2

Waste Incineration Overview

This chapter provides an overview of waste generation, waste stream composition, and incineration in the context of waste management. Communities are faced with the challenge of developing waste-management approaches from options that include reduction of waste generated, incineration, landfilling, recycling, reuse,1 and composting. Waste-management options other than incineration are discussed here to illustrate that a combination of options, such as recycling, with incineration can alter the characteristics of waste streams fed to incineration facilities. However, the committee was not charged to undertake a comparative assessment of waste-management options.

In general, any incineration facility will incorporate the following processes: waste storage and handling, processing to prepare waste, combustion, air-pollution control, and residue (ash) handling. The types of waste-incineration facilities discussed in this report include incinerators, industrial boilers, furnaces, and kilns (see Chapter 3). There is a large variety of technology, varying from stationary facilities designed to combust millions of tons of waste per year collected from a broad geographical area, down to mobile incinerators used to remediate wastes from specific sites that are contaminated by hazardous waste.

TYPES OF WASTE INCINERATED

Three types of waste to which incineration is applied extensively are municipal solid waste, hazardous waste, and medical waste. Incineration of those three

|

1 |

Reuse refers to using a material more than once in its original manufactured form (e.g., refilling a returned glass bottle). |

TABLE 2-1 Waste Generation in the United States, Numbers of Incineration Facilities, and Amounts of Waste Combusted

|

Type of Waste |

Amount Generated (million tons/yr) |

Number of Incineration Facilities |

Amount of Waste Combusted (million tons/yr) |

|

Municipal solid waste |

209a |

122b |

36a |

|

Hazardous waste |

276c |

3c |

|

|

On-site Incinerators |

129 |

||

|

Commercial Incinerators |

20 |

||

|

Industrial Boilers and Furnaces |

950d |

||

|

Cement Kilns |

18 |

||

|

Light Weight Aggregate Kilns |

5 |

||

|

Medical waste |

—e |

1,655f |

0.8g |

|

a Estimate is for 1996 as presented in “Characterization of Municipal Solid Waste in the United States: 1997 Update” Franklin Associates 1998. b The Integrated Waste Services Association reports that there are 103 waste-to-energy facilities operating in the United States http://www.wte.org. In addition, Franklin Associates (1998) reported that 19 facilities incinerated municipal solid waste without energy recovery. c Estimate for 1991, presented by OECD 1996. Amount generated is largely in aqueous form. Does not include soil contaminated by hazardous waste. EPA estimates that hazardous waste incinerators burn 1.5 × 106 tons per year (Fed. Regist. 61(April 19):17358-17536). d EPA (1997a) estimates that there were around 900 boilers in the United States in 1993. There were less than 50 hazardous waste-burning industrial furnaces operating in the United States during that time. e OTA (1990) reports that estimate for medical waste, exclusive of that generated from home health-care, range from 0.3 to 2% of the total municipal solid-waste stream. f Brian Strong and Katie Hanks, MRI, Feb. 22, 1999, memorandum “Emissions Inventory for Hospital, Medical, Infectious Waste Incinerators Covered by the Proposed Section 11(d)/129 Federal Plan.” EPA Docket number A-98-24, item II-B-1. g Estimate of 845,500 is based upon 2,373 incinerators. Brian Hardee and Katie Hanks, MRI, July 16, 1997, memorandum “Revised Impacts of the Regulatory Options for New and Existing Medical Waste Incinerators (MWIs).” EPA Docket number A-91-61, item IV-B-072. |

|||

types is the focus of this discussion. Table 2-1 presents estimates of the amounts of those wastes generated, numbers of incineration facilities, and amounts combusted in the United States.

Municipal Solid Waste

Municipal solid waste is defined as the solid portion of the waste (not classified as hazardous or toxic) generated by households, commercial establishments, public and private institutions, government agencies, and other sources. This waste stream includes food and yard wastes, and a multitude of durable and

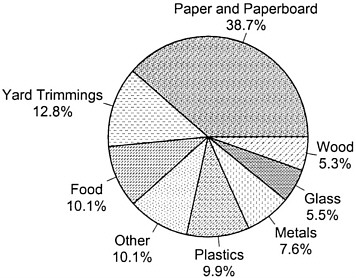

nondurable products and packaging. Figure 2-1 illustrates the composition of municipal waste in the United States in 1997. Almost 40% of the municipal waste stream is composed of paper and paperboard, about 10% plastics, about 13% metals and glass, and about 13% yard trimmings. The remainder consists of miscellaneous materials (wood, rubber, textiles, and so on). Municipal solid waste does not include segregated medical waste, but does include some medical waste that is mixed in.

The quantity of municipal solid waste in the United States has been increasing (see Table 2-2) despite government attention to the practices of waste reduction at the source and to recycling. Factors that contribute to the rate increase include the following: the U.S. population is growing (from 180 million in 1960 to 249 million in 1990 to a projected 276 million in 2000); per capita generation of waste has increased because of increasing consumption of nondurable, disposable items, and durable items, as well as extensive use of packaging.

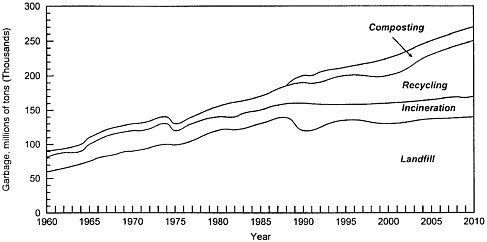

As shown in Table 2-2, the per capita generation of municipal solid waste in the United States increased from 1960 to 1990, but decreased from 1994 to 1996. The decrease in per capita generation is attributable to increased on-site composting of organic materials from 1990 to 1996. Despite the results of recycling and composting, the nation faces the challenge of increased total waste generation as long as population continues to increase (Figure 2-2). The amount of discards after recovery was higher in 1996 than in 1970, which indicates that the

FIGURE 2-1 Municipal solid-waste composition by weight, 1997. (Total weight = 217 million tons.) Source: Franklin Associates 1998.

TABLE 2-2 Per Capita Generation, Materials Recovery, Incineration, and Discards of Municipal Solid Waste, 1960 to 1996 (in pounds per person per day; population in thousands)a

FIGURE 2-2 Trends in municipal solid-waste generation and management in the United States, 1960-2010. Source: Franklin Associates 1997.

increased generation since 1970 has more than compensated for reductions due to recycling and composting.

Although it is still the predominant method of solid-waste management in the United States, the fraction landfilled was smaller in 1996 at 56% than it was in 1985 at 83% (Franklin Associates 1998). Incineration rates have varied over the last few decades (Figure 2-2 and Table 2-2). In 1960, combustion in low-efficiency combustors without energy recovery or advanced pollution-control technology burned 31% of the municipal solid waste generated. In 1980, incineration was down to 9%. However, because of increased emphasis on waste-to-energy conversion, by 1990, incineration had increased to 16% of total waste generation. By 2000, incineration is projected by EPA to decrease slightly to 15.6%.

A decrease in the total capacity of municipal-waste incinerators is thought to have occurred for several reasons: the continued availability of lower-cost disposal alternatives (such as landfilling); opposition from local advocacy groups, which has resulted in municipal planners ' rejection of waste-incinerator construction at many locations; mandatory recycling programs and increasing confidence in reduction and reuse as options; and the loss of flow control of municipal wastes.2

Uncontrolled combustion of municipal solid waste has been practiced for many years by individual homeowners burning trash, and by managers of hotels

|

2 |

“Flow control” refers to legal provisions that allow state and local governments to designate the places where municipal solid waste is taken for processing, treatment, or disposal. |

and community housing units burning their waste in small incinerators. But large-scale incineration in specially designed furnaces, with or without energy recovery, is of more-recent origin in the United States. The first U.S. waste-to-energy plant was operating in 1905 in New York City. Redesign of these systems for specialty use on municipal wastes led to today's generation of furnaces, most of which represent proprietary technologies from European manufacturers (IAWG 1995). According to the Integrated Waste Services Association (IWSA) in 1999, 103 waste-to-energy facilities in the United States combust about 15% of the nation's municipal solid waste (http://www.wte.org).

Hazardous Waste

Hazardous waste is defined by EPA under the Resource Conservation and Recovery Act (RCRA) as a waste material that can be classified as potentially dangerous to human health or the environment on the basis of any of the following criteria:

-

It might ignite easily, posing a fire hazard.

-

It might be corrosive, capable of damaging materials or injuring people.

-

It might be reactive—likely to explode, catch fire, or give off dangerous gases when in contact with water or other materials.

-

It might be toxic, capable of causing illness or other health problems if handled incorrectly.

-

It might be on a list of specific wastes or discarded compounds that EPA has classified as hazardous.

Hazardous wastes are generated by entities such as manufacturers, service and wholesale-trade companies, universities, hospitals, government facilities, and households. They are generated both by the chemical manufacturing industry and by users. However, pollution-prevention programs are proliferating. Such programs are used in industry and are encouraged by federal agencies. They can be designed to study each manufacturing process with an eye to reducing hazardous materials used or generated, and thereby, reducing the amount of hazardous materials that could be released as air pollution, water pollution, or hazardous solid wastes. Such programs are used in industry and are encouraged by federal agencies. Not only can they reduce environmental effects at lower expense than do on-site emission control devices and water-treatment facilities, but they can save manufacturers money.

When a hazardous waste is generated, the generator can either manage the waste on site or move it off site for treatment, disposal, or recycling. Before the establishment of EPA and the enactment of stricter environmental laws and regulations in the 1970s, dumping of chemical wastes into inadequately designed landfills or simply onto the land or into rivers or oceans was common. Before

there was awareness of potential health hazards associated with soil contamination, land dumping was often seen as the most practical way to dispose of chemical wastes.

Concern over contamination of air, surface water, and groundwater from uncontrolled land-disposal sites provoked the emergence of tougher regulations for land disposal. Those provided incentives for industry to use a wide variety of traditional and advanced technologies for managing hazardous wastes. The regulations also require that many wastes be treated by incineration or other methods to reduce organic content to specified levels before the wastes can be disposed of in a secured landfill.

EPA estimates that regulations forbidding land disposal of any hazardous waste that contains liquid will substantially increase the quantity of hazardous waste directed to incinerators, boilers, and furnaces. Although industrial growth is also likely to increase hazardous-waste generation, increasing emphasis on waste minimization and recycling is likely to exert pressure to reduce such generation.

Many kinds of hazardous waste are fed to incinerators, boilers, and industrial furnaces essentially as received. These wastes are often difficult to handle because of their consistency or hazardous nature, so minimal handling is preferred. Where feasible, however, pretreatment operations are desirable to facilitate homogenization of the waste and continuous feeding to the combustor. Common pretreatment operations for liquid wastes are blending and solids filtration; for solids, screening and size reduction (crushing or shredding); and for wastes in containers, liquid-phase decanting and shredding to allow continuous auger feeding.

Several types of industrial furnace systems are used to incinerate hazardous waste to recover energy or material. The major ones are cement kilns, lightweight-aggregate kilns, halogen-acid furnaces, and metal-recovery and smelting furnaces.

Cement is produced by feeding raw materials into a rotary kiln and burning them with fuel under controlled-temperature conditions. Suitable hazardous waste is used as an auxiliary or replacement fuel. Lightweight aggregate is produced much like cement, in a kiln configured and fueled much like a cement kiln using feed stocks that include special clays, pumice, scoria, shale, and slate. It is used to make insulation and monostructural and lightweight concrete. Halogen-acid furnaces are typically modified firetube boilers that process secondary waste streams containing 20-70% chlorine or bromine. The combustion gases are “scrubbed” with water to produce a halogen-acid product.

Cement kilns have been used to burn hazardous waste since 1972, when PCBs were combusted in Ontario, Canada. Since then, the use of waste-fueled kilns has become widespread in the United States, Belgium, and Switzerland. An intended benefit of combustion of waste as fuel in kilns is the recovery of energy from the waste and the consequent conservation of nonrenewable fossil fuels. Moreover, there is a strong economic incentive in that the kiln operators

are paid to take the waste, rather than having to pay for fuel. A substantial portion of the energy supplied by coal in a cement kiln can be replaced with waste-derived fuel.

Other common combustors used for hazardous wastes are mobile incinerators and industrial boilers. Mobile incinerators are most commonly used for contaminated-soil remediation projects. A typical mobile incinerator that is used at a site to treat contaminated soil consists of an incineration module, an air pollution control system, and other site-specific ancillary systems. As of March 1992, a survey showed that mobile incinerators were in various stages of remediating 2,139,700 tons of contaminated soil at 56 sites (Dempsey and Oppelt 1993). The sites included CERCLA-Superfund sites, RCRA sites, and spill cleanup sites, although the survey did not include underground storage tank sites that were contaminated by leaked material.

The boilers used to burn hazardous waste are standard industrial boilers widely used for steam generation in the process industries. They include fuel and combustion air delivery systems, waterwall furnace sections, and convective heat transfer sections. The waste feeding system is usually the only nonstandard equipment added to burn hazardous waste. Many natural gas-fired and oil-fired and a smaller number of coal-fired boilers also burn hazardous waste. Most gasfired and oil-fired boilers burn only wastes that contain essentially no ash or chlorine, because they do not have air-pollution control devices.

Medical Wastes

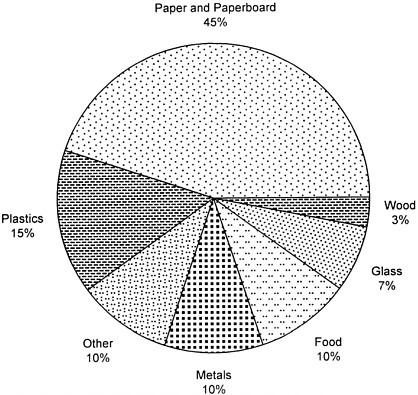

Medical (biomedical) wastes can have infectious or toxic characteristics that, with improper disposal, pose public-health concerns. Medical waste is created by a wide variety of activities. Essentially every aspect of the healthcare delivery system contributes, but hospitals are the largest medical-waste producers, generating up to about 26 pounds of waste per bed per day (Lawrence Doucet, Doucet & Mainka, Inc., pers. commun., September 1995). Large quantities of waste are also generated in analytic laboratories, medical and dental offices, and other primary and secondary health-care facilities. However, because of the potential handling dangers (for example, of blood-borne pathogens), few studies have directly analyzed the physical and chemical composition of medical waste. It is extremely heterogeneous, and its chemical composition and combustion characteristics, are determined largely by where it is generated. Nevertheless, Figure 2-3 indicates an average composition in 1995. By law (RCRA, subtitle J), infectious waste (e.g., microbiological cultures) should be incinerated or disposed. Noninfectious medical waste may be disposed together with regular municipal wastes. Public concerns with management of medical waste have increased by the possibility of spreading Acquired Immune Deficiency Syndrome (AIDS), by poorly operated hospital-waste incinerators, and improperly disposed medical debris washing up on public beaches in the 1980s.

FIGURE 2-3 Medical waste composition. Data from AHA 1993.

Typically, in hospitals today, about 15% of the total hospital waste is “red-bag” waste—waste that is considered infectious, and so must be incinerated or otherwise sterilized to prevent the spread of disease (AWMA 1994). However, some hospitals arbitrarily treat as much as 90% of their waste as red bag, apparently due to a lack of standard practices in health-care facilities for separating wastes that are truly red-bag from other waste. A 1992 study of New York City medical waste determined that much of the waste put into red bags did not qualify as red-bag waste and that much waste placed in brown bags should have been put into red bags. It was determined that the amount of red-bag waste can fall to less than 5% of the total when proper procedures are followed (Waste-Tech 1991). Such procedures include segregating recyclable material and compostable material (such as cafeteria food waste), implementing purchasing procedures that reduce the use of disposable material (for example, by installing electric hand dryers to replace or augment paper towels), and educating personnel to correctly dispose of waste as infectious or noninfectious. The study indi-

cated that one key to reducing red-bag waste is a thorough waste characterization for a facility, followed by the implementation of a plan for waste minimization and recycling.

A study by the Waste Energy Technologies, Inc. and the New York City Department of Sanitation indicates the degree to which red-bag waste is recyclable and preventable if changes in procurement and good maintenance practices are implemented (Wally Jordan, Waste Energy Technologies, Inc., pers. commun., July 1999). If such recycling becomes widespread, the need for medical-waste incinerators could be reduced to the quantity corresponding to the amount of red-bag waste.

Today, the two most-common medical-waste management practices are autoclaving (steam sterilization) and incineration followed by landfilling. In auto-claving, bags of infectious waste are placed in a sealed chamber, which is sometimes pressurized, and heated by direct contact with steam to sterilize them.

As a waste-management strategy, properly conducted and controlled incineration of medical waste will reduce both its volume and its infectious character. Most facilities that incinerate medical waste burn a diverse mixture that might include pathologic waste. Most of the materials that make up the general medical waste stream burn readily and, given the proper conditions, will continue to burn once ignited. Metal and glass sharps do not burn but do not greatly impede combustion of other materials. Pathologic waste has a very high moisture content and will not support self-sustained combustion, but it will burn if adequate heat is applied to drive off excess moisture. However, given the quantity of chlorinated or metals-laden (e.g., cadmium) plastics placed in medical-waste incinerators, antiquated and inefficient designs of some incinerators, and suboptimal operation and emission monitoring at many on-site facilities, the potential exists for relatively high emissions of various pollutants including dioxins and furans.

WASTE MANAGEMENT

The committee was not charged to evaluate integrated waste-management strategies. However, discussion of incineration in a community requires some consideration of the many alternative options and technologies available. The use of different management strategies can substantially affect the size and composition of the waste stream that is fed to an incineration facility.

Historically, waste has been disposed in the cheapest available manner. In areas with ready access to cheap land and transport, such as most of the United States, wastes were simply landfilled. In areas with little available land and high transport costs, incineration of wastes was adopted as a way to reduce the volume to be transported and landfilled. The addition of a waste-to-energy component to such incinerators was adopted as a way to reduce the overall costs of the process. Public concern about environmental deterioration as global and local phe-

nomena, engendered concern about reliance on incineration and on landfill practices, have led to calls for increased efforts to prevent, recycle, and compost waste.

Such calls have led to more attention to solid-waste management options as well as a transition from old-style incinerators (those which do not recover energy and do not have advanced combustors or emission-control systems) to modern waste-to-energy (WTE) plants.

In 1988, the federal government and several states set goals or enacted laws requiring the development and implementation of integrated waste-management plans. EPA devised a hierarchy of waste-prevention and waste-management methods that could be implemented in an integrated system and that would reflect the relative desirability of each method from the point of view of environmental protection. These methods include volume source reduction, reuse, recycling, composting, waste-to-energy conversion, and landfilling.

Some methods—such as recycling, composting, reuse, and reduction—decrease the amount of waste for disposal, and so have been considered to be environmentally preferable. Simple waste-prevention practices, such as reducing paper use by copying on both sides, or taking reusable bags to the supermarket, are examples of waste-reduction actions that also conserve natural resources. Similarly, for products made directly from raw materials, use of smaller amounts of the raw materials is expected to lessen environmental effects of the manufacture, transportation, treatment, and disposal of packaging. Waste reduction, reuse, recycling, and composting are all designed to reduce the quantity of material that must be incinerated and ultimately landfilled, and they are also likely to change the characteristics of the wastes that are incinerated and landfilled. The object is to reduce the quantities of toxic materials that may be released to the environment, from incinerator or landfill emissions.

Thus, various factors help determine whether a waste-incineration facility can be sited and operated successfully, including the amount of incineration capacity relative to the amount of waste that will not be committed to reduction, reuse, recycling, and composting; the extent to which an incinerator is designed with the most-effective technologies available and designed to reduce emissions, as much as technologically feasible; and the operation of the facility so as to properly use the advanced designs to maximize combustion and emission-control efficiency.

Volume Source Reduction

Volume source reduction methods are used to reduce waste generation. Such reduction is accomplished by changing the design of products and packaging (for example, to eliminate or reduce packaging, stimulate reuse, increase the durability of products, and eliminate disposables) and by modifying consumers' purchasing habits (for example, leading them to purchase fewer disposables, more durables, and products in less packaging).

Durables (consumer products that are designed and manufactured to have a useful life of at least 3 years, and that are easily maintained, repaired, and reused) made up about 15% of the U.S. waste stream in 1996, nondurables and throwaways 27%, containers and packaging about 33%, and yard waste and food waste, both of which are compostable, about 24% (Franklin Associates 1998). Yard waste has decreased as a percentage of the waste stream, from 23% in 1960 to 13% in 1996, but has increased in tonnage from 20 to 28 million tons/year in that time. But yard waste composting is expected to account for a 0.1% decrease by 2000 in overall per capita generation of waste that would be landfilled or incinerated, according to EPA. That will be the result of programs that encourage homeowners to leave grass clippings on the lawn and compost yard waste on-site and of limitations on landfilling of yard wastes. However, this effect could be offset by increased generation of waste from packaging and nondurable and durable products.

Nondurables, containers, and packaging make up roughly 55% of the waste stream and are considered the main targets for volume source reduction. Since 1960, smaller numbers of packages made of heavy materials, such as glass and metal, have been replaced with larger numbers of packages made of lighter but more voluminous plastic and paper. But nondurables have been increasing as a percentage of the waste stream since 1960, from 18.5% to 26.7% in 1993, and account for much of the overall increase in total and per capita generation. Much of the overall increase is doubtless due to the replacement of durables with single-use, disposable products.

Reuse

The durables component of municipal solid waste is the prime target of reuse programs. Such programs include encouragement of remanufacturing of items (e.g., electronics, furniture, and automobiles), and particularly encouragement of design of new items specifically with remanufacturing in mind, as well as encouragement of repair, cleaning, and recharging. In 1993, this component of durables constituted 17.2% of the waste stream, and they have been increasing steadily since 1960, when durables contributed 11.1% to the waste stream. Reuse methods may involve changing consumer habits with respect to the repair, cleaning, and other means of extending the lifespan of products already purchased; or perhaps a change in consumers' disposition of products that would otherwise have been thrown away (for example, resale, renting, donation, swapping, lending and borrowing, or return to the manufacturer for re-manufacture).

Recycling and Composting

Recycling and composting both involve the recovery of some substantive value from materials discarded in municipal solid waste. Once waste-prevention

methods, such as source and toxic reduction and reuse, have been applied where appropriate, the remainder of the waste stream is a candidate for recycling and composting strategies. Recycling entails recovery, processing, and refining of materials in the waste stream to create new products. Recyclable materials generated in 1993 include much of the glass (6.6%), several metals (8.3%), several resins of plastics (9.3%), most grades of paper (37.6%), and wood (6.6%). New materials (textiles, for example) are entering the recyclables stream with the development of new technologies.

Composting involves conversion of the organic materials in municipal solid waste to compost, a soil conditioner, through the exploitation of bacterial and fungal decomposition. The quality, and therefore use, of compost is limited by the types of materials used in the composting process. Any organic waste is compostable, the principal ones in the waste stream being soiled paper and cardboard (38%), yard waste (13%), and food waste (10%) (Franklin Associates 1998). Because much of the paper is also recyclable, and paper makes up a considerable fraction of the waste stream, there is considerable overlap between the potentially recyclable and compostable fractions. (In fact, paper waste, can be prevented, recycled, composted, incinerated, or landfilled.)

Some methods for increasing recycling and composting rates include the following:

-

Economic incentives, such as paying people and businesses for recyclables and compostables or, not charging for collection of recyclables and compostables.

-

Changes in packaging design to increase the availability to consumers of recyclable packaging and recyclable products.

-

Consumer education designed to motivate people and businesses to separate products and packaging for recycling and organic materials for composting. Also, to purchase products and packaging made from recycled materials and purchase products and packaging that are themselves recyclable.

-

Mandatory recycling requirements (for residential, institutional, and commercial sectors) with penalties for noncompliance.

-

Economic incentives for manufacturing of products and packaging to use secondary (recycled content) materials as feedstock.

Sizing An Incineration Facility

Deciding whether to use incineration as a municipal solid waste-management option within a community involves the difficult process of weighing economic, social, and public-health considerations. One problem is deciding the amount of incineration capacity that is desired, given the lifetime of typical incinerators (20-30 years); the need to recover construction and operating costs;

and the concern that too large an incinerator might distort a community 's options for source reduction, reuse, recycling, and composting (for example, through contractual requirements with the incinerator builder or operator).

Sizing an incineration facility in this era of changing waste stream characteristics and changing waste-management programs is not straightforward. Municipal solid-waste incinerators designed in the 1980s to burn 100% of the waste stream would be expected to see at least some decline in demand (about 30% under current conditions) as reuse, recycling, and composting took place during the 20-30 years of their design life. From a national perspective, recycling and composting alone accounted for about 27% of the waste stream in 1998 and it continues to grow. But that percentage is more in the many areas that have local or state requirements for higher recycling, composting, and reduction rates. Some states (such as California, New Jersey, and New York) have set goals of 50-60%, and a number of localities (such as Minneapolis and Newark) have reduced their disposal rates by 50% through waste stream reduction, recycling, reuse, and composting (e.g., Sudol 1994). The ultimate potential for all four methods could be well over 80% for some places, assuming intensive programs designed to address as many categories of materials, products, and packaging as possible and to educate the general public and businesses to the greatest extent feasible. That potential was determined through an extensive 46-material waste-composition study done for New York City in 1989, which suggested that 80% of that city's waste stream was theoretically recyclable or compostable and some additional quantity was reusable or repairable. Roughly half, or 40% of the waste categories, were recyclable in the city's early curbside-collection program (DOS 1992); other considered categories fell under its intensive recycling program. New York City now recycles newspapers, magazines, catalogs, phone books, corrugated cardboard, milk and juice cartons, household metallic items, plastic containers, glass containers, metal cans, and aluminum foil.

THE DEVELOPMENT OF POLLUTION PREVENTION, COMBUSTION CONTROLS, AND EMISSION CONTROLS

Waste-incineration technology, in general, and emission control, in particular, have improved substantially over the past years. The technologies and practices for controlling and processing the waste stream, for incinerating waste, and for controlling and managing the emissions and ash output have changed substantially in the last two decades. Today, in many cases, incineration takes place in the context of waste prevention (to reduce both the volume and the toxicity of the waste generated), recycling, and composting. Such activities affect the types and quantity of wastes incinerated and emissions generated.

Before the era of recycling, waste prevention, and emission controls, a typical large incinerator might be fed a heterogeneous mix of unprocessed municipal solid waste and lower-volume waste streams from different sources (such as

medical waste). The combustion process was largely unregulated with respect to temperature and oxygen control; consequently, waste was often not completely burned. There were considerable emissions of air pollutants and uncontrolled handling of the ash residue.

The principal products of waste incineration are carbon dioxide (CO 2) and water vapor, as for almost all other combustion processes, because the major process occurring is oxidation of the carbon and hydrogen in the waste. Also in common with other combustion processes, incineration produces byproducts, such as residual (bottom) ash and fly ash (from incombustible materials), and trace organic and inorganic compounds in the exhaust gases. The composition of these residues is determined by the composition of the incinerated waste stream, by the combustion process, and by reactions occurring in the waste gases after combustion. Because the input wastes may have higher concentrations of nonfuel components (including metals, chlorine, sulfur, and nitrogen compounds3 ) than fuels or biomass, there is more solid residue (bottom ash and fly ash), and the concentrations of trace compounds in the waste gases tends to be higher than for combustion with an equal heat output from fuel or biomass.

Pollution Prevention

A first step in controlling emissions is to minimize their creation in the incinerator. Measures for pollution prevention include reductions of pollutant precursors in the waste stream (for example, metals, chlorine, sulfur, and nitrogen). Such reductions can be brought about by means of product and packaging redesign, the reuse of products and packaging that contain precursors or catalysts for production of trace toxics, and recycling products and packaging, especially those containing such precursors. With smaller amounts of pollutant precursors entering an incinerator, their availability to produce air pollutants and ash in the incinerator is reduced; with larger amounts of such precursors entering an incinerator, greater and costlier effort is needed to prevent their escape to the air from the control devices.

Reduction of the quantity of toxic elements in the waste stream or reduction of elements that are transformed into, or catalyze production of, pollutants of concern upon incineration are often-overlooked components of source reduction. Heavy metals are found in batteries, pigments, leather, solder, and cans; chlorine is contained in PVC plastics and some bleached paper; polystyrenes might contain chlorofluorocarbons; sulfur is in tires and gypsum wallboard; and nitrogen is

|

3 |

Metals may themselves be toxic, or may catalyze the production of toxic inorganic or organic trace compounds in flue gases, for example, toxic chlorinated compounds like the dioxins and furans. Sulfur in the input stream will produce sulfur oxides in the flue gases, and nitrogen compounds will produce nitrogen oxides. |

in food and yard waste. Consumer products and packaging are also responsible for heavy-metals in incinerator ash and in leachate from landfills.

It is expected that most of the metals in the waste stream are contained in metallic items, such as cans. However, the heavy-metal and chlorine content in plastics and paper is especially relevant in a discussion of source reduction. The use of plastic and paper is among the fastest-increasing in the production of nondurables and packaging. Development of products and packaging that do not require any metals and other pollutant precursors, or that use fewer or less-toxic precursors (such as less-toxic substitutes for metals as pigments and stabilizers in plastics) would have the greatest effect on reducing the toxic precursors of the waste stream. But volume source reduction of packaging and nondurables in the waste stream would also result in reduction of some pollutant precursors.

Research by Franklin Associates for EPA (1994a) showed that after 80% recycling, lead-acid car batteries still contribute 66% of the lead in the waste stream, with contributions also from electronic items (from the solder that is used), leaded glass (particularly from TV and computer monitor tubes), leaded ceramics, and leaded plastics. Batteries are a similarly large contributor for cadmium: even after nickel-cadmium battery recycling, such batteries still contribute 54% of the cadmium in the waste stream. The second leading contributor of cadmium in the waste stream is plastics, with further contributions from electronic items, appliances, and pigments. Similar results were found for mercury. Batteries are the leading contributor of lead, and fluorescent tubes, thermometers, thermostats, and a few other categories contribute most of the rest.

However, the committee emphasizes that such data by themselves can not be used to predict the metals composition in the emissions of an incinerator combusting the waste. Minimizing the use of precursors in consumer products via design changes (and maximizing the recycling of materials that contain precursors) would reduce, but not eliminate, the environmental effects of solid-waste disposal by incineration and landfilling.

CONCLUSIONS

-

The use of different waste management strategies can substantially affect the size and composition of the waste stream that is fed to an incineration facility. Waste reduction, reuse, recycling, and composting are all designed to reduce the quantity of material that must be incinerated and ultimately landfilled, and they are also likely to change the characteristics of the wastes that are incinerated and landfilled.

-

A first step in controlling emissions is to minimize their creation in the incinerator. Measures for pollution prevention include reductions of pollutant precursors in the waste stream (for example, metals, chlorine, sulfur, and nitrogen) by means of product and packaging redesign, the reuse of products and packaging that contain precursors or catalysts for pro-

-

duction of trace toxics, and recycling products and packaging, especially those containing such precursors. Reduction of the quantity of toxic elements in the waste stream or reduction of elements that are transformed into, or catalyze production of, pollutants of concern upon incineration are often-overlooked components of source reduction.