Appendix E

Abstracts of Invited Workshop and Poster Presentations

This appendix contains a collection of abstracts of individually authored background papers and posters that were presented at the May 13-15, 1996, Glass as a Waste Form and Vitrification Technology: An International Workshop, sponsored by the Board on Radioactive Waste Management of the National Research Council. These abstracts, intended solely for discussion at the workshop, have not been reviewed or approved by the National Research Council.

Contents

Invited Presentations

|

Mechanical Properties of the Waste Form Glass, |

||||

|

Radiation Effects in Glass Waste Forms, |

||||

|

Experience in Belgium, |

||||

|

Vitrification Experience in France—Development and Perspectives, |

||||

|

Experience in the United States: West Valley, New York, |

||||

|

Vitrification Experience of TVF in Japan, |

||||

|

Vitrification Experience in the UK, |

||||

|

Experiences with Vitrification HL W and Development of New Approaches in Russia, |

||||

|

Vitrification Experience in China, |

||||

|

Vitrification Experience at the Defense Waste Processing Facility (DWPF), |

Poster Presentations (Alphabetical, First Author)

|

Natural Glasses as Analogs for Nuclear Waste Glasses, |

||||

|

Alteration of Nuclear Waste Glasses Characterized by Radon Emanation Method, |

||||

|

DOE Regulatory Initiative For Vitrified Mixed Waste, |

||||

|

Stabilization of Plutonium in Hybrid Glass Materials Using a Cyclone Melter, |

||||

|

DOE Regulatory Initiative: Immobilized Mixed Debris Proposal, |

|

Reexamination of Variables Affecting the Hydration of Obsidians Using Empirical Chronological Data and Laboratory Induced Hydration Experiments, |

||||

|

A Plasma Arc-Vitreous Ceramic Process for Hazardous and Radioactive Waste Stabilization, |

||||

|

Direct Conversion of Metals, Ceramics, Amorphous Solids, Halogens, and Organics to Borosilicate Glass Using the GMODS Process, |

||||

|

Surface Layer Formation of the French SON68 Nuclear Waste Glass During Vapor Phase Alteration at 200° C, |

||||

|

Potential Application of Electron Spin Resonance to the Study of Radiation Effects in High-Level Nuclear Waste Disposal Glasses, |

||||

|

Leaching Behavior of Pu and Cm From Waste Glass Under Reducing Condition, |

||||

|

Glass and Glass-Ceramic Waste Forms Developed at the Idaho Chemical Processing Plant for Immobilizing HL W and Actinides, |

||||

|

Reproduction of Natural Corrosion by Accelerated Laboratory Testing Methods, |

||||

|

Colloid Formation During Waste Glass Corrosion, C. J. Mertz, E. C. Buck, |

||||

|

Use of DC Graphite Arc Melter Technology For Production of Stable Vitrified Waste Forms, |

||||

|

Hanford Low Level Waste Melter Tests, |

||||

|

Experimental Determination of Uranium Oxide Solubility in Hydrous Silicate Melts of Granitic Composition, |

||||

|

Mixture Models Versus Free Energy of Hydration Models for Waste Glass Durability, |

|

Microstuctures and Leach Rates of Glass-Ceramic Waste Forms for Immobilizing Plutionium and Associated Components, |

||||

|

Hot Isostatic Press (HIP) Vitrification of Radwaste Concretes, |

||||

|

Waste Glass Leaching During Open Site Tests, |

||||

|

In Situ Vitrification of Plutonium and Uranium Contaminated Buried Wastes: Microcompositional Analyses of Vitreous and Crystalline Phases and Corresponding Leach Test Results of the Vitrified Products, |

||||

|

The Interaction Between HL W Glass and Clay: Present Status and Future Programme, |

||||

|

Verification Studies on the Pamela High-Level Waste Glasses, |

||||

|

Synroc - An Alternative Waste Form, |

||||

|

Chemistry of Irradiated Solids, |

||||

|

CORAL US: In-Situ Corrosion Test on Active HLW Glass, |

Workshop on Glass as a Waste Form and Vitrification Technology

Washington, May 13-15, 1996, Washington, D. C.

Vitrification of Radioactive Waste: Past Accomplishments and Future Challenges

Werner Lutze

Center for Radioactive Waste Management (CeRaM) and Department of Chemical and Nuclear Engineering

The University of New Mexico

Albuquerque, NM 87131

Abstract

The history of vitrification of HLW is reviewed. The development of various vitrification technologies, pretreatment strategies, and the focus on two types of melters, the metallic and the ceramic melter, are explained. Various vitrification plants are in operation worldwide with France being the leader where three plants are in operation, AVM at Marcoule, R7, and T7 at La Hague. R7 and T7 are commercial plants. Another commercial vitrification plant, based on the French process, is in operation in Sellafield, England. Very recently, the first vitrification plant for defense waste was put into operation in the United States at the Department of Energy facility at Savannah River, S. C. Another vitrification plant in the U.S. will go into operation at West Valley Nuclear Services, N. Y. later this year. Experience with both melter types in hot operations (France, England and Germany) and lessons learned are highlighted. Research and development toward a new melter type, the cold crucible, is addressed and the potential advantages over existing melters are outlined. The main drivers for this effort are 1) significantly decreased melter corrosion and thus increased life time and operation safety, 2) greater flexibility in the melting temperature, and 3) greatly reduced contamination of the melter and less melter waste. For an overview of waste form development and vitrification technologies see reference 1 and for glass corrosion reference 2.

The development and selection of waste forms, glass vs. crystalline materials, is addressed and the selection criteria are discussed. Borosilicate glasses has become the most widely used waste form for high-level radioactive reprocessing waste for both defense and commercial waste. However, large quantities of high-level waste are immobilized in phosphate glass in Russia.

New glass waste forms are under development in the United States to vitrify and to dispose of surplus weapons plutonium and other waste streams high in actinides. Alternatively, a variety of ceramics is under investigation in Russia and in the United States.

Vitrified waste must meet certain waste acceptance criteria for disposal. These criteria are derived from glass properties measured in the laboratory. Glass properties are reviewed and the state of the art is presented. Glass properties are ranked in terms of significance for glass performance in the repository. Areas for further research, e.g., long-term radiation effects and long-term chemical durability and the use of natural glasses as analogs are pointed out. The dependence of glass performance on the geochemical (repository) environment is addressed.

Finally, areas of research on alternative glass processing are addressed, for example sub-liquidus processing. The wide variety of existing waste streams calls for various types of pretreatment prior to solidification. The choice of the waste form and the process to make the waste form are important considerations for the design of waste pretreatment procedures. Glass and the melting process are not always the best choice no matter how much experience has been acquired with vitrification. The limits for glass as a waste form are demonstrated using particular waste streams as examples.

References

1. Radioactive Waste Forms for the Future, W. Lutze and R. C. Ewing, eds., North Holland, Amsterdam 1988, 778p.

2. High-Level Waste Borosilicate Glass, A Compendium of Corrosion Characteristics, 3 volumes, DOE-EM-0177, 1994

OVERVIEW OF CURRENT DOE PLANS AND ACTIVITIES INVOLVING VITRIFICATION

Summary of Presentation to:

National Academy of Sciences Vitrification Workshop

by

Stephen P Cowan, U. S. Department of Energy

The Department of Energy must address the legacy of over fifty years of nuclear weapons research, development, and production. Wastes with varying levels of a broad range of radionuclides and hazardous chemical constituents must be managed to minimize: current risks to workers; future risks to the environment and potential surrounding populations; and the costs to the nation. Newly generated wastes, and wastes in storage, are the responsibility of the Office of Waste Management.

The fundamental problem the Department must address is that the wastes to be managed are not currently in the correct form or location for permanent isolation. Therefore, the waste must be treated. The question is: "What would be the ideal process for this treatment?". The ideal process would result in a reduced volume of waste in a stable, durable solid. The process should be relatively simple - suitable for remote operations in a radioactive environment, adaptable to a wide variety of feeds, and capable of destroying or immobilizing the hazardous constituents of concern as well as the radioactivity over the time period during which an unacceptable risk is posed. The vitrification process, and the glass waste form, are the best candidates the Department, and indeed other nations, have found.

A brief history: Beginning in the 1940's, the Manhattan Project scientists knew that tank storage of liquid wastes was a temporary measure.

The Atomic Energy Commission began examining immobilization and disposal options in the 1960's, and by the 1970's specific waste forms were being evaluated. Options examined included stabilizing the wastes in the tanks or making grout for underground injection beneath the sites where the wastes were stored. But the option that seemed consistently most appealing was the removal of the wastes from the tanks, separation of the high activity fraction from the low activity fraction, and immobilization of the high activity fraction in a stable, leach resistant form. Waste forms evaluated included concrete, a variety of glass formulations, and ceramics. Two criteria were of premier importance - the durability of the waste form and the simplicity of the process to enable remote operations in a radioactive environment.

Through a formal Departmental process, the Department selected borosilicate glass for high level waste immobilization. A number of vitrification processes for low level, mixed, and environmental restoration wastes are in various stages of evaluation, demonstration, or implementation.

Implementation of the vitrification waste form initially focused on high level waste (HLW) because it contains the largest inventory of curies. Of the four sites with HLW, the Savannah River Site has the most curies, followed by the waste stored at Hanford. The waste at both of these sites, as well as most of the volume at the West Valley site, is alkaline liquid stored in carbon steel tanks. The HLW at the Idaho National Engineering Laboratory is stored both as

an acidic liquid in stainless steel tanks and as calcined solids in stainless steel bins, with more than 90% of the radioactivity in the calcine. The total inventory of DOE HLW is approximately 950 million curies. Vitrification has been recognized by the Environmental Protection Agency as the "best demonstrated available technology" for HLW. Glass is also the waste form for immobilizing HLW in France, the United Kingdom, Belgium, and Japan.

The Defense Waste Processing Facility at the Savannah River Site, initiated radioactive activities on March 12, 1996; the first canister of radioactive glass is scheduled to be produced in the very near future. Initiation of radioactive activities at the West Valley Demonstration Project are imminent, with production of the first canister of radioactive glass scheduled for late June.

For the waste at the INEL, DOE is proposing a "Full Treatment Alternative" for integrating all the waste streams managed by the Office of Environmental Management. This alternative includes operation of a vitrification/ separations facility after 2017 which will process remote-handled transuranic waste, as well as the liquid HLW and the high-activity fraction of the calcine.

DOE is also planning to use vitrification technology for low level wastes at the Fernald site, Mound, and at Hanford. Wastewater treatment sludges containing both hazardous constituents and radioactivity (i.e., mixed wastes) will be vitrified for disposal at Oak Ridge, Los Alamos National Laboratory, the Rocky Flats Environmental Technology Site, and the Savannah River Site.

IDENTIFICATION AND SUMMARY CHARACTERIZATION OF MATERIALS POTENTIALLY REQUIRING VITRIFICATION1

Allen G. Croff

Oak Ridge National Laboratory2

The United States and many other nations have and continue to produce a wide variety of radioactive materials that are wastes or may otherwise be declared to be surplus and be managed as if they were wastes. In either case, it is commonplace to subject these materials to treatment processes to appropriately condition them for subsequent storage, transportation, and disposal. Less toxic wastes are generally accorded minimal treatment whereas highly toxic wastes are accorded extensive treatment. One of the more common treatment technologies applied to the more toxic end of the waste spectrum is vitrification. The purpose of this paper is to identify those materials that have some potential for vitrification and to summarize their characteristics as background for subsequent papers.

Identification of materials having some potential for vitrification begins by considering the broad categories of existing nuclear wastes or materials that may be declared surplus, which are listed in the first column of Table 1. Uranium mill tailings and enrichment plant tails are excluded because their large volume and low toxicity result in essentially no potential for vitrification.

The next three columns of Table 1 provide summary information concerning the inventory and/or production rate of the materials, the radioactivity density, and the power (radioactive heat) density. The densities can be viewed as crude measures of the toxicity of the material. The trend of these numbers reflects a longstanding paradigm for management of radioactive materials that results in the high radioactivity/power materials being concentrated in relatively small volumes and conversely for the low radioactivity/power materials. In general, as the volume of the materials increase, the practicality of applying advanced treatment technologies such as vitrification decreases. Further, as the radioactivity and power density of the material increases, the appropriateness of a process such as vitrification that yields a high-integrity product increases.

The fifth column of Table 1 provides a very brief description of the subject material. In some cases, the material is relatively uniform (e.g., LWR spent fuel, Cs/Sr capsules, surplus Pu). In other cases, the nature of the material in a waste category is extremely diverse ranging from liquids to soil to contaminated rabble to trash (e.g., transuranic waste, low-level waste).

The above considerations strongly affect the extent to which various material types or sub-types are considered to be candidates for vitrification. However, at least as important as the technical considerations given above are precedent, current Federal policies, and stakeholder views (e.g., agreements negotiated between a state and the U.S. Department of Energy). As a result, combining all of these to arrive at a conclusion of the vitrification potential of a particular material is subjective. The author's views concerning the vitrification potential of the material types and selected sub-types is given in the last column of Table 1.

TABLE 1. SUMMARY OF U.S. MATERIALS HAVING SOME POTENTIAL TO BE VITRIFIED

|

Material Type |

Volume, m3 or m3/yra |

Radioactivity Density, Ci/m3 |

Power Density, W/m3 |

Material Description |

Vitrification Possibilities |

|

1. Spent civilian nuclear fuel |

12000 |

10,000,000 |

50000 |

Light-water reactor spent fuel |

Unlikely unless required by repository |

|

2. DOE spent fuel |

1200 |

Not quantifiable; Moderate-to-high |

Not quantifiable; Moderate-to-high |

Variety of spent fuels |

Likely for Al-clad fuels, possible for others |

|

3. DOE "tank" wastes |

375000 |

1,000 - 10,000 |

5 - 50 |

Alkaline liquid, saltcake, sludge; calcine |

Highly likely for essentially all retrieved tank waste |

|

4. Capsules: Cs Sr |

3.5 1.1 |

23,000,000 21,000,000 |

115,000 140,000 |

Capsules of CsCl Capsules of SrF2 |

Likely if overpack is unacceptable |

|

5. Transuranic wastes |

|

|

|

Wide variety of materials with TRU >100 nCi/g |

Likely for only a small fraction unless WIPP-WAC change substantially |

|

Remotely handled |

2,500 + 14/yr |

1,000 |

1 - 2 |

|

|

|

Contact handled |

70,000 + 1500/yr |

25 - 50 |

0.5 - 1.5 |

|

|

|

6. Low-level radioactive waste |

|

|

|

Extremely wide variety of materials with <<100 nCi/g |

Likely for LLW from tank waste processing. Unlikely for most other LLW. |

|

DOE |

38,000/yr |

9 - 27 |

0.01 - 0.05 |

|

|

|

Commercial: Class A |

|

0.6 |

0.03 - 0.1 |

|

|

|

Commercial: Class B |

24,000/yb |

60 |

15 |

|

|

|

Commercial: Class C |

|

0.1 - 7,000 |

0.003 - 115 |

|

|

|

Commercial: > Class C |

63 + 20/yr |

>0.1 - high |

>0.003 - high |

|

|

|

7. Low-level mixed waste |

|

|

|

Extremely wide variety of materials with <100 nCi/g and hazardous chemicals |

Likely in selected applications, but extent is unpredictable |

|

Commercial |

2,100 |

Not quantifiable; low |

Not quantifiable; low |

|

|

|

DOE |

138,000 |

|

|

|

|

|

8. Surplus plutonium |

2 |

11,000,000 |

44,000 |

Plutonium metal shapes |

Either vitrification or irradiation will be used |

|

9. Environmental restoration |

78,000,000 |

Not quantifiable; low with small-volume exceptions |

Not quantifiable Low with small-volume exceptions |

Extremely wide variety of materials and contamination |

High-toxicity wastes and some in-situ are likely. Unlikely for the bulk of the waste. |

|

a Fixed values are existing volumes which are given where production has essentially ceased or where disposal rates are approximately equal to production rates. Rates are given where volumes continue to increase significantly. b Sum of annual production rates for Classes A, B, and C. |

|||||

Hanford Wastes and Glass Composition

Pavel Hrma, Pacific Northwest National Laboratory, MS P8-37, Box 999, Richland, WA 99352; PR_Hrma@PNL.GOV

Hanford Site high-level and low-level wastes (HLW and LLW) vary over a broad range of compositions. Vitrification of these wastes require the formulation of glasses that are chemically durable, processable by the melting technology available, and can achieve a minimum volume of vitrified waste (volume minimization can save $ 20 to 40 billion). This process entails producing acceptable glasses with both traditional (Na2O, Al2O3, ZrO2, Fe2O3) and unusual (P2O5, CeO2, Cr2O3, NiO) components at high concentrations that have not been attempted in commercial borosilicate systems. To achieve the minimum volume of the vitrified waste form, each step of the immobilization sequence, i.e., retrieval, pretreatment, blending, and melting, must be optimized with respect to glass formulation, which is the axial tool in the waste vitrification strategy.

Obtaining a minimum volume of waste glass translates into achieving a maximum waste loading (the mass fraction of non-volatile matter in the waste glass). The maximum waste loading is defined in terms of limiting values of key glass properties, which in turn are functions of glass composition. For glasses with maximum loading of Hanford Site wastes, the properties that limit waste loading are liquidus temperature and chemical durability. Available and demonstrated melting technology may impose a limit on melting temperature (the temperature at which glass viscosity is 5 Pa·s), but glass melting temperature does not limit waste loading per se.

The major components that limit waste loading for the Hanford Site tank wastes are Na2O, Fe2O3, Al2O3, ZrO2, P2O5, and Cr2O3. No fixed limiting concentrations of these components exist because glass properties are functions of the overall composition. When formulating the glass, its properties are adjusted by glass forming and modifying additives, namely SiO2, B2O3, Na2O, and Li2O. The task is to find an optimum mix of these additives that would enable the maximum concentration of the particular waste component that limits waste loading. Laboratory experiments have shown that waste loading as high as 80 wt% may be possible for the Hanford Site all-blend HLW (the vitrified product has a substantial fraction of crystallinity precipitated during cooling), while waste loading higher than 35 wt% is unlikely for the Hanford Site LLW.

Chemical durability is the ultimate intrinsic waste loading limitation, and, hence, the ultimate challenge to the glass formulation effort. Liquidus temperature limits waste loading in glass because most of the current continuous melters do not tolerate crystallinity; thus, this problem can be eliminated through melter development. Highly loaded HLW glass may contain a substantial fraction of crystalline phase, which does not impair durability. However, crystallization of nepheline or eucryptite during cooling weakens the glass structure by removing both aluminum and silicon from the glass network. This has a detrimental effect on glass durability and thus imposes a limit on the waste loading. Generation of other crystalline phases (e.g., spinel and zircon) or segregation of liquid phases (sulfate-phosphate-chromate) usually causes processing problems. Interestingly, though sulfate is not in sufficient concentrations m Hanford wastes to cause harm in itself, it may induce segregation of phosphates.

Formulation of Hanford waste glasses can be effectively achieved with the use of mathematical models that relate glass properties to glass composition. The model response functions are typically nonlinear because the effects of glass components on key glass properties are interactive. Therefore, the simplest form of the property-composition response functions is a second-order polynomial. Second-order empirical mixture models have been developed for viscosity, electrical conductivity, liquidus temperature, and chemical durability of Hanford

HLW glasses using statistically designed studies. These models span a broad region of composition, but are not yet fully sufficient for waste loading maximization because their original design was focused on glasses with low waste loading values (25 to 28 wt%) and low processing temperatures (1150°C).

Liquidus temperature is a property that is difficult to model because several primary crystalline phases appear in Hanford HLW glasses and each of these phases requires a special response function. This puts an extra demand on the amount of measured data required and brings a problem of determining which crystalline phase is primary for a given composition. The FACT model (Facility for the Analysis of Chemical Thermodynamics), which is semiempirical, successfully approaches these difficulties, but has not yet been developed enough to predict the primary phase and liquidus temperature with the required accuracy. Experiments are underway to improve the liquidus temperature database for more accurate model coefficients. Nepheline and eucryptite formation, which impairs durability, is even more difficult to predict because nonisothermal crystallization kinetics is involved in the process. Fortunately, promising results have been recently obtained in this area as well.

Hanford Site wastes are generally rich in sodium. The LLW contains approximately 80 wt% Na2O on the nonvolatile oxide basis, which limits waste loading to 25-40 wt%. Hanford HLW contains 20 to 30 wt% Na2O, the rest being mainly refractories. As the waste loading increases, refractory oxides precipitate forming crystalline phases while Na 2O accumulates in the residual glassy phase, which is at the same time depleted of SiO2, Al2O3, and ZrO2. Hence, both for Hanford HLW and LLW, the waste loading is ultimately limited by insufficient chemical durability due to high concentration of Na2O in glass.

Presently, Hanford HLW glass cannot be loaded to its maximum level determined by the chemical durability of the waste form because such glass may contain a substantial fraction of crystalline phase, a part of which may precipitate at a high temperature and thus may interfere with the operation of continuous melters. The rate of formation of the crystalline phase within continuous melters is strictly limited to ensure a sufficiently long melter campaign.

The major points to consider with regard to Hanford wastes and glasses are:

-

HLW glass processability is constrained by liquidus temperature, which increases with the fraction of refractory components in the glass.

-

The robustness of the glass structure deteriorates quickly when crystallization concentrates alkali oxides within the residual glass phase and removes glass stabilizing oxides, such as silica, alumina, and zirconia into crystalline phases.

-

Phase separation of a phosphate-rich liquid phase, which may or may not crystallize on cooling, constrains both glass processability and performance.

-

Glass crystallization and phase separation will be the major issue dominating HLW glass formulation in the future as long as the waste form volume minimization is targeted.

-

The main issue for the LLW glass is incorporation of a high level of sodium oxide into the glass structure without destroying its integrity.

ACCEPTANCE OF WASTE FOR DISPOSAL IN THE POTENTIAL UNTIED STATES REPOSITORY AT YUCCA MOUNTAIN, NEVADA

David Stahl

Framatome Cogema Fuels

Civilian Radioactive Waste Management System Management & Operating Contractor

Las Vegas, Nevada

INTRODUCTION

The Nuclear Waste Policy Act (NWPA) of 1982 (Public Law 97-425) established a national plan to develop a repository for the permanent disposal of high-level radioactive waste. The U.S. Department of Energy's (DOE) Office of Civilian Radioactive Waste Management (OCRWM) has the responsibility of developing the nation's first high-level waste (HLW) repository. HLW includes wastes — from defense and commercial reprocessing operations — that are encapsulated in borosilicate glass as well as spent nuclear fuel (SNF) from commercial power reactors. As described in the following paragraphs, the mix of fuel may be amended to include other DOE SNF. The U.S. Nuclear Regulatory Commission has the responsibility for promulgating the technical requirements necessary to license all phases of repository operation. The development of the repository has been delegated to the DOE's Yucca Mountain Site Characterization Project Office. Framatome Cogema Fuels (formerly B&W Fuel Company), as part of the Civilian Radioactive Waste Management System Management & Operating Contractor, is responsible for designing both the waste package and the engineered barrier system.

The goal of the DOE's Yucca Mountain Site Characterization Project is to characterize the Yucca Mountain site and design a potential geologic repository for the safe disposal of SNF and solidified HLW. Yucca Mountain is about 160 km northwest of Las Vegas, Nevada and consists mainly of compacted layers of volcanic ash flows (tuff). The repository horizon lies in the densely welded Topopah Spring member. Safe disposal of waste will rely on: the unsaturated nature of the Yucca Mountain site in which the flow of groundwater into the repository will be slow; a robust multi-barrier waste package that will remain intact for thousands of years; the slow mobilization of radionuclides from the waste forms; the retardation of radionuclides within the engineered barrier system; and the dispersion and mixing of radionuclides in the groundwater system below the repository.

WASTE ACCEPTANCE

The NWPA of 1982 limits the content of the first U.S. repository to 70 000 metric tons of heavy metal (MTHM) until a second repository is in operation. The DOE Mission Plan and Mission Plan Amendment (MPA) describe the implementation of the provisions of the NWPA for the waste management system. In the Draft 1988 MPA, the repository inventory was further broken down into about 63 000 MTHM of spent fuel and 7,000 MTHM of HLW glass. The current inventory of spent fuel located in storage at the reactor sites is about 30,000 MTHM and is expected to reach 40,000 MTHM by the year 2000. The HLW is currently anticipated to be borosilicate glass logs like those to be produced by Savannah River and West Valley. In response to a recent request from the Office of Environmental Management, OCRWM has agreed to revise its waste acceptance planning baseline to accommodate the potential substitution of DOE-owned spent fuel for some portion of the HLW glass, 7,000 MTHM defense-waste allocation, DOE-owned spent fuel proposed for geologic disposal includes types such as production reactor, research reactor, and U.S. navy.

The acceptance of waste into the waste management system is constrained by technical baseline requirements such as those delineated in the Waste Acceptance System Requirements Document (WA-SRD), DOE/RW-0351P Revision 1, March 1994. The requirements for the DOE-owned SNF have been collected in the Preliminary Requirements for the Disposition of DOE Spent Nuclear Fuel in a Deep Geologic Repository (December 1995). Future revisions to the waste acceptance requirements documentation will incorporate those requirements for the other waste forms. The WA-SRD currently picks up regulatory requirements from Title 10 of the Code of Federal Regulations. These include Part 60, Disposal of High-Level Radioactive Wastes in Geologic Repositories, Part 71, Packaging and Transportation of Radioactive Material, and Part 961, Standard Contract for Disposal of Spent Nuclear Fuel and/or High-Level Radioactive Waste. Other Title 10 regulations, DOE Executive Orders and other requirements are also included, the latter drawn from upper-tier system requirements documents or derived as a result of practice or analysis.

Particular Part 60 requirements of interest to waste acceptance include 60.135 that defines specific design criteria for the waste package and its components. These criteria include constraints on the general performance of the package, its chemical reactivity, and provisions for its handling and labeling, as well as design criteria for the waste form. Of relevance is the limitation of explosive, pyrophoric or chemically reactive materials that could compromise the ability of the waste packages to meet their containment and waste isolation requirements (identified in 60.112 and 60.113). In addition, 60.21(c)(1)(ii)(D) requires the comparative evaluation of alternative designs that would provide longer radionuclide containment and isolation. Another requirement of concern, defined in 60. 131(b)(7), is the assurance that criticality control is maintained during the period of waste isolation in the repository.

For commercial light-water reactor fuels and borosilicate glass HLW, waste form contribution to repository performance has been assessed through the use of computer models (total system performance assessment) and physical testing of spent fuel. To accommodate the acceptance and disposal of DOE-owned spent fuel, similar performance and compliance issues must be addressed through modeling and testing programs specifically oriented towards these materials.

To this end, the DOE Offices of Environmental Management and Civilian Radioactive Waste Management have established technical coordinating groups for both HLW and DOE-owned SNF which meet on a quarterly basis to monitor interface issues between these programs. The objectives if this coordination are to provide reasonable assurance that the disposal system will be able to accommodate the waste forms as designed and to craft resolution strategies for emerging technical issues.

SUMMARY

The process for the acceptance of waste into the waste management system is discussed, with detailed requirements identified from the Waste Acceptance System Requirements Document. Also described is the recently initiated issue resolution dialogue between OCRWM and the Office of Environmental Management, including the appropriate interpretation and application of regulatory and system requirements to DOE-owned spent nuclear fuel.

A Review of Status of Science of Vitrified Waste Form Development

George G. Wicks

Westinghouse Savannah River Technology Center

Aiken, SC 29802

As a result of more than three decades of study and evaluation, glass is the material of choice for incorporating and immobilizing potentially hazardous radionuclides found in high level radioactive wastes (HLW). It is also being considered for isolation of a variety of other hazardous waste types, both radioactive as well as non-radioactive. This includes vitrification of a variety of actinides resulting from clean-up operations and the legacy of the cold war as well as possible immobilization of weapons grade plutonium resulting from disarmament activities. Other types of wastes being considered for immobilization into glasses included transuranic wastes, mixed wastes, contaminated soils, asbestos, incinerator ashes, medical wastes, electronic circuitry, weapons parts, and a variety of other potential hazardous materials and components.

There are many factors which contribute to the suitability of glasses for immobilization of these wastes. In general, these considerations fall into two major technical categories. First, involves PROCESSING CONSIDERATIONS, which include the ease of being able to produce waste forms, routinely and reproducibly, even under difficult remote conditions if necessary, and second, the TECHNICAL PERFORMANCE FEATURES of the final solidified forms. Technical performance features include good waste form performance in five major areas of interest; (a) flexibility/ waste compatibility (b) mechanical integrity, (c)thermal stability, (d) radiation effects and (e) chemical durability. Chemical durability is generally considered as the most important technical property of the final waste form. There are also other important considerations of a less technical nature such as immediacy of implementation, use of existing resources, including experience, expertise and facilities, and also, the economics of the effort. Consideration of all these factors are essential in the development of high integrity, cost-effective waste forms and subsequent systems designed to manage or permanently dispose of the hazardous materials.

Using an interdisciplinary approach and building upon the experience and knowledge of classical glass science, complex borosilicate glass systems have been developed which have successfully immobilized the more than 40 elements contained within HLW as well as the large fluctuations in waste composition that can exist. This technology has now become the cornerstone of our understanding of fabrication and

performance of nuclear waste glasses as well as for vitrification of a variety of other waste systems. Significant contributions to the science of waste form development have come from many sources, including academia, industry, federal and national laboratories, and international cooperative programs. Over the past years, many hundreds of papers have been published in this field which has advanced our understanding and confidence of the waste glass systems and further defined important new areas for research. It will be the objective of this presentation to review the status and science of waste glass forms. This will be undertaken by first, providing a brief historical background into the subject, while emphasizing the U.S. HLW program and development of HLW waste glasses. Next, an overview will be given of key properties of the waste glass forms along with examples of both important and interesting data. More detailed technical discussions will be provided in each of these technical areas by experts in subsequent presentations. Finally, some key properties of waste glass systems will be related to the structure of glass and a correlation will be given which ties together the many different HLW glass systems developed world-wide.

Leach Tests and Chemical Durability

Robert H. Doremus*

Rensselaer Poly. Inst.

Troy, NY 12180

Experimental tests of the rate of reaction of water with glass allow one to judge the relative durability of different glass compositions and to predict the long term stability of encapsulants of radioactive materials. In this discussion steps in the reaction of water with glass are first described, and then methods of analyzing for the effects of this reaction are considered. Then the types of leach tests are listed and compared. Finally some results of tests of durability of different glass compositions are described.

In liquid water, there are at least three different processes taking place during reaction with silicate glasses. The mobile alkali ions in the glass exchange with hydronium (H3O+) ions from the water. The result is a surface layer depleted in alkali ions and containing H3O+ ions. When the glass is removed from the water, water molecules from decomposition of the H3O+ ions can diffuse from the glass or ''outgas.'' The exchanged alkali ions form alkali hydroxide in the liquid water. 2. The glass dissolves in the water. Silicon-oxygen bonds are broken in the glass to form SiOH groups, and finally H4SiO 4, silicic acid, dissolves in the water, as well as the other oxide constituents of the glass. 3. Surface layers form by precipitation of substances from the water, or from reaction of ions in solution with glass components at its surface. If the glass is reacting with water vapor rather than liquid water, processes 1 and 3 above are possible. The product of ion exchange is, for example, sodium hydroxide, which reacts with carbon dioxide in the atmosphere to form solid sodium carbonate, which remains on the glass surface. A variety of other compounds can also form on the glass surface in a vapor test, depending on the glass composition and temperature.

To analyze the results of these processes a variety of tests are possible. Measuring the weight change of the glass was the first method used to follow reaction of water with glass, and in carefully controlled tests this method gives valuable information. Chemical analysis of solution constituents as reaction progresses is the most common method of following leach tests in liquid water. Analysis of the constituents on the glass surface, and profiles of elements into the glass, are possible by a variety of modern techniques, such as electron microscopy, diffraction, nuclear analysis (Rutherford backscattering, RBS, and resonant nuclear reactions), electron microprobe, and secondary ion mass spectrometry (SIMS). The choice of methods requires care, to be certain that the information needed can be deduced from the analyses.

The way in which a leach test is carried out can have a large influence on the results. The rates of the processes described above depend on the following variables at least: temperature, solution concentrations, especially pH, glass composition, flow in the liquid, and relative humidity in a vapor test. To obtain reliable results that can be used to model the prognosis of the reaction and understand mechanisms, these variables must be controlled, as described by Dr. Bourcier. A static test in which solution conditions are allowed to wander is a poor test for comparing glass compositions and predicting long-term durability; for example, in such a test pH can increase to a maximum and then decrease. Repository conditions can vary widely, and a static test is not a model for most of them.

Ion exchange results in a hydrated surface layer on silicate glasses. In more durable glasses the surface structure remains the same as in the dry glass, with consequent low mobilities of ions and molecular water in the hydrated layer. In tests in which solution conditions are held constant, for example at pH7, there is a wide difference in rates of dissolution of different glasses. The sequence of selected

compositions is, most durable first: Obsidian < fused silica and soda-lime with 2% alumina < Pyrex borosilicate < commercial soda-lime without alumina < high soda soda-lime < binary soda-silicate. As the amount of silicic acid dissolved in the water is increased, the rate of dissolution decreases. Silicate glasses dissolve more rapidly as the pH is increased above 7.

These results show that there is a large potential for increasing the durability of glasses for encapsulating radioactive waste.

References:

1. D.E. Clark and B.K. Zoites, eds., "Corrosion of Glass, Ceramics and Ceramic Superconductors," Noyes Pub., Park Ridge, NJ, 1992.

2. R.H. Doremus, "Glass Science," 2nd ed., Wiley, New York, 1994, Chpt. 13.

3. G. Perera, R.H. Doremus, and W.A. Lanford, J. Am. Cer. Soc. 74, 1269 (1991).

4. H.H. Dunken, "Physikalische Chemie der Glasöberflache," VEB Deutscher Verlag für Grundstoffindustrie, Leipzig, Germany, 1981.

Status of Vitrification Technologies

M. J. Plodinec

Westinghouse Savannah River Company

P. O. Box 616

Aiken SC 29802

ABSTRACT

Vitrification (here defined as any thermal technology which produces a vitreous product) is internationally accepted as the technology of choice for the immobilization of highly toxic radioactive waste. The French, British, Japanes, and Belgians are all operating vitrification plants for high level nuclear waste (HLW). In the US, the Defense Waste Processing Facility (DWPF) recently began radioactive operations on the HLW stored at Savannah River. The US Environmental Protection Agency has declared vitrification to be the "Best Demonstrated Available Technology" for the treatment of HLW.

Vitrification has been widely accepted for several reasons. The glass waste form is very tolerant of chemical variability; as a result, nearly all of the hazardous radionuclides (the most important exception is tritium) can be captured in glass. The waste form itself is robust, and has stood up well to extended testing in geologic conditions, even at elevated temperatures. In general, vitrification of toxic wastes greatly reduces the volume of material which may have to be transported, stored and placed in final disposal. Since glassmaking has been carried out for over two thousand years, the processing technology is reliable and relatively well-understood.

However, vitrification is not just a single technology, but rather a family of technologies. The main branches are differentiated by the method of heating to melt materials to form a glass. For example, bushing melters use metal screens as electrical resistance elements which heat chemicals to form a molten glass. Joule-heated melters are heated by passing a current through the glass. Plasma torch melters use torches to generate extremely high temperatures. Combustion melters burn fuels to generate heat. Graphite arc furnaces generate heat by a spark passing from a graphite electrode to either the material to be melted or another electrode. High frequency melters use either microwave energy or induction heating to form a melt.

Each of these is compatible with some types of wastes or other materials to be vitrified; none of these is compatible with all such materials. Compatibility with a particular type of waste must be judged in terms of several factors, which may include

-

Amount of characterization needed.

-

Amount of feed preparation needed.

-

Reduction of volume compared to starting material.

-

Corrosion and erosion of the melter and downstream process vessels.

-

Capability to be operated and maintained remotely.

-

Costs of facility and of operation.

-

Upstream processing.

For each application of vitrification technology, production of an acceptable waste form is

of paramount importance. This can be assured either through exhaustive characterization of materials (e.g., of waste feeds) prior to processing, or through characterization of the final product DOE has found that both paths can be followed. For HLW, extensive characterization of the waste is needed to ensure reliable processing. In this case, the processing information is sufficient to ensure that a durable glass product will be made. Conversely, the cost and risks associated with handling highly radioactive glass samples are high. While after-the-fact sampling can determine whether a given glass sample is acceptable, it would then require recycle of any unacceptable glass produced. Thus, HLW glass producers in the US are relying on feed characterization and process control to ensure production of an acceptable glass.

For LLW, or other heterogeneous materials, product sampling may be more cost-effective. Waste characterization is much more difficult than for HLW. Handling of the product samples is often almost trivial, and may provide a more representative view of the final product than feed sampling.

The probability of identifying an unacceptable product as acceptable through direct product sampling should be quite low. With a properly executed process control program, the probability of producing an unacceptable product through characterization of feed material is also quite low. As an example, during the Waste Qualification Runs in the DWPF, the feed was intentionally varied over the full range of waste types which are expected to be processed. Changes in composition were accomplished much more abruptly than is likely to occur in actual production, providing a strenuous test of the DWPF product control system. Each of the canisters of simulated waste glass produced was destructively examined, and the results compared to the specifications for the glass product. The results were outstanding — all of the glass samples tested were far below the acceptance limit, and there was greater than 99% confidence that more than 99.9% of the glass produced was acceptable.

Based on this experience, there is great confidence that vitrification technologies employed in a production setting will successfully produce glass products which will effectively immobilize hazardous species. The keys to this success will be selection of melters based on compatibility with the feed material, and application of product control programs which will ensure reliable production of acceptable products.

THE CHEMISTRY AND KINETICS OF WASTE GLASS CORROSION

John K. Bates, Chemical Technology Division, ARGONNE NATIONAL LABORATORY, Argonne, IL 60439-4837, bates@cmt.anl.gov

Under repository disposal conditions, the reaction of glass with water comprises the source term for release of radionuclides to the near-field environment. An understanding of glass reaction and the manner by which radionuclides are released is needed to design the waste package and to evaluate the total performance of the repository. The ASTM Standard C-1174-91 [1] provides a general methodology for obtaining information related to the behavior of glass. This paper reviews the application of this standard to glass reaction.

In the first step in the ASTM approach, the researcher identifies the materials and the conditions under which the long-term behavior is to be determined. Neither of these factors is easily defined, yet the successful evaluation of glass behavior requires estimates of each in order to proceed. Glass compositions have undergone a genesis over the past 15 years in response to concerns about feed streams, processing, and durability. A range of borosilicate compositions has been identified [2], but as new applications for vitrification occur, for example, immobilization of weapons plutonium and residue from plutonium processing, different compositions must be evaluated. The repository environment depends on the spatial emplacement of waste containers (glass and spent fuel) [3], and both "hot" and "cold" scenarios have been proposed for the Yucca Mountain site. Regardless of the exact configuration, the near-field hydrology is expected to be unsaturated: that is, the waste packages are contacted initially by water vapor, and ultimately by small amounts of dripping or standing water. The behavior of glass can be studied as a function of composition within the constraints the environmental conditions place on the physical parameters that affect glass reaction (temperature, radiation field, groundwater composition, etc.).

In the second step, the researcher reviews the literature and proposes a reaction pathway by which glass reacts in an unsaturated environment. This allows bounding ranges of important physical parameters to be established so that the effect of each parameter on the anticipated alteration process can be established. A reaction pathway for glass is proposed that divides glass reaction into three stages. In a thermodynamic sense, the reaction of glass with water proceeds to minimize the free energy of the system and also to minimize the chemical potential gradients between the solution and the glass. When the gradients are steep, particularly for major glass-forming components such as SiO2, the rate of reaction will be relatively high, whereas when the gradients are comparatively shallow, the rate of reaction will be relatively low. The slope of the chemical potential gradients and the energy required to extract the rate-limiting component from the surface of the glass are controlling factors in determining the rate of glass corrosion. The chemical potential gradients between the glass and water are initially large (Stage I) because the leachant is dilute, and the reaction proceeds at the forward rate. As the silicic acid concentration in solution increases, the chemical potential gradient decreases (Stage II). Glass reaction during Stages I and II usually results in the formation of a reacted layer, which may or may not be crystalline, but does not result in an increase in the glass reaction rate. However, the glass is unstable with respect to certain alteration phases that nucleate during corrosion. These phases will serve as sinks for key glass forming elements such as Si, Al, and Ca. When this occurs, the rate of glass corrosion is controlled not by the chemical potential gradient between glass and solution, but by the gradient between the glass and alteration phases. This, in turn, may accelerate the rate of glass corrosion (Stage III).

Working from the proposed reaction pathway, the researcher develops modeling and testing approaches in concert. Modeling is used to calculate the behavior of glass for long

time periods, while tests provide information regarding the mechanism of reaction and are used to validate and confirm the models.

When evaluating glass corrosion under conditions relevant to the Yucca Mountain repository, it is found that the reaction of glass in a humid environment can result in Stage III reaction because of the high ratio between the surface area of the glass and the volume of water (S/V). Tests conducted above 100°C are used to accelerate the corrosion, give a qualitative indication of the tendency of a glass to reach Stage III, and to determine the distribution of radionuclides among alteration phases. Tests done at lower temperatures confirm the application of the accelerated tests, and provide information on the rate of reaction under in-service conditions provided the duration of the tests is sufficiently long. Glass reaction in a humid environment alters the glass, but radionuclide release can occur only through thin-film diffusion.

Tests done with standing and dripping water conditions provide additional information regarding glass reaction and the distribution of radionuclides. Tests with standing water yield information about all stages. Tests performed at low S/V for short periods may be used to estimate Stage I reaction. If the S/V is increased, or the period is extended, Stage II may be observed and the reaction rate may typically decrease by about a factor of 100. performing the tests for even longer time periods or at higher S/V may result in Stage III behavior depending on the glass composition., and the reaction rate increases from the Stage II rate up to the forward rate at the solution condition. Static tests that reach Stage HI yield the same alteration phases as vapor tests when performed with the same glass. The distribution of radionuclides between the solution, glass, and other waste package components depends on the solution chemistry and whether the radionuclides are associated with colloidal phases that form as the glass reacts.

In the dripping water mode, the reaction progress depends on the rate of water contact. At an exposure of about 16 mL/d/m2 (an upper bound for water contact), as-cast glass forms a clay layer which spalls from the glass surface. As a result, the radionuclide release is dominated by a colloidal fraction, and the reaction remains between Stages I and II. If the test is done such that the dripping water contacts glass that was previously reacted in a humid environment—a likely repository scenario—the radionuclides are released initially as soluble species, which can be correlated with the large anionic content of the leachate. However, with time, the colloidal Content of the solution increases. The condition of the glass when finally contacted by water plays an important role in determining the source term for performance assessment calculations and in designing a waste package to retard radionuclide transport.

REFERENCES

1. American Society for Testing and Materials (1991) "Standard Practice for Prediction of the Long-Term Behavior of Waste Package Materials Including Waste Forms Used in the Geologic Disposal of High-Level Nuclear Waste," ASTM C-1174-91.

2. Westinghouse Savannah River Company (1993) "DWPF Waste Form Compliance Plan (U)," Savannah River report WSRC-IM-91-0, Rev. 2.

3. Buscheck, T. (1996) "Localized Dry-Out: An Approach for Managing the Thermal-Hydrological Effects of Decay Heat at Yucca Mountain," Mater. Res. Soc. Symp. Proc. Vol. 412, pp. 715-722.

This work is supported by the U.S. Department of Energy, Office of Environmental Management, under contract W-31-109-ENG-38.

Waste Glass Leaching and Long-Term Modeling

W. L. Bourcier

Lawrence Livermore National Laboratory

The important processes which take place during glass dissolution have been identified and coupled into models that are used to make predictions of glass dissolution rates. These coupled models of hydration, surface dissolution, ion exchange, and alteration mineral formation have been satisfactory in predicting glass dissolution rates over laboratory time frames. Using these models, it appears to be possible at present to place conservative bounds on long-term rates of glass corrosion and radionuclide release. However, further refinement of these models and increased accuracy of our long-term release rate predictions depend on additional work in the following areas.

We currently lack a clear mechanistic understanding of the controls on long-term glass reaction rates under near-saturation conditions, characteristic of long time periods. Our models reflect this uncertainty in their use of parameters which fix the long-term dissolution rate at some arbitrary or experimentally determined value. Because of this deficiency, the only justifiable conservative assumption is that of assuming the relatively rapid short-term rate continues over long time periods. For typical borosilicate waste glasses, such rates are generally slightly higher than the current regulation of one part in 10^5 release per year.

Few experiments have addressed this issue. Typical process control tests of glass durability are brief, complex, and difficult to interpret in terms of an analysis of rate control by multiple competing processes. Similarly, experiments that have addressed this issue indicate that long-term rates are not simple functions of silica saturation. Other factors besides or in addition to silica saturation control dissolution rates (Petit and others, 1990). There is currently a small body of empirical data on the effects of dissolved metal species on glass dissolution rates. Metals such as Mg and Pb are known to enhance glass durability, metals such as Fe and Al may degrade glass durability. In addition, glass dissolution rates are affected by solution ionic strength. Pure silica glass dissolves four times faster in 1 molal NaCl solution than in 0.01 molal NaCl solutions. Recent data on the effects of surface layers suggest they may be partially protective (Xing, Buechele, and Pegg, 1994), whereas most models assume they give rise to no slowing in corrosion rate. Many such second order effects on rates of dissolution remain to be sorted out and quantified before the existing test data can be adequately reconciled and understood.

In order to reconcile a large body of test data on glass corrosion rates, and in so doing resolve the mechanistic controls on the long-term dissolution rates, some carefully defined experimental work is needed. First, a matrix of dissolution tests of simplified glass compositions under controlled conditions are needed to separate out dissolution rate control due to saturation (affinity control), pH, ion exchange, and the effect of surface adsorption of dissolved species. It must be possible to extract from these tests the rates of each of these processes and their functional dependence on test parameters such as temperature, glass composition, and in the case of adsorbed species, the concentration of these species in

solution. Modeling is then needed to couple these mechanisms and rate dependencies to make predictions of long-term dissolution rates. A comparison of predicted versus experimentally measured rates can be used to refine or redefine the model in an iterative process. Previously identified high SA/V and vapor hydration tests provide the best indications of long-term dissolution rates.

This experimental and modeling program should be accompanied by additional work aimed at understanding glass dissolution on a molecular level. This work should identify the rate-limiting step in surface hydrolysis, the structure of the activated complex, and its dependence on surface charge (pH). This type of work is currently being performed for simple crystalline oxide and silicate phases using molecular orbital calculations of the mineral/solution interface structure. Application of this existing methodology should readily extend to oxide glasses.

There is still no glass structure model that adequately explains observed glass composition-durability relations. We cannot yet accurately relate a glass composition to its short-term durability in different types of durability tests. It is clear however that this is a difficult relationship to quantify and must follow the identification of the long-term rate controlling mechanism, as well as better information on glass structure. More fundamental work on the structures of simplified water-glass compositions using NMR and Raman and other types of spectroscopies is needed.

Finally, thermodynamically based glass leaching models are acutely dependent on the thermodynamic database used to calculate the saturation states of alteration minerals. We still lack an adequate thermodynamic database for many of the radionuclide and stable elements contained in the glass. We also lack a comprehensive database for activity coefficients for ionic species in waters having ionic strengths beyond 0.1 molal. No glass leaching model can ever be used with confidence to make long-term predictions of glass durability without this foundation of thermodynamic data, a foundation that is still lacking.

Petit, J. C., Magonthier, M. C., Dran, J. C., and Della Mea, G., 1990, Long-term dissolution rate of nuclear glasses in confined environments: does a residual chemical affinity exist? Journal of Material Sciences, v. 25, p. 3048-3052.

Xing, S.-B., Buechele, A., and Pegg, I. L., 1994, Effect of surface layers on the dissolution of nuclear waste glasses: Materials Research Society Symposium Proceedings, v. 333, p. 541-548.

Author's e-mail address: BILLB@LLNL.GOV

Waste Glass Leaching and Long-Term Durability

Etienne Y. Vernaz

Commissariat à l'Energie Atomique (CEA)

Rhône Valley Research Center

BP 171, 30207 Bagnols-sur-Cèze Cedex, France

The long-term durability of radioactive waste glass will be assessed by modeling. A strict methodology is necessary to develop a predictive model valid over long time periods, and may be summarized as follows:

-

Begin with a satisfactory material specification and characterization.

-

Identify and study the mechanisms of glass alteration by water (this requires comprehensive knowledge of the mechanisms involved in the long-term alteration of glass containment properties and their kinetics).

-

Determine the effects of various repository concepts and allow for all relevant environmental conditions (pH, Eh, flow rate, effect of container materials, host rock, groundwater composition, etc.).

-

Develop a glass alteration model applicable to a geological repository environment with the objective of modeling the alteration kinetics of the glass package in order to assess the performance of the waste form itself as the primary containment barrier.

-

Assess the release mechanisms of individual radionuclides and determine kinetic control by solubility, sorption or coprecipitation.

-

Obtain a "glass source term" for incorporation in the general codes that take into account migration and transport to the biosphere for safety purposes.

-

Validate the models by dedicated experiments (highly radioactive samples, full-scale tests, in situ tests, comparison With natural analogs, etc.).

This paper reviews the state of the art of each of these points, with a focus on long-term glass alteration mechanisms.

The French PREDIVER code integrates the principal alteration mechanisms to estimate the glass lifetime under realistic repository conditions. The code will be presented and some estimates will be given in a granitic environment. Under the disposal conditions expected in France, the lifetime of an R7T7-type reference glass package may be estimated as 107 years, and appreciably longer if the gel conserves its protective effect over the long term.

The following essential scientific issues remain to be addressed to improve the degree of confidence in long-term predictions:

What is the validity of the first-order law?

The "first-order" law ![]() where r0 is the initial glass dissolution rate in pure water and

where r0 is the initial glass dissolution rate in pure water and ![]() the affinity term, is used in PREDIVER as in most other nuclear glass alteration models. However, this law cannot account for certain experimental situations - notably with many clays - and there is not always an unequivocal relation between the silicon concentration (or the H4SiO4 concentration) and the alteration rate. For example, flowing experiments with a silicon-rich leachate show that the glass alteration rate increases with the flow rate even when the silicon

the affinity term, is used in PREDIVER as in most other nuclear glass alteration models. However, this law cannot account for certain experimental situations - notably with many clays - and there is not always an unequivocal relation between the silicon concentration (or the H4SiO4 concentration) and the alteration rate. For example, flowing experiments with a silicon-rich leachate show that the glass alteration rate increases with the flow rate even when the silicon

concentration in the leachate remains constant. This result indicates that other species than Si are involved in the kinetically limiting surface reaction. The role of aluminum has been established, but it may also be necessary to take into account other glass network-forming elements (e.g., Zr, the rare earths and perhaps Fe) in the network hydrolysis reaction. A more general rate equation would be necessary to describe nuclear waste glass alteration in any environment.

Nevertheless, we consider that the first-order law remains a justified approximation in many environments (including pure water, granite, salt or silica-saturated clay) where elements other than silicon (A1, Zr, the rare earths, etc.) quickly reach constant concentrations imposed by the low solubility of the hydroxides, clays or the surface gel.

Is there a "residual affinity"?

The first-order law predicts that under saturation conditions the alteration rate will drop to zero. This is not in contradiction with the very low alteration rates measured in the laboratory for the French R7T7 glass under "saturation conditions":

-

A "final" rate of less than one ten-thousandth of the initial rate has been observed, corresponding to better than 99.99% saturation.

-

The low "final" rates observed in pure water may generally be explained by a slight drift in the pH, increasing the apparent solubility of the glass.

-

It has been established that for a large number of glass compositions this "residual" rate is not constant, but diminishes as the product increases. This variation with the square root of time reflects the fact that interdiffusion again becomes the predominant mechanism when hydrolysis of the glass network ceases as saturation conditions are reached.

We consider the investigation of the "residual rate" to be irrelevant. The important phenomena affecting long-term glass behavior are those liable to retard (sorption) or even prevent (precipitation) saturation conditions from occurring with respect to the glass. In this regard, the choice of engineered barrier materials is decisive. The role of secondary phase precipitation on the long-term rate of glass alteration and on the retention of radionuclides must be determined for each scenario. This issue cannot be addressed in general terms: it is site-specific, and depends on the backfilling and the glass composition.

What are the long-term properties of the gel layer?

Experiments with pre-leached glass specimens have shown that the protective role of the gel depends to a greater extent on the conditions under which it was formed than on its thickness. A very thin gel formed under silica saturation conditions may provide much greater protection than a thick gel obtained in a dilute medium, at a low S/V ratio or with high flow rates.

The long-term behavior of the gel layer must be assessed by investigating natural analogs and by performing specific experiments. If it can be demonstrated that this layer conserves its transport properties over the long term, the predicted glass lifetime will be increased by about three orders of magnitude. If it can be demonstrated that this layer conserves its sorption properties over the long term for most actinides, the "glass source term" will be several orders of magnitude lower than the one predicted from glass alteration.

Corrosion Behavior of Glass: Remaining Scientific Issues

B. Grambow, Forschungszentrum Karlsruhe,

Abstract

We must address the current state of understanding of nuclear waste glass corrosion and the remaining scientific issues in the context of the needs to reliably assess the role and long-term performance of glass within the multibarrier containment system of the repository. During the last decades significant efforts and progress were made, and glass/water interactions belong now to the best studied solid/water systems. The clear result of these studies is that glass corrosion resistance is not an inherent materials property but depends on its disposal conditions. Do we know sufficiently to accurately predict its long-term behavior under realistic disposal conditions? The answer is: No, an accurate prediction is not possible. Every natural hydrogeological location is already undisturbed extremely complex and the introduction of the various engineered barrier materials multiplies potential synergetic effects and unforeseen evolution scenarios. The answer may be different if we allow for certain acceptable bounds of uncertainty. What is ,,acceptable'' will depend on the overall systems performance assessment. In most current repository performance assessments worldwide the effect of glass as a barrier is masked by the geological barrier or by other engineered barriers (bentonite, etc.). Do we now understand glass corrosion better to reassess the isolation potential of glass as a waste form? Let us see.

(1) General glass dissolution phenomena

The reaction path and rates of glass in aqueous repository environments as well as the associated radionuclide chemistry are governed by a combination of thermodynamic and kinetic factors. Today we know probably most of the main solid glass alteration products such as the initial gel phase, clay minerals, zeolites or metal oxide hydrates. Their occurrence and composition as well as the geochemical evolution (pH, etc.) of the ionic composition of the contacting groundwater can be predicted fairly realistically using geochemical codes, for saline environments as well as for granite water, tuff pore waters, etc. Some uncertainty rests with respect to the formation of borate containing phases at extremely high reaction progress (large glass/water ratios). The geochemical evolution of the near field caused by interactions with engineered barrier materials also can be predicted with some confidence and in certain bounds of uncertainty.) or the alteration products of container materials (e.g. magnetite in case of iron). However, only premature experimental and modeling experience exists for taking into account synergetic effects. Also, it is not yet possible to include radiolysis in an integrated geochemical model of glass dissolution under near field conditions. This is very critical, as the solution Eh may depend on it.

With respect to reaction rates, affinity based rate laws are now generally accepted for the initial dissolution process until ,,saturation'' has been achieved. Dissolved silica plays a key role in controlling the dissolution affinity, but Al, Fe, etc. may contribute. This ,,saturation process" is a safety relevant glass characteristics as reaction rates decrease afterwards by some orders of magnitude. Caused by silica sorption on near field materials (clay or iron corrosion products) the time to reach saturation may in some cases be quite long. Little is know on the various parameters that control this period. After saturation, the rate slows down, controlled either by resumption of water diffusion into the glass network, by the formation of secondary phases or by silica sorption on near field materials surfaces. This question is highly safety relevant and may become decisive when assessing the suitability of a given glass composition. In case of water diffusion, times for

complete glass dissolution may well exceed 107 years. On the other hand secondary phase formation has in some cases been found to reaccelerate glass corrosion. Even if we do not see any accelerating influence of secondary phases in our experiments, we cannot exclude such influence the 1st day after test termination. Hence, we may no extrapolate the square root of time diffusion rate law. We may generalize the questions: Does the hierarchy of rate controlling mechanism change when scaling up experimental data to repository relevant geometry and time frames? How to validate rate or models and how to assure their applicabilities? How to deal with uncertainties (in particular uncertainties in the conceptual model related to alternatives in interpreting experimental data) and which are the key uncertainties? There is no answer yet, as long as natural analog studies do not provide unambiguous rate laws for natural settings.

(2) Behavior of safety relevant radionuclides during glass dissolution

Depending on the geochemical environment glass corrosion may or may not be accompanied by transfer of safety relevant radionuclides to a potentially mobile aqueous phase. The relation of glass dissolution characteristics and radionuclide mobility is of key concern. Sometimes congruent dissolution of all radionuclides with the glass matrix is assumed as conservative bounding estimate. This approach is useful for the soluble nuclides (i.e. Tc under oxidizing conditions) or for those elements (Se, etc.) for which we know little on their geochemical behavior. In some cases (Mg-rich brines) such approach even gives a realistic description of experimentally observed actinide release pattern. In most cases, however, glass dissolution is incongruent and sparingly soluble phases or sorption phenomena often control release of most of those nuclides that dominate the long-term radiotoxicity of the waste, in particular for Pu and Am. This is in particular true for the actinides (Np, Pu, U) and Tc in their tetravalent oxidation states. Higher radionuclide release is observed if these Elements occur in the penta- (Np, Pu) hexa- (Pu, U) or heptavalent (Tc) states. The oxidation states strongly depend on the nuclide, on the geological formation of the repository, on radiolysis and on the presence of engineered barrier materials. For example, experiments under strongly reducing conditions, in the presence of corroding iron containers, have shown that the solution concentrations of some of the key nuclides of overall performance assessments (Np237, Tc99) almost comply to drinking water standards already at the glass/groundwater interface.

Currently there exist only premature experience in coupling of geochemical glass dissolution modeling with actinide and Tc chemistry. Remaining scientific issues deal with

-

basic unknowns of radionuclide chemistry in natural aquifers: e.g. poor understanding of the thermodynamics of tetravalent actinides and tetravalent Tc

-

temperature dependency of actinide chemistry

-

poor knowledge in the dominant redox states in particular of Pu and Np during glass dissolution

-

competition of reducing effects of container materials and host rock with oxidizing effects of radiolysis

-

stability of colloids and mechanism and limitations for colloid generation, transition from polynuclear complexes towards colloids

-

(Al)-silicate or molybdate based solid actinide phases

-

solid solution formation of radionuclides in secondary alteration products

-

sorption isotherms for radionuclides on surface gels and clay minerals

NATURAL GLASSES AND THE VERIFICATION OF THE LONG-TERM DURABILITY OF NUCLEAR WASTE GLASSES

Rodney C. Ewing

Department of Earth & Planetary Sciences

University of New Mexico

Albuquerque, New Mexico 87131

One of the unique and scientifically most difficult aspects of nuclear waste isolation is the extrapolation of short-term laboratory data (hours to years) to the long time periods (103 to 105 years) required by regulatory agencies for performance assessment and the determination of compliance. The direct verification of these extrapolations is not possible, but methods must be developed to demonstrate compliance with regulations and to satisfy the public that there is a demonstrable and reasonable basis for accepting the long-term extrapolations. Natural analogues studies, that is the study of natural systems, have been used to assess the long term behavior of components of the repository barrier system. There has been considerable effort (see selected references) devoted to the study of the alteration and dissolution of natural glasses in an effort to assess the long term behavior of nuclear waste glasses. This presentation reviews that work.

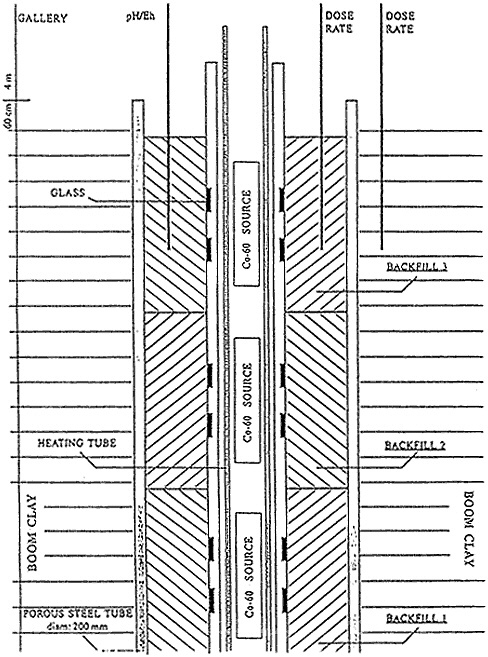

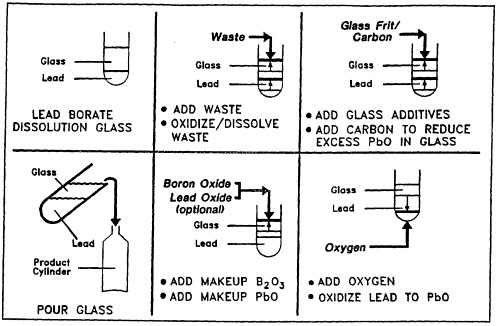

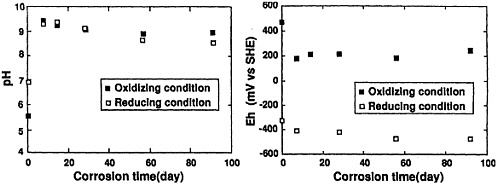

Natural glasses span a rather wide range of compositions which can be conveniently distinguished based on their silica contents: obsidians and rhyolite glasses (>70 wt. % SiO2); tektites (>65 wt. %); basalt glasses (45 wt.%); lunar glasses (45 wt.%). These natural glasses form as quenched glasses from magmas or melts generated during impact events (i.e. tektites and lunar glasses). Natural glasses show a wide variety of types and degree of alteration which are a function of the composition of the glass (in general, high silica glasses are more durable) and the geochemical environment (in the absence of water, natural glasses may show essentially no alteration). In typical terrestrial environments, the majority of the glasses are less than ten million years old, and older glasses become increasingly rare with age because of alteration. Some very old (hundreds of millions of years) glasses have been identified, but in most cases this is a result of the lack of contact with altering solutions. In addition, there have been a number of studies of anthropomorphic glasses (medieval stained glass windows, Phoenician glass containers, Th-doped borosilicate glasses, etc.) that are on the order of tens to thousands of years old.