3

Technologies for the Small System

Most source waters used for public drinking water supplies are not of suitable quality for consumption without some form of treatment. The U.S. Environmental Protection Agency (EPA) has ruled that all surface waters must be filtered and disinfected before consumption unless the purveyor can justify avoidance of filtration; some surface waters also need to be treated with additional processes to remove chemical contaminants before they are suitable for use as drinking water. Many ground water sources are disinfected, and many are treated to remove nuisance chemicals (such as iron and manganese) and chemical contaminants before distribution. This chapter evaluates water treatment processes that can be used by small systems and discusses their suitability under various conditions.

The fundamental responsibility of a public water system is to provide safe drinking water, as defined by the Safe Drinking Water Act (SDWA) and its amendments. Water utilities are required by the SDWA to monitor drinking water quality. When source water used by a water system does not meet quality requirements, the utility has several options. The first that should be considered is finding a cleaner, safer source water that requires less treatment than the existing source water, for this is often the most cost- and resource-efficient way to meet demand. Surface water sources tends to be turbid and typically contain higher concentrations of colloidal and microbiological material than ground water sources. Ground water sources generally have higher initial quality and tend to require less treatment than surface water sources, making ground water sources a good choice for small water systems. In fact, as shown in Table 3-1, most small systems already use ground water sources. Before installing new treatment systems, a small utility using surface water might seek a ground water source, or a

TABLE 3-1 Water Source for Community Water Systems of Various Sizes

|

|

Water Source |

|

|

Population Served |

Ground Water |

Surface Water |

|

Small systems |

||

|

Under 500 |

91% |

9% |

|

501-3,300 |

74% |

26% |

|

3,301-10,000 |

58% |

42% |

|

Large systems |

||

|

10,001-100,000 |

46% |

54% |

|

More than 100,000 |

28% |

72% |

|

SOURCE: EPA, 1994. |

||

utility using a poor ground water source might develop a new well in an alternative location or use a deeper aquifer by extending the depth of a well or drilling a deeper one. In either case, if alternative sources of high-quality raw water are not available, the utility might seek a source of treated water from a water utility that has an adequate supply of water and is located close enough to extend a transmission main at an affordable cost. If such options cannot be found, however, then the utility needs to explore adding additional treatment systems.

Treatment Technologies: Overview

Table 3-2 lists treatment processes according to the water quality problems they address. No single process can solve every water quality problem. Rather, a utility must choose from a wide range of processes that are used for different purposes. The treatment technology or combination of technologies to be used in a specific situation depends on the source water quality, the nature of the contaminant to be removed, the desired qualities of the treated water, and the size of the water system. For very small systems, treatment may not be a feasible alternative because of the high cost of having a treatment system designed and installed and the complexity of maintaining it.

Historically, the design of drinking water treatment systems has been driven by the need to remove microbial contaminants and turbidity. Microbial contaminants are the central concern because they can lead to immediate health problems. Turbidity is a concern not only because water containing particles can have an objectionable taste and appearance but also because particles of fecal matter can harbor microorganisms, and soil particles can carry sorbed contaminants such as pesticides and herbicides. Aesthetic problems such as excess hardness, which

TABLE 3-2 Treatment Technologies by Contaminant Type

|

|

Disinfectants/Oxidants |

|

Air Stripping Systems |

|||||

|

|

Free Cl2 |

NH2Cl |

CIO2 |

O3 |

Ultraviolet Radiation |

KMnO4 |

Aeration |

Membrane Aeration |

|

General water quality parameters |

|

|||||||

|

Turbidity |

|

|||||||

|

Color |

|

X |

|

X |

|

|

||

|

Disinfection byproduct precursors |

|

|||||||

|

Taste and odor |

|

X |

X |

X |

X |

X |

||

|

Biological contaminants |

|

|||||||

|

Algae |

|

|||||||

|

Protozoa |

|

X |

X |

|

||||

|

Bacteria |

X |

X |

X |

X |

X |

|

||

|

Viruses |

X |

X |

X |

X |

X |

|

||

|

Organic chemicals |

|

|||||||

|

Volatile organic compounds (VOCs) |

|

X |

X |

|||||

|

Semivolatile compounds |

|

X |

||||||

|

Pesticides |

|

|||||||

|

Biodegradable organic matter |

|

|||||||

|

|

Adsorption Systems |

|||

|

|

Powdered Activated Carbon |

Granular Activated Carbon |

Ion Exchange |

Activated Alumina |

|

General water quality parameters |

|

|||

|

Turbidity |

|

|||

|

Color |

X |

X |

|

|

|

Disinfection byproduct precursors |

X |

X |

|

|

|

Taste and odor |

X |

X |

|

|

|

Biological contaminants |

|

|

|

|

|

Algae |

|

X |

|

|

|

Protozoa |

|

X |

|

|

|

Bacteria |

|

X |

|

|

|

Viruses |

|

X |

|

|

|

Organic chemicals |

|

|||

|

VOCs |

X |

X |

|

|

|

Semivolatile compounds |

X |

X |

|

|

|

Pesticides |

X |

X |

|

|

|

Biodegradable organic matter |

X |

X |

|

|

|

|

Membrane Processes> |

||||

|

|

Microfiltration |

Ultrafiltration |

Nanofiltration |

Reverse Osmosis |

Electrodialysis/ Electrodialysis Reversal |

|

General water quality parameters |

|

||||

|

Turbidity |

X |

X |

X |

|

|

|

Color |

|

X |

X |

X |

|

|

Disinfection byproduct precursors |

|

X |

X |

X |

|

|

Taste and odor |

|

||||

|

Biological contaminants |

|

||||

|

Algae |

X |

X |

X |

|

|

|

Protozoa |

X |

X |

X |

X |

|

|

Bacteria |

|

X |

X |

X |

|

|

Viruses |

|

|

X |

X |

|

|

Organic chemicals |

|

||||

|

VOCs |

|

||||

|

Semivolatile compounds |

|

X |

|

||

|

Pesticides |

|

|

X |

X |

|

|

Biodegradable organic matter |

|

||||

|

|

Filtration Systems |

|||||||

|

|

Direct Filtration |

Conventional Filtration |

Dissolved Air Flotation |

Diatomaceous Earth Filtration |

Slow Sand Filtration |

Bag/Cartridge Filters |

Lime Softening |

|

|

General water quality parameters |

|

|||||||

|

Turbidity |

X |

X |

X |

X |

X |

|

X |

|

|

Color |

X |

X |

X |

|

||||

|

Disinfection byproduct precursors |

X |

X |

X |

|

X |

|

|

|

|

Taste and odor |

|

X |

|

|

||||

|

Biological contaminants |

|

|||||||

|

Algae |

|

X |

X |

X |

|

|

|

|

|

Protozoa |

X |

X |

X |

X |

X |

X |

X |

|

|

Bacteria |

X |

X |

X |

X |

X |

|

X |

|

|

Viruses |

X |

X |

X |

X |

X |

|

X |

|

|

Organic Chemicals |

|

|||||||

|

VOCs |

|

|||||||

|

Semivolatile compounds |

|

|||||||

|

Pesticides |

|

|||||||

|

Biodegradable organic matter |

|

Xa |

Xa |

|

Xa |

Xa |

|

|

can lead to scaling of water heaters and excess soap consumption, and objectionable tastes and odors have also played an important historical role in the development of drinking water treatment technologies. Finally, the corrosivity of the water has been a long-standing concern because of the need to protect water mains and plumbing. Drinking water treatment systems are still designed primarily with these objectives in mind rather than being based on the need to remove trace levels of synthetic chemicals to comply with requirements of the SDWA and its amendments.

Because so many regulations apply to drinking water, small systems must look at the entire spectrum of drinking water regulations before deciding on a treatment method. The system manager who considers the regulations and other water concerns on a piecemeal basis can end up using first one process and then another until finally the treatment plant becomes a costly chain of processes inefficiently tacked on to one another. Eventually the small system could find that it can no longer afford to install further treatment systems, and the whole investment might be made for naught.

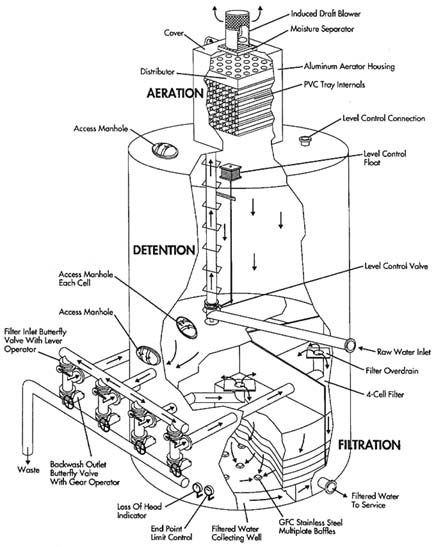

A number of the treatment processes listed in Table 3-2 and described in more detail below are available to small communities as package plants. The term ''package plant" is not intended to convey the concept of a complete water treatment plant in a package. Rather, a package plant is a grouping of treatment processes, such as chemical feed, rapid mixing, flocculation, sedimentation, and filtration, in a compact, preassembled unit. To provide a complete treatment plant, other equipment, or in some cases a series of package plants, generally is required. For example, most package plants designed to provide water filtration are not also equipped with equipment for disinfection, corrosion control, or adsorption of organic contaminants by granular activated carbon (GAC).

Some manufactures prefer to call package plant "preengineered" process equipment because the process engineering for the package plant design has been done by the manufacturer. What remains for the water system's engineer to design is the specifics of the on-site application of the equipment. Because package plants do not require custom design, and because the process facilities (for example, mixing chamber, flocculation basin, sedimentation basin, and filter) are built in a factory instead of on-site, such systems have the potential to provide significant cost savings to small communities.

Table 3-3 outlines important capital considerations for common water treatment processes. Water treatment technologies change constantly. As shown in the table, at any given time they fall into one of several broad categories:

- Conventional technologies are in widespread use and familiar to practicing treatment engineers and operators.

- Accepted technologies are not as widely used as conventional technologies. Sometimes these technologies have been developed for other fields and adopted by the water community. Some process of this type have performed

- satisfactorily in water treatment, but some personnel in the field may not be familiar with them.

- Emerging technologies include those that have not been applied to water treatment in an operating system but show great promise for acceptance in the near future. These technologies are likely to be in the research or pilot plant stage.

Table 3-3 also shows the costs of different treatment processes on a relative scale. Precise cost information cannot be provided because costs change constantly. For example, advances in membrane processes are reducing the costs of membrane systems.

Table 3-4 shows operating considerations—raw water quality, operator skills, monitoring requirements, and costs—for common treatment processes. As shown in the table, different treatment processes have different requirements for source water quality. Some processes require "high-quality" or "very-high-quality" source water. Details about quality requirements are provided with the individual technology descriptions later in this chapter.

Once a treatment system has been selected and installed, it is common to believe that the major expenditure is over. This is true for relatively few technologies. Operation and maintenance costs must be considered in long-term planning and in selection of treatment processes because they vary with the technology, as shown in Table 3-4. Skill levels required of water treatment plant operators also vary with system complexity and type of technology. Table 3-4 indicates different skill levels:

- In a basis system, an operator with minimal experience in the water treatment field can perform the necessary system operation and monitoring if provided with proper instruction. The operator is capable of reading and following explicit directions but would not necessarily have water treatment as a primary career.

- In an intermediate system, the operator needs to understand the principles of water treatment and have a knowledge of the regulatory framework. The operator must be capable of making system changes in response to source water fluctuations.

- In an advanced system, the operator must possess a thorough understanding of the principles of system operation. The operator should be knowledgeable in water treatment and regulatory requirements, with water treatment being the career objective. (The operator may, however, have advanced knowledge of only the particular treatment technology.) This operator seeks information, remains informed, and reliably interprets and responds to water fluctuations and system intricacies.

Tables 3-3, 3-4, and others in this chapter are meant only to guide preliminary

TABLE 3-3 Capital Considerations for Treatment Technologies

|

Technology |

Contaminants |

State of Technology |

Relative Capital Cost |

|

|

All water sources |

|

|

|

|

|

Disinfection |

Microbiological contaminants |

|

|

|

|

Free Cl2 |

|

Conventional |

Low |

|

|

NH2Cl |

|

Conventional |

Low |

|

|

ClO2 |

|

Accepted |

Low |

|

|

O3 |

|

Accepted |

Medium |

|

|

Ultraviolet radiation |

|

Accepted |

Medium |

|

|

Corrosion control |

Prevention of system corrosion, lead, copper |

|

|

|

|

Chemical feeders |

|

Conventional |

Low |

|

|

Limestone contactor |

|

Accepted |

Medium |

|

|

Membrane filtration systems |

Turbidity, protozoa (Giardia and Cryptosporidium), algae, and the following: |

|

|

|

|

Microfiltration |

Some bacteria |

Accepted |

Medium |

|

|

Ultrafiltration |

Bacteria, some viruses, some color |

Accepted |

Medium |

|

|

Nanofiltration |

Bacteria, viruses, color, some organic chemicals, hardness |

Emerging |

Medium |

|

|

Reverse osmosis |

Bacteria, viruses, humic acids, some organic chemical, inorganic chemicals, hardness, radium, salts |

Conventional |

Medium |

|

|

Electrodialysis/electrodialysis reversal |

Inorganic chemicals (charged) |

Accepted |

High |

|

Adsorption |

|

|

|

|

Powdered activated carbon (PAC) |

Organic chemicals, tastes and odors |

Conventional |

Low/medium |

|

Granular activated carbon (GAC) |

Organic chemicals, tastes and odors, radon, microorganisms |

Accepted |

Medium/high |

|

Lime softening |

Hardness, iron, manganese, turbidity |

Accepted |

High |

|

Ground water sources |

|

|

|

|

Aeration |

|

|

|

|

Diffused air |

Volatile organic chemicals, radon, tastes and odors |

Accepted |

Low |

|

Mechanical aeration |

Volatile organic chemicals, radon, tastes and odors |

Accepted |

Low |

|

Tray aerators |

Volatile organic chemicals, radon, tastes and odors |

Conventional |

Low/medium |

|

Packed tower aeration |

Volatile organic chemicals, radon, tastes and odors |

Conventional |

Medium |

|

Membrane aeration |

Volatile and semivolatile organic chemicals radon, tastes and odors |

Emerging |

Medium |

|

Oxidation/filtration |

|

|

|

|

Permanganate |

Reduced iron and manganese, organic chemicals, radon, tastes and odors |

Conventional |

Low |

|

O3 |

Reduced iron and manganese, organic chemicals, tastes and odors |

Accepted |

High |

|

Technology |

Contaminants |

State of Technology |

Relative Capital Cost |

|

Ion exchange |

Inorganic chemicals, radium, nitrate |

Accepted |

Medium |

|

Activated alumina |

Arsenic, thallium, selenium, fluoride, other inorganic chemicals |

Accepted |

High |

|

Surface water sources |

|

|

|

|

Coagulation-filtration |

Turbidity, color, disinfection byproduct precursors, microorganisms, algae, iron, manganese, biodegradable organic matter,a ammoniaa |

|

|

|

Direct filtration |

|

Accepted |

High |

|

Conventional, with sedimentation |

|

Conventional |

High |

|

Dissolved air flotation |

|

Accepted |

High |

|

Diatomaceous earth filtration |

Turbidity, algae, Giardia, Cryptosporidium, biodegradable organic matter,a ammoniaa |

Accepted |

Medium/high |

|

Slow sand filtration |

Turbidity, microorganisms, biodegradable organic matter,a ammonia,a tastes and odors |

|

|

|

Uncovered filters |

|

Conventional in some states |

Medium |

|

Covered filters |

|

Conventional in some states |

Medium/high |

|

Bag filters cartridge filters |

Giardia cysts and Cryptosporidium oocysts |

Accepted in some states |

Low |

|

a If operated in biologically active mode. |

|||

consideration of a treatment process. Reference to the textual description of the process later in this chapter is also necessary to further assess its applicability to a given water system.

In the descriptions that follow, treatment processes are grouped according to whether they are suitable for small systems using either surface water or ground water, are best suited to ground water systems, or are used primarily for surface water systems.

Technologies for All Systems

Contamination with microorganisms is common to surface water sources and is becoming an increasing concern for ground water sources. Other water quality concerns common to both surface and ground water systems are excess corrosivity, hardness, and, increasingly, contamination with synthetic organic chemicals. The technologies described in this section address these water quality concerns, as well as some others, and are suitable for use in treating either surface water or ground water.

Disinfection

How the Process Works

Disinfection is the inactivation of pathogens in drinking water. Although not entirely effective against all pathogens, disinfection is the most cost-effective way to reduce the incidence of waterborne disease. Two common techniques are chemical disinfection and irradiation with ultraviolet (UV) light.

UV disinfection is used primarily in small systems that treat ground water. UV radiation has been demonstrated to be effective against bacteria and viruses, which are the microbiological contaminants likely to be found in ground waters for which the quality is not directly influenced by surface water. However, because it does a poor of killing Giardia and Cryptosporidium, UV radiation is not an accepted means for disinfecting surface waters, unless they have already been treated in a way that would physically remove the cysts and oocysts of the Giardia and Cryptosporidium.

The chemical disinfectants used in drinking water treatment are free chlorine, chloramine, ozone, and chlorine dioxide. Iodine has been studied as a disinfectant, but the EPA restricts its use to short-term, limited, or emergency purposes because of concerns over possible adverse health effects such as iodine hypersensitivity and thyroid problems (EPA, 1982, 1995).

Of the chemical disinfectants, free chlorine is probably used most commonly, with chloramine next in popularity. In a survey conducted in 1989 and 1990, approximately 72 percent of the nearly 280 water utilities responding reported using free chlorine (AWWA Committee, 1992). Approximately 21 percent

TABLE 3-4 Operational Considerations for Treatment Technologies

|

Technology |

Raw Water Quality Rangea |

|

All water sources |

|

|

Disinfection |

All, but better with higher quality |

|

Free Cl2 |

|

|

NH2Cl |

|

|

ClO2 |

|

|

O3 |

|

|

Ultraviolet radiation |

|

|

Corrosion control |

|

|

Chemical feeders |

All ranges |

|

Limestone contactor |

Low iron, low turbidity |

|

Membrane filtration systems |

|

|

Microfiltration |

Needs high water quality (or pretreatment) |

|

Ultrafiltration |

Needs very high water quality (or pretreatment) |

|

Nanofiltration |

Needs very high water quality (or pretreatment) |

|

Reverse osmosis |

Requires prefiltration for surface water |

|

Electrodialysis/electrodialysis reversal |

Requires prefiltration for surface water |

|

Adsorption |

|

|

Powdered activated carbon (PAC) |

All waters |

|

Granular activated carbon (GAC) |

Surface water may require prefiltration |

|

Lime softening |

All waters |

|

Ground water sources |

|

|

Air stripping |

|

|

Diffused air |

All ground waters |

|

Mechanical aeration |

All ground waters |

|

Tray aeration |

All ground waters |

|

Packed tower aeration |

All ground waters |

|

Membrane aeration |

All ground waters |

|

Oxidation/filtration |

|

|

Tray aerators |

All ground waters |

|

Permanganate |

All ground waters |

|

O3 |

All ground waters |

|

Cl2 |

All ground waters |

|

Ion exchange |

All ground waters |

|

Activated alumina |

All ground waters |

|

Surface water sources |

|

|

Coagulation-filtration |

|

|

Direct filtration |

Needs high raw water quality |

|

Conventional, with sedimentation |

Can treat wide range of water quality |

|

Dissolved air flotation |

Very high algae OK, high color OK, moderate turbidity |

|

Diatomaceous earth filtration |

Needs very high water quality |

|

Slow sand filtration |

Needs very high water quality |

|

Bag and cartridge filters |

Needs very high quality water |

|

a Refer to text for detailed description of water quality needs. |

|

|

Operator Skill Level Required |

Monitoring Requirements |

Relative Operating Cost |

|

Basic |

Low |

Low |

|

Basic |

Low |

Low |

|

Intermediate |

High |

Low |

|

Intermediate |

Low |

Medium |

|

Basic |

Low |

Low |

|

Basic |

Low |

Medium |

|

Basic |

Low |

Low |

|

Basic |

Low |

Low |

|

Basic |

Low |

Medium |

|

Basic |

Low |

Medium/high |

|

Advanced |

Medium |

High |

|

Advanced |

Medium |

High |

|

Intermediate |

Low |

Medium/high |

|

Basic |

Low/medium |

Medium/high |

|

Advanced |

High |

High |

|

Basic |

Low |

Low |

|

Basic |

Low |

Low |

|

Basic |

Low |

Low |

|

Intermediate |

Low |

Medium |

|

Intermediate |

Low |

Medium |

|

Basic |

Low |

Low |

|

Intermediate |

Medium |

Medium |

|

Intermediate |

Low |

Low |

|

Basic |

Low |

Low |

|

Intermediate |

Medium |

Medium/high |

|

Advanced |

Medium |

High |

|

Advanced |

High |

Medium/high |

|

Advanced |

High |

Medium/high |

|

Advanced |

High |

Medium/High |

|

Intermediate |

Medium |

Medium/high |

|

Basic |

Low |

Low, with good raw water |

|

Basic |

Low |

Low/high; depends on cycle length |

of the utilities reported using chloramine; approximately 5 percent used chlorine dioxide in conjunction with free chlorine or chloramine. Ozone was used by approximately 0.4 percent of the utilities.

Since 1990, a considerable number of ozone facilities have come on line, although the percentage of utilities using ozone remains small compared to the percentages using chloramine or free chlorine. If ozone is used for disinfection of surface waters, the ozone can break down complex organic molecules into smaller organic molecules or molecular fragments that are more readily used by bacteria as a food source. Using ozone can thus increase the biological instability of the water and result in a higher level of bacterial growth in the distribution system. One remedy for biological instability is to employ biological filtration. This is done by using conventional filter media or GAC as a filter media in conjunction with a delay in the application of chlorine, chloramine, or chlorine dioxide until after the water is filtered. The growth of bacteria in the biological filter does not impair filtration efficacy, and some organic matter can be removed, improving the biological stability of the water. Any filtration plant that does not apply a disinfectant other than ozone before filtration is, in effect, practicing a form of biological filtration, so this practice would not be beyond the capability of small system operators.

EPA regulations require that a disinfectant residual be maintained in distribution systems of water utilities that treat surface water. UV radiation leaves no residual, and ozone dissipates too rapidly to leave a residual. Therefore, maintaining a distribution system residual requires using free chlorine, chloramine, or chlorine dioxide.

An emerging approach to disinfection involves the electrolytic generation of mixed disinfectants, which produces ozone, chlorine dioxide, and chlorine. Electrolytic equipment has been used in water treatment for at least 20 years in the United States to generate chlorine from a sodium chloride solution, but use of such equipment to generate a mixture of disinfectants is a new concept. However, such processes currently are not a suitable option for small systems to use in meeting the EPA's disinfection requirements because of the difficulty of measuring the concentrations of multiple disinfectants in water and lack of data for evaluating the effectiveness of mixed disinfectants. Measurement of ozone, chlorine dioxide, chlorite, chlorate, and free chlorine in a single sample probably is not possible outside of a chemistry research laboratory, if it can be done there. Furthermore, the effectiveness of disinfectants in inactivating bacteria, viruses, and protozoa is estimated based on empirical data, and insufficient data are available for disinfectant mixtures. In the absence of data on the performance of mixed disinfectants under a wide range of water quality conditions, this type of technology cannot be applied to meet the EPA's requirements for disinfection.

Monitoring Requirements

EPA regulations require systems to periodically monitor the residual concentration of disinfectant before water is served to the first customer on the distribution system. This regulatory requirement reflects the practical reality that monitoring is essential to successful disinfection because it provides evidence that a disinfectant residual has been attained. Without monitoring capability, an operator has no basis for knowing that disinfection is adequate. Test kits or spectrophotometers allow for easy monitoring of the disinfectant residual for free chlorine, total chlorine (free and combined), and ozone. Monitoring residual levels of chlorine dioxide and its degradation products, chlorate and chlorite, is more challenging and probably beyond the capability of most small systems.

The intensity or rigor of chemical disinfection provided in the treatment plant, before water is delivered to customers, is assessed in terms of CT, in which C is the residual concentration of the disinfectant in milligrams per liter and T is the time in minutes for which the water and disinfectant chemical were in contact. The product of these parameters is a measure of the effectiveness of disinfection and is used to determine compliance with drinking water standards.

The second factor in the CT value, contact time, depends on, among other things, the geometry of the vessel or basin containing the water to which disinfectant has been added and the rate of flow of the water through the contact basin. The EPA requires that the contact time be based on the time (T10) in which the first 10 percent of water entering the basin would leave, rather than on the theoretical contact time. This is a conservative approach, but it ensures that only 10 percent of the water in the contact basin has a contact time equal to or less than the time used for assessing the value of CT. Therefore, to be able to report CT values the plant operator must also know the rate of flow at the plant and the value of T10.

Because temperature influences the efficiency of disinfection, water temperature must be monitored. The values of CT required for effective disinfection increase as water temperature decreases, reflecting the experimental observation that the resistance of microorganisms to disinfectants increases by factors of 2 to 3 for each 10°C decline in temperature.

When free chlorine is used as a disinfectant, its efficacy decreases as pH increases. Therefore, monitoring the pH of the water during disinfection is important for free chlorine. The EPA's CT values for free chlorine reflect this dependence on pH.

UV disinfection devices need built-in monitors to indicate the intensity of the UV radiation. Ideally, an automatic shut-off should prevent water flow if the UV intensity is not adequate to provide the level of disinfection required.

Disinfection byproducts, harmful compounds that form when water is disinfected, will become another aspect of water quality that small water systems must monitor and manage when the EPA's proposed Disinfection/Disinfectant

Byproducts (D/DBP) Rule takes effect within a few years. While water systems serving fewer than 10,000 persons were not included in the rule that established a drinking water standard for trihalomethanes (THMs), which are common disinfection byproducts, small systems will be included in the new D/DBP Rule. The new rule will set lower limits for THMs and new standards for haloacetic acids (HAAs). Therefore, in the next century small water systems will need to use disinfection methods that are effective for killing pathogens without forming excessive disinfection byproducts. Disinfection byproduct compliance is more likely to be a problem for small water systems treating surface waters than for those treating ground waters because surface water sources tend to contain more natural organic matter that forms byproducts when mixed with disinfectants.

Formation of byproducts depends on the quality of the source water and on the disinfectant used. Free chlorine forms THMs, HAAs, and other compounds classified as disinfection byproducts. Adding ammonia to chlorinated water forms chloramine and stops formation of most byproducts. Chloramine can cause formation of cyanogen chloride, but this compound is not regulated, nor does EPA plan to regulate it in the near future. Ozone does not form chlorinated byproducts, but in some waters that contain bromide it can form bromate and brominated byproducts that will be regulated in the D/DBP Rule. Ozone also forms aldehydes, but these are not currently scheduled for regulation. Chlorine dioxide minimizes the formation of byproducts, but this disinfectant breaks down over time and forms chlorite and chlorate. The EPA plans to regulate chlorate in the future. UV radiation produces no disinfection byproducts that are of concern at the present time.

When disinfection byproducts are regulated for small water systems, systems that use a disinfectant other than UV radiation will need to monitor for these products in their distribution systems. Small systems planning to begin use of disinfection will need to evaluate byproduct formation to be sure that they will not create regulatory compliance problems from the disinfection techniques they are planning to use.

Operating Requirements

Of all operating requirements, the most critical aspect for any disinfection process is that it MUST operate whenever drinking water is produced. This is especially true for disinfection systems used in conjunction with filtration processes, such as bag filters and cartridge filters, that are not capable of removing viruses and most bacteria. Any disinfection system intended to function in the absence of a plant operator should include automatic monitoring devices that shut down the plant if disinfection becomes inadequate. Such cases require that an adequate treated water supply be on hand when the water system is shut down, or that a ''boil water" order be issued.

Routine tasks for a plant operator include monitoring disinfectant residual,

maintaining disinfectant feed equipment, and ensuring that an adequate supply of disinfectant is on hand when chlorine or chloramine are used. When chlorine dioxide is used, adequate quantities of feedstocks must be kept. Operators of systems using ozone need to maintain the ozone generation and air preparation equipment.

When chloramine is used, both chlorine and ammonia must be added to the water. This can be done with solution feeders for calcium hypochlorite or sodium hypochlorite and ammonium sulfate. Liquid chlorine in cylinders that provide chlorine gas under pressure can also be used, although its use is not favored by some systems because of transportation and storage hazards. With chloramine, chemicals must be fed accurately. If the ratio of chlorine to ammonia falls outside of the appropriate range, water quality problems can arise in the distribution system, either from production of dichloramine and nitrogen trichloride (which can cause odor problems) if chlorine is overfed or from the presence of ammonia (which can lead to biological instability of the water) if ammonia is overfed. While chloramine use provides important advantages in the distribution system, particularly with respect to minimizing disinfection byproduct formation, chloramination must be monitored and controlled carefully. In addition, chloramine is not as strong a disinfectant as chlorine, so it requires a much higher CT value.

Generation of chlorine dioxide is more complex than production of chloramine. Because of this complexity, as well as the complexity of monitoring, chlorine dioxide may not be appropriate for most small systems.

A shortcoming of many small systems, particularly those with package plants, is the small amount of disinfection contact time (T) available. To reduce capital costs, many small systems do not have the extensive storage needed to ensure the proper contact time, particularly when water temperatures are near freezing. Opferman et al. (1995), in a paper that assessed CT compliance in Ohio, reported, "In Ohio, several small operators elected to close their treatment plants and link with a larger countywide water supply system rather than invest in clearwell upgrades." Meeting the CT requirement may be a major challenge for some small systems, particularly those that use chloramine.

A second shortcoming for many water systems, both small and large, is that chemical disinfectants (mainly chlorine and chloramine, the most widely used disinfectants) are often added to water without provision for thorough and rapid mixing into the water being treated. Much greater care is used to mix coagulant chemicals in water than to mix chlorine into water, yet both can accomplish their intended functions only after they have been dispersed into all of the water. The past practice of adding chlorine to water without much forethought as to how it was mixed may reflect lax attitudes toward disinfection in the era before Giardia (i.e., to the end of the 1970s), when maintaining a free chlorine residual of 0.2 mg/liter at the end of 30 minutes (a CT of 6) was considered an adequate disinfection

practice. This practice would no longer be acceptable for surface water treatment.

Suitability for Small Systems

Some disinfection processes have already been customized for small systems. UV disinfection, in particular, is probably more appropriate for small systems that treat ground water than for large systems. UV disinfection systems require electricity to power the UV lamps in the device. If water is pumped during treatment, the UV device could be wired to operate whenever the pump runs. This sort of arrangement lends itself to operation without an operator in attendance, although some monitoring is needed to verify that the UV disinfection process is operating properly when water is being pumped.

A key factor related to the use of free chlorine in small systems is feeding the chlorine. A number of chemical solution feeders are available for feeding calcium hypochlorite or sodium hypochlorite solutions. Sodium hypochlorite is easily added to the water using a diaphragm pump, but calcium hypochlorite sometimes contains insoluble particles that can cause problems with these solution feeders. To prevent such problems, some types of equipment can add hypochlorite to the water in solid form. One such feeder discharges small hypochlorite pellets at a measured rate that can be changed by adjusting the feeder. This chlorinator typically is mounted near the top of a well casing and wired to operate whenever the well pump runs. This way, hypochlorite pellets drop into the well casing whenever water is pumped. This type of feeder is most appropriate for disinfection of ground water, but a clever operator probably could adapt it to treatment of surface waters. Another type of chlorine feeder works on the erosion feed principle. In this device, hypochlorite disks shaped like hockey pucks slowly dissolve when water flows through the feeder. This feeder has the advantage of being able to operate without electrical power, but a disadvantage is the fluctuation of chlorine dose that results from uneven rates of dissolution of the hypochlorite disks. A possible solution to the problem of uneven feed rates would be use of an equalization tank ahead of the tank or basin providing chlorine contact time. The equalization tank would be designed to dampen fluctuations in influent chlorine concentration and provide a more steady effluent chlorine concentration.

A number of manufacturers make small package ozone-generating systems. To use ozone, a utility must also provide a contractor or series of contractors. Typically these need to be 6 m (20 ft) deep to provide for efficient contact between ozone and the water being treated as the ozone bubbles added at the bottom rise to the top of the contractor. Some small systems might have flows low enough that ozone contact chambers could be made from large-diameter reinforced concrete pipes placed in the ground and aligned on a vertical axis. A

number of ozone systems use ejector or diffuser systems that do not require deep contact basins.

Within the present regulatory framework, for most small systems use of free chlorine will be the easiest disinfection process to manage because of the greater complexity associated with using the other disinfectants. If free chlorine causes formation of disinfection byproducts, a logical next step would be to use free chlorine for pathogen kill and chloramine to provide a distribution system residual. If that approach does not adequately control disinfection byproducts, use of ozone followed by chloramine would be appropriate.

Corrosion Control

How the Process Works

Many water systems include corrosion control technologies to prevent corrosion of the water distribution system and to reduce lead and copper concentrations in the water where lead and copper pipes or fittings are used. Corrosion control generally involves modifying the chemistry of the water, forming a precipitate or stabilizing compound on the surfaces of piping in contact with water, or both. Most approaches include adding chemicals that can increase the alkalinity or pH of the water or can act as corrosion inhibitors by lining pipe surfaces.

One approach to corrosion control for small systems is the use of limestone contractors to modify water chemistry. Instead of using a feeder to add chemicals that increase alkalinity and pH, low-pH, corrosive water is passed through a bed of limestone rock. The water dissolves the calcium carbonate in the limestone, increasing the alkalinity and pH. One advantage of this approach is that because the chemicals are added to the water by dissolution, they cannot be overdosed, as could happen during a malfunction of a chemical feeder. Letterman et al. (1987) have shown that this process can work for small water systems, and the application of a limestone contractor for a small water system was discussed by Benjamin et al. (1992). An approach for steady-state design of limestone contractors was described by Letterman et al. (1991).

Another approach to corrosion control is the use of orthophosphates and polyphosphates (AWWARF, 1996). Orthophosphates are effective corrosion inhibitors at concentrations of 1 to 3 mg/liter as phosphate. They will aid in the reduction of lead and copper concentrations at the tap and will also reduce the rate of iron corrosion. Polyphosphates are effective as an agent to prevent red water, an undesirable effect of iron corrosion, because they will complex the iron before it can form a reddish precipitate. They also revert to orthophosphates, and this is thought to be a major reason for their effectiveness in controlling lead and copper concentrations at the tap.

Some ground waters have high concentrations of carbon dioxide (CO2). For such waters the removal of CO2 by air stripping can raise the pH and reduce

corrosivity. Air stripping is especially useful for copper corrosion control in low-pH, high-alkalinity waters (Edwards et al., 1996).

Appropriate Water Quality and Performance Capabilities

Chemicals added through feeders can change the pH of water to virtually any desired value, depending on the type and concentration of corrosion control chemical being fed.

The range of pH and alkalinity increase that can be attained by limestone contractors is limited by the equilibrium chemistry for calcium carbonate solubility. Thus limestone contractors have a practical upper limit for the pH of treated water. If a high-pH approach to corrosion control is desired, limestone contractors will not suffice. In addition, waters containing reduced, dissolved iron could cause problems in a limestone contractor if the pH increase is sufficient to precipitate iron onto the limestone rock in the contractor. Turbidity also might foul a contractor. For these reasons, the quality of the water to be treated by a limestone contractor should be evaluated before a contractor is installed.

For orthophosphates and polyphosphates, pH control is important, because the orthophosphates work best at a pH in the range of 7.2 to 7.8 for lead and copper control.

Aeration to strip CO2 from ground water could result in oxidation of dissolved iron and thus might be inappropriate for some waters or might require use of additional treatment processes for removal of precipitated iron.

Monitoring and Operating Requirements

Distribution system and customer tap monitoring requirements for corrosion control are set forth in the EPA's Lead and Copper Rule. In addition, corrosion control process equipment should be monitored as a means of maintaining control of the treatment process. Chemical feeders require regular checking for operational status, feed rate, and amount of chemical fed during the time interval since the last check. Limestone contractors should be inspected periodically to determine the amount of limestone remaining in the contractor. (Because limestone dissolves, it must be periodically replaced.) Regular inspections to check for fouling are also wise.

Suitability for Small Systems

Chemical feeders for use in small water systems are readily available, but determining and adjusting chemical feed rates may be difficult for small systems. Water quality problems can result from both underfeeding and overfeeding pH adjustment chemicals or corrosion inhibitors. The dosages must be correct for the corrosion control chemicals to work properly, so careful monitoring is required.

In contrast, the limestone contractor concept for corrosion control was developed specifically for small systems, and if raw water quality is amenable to this treatment technique it is well suited to small systems. Use of aeration for stripping CO2 from ground water also is a manageable process for small systems, although it must be carefully controlled to prevent excessive calcium carbonate precipitation in the distribution system.

Membrane Filtration Systems

How the Process Works

Once considered a viable technology only for desalination, membranes are increasingly employed for removal of bacteria and other microorganisms, particulate material, and natural organic matter, which can impart color, tastes, and odors to the water and react with disinfectants to form disinfection byproducts. As advancements are made in membrane production and module design, capital and operating costs continue to decline.

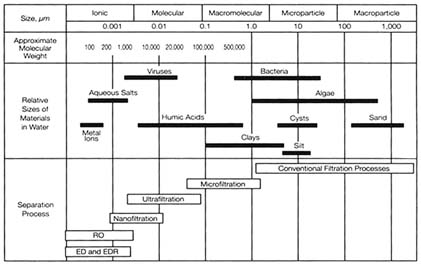

The several membrane filtration technologies appropriate for water treatment are distinguished by their nominal pore size or nominal molecular weight cutoff (MWCO). The MWCO is an estimate of the smallest size molecule that will be retained by the membrane in a filtration process. By these guidelines, membrane filtration technologies are classified as employing microfiltration, ultrafiltration, or nanofiltration, with microfiltration using the largest pores and having the highest MWCO and nanofiltration using the smallest pores and having the lowest MWCO (see Figure 3-1). All three types use similar principles.

Pressure-driven membrane filtration systems use applied pressure to drive water from the source water side of a semipermeable membrane to the produced-water side. Impurities are retained by size separation on the membrane while the water passes through the membrane, and they concentrate in the retained concentrate stream. The membrane permeate or product water is generally of a very high quality.

Membranes are thin, porous structures produced from a variety of materials. Early membranes were commonly made of cellulose acetate, and this type of membrane remains a choice today. Membranes are also now made of polypropylene, polyethylene, aromatic polyamides, polysulfone, and other polymers. Each membrane material has relative advantages and disadvantages. Cellulose acetate membranes permit fairly high water flux but are limited to operation in fairly narrow ranges of temperature (less than 30°C) and pH (3 to 6) and are sensitive to chlorine. Polyamide membranes have a higher resistance to pH and temperature extremes but are similarly intolerant of chlorine. Polysulfone membrane materials are more resistant than either of the other types to pH extremes, temperature, and chlorine exposure but, being hydrophobic, may foul more rapidly. Reliable, durable membranes are presently available, but the science of membrane production

FIGURE 3-1 Sizes of molecules removed by various membrane processes in comparison to conventional filtration processes. SOURCE: Reprinted from Electrodialysis and Electrodialysis Reversal (M38), by permission. ©1995 by the American Water Works Association.

is still advancing. In addition, while all membrane materials work well under the proper conditions, choosing the most appropriate membrane for a given application still remains an art. The longevity of various membranes should be compared based on manufacturer information prior to choosing a given membrane material.

Many membranes are anisotropic in nature, consisting of a thin surface skin approximately 0.1 to 2 microns in thickness supported by a sturdier, more porous structure 100 to 200 microns in thickness (Cheryan, 1986). The surface skin performs the needed sieving of impurities from water. Composite membranes are also available. These consist of a highly resistant porous polymer, such as polysulfone, coated with a highly selective skin layer, such as cellulose acetate. Membranes can also be surface treated, as in a surface-sulfonated polysulfone membrane. This modified surface is more hydrophilic than the parent polymer, thus reducing fouling potential.

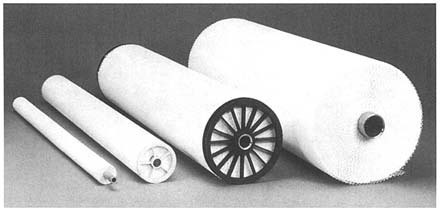

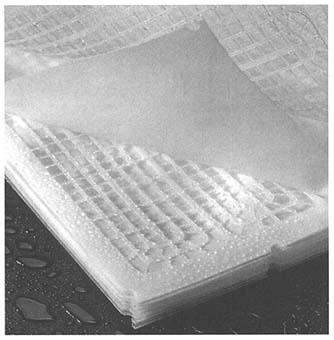

Membranes can be arranged in any of several types of configurations, the most common being hollow fine-fiber modules and spiral-wound modules. In either setup, the operating principle is the same. Water is pushed through the membrane by a higher upstream pressure. Contaminants are removed from the permeate water by sieving. Hollow fine-fiber membrane modules consist of thousands of hollow membrane tubes, approximately 500 to 1,000 microns in

FIGURE 3-2 Spiral-wound membrane elements.

SOURCE: Courtesy of Osmonics, Minnetonka, Minnesota.

diameter each, with the selective skin layer either on the interior or exterior surface of the tube. If the skin is on the interior surface of the tubes, pressurized source water is fed through the inside of the tubes, permeate water passes through the pores in the membrane, and the concentrate water with its impurities remains inside the fibers. The concentrate water flows out the opposite end of the membrane tubes and can be sent through a series of membrane modules for further treatment. An advantage of hollow fiber modules is the low pressure drop within a membrane module in comparison to spiral-wound modules, meaning that power requirements are lower for these units than for spiral-wound modules.

A spiral-wound module is made up of multiple sheets of flat membranes, with a mesh spacer material sandwiched between (see Figure 3-2). In order to provide a large membrane surface area within a fairly small module volume, the stack of membranes is rolled like a jelly roll, with the influent water fed to the individual membrane sets by a tube in the center of the roll, hence the term "spiral-wound." The membranes are arranged in sets of two, with the selective surfaces of the two membranes facing each other in each set. Source water passes under pressure through the interior surface of each set. Permeate water passes through the membranes and collects in the channels between membrane sets, then flows to a permeate water collection system. Concentrate water remains in the channel within the membrane sets, and, as with the hollow fine-fiber modules, this water can be further processed in a series of spiral-wound modules.

Appropriate Water Quality and Performance Capabilities

Membrane filtration is a physical rather than chemical treatment process.

Chemical characteristics of the water source do not greatly affect the process except in their potential for fouling the membrane surface. The concentration of particulate matter, such as bacteria and clays, and natural organic matter is of concern, for these substances can foul the membranes. To avoid this, water must be relatively free of particulate material prior to entering a membrane module. Surface waters may require pretreatment by a more conventional treatment process prior to polishing by membrane filtration, although membrane systems are capable of tolerating a lower quality surface water than direct filtration systems (discussed later in this chapter). Generally, coarse filtration, such as that provided by a bag or cartridge filter, will sufficiently pretreat the source water. Sometimes a coarser mode of membrane filtration is used prior to a finer filtration operation, such as pretreating a surface water with microfiltration prior to removal of disinfection byproduct precursors with a nanofiltration system.

Microfiltration is loosely defined as a membrane separation process using membranes with a pore size of approximately 0.03 to 10 microns, an MWCO of greater than 100,000 daltons, and a relatively low feed water operating pressure of approximately 100 to 400 kPa (15 to 60 psi). Representative materials removed by microfiltration include sand, silt, clays, Giardia and Cryptosporidium cysts, algae, and some bacterial species.

Ultrafiltration involves the pressure-driven separation of materials from water using a membrane pore size of approximately 0.002 to 0.1 microns, an MWCO of approximately 10,000 to 100,000 daltons, and an operating pressure of approximately 200 to 700 kPa (30 to 100 psi). Ultrafiltration will remove all species removed by microfiltration as well as some viruses and humic materials.

Nanofiltration membranes have a nominal pore size of approximately 0.001 microns and an MWCO of 1,000 to 10,000 daltons. Pushing water through these smaller membrane pores requires a higher operating pressure than either microfiltration or ultrafiltration. Operating pressures are usually near 600 kPa (90 psi) and can be as high as 1,000 kPa (150 psi). These systems can remove virtually all viruses and humic materials. They provide excellent protection from disinfection byproduct formation if the disinfectant residual is added after the membrane filtration step. Because nanofiltration membranes also remove alkalinity, the product water can be corrosive, and measures such as blending raw water and product water or adding alkalinity may be needed to reduce corrosivity.

Membrane filtration greatly reduces the need for disinfectants. Protozoa, bacteria, and even viruses can be removed in the process, which can relieve a portion of the CT disinfection requirement, if proven to the satisfaction of regulators. Nanofiltration also removes hardness from water, which accounts for nanofiltration membranes sometimes being called "softening membranes." (Hard water treated by nanofiltration will need pretreatment to avoid precipitation of hardness ions on the membrane.) Although membrane filtration is most commonly used to remove inorganic or microbiological contaminants, a pilot-scale demonstration showed that a nanofiltration system removed a variety of synthetic

organic chemicals (Duranceau et al., 1992). Removal was related to the molecular weight of the synthetic organic compound. Lower molecular weight synthetic organic compounds such as ethylene dibromide and dibromochloropropane passed through the membrane, while the slightly higher molecular weight pesticides chlordane, heptachlor, and methoxychlor were removed from the permeate. Based on the results of such studies, larger organic compounds such as natural organic matter would be removed by nanofiltration.

Membrane classification standards vary considerably from one filter supplier to the next. One supplier may sell as an ultrafiltration membrane a product similar to what another manufacturer calls a nanofiltration system. It is best to look directly at pore size, MWCO, and applied pressure needed when comparing two membrane systems.

Monitoring and Operating Requirements

Efficient operation of a membrane separation system relies as much on module design as on membrane material choice. Capital costs of membrane systems are a function of the type of system configuration and the membrane surface area: volume ratio for a given module. Operating costs are influenced by module replacement costs, pressure requirements, ease of cleaning, and cleaning solution and concentrate disposal costs. While the initial membrane purchase is a relatively minor portion of the capital cost, membrane replacement is the largest component in the cost of operation (Wiesner et al., 1994).

Prevention of fouling of microfiltration and ultrafiltration membranes requires regular backwashing of the membranes. Operation is usually automated, with backwash of contaminants from the membrane surface occurring at a prearranged time, a prescribed effluent turbidity, or a predetermined change in operating pressure. For this reason membrane plants often can be allowed to operate unattended much of the time. The principle of operation is simple and not tied directly to source water chemistry. Antiscalant chemicals may need to be added to the water when the concentrated water retained by the membrane exceeds solubility limits for salts such as calcium carbonate. This is more likely in tighter membrane systems such as those using nanofiltration.

Waste stream disposal is a significant problem in many areas. Unlike conventional treatment processes, in which approximately 5 to 10 percent of the influent water is discharged as waste, membrane processes produce waste streams amounting to as much as 15 percent of the total treated water volume. Because little or no chemical treatment is used in a membrane system, the concentrate stream usually contains only the contaminants found in the source water (although at much higher concentrations), and for this reason the concentrate can sometimes be disposed of in the source water. Other alternatives include deep well injection, dilution and spray irrigation, or disposal to the municipal sewer; these alternatives are usually necessary for nanofiltration waste, which usually

contains concentrated organic and inorganic compounds. Regardless of the type of membrane, concentrate disposal must be carefully considered in decisions about the use of membrane technology.

Suitability for Small Systems

Membrane filtration systems have very little economy of scale, so capital costs on a basis of dollars per volume of installed treatment capacity do not escalate rapidly as plant size decreases. This makes membranes quite attractive for small systems. In addition, for ground water sources not needing pretreatment, membrane technologies are relatively simple to install, and the systems require little more than a feed pump, a cleaning pump, the membrane modules, and some holding tanks. Most experts expect that membrane filtration will be used with greater frequency in small systems as the complexity of conventional treatment processes for small systems increases.

In a cost comparison of membrane filtration and conventional treatment, particle removal by ultrafiltration was estimated to be substantially less expensive than by conventional filtration technologies for small systems (Wiesner et al., 1994). As facility capacity decreased, the membrane cost advantage increased. Similarly, when nanofiltration was compared to conventional treatment with the addition of ozone and granular activated carbon to control disinfection byproduct and total organic carbon levels, the two treatment techniques produced similar water quality, but the membrane systems were substantially less costly for small system sizes (Wiesner et al., 1994).

The operation of a nanofiltration system is substantially less complicated than operation of the multiple treatment train needed to reach the same result by conventional systems. Membrane filtration should be considered for small systems that need to remove multiple contaminants. There are few limitations to the types of raw water that membrane filtration systems can treat, although pretreatment of the water to remove particles may be necessary, and testing to determine potential fouling by organic matter should be performed.

Reverse Osmosis

How the Process Works

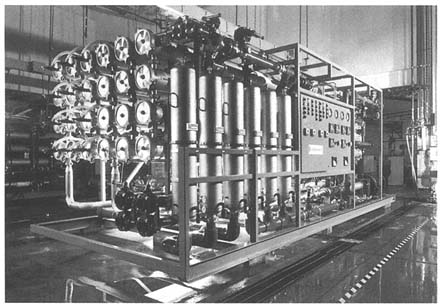

Reverse osmosis (see Figure 3-3) is a highly efficient removal process for inorganic ions, salts, some organic compounds, and, in some designs, microbiological contaminants. Reverse osmosis resembles membrane filtration processes in that it involves the application of a high feed water pressure to force water through a semipermeable membrane. In osmotic processes, water spontaneously passes through a semipermeable membrane from a dilute solution to a concentrated solution in order to equilibrate concentrations. Reverse osmosis is produced

FIGURE 3-3 Skid-mounted reverse osmosis system. SOURCE: Courtesy of Osmonics, Minnetonka, Minnesota.

by exerting enough pressure on a concentrated solution to reverse this flow and push the water from the concentrated solution to the more dilute one. The result is a clear permeate water and a brackish reject concentrate.

Several differences distinguish reverse osmosis from membrane filtration. Unlike in membrane filtration, in reverse osmosis the membrane is essentially nonporous; transport of water through the membrane takes place by sequential dissolution of the water into the membrane and diffusion through the membrane to the permeate side. Any contaminants that can dissolve into and diffuse through the membrane can also pass into the permeate in this system, though such contaminants are few. The membrane rejects most solute ions and molecules, allowing water of very low mineral content to permeate; some organic contaminants can permeate reverse osmosis membranes.

Reverse osmosis produces a larger volume of reject concentrate solution than membrane filtration. The concentrate volume can be as much as 25 to 50 percent of the raw water volume. In addition, though module configurations resemble those of membrane filtration processes, operating pressures are much higher, ranging from approximately 1,400 kPa (200 psi) for water with a total dissolved solids concentration of less than 1,000 mg/liter to as high as 10,000 kPa (1,500 psi) for seawater with a total dissolved solids content of 35,000 mg/liter. The higher pressure is needed to overcome the solution osmotic pressure and

force water through the membrane from the concentrated feed side to the dilute permeate side.

The permeate from a reverse osmosis system is virtually demineralized and therefore quite corrosive. To maintain stable water in the distribution system, a predetermined fraction of the raw water is usually allowed to bypass the system and is mixed with the permeate. Posttreatment may include degasification if carbon dioxide and/or sulfide is present in the water, pH adjustment to reduce corrosiveness, and disinfection.

Appropriate Water Quality and Performance Capabilities

Removal efficiencies for inorganic ions and salts range from 85 to 99 percent. Removal of organic chemicals varies with the chemical in question. Low-molecular-weight organic compounds, as well as organic compounds with an affinity for the particular membrane material, may diffuse through the membrane. The removal efficiencies for organic compounds range from no removal to better than 99 percent removal. Humic materials, particulate matter, microorganisms, and viruses are generally removed in the process, but the bypass water will add microbiological contaminants to the treated water when the two are mixed to reduce corrosiveness. Also, leaks of concentrate water containing bacteria and viruses can occur around o-ring seals under the high operating pressures of a reverse osmosis system.

A reverse osmosis membrane can severely foul if proper pretreatment is not provided. Influent total organic carbon concentrations can be as high as 20 mg/liter, but pretreatment must be used to reduce influent turbidity and to remove any iron, manganese, and chlorine. Stabilization of the water to prevent scale formation may also be necessary, as the concentrate solution may contain inorganic contaminant concentrations so high that precipitation could occur. The water's pH may have to be adjusted to avoid reducing membrane life.

A typical membrane module lasts 3 to 5 years, after which module replacement is necessary. Membrane module replacement costs remain high and are a significant consideration in the overall cost of the treatment system.

Monitoring and Operating Requirements

Most reverse osmosis systems are set up to backwash automatically, and therefore the pressure unit itself requires little operator attention. However, pretreatment may require a skilled operator.

The membrane must be cleaned periodically to remove scale at the surface. Caution is required to avoid contamination of raw or finished water with the generally acidic cleaning solution. In addition, membranes must be flushed with product water prior to shutdown to prevent prolonged contact between the membrane and a concentrated solution; otherwise, scaling from chemical precipitation

can occur within hours of shutdown. If the plant is not operated for several days, the membranes should be filled with a disinfectant solution to prevent biological growth and possible membrane damage.

Disposal of reject water poses an even greater problem for reverse osmosis systems than for lower-pressure membrane filtration processes such as ultrafiltration or nanofiltration because they produce a larger quantity of reject water, and the contaminants are more concentrated than those produced by filtration processes. Release to evaporation ponds or the municipal sewer or injection in deep wells are current disposal strategies. However, in the future some of these strategies may no longer be permitted in some areas. Disposal needs and local regulations governing disposal must be considered in planning a reverse osmosis treatment plant.

Suitability for Small Systems

Like other modular membrane processes, reverse osmosis has little economy of scale and therefore is just as suitable for a small system as it is for a large one. Reverse osmosis is a rugged and reliable treatment process on the small scale. Air-droppable reverse osmosis units were used during the Gulf War to supply water to troops near saline water supplies. Plant expansion can be as easy as adding an additional series of membrane modules to the treatment train. Operation can be automated, allowing reverse osmosis systems to be run by part-time operators. There are 142 operating reverse osmosis drinking water plants in North America, with more than a third of them serving fewer than 3,500 people (Morin, 1994). The technology is commonly used in Florida to treat drinking water for condominiums and mobile home parks (Sorg et al., 1980).

One example of a small community that uses reverse osmosis is Wenona, Illinois. Prior to installation of a reverse osmosis system, the town's approximately 1,200 residents experienced problems with the deep-well ground water they use. The source water has high levels of dissolved solids, which imparted a salty taste to the water and damaged equipment such as water heaters and washing machines. Most residents drank bottled water. In addition, radium levels in the source water are above the drinking water standard. The reverse osmosis plant removes 99 percent of radium-226 and 95 percent of dissolved solids. Most consumers have since taken their water softeners off line and are able to use approximately half of the soap and shampoo once necessary (JAWWA, 1993).

Electrodialysis/Electrodialysis Reversal

How the Process Works

Electrodialysis (ED) and electrodialysis reversal (EDR) systems, usually employed to produce demineralized water from brackish water sources, use electrochemical

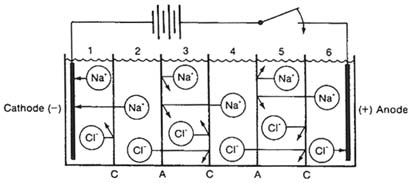

separation processes to concentrate salts from the feed water into a smaller-volume, higher-concentration solution. ED and EDR systems consist of stacks of alternating anionic and cationic selective membranes. The ionic components of dissolved salts pass through the membranes in response to an electric current applied to the water perpendicularly to the membranes. The system creates a demineralized product water stream and a brine concentrate stream.

In ED and EDR systems, the anions travel from the feed water channel toward the anode and pass through an anionic selective membrane but are rejected from transfer through the cationic selective membrane; the result is that anions are retained in the channel between the anionic and cationic membranes (see Figures 3-4 and 3-5). Simultaneously, cations from another feed channel travel toward the cathode in response to the electric current, pass through a single cationic membrane, and are concentrated in the same channel as the anions between the cationic and anionic membranes. In this matter, all the ions in a given feed channel are removed and concentrated in a concentrate channel.

In EDR, the polarity of the electrodes is reversed every 15 to 20 minutes. The change causes a reversal in ion movement. A concentrate channel at one polarity becomes a demineralized channel at the opposing polarity. Automatically operated valves tied in to the polarity change transfer incoming and outgoing flows to the proper piping. Reversing the polarity, and consequently the water flows, minimizes scale buildup by providing regular washing of the membrane surface. EDR systems can thus operate for longer periods of time between cleanings than ED systems. The majority of plants in the United States using this technology are EDR plants (Morin, 1994).

Appropriate Water Quality and Performance Capabilities

ED and EDR systems require feed water pretreatment, at a minimum with cartridge filters. Feed water turbidity should be less than 2.0 nephelometric turbidity units (NTU), the free chlorine concentration less than 0.5 mg/liter, manganese less than 0.3 mg/liter, and hydrogen sulfide less than 0.3 mg/liter (Conlon, 1990). Hydrogen sulfide is highly unlikely to be present in surface water and would generally be a concern only for ground water sources. Total dissolved solids levels of up to 4,000 mg/liter have been tolerated by EDR plants successfully producing water that meets drinking water total dissolved solids standards (Morin, 1994).

In contrast to membrane filtration processes and reverse osmosis units, the product water in ED and EDR systems does not pass through the membrane. This reduces the potential for concentration polarization and organic fouling of the membrane surface but provides no means for removing microbiological contaminants, organic compounds, or particulate or colloidal materials. SDWA requirements for these contaminants must be met through pretreatment or posttreatment of the water by other means, if necessary.

FIGURE 3-4 Removal of sodium chloride from water in an ED system. Chloride ions move toward the anode and pass through the anion selective membranes (A) but are trapped by the cation selective membranes (C); sodium ions move toward the cathode and pass through the cation selective membranes but are trapped by the anion selective membranes. The result is a demineralized water in channels 2 and 4. SOURCE: Reprinted, with permission, from Meller (1984), Electrodialysis (ED) and Electrodialysis Reversal (EDR) Technology. ©1984 by Ionics, Inc., Watertown, Massachusetts.

FIGURE 3-5 Typical membranes and membrane spacers used in ED and EDR systems. SOURCE: Courtesy of Ionics, Inc., Watertown, Massachusetts.

Both the anionic and cationic membranes used in ED and EDR systems are fairly sturdy and resistant to water quality conditions. They are 0.5 mm in thickness and resist damage from pH extremes in the range of pH 1 to 10. They can tolerate temperatures up to 46°C (115°F) (Conlon, 1990).

A disadvantage of ED and EDR systems is their high energy requirements. Pumping requirements are similar to those for an ultrafiltration system, with the costs for maintaining the direct current at least equal to the pumping costs. Energy costs other than pumping are a function of feed water salinity. The energy required to provide the current is approximately 2.0 kWh per 3,800 liters (1,000 gals.) treated per 1,000 mg/liter total dissolved solids removed (Conlon, 1990).

The recovery rate in an ED or EDR process is the percentage of feed water that becomes product water. Most EDR plants operate at a recovery rate of 70 percent or better. The remaining 30 percent is disposed of as the concentrate stream (Morin, 1994). Like water treated by reverse osmosis and nanofiltration, ED/EDR water is corrosive, so some bypassed water may be needed to stabilize the product water.

Monitoring and Operating Requirements

ED and EDR systems are usually fully automatic. Recordings of system operation may be taken by a computer or by an operator, if available. Membranes and, less frequently, electrodes will need to be replaced. Routine maintenance is fairly simple. Equipment such as pumps and chemical feed systems requires the usual maintenance. ED (but not EDR) systems need antiscalant chemicals.

Operation must be performed at a direct current density less than the limiting density of the system. A limiting voltage also applies in order to prevent heating the system and causing damage to the membranes and/or spacer material. These operating parameters are set at installation by the supplier.

Suitability for Small Systems

ED and EDR plants are well suited to small systems with brackish water sources. More than half of the operating ED and EDR plants in North America serve fewer than 3,500 people (Morin, 1994). Some plants serve as few as 200 people. ED and EDR plants are generally automated, allowing for part-time operation. As with reverse osmosis, energy consumption must be considered when evaluating whether to apply this technology.

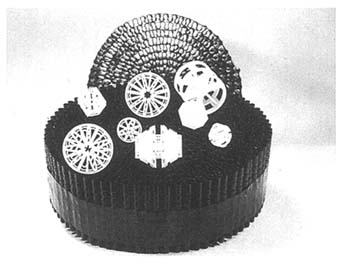

Adsorption

How the Process Works

Adsorption is the physical and chemical process by which an organic contaminant

accumulates on the surface of a solid, removing the contaminant from solution in the water. Organic contaminants, including toxic synthetic organic chemicals, color-causing compounds, and taste- and odor-causing compounds, are all less polar than water and therefore have low solubility in water, which is a polar liquid. Thus, they are attracted to the nonpolar solid surface.

The most common adsorbent used to remove organic contaminants from water is activated carbon. Activated carbon is similar to charcoal. It differs from charcoal in that the base material (typically bituminous coal, lignite, petroleum coke, or bone char) has been heated in the absence of air to carbonize it and then activated by oxidation at 200°C to 1,000°C to develop a favorable pore structure. The result is a highly porous structure with a very high surface area per unit volume, which allows for significant adsorption of impurities from water. In general, the less soluble an organic compound, the better it adsorbs from solution onto the activated carbon (Lundelius, 1920; Weber, 1972).

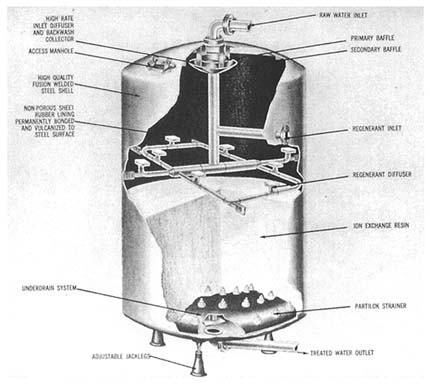

Activated carbon is available in two common forms, powdered activated carbon (PAC) and granular activated carbon (GAC), the difference between the two being obvious from their names. PAC is generally less than 50 µm in diameter and is added to the raw water line or to a mixing basin. For effective treatment, the PAC must contact all of the incoming water. Because of its small particle size, adsorption to the surface occurs quickly. The normal contact time of mixing basins used for other elements of water treatment is sometimes sufficient for contaminant adsorption onto PAC. In such cases, no modification other than the addition of PAC dosing equipment needs to be made to an existing plant. In other cases, adsorption can require up to 8 hours of contact time. Testing prior to design is needed to determine the required contact time. Following adsorption, the carbon containing the organic compounds is settled or filtered from the water and disposed of with the plant sludge.