3

Managing Ballast Water

The principles for managing ballast water1 are similar to the basic principles of quarantine science. The process of managing ballast water should prevent introductions of nonindigenous species, including bacteria, viruses, algae, protists, invertebrates, and fish. An important corollary is that no control options practiced today totally prevent the unintentional introduction of nonindigenous aquatic nuisance organisms through ships' ballast operations. Technologies to achieve this goal need to be:

-

safe for a ship and its crew

-

effective in destroying potential invading organisms

-

environmentally acceptable

-

practicable in application

-

compatible with normal ship operations

-

cost effective

There are measures currently available that can reduce the risk of releases of nonindigenous aquatic organisms into the marine environment. The most effective control method currently in use for ships in international trade involves changing ballast water loaded in port (or taken on board while transiting inshore waters) with ocean water that is loaded during passage between ports of call.

|

1 |

As noted in Chapter 1, ballast water includes associated sediment. |

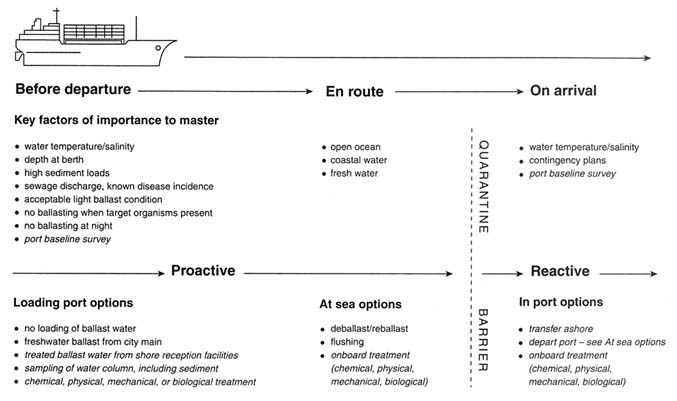

VOYAGE APPROACH

The voyage approach to managing ballast water is a useful means of categorizing the wide spectrum of suggested control options (see Figure 3-1). Three stages in a ship's voyage and related control options can be identified as follows:

-

On or before departure. Control is based on preventing or minimizing the intake of organisms during loading of ballast water at the port of origin.

-

En route. Control is based on the removal of viable organisms prior to discharge of ballast water at the destination port either by treatment or by open ocean ballast water change. Shipboard treatment could commence immediately upon departure and continue throughout the voyage.

-

On arrival. Control at the port of arrival begins when the vessel's master intends to discharge all or some of the ballast water on board. Control strategies are aimed at preventing the discharge of unwanted organisms that could survive in the target environment.

The viability of various control options is dependent on vessel size and type and the upload and discharge capacity of pumping and piping systems. In the future, modified ship designs that (1) minimize the quantity of ballast water discharged, (2) permit safe ballast change at sea under a wide range of operational conditions, and (3) facilitate cleaning of ballast tanks may be part of an overall ballast water control strategy (see Appendix D).

Although proven shipboard systems for treating ballast water are not yet available (see Chapter 4), there are a number of control options that could be undertaken today that would immediately reduce the transport of nonindigenous species by ballast water. For example, vessels could avoid taking on ballast in ports with high sediment loads, in areas of sewage discharge, or in "hot spots" where certain unwanted organisms were known to be present. A plan for managing ballast water, developed in conjunction with the ship cargo plan, would assist the ship's master in adjusting ballast loading and discharging needs to meet constraints on ballasting in these locations. In addition, a requirement for official logs indicating when and where ballast was taken on or discharged would be helpful for implementing existing (and future) strategies for managing ballast water. The following discussion of options for controlling ballast water includes measures that could be taken in the immediate future, as well as methods that require further development.

On or before Departure

Approaches to ballast water control that prevent or minimize the intake of organisms at the port of origin need to take account of ballast requirements for safe ship operation, locations and times of ballasting, and practical limitations on treating ballast water as it is loaded. As the first line of defense to control

introductions of nonindigenous aquatic species through ballast water, a vessel's master may consider not loading ballast water if the vessel is capable of operating safely and efficiently without it. Locations and times when ballast is likely to contain such organisms include:

-

global "hot spots" where targeted organisms are known to be present in the water column

-

ports with high sediment loads

-

areas of sewage discharge or known incidence of disease

-

certain sites at certain times of year, depending on seasonal variations in populations of organisms

-

at night, when some planktonic organisms migrate higher up the water column

Despite concerns about nonindigenous species, ships may need to take on ballast water in port to preserve safety. The need for ballast to ensure ship safety during cargo loading and unloading imposes practical restrictions on available control options (see Chapter 2, Ballast Conditions in Port). For example, certain classes of vessels, such as bulk carriers, need to load ballast water simultaneously with the discharge of cargo. Thus, the option of treating ballast water as it is loaded may merit consideration under some circumstances.

Most large ships routinely load or discharge ballast at rates of thousands of cubic meters (metric tons) per hour. Pumping systems associated with ballast movements meters abroad ship are large, and flow velocities may be as high as 2.6 to 3 m/s. These high flows are similar to those encountered in large drinking or waste water treatment plants common in the United States. However, typical units required for these treatment plants are much larger than could be fitted on board a ship.

In addition to handling high flows and volumes, a treatment system used in conjunction with ballast loading operations would be required to remain on standby when not in use. During loading operations in port, for example, the system could be cycling on and off as the ship discharged ballast to accommodate cargo being loaded. This is not an optimum scenario for existing complex water treatment systems, which are designed to operate continuously at a predetermined load factor.

Despite these technical challenges, treating ballast water as it is loaded remains a potentially attractive option because it would obviate the need for controls en route. Thus, the operational hazards accompanying ballast change would be avoided, as would the need for onboard treatment of a sediment/water mixture (see Chapter 4).

Most ballast water is taken on board in coastal and estuarine areas that tend to contain high levels of suspended solids. In some cases, ships taking on ballast are floating very close to the bottom and can scour bottom sediment into the ballast system. As a result, ballast water often contains high concentrations of

suspended material, which presents a problem for both the ship operator and the treatment system engineer. Sediment accumulates in ballast tanks in large quantities (hundreds of cubic meters) and is costly to remove and to transport. Suspended sediment also interferes with most treatment systems, whether they are physical separation processes or advanced oxidation processes. In the first case, suspended sediment tends to plug screening systems rapidly, necessitating the use of substantial bypass systems. In the second case, suspended material may shield target species from any treatment process. Thus, treatment efficacy—defined in terms of inactivation of target organisms—may be severely limited in the presence of suspended solids.

En Route

Ships that traverse large areas of open-ocean water have different options for controlling ballast water than ships that traverse inshore and coastal waters. For instance, many ships crossing a large body of open water may have the option of changing ballast water at sea. If ballast can be changed, treating ballast water on board may not be necessary. However, in some cases only a partial or incomplete change of ballast is possible, particularly in bad weather. Thus, changing ballast and treating ballast water on board are not always mutually exclusive.

Shipboard Treatment

Once ballast water has been loaded on board, the ideal mechanism for preventing subsequent introductions of nonindigenous aquatic species is to kill or remove the organisms prior to discharging ballast water overboard. This can be done by chemical, physical, mechanical, or biological treatments, or by any treatment combination. In all cases, the offending organisms or treatment residues must be dealt with in an environmentally safe way before deballasting or subsequent disposal. A detailed discussion and evaluation of possible onboard technologies for treating ballast water is provided in Chapter 4.

Ballast Change

The change of coastal and port ballast water with ocean water is an approach to the reduction of nonindigenous species inoculations.2 There are two major biological and ecological principles that provide the scientific basis for this control option. First, the probability of reciprocal introductions is virtually nonexistent. The oceanic environment is inhospitable for freshwater, estuarine, and most inshore

coastal (neritic) planktonic organisms discharged. Similarly, oceanic organisms taken in ballast and later discharged into freshwater, estuarine, or inshore coastal waters encounter hostile conditions and are unlikely to survive. Second, the transport of viable released organisms back to neritic (inshore coastal) waters from mid-ocean by ocean currents is extremely unlikely.

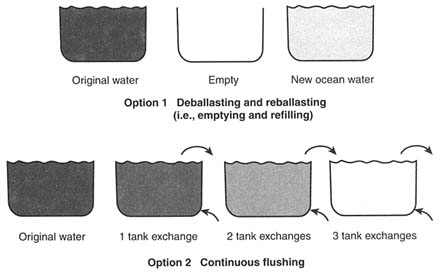

Ballast change can be carried out by two methods (see Figure 3-2):

-

pumping out ballast water taken on in ports, estuarine, or territorial waters until the tank is empty, then refilling it with mid-ocean water

-

flushing out ballast water by pumping in mid-ocean water at the bottom of the tank and continuously overflowing the tank from the top until sufficient water has been changed to minimize the number of original organisms remaining in the tank

Both options must be determined safe by the crew, classification societies, and flag state authorities before use because of ship design variances. Depending on sea conditions, the ship may become unstable or the allowable forces on the hull may be exceeded (see Chapter 2), with catastrophic results, if the first option is used. If the second option is used, the ballast tank or ballasted cargo hold may be pressurized or the integrity of the ship may be jeopardized.

FIGURE 3-2 Basic options for changing ballast water. Note: The effectiveness of ballast water change using continuous flushing has been monitored using a dye tracer. After three tank exchanges, 95 percent of the original ballast water had been changed (AQIS, 1993). Source: Adapted from Rigby and Taylor (1994).

A very limited analysis of possible hazards caused by emptying and refilling ballast tanks at sea was conducted by Woodward et al. in 1992. A later study conducted for the Transport Canada Marine Regulatory Directorate analyzed ballast change operations for a Panamax bulk carrier and a Cape Size bulk carrier (Transport Canada, 1995). The results of that study showed that, although both vessels would meet all relevant stability criteria during a ballast change operation, changes in forward and aft drafts would produce several instances of propeller emergence and an increased risk of forward slamming. The study also found that both vessels would be unable to comply with the Great Lakes Ballast Water Control Guidelines introduced by the Canadian Coast Guard on May 1, 1989.

In addition to the safety constraints that restrict the use of ballast change, the effectiveness of this method for controlling introductions of nonindigenous aquatic species is limited by vessel design and operational considerations. Ballast change can rarely, if ever, remove all original organisms from ballast water. Most ballast pumping systems and tanks are designed to remove as much water and sediment as practicable, but they cannot remove all ballast and associated biota. In addition, voyage passage times or bad weather may not permit a complete change of ballast by either method (deballasting/reballasting or flushing). As noted in Chapter 2, even sister ships must be treated separately because differences in cargo loading will result in differences in the forces acting on the hull. Therefore, ballast change must be evaluated on a case-by-case basis and cannot be required by regulators as a universally viable method to minimize the introduction of unwanted nonindigenous organisms.

Despite the aforementioned difficulties, ballast change is an important component of initiatives that attempt to control the introduction of harmful nonindigenous aquatic species into port and coastal areas by ships' ballast. (Current international, national, regional, state and local initiatives are summarized below.) In some circumstances alternative control options are necessary. For maximum flexibility in managing ballast water during transit, a vessel needs both onboard treatment methods and ballast change. If acquainted with all the accepted options available for a particular voyage, the master would be able to plan ballast operations to minimize the risk of introducing nonindigenous aquatic organisms.

On Arrival

A vessel may arrive in port intending to discharge ballast, but without having performed satisfactory ballast management procedures. If such procedures are deemed necessary by the appropriate authorities, there are two options for managing ballast water on arrival: ballast can be transferred ashore for treatment at shore-based facilities, if these exist; or the vessel may be directed to depart port and use one of the "en route" options for ballast water management. Onboard treatment could conceivably be conducted in port, but at this time there is no known technology that is effective under these circumstances.

Previous experience has shown that shore-based treatment to avoid oil pollution (MARPOL 73/78)3 is less than satisfactory in many cases because global commitment to establishing suitable facilities is lacking.4 In the case of shore-based facilities for treating ballast water, some ports will be able to establish facilities, but others will not. Therefore, it is highly likely that ships will still be required to manage their ballast water using onboard treatment or other procedures that minimize the translocation of unwanted species.

In the absence of shore-based facilities for receiving and treating ballast water, a contingency plan must be developed. Such a plan might direct a ship to depart port to discharge ballast water or to change ballast at sea in an area considered safe and environmentally acceptable before returning to take on cargo. When developing contingency plans, port administrations need to be watchful to ensure that this approach to managing ballast water does not become a routine, accepted control option for arriving ships. If vessels routinely depart port to change ballast there could be serious delays in cargo operations, which would, in the end, work to the severe disadvantage of the ship, the cargo owners, and ultimately the port administration.

Shore-Based Treatment and Ballast Lighters

The advantages and limitations of shore-based water treatment facilities have been discussed in two recent reviews (AQIS, 1993; Carlton et al, 1995). Both reviews considered a land-based treatment facility and a mobile "treatment ship" that could accommodate widely spaced berths or be shared between ports. However, treatment facilities on board a "treatment ship" would be subject to the same limitations (except space) as a commercial ship and standardized connections, and piping would be required to transfer ballast water.

In some ports, where there is space, the option of establishing large-scale, shore-based facilities to treat ballast water may exist. Sizing of the treatment process units would depend on the number, timing, and type of ships entering the port. If ballast-water storage tanks were provided such that water did not have to be pumped directly from a ship to the treatment plant, the capacity of the process units could be reduced (AQIS, 1993). The review by Carlton et al. (1995) notes that shore-based facilities would require a potentially expensive industrial infrastructure and supporting administrative framework, neither of which currently exists in the United States. There is also no precedent for recovering associated costs.

Many oil refineries have dirty ballast water reception facilities that receive oil-contaminated ballast water from oil tankers. These facilities were specifically designed to remove the oil from the ballast water before releasing it to the port water. Such reception facilities were required under Annex I of MARPOL 73/78. It may be possible to modify these facilities to incorporate a ballast water treatment facility to remove unwanted nonindigenous aquatic organisms. Carlton et al. (1995) note that the comparatively few ballast facilities now treating oily ballast from tankers "can only be minimally compared to a ballast water supply and treatment industry on a national scale."

Another possibility is to provide mobile transport facilities (lighters) to transport ballast to a shore-side facility. This would require the transport of large quantities of ballast for some large cargo carriers and could severely limit a ship's ability to ballast or deballast quickly.

Advantages and Disadvantages of Shore-Based Treatment

The main advantages of shore-based treatment are:

-

Port (or regional) authorities could operate and maintain the facilities and could routinely monitor them to determine the extent and effectiveness of treatment.

-

Operation of a land-based facility permits better control of treatment than under potentially difficult operational conditions onboard ship.

-

Waste from the treatment process could be disposed of in an environmentally acceptable manner under the control of an appropriate authority.

The main disadvantages of shore-based facilities are:

-

Connecting pipelines would be needed between the treatment facilities and all berths, and every ship would need to have its ballast water pumping system modified (AQIS, 1993). Larger ports would need multiple shore-reception facilities.

-

Delays in shipping could occur if the ballast capacity of ships exceeded the capacity of the treatment plant (including storage tanks).

-

If ships are capable of ballast change at sea, ship operators would probably elect to use this option rather than shore-based facilities, thus limiting the economic viability of such facilities.

Despite these disadvantages, shore-based treatment remains an option within the amalgam of currently available options for treating ballast water, provided the criteria for safety, environmental acceptability, technical feasibility, practicable operation, and cost effectiveness are met.

CONTROL OPTIONS

The committee considered the possibility of the concurrent development of a plan for loading and discharging ballast water and the ship cargo plan. For example, if a ship is to load bulk cargo of various grades, or different bulk cargoes in different ports, it would be useful to develop an associated ballast water operations plan, taking account of information on locations and times when ballast is likely to contain unwanted organisms (see above). In this way, the master could adjust the requirements for loading and discharging ballast. Even though the plan for managing ballast could be as complicated as the typical cargo plan, this method would provide flexibility in planning for contingencies.5 The committee agreed that a plan for managing ballast water should be mandatory when target organisms, such as those from global hot spots, are involved.

The various options described earlier complement the plan for managing ballast water because they give the ship operator more flexibility for planning for each voyage and each port of call on a case-by-case basis. To take maximum advantage of this approach, educational and operational guidelines that address each option would be beneficial. In some cases, specific operational procedures would have to be approved in advance by the ships' classification society or flag state administration.

Some specific examples of control options for managing ballast water that may minimize or prevent the unintentional introduction of nonindigenous aquatic nuisance organisms are given below:

-

Change ballast water at sea with engine cooling water heated to a temperature in excess of 45°C (110°F).6 Research has shown that cooling water heated to this temperature is completely free of live microplankton (AQIS, 1993). This is not necessarily an option for treating all the ballast water on board for all micro-organisms or for dealing with large quantities of ballast water. (Onboard thermal treatment is discussed in Chapter 4.)

-

Take ballast water on board using high-ballast-water suction if unwanted organisms are known to exist in the bottom sediment. Alternatively, the ship could partially ballast at the cargo discharge berth and finish ballasting upon departure but while still in calm waters.

-

Prohibit deballasting in U.S. waters by ships on some voyages when ballast water can be retained on board. Some container ships have computerized plans for discharging ballast water. With careful preplanning, these ships could dispense with discharging ballast in U.S. ports. In other circumstances, ships engaged in liner/break-bulk cargo trades may have enough ballast water tanks to keep ballast water on board during a roundtrip voyage. For example, the ship's ballast water intake can be planned such that alternate ballast tanks are used to carry water picked up in a given U.S. port of discharge later into the same port area.

|

5 |

6 |

Most ships currently plan ballast loading and discharge based on ship strength and stability, without consideration of possible introductions of nonindigenous species. The quantity of heated cooling water on board a ship is directly related to the horsepower of the main engine. |

The examples above do not pertain to all ships and are not candidates for mandatory requirements for managing ballast water. They are given here only as examples of specific methods that can be used to manage ballast water discharges on an ad hoc or case-by-case basis to illustrate the options that can be used to control ballast water operations.

Ongoing activities by international, national, regional, and other organizations aimed at controlling ballast-mediated introductions of nonindigenous aquatic species are discussed below. These organizations have given much attention to controlling introductions of nonindigenous species by ships' ballast operations. The approaches described in this report generally are compatible with options for managing ballast water that are currently under discussion globally and regionally. Since existing regulations and guidelines for managing ballast water are in their infancy, any assessment of their biological effectiveness and of associated administrative procedures is premature at present. Assessments of effectiveness will rely heavily on the results of monitoring ballast and port waters (see Chapter 5).

INTERNATIONAL ACTIVITIES

In June 1991 the International Maritime Organization (IMO), a specialized agency of the United Nations (see Box 3-1), developed voluntary guidelines to prevent the introduction of unwanted aquatic organisms and pathogens through ships' ballast water and sediment. On November 4, 1993, Resolution A.774(18) was adopted by the 18th Assembly of IMO (IMO, 1993). By this resolution the Assembly requested member states to apply the voluntary guidelines to minimize the introduction of unwanted aquatic organisms and pathogens in ships' ballast water and sediment discharges.

The work of IMO is done by committees or subcommittees composed of representatives from member states. For conventions and amendments to conventions, a draft instrument is prepared. This draft is submitted to a conference to which delegations from all states within the United Nations—including states that are not IMO members—are invited. The conference adopts a final text that is submitted to governments for ratification. Implementation of the requirements of a convention is mandatory for countries that are party to the convention.

The first comprehensive anti-pollution convention that related directly to the reduction of intentional and accidental pollution by ships was the Protocol of 1978 relating to the International convention for the Prevention of Pollution from Ships, 1973. This convention, known as MARPOL, addresses pollution from oil,

|

BOX 3-1 International Maritime Organization (IMO) The IMO is a specialized agency of the United Nations, chartered in 1948 as the international body devoted exclusively to maritime matters. Since its inception, the improvement of maritime safety and the prevention of marine pollution have been the IMO's most important objectives. The IMO is an organization of member states made up principally of flag states, coastal states, and port states. To achieve its objectives, IMO has promoted the adoption of some 30 conventions and protocols in the past 30 years, and has adopted well over 700 codes and recommendations concerning maritime safety, the prevention of pollution, and related matters. |

chemicals and other harmful substances, garbage, and sewage. The MARPOL convention, which is currently in force internationally, comprises a set of annexes addressing ship pollution issues. Some of these annexes make reference to separate guidelines that provide detailed technical information. The guidelines can be updated to take advantage of technology developments and improved operating practices without revising the related annex.

The Marine Environment Protection Committee of IMO is currently drafting regulations for a new proposed annex to MARPOL 73/78 dealing with the ballast water issue. This annex, which will employ the guidelines strategy, will make use of the guidelines mandatory. The guidelines can be implemented by reference and will be continuously reviewed and updated to take into account improvements in methods for controlling ballast water. The annex probably will not be adopted before the turn of the century.

Codes and recommendations adopted by the IMO assembly are not binding on governments unless they are specifically adopted by reference in conventions and amendments to conventions. However, in many cases, the contents are incorporated into domestic legislation.

When the new MARPOL annex is in force, the ships of those member nations party to the convention will be required to use the guidelines to minimize the introduction of unwanted aquatic organisms and pathogens in ships' ballast water and sediment discharges. In view of the time it will likely take until MARPOL is amended, the United States has acted to stimulate use of the voluntary IMO guidelines by appending them to the U.S. Coast Guard Ballast Exchange Education Program guide for shipping agents in U.S. ports.

There is no international requirement for keeping a log of ballasting operations, other than on tankers where the oil pollution record book includes ballast

transfer as a measure to prevent oil pollution. However, an ongoing discussion at IMO on plans for managing ballast water might result in a requirement to maintain a log of ballasting operations. Meanwhile, international attention and coordination on ballast water monitoring and related research continues in forums other than IMO. For example, the first international scientific symposium on measures to reduce the risk of adverse effects arising from the introduction and transport of marine species by ships' ballast water was convened in September 1995 at Aalborghallen in Aalborg, Denmark, as a session of the International Council for the Exploration of the Sea (ICES) 83rd Statutory Meeting. The symposium was co-sponsored by IMO and the Intergovernmental Oceanographic Commission. Some major conclusions of the symposium, many of which parallel the work of the committee (see Chapter 6), identified requirements for international coordination of research efforts, continued research on practical control technologies, increased understanding of the environmental conditions influencing the survival of the diverse aquatic organisms carried in ballast water, and educational programs supporting the implementation of strategies for managing ballast water (ICES, in press).

NATIONAL ACTIVITIES

The United States, Canada, Australia, New Zealand, and Japan are also addressing ballast water control options and issues. Unilateral mandatory requirements for preventing introductions of harmful aquatic nonindigenous species from ballast water are currently in place for the Great Lakes and the Hudson River, Chile, and the port of Haifa in Israel. Following the introduction of Japanese dinoflagellates into its waters, Australia initiated extensive ballast-water studies and began to explore regulatory measures to establish guidelines for managing coastal ballast water.

In 1990, the U.S. Congress enacted P.L. 101-646 (the Nonindigenous Aquatic Nuisance Prevention and Control Act of 1990) aimed at preventing future introductions of harmful aquatic nonindigenous species and controlling existing unintentional introductions. The act contains five basic precepts: prevent unintentional introductions; coordinate research and information dissemination; develop and implement environmentally sound control methods; minimize economic and ecological impacts; and establish a research and technology program beneficial to state governments. The act tasked a new interagency aquatic nuisance species task force with facilitating implementation of these five precepts.

P.L. 101-646 called for mandatory regulations for managing ballast water for vessels that operate beyond the Canadian or U.S. exclusive economic zones (EEZ) and enter the Great Lakes. The act was amended in 1992 to extend the regulations to vessels operating beyond the EEZ that intended to visit a port on the Hudson River above the George Washington Bridge. These regulations (see Box 3-2) allow for alternatives to ballast water change as a control method.

|

BOX 3-2 U.S. Regulations for the Control of Nonindigenous Species in Ballast Water in the Great Lakes U.S. regulations implementing mandatory compliance with the Nonindigenous Aquatic Nuisance Prevention and Control Act of 1990 went into effect May 10, 1993. The U.S. Coast is the cognizant implementing authority within the United States. These regulations apply to all vessels that have operated outside the EEZ of the United States or Canada and that carry ballast and pass through Snell Lock at Massena, New York—regardless of other ports of call in the United States or Canada. Currently a master of any vessel to which these regulations apply has three options to choose from to comply with the requirements:

|

Several U.S. agencies have voluntarily heightened efforts to manage ballast water on a national scale. For example, the U.S. Navy has modeled its procedures for ballast water and anchor system sediment after the IMO guidelines. The Navy's procedures apply to U.S. Navy vessels worldwide (Chief of Naval Operations, 1994). The U.S. Coast Guard has taken steps to educate the shipping industry. The U.S. Coast Guard has also begun collecting basic information about whether ships inbound from foreign ports have plans for managing ballast water.

REGIONAL, STATE, AND LOCAL ACTIVITIES

There have been several regional approaches aimed at controlling introductions of aquatic nuisance species by ships' ballast operations, notably in the Great Lakes and Chesapeake Bay. Such initiatives are aimed at guiding those states that wish to cooperatively develop and implement regional plans for managing ballast water. These regional activities have involved a broad range of interest groups, including representatives from shipping ports; the scientific community; and

''No room at the intake." By Steve Lindstrom. Reprinted with permission from the Seaway Port Authority of Duluth.

regional, state, and federal governments. Cooperation has been achieved at a regional level outside of legal mandates. The committee judged such cooperation to be an important factor in addressing the problem of nonindigenous species transfer, which is not simply an issue for the shipping industry but has implications for society as a whole. Even if the Coast Guard is ultimately responsible for the implementation of guidelines and regulations, ports, terminal operators, and state authorities have a role to play in their development and in creating processes for their implementation.

Affected vessel owners, agents, ports, and government agencies cooperatively developed and implemented the Great Lakes Maritime Industry Voluntary Ballast Water Management Plan for the Control of Ruffe in Lake Superior Ports (Appendix E). This plan was designed to prevent the Eurasian Ruffe from infesting the lower Great Lakes through ballast water. The plan was implemented on March 18, 1993, to coincide with the opening of the 1993 shipping season. The states bordering Lake Superior have also instituted an aggressive public education campaign aimed at reducing the likelihood that the Ruffe will be spread by other means. Contingency plans have been developed in case the Ruffe becomes established in inland waters.7

In 1993, the Chesapeake Bay Program, a regional organization committed to the restoration of the Bay, adopted a policy that lays out framework of cooperative management approaches and public outreach efforts for introductions of aquatic nonindigenous species (Chesapeake Bay Commission, 1992). The policy guides the signatory parties of Maryland, Virginia, Pennsylvania, and the District of Columbia in the development and implementation of management plans for both intentional and unintentional introductions. The Chesapeake Bay Commission, a tri-state legislative commission serving the General Assemblies of Virginia,

Maryland, and Pennsylvania, also helps guide the states in cooperatively managing the Chesapeake Bay. To this end, the Commission convened a ballast water committee and issued a report setting forth a series of recommendations that could be adopted by individual states (Chesapeake Bay Commission, 1995).

Because federal regulatory response has been limited to the Great Lakes and Hudson River, some states have attempted to pass their own legislation or resolutions rather than wait for additional federal action. Four states (California, Washington, Hawaii, and Alaska) have pursued legislative efforts to regulate ballast water discharges, but none has been successful, either because of resistance in their own legislatures or anticipated legal challenges. As a general legal precept, state regulation may not pose undue burden on either interstate (domestic) commerce or enforce a maritime rule that interferes with the federal maritime jurisdiction (international obligations).

INTERNATIONAL FRAMEWORK FOR REGULATION

IMO is the international body under whose auspices international maritime pollution-control and safety agreements are developed. As noted above, the Marine Environment Protection Committee of IMO is currently drafting regulations for a new proposed annex to MARPOL 73/78 dealing with the ballast water issue. Such regulatory coordination by IMO has notable advantages over the introduction of unilateral legislation and regulations by individual nations or by individual states or port authorities.

The regulatory challenge of managing ballast water is heightened by the diversity both of vessels and their ballasting systems (see Chapter 2) and of shipping routes, ports, and associated ecosystems (see Chapter 1). Uniformity in operating procedures and training standards in accordance with a framework grounded in international law will reduce confusion and associated opportunities for human error and will promote safe and economic operation. In contrast, mandatory ballast water control measures at the port or regional level, in the absence of a governing international framework, would lead to a complicated patchwork of differing requirements, which would hinder compliance and effectiveness. Further, it is not clear from an ecological perspective that local controls on ballast water operations would be effective. For example, the closing of particular ports to shipping has been proposed as a possible control measure, despite the severe economic consequences. However, this approach would not be effective since coastal traffic and natural currents would disperse organisms to the closed port.

The above arguments militate strongly in favor of a coordinated, international approach to the development of a regulatory framework for managing ballast water. This approach does not preclude the subsequent introduction of more stringent local requirements that build on a basic, comprehensive international regulatory framework.

AUDITING REQUIREMENTS AND MONITORING

To be effective in practice, any ballast-water control mechanism must be capable of being audited or checked for compliance with standard procedures. Such auditing is an integral part of the process for managing ballast water. Auditing of vessel operations currently is conducted by the U.S. Coast Guard. There is no nationally accepted method for testing or monitoring ballast water and its movement from one location to another. Vessels entering the Great Lakes currently are monitored by measuring the salinity of their ballast water. One of the major impediments to the implementation of ballast water management strategies is the absence of appropriate, proven monitoring procedures. Whether a ship's operator selects onboard treatment or open-water ballast change, the quality of the ballast water arriving in port for discharge must be monitored to ensure that it meets appropriate standards. A reliable monitoring procedure is needed so that both ship operators and regulatory agencies can easily determine when ballast water may be safely discharged in certain regions of the world and when further treatment is necessary. Ultimately, the ship's master must be cognizant of the quality of all the ballast water on board.

Auditing ballast operations can take many forms, including requiring official log entries indicating where and when ballast was taken on board or discharged, what treatment methods, if any, were used, and so forth. Under ideal circumstances, boarding authorities would be trained and equipped to sample ballast water quickly and check it for compliance with standards. The ultimate aim would be to establish compliance-audit procedures applicable to all international and domestic vessels that carry significant quantities of ballast water on board. Such procedures should include both periodic and random inspections.

TRAINING

The introduction of new technologies and equipment for the control and monitoring of ballast water will need to be accompanied by suitable training of personnel, together with educational efforts to raise awareness of the nonindigenous species problem. Ships' officers and crews will need to be trained in the use of new procedures and the use and maintenance of new equipment for treating and monitoring ballast water. Not all candidate ballast water treatment technologies would require the same level of training (see Chapter 4). For example, many crews are already familiar with the operation and maintenance of filtration systems for engine cooling water, which are similar to systems that would be used to treat ballast water. Management and staff of shore-based treatment facilities will also require appropriate training, a will regulatory personnel charged with the administration of and compliance with ballast water guidelines.

RISK-BASED PERSPECTIVE ON MANAGING BALLAST WATER

The total prevention of unwanted introductions of nonindigenous aquatic species cannot be guaranteed. Totally sterilizing ballast water may never be

economically feasible or otherwise practical, but implementing a system of ballast water management and controls can reduce the probability that unwanted or harmful introductions will occur. Selecting the appropriate level of risk of introducing unwanted organisms has important implications for worldwide requirements for ballast water management and control.

Current guidelines for controlling introductions of nonindigenous aquatic nuisance species do not identify an acceptable level of risk. For example, avoiding ballasting in known "hot spots," in areas where the sediment content of the water column is high, at night, or at certain times of the year are crude but effective measures for managing risk by reducing the number of organisms loaded with ballast water. Although these measures may be effective, they are required or recommended on the basis of very limited knowledge about the risk of introductions. Therefore, the ecological effectiveness and economic efficiency of control measures cannot be quantified.

The fundamental question that remains to be addressed is what level of ballast water control is effective. Biological science cannot currently answer this question. The answer depends in part upon the receiving country's specific concerns about which potential introductions pose economic, ecological, human health, and other risks. In addition, it is not known how many individuals of a given species are needed to establish a viable, self-reproducing population at a new site. Even if this number were known, it would not be consistent from one receiving environment to another.

Issues such as these can be addressed by risk analysis. Risk analysis is used in many settings as a strategic tool for setting priorities and optimizing management and control measures. In the United States, for example, risk assessment is used to establish safe levels of exposure to carcinogens and other toxic chemicals. The Aquatic Nuisance Species Task Force is developing a generic risk analysis for nonindigenous aquatic organisms (Risk Assessment and Management Committee, 1995). In Australia, the coastal water guidelines working group is developing a voyage risk assessment and management process. The proposed risk-based approaches to managing ballast water use quantitative risk assessment methodology to combine a determination of the likelihood of introduction of a specified unwanted organism with an assessment of the economic and social impact resulting from the introduction (see Box 3-3). Lessons learned from successful efforts that use risk analysis as a strategic decision aid underscore the importance of standardizing methods and assuring that assumptions and methods are clear to all (NRC, 1994).

Even though detailed scientific information, such as species-specific data on probabilities of establishment, is generally lacking, risk analysis methodology can help decision makers in two ways. First, it can assist regulators in establishing appropriate levels of protection by helping them understand and balance technical, economic, and social factors. Second, when a specific organism is of concern, risk analysis methods can help evaluate alternatives and optimize the selected control strategy. Thus, a probabilistic risk analysis based on limited available

|

BOX 3-3 Theoretical Elements of Risk Assessment A risk assessment combines two components—the likelihood of an adverse event and the resulting consequence if the event occurs. These two major components are further divided into seven basic elements that serve to focus scientific, technical, and other relevant information into an assessment. In the case of introductions of nonindigenous aquatic organisms, the basic elements are as listed below (Orr, 1995). Group I: Assess Probability of Establishment8

Group II: Assess Consequences of Establishment

|

data (Englehardt, 1995) can be a useful indicator of cost-effective management strategies. Its principal value in decision-making is as a strategic tool, illuminating the dimensions of a problem and the implications of alternatives. As knowledge of the marine environment, potential threats, and control technologies improves, (making more extensive and reliable data available for risk assessments), risk analysis will become more accurate in establishing levels of protection and more effective as a planning aid and a decision-making tool.

REFERENCES

AQIS. 1993. Report No. 2: Shipping Ballast Water Trials on the Bulk Carrier M.V. Iron Whyalla. Report prepared for the Australian Quarantine and Inspection Service, Department of Primary Industries and Energy. Canberra: Australian Government Publishing Service.

Carlton, J.T., D.M. Reid, and H. van Leeuwen. 1995. The Role of Shipping in the Introduction of Nonindigenous Aquatic Organisms to the Coastal Waters of the United States (other than the Great Lakes) and an Analysis of Control Options. Washington, D.C.: U.S. Coast Guard and U.S. Department of Transportation, National Sea Grant College Program/Connecticut Sea Grant. USCG Report Number CG-D-11-95. NTIS Report Number AD-A294809.

Chesapeake Bay Commission. 1992. Chesapeake Bay Policy for the Introduction of Nonindigenous Aquatic Species. Annapolis, Maryland: Chesapeake Bay Commission.

Chesapeake Bay Commission. 1995. The Introduction of Nonindigenous Species to the Chesapeake Bay Via Ballast Water, January 5. Annapolis, Maryland: Chesapeake Bay Commission.

Chief of Naval Operations. 1994. Instruction 5090.1B, Section 19-10. Ship Ballast Water and Anchor System Sediment Control (November 1). Arlington, Virginia: Office of the Chief of Naval Operations.

Englehardt, J.D. 1995. Analysis of Risks of Nonindigenous Species Invasions. Presentation to the Committee on Ships' Ballast Operations, NRC Georgetown Facility, Washington, D.C., October 2, 1995.

ICES. (in press). Proceedings of the 1995 Annual Scientific Conference of the International Council for the Exploration of the Sea, held September 21–29, 1995 in Aalborg, Denmark .

IMO. 1993. Resolution A. 774(18), International Guidelines for Preventing the Introduction of Unwanted Aquatic Organisms and Pathogens from Ships' Ballast Water and Sediment Discharges. London: International Maritime Organization.

NRC. 1994. Building Consensus Through Risk Assessment and Management of the Department of Energy's Environmental Remediation Program. Commission to Review Risk Management in the Department of Energy's Environmental Remediation Program, National Research Council. Washington, D.C.: National Academy Press.

Orr, R.1995. The Proposed Nonindigenous Aquatic Organisms Risk Analysis Review Process. Presentation to the Committee on Ship's Ballast Operations, Irvine, California, February 7, 1995.

Rigby, G., and A. Taylor. 1994. Ocean Exchange of Ships' Ballast Water to Minimise the Transfer of Harmful Marine Organisms: Review of Research Work and Recommendations for the Use of Different Options. Report BHPR/ENV/R/94/015. Prepared for the Australian Quarantine and Inspection Service. Melbourne, Australia: Broken Hill Proprietary.

Risk Assessment and Management Committee. 1995. Draft Generic Nonindigenous Aquatic Organisms Risk Analysis Review Process. Risk Assessment and Management Committee, Aquatic Nuisance Species Task Force (July 10).

Transport Canada. 1995. Ballast Water Exchange Study, Phase I. Ottawa, Canada: Melville Shipping for Transport Canada Marine Regulatory Directorate.

Woodward, J.B., M.G. Parsons, and A.W. Troesch. 1992. Ship operational and safety aspects of ballast water exchange at sea. Marine Technology 31(4):315–326.