3

State of the Practice of Ground Water and Soil Remediation

Innovation in the environmental industry is driven by the need to solve difficult problems and the desire to improve upon existing solutions. When a ground water or soil cleanup technology is developed and applied, frequently in response to an unsolved problem, its acceptance and application are often limited initially to specific contaminants and specific hydrogeologic conditions. As the technology matures, it typically addresses the same range of contaminant types, but its range of application in subsurface environments becomes better defined. This evolutionary process is similar for most remediation technologies, but the rate at which new technologies are adopted varies considerably. For example, soil vapor extraction (SVE) technologies, used for removing volatile contaminants from soil, were virtually unused at Superfund sites in 1985 but by 1995 had been selected for source control at 20 percent of Superfund sites (EPA, 1996a). However, for other technologies, especially those for cleaning up contaminants in situ, this evolution is occurring much more slowly than one would predict based on the large number of contaminated sites and the hundreds of billions of dollars in projected cleanup costs for these sites. There is no shortage of new ideas for improving the ability to restore contaminated ground water and soil. However, for reasons explained in Chapter 2, successful commercialization of all but a few new ideas has been limited.

This chapter reviews the state of development of technologies for cleaning up ground water and soil, highlighting knowledge and information gaps, and describes challenges and strategies for cleaning up different types of contaminants. The chapter defines all technologies for cleaning up contaminants below the water table as "ground water cleanup technologies" and all technologies for cleaning up contaminants above the water table as "soil cleanup technologies." This dis-

tinction is somewhat artificial, because many technologies for restoring areas below the water table address contaminated geologic materials rather than the water itself. Nevertheless, although these technologies do not specifically treat the water, but rather contaminants in the geologic materials, users of the technologies generally refer to them as ground water cleanup technologies because their primary intent is to prevent the contaminants from dissolving in and contaminating the ground water.

Included in this chapter are technologies that treat ground water contaminants in place in the subsurface and soil technologies that treat the soil either in place or on site in a treatment unit. The chapter does not cover technologies for removing contaminants from ground water once it has been pumped to the surface. The challenge of removing contaminants from water at the surface has already been largely addressed through the development of systems for treating municipal and industrial wastewater. In comparison, relatively few technologies are available for removing contaminants from soil or geologic materials to which the contaminants have tightly bound. Even fewer technologies exist for treating contaminated ground water in place in the subsurface. Furthermore, the processes that can be exploited in these technologies are still not fully understood.

WHAT IS INNOVATIVE REMEDIATION TECHNOLOGY?

"Innovative technology" as applied to the cleanup of ground water and soil is an elusive term, for two primary reasons. First, government agency representatives and others involved in waste-site cleanup may have different perspectives on which technologies are innovative. For example, the Environmental Protection Agency's (EPA's) 1996 Innovative Treatment Technologies: Annual Status Report classifies in situ bioremediation of contaminated soils as an innovative technology, while the Air Force specifies bioventing (a type of in situ bioremediation) as the standard remedy for soils contaminated with petroleum hydrocarbons and other volatile organic compounds (DOD Environmental Technology Transfer Committee, 1994). The Department of Energy (DOE) considers any technology innovative if it has not been used at DOE sites (J. Walker, DOE, personal communication, 1995). Thus, the definition of innovative varies depending on the perspective of the user.

A second reason why "innovative" is hard to define is that technologies are continually evolving. In the ground water and soil remediation business, only a few technologies represent true breakthroughs, in the sense that they apply concepts never before used in the field. More commonly, innovation occurs incrementally, evolving from existing technologies. This evolution is a product of several factors. The first factor is increased experience. As a technology is implemented at various sites, the experience gained provides a basis for defining and overcoming limitations, establishing best practices, and expanding the technology's application to new contamination problems. The second factor is com-

petition, both among the technologies and among practitioners who design the technologies. The third factor is the technology's performance limitations. All technologies have practical limitations that affect their market viability; a given technology may not perform well initially for certain contaminant types and hydrogeologic settings, but as these limitations are addressed, the applicability and marketability of the technology may increase. The fourth factor is cross-fertilization with other technologies. A technique or even a whole new technology may be incorporated into an existing technology to improve its performance or overcome a limitation.

The net result of this evolution is that remediation technologies go through a cyclical or generational life cycle. The first stage is the initial, and often crude, application of the technology. During this period, acceptance of the technology increases as it is successfully applied and its success is communicated. During the second stage of evolution, design practices for the technology become established. Acceptance and application grow rapidly as the benefit of the technology becomes known. The third stage is the mature, common practice of the technology. In this stage, the focus shifts from the benefits of the technology to its limitations, and acceptance and application may decline. During this mature application stage, the technology is vulnerable to replacement. However, use of the technology may increase again, either as its limitations are overcome or as the technology becomes applicable to new contaminant types and/or hydrogeologic settings. When a significant limitation is overcome, the technology enjoys a rebirth. The two best examples of remediation technologies that have developed through this evolutionary process are in situ bioremediation and SVE (see Boxes 3-1 and 3-2).

This chapter reviews a broad range of remediation technologies other than those based on conventional pumping and treating of ground water or digging and either hauling or burning of soil. Many of the technologies discussed in the chapter, including SVE and in situ bioremediation, have a significant experience base and are not new. In addition, many are enhancements to conventional approaches rather than new developments. Nevertheless, all of these technologies have in common the ability (whether potential or proven) to increase the effectiveness and/or decrease the costs of subsurface cleanup when compared to the historical approaches of pumping and treating ground water and hauling or burning soil.

AVAILABILITY OF INFORMATION ON INNOVATIVE REMEDIATION TECHNOLOGIES

Application of innovative remediation technologies has been slowed by lack of uniform, synthesized information about remediation technology performance. While considerable effort is being invested in researching and developing remediation technologies, these efforts are often isolated and do not benefit the general industry because circulation of information is limited. Broad acceptance of a tech-

|

BOX 3-1 Innovations in Engineered in Situ Bioremediation Engineered in situ bioremediation, the purposeful stimulation of microorganisms in ground water and soil to degrade contaminants, was first applied in 1972 to clean up a spill of gasoline from a pipeline in Ambler, Pennsylvania (Raymond et al., 1977). At that time, in situ bioremediation addressed the unsolved problem of residual petroleum contamination in soil and ground water. The related generations of technology that followed this first in situ bioremediation system focused primarily on petroleum hydrocarbons and were essentially water-based systems: both the oxygen and nutrients necessary to stimulate growth of contaminant-consuming organisms were supplied by circulating ground water. From 1972 to 1983, only about a dozen in situ bioremediation projects were conducted nationwide (Brown et al., 1993). Performance was limited by the low solubility of oxygen in water. The second generation of in situ bioremediation systems used hydrogen peroxide (H2 O2) to provide a more efficient method of supplying oxygen in soluble form. H2 O2 supplied 10 to 50 times more oxygen equivalents than did the existing aeration systems. The third-generation in situ bioremediation system employed SVE (see Box 3-2) to supply oxygen above the water table and used H2 O2 to provide oxygen below the water table. Both the second- and third-generation technologies were limited by the expense and difficulty of using H2 O2 , and there was a significant effort to find an alternative. Several alternatives to H2 O2 were explored, but the most successful was air sparging, which involves injecting air directly into the subsurface. Air sparging was initially developed as a separate technology to remove volatile contaminants by evaporative processes, but it was soon incorporated into bioremediation technology, sometimes called biosparging. Due in part to the success in improving oxygen delivery systems, in situ bioremediation systems are now in use at thousands of underground storage tank sites and dozens of Superfund sites (see Chapter 1). Parallel to the development of the different generations of in situ bioremediation systems for treatment of petroleum hydrocarbons has been the development of a number of spin-off technologies. The first of these was improved ex situ soil bioremediation technology. Ex situ bioremediation employs the principles and techniques of in situ bioremediation to treat excavated soils. A second improvement has been the increased understanding of bioremediation of chlorinated hydrocarbons, which was largely unknown until the mid-1980s (McCarty and Semprini, 1994). A third spin-off has been the development of intrinsic bioremediation (bioremediation without using engineered systems to stimulate native soil microbes) to control and mitigate contaminant plumes. |

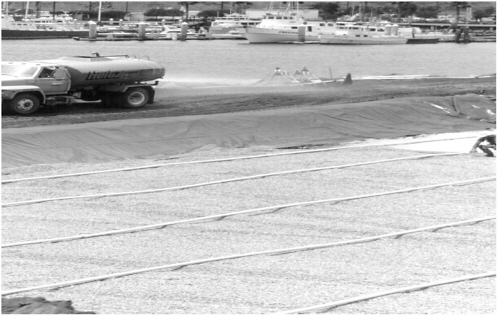

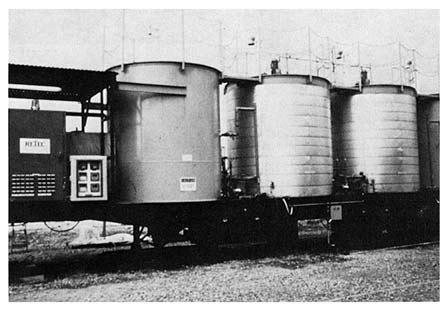

Petroleum-contaminated soils being treated in above-ground bioremediation cells engineered with vapor extraction systems. Courtesy of Fluor Daniel GTI.

nology requires documentation of the technology's performance and accessibility of performance information. Often in the development of remediation technology, data collection is minimal. As a result, much of the available information is anecdotal and empirical. This relative lack of documented performance data makes it difficult to judge the benefits and limitations of a technology without trying it. As a result, remediation technology development is somewhat repetitive, as individual practitioners tend to repeat the same work until the experience base is sufficiently distributed that knowledge of the technology is also well distributed.

The lack of consistent information is pervasive in the remediation market and encompasses all of the following problems:

-

technology reports are often incomplete;

-

critical scientific evaluation of technology application most often is not conducted or is not conducted with the goal of collecting comparable data sets;

-

reliable cost data are lacking and inconsistent;

-

methods for determining costs and evaluating successes can vary enormously; and

-

much information is proprietary.

These factors combine to make it very difficult to conduct rigorous comparisons

between technologies and across problem contexts with existing data. In addition, there are no complete, centralized data bases that cross markets and government programs. The 1995 publication Accessing Federal Data Bases for Contaminated Site CleanUp Technologies lists 25 different data bases that could be potentially useful in evaluating remediation technologies (Federal Remediation Technologies Roundtable, 1995a), but these data bases are not coordinated, and many of them are difficult to access (see Appendix A for a listing of data bases). In fact, the existence of such a large number of data bases in itself creates confusion, because the data bases contain information in different formats that may not be comparable, and the quality of the data from different data bases is variable and difficult to assess.

A few programs exist or are developing to facilitate evaluation of technologies. The EPA's Technology Innovation Office is collecting information on Superfund technology selections. The Federal Remediation Technologies Roundtable (a consortium of federal agency personnel involved in remediation) has developed protocols for standardized cost evaluations (Federal Remediation Technologies Roundtable, 1995b). Joint programs between states allowing sharing of information collected for technology evaluation are being created, and the results from these programs should help alleviate some of the information deficit. The EPA has established the Ground Water Remediation Technologies Analysis Center to help disseminate information on new remediation technologies (GWRTAC, 1995). These efforts are useful for developing a global view of what categories of remediation technologies are being tested and implemented. However, the fact remains that there are few reports that contain well considered evaluations of technologies, rather than mere compilations of information lacking careful analysis. A few examples of thoughtful technology evaluation may serve as models for future work.

The American Academy of Environmental Engineers' WASTECH® project has produced eight monographs of innovative waste-site remediation technologies. Generally, the scope of the analysis for this project was limited to technologies that are not commonly applied; have been sufficiently developed so that they can be used in full-scale applications; have sufficient data available to describe and explain the technology; and have sufficient data to assess effectiveness, limitations, and potential applications. An important contribution of this effort was applying such criteria to a wealth of information and synthesizing the findings by a task group of experts, whose work was peer reviewed, to produce a discussion of potential applications, process evaluations, limitations, and technology prognoses. Although restricted in scope and not uniform in coverage, the WASTECH® monographs provide a measure of consensus on performance of the technologies reviewed in the series; the philosophy and approach are laudable. A follow-up WASTECH® series of seven monographs emphasizing remediation technology design and implementation is in preparation.

An example of a focused report on a particular problem context is Dávila et

|

BOX 3-2 Innovations in Soil Vapor Extraction (SVE) SVE has been used to treat volatile hydrocarbons since the mid-1970s. Originally, the technology was used to remove vapors from soils to prevent the vapors from entering buildings. This first-generation technology was derived from methane collection systems employed at landfills and typically consisted of lateral collection pipes placed along building foundations. A vacuum was applied to these lateral pipes to collect the organic vapors. Engineers soon observed, however, that the removal of vapors led to significant contaminant mass removal and a reduction of the level of contamination in the soil. The second-generation (circa 1983) SVE technology focused specifically on the removal of volatile organic compounds (VOCs) from soil instead of the simpler collection of vapors. Two theories developed concerning SVE. The first postulated that the function of the vacuum was to ''vacuum distill" the VOCs from the soil matrix and was based on the principle that the boiling point of most VOCs decreases with decreasing pressure. With this approach, typically a high vacuum (greater than 500 mm, or 20 in., Hg) was applied to decrease the boiling point of the VOCs and allow them to volatilize. The second theory of SVE postulated that the process was an evaporative one. The purpose of the vacuum was to induce air flow through the subsurface to evaporate the VOCs. This theory has become the dominant SVE theory and is the basis for most SVE designs. The evaporative model uses low to moderate vacuums of less than 380 mm (15 in.) Hg. The main evolution of SVE has been in the design tools. The second-generation systems were typically designed on the basis of vacuum radius. Designers assumed that as long as there was a detectable vacuum, |

al. (1993), which discusses technology applications for cleanup of soil and sediment contaminated with polychlorinated biphenyls (PCBs). This report discusses succinctly a number of technologies from an engineering perspective, pointing to specific examples of successes and problems from field evaluations. A report by Grubb and Sitar (1994) that discusses in situ remediation of dense nonaqueousphase liquid (DNAPL) contaminants provides another example of a report that critically evaluates technologies for solving a particular type of contamination problem. A report by Troxler et al. (1992) on thermal desorption for petroleum-contaminated soils provides a useful perspective on a particular technology application and its status of development. Reports by Vidic and Pohland (1996) on in situ treatment walls and by Jafvert (1996) on cosolvent and surfactant flushing systems provide peer-reviewed evaluations of these technologies.

|

there was sufficient air flow. With this simple design basis, however, many SVE systems proved less effective than planned. Designs based on simple vacuum readings do not reflect true air flow unless they are adjusted for air permeability using Darcy's law. Once models were used to adjust vacuum readings to actual air flow rates, the performance of SVE systems improved. In retrospect, use of air flow-based designs seems like an obvious improvement. However, implementation has not been easy because of the need to use flow models. While SVE has not evolved as extensively as bioremediation, it has engendered a much more varied set of spin-off technologies. This may be in part due to the clarity of the limitations of SVE, which removes volatile compounds from unsaturated soils by induced air flow. By this definition, there are three basic limitations: (1) the volatility of the contaminant, (2) the lack of air in saturated environments, and (3) the permeability of the soil matrix to air flow. The limitation of volatility has fostered two other innovations. The first is the use of thermal energy to increase the contaminant volatility. Thermal systems under development use hot air, steam, radio waves, microwaves, or electrical resistance to heat the soil. The second is the use of biodegradation to enhance contaminant removal. While SVE was recognized as an efficient source of oxygen for bioremediation as early as 1984, the full development of bioventing did not occur until about 1990. The lack of air in the saturated zone has fostered the development of dual-phase technology. This is the direct use of a high vacuum to dewater and vent saturated soils. Dual-phase technology has allowed SVE to treat contamination below the water table. Finally, the lack of air permeability has led to the development of fracturing systems. Fracturing systems inject pressurized air or water to open channels in the soil, which then allow air to circulate more freely. |

STATE OF INNOVATIVE REMEDIATION TECHNOLOGY DEVELOPMENT

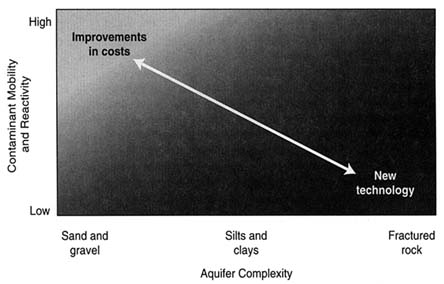

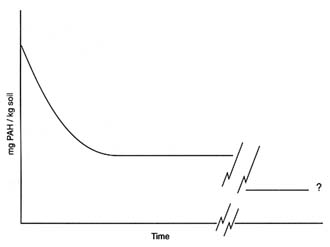

The current state of remediation technology development is relatively rudimentary. That is, technologies are available for treating easily solved contamination problems—mobile and reactive contaminants in permeable and relatively homogeneous geologic settings—but few technologies are available for treating recalcitrant contaminants in complex geologic settings. Figure 3-1 shows a conceptual diagram of where innovation is most needed to improve the performance and reduce the costs of ground water and soil remediation projects.

The greatest successes in remediation to date have been in the treatment of petroleum hydrocarbon fuels—gasoline, diesel, and jet fuel—which are generally mobile and biologically reactive and to a lesser extent in the treatment of chlori-

Figure 3-1 Technology needs for remediation of contaminated ground water and soil. At the left side of the figure, improvements are needed primarily to reduce costs. At the right side, new technologies are needed to solve contamination problems that are currently intractable.

nated solvents, which are generally mobile but are less readily biodegraded than petroleum hydrocarbons. The greatest challenge in remediation is in the location and cleanup of contaminant source material. This source material may comprise organic solids, liquids; or vapors; inorganic sludges and other solid-matrix wastes; compounds adsorbed on mineral surfaces; and compounds adsorbed in natural organic matter such as humus. Often, contaminant sources are difficult to locate and delineate because of lack of information about the contaminant spill or disposal history at the site and because contaminant source material may migrate away from where it was originally lost to the environment. Once found, source material may be inaccessible, lying under structures, or at great depth, or in fractured rock. Because of the possibility of continual contaminant release, partial source removal may not result in a proportional increase in ground water quality. The time for source diminution may be excessively long. Further, directing pumped fluids to the region where such fluids are most beneficial may be very difficult because of the problem of preferential flow, which causes fluids to bypass altogether the less permeable regions containing contaminants. A special challenge in the cleanup of source material is in the development of methods to enhance the mobility or reactivity of material that, by its nature, is not particularly mobile or reactive.

Three Categories of Remediation Technologies

Remediation technologies can be divided into three general categories: (1) technologies for solidification, stabilization, and containment; (2) technologies exploiting biological and chemical reactions to destroy or transform the contaminants; and (3) technologies involving separation of the contaminants from the contaminated media, mobilization of the contaminants, and extraction of the contaminants from the subsurface. Box 3-3 provides definitions of the different types of technologies in each of these three categories.

Solidification and stabilization processes are directed at decreasing the mobility and/or toxicity of contaminants by reducing contaminant solubility or volatility and medium permeability. Most such techniques have been developed for ex situ treatment of soil contaminated with heavy metals, although a few methods for in situ treatment of relatively shallow contaminated soils are in use. These processes are generally not suited for contaminants located at significant depth or for very volatile or soluble organic contaminants, although some of the methods are now being applied to a limited number of organic contaminants.

Containment methods are designed to prevent movement of contaminants away from the zone of contamination by providing a physical or hydraulic barrier. Low-permeability clay and/or geotextile caps and low-permeability slurry walls are fairly standard technology. Combinations of reactive processes with physical containment systems are a new innovation being implemented in the field. Pump-and-treat systems are also often used to hydraulically contain contaminated ground water.

Biological and chemical reaction processes use biological or chemical reactions to transform contaminants to innocuous, or at least less harmful, products. Biological processes, known generally as bioremediation, rely on microorganisms to mediate contaminant transformation reactions and degrade the compounds. Many organisms native to soils can use contaminants as sources of carbon and energy for growth. Some organisms (known as aerobes) require oxygen to thrive, while others (known as anaerobes) thrive in oxygen-free environments and use other electron acceptors, such as nitrate, iron, sulfate, and carbon dioxide. Addition of nutrients, moisture, or the appropriate electron acceptors can increase microbial activity and thus enhance the reaction rates. Pretreatment with enzymes or chemical oxidants can make complex chemicals more readily degradable. For in situ bioremediation applications, the primary challenges are largely related to creating the necessary environmental conditions in situ that will cause biodegradation of the contaminants; this includes delivery of the necessary amendments to contaminated locations. Chemical reaction processes are not used as frequently as biological processes. Few chemical reaction processes are available, and even fewer have been tested extensively. However, several technologies are now being tested, as shown in Box 3-3. Reaction processes, whether biological or chemical, are the only processes that can completely destroy organic contaminants. The

|

BOX 3-3 A Glossary of Remediation Technologies Stabilization/Solidification and Containment Technologies Asphalt batching. Encapsulates contaminated soil in an asphalt matrix. Volatile organic compounds (VOCs) generally volatilize during the process and are captured and treated in an off-gas system. Biostabilization. An ex situ microbial process to rapidly degrade the bioavailable components (the more volatile and soluble fractions of contaminant mixtures). The process leaves behind a much less mobile and less bioavailable residue. Enhanced sorption. A passive-reactive barrier (see definition below) that creates zones that cause contaminant sorption, either microbiologically (biosorption) or chemically (using surfactant coatings). In situ precipitation/coprecipitation. A passive-reactive barrier (see definition below) that causes the precipitation of a solid (usually carbonate, hydroxide, or sulfide mineral) to maintain a toxic metal in an immobile form. Formation of solid phases is controlled primarily by pH, redox potential, and concentration of other ions. In situ soil mixing. A method of achieving stabilization of contaminated soil in situ. Soil is mixed with stabilizing agents using large augers in successive drillings across a site. Lime addition. A method that decreases permeability of soils by filling interstitial pore spaces and forming weak bonds between soil particles. Heat generated due to hydration can aid in thermal desorption of VOCs. Passive-reactive barriers. Permeable containment barriers that intercept contaminant plumes and remove contaminants from ground water solution using chemical and/or biological reactions within the barrier. Pozzolonic agents. Cement-like materials that form chemical bonds between soil particles and can form chemical bonds with inorganic contaminants, decrease permeability, and prevent access to contaminants. The most common pozzolonic materials are portland cement, fly ash, ground blast furnace slag, and cement kiln dust. Slurry walls, sheet pile walls, and grout walls. Low-permeability barriers designed to prevent contaminant transport in situ. The success of these technologies depends on achievement of a long-lived, low-permeability barrier. Because these walls create hydraulic confinement, fluid must either be allowed to flow around them or be removed from the system and treated if necessary. Alternatively, the barrier wall must contain permeable zones in which reactions can occur. Vitrification. Melting of contaminated soil combined with amendments as needed to form a glass matrix from the soil, either in place (in situ vitrification) or in a treatment unit. Nonvolatile metals and radioactive contaminants become part of the resulting glass block after cooling. Organic contaminants are either destroyed or volatilized by the ex- |

|

tremely high temperatures. The method is generally expensive due to large energy requirements. Biological Reaction Technologies Biopile. Soil placed around or over ventilation pipes and often amended with nutrients (during emplacement, or by irrigation or batch additions). Biopiles are supplied with oxygen by vacuum-induced air flow. Bioslurry reactor. Biological (ex situ) reactors that slurry, suspend, and typically aerate solids. Reactors can be enclosed or in the form of treatment lagoons. When volatile constituents are present, vapor capture and treatment may be necessary. This technology is usually used for sludges with high water content. Biostabilization. See above definition (under "Stabilization, Solidification, and Containment Technologies"). Bioventing and biosparging. A form of engineered in situ bioremediation involving addition of oxygen to stimulate aerobic microbial activity. Oxygen is added by soil vapor exchange (bioventing) in the vadose zone and by air sparging (biosparging) in the saturated zone. Air flow is generally lower in bioventing and biosparging than in SVE and air sparging systems, which are designed to maximize extraction of volatile components from the subsurface. Composting. Related to biopiles. Additional carbon, in the form of manure, sludge, plant byproducts, or wood chips, is added to increase biological activity and pore size. Engineered in situ bioremediation. Addition of electron acceptors (usually oxygen) or donors and nutrients in situ to ground water or soil to facilitate biodegradation. Biodegradation occurs in the ground water system downgradient from the point of nutrient addition. The systems generally do not require large energy inputs. Enhanced sorption. See above definition (under "Stabilization, Solidification, and Containment Technologies"). Fungal treatment. Addition of wood-degrading fungi, either white rot or brown rot, to a biopile or land farming application. The fungi degrade complex organic compounds by producing extracelluar enzymes. Intrinsic bioremediation. The use of native soil microorganisms to degrade contaminants without human intervention other than careful monitoring. The method can be used both to destroy contaminants and to control the spread of contaminant plumes. It requires monitoring and modelling to document the existence and rate of biodegradation. Treatment time can be very long (decades). Land farming. Spreading of contaminated soil over a prepared bed on the land surface in shallow lifts followed by tilling to provide aeration. Treatment time depends on contaminant and soil properties, including the rate of compound release from the solids. Tilling and nutrient addition frequencies can affect remediation rates. |

|

Organic biofilters. A form of engineered in situ bioremediation that uses a large mass of microorganisms for sorption or transformation of contaminants. Electron acceptors and nutrients are added to sustain the microorganisms. Passive-reactive barriers. See above definition (under "Stabilization, Solidification, and Containment Technologies"). Phytoremediation. Remediation of contaminated soil in situ using vegetation. Sparge barriers. A form of engineered in situ bioremediation in which oxygen is provided to the subsurface via air injection wells placed directly into the formation or in a permeable trench. Chemical Reaction Technologies Chemical oxidation. Use of strong oxidants to destroy organic contaminants. The process works best on compounds, such as olefins and substituted aromatics, that contain unsaturated carbon-carbon bonds. Several chemical combinations can be used: peroxide, peroxide and iron (Fenton's reagent), ozone, hydrogen peroxide and ozone (peroxone), and potassium permanganate. Incineration. Oxidation of organic compounds at extremely high temperatures (ex situ). Organic compounds that are difficult to treat by other methods can be destroyed by incineration. Substitution. Use of ex situ organic chemical reactions to convert soil contaminants into components that are less toxic or unregulated, typically by replacing a halogen with a hydrogen or functional group, such as an ether. Thermal reduction. Use of hydrogen (ex situ) at elevated temperatures to reduce and decompose organic contaminants in soils to nontoxic compounds. Zero-valent iron barrier. A passive-reactive barrier (see above definition) that creates very reducing conditions, resulting in hydrogen generation. Dissolved chlorinated solvents (ethenes, ethanes, and methanes) are chemically degraded at relatively rapid rates. Some metals form relatively insoluble solids at low redox potential and can be treated with this method. Separation, Mobilization, and Extraction Technologies Air sparging. Injection of air under pressure below the water table in unconfined aquifers. The method removes VOCs by volatilization while incidentally stimulating aerobic biodegradation processes. It is applicable in permeable and homogeneous soils. Cosolvent flushing. Addition of a solvent to significantly increase the solubility of nonaqueous-phase liquids (NAPLs) and, in the case of heavy organic mixtures, to reduce overall NAPL viscosity and improve re- |

|

covery. Cosolvents greatly increase the solubility of sorbed organic contaminants. Dual-phase extraction. A process of simultaneously removing water and air from a common borehole by the application of a high vacuum. The process dewaters the area to be treated and subsequently removes the contaminant by volatilization. Electrokinetics. The migration of chemicals through a soil matrix under the application of electrical and hydraulic gradients to effect contaminant removal. The process can function in both saturated and unsaturated environments. Electroosmosis. Use of an electrical potential to cause movement of pore water through a clay aquifer formation to treatment zones. This technique has been long understood as a means to control water movement in fine-grained media and is currently being investigated at waste sites to treat contaminants in ground water. Fracturing technology. Injection of fluid under pressure into the soil matrix to break up the soil and facilitate movement of treatment fluids. The process employs the principle that if the overburden pressure is exceeded, the soil will fracture, creating fissures. Both pneumatic and hydraulic fracturing are employed. In many cases, a prop material is injected into the fracture at the time of fracturing or before the pressure is released to keep the fracture open while filling it with a transmissive material. Fractures generally occur along weak points in the soil matrix, such as in preexisting fractures, lenses, bedding planes, discontinuities, or desiccation cracks. In some cases, the soil may be notched to promote fractures at a particular horizon or in a particular direction. Once created, fractures provide a transmissive pathway for the injection or extraction of fluids. In situ soil mixing. Use of augers or impellers to break apart the soil structure and increase its transmissivity. The increase in transmissivity is accomplished by the disruption of the soil matrix, creating channels throughout the soil. A diluent or bulking agent can be added to further increase transmissivity. NAPL recovery. The physical removal of separate-phase organic liquids. The simplest form is a gravity drainage system, in which NAPLs flow into downgradient collection points. For light NAPLs (LNAPLs), recovery can be enhanced by depressing the water table and increasing the hydraulic gradient. The rate and extent of product recovery are inversely related to NAPL viscosity and proportional to hydraulic gradient; recovery is greatest for lighter products such as gasoline, diesel, and jet fuel. Dense NAPLs (DNAPLs) may be pumped from a depression in a confining layer located at the interface between relatively coarse- and fine-grained media. Pump-and-treat system. A process for removing dissolved contaminants |

|

from ground water by pumping the water to the surface and treating it. The process is effective for controlling and diminishing the size of plumes of dissolved contaminants. However, for source areas, it is effective only as a containment or control method due to the low solubility and large masses of contaminants present. Soil flushing. An in situ process that uses chemical amendments and fluid pumping to mobilize and recover contaminants (see also cosolvent flushing and surfactant flushing). Soil vapor extraction (SVE). The removal of volatile organic contaminants from unsaturated soils by inducing air flow and thus speeding contaminant volatilization. The treatment rate is a function of the volatility of the contaminant and the ratio between the air flow rate and contaminant mass. A secondary benefit of technology is that it stimulates aerobic biodegradation. Soil washing. An ex situ process that first segregates the most contaminated soils and then washes them with a water-based solution. Generally, soil fines have a high concentration of contaminants, while coarse materials may be sufficiently clean that contaminant concentration are below action levels, allowing coarse materials to be disposed of separately. Once fines are separated from coarse soils, the fines are washed with a solution that may include surfactants, acids, chelating agents, or other amendments to enhance desorption and solubilization. Steam sparging. Addition of steam to enhance contaminant volatilization in air sparging systems. Treatment rates are significantly faster than in standard air sparging systems. Surfactant flushing. Application of anionic and nonionic surfactants in situ to enhance the removal of organic contaminants. Using surfactant doses greater than the critical micelle concentration for the surfactant (usually greater than 0.5 to 1.0 percent in soils), organic contaminants partition into mobile micelles, allowing them to be transported with ground water at concentrations many orders of magnitude greater than would otherwise be possible. The contaminant-laden solution is collected and treated ex situ. Surfactants also decrease surface tension between the NAPL and water and can cause remobilization of NAPL. Remobilization can be used to increase recovery of LNAPLs, but it is generally not considered favorable in most DNAPL treatment schemes. Variations on surfactant flushing systems include the use of foams and stable gases. Thermal desorption. A process (different from incineration) that removes volatile and semivolatile organic compounds from excavated soils by transfer to a gas phase. Volatilization is a function of compound volatility, surface area, and temperature. The simplest desorbers use soil shredding to expose surface area. Either hot gases are applied to the |

|

soil, usually in a rotary kiln or fluidized bed, or heat is transferred by solid-solid contact with the contaminated soil as it travels along a heated screw or conveyor. The vaporized contaminants are captured and collected or destroyed. The process may be augmented with the addition of quick lime, which generates heat as it hydrates. With compounds having medium to low volatility, thermal energy is added to enhance volatilization. Thermally enhanced NAPL recovery. Use of steam or radio-frequency energy to supply heat and reduce NAPL viscosity. For heavy fuels or oils, the process can increase recovery by as much as an order of magnitude. Thermally enhanced SVE. Addition of thermal energy to accelerate SVE cleanups or extend SVE application to less volatile organic mixtures such as diesel or fuel oil. Thermal energy can be supplied by steam, hot air, radio waves, microwaves, or electrical resistance. Vacuum-assisted NAPL recovery. Application of a vacuum to reduce interstitial pressure, allowing NAPLs to move through soil more easily. Vacuum assistance can increase the rate and ultimate amount of product recovery by several fold. |

In above-ground bioremediation cells (under construction), oxygen is supplied to soil via a network of embedded piping. Courtesy of Fluor Daniel GTI.

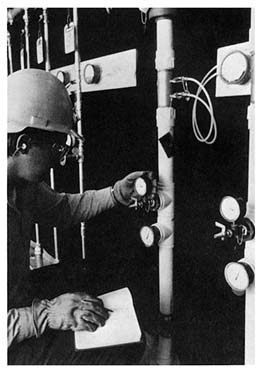

Monitoring an air sparging and soil vapor extraction system. Courtesy of Fluor Daniel GTI.

vast majority of the practices in this category are biological treatment methods for hydrocarbon-contaminated sites. For all other classes of chemicals, far fewer tested reactive treatment options are available.

Separation, mobilization, and extraction processes are designed to separate contaminants from geologic materials in the subsurface, mobilize them into the ground water or air in soil pores, and extract them from the subsurface. Some of these technologies use heat, chemicals, vacuums, or electrical currents to separate the contaminants from geologic materials and move the contaminants to a location where they can be extracted. For example, heat has a pronounced effect on decreasing the viscosity of nonaqueous-phase liquids (NAPLs) and increasing the vapor pressure of organic chemicals, making it easier to mobilize and extract them. Other technologies in this category alter the physical structure of the soil matrix by fracturing or mixing it, which facilitates the addition or extraction of fluids for subsurface treatment. Separation, mobilization, and extraction processes can enhance the efficiency of conventional pump-and-treat or SVE systems.

Availability of Remediation Technologies for Various Problem Contexts

Table 3-1 shows the availability of technologies in the three categories for treating four different types of contaminated media: (1) surface soils, sediments, and sludges; (2) the unsaturated zone (soil contamination below the surface but above the water table); (3) the saturated zone (contamination below the water table); and (4) subsurface source zones. As shown in Table 3-1, the availability of technologies is greatest for treatment of soils, sediments, and sludges. The deeper and more entrenched the contamination problem, the more limited is the menu of technology options.

Table 3-2 shows the availability of the three general categories of technologies for treating different classes of contaminants. As shown in the table and in Figure 3-1, a range of treatment alternatives has been developed for the relatively mobile and biodegradable contaminants (petroleum hydrocarbons and chlorinated solvents). The number of potential treatment technologies is much smaller for the other classes of chemicals. The remainder of this chapter discusses in detail the technology options for treating the six categories of contaminants shown in Table 3-2. These classes of contaminants are representative of contaminants typically found at hazardous waste sites.

CLEANUP OF PETROLEUM HYDROCARBONS

Sources

The presence of petroleum hydrocarbons in the subsurface is generally related to the transport, distribution, and use of fuels and oils. There are five main sources of petroleum hydrocarbon contamination: underground or above-ground storage tanks, tanker trucks, transfer terminals, pipelines, and refineries. Contamination in the subsurface typically is a result of leakage or spillage (slow, periodic, or catastrophic) or of disposal of wastes (separator sludges, waste oils, and refinery sludges and residuals). The vast majority of hydrocarbon-contaminated sites are associated with underground storage tanks. As shown in Table 1-2 in Chapter 1, there are an estimated 300,000 to 400,000 leaking underground storage tanks in the United States. In comparison, refinery and pipeline sites are fewer but typically much greater in both affected area and volume of contaminant released. According to the American Petroleum Institute, there are approximately 150 refineries in the United States (API, 1996).

Fate

Hydrocarbons are biodegradable and volatile with moderate to low solubility. Hydrocarbon contaminants in the subsurface can be found distributed among four phases: (1) sorbed to solids, (2) as an NAPL, (3) dissolved in the ground

TABLE 3-1 Technology Types Applicable to Different Contaminated Media

|

Context |

Solidification, Stabilization, and Containment |

Biological and Chemical Reaction |

Separation, Mobilization, and Extraction |

|

Surface soils, sediments, and sludges |

Excavation, e Pozzolanic agents, e, i Lime / fly ash, e, i Vitrification, e, i Asphalt batching, e |

Biopiles, e Composting, e Land farming, e (Fungal treatment, e) Bioslurry systems, e, (i) Incineration, e Phytoremediation, i (Biostabilization, e, i) Substitution, e Thermal reduction, e |

Solvent extraction, e Thermal desorption, e Soil washing, e (Electrokinetic systems, e, i) |

|

Unsaturated zone |

Deep soil mixing Excavation (Polymer walls) Grout walls Slurry walls Sheet pile walls |

Bioventing |

SVE Thermally enhanced SVE (Soil flushing with surfactants or cosolvents) (Electrokinetic systems) |

|

Saturated zones |

Excavation (Polymer walls) Grout walls |

Engineered in situ bioremediation Intrinsic bioremediation Biosparging |

Pump-and-treat systems Sparging: air and steam (Electrokinetic systems) |

Table 3-2 Treatment Technology Options for Different Classes of Contaminants

water, and (4) as a vapor in unsaturated soil. Because hydrocarbon mixtures have low solubility, most of the hydrocarbon mass is typically in the sorbed or NAPL phase. For example, a typical phase distribution of gasoline in sand is 30 to 50 percent as NAPL, 40 to 50 percent sorbed, 2 to 5 percent dissolved, and less than 0.5 percent in the vapor phase (Brown et al., 1987b).

When hydrocarbon liquids are released to soil, they migrate downward until they are retained as a residual in soil pores. The amount of hydrocarbon liquid retained is a function of the fluid viscosity and the soil texture, which vary widely. More viscous (heavier) hydrocarbon mixtures and fine soil textures generally result in greater hydrocarbon retention within the soil. The residual hydrocarbon concentration in soil ranges from approximately 10,000 to 15,000 mg/kg for gasoline in fine sand to 60,000 to 80,000 mg/kg for no. 6 fuel oil in fine sand (Lyman et al., 1992). Because hydrocarbon mixtures are less dense than water, they typically accumulate in a layer on the water table when sufficient hydrocarbon has spilled or leaked to saturate the soil, allowing free-phase liquid to migrate to the water table.

Three mechanisms serve to attenuate petroleum hydrocarbon liquids in the subsurface: (1) biodegradation, (2) volatile transport and exhaust to the soil surface and (3) dissolution. Because the effective solubilities and vapor pressures of the various components of hydrocarbon mixtures are low, removal of these source materials by solubilization or volatilization is slow. Biodegradation is usually the more significant mechanism for attenuation of hydrocarbons except near the soil surface, where volatilization may play a more significant role. Biodegradation is relatively slow for sorbed hydrocarbons, but biodegradation of dissolved hydrocarbons is relatively rapid.

Biodegradation is carried out by ubiquitous native soil microorganisms (Claus and Walker, 1964; Alexander, 1994; Chapelle, 1993). The number of hydrocarbon-degrating microorganisms is much greater in hydrocarbon-contaminated sediments than in uncontaminated zones (Aelion and Bradley, 1991). The rate of biodegradation and the metabolic products produced are controlled primarily by the types of hydrocarbons present and the availability of electron acceptors and nutrients needed by the microorganisms to conduct the reactions (National Research Council, 1993). Aerobic biodegradation is more rapid than anaerobic biodegradation, but oxygen is generally limited in the immediate vicinity of subsurface hydrocarbons because of the low solubility of oxygen and the high oxygen demand created by the hydrocarbon-degrading organisms. In the absence of sufficient oxygen, microorganisms can use alternative electron acceptors such as nitrate, iron, sulfate, and carbon dioxide to biodegrade hydrocarbons (Chapelle, 1993; Hutchins and Wilson, 1994; Barbaro et al., 1992; Wilson et al., 1994).

Dissolution, volatilization, and biodegradation do not rapidly or completely remove hydrocarbon mass from the subsurface. However, these processes together cause weathering of the petroleum product. As a product weathers, the

TABLE 3-3 Treatability of Petroleum Hydrocarbons Volatile Fraction

|

Hydrocarbon |

Volatile Fraction (Percent) |

Degradability |

Treatability |

|

BTEX solvents |

100 |

High |

Very high |

|

Gasoline |

>95 |

High |

High |

|

Jet fuel |

75 |

High |

High |

|

Diesel/kerosene |

35 |

High |

Moderate-high |

|

No. 2 fuel oil |

20 |

Moderate |

Moderate |

|

No. 4 fuel oil |

10 –20 |

Low-moderate |

Low-moderate |

|

Lube oil |

10 –20 |

Low-moderate |

Low-moderate |

|

Waste oils |

<10 |

Low |

Low |

|

Crude oils |

<10 |

Low |

Low |

|

SOURCE: Brown and Norris, 1986. |

|||

more mobile (volatile and soluble) and degradable fractions are removed. The remaining residue is more viscous and less soluble than the original contaminant mixture, reducing the risk of continued contamination of soil and ground water.

Remediation Technology Options

Because some components of petroleum hydrocarbons are relatively mobile and biodegradable compared to other types of contaminants, a large number of technologies are applicable to hydrocarbon remediation. Applicable technologies include NAPL recovery, dual-phase extraction, in situ bioremediation, biopiles, land farming, SVE, bioventing, biosparging, soil washing, and soil flushing. The processes that can be applied to various sources of hydrocarbon contaminants vary considerably and are a function of the type of hydrocarbon product. In general, which remediation technologies will be applicable to hydrocarbon contamination is a function of the mobility and reactivity of the hydrocarbon. Mobility and reactivity, in turn, are functions of the properties and quantities of the particular hydrocarbon and the hydrogeologic setting in which it is found. In general, lighter hydrocarbons are more volatile and degradable and thus more readily treatable than other types of hydrocarbons. Table 3-3 shows the treatability of various petroleum hydrocarbon products (Brown et al., 1987a).

Separation Techniques

Soil Vapor Extraction. SVE removes petroleum hydrocarbons by two mechanisms: violatilization and biodegradation (P. Johnson et al., 1990; R.L.Johnson et al., 1992). Volatilization occurs when the air stream contacts residual hydrocarbons or films of water containing dissolved hydrocarbons in soil. Biodegradation

occurs because the induced air flow supplies oxygen for aerobic biodegradation. All petroleum hydrocarbon fuels are essentially biodegradable (Chapelle, 1993). However, the volatile fraction, and therefore the rate of treatment of hydrocarbons, varies. Hydrocarbon fuels with a high volatile fraction will be removed most rapidly using SVE; those with a low volatile fraction will be less responsive. Volatility ranges from more than 90 percent for gasoline to less than 10 percent for crude oil (see Table 3-3). Based on approximate volatilities. SVE is a primary technology for the remediation of gasoline, jet fuel, and mineral spirits. SVE can be used to treat the other, less volatile hydrocarbon mixtures as part of a biodegradation strategy, a process often termed bioventing.

SVE is commonly limited by the permeability of the soil and by the degree of saturation. SVE will not work well in low-permeability soils such as silts and clays or in highly saturated areas, such as the capillary fringe or below the water table.

SVE is a widely used commercial technology for the treatment of petroleum hydrocarbon releases; as of 1995, it was in use or had been used at 139 Superfund sites and nearly 9,000 underground storage tank sites (see Figures 1-7 and 1-8 in Chapter 1). It has moderate to high success in achieving specific regulatory goals. Generally, SVE is most successful for treating more volatile hydrocarbon products and more permeable soils.

Soil Washing and Soil Flushing. Significant quantities of petroleum hydrocarbons can be retained in soils as a residual, discontinuous NAPL phase. One approach to removing residual petroleum products is to use surfactants or cosolvents. Surfactants and cosolvents can desorb hydrocarbons from soils and can decrease the interfacial tension of the NAPL, forcing it from the soil matrix and allowing it to coalesce into a recoverable, continuous NAPL phase (Gotlieb et al., 1993).

There are two basic types of surfactant and cosolvent applications. One is soil washing, which is a process for removing hydrocarbons from excavated soils. The other is soil flushing, which is the in situ application of surfactants or cosolvents to contaminated soils. Both of these processes have significant variations. With both types of applications, site-specific blends of additives are generally used. A significant portion of the cost is associated with unrecovered additives and disposal of generated fluids.

In soil washing, the petroleum-contaminated soil is excavated, slurried, and processed. In some soil washing systems, the soil slurry is processed by soil sizing to concentrate the hydrocarbons in the finer soil fractions. The surfactant or cosolvent is then added to the fine soil slurry fraction, minimizing the amount of additives required. Other systems add the remedial agent directly to the soil and then agitate the slurry. The soil, water, and NAPL phases are then separated. Some soil sizing may be used to enhance the separation (coarser fractions are easier to dewater). Soil washing is used commercially to treat petroleum-contaminated soils (Delta Omega Technologies, 1994). It is not as commonly used to

treat lighter, more volatile products such as gasoline, jet fuel, or mineral spirits, because removing these products by volatilization is more cost effective. While soil washing is used to treat a wide range of soil types, it has limited applicability to soils with high clay content due to problems in separating the fine clay particles.

There are three principal variations to in situ soil flushing: (1) enhanced solubilization, (2) emulsification, and (3) displacement. In the first approach, chemical additives (such as surfactants and cosolvents) are used to enhance the aqueous solubility of contaminants in order to more efficiently dissolve or desorb the petroleum hydrocarbons (or other organic contaminants). In the second approach, higher concentrations of these additives are used to emulsify the NAPLs, either as microemulsions or middle-phase emulsions, and flush them out more effectively. The contaminant molecules dissolve into mobile micelles of the additive, which are entrained in the water. In the third approach, additives that decrease NAPL-water interfacial tensions to very low values (less than 1 dyne/cm) are used to mobilize the trapped ganglia and displace the resulting bank of free-phase liquid. The first approach involves miscible displacement (i.e., resident and introduced fluids mix completely), while the other two methods involve immiscible displacement (two immiscible fluids—oil and water—are displaced). Combinations of various surfactants and cosolvents can be used to achieve solubilization, emulsification, or displacement. In situ flushing with steam has also been attempted. All of these technologies have been tested and used for enhanced recovery in oil fields, but use for site remediation purposes has been limited to several pilot-scale and a few commercial-scale tests (Grubb and Sitar, 1994; EPA, 1995a).

Thermal Desorption. Thermal desorption is a commonly used technology for treating excavated petroleum-contaminated soils. It is based on the principle that volatility increases with increasing temperature. What distinguishes thermal desorption from incineration is that the soil does not contact a flame. The petroleum product is volatilized off the soil, and the resulting vapor stream is captured and treated. There are two variations: low temperature and high temperature. Low temperature thermal desorption uses temperatures of less than 200 °C (400 °F). It is used to treat more volatile products such as gasoline, jet fuel, mineral spirits, and sometimes diesel. High temperature thermal desorption uses temperatures of 320 to 430 °C (600 to 800 °F). It is used to treat soil contaminated with diesel and fuel oil. Neither process is effective with very heavy products such as no. 6 crude oils. With thermal desorption, the heat is applied either through hot air or through radiant or convectional heating. With hot air systems, a fuel is combusted, and the combustion gases are fed into the desorption unit.

Thermal desorption is used for a wide range of products, but use is most common for motor fuels (gasoline, diesel, and jet fuel). Units range in size from those that can process 5 to 10 tons per hour to those that can handle more than 40

tons per hour. The process is generally able to achieve regulatory standards that allow the soil to be reused or disposed of on site.

NAPL Recovery. NAPL recovery is the removal of separate-phase liquid hydrocarbons (at amounts greater than residual saturation) from the soil matrix. NAPL recovery is best accomplished with low viscosity hydrocarbon products. Viscous products such as no. 6 fuel oil or crude oils do not flow readily through soils and are not typically recovered. Most NAPL recovery systems also produce water. Because gravity drives the collection of NAPLs, the water table is often depressed to increase the flow of NAPL into the collection point.

The variations in NAPL recovery are a function of how and where the NAPL and water phases are separated. In permeable formations and with low viscosity products, the separation process is accomplished in situ using dual pumps (product and water), automatic bailers, or oil skimmers. In low-permeability formations, a total fluid extraction system is used to recover both product and water. These are then separated on the surface with conventional technologies for separating oil and water. A recent innovation in NAPL recovery is vacuum-assisted NAPL recovery (Kittel et al., 1995). In this process, a vacuum is applied to the recovery well to promote the flow of NAPL into the collection point. The vacuum application minimizes the amount of water that is collected by creating a driving force that is an alternative to depressing the water table. The vacuum may be applied to the well bore directly or through an inner tube (drop tube). The use of a drop tube is sometimes referred to as "bioslurping" (Kittel et al., 1995).

NAPL recovery is a standard remediation technology employed at almost any site having recoverable NAPL. Most applications use water table depression as the driving force for NAPL recovery. Vacuum assisted recovery is being increasingly used because it minimizes the amount of water that needs to be treated and disposed. NAPL recovery is generally able to remove NAPLs to the point where all that remains is a thin film of oil noticeable only by its iridescent sheen on the water. It is ineffective for NAPLs present as residual saturation in soil.

Thermally Enhanced Product Recovery. Highly viscous petroleum products such as no. 4 and no. 6 fuel oils or crude oils do not flow readily through geologic formations and are therefore not easily recovered with conventional NAPL recovery techniques. A means of promoting their recovery directly from soils is to use thermally enhanced product recovery. Viscosity is a function of temperature: the higher the temperature, the lower the viscosity. Typically, subsurface temperatures need to be in the range of 66 to 93°C (150 to 200°F) for the technology to be effective. The subsurface temperature may be raised using hot air, steam, electrical heating, or radio frequency heating. Hot air has limited application because of its low thermal capacity. The application of heat has been demonstrated to increase recovery of heavy oil products by an order of magnitude.

Thermally enhanced product recovery is a commercial technology but has

limited utility (EPA, 1995b). Generally, it is used for heavy products and where steam is readily available, such as at sites with existing boilers. The cost of a transportable boiler makes this technology too expensive for routine operations.

Thermally enhanced product recovery is generally able to remove NAPL's from wells down to about a tenth of a meter (several inches). It can remove some, but not all, NAPLs present as residual saturation in soil.

Dual-Phase Extraction. Dual-phase extraction is the simultaneous removal of vapors and water from a common borehole by the application of a high vacuum. The purpose of the technology is to treat soil contamination below the water table so that the volatile components may be removed. The technology combines dewatering and venting. It is generally applied to lower permeability formations to minimize the amount of water that needs to be recovered or treated.

There are two variations of this technology. The first uses an internal drop tube to apply the vacuum to the bottom of the borehole. The drop tube removes the water in the well; once the well is dewatered, it will also remove vapors. The second variation uses conventional down-hole water pumps and applies a vacuum to the borehole. The applied vacuum aids in water removal and promotes volatilization in the dewatered soil.

Dual-phase extraction is best applied to hydrocarbon mixtures (such as gasoline, jet fuel, and mineral spirits) that have highly volatile components. It also

Sparging point being checked during regular site inspection. Courtesy of Fluor Daniel GTI.

may be used in conjunction with bioremediation to treat less volatile but degradable hydrocarbons. Use of this technology is increasing due to reports that it can be applied at low-permeability or heterogeneous sites for which few other remediation options exist (Brown and Falotico. 1994).

Air Sparging. Air sparging is the injection of air directly into the saturated zone (Brown. 1992). The injected air treats adsorbed and dissolved hydrocarbons through volatilization and/or biodegradation. The success of air sparging depends on the distribution of air through the saturated zone and the degree of mixing of the ground water. Air sparging works best in homogeneous, moderately permeable media such as fine to medium sands.

Air sparging is used to treat both volatile and nonvolatile hydrocarbon mixtures. With volatile mixtures such as gasoline and jet fuel, air sparging operates as both an extraction (volatilization) and a transformation (biodegradation) process. With less volatile mixtures, it is primarily a means of supplying oxygen to enhance biodegradation. For volatile hydrocarbons, air sparging systems are generally applied with an SVE system to capture and released hydrocarbons.

Air sparging is more effective for treating dissolved hydrocarbon plumes than for treating source areas (Bass and Brown, 1996). Air sparging has achieved regulatory goals with little rebound in contaminant levels for plumes of dissolved hydrocarbons at numerous field sites. Because of its effectiveness in treating dissolved hydrocarbons, air sparging can be used as a barrier system, in which a line of sparge wells is placed across a plume to intercept and remove dissolved constituents. The ability of air sparging to treat dissolved contaminants has made it an alternative to conventional pump-and-treat systems.

When air sparging systems are used to treat contaminant source areas, there is a higher probability of rebound of contaminant concentrations after treatment, especially when the NAPLs are present. The use of air sparging to treat source areas requires close well spacing and moderate to high air flows.

A related technology is "biosparging" which uses low air flows to minimize the amount of volatilization, so that any volatilized hydrocarbons are biodegraded in the vadose zone before being discharged to the atmosphere. This technique eliminates the need for an SVE system to accompany the sparging system.

Air sparging is a commonly used technology, especially for gasoline contaminated sites. It is also, used, although less commonly, at sites contaminated with diesel and jet fuel.

Biological Reaction Techniques

As Table 3-3 shows, bioremediation techniques (including biopiles, land farming, bioventing, biosparging, sparge barriers, and intrinsic bioremediation, as well as other bioremediation systems) are widely applicable for the control and

remediation of petroleum hydrocarbons. Many of the current bioremediation technologies on the market were initially developed to treat petroleum hydrocarbons.

The rate at which petroleum products biodegrade varies. Generally, the heavier the product, the slower the rate of biodegradation. Natural hydrocarbon biodegradation rates can be enhanced when the substance that most limits microbial growth is supplied to the contaminated zone. This premise provides the basis for most bioremediation processes. Because the hydrocarbon contaminants supply carbon for growth, in most cases the growth-limiting factor is the electron acceptor. In unsaturated soil, oxygen can be supplied by increasing air circulation. SVE, bioventing (see Box 3-4), and biopiles are three technologies designed to increase air circulation. The U.S. Air Force has applied bioventing systems at sites across the country, with consistent hydrocarbon degradation rates of 2.4 to 27 mg hydrocarbon per kg soil per day at soil temperatures between 4 and 25°C (39 and 77°F) (Ong et al., 1994). In the presence of sufficient oxygen, elements such as nitrogen, phosphorus, and potassium in nutrient-poor soils can limit microbial growth and biodegradation (Aelion and Bradley, 1991; Armstrong et al., 1991; Allen-King et al., 1994a,b), and addition of these limiting nutrients can also enhance biodegradation rates (Allen-King et al., 1994b).

Oxygen (O2) can also be added to the saturated zone using one of several methods (Brown et al., 1990). The first bioremediation systems used aerated water, but these systems were limited by the relatively low solubility of O2 in water (8–12 mg/liter) relative to air. Typically, about 2 to 3 g of O2 are required per g of hydrocarbon for complete mineralization; only about 3 mg/liter of total dissolved hydrocarbon can be mineralized in water saturated with respect to atmospheric O2. The next generation of bioremediation technology used hydrogen peroxide (H2O2) to stimulate saturated-zone biodegradation (Brown et al., 1993). Air sparging is currently the most common method for supplying O2 for enhanced biodegradation (Brown and Jasiulewicz, 1992). Solid O2-releasing sources can also be used to promote biodegradation by adding O2 to the ground water in situ as it flows through a permeable barrier (Bianchi-Mosquera et al., 1994).

With petroleum hydrocarbons, intrinsic remediation is a significant process. Intrinsic remediation is the reliance on natural processes, including volatilization, sorption, dilution, reactions with naturally occurring chemicals, and, most commonly, biodegradation, to decrease contaminant concentrations without human intervention other than careful monitoring. Intrinsic bioremediation (the type of intrinsic remediation in which biological processes predominate) has been well documented to occur in plumes of dissolved petroleum hydrocarbon contaminants. As documented in a survey of sites in California, petroleum hydrocarbon plumes reach an equilibrium point, often within 60 to 90 m downgradient of the source, beyond which ground water contamination generally does not pass (Rice et al., 1995). The location of the equilibrium point depends on the size of the source area, the ground water flow rate, and other environmental conditions. Equilibrium is reached though a combination of anaerobic and aerobic degradation

|

BOX 3-4 History of Development of Bioventing The development of bioventing illustrates the evolution of a technology driven by market need. The market for hydrocarbon treatment technology has been significant because of the widespread use and environmental release of hydrocarbon fuels by government, industry, and the public and the enactment of legislation requiring contaminated site cleanup. While technology existed for the treatment of hydrocarbon contamination, the cost and complexity of treatment often precluded widespread use of these technologies other than in areas of heightened exposure, such as at retail gasoline stations in urban and suburban areas. The Department of Defense (DOD), in particular the Air Force, has a large number of fuel handling and storage areas, many of which have associated environmental problems. Many of these sites are in remote locations where the installation and operation of treatment systems is difficult and costly. Thus, there was a need for a simple but effective technology that could address hydrocarbon contamination in remote areas. This need for inexpensive but effective treatment technology was the market driver for the development of bioventing. The basis for bioventing lies in two technologies: SVE (see Box 3-2) and bioremediation. Early in its application, SVE was considered a very cost-effective technology as long as the recovered vapors could be discharged directly to the atmosphere without treatment. However, concerns about air quality necessitated the use of vapor treatment, which significantly raised costs. Parallel to the development of SVE, developers of in situ bioremediation recognized that oxygen supply was a key to stimulating the biodegradation of hydrocarbons (see Box 3-1). However, the oxygenation systems used for in situ bioremediation were either ineffective or costly. Early in its development, the potential of SVE to supply oxygen and stimulate biodegradation was recognized (Thorton and Wooten, 1982; Texas Research Institute, 1982; Ely and Heffner, 1991). Despite these parallel developments, SVE and bioremediation remained separately applied technologies. Keeping SVE and bioremediation apart were concerns that bacteria would be unable to effectively scavenge oxygen from an SVE flow stream and that typical SVE systems generated considerable vapors, which often required costly vapor collection and treatment. Thus, practitioners believed that SVE would be an ineffective and costly from of bioremediation. Several factors changed the separate application and development of SVE and bioremediation and led to the emergence of bioventing. First was the recognition that bacteria were able to effectively use oxygen from an SVE system. Early work at Hill Air Force Base demonstrated that, even at high SVE flow rates, oxygen levels were significantly depleted due to hydrocarbon biodegradation activity (Hinchee et al., 1989), demonstrating the ability of bacteria to scavenge oxygen from an air |

|

stream. Second was the recognition that vapor levels produced during SVE operation were a function of the rate of air flow and could be controlled. (Hoag and Bruel, 1988; Johnson and Ettinger, 1994). Third was the finding that many fuels at DOD sites had diminished concentrations of volatile hydrocarbon components compared to gasoline, making the control of vapor emissions even less problematic. Based on these findings, researchers postulated that an air-based bioremediation system could be developed; the rate of volatilization could be balanced with the rate of biodegradation so that there would be no appreciable volatile discharge. Early test work on Air Force sites demonstrated that such a balanced system could be designed and operated (Miller et al., 1990; Hinchee and Ong, 1992). This early work was expanded into the Air Force's bioventing initiative, as a result of which more than 150 bioventing projects have been installed to date. Bioventing has now evolved from an adapted form of SVE to a separate, low-cost technology. Early forms of bioventing used a vacuum-based withdrawal system augmented with nutrient addition. With the demonstration that vapor levels could be readily controlled by adjusting the air flow rate, bioventing systems switched to lower cost air injection systems. Test work demonstrated that nutrient addition was not usually necessary because oxygen is the factor limiting microbial growth, making bioventing a simple air injection system. Finally, the understanding of how hydrocarbon-utilizing bacteria scavenge oxygen has led to the development of an effective but low-cost monitoring method: in situ respirometry. With in situ respirometry, the rate of oxygen uptake and/or carbon dioxide production is used as an indicator of biodegradation activity. When the respiration rate approaches background levels (i.e., the rate determined in a nearby uncontaminated location), remediation is considered complete. This method eliminates the need for expensive soil sampling. |

processes. As noted above, O2 is limited in the immediate vicinity of subsurface hydrocarbons. In the absence of sufficient O2 organisms will use alternate electron acceptors. Alternate electron acceptors become important when the dissolved O2 level drops below approximately 2 mg/liter (Salanitro, 1993).

As pictured in Figure 3-2, plumes of dissolved hydrocarbons typically have an anaerobic core area surrounded by an aerobic zone (Norris and Matthews 1994). In the anaerobic core, hydrocarbons may be degraded by denitrification iron reduction, sulfate reduction, and methanogenesis (see National Research Council, 1993). In the aerobic zone, they are oxidized by O2

FIGURE 3-2 Plumes of petroleum hydrocarbons in ground water typically have an anaerobic (oxygen-free) core area surrounded by an aerobic (oxygen-containing) margin. Anaerobic microorganisms degrade contaminants in the core, while aerobes degrade them in the margin. SOURCE: Reprinted, with permission, from Norris and Matthews, 1994 © 1994 by Lewis Publishers.

Research Needs

While an abundance of technologies is available for cleaning up sites contaminated with petroleum hydrocarbons, some problem areas still need resolution. The main needs are technologies for treating heavy hydrocarbon mixtures and hydrocarbons in low-permeability or highly heterogeneous formations. Heavy hydrocarbons have very low solubilities, sorb strongly, and resist degradation, rendering existing technologies relatively ineffective. At the same time, the impact of heavier, less soluble hydrocarbons on ground water quality needs careful study, because lack of mobility and bioavailability may limit adverse effects. Existing technologies are most limited in cleaning up low-permeability or heterogeneous geologic media because of the reduced circulation of fluids (air, water, NAPLs) in these media; technologies are needed to improve the ability to move fluids through such media. In addition, there is a continual need for investigation of ways to optimize existing processes for the treatment of all types of petroleum hydrocarbons and for the development of more cost-effective processes for hydrocarbon treatment.

CLEANUP OF CHLORINATED SOLVENTS

Sources

Chlorinated solvent use has been ubiquitous in society since these compounds were widely introduced after World War II, although in recent years use has declined somewhat due to more stringent environmental regulations. Global use of the chlorinated solvents trichloroethylene (TCE), perchloroethylene (PCE), and 1,1,1-trichloroethan e (1,1,1-TCA) in 1994 totaled 900,000 metric tons, with U.S. use accounting for 40 percent of the total (Leder and Yoshida, 1995). Users vary from large manufacturing facilities, to local businesses such as garages, photographic shops, and neighborhood dry cleaners, to homeowners. Chlorinated solvents can dissolve oily materials, have low flammability, and are fairly stable, both chemically and biologically. They are commonly used in industry as chemical carriers and solvents, paint removers, and cleaning solvents. Some of the common cleaning applications of these materials are metal degreasing, circuit board cleaning, metal parts cleaning, and dry cleaning. Chlorinated solvents are also used as intermediates in chemical manufacturing and as carrier solvents in the application of pesticides and herbicides. They have also been employed as fumigants. For a period of time, because of their solvent properties and density, TCA, TCE, and PCE were also used as household drain cleaners (Pankow and Cherry, 1996).

Because of their widespread use in industry, commercial establishments, agriculture, and homes, chlorinated solvents are among the most common ground water contaminants. Nine of the 20 most common chemicals found in ground water at Superfund sites are chlorinated solvents. TCE is the contaminant most commonly detected in ground water at Superfund sites, and PCE is third most common (National Research Council, 1994).

Fate

Chlorinated solvents may be released to the environment through the use, loss, or disposal of the neat liquids or through the use or disposal of wash and rinse waters containing residual solvents. In the latter case, the site will be affected primarily by dissolved-phase contaminants with concentrations as high as tens to hundreds of parts per million.

The movement and dispersion of chlorinated solvents in the subsurface vary depending on whether the solvents were released as a neat liquid or in dissolved form. If released in dissolved form, chlorinated solvent migration is governed largely by hydrogeological processes. The presence of solubilizing agents such as soaps (from wash waters) that counteract natural soil sorption-retardation mechanisms may facilitate the migration of the dissolved solvents. If the chlorinated solvent was released as a neat liquid, the liquid solvent will migrate downward