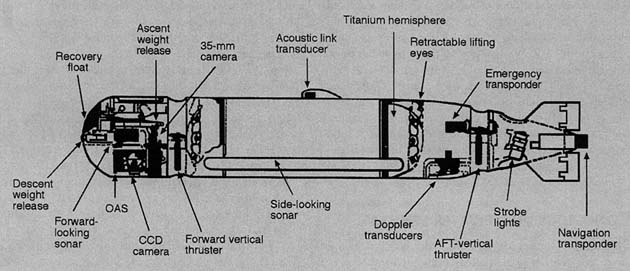

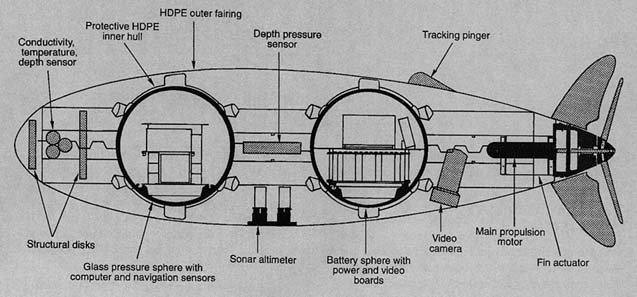

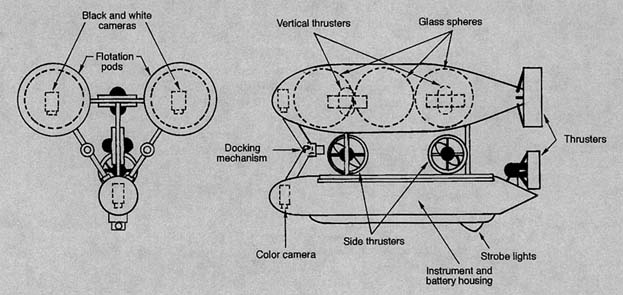

Several different types of AUVs have already been developed, each designed to respond to one of a variety of missions. The AUSS, shown in Box 2-1, addresses large area search and detailed inspection requirements. The lightweight AUV sensor platform (e.g., Odyssey; see Box 2-2) aims at fulfilling needs for medium-area surveys under ice and in deep water. The long-duration, deep sea survey vehicles, for example, ABE (see Box 2-3), perform detailed inspections in deep water over long time periods (Michel et al., 1987; Walton, 1991; Walton et al., 1993; Bellingham et al., 1992; Bradley and Yoerger, 1993).

A recent emphasis in AUV development is on very small vehicles that can be deployed in large numbers to perform localized, relatively simple tasks such as shallow water mine clearance. These vehicles could be very simple and inexpensive, using basic sensor suites and commercial off-the-shelf electronics. Working together, a constellation of such devices could accomplish the same work as a single, larger AUV. Because multiple units could be programmed to carry out the same task, redundancy would provide reliability. Although this concept is quite new and unproven, it has shown sufficient progress and promise to warrant continuing development.

As AUVs enter nonmilitary applications, it is likely that marine science will become a primary early mission and technology driver. As the technology matures, a number of applications in the offshore oil and gas industry, such as cable laying and inspection, and in a variety of other fields can also be envisioned (Fricke, 1992; Collins, 1993; Asakawa et al., 1993; Walsh, 1994). At present, virtually all AUVs are experimental prototypes or proof-of-concept vehicles. None is in routine operational service.

AUVs in existence today are vehicles with limited decision making capabilities and endurance. The missions for AUVs call for simple data-gathering, conducting searches, performing surveys, and laying fiber-optic cable. However, until more advanced capabilities evolve, missions requiring probabilistic decision making and true autonomy will be developed only for high-value objectives. AUVs are still in their infancy, and the lack of operational experience with these vehicles in the open ocean marks them as an immature technology with very important future potential. Even now,

|

BOX 2-1 AUV Example: AUSS AUSS, the Advanced Unmanned Search System locates and inspects objects on the ocean bottom over wide areas. Mission logic allows the vehicle to perform a side-scan sonar search, break off the search when it identifies a target for close-in optical inspection, and then resume the search where it left off after imaging the target. AUSS acoustically transmits its imagery and data to a vehicle supervisor on a surface ship. The vehicle uses Doppler sonar and a gyrocompass to navigate. It employs a cylindrical graphite epoxy pressure hull with titanium ends. It has demonstrated sustained searches at a rate of 1 sq-nm/hr, including evaluating individual targets discovered along the search path.

|

AUVs are capable of performing a number of clearly defined missions, but they have not been used because of their high initial development cost, lack of awareness of present vehicle capabilities, or lack of confidence by the potential user community.

Vehicle success in missions attainable with present system technical capability should provide both the experience and the support required for critical technology advancements to enable undertaking more complex missions. There is already evidence of this progress, as demonstrated by the AUV under ice operations in the arctic (Bellingham et al., 1993) and in recent Odyssey II surveys over the Juan de Fuca Ridge (see Chapter 3). For example, high-level (low-bandwidth) human control of tasks requiring use of manipulators in real-time is one important area under development. The human operator can command directly what is to be done with the object of interest within the water column or on the sea bed, and the vehicle manipulator system will plan and carry out that command in near real-time (Wang et al., 1992; 1993). This technology is similar to the approach being developed to deal with the time delays associated with robotic manipulation in space, and there has been some crossover of

|

Box 2-2 AUV Example: ODYSSEY The Massachusetts Institute of Technology Sea Grant AUV Laboratory has built six Odyssey class vehicles, of which five are presently operational. The five operational vehicles, designated type Odyssey II, are being used for Autonomous Ocean Sampling Network (AOSN) research and for development of a rapid event-response capability. A variety of field operations have employed the vehicles, including operations of the original Odyssey from the Nathaniel B. Palmer during an Antarctic cruise in January 1993. In March of 1994 Odyssey II was operated from an ice-camp in the Beaufort Sea. Deep water operations of Odyssey II in summer 1995 culminated in dives to 1,400 meters deep and surveys lasting more than three hours. Vehicle development has been funded by the MIT Sea Grant College Program, the Office of Naval Research, the MIT, U.S. Navy Program Management Office 403, the National Undersea Research Program, and the National Science Foundation. The construction of the latest five vehicles has been supported by the Office of Naval Research.

|

|

Box 2-3 AUV Example: ABE Woods Hole Oceanographic Institution built ABE, the autonomous benthic explorer for deep, near-bottom seafloor surveys. In 1995, ABE completed a geophysical survey on the Juan de Fuca Ridge at 2,200-meter depth, including magnetometer, conductivity, temperature, depth (CTD) instrument, and video survey. ABE has the ability to dock to a mooring and remain in "sleep" mode to perform preprogrammed, repeatable seafloor measurements over extended periods.

|

National Aeronautics and Space Administration (NASA) research with undersea vehicle development (Stoker, 1994).

OPERATIONAL ATTRIBUTES OF VEHICLE SYSTEMS

Each type of vehicle has inherent attributes that make it more suitable for certain tasks than are other systems. Because of their stability and ability to provide direct viewing for occupants/operators, DSVs are very good for observation and most work tasks requiring manipulators and samples. However, because of their limitations of range and time on bottom or in the water column, which is dictated by the on-board energy source, human endurance, and the cost of support ship and crew, DSVs generally are not well suited for large area search and survey or extended observation—tasks that are most efficiently carried out by towed vehicles at present.2 Furthermore, because of their human occupants,

TABLE 2-2 Current Undersea Vehicle Capabilities

|

Vehicle Functions |

Requisite Characteristics and Capabilities |

DSVs |

ROVs |

AUVsa |

|

Reconnaissance |

Forward observation, search, measurements |

Good |

Good |

Good |

|

Local survey |

Small area observation and measurement, precise navigation |

Good |

Good |

* |

|

Broad area survey |

Large area (up to 300 sq km) observation and measurement, medium geodetic or relative navigation accuracy |

Limited |

Limited |

* |

|

Waste site monitoring |

Specific site observation, sensing, and water sampling |

Good |

Good |

* |

|

Mapping |

Terrain feature survey, tied to accurate geodetic navigation, larger areas |

Poor |

Limited |

Good |

|

Search |

Relatively large area coverage, acoustic and optical sensing, object identification, good navigation |

Good |

Limited |

* |

|

Inspection |

Close-up observation, optical and other sensors, good vehicle positioning and stability |

Good |

Good |

* |

|

Observation |

Similar to inspection, but implies real-time witnessing of dynamic events |

Good |

Good |

Poor |

|

Work |

General tasks involving vision, object manipulation, and use of tools |

Good |

Good |

* |

|

Sediment sampling |

Specific work task involving collection of material, including coring |

Good |

Limited |

Limited |

|

Installation/Retrieval |

Placement or recovery of objects and instruments in/from specific locations |

Good |

Good |

Good* |

|

|

|

|

|

Limited |

|

Accident investigation |

Observation, local area search, collection of material evidence |

Good |

Good |

Limited |

|

Waste disposal |

Transport and placement of toxic materials in predetermined locations. May be large quantities or a deep site. |

Poor |

Good |

Poor |

|

Water quality measurements |

In situ sampling and analysis in varying depths and locations |

Good |

Good |

* |

|

a Asterisks indicate that, while current AUVs are not suited to these tasks, developments are under way that could improve system capabilities to the point that the vehicle system should be suitable for the application. |

||||

DSVs are not suitable for operating in dangerous areas, such as in tunnels or around explosives.

ROVs, which are powered from the surface, have no real energy limitations. They are also generally stable. Viewing facilities for the human operator are good and continue to be improved, including stereo and new "augmented reality" compatibility.3 Hence, ROVs are inherently suited for working for extended periods, performing local surveys, operating in high-risk areas, and passing large quantities of real-time sensor information back to a surface support vessel. However, due to tether drag, ROVs are limited in how far and how fast they can travel from their support craft, and they are less suitable for large area, long-range search or survey and long, under ice transits.

AUVs can move rapidly and, subject to limitations of the on-board energy storage, can generally traverse great distances relative to the other two types of vehicles. This makes them well suited for transporting sensors over large areas for surveys of various kinds. Some AUV systems have used a fiber-optic communications link for all or part of their operation. However, this is not a routine mode of operation, and, without a tether, the communication mechanisms for real-time human intervention are limited. Nevertheless, the narrow beam acoustic links have passed at least 50,000 bits per second (bps), and even low-bandwidth links can pass some useful data. To extend the range of AUV applications, increasingly effective autonomous work systems are evolving rapidly along with the general field of robotics. Another present AUV limitation is that data transfer must wait until the AUV vehicle is recovered on-board a mother ship. In response to this problem, acoustic telemetry schemes now emerging offer a hybrid arrangement where the human can intervene on a limited, non-real-time basis. New advances in task-level control architecture will enable the operator to command tasks at a high-level in real-time (within the new bandwidth). AUVs are limited by the current lack of maturity of task-management architecture that can be placed on-board. Overcoming this limitation is the focus of present research at the Monterey Bay Aquarium Research Institute (Wang et al., 1993; Marks et al., 1994a; Wang et al., 1995).

Table 2-2 summarizes the foregoing discussion and includes a list of generic tasks that may be performed by vehicle systems. The committee has characterized the relative abilities of the different vehicle types to carry out these tasks; several qualitative descriptors are used, each representing the collective opinions of the committee and each based on considerations such as those discussed above.

EVALUATION OF THE STATE OF TECHNOLOGY

This section evaluates the state of the art and state of practice for vehicle technologies and assesses the potential for future developments. In the total system context described

earlier, vehicle technologies are discussed here in relation to the various subsystems that are common to all subsea vehicles. The technologies described are typically applicable to several if not all types of vehicles covered in this report. This section groups the subsystems into two categories: those that directly support vehicle operations, that is, energy, propulsion, and control; and those that are related to payloads to support various missions, that is, sensing, survey, and manipulation. These two categories may overlap in some cases, but the distinction is useful for analysis. New developments with near-term usefulness are cited for each area, and the status of synergistic technology developments from other industries is discussed.

Vehicle Subsystems

Each subsystem and its driving technologies play a role in overall vehicle performance and contribute to the vehicle's capability to accomplish specific mission objectives. Lack of development in certain technology areas inhibits progress and further applications because they determine or facilitate vehicle capabilities. The technologies in other subsystems are highly developed, and further advancement will not appreciably improve the overall performance of the system. Accordingly, during the committee's evaluation, each subsystem was given an importance rating of "critical," "incremental," or "mature," depending on our evaluation of its impact on further vehicle development. These ratings are characterized as follows:

-

Critical—Improvement in the subsystem will enable or create important new vehicle capabilities.

-

Incremental—Vehicle progress can benefit from development of subsystems technologies in an evolutionary manner.

-

Mature—Development has been successful and further improvement may occur, but development will contribute only marginally to improved vehicle performance, and improvements will be used only if they are cost-effective compared to current techniques.

Energy

Existing energy sources pose limitations for systems without cable connections (i.e., DSVs and AUVs), affecting system size, payload, and endurance. Energy limitations on AUVs are critical, and they are becoming more critical for DSVs because of the growing power demands of sensors, lights, computers, and manipulators. High-energy density batteries could lengthen missions and generally improve performance.

Energy sources are rated in terms of both energy and power. The most frequently used ratings are "specific energy" (watt-hours per kilogram) or "energy density" (watt-hours per liter). Batteries are usually used in underwater vehicles; numerous other energy technologies are also available, but they are more costly. The performance characteristics of available energy sources are compared in Table 2-3. The table is divided into four types of energy systems: secondary batteries, primary batteries, fuel cells, and heat engines. Secondary batteries are electrically rechargeable, while primary batteries are used for only a single cycle. (Ag-Zn may be included in either category; in its primary configuration it may be recharged as many as five cycles, which hardly counts as rechargeable.) Fuel cells are electrochemical devices that passively (without heat) react a fuel and an oxidizer to produce electricity; power levels are controlled by the amount of reactant injected into the cell. Many fuel cells are rechargeable, but not in the same way as secondary batteries; instead, reactant tanks are filled, and in some cases sacrificial metallic elements are replaced. Heat engines are generally closed-cycle, air-dependent systems that react fuel and oxidant in a mechanical cycle to drive an engine, which in turn directly drives the propulsion system or a generator to support electronic equipment. Table 2-3 is not intended to be all-inclusive. Instead it provides an overview of available energy technologies that can be considered for undersea vehicles.

Battery and fuel cell technologies developed for applications in space, automobile, and communications industries have not been adapted for use in undersea vehicles because of their cost, safety, immaturity in development, or incompatibility with marine missions. Cost is a primary factor and, as shown in Table 2-3, varies by orders of magnitude for different systems. Cost roughly increases as the energy density increases. For commercial AUVs and DSVs, the most advanced, high-energy systems are presently out of economical reach. These types of energy sources are found mostly in military systems where mission and endurance are primary factors that outweigh cost.

Factors important in selecting a battery include power density (the ability to deliver stored energy at the rate needed), outgassing properties, failure modes, reliability, ease and speed of recharge, and ability to operate over broad temperature and pressure ranges. Considerations of safety in handling energy sources, both aboard ship and aboard the vehicle, are critical and have limited the use of some chemistries, such as lithium, despite their high energies. (Some systems give off explosive gases during operation, and others may start fires if they fail.)

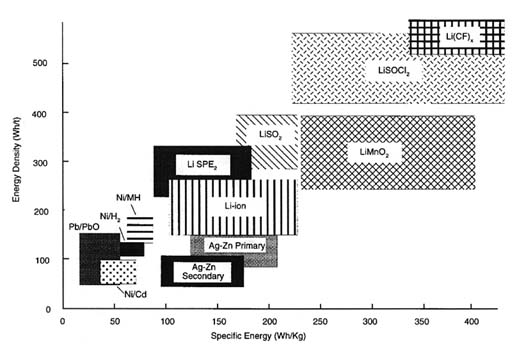

Current battery types used in undersea vehicles include standard lead-acid and nickel-cadmium batteries as well as silver-zinc and lithium-thionyl-chloride batteries. Figure 2-2 provides a helpful way to visualize the power and energy capabilities of various battery chemistries. For military applications, silver-zinc has been the de facto standard for over 20 years. Recently lithium-thionyl-chloride (see primary lithium in Figure 2-2) has seen some use because of its significantly higher energy rating. However, both silver-zinc and lithium-thionyl-chloride batteries are quite expensive ($300 to $1,000/kWhr) and have high life-cycle costs. Silver-zinc batteries are typically usable for 20 to 30 cycles,

TABLE 2-3 Performance Characteristics of Available Energy Sources

|

|

ASSESSMENT OF ENERGY TECHNOLOGIES FOR USVs |

|||||

|

Technology |

Specific Energy Wh/kg |

Energy Density Wh/Liter |

Cycle Life |

Cost $/kWh |

Maturity for Undersea Vehicles |

Safety Concerns |

|

SECONDARY BATTERIESa |

|

|

|

|

|

|

|

Lead Acid (Pb/Pb0) |

35 |

90 |

800 |

50 |

Proven |

H generation |

|

Nickel Cadmium (NiCd) |

55 |

130 |

1,000 |

1,500 |

Proven |

Cd toxicity |

|

Nickel Hydride (NiH2) |

60 |

150 |

10,000 |

2,000 |

Proven |

High pressure H |

|

Nickel Metal Hydride (NiMH) |

70 |

175 |

300 |

50 |

Proven |

High pressure venting |

|

Silver Zinc (Ag-Zn) |

140 |

380 |

20 |

1,000 |

Proven |

H generation |

|

Silver Iron (Ag-Fe) |

150 |

200 |

200+ |

500–800 |

Demo |

H generation |

|

Li-Solid Polymer Electrolyte (Li-SPE) |

150 |

360 |

200 |

100–1,000 |

Lab |

Lithium fire |

|

Lithium Ion Solid State (Li-Ion-SPE) |

150 |

360 |

1,000 |

100–1,000 |

Lab |

None |

|

Lithium Ion (Li-Ion) |

200 |

200 |

2,000 |

500–1,000 |

Proven |

Venting |

|

Lithium Cobalt Dioxide (LiCoO2) |

220 |

300 |

50 |

1,000 |

Lab |

Pressure venting, Li fire |

|

PRIMARY BATTERIES* |

|

|

|

|

|

|

|

Lithium Sulfur Oxide (LiSO2) |

140 |

500 |

1 |

400 |

Demo |

Li fire |

|

Silver Zinc (Ag-Zn) |

220 |

400 |

5 |

3,000 |

Demo |

H generation |

|

Lithium Manganese Dioxide (LiMnO2) |

400 |

450 |

1 |

200 |

Proven |

Li fire |

|

Aluminum-Seawater |

450 |

400 |

1 |

100 |

Demo |

N/A |

|

Lithium Thionyl Chloride (LiSoCl2) |

480 |

500 |

1 |

300 |

Demo |

Thermal runaway |

|

Lithium Carbon Monofluoride (Li(CF)x) |

800 |

1,200 |

1 |

1,700 |

Proven |

Li fire |

|

FUEL CELLS |

|

|

|

|

|

|

|

Alkaline |

100 |

90 |

400 |

5,000 |

Demo |

Gaseous H and O fires |

|

Proton Exchange Membrane (PEM/GOX/GH) |

225 |

200 |

50 |

10,000 |

Demo |

Gas H and O fire |

|

Proton Exchange Membrane (PEM/LOX/LH) |

450 |

400 |

50 |

15,000 |

Lab |

H and O fires |

|

Proton Exchange Membrane (PEM/SOX/SH) |

1,000 |

883 |

50 |

5,000 |

Lab |

N/A |

|

Aluminum-Water Semi-cell (A1/H2O/LOX) |

1,200 |

800 |

1 |

10,000 |

Demo |

H and O fire |

|

HEAT ENGINES (Closed-Cycle Air Independent Propulsion Systems) |

|

|

|

|

|

|

|

Internal Combustion Engine |

75 |

170 |

2,000 |

50–100 |

Demo |

Fuel fire |

|

Diesel Engine |

125 |

75 |

1,000 |

100–200 |

Demo |

Fuel fire |

|

Brayton-Lithium Sulfur Hexafluoride (LiSF6) |

400 |

700 |

1 |

15 |

Demo |

Fuel fire |

|

Stirling |

200 |

250 |

2,000 |

50–100 |

Proven |

Fuel fire |

|

a Battery parameters are based upon single cells; non-battery performance parameters are system level. |

||||||

and lithium-thionyl-chloride batteries are primary batteries (not rechargeable). The higher energy batteries hold the potential for violent release of energy under certain circumstances and are not generally used in commercial and scientific applications (Harma, 1988; Moore, 1988).

Although higher energy systems are critically important to high-endurance AUVs, cost and safety must be primary objectives as new sources are developed. Newer secondary lithium chemistries hold the promise of reasonable production cost, high numbers of recharge cycles (approaching the lifetimes of lead-acid automobile batteries), no outgassing, benign failure modes, and energy densities better than offered by silver-zinc batteries. Development of these batteries is largely being driven by laptop computer and portable electronics applications, but they are presently being adapted to larger-scale batteries for automotive use and should be available for military and commercial undersea vehicles within three to five years.4

Recharging techniques for secondary batteries are being developed for a variety of user applications in the telecommunications, automotive, and undersea vehicle industries. The intent is to reduce the recharge time, extend the ratio of operating to charging time, improve battery cycle life, and promote personnel safety. Charging techniques such as pulse charging can be used to manage the recharge process and decrease recharge time, to reduce heat generation, and to minimize cell degradation. For undersea vehicles, some new

FIGURE 2-2 Battery cell comparisons. Source: Lockheed Martin Corporation.

lithium chemistries that emit little or no gas during charge and discharge are attractive because they can be charged in place (without recovery or vehicle disassembly). Other charging schemes include charging with solar cells, either by surfacing or by connecting to a subsurface charging station powered from the surface.

Other energy system developments include seawater batteries, which react metals with the oxygen dissolved in seawater. These batteries have been difficult to use because they produce very low- voltage and power due to the limited quantity of dissolved oxygen in seawater. However, efficient dc-to-dc conversion can overcome some of these limitations. Since seawater batteries depend on dissolved oxygen, these batteries also may not be suitable in some parts of the ocean, such as in hypoxic areas (Blase and Bis, 1990). Military research and development efforts have explored using seawater batteries, but little work is ongoing in this area in the United States. The Norwegian Defense Research Establishment has built and successfully tested a long-range (approaching 1,800 km) AUV that employs magnesium seawater batteries with a specific energy of over 540 Wh/kg (Apel, 1993; Zorpette, 1994).

Metals can also be reacted with oxygen carried on-board a vehicle. An aluminum-oxygen semi-fuel cell has been built and tested at sea with some success (Collins et al., 1993; Walsh, 1994). ARPA is developing a higher power density version (Gibbons et al., 1991) of this type of cell that contains a chemically stable anode (aluminum), works at low temperature, and has environmentally benign byproducts, mainly Al2O3. The key concerns in this technology are oxygen storage and manufacturability. Canadian companies have also developed an aluminum semi-fuel cell, which uses pumped alkaline electrolyte and oxygen sources. This energy subsystem has been tested in an AUV (Stannard et al., 1995).

NASA has used alkaline fuel cells widely in spacecraft for over 20 years. One of these fuel cells was successfully demonstrated in a DSV in the late 1970s; however, cost and logistical problems limited further development for undersea use. ARPA is now evaluating a proton exchange membrane fuel cell (Meyer, 1993; Pappas et al., 1993). In this concept, stored hydrogen and oxygen are reacted in a fuel cell with the potential of rechargeability and specific energies of over 600 Wh/kg. The newer proton exchange membrane fuel cells offer many advantages over alkaline fuel cells, including lower cost, higher power capacities, improved tolerance to impurities in the reactant gases, and better long-term cycle performance. Energy capabilities of fuel cells are high, but they are limited by the difficulty of storing hydrogen and oxygen at high densities. To achieve truly high specific energies in fuel cells (>1,000 Wh/kg) practical cryogenic (liquid oxygen) storage and solid hydride fuel are required. The logistics of reactant handling and storage continues to make cost reductions and practical usage of fuel cells elusive.

Isotope-based systems and small nuclear reactors have been proposed as ultrahigh energy sources (10,000 to 50,000 Wh/kg) for AUVs; however, these have not been implemented due to regulatory and cost restrictions.

Closed-cycle heat engines are another potential high-energy source for AUVs and DSVs. These can use conventional or hydrogen fuels in combustion cycles (e.g., Diesel,

Brayton, Stirling) similar to engines developed for the transportation industry. A Stirling engine was tested successfully in an undersea vehicle by a Swedish company and is operational on-board the French Saga vehicle.

The Office of Naval Research (ONR) has been pursuing improved thermal engines for torpedo propulsion for years. They have performed significant work in wick combustors, using liquid lithium reacted with sulphur hexaflorate to create a high-temperature heat source for a Rankine or Stirling thermal engine (Hughes, 1995). In an attempt to achieve a more environmentally benign, refuelable, high-energy density product (which is 80 percent of the energy generated by liquid lithium), the Applied Research Laboratory at Pennsylvania State University is investigating a wick combustor fueled with JP-5 (standard Navy jet fuel) and a lithium perchlorate oxygen source to drive the heat engine (Hughes, 1995). If successful, this approach may provide a less costly power source for AUVs in the future.

Most research and development in the field of energy storage occurs outside the undersea vehicles area. The committee anticipates that future energy system development applicable to undersea vehicles will derive mostly from the aerospace and automobile industries, where batteries and fuel cells are being evaluated for near-term use, and from the telecommunications and personal computer industries, where small-format lithium batteries are in development.

Energy systems are a low development priority for ROVs, whose performance is limited by other considerations. However, size, cost, and duration limitations related to DSVs and AUVs will be mitigated only when practical, safe, and readily available energy sources are developed. The advisability of making large investments in energy system research and development for commercial applications is questionable, and the decision must be made in the light of true development costs. Since most near-term AUV and DSV applications can be accomplished with existing and proven battery chemistries, research and development funds will be better spent in technology areas that are specifically marine, such as underwater navigation, acoustic communications, or subsea sensors. Energy systems will be advanced by industries such as the space, automotive, and telecommunication industries that have a more immediate need for them and can obtain development capital based on large markets for their products.

Propulsion

Most undersea vehicle thrusters now use fixed-pitch propellers driven by electric or hydraulic motors. The propeller configurations used derive from mature technology developed for ships and boats. However, optimization of propeller efficiencies continues as new undersea vehicle designs emerge. Brushless motors are often used for low-cost ROVs and most AUV applications. Heavy duty ROVs at work in the offshore petroleum industry use hydraulic motors to power thrusters; power is supplied from an electrohydraulic unit mounted in the vehicle. The pumps, motors, and valves used in system integration are largely standard commercial products. Because of high propeller loading, DSV and ROV thrusters are frequently mounted in nozzles to improve efficiency. If nozzles are used on AUVs, they usually serve as propeller guards rather than as thrust enhancers.

Other thruster types, such as variable pitch propellers, cycloidal devices, and water jets have been abandoned because of complexity or inefficiency (Gangadharan and Krein, 1989). Oscillating foils, which function like a fish tail, are being studied and have achieved limited drag reduction (Triantafyllou et al., 1992). This concept may be applicable to AUV propulsion in the future.

Another interesting new direction in propulsion for long-distance observations is using controlled buoyancy or combinations of buoyancy and thrusters to propel undersea vehicles. The "Slocum" for example, is a concept that would use a heat engine, drawing on the ocean thermocline to adjust the buoyancy of an AUV; wings would provide lift and limited horizontal steering (Kunzig, 1996; Stommel, 1989). The concept offers the promise of low-cost (tens of thousands of dollars, per vehicle, rather than millions); long-range (2,000 km as a near-term goal); and increased endurance (50 days). The ultimate goal is to offer a fleet of low-cost, long-range AUVs that would operate simultaneously, taking oceanographic measurements with higher spatial and temporal resolution than are available with current techniques and at substantially lower costs. (The Odyssey vehicle, described in Chapter 1, is another low-cost vehicle that could be deployed in fleets, although it has a shorter range.) The Slocum buoyancy-adjustment mechanism (without lift or steering) has been tested at depths to 1,300 meters. The system currently being developed uses a battery-powered pump to enhance buoyancy control and propulsion (Webb, 1996).

Propulsion systems are a mature technology and a low priority for development since existing systems are adequate—although improvements in efficiency are always useful—for most underwater vehicle applications anticipated in the next decade.

Materials and Structures

Structural materials currently used for DSVs, ROVs, and AUVs have been adapted from the submarine and shipbuilding industries as well as from advanced aerospace programs. Design approaches derive from work by ship classification organizations, such as the American Bureau of Shipping, as well as from finite-element analysis techniques used in naval architecture and in many industries. Thus, with the exception of full-ocean depth vehicles (11,000-meter depth capability), materials and design capabilities can be considered relatively mature. Improvements in materials tend to be more important for vehicles intended for deep applications because of the strength required to counter high pressures.

Improvements in material are also important for applications to AUVs, where lightweight materials can be translated into energy and payload for additional range and endurance and for work or sensing capabilities that require energy.

Currently, nonmetallic materials, including filamentwound epoxies, Kevlar, and graphite composites and ceramics, are used for military applications in both primary structures (pressure hulls) and secondary structures (fairings). However, the cost of some of these materials discourages commercial use. The Navy's AUSS uses graphite reinforced plastic/epoxy for its main pressure vessel, but the future of such materials in pressure vessel applications remains unclear, primarily because of difficulties in manufacturing processes and high cost (Stachiw and Frame, 1988; Stachiw, 1993). Ceramic alumina cylinders have been tested for pressure housings and hulls, with potential weight reductions of 85 percent compared with titanium; however, economical manufacturing techniques are still under development (Stachiw, 1992; Kurkchubasche, 1992, DeRoos et al., 1993). Other ceramics being considered include silicon nitride, silicon carbide, and boron carbide materials (Ashley, 1993).

Advanced materials for fairings include graphite epoxy layup or fiberglass constructions using a fiber-impregnated, high-density polyethylene that is also acoustically transparent (Sloan and Nguyen, 1992). AUSS uses this polyethylene material for its fairings. Advances in high quality acrylic and quartz glass will provide greater visibility to pilots of DSVs. Developments in important materials technology for vehicles aim to provide low-cost, lightweight, high-buoyancy materials for flotation. Sandwiched composite and syntactic buoyancy materials are being used to provide lightweight, high-displacement secondary structures. Although strength, density, and buoyancy are key design factors, longevity, corrosion resistance, and reliability also affect materials selection.

Design innovations have been demonstrated during development of new structures despite the relative maturity of conventional technology in this field. The two Deep Flight vehicle prototypes for a single-occupant, free-flying, full-ocean depth DSV represent an innovation in alternatives for supporting human activity in the deep sea (Hawkes and Ballou, 1990; Ashley, 1993). Deep Flight's pressure hulls are wound glass filament and epoxy matrix. Such a vehicle depends on advanced materials for structures to support its performance goals.

Russian and Ukrainian undersea vehicle programs have developed advanced techniques for fabricating structures of titanium, ceramic, and composite materials, according to two teams of experts who recently surveyed the undersea vehicle programs of western Europe and the former Soviet Union, under the auspices of the World Technology Evaluation Center (Mooney et al., 1996; Seymour et al., 1994).5 (Appendix B reviews the status of foreign undersea vehicle programs throughout the world.)

Another materials technology area of importance to system improvement is using coatings and other methods to resist biofouling or degradation of the vehicle's outer skin. Biofouling can create dynamic drag and interfere with the performance of skin-mounted sensors. This can be an especially critical problem for long-duration missions. Conventional coating systems that are used on surface ships may not be desirable for vehicles because the toxic compounds they use to kill organisms might cause chemical contamination of the vehicle's scientific sensors.

Navigation and Positioning

The success of most undersea vehicle applications depends on accurate navigation and positioning. Navigation is the function that continuously locates the vehicle within geodetic or relative coordinates and is critical to vehicle safety, operational productivity in real-time, and post-mission scientific and information processing. Positioning refers to the localized and more precise measurements often used to determine specific distances relative to some fixed point. For example, vehicle work in the offshore oil and gas industry frequently involves precision measuring and positioning of equipment relative to installations on the seafloor. When operating a vehicle in a localized area, most contemporary navigation and positioning systems make use of acoustic transponders such as the long-baseline networks widely used in many types of deep water work. Systems of this type use bottom-placed transducers in array fields with typical transponder separations of up to 4 km and can offer accuracies of 1 meter at frequencies of 26 to 36 kHz. Recent developments in acoustic positioning include a high-frequency, high-accuracy system that determines the position of a vehicle with an accuracy of a few centimeters in a bottom-placed transponder field. Other systems, which utilize transducers mounted on the surface ship and a transponder on the vehicle (short baseline), do not require transponders on the seafloor. These systems are widely used for navigating vehicles relative to a support ship. Combinations of these acoustic systems are used to maximize the advantages of each for best navigational accuracy for specific environmental conditions.

Numerous other acoustic and nonacoustic sensor technologies are used on the vehicle to enhance navigation and positioning. Simple video cameras are useful, especially for ROVs and DSVs, when operating near the bottom of a structure and can provide the operator a reference for motion. Computerized image processing techniques have been developed that can use information from video cameras to navigate vehicles automatically (Wang et al., 1992; Marks et al., 1994a, 1994b). Further developments of this type will enhance the value of video as a navigation aide, especially for AUVs, where precise autonomous, near-field navigation is

still under development. Other optical sensors such as laser imaging distance and ranging (LIDAR or laser radar) and line scanning lasers are becoming useful for short-distance ranging and imaging and have recently been developed in low power versions (< 200 watts) that will permit their use on AUVs and DSVs.

Scanning or multibeam sonars are used to provide operators with images of obstacles and terrain in the immediate area surrounding the vehicle. These systems are very popular and have developed to the point that high-frequency, high-resolution systems are reliable and economically available on the commercial market. Current developments in sonar and signal processing include obstacle-avoidance sonars that can construct a terrain map and guidance strategies for optimum pathfinding.

Navigation over long distances or for prolonged durations is generally a requirement for AUV missions and is critical to mission success. AUV navigation systems typically use magnetic or gyro compasses and a velocity sensor to provide dead-reckoning.6 Inertial navigation systems, aided by Doppler sonars, are an advanced implementation of this technique. These systems, derived from extensive use on aircraft and spacecraft, provide inertial navigation, which is then corrected by velocity estimators and by position fixes, as available. Estimated vehicle speed is obtained from current and flow sensors, Doppler sonars, or correlation sonars. Doppler sonar uses reflected echoes to provide highly accurate measures of motion relative to the bottom or fixed points in the water column. Similarly, correlation sonars accurately (+/- 0.1 kt) measure speed relative to the bottom (Grose, 1991). Doppler correlation sonars can "bottom-lock," referencing the vehicle's motion to the bottom, from altitudes of 3,000 meters or more. The advent of small inertial devices, such as ring laser gyros (a solid-state version of the conventional rotating gyro), are making this type of navigation increasingly useful as accuracy goes up and cost goes down (Moore, 1991; Ezekiel, 1991). The result is that velocity-aided inertial navigation systems are now available that provide accuracies on the order of 0.1 percent of distance traveled, and further improvement will result from integration with better location and true movement sensors. As these improvements continue, costly, time consuming transponder fields will become increasingly unnecessary.

The greatest advances in undersea navigation in the near future will come not from any one isolated type of system but from integration of an increasing number of systems and components. Most of the above techniques benefit greatly from position referencing to the Global Positioning System. Recent work in the combination of inertial units with ultrashort baseline transponder systems and Doppler sonars has shown that combining sensors with different characteristics can synergistically improve navigation performance (Hutchison and Skov, 1990; Hutchison, 1991). Accuracy on the order of 0.05 percent of distance traveled are achievable with inertial navigation systems and Doppler sonars, which are becoming available at moderate cost.

Guidance and Control

Navigation, guidance, and control functions are often separated for discussion, as is the case in this report. This modularization assists in understanding the complex operating concept for undersea vehicles and is also helpful to the vehicle designer. In practice, however, these functions are highly interactive and, in fact, use many common sensors and processors. Thus advances or improvements in one function normally are linked to advances in other functions. For example, the development of a highly accurate, long-duration navigation system would be useless without guidance and control capabilities that support mission intelligence and reliable navigational capabilities.

Guidance and control of an undersea vehicle are generally implemented in a layered or hierarchical architecture. Guidance involves higher-level mission management activities, such as planning and directing vehicle movement through the water column; control operates at a lower functional level to interact with specific equipment on the vehicle. The control level includes the closed loop functions (autopilot) that provide stable, controlled operation of the vehicle. The control level receives orders from guidance and, in turn, commands physical actuators, propulsors, and effectors to maneuver and operate the vehicle in a manner that accomplishes higher-level guidance objectives.

In the early days of undersea vehicle development, maneuvering depended almost exclusively on the direct manual control skills of human pilots, and all higher-level planning was accomplished by the pilot. With ROVs, pilots worked primarily from video images, using visual references to keep track of vehicle and tether location. Later, automatic heading and depth controls became common on most vehicles because of the evolution of reliable sensors, modern computing equipment, well-understood control algorithms, and efficient software. Tracking systems, imaging sonars and inertial navigation systems also improved the human operator's ability to determine vehicle position in geodetic or local reference coordinates, thus enhancing vehicle guidance and control.

Continuing improvements in navigation and control technology permit automation of all vehicle motions. A vehicle with full automation and control of movement and direction can hover for long periods and can follow preplanned track lines precisely while under "supervisory control," that is, with the human operator providing high-level, task-oriented commands rather than exercising direct control over all functions of the vehicle (Yoerger and Slotine, 1987; Wang et al., 1993). Vehicles equipped with such capabilities have

performed detailed, three-dimensional scientific surveys of archaeological sites and deep ocean hydrothermal vent plumes, dam and nuclear reactor inspections, "hands-off" docking on oil field structures, and automated operation of valves (Somers and Geisel, 1992). Techniques are also being developed to allow vehicles to hold position based on video, laser, and acoustic imagery and to use imagery for guidance (Marks et al., 1994a, 1994b; Negahdaripour, 1993; Wang et al., 1992). Many advances in control depend on improved understanding of vehicle dynamics and improved signal processing algorithms for closing feedback loops around sensors to form servo loops (Yuh, 1990; Healy and Leonard, 1993; Fossen, 1994).

Future developments may extend these capabilities in several directions. Improved navigation that combines inertial and velocity measurements (as described in the previous section) currently being developed for military AUVs will enable precise automated vehicle motion without the need for a transponder network. Control systems combined with sensors that detect cables, pipelines, hydrocarbon leaks, or other pollutants allow highly efficient automated tracking and surveying (Greig et al., 1992). Likewise, improvements to in situ sensors for oceanographic parameters and chemical samples, combined with advanced vehicle control systems, will allow scientists to map distributions with unprecedented sampling density at reasonable cost, perhaps with multiple vehicles (Triantafyllou, 1992; Curtin et al., 1993). At the heart of these improvements is the ability to integrate navigation, guidance, and controls with sensors, using modern hierarchical architecture techniques to enhance accuracy, efficiency, ease of human task-level control, and reliability of vehicles for a wide range of mission needs.

A significant step toward achieving these integrated goals was demonstrated in a series of 13 dives over the Juan de Fuca Ridge by MIT's AUV Odyssey II. Odyssey II reached a depth of 1,400 meters and ran surveys designed to characterize spatial variability of temperature and salinity in three dimensions. Navigation was provided by a long-baseline acoustic navigation system. In a 3.25-hour dive, the vehicle excursions centered on a thermocline at 45 meters beneath the sea surface. To provide an understanding about temporal evolution in the survey volume, the grid survey was preceded and followed by vehicle paths crossing the survey volume.7

As indicated above, developments in guidance and control, at all levels, are critical for progress in AUV applications where robust mission management is key to reliable and repeatable performance. Artificial intelligence techniques are being applied to offer AUVs an interpretive logic capability based on processing probabilistic data.

In the future, AUVs should be capable of pursuing tasks that have abstract descriptions; for example, finding and following a chemical gradient or surveying a given area with the ability to replan and reconfigure the mission based on a wide range of changing internal and external factors. Included in these tasks are a number of lower-level operations, including obstacle avoidance, homing and docking, and following terrain, as well as manipulative tasks that involve control of the vehicle/manipulator system to carry out a command.

Failure detection and recovery are perhaps the most critical operations and the most difficult. The vehicle must be able to sense when one or more of its subsystems have failed and must be capable of reconfiguring its controls and replanning the mission in real-time to work around in the worst case, aborting the mission in the safest manner. The the problems; accomplishing the highest priority objectives; and vehicle must also be able to handle high-level failures such as reattempting and Bellingham, 1992). "Layered control" is one approach to this problem. Vehicle software provides commands for a set of quasi-independent "layered" behaviors, such as "detect collision," "hold heading," or "head to way-point." Layered control has demonstrated some success a docking operation that fails the first time (Ricks, 1989; Perrier as an overall philosophy for AUV programming (Bellingham and Leonard, 1994). A Navy-sponsored project is developing an intelligent, fault-tolerant vehicle guidance and control system, and system testing and demonstration are planned. While much of this development is directed toward specific use by AUVs, it is supported by complementary work of the computer aerospace and automated manufacturing industries. Continuing advances in task-level control architectures and higher bandwidth communications have resulted in robots that respond directly to graphical task-level human input. These robots use an advanced form of "telerobotics," or control from a distance, which until recently allow only a "joy stick" human interface.

For many mid-water tasks the vehicle and its manipulators need to be controlled as a single moving system. The new capability called "object-based task-level control" enables the direct human command to the task that will be performed; the control system then plans and executes the task. Because of the much lower bandwidth required for task-level commands, object-based task-level central will enable near real-time control of AUVs, which will be a powerful new capability (Wang et al., 1993). Techniques for vehicle control are continuously being improved. Research and development activities are being directed toward adaptive systems that can successfully control a vehicle with widely varying characteristics (e.g., mass or hydrodynamic coefficients). The use of sliding mode controllers is one approach; another involves intelligent systems that estimate vehicle characteristics in real-time.

Improved guidance and control techniques can enhance the capabilities of ROVs and DSVs and are crucial to the success of AUVs. Improvements in fault tolerance can permit vehicles to complete missions after sensors, actuators, or processors fail or degrade. Another important direction for AUVs is to move beyond simple way-point control to permit the vehicle to pursue tasks from more abstract descriptions.

Data Processing

Undersea vehicles typically require two types of data processing, payload and vehicle- management. The payload processor collects, processes, compresses, and records the data produced by the vehicle and its sensors, often on disk in the vehicle itself or on a support vessel. The data are generally recorded during operations and processed afterward, especially in scientific applications. Data compression is essential when recording devices or the uplink bandwidth are limited and data volumes are large. The payload processor also can perform processing to augment and fuse the data that are collected; for example, the vehicle data can be matched to the image from a sonar, and the fused result gives an accurate picture of the situation encountered by the vehicle at a given time and place. The advent of fiber-optic communications and advanced sensors for ROVs has allowed transmission of large volumes of data up the tether for data logging, management, and display.

The second type of data processing is performed by the vehicle-management computer, which can be located on-board the vehicle or on a support vessel. These data may also be processed in real-time for use in decision making, such as for mine detection and target classification applications. The vehicle-management computer typically performs all the housekeeping functions necessary to keep the vehicle in motion along the prescribed path. The data can be used to control vehicle functions such as thrusters, control surfaces, valves, and manipulators in real-time. As the human operator becomes more removed from the vehicle control loop, and as tasks become more automated, the performance of vehicle-management computers becomes critical to mission success.

Another key issue in the data processing chain is calibrating the sensors used to make measurements and detecting a failed or faulty sensor. The vehicle-management processor must continuously monitor the sensor output for validity and presence. Sensor redundancy can help considerably in this process; however, deciding when a sensor has failed and when to switch to a backup sensor is a difficult process without an operator in the loop. In scientific operations using tethered systems, the sensor outputs are continuously monitored by the operations team, and the team decides whether to continue the mission or retrieve the system and initiate repairs. This process must be automated in AUVs; therefore, it is a critical area for improvement. Intelligent systems are currently being developed that will be able to monitor and compare sensor outputs. Upon detection of a failed sensor, these systems will make an informed decision about the goals of the mission and cause the vehicle to surface or continue depending on criteria that have been preprogrammed by the scientist or operator.

Developments in data preparation, fusion, presentation, and analysis are necessary to fully use and understand data collected by undersea vehicles. Fusion of many different types of data, including sonar, video, still images, water column measurements, and vehicle positioning data, must be available for scientific evaluation (Rosenblum et al., 1993; Gritton and Baxter, 1993). In the past, post-mission processing of data was performed by a human, who correlated photos, sonograms, strip charts, and computer data in a time consuming and not always accurate attempt to evaluate the vehicle's mission. Current advancements in post-mission processing, which incorporate simulation and display of the data collected from a mission using three-dimensional graphic software tools, aid the scientist in accurately reconstructing the mission and evaluating the data. Real-time map and chart construction fuses vehicle positioning, terrain, and targets encountered during a mission and allows faster evaluation of post-mission data (Howland et al., 1993). These techniques also aid the pilot and the observer in constructing a mental image of the subsea environment while they are working. Designers of vehicles for scientific applications will increasingly build data management into their basic design philosophies to make the data collected by undersea vehicles more useful and more easily understood (Newman and Robison, 1993).

Some help for vehicle designers may be provided by software systems designed for data processing in military applications. Current studies on the correlation of satellite telemetry and image data can be directly applied to the undersea world in the future. Commercial systems are also emerging that can handle diverse vehicle data. The new PC processors are now powerful enough to display complex data in real-time, complete with three-dimensional colorized representations of detailed images. Contemporary commercial software tools make plotting numerous pieces of data on multiple charts easier. New display techniques, including virtual presence, will further ease the task of understanding and interpreting data from the undersea environment by enabling scientists to position themselves aboard the vehicle and fly the mission, experiencing firsthand the situations surrounding the data as they are collected (Gwynne et al., 1992).

Enhancements in undersea vehicle capabilities are closely tied to advancements in microprocessors and computer science. In the past 10 years processing signals and managing underwater vehicle systems have progressed from implementing a single desk-sized minicomputer to incorporating many, in some cases hundreds, of printed circuit board processing elements. This improvement enabled major reductions in cost and size and has increased the availability of microcomputers that continuously improve in

terms of low power operation and computational through-put. The microprocessor boom, in conjunction with the shift toward distributed networks of specialized computers, has resulted in a revolution in processor system capabilities for undersea vehicles.

DSVs and ROVs have benefited from increased reliability of on vehicle data processing systems and advanced operator displays that are adaptable to various missions and operators. Miniaturization of control systems has allowed integrated operations of DSVs and ROVs, extending their combined capabilities beyond that of a DSV operating alone. Increased capabilities for storing and managing data aboard DSVs has also enhanced data integrity and accessibility for scientific applications. Underwater vehicles have also borrowed from advanced computer science in the move toward distributed processing of vehicle sensor information through "smart" sensors that are directly integrated with a microprocessor. This has the additional benefit of standardizing sensor protocols and message formats and increasing design simplicity for human applications. Data incorporation from multiple sensors through a single analog to digital converter has given way to on vehicle networks that extend through the data transmission system to the support platform to provide better displays of sensor information and increase reliability.

AUV missions are clearly the most computation-intensive of undersea vehicle applications; yet these are easily being implemented with current computational capabilities. Over the past decade, the computing revolution has resulted in order of magnitude increases in processor capacity every few years at continually reduced power levels. A central processor the size of a small loaf of bread, weighing under 4.5 kg and drawing less than 10 w, can implement all guidance, navigation, and control functions required by an AUV.8 Future AUV missions will demand the higher levels of on-board signal processing and data processing that are associated with increased levels of autonomy. However, it is expected that developments in semiconductor materials, improved board geometries, and more efficient operating systems for compilers will easily meet the computing requirements. In addition, the use of advanced paradigms, including artificial intelligence, fuzzy logic, and neural computing, is becoming more mature, and these paradigms will implement efficient sensor-based perception and data fusion for object interaction and advanced fault detection, isolation, and management.

Current work in signal processing is benefiting acoustic communications and sensor signal processing. The incorporation of low power, algorithm-specific processors with high processing rates provides the required through-puts for separating signal from noise and integrating signals into meaningful information. Advancements include distributed and parallel processors to interpret on vehicle acoustic, video, and laser imagery when evaluating objects in the environment.

Vehicle design, analysis, simulation, and verification, especially for AUV applications, have benefited from advancements in computational capability. Vehicle development and construction have progressed from empirical hand-drawn designs to completely computer-developed and maintained representations that can facilitate automated manufacturing. Analysis is enhanced through solid modeling and simulation that approaches real-time in complex tasks such as fluid flow and vortex analysis. At the far extreme of capability are the enhancements being made in ARPA's Simulation Based Design Program, which extend the current capability to allow three-dimensional virtual reality visualization of the vehicle and its subsystems, combined with physics-based modeling, to evaluate performance before physical construction.

As mainstream computing hardware and software evolve, these advances can be incorporated into underwater vehicles to make them more capable and reliable. In particular, techniques that combine diverse types of data will allow scientific and commercial data products to be produced more quickly, more cheaply, and with higher quality. In addition, automated techniques to monitor and manage sensors will be vital to permitting AUVs to produce high quality data sets without intervention.

Communications

Communication between human operators and the vehicle system—to receive control signals, report mission status, and transfer sensor data—encompasses several technologies, the use of which depends on the vehicle type. In general, AUVs use communication transmitted acoustically through water at 8.075 kHz and 27 kHz (operated half-duplex) as the most common frequencies. ROVs use an umbilical cable or link that contains coated, shielded, twisted-pair and/or fiber-optic members.

Communication capability with tethered vehicles (ROVs) has significantly improved with the transition from copper-based to fiber-optic-based systems. This advancement has closely followed developments in the telecommunication industry. The emergence of fiber-optic data transmission and communications technology has increased the capability of ROVs to pass enormous volumes of data through the tether for data logging, management, and display. As the volume rate and reliability of the data have increased, so has the data value to operators and users. It is now possible to tie sensor information regarding temperature and chemical composition, for example, to precise, specific locations relative to geological resources. The collection of sensor information and geolocation has also become critical in military mine countermeasures and explosive ordnance disposal applications.