7

Materials Technologies

Introduction

Materials science is an interdisciplinary field, and the national research and development effort in this area is robust and broadly based. In 1989, the National Research Council published a report, Materials Science and Engineering for the 1990s,1 which was the culmination of a comprehensive survey of materials science and engineering in the late 1980s. The technology-development trends identified in that report are likely to continue to be relevant over the next few decades. Rather than conduct its own independent survey of such an extensive field, the Panel on Technology chose instead to highlight a few materials technologies that may be useful for developing improved capabilities for future naval forces. The panel's review is not meant to be comprehensive. For example, semiconductor technology is expected to continue its rapid pace of development2 and contribute significantly to the capability of future Navy and Marine Corps forces, but it is not discussed in detail here.

That being said, the opportunities are legion for developing enhanced capabilities for future naval forces through the application of materials technologies. Materials affect the operations, maintenance, and safety of all naval systems. The

development of advanced materials with improved properties can lead to enhanced capability and reduced life-cycle costs. The Department of the Navy can ensure the development of new materials required for future naval systems by continuing to fund basic research in materials science.

Development Drivers

The panel envisions a systems approach to materials development in the future, whereby physical and mechanical properties are understood at the atomic scale and the design of new materials is carried out computationally based on this knowledge. Capitalizing on the opportunities presented by an atomistic simulation-based design approach may enable breakthroughs in, for example, ferrous alloys, titanium matrix composites, polymer composites, high-temperature ceramics, wide-bandgap semiconductors, optical materials and coatings, and smart materials based on ferroelectrics, ferromagnetic materials, and ferroelastic materials. Advances in materials technology are expected to enable the development of improved microelectromechanical systems, leading to more capable systems-on-a-chip. Sensors that are mechanically and electrically adaptive will likely be part of this improved systems-on-a-chip capability.

Advances in materials processing and synthesis will be needed in order to meet the requirements of future Navy and Marine Corps missions. The processing of nanophase materials could be scientifically based on high-frequency cluster sputter techniques. The processing of diamond, based on chemical vapor deposition and flame techniques, could be extended so that low-defect-density materials can be achieved.

In the panel's view, the technology drivers for future naval requirements will be as follows:

- Computationally designed materials and processing;

- Unique nanophase materials systems for new applications;

- Smart materials and systems based on shape memory alloys, ferroelectrics, and ferromagnets adaptive for mechanical and electrical applications; and

- Wide-bandgap semiconductors, materials for microelectronics, photonics, and RF and microwave applications.

Technology Trends and Future Materials Developments

Computationally Driven Materials Development

The panel believes that a key development in the materials area will be the emergence of a computational design approach based on knowledge of the physical and mechanical properties of materials at the atomic level. This approach will

lead to the development and manufacturing at low cost of smart materials and nanophase materials that will, in turn, be enablers of new structures and devices. Design will follow from first principles, giving rise to a systems approach in materials development. Simulation of materials characteristics using this approach will include modeling of microstructure, defects, surface structure, interface properties, transport properties, reaction kinetics, prediction of adhesion and bonding, thermodynamic properties, and general mechanical behavior.

Process-simulation modeling will be another materials technology enabler. Processes based on thin-film growth techniques, such as advanced chemical vapor deposition (CVD) and molecular beam epitaxial growth, could be first simulated in the computer before actual growth takes place. Other processing techniques for molding, extrusion, solidification, and physical spray techniques for nanophase materials could also be simulated.

Materials Simulation

Materials simulations can be classified into three domains: (1) simulations based on quantum mechanics and statistical mechanics, (2) atomistic simulations based on classical equations of motion, and (3) simulations based on phenomenological models. These three domains will be interfaced with the appropriate process models and finally extended to the simulation of materials systems. Such an approach will likely be cost effective, since it will allow the development of materials systems specifically designed to meet the required specifications.

Simulation of Materials Component and Materials System Integration

Integrated simulations of materials systems will require greater understanding of thermomechanical phenomena for naval components. A continuously upgradable materials database would greatly facilitate the development of computational materials science and engineering, and the development of such a database is worthy of the Department of the Navy's attention. The database should provide the material parameters required for system simulation and for prediction of bulk properties.

Modeling of Heterogeneous Materials

Current models typically focus on homogeneous materials, but future performance requirements will most likely be met with heterogeneous materials that have properties controlled by surfaces and interfaces and behavior based on phase transitions and material degradation. Therefore, simulation models for heterogeneous materials that incorporate the role of defects and dynamic behavior must be developed. Further development of molecular dynamics for organic molecular polymers and inorganic crystals will be needed.

Modeling of reaction paths for intermetallic compounds, ceramics, metal alloys, high-strength steels, and titanium alloys will be an enabling path for the development of these materials. Likewise, the processing and synthesis of photonic materials and phonon-engineered materials will be required to meet the system requirements utilizing these materials.

Smart Materials and Sensors

Smart materials technology consists of the application of ferromagnetic, ferroelectric, and ferroelastic materials, better known as shape-memory alloys, as mechanical actuators and/or sensors to improve the performance of components, structures, and systems. The panel envisions the integration of smart materials with nanoscale electronic processors resulting in mechanically and electrically adaptive elements.

Many proposed systems will benefit from the utilization of smart sensors. For example, smart sensors could increase the performance and efficiency of personnel and equipment in areas such as condition-based maintenance. Overall, a full assessment of smart materials and MEMS materials will need to be carried out. System integration including data sampling, networking, and communication issues will have to be addressed. Smart materials on the microscale will be combined with electronics on the nanoscale to form smart sensors, all as part of a micro-nano-electronic technology thrust.

Nanophase Materials

A new emphasis in materials science centers on the nanometer (10-9 meter) size regime, which is intermediate between the well-studied macroscopic and atomic size regimes. The understanding of structural and compositional features in the nanometer size range will facilitate the control of the magnetic, electrical, and optical properties of materials. Nanophase or nanomaterials is an area of prime importance for future naval applications, especially with the expected conversion of most ships to integrated electric power and propulsion systems. Magnetic nanomaterials may offer dramatically improved performance for magnetic-storage applications. The enhanced strength of nanophase coatings and the potential for improved mechanical behavior of consolidated nanocrystalline materials have obvious applications in the area of structural materials. One important example is the superplasticity of nanocrystalline materials, a property appropriate for missile nose cones and armor.

Nanophase materials could be combined with nanoscale electronics to produce a new class of sensors able to achieve ultrahigh speed and low-power dissipation. The capacity to carry out high-resolution lithography capable of

manufacturing devices with critical dimensions on the order of a nanometer is required before nanophase materials technology can become practical for naval applications. Other related technologies that will require further development before nanophase materials can be widely deployed include plasma-etch technologies and interconnects for quantum electronics. In photonic systems, nanophase structures will enable the development of nonlinear optical systems or possibly smart nanosensors that are optically interconnected to form a highly capable metasensor.

Structural Materials

Structural materials are widely used in naval systems, and some applications, such as engine components and ship structures that are exposed to salt water, are quite demanding. The future trend in the development of new structural materials will be to integrate functionality into the structure. An example of this type of integration would be the development of a submarine hull that contains embedded MEMS devices to maintain laminar flow around the hull and embedded networked conformal sensor arrays for both acoustic (sonar) and nonacoustic sensing.

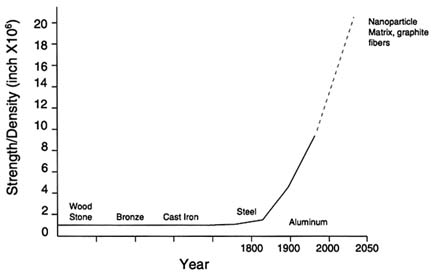

Improved strength and stiffness are always desirable in structural materials, and such improvements may become available through the engineering of covalently bonded materials or, alternatively, though the use of thin lamellar structures that combine high strength and high modulus with a designed-in anisotropy to fit the specific application. The panel anticipates that materials will be available by 2035 with a strength-to-density ratio that is double that available today. This projection, which is illustrated in Figure 7.1, is based on the development of high-strength single-crystal graphite fibers.

High-temperature Structural Materials and Coatings

High-temperature materials and coatings, including metal composites, ceramic-metal composites, intermetallic alloys, and carbon-carbon composites, which are useful in a number of applications including aircraft engine components, may be amenable to low-cost synthesis through the application of computational materials design. Metal-matrix composites will likely address most requirements for materials that can withstand temperatures up to 500 °C. For systems requiring components that can withstand 1,000 to 2,000 °C, oxide materials will be needed, such as the yttrium aluminum oxides.

Metallic and ceramic surface coatings are currently used to improve the performance and prolong the life of advanced turbine materials. Protective coatings used in aircraft, marine, and power generation turbines to increase operating temperatures extend component life by providing protection from high-temperature oxidation and high-temperature corrosion. This dependence on coatings to

FIGURE 7.1 Tensile strength-to-density ratio of structural materials projected through 2035. The extrapolated values are based on a calculation of the maximum strength-to-density ratio of high-density single-crystal graphite fiber. SOURCE: Adapted from National Research Council, 1989, Materials Science and Engineering for the 1990s: Maintaining Competitiveness in the Age of Materials, National Academy Press, Washington, D.C., Figure 1.1, p. 20.

improve performance, extend service life, and reduce maintenance will be increasingly important as military budgets decrease. Advances in ceramic coatings will be required for future naval systems.

In the temperature range of 1,500 to 2,100 °C, materials such as silicon carbide, silicon nitride, and other systems able to limit oxidation will be needed. Candidate processing technologies for these difficult-to-shape materials include microwave and laser processing.

For systems above 2,000 °C, carbon-carbon composites, diamond-like coatings, synthetic-diamond thick films, and carbides such as boron tetracarbides and titanium carbides will be needed.

Processing and Synthesis of High-temperature Structural Materials

The technologies that may enable the manufacture of high-temperature structural materials are rapid solidification (splat cooling) and electron-beam evaporation. These techniques will allow the development of lamellar composition and functionally graded materials. Methods of processing of fiber with a polymer matrix that combine joining processes with material synthesis will be needed.

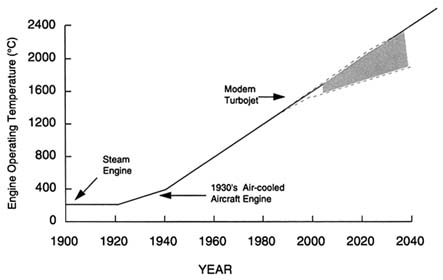

FIGURE 7.2 Projected high-temperature capability of NiAl superalloys. SOURCE: Adapted from National Research Council, 1989, Materials Science and Engineering for the 1990s: Maintaining Competitiveness in the Age of Materials, National Academy Press, Washington, D.C., Figure 1.2, p. 21.

Engine Materials

Key materials-related goals for future naval engines are to reduce weight, increase temperature capabilities, improve mechanical properties, and improve corrosion and oxidation resistance. Candidate high-performance materials include organic matrix composites, titanium alloys, and intermetallic compounds. For turbine components, nickel aluminum (NiAl) polycrystalline materials could be extended so that they are available in a single-crystal form. Intermetallic compounds, along with titanium-based metal-matrix composites such as TiAlNb with SiC fibers, may be useful for compressors. Static engine components will require high-modulus intermetallic compounds such as g-TiAl. The high-temperature capability of superalloys based on NiAl is expected to exceed 2,000 °C by the year 2035, as shown in Figure 7.2. Progress will be based on advances in synthesis and microstructure control.

Marine Materials

There is a continuing need for stronger, easily weldable, and less expensive steels for marine structures such as ship and submarine hulls. Steel-alloy designs based on first principles with controlled microstructures and predicted mechanical

properties should be available in the near future. An achievable goal is 130 kips per square inch (ksi) yield-strength steel with high-fracture toughness that is able to withstand stress-corrosion cracking and fatigue-crack propagation. By using basic atomistic principles to model stress-corrosion cracking, greater understanding of stress-corrosion effects can be achieved. This knowledge can be extended to the design of new steels. A combination of new materials such as ultralow-carbon bainite (ULCB) and high-strength, low-alloy (HSLA) steels will yield significant advances in strength and corrosion resistance.

Titanium and titanium alloys exhibit good fracture toughness, corrosion resistance, high-temperature strength, and low magnetic signature. Titanium alloys in aircraft offer as much as a 50 percent weight savings as compared with aluminum parts. Ti-Al-V is used extensively in air frames today, but higher-temperature titanium alloys such as alpha-2, g, and orthorhombic titanium aluminides are under development and offer improved temperature capability beyond the 700 °C limit of current production alloys. The new alloys, which should be available in about 10 years, possess ductility in the range of 2 to 4 percent, which is adequate for most manufacturing processes. Titanium matrix composites (TMCs) consisting of titanium alloys reinforced with silicon carbide fibers may provide significant performance improvements, particularly for use in high-temperature engines.

Specialty Materials

Future naval systems for 2035 will require technology advances in the following specialty areas: superconductors and magnetic materials, organic materials and coatings, energetic materials, and high-temperature semiconductors. These material systems affect a number of areas and are summarized in the following sections.

High-Temperature Superconductivity

Naval applications for superconductivity include (1) superconducting magnets for electrical motors and ship propulsion, (2) superconducting magnetic sensors for mine detection, (3) superconducting magnetic systems that store energy for burst power, (4) high-Q cavities for high-resolution radar systems, and (5) low-power analog and digital circuits. In order to realize the benefits of superconductivity in fleet applications, further technology development will be needed in materials engineering, manufacturing, and systems integration.

Since the discovery of HTS in 1986, numerous applications have emerged, including superconducting cables, transformers, motors, and energy-storage devices. HTS conductors are typically fabricated as a multifilamentary flat tape. These conductors use a ceramic precursor powder placed in a silver billet. The billet is then formed into a thin filament using commercial deformation processes, and multiple filaments are then placed into a silver tube and deformed

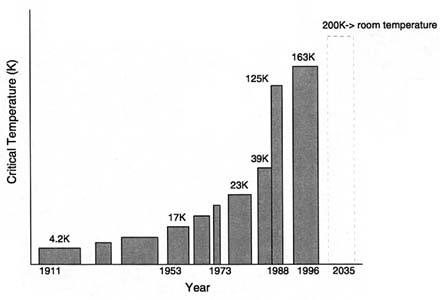

FIGURE 7.3 The increase over time in the critical superconducting temperature of HTS materials. SOURCE: Adapted from National Research Council, 1989, Materials Science and Engineering for the 1990s: Maintaining Competitiveness in the Age of Materials, National Academy Press, Washington, D.C., Figure 1.4, p. 23.

again into a bundle of filaments. These steps are repeated until the conductor contains the appropriate number of filaments. The conductor is then rolled into a flat configuration and heat treated to transform the ceramic precursor into a superconductor. This process is referred to as oxide powder in tube (OPIT).

OPIT conductors have shown linear performance improvements over the last 10 years, and manufacturing costs have steadily declined. HTS manufacturers are working with U.S. national laboratories to develop the next generation of HTS-coated conductors. Coated conductors use a thin film of HTS deposited onto a substrate; they exhibit significant performance gains as compared with OPIT conductors and can be significantly less expensive to manufacture.

The projected future critical superconducting temperature for high-temperature superconductors is shown in Figure 7.3.

Magnetic Materials

Improved magnetic materials will be required for magneto-optic devices and high-sensitivity, low-cost magnetic sensors to be utilized as magnetometers, radio-frequency antennas, and biological and chemical sensors. Improvements in

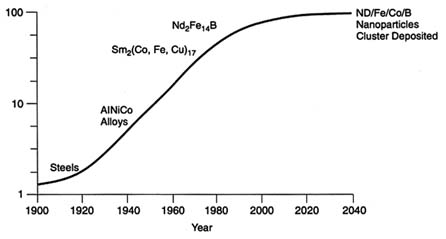

FIGURE 7.4 The projection for magnetic materials, with the fluxmagnetization product as a figure of merit. SOURCE: Adapted from National Research Council,1989, Materials Science and Engineering for the 1990s: Maintaining Competitiveness in the Age of Materials, National Academy Press, Washington, D.C., Figure 1.3, p. 22.

material properties through enhanced processing techniques and modeling will enable these applications. The projection for magnetic materials is shown in Figure 7.4 using the flux magnetization product as a figure of merit. Nanoparticle materials are expected to achieve the ultimate projected performance illustrated in the figure.

Advanced Energetic Materials

For the naval forces of 2035, a competitive edge in the power and range of missiles is required, in addition to improved warhead explosion devices. Advances in techniques for the synthesis of very dense organic compounds that are highly substituted with energetic groups will be required. The approach will be computationally based initially, followed by a synthesis simulation and prototype production. Continued development of new chemical processes to produce novel energetic materials and improvements of initial chemical processes to produce novel structures economically and environmentally are essential.

Coating Materials

The issue of life extension will be a critical one for the Navy and Marine Corps of the future. In addition, coatings reduce drag, increasing speed and range. The development of silicon-based coatings with natural antifouling agents

will be required. In most instances, these coatings will be self-cleaning through the action of water flow across the hull.

Organic Materials—Flame-resistant, High-temperature Organic Composites

Polymers and polymeric composites are required for superior flame-resistant and high-temperature properties. These proposed materials are phthalonitrile-based composites with thermo-oxidative stability up to 500 °C. These novel flame-resistant materials will enhance ship and submarine safety.

Anticipated Benefits of the Application of Materials Technologies

A competitive edge in the power, range, and performance of Navy and Marine Corps missiles will be acquired from advanced energetic materials. UAVs with high-performance sensors will be available. Naval craft will be protected with flame- and corrosion-resistant coatings able to extend the life of systems while achieving enhanced performance. New materials will enable new sensors, including those with the capability to detect and assess damage in microseconds, allowing for a reaction time in the range of seconds. Advanced sensor and actuator systems will combine damage detection with damage control.

The further advances in superconducting materials will lead to both new and improved military capabilities. Motors and generators will be smaller and lighter and more efficient. These will permit ship-design changes resulting in greater payload capacity or ships with smaller radar cross sections. Superconducting magnets will allow for high-sensitivity mine sweepers. Superconducting filters will allow for low-loss, in-band communications in areas of high electronic noise and will facilitate the development of high-bandwidth underwater communications.

High-temperature materials and coatings will result in more reliable, more efficient gas turbine engines with prolonged service life and lower fabrication costs. The development of new ferrous and titanium alloys will result in more capable ship and submarine hulls and structures with lower life-cycle costs.

Developments in wide-bandgap semiconductors and photonic materials will result in optimized performance of microwave and millimeter-wave detectors and transmitters. The development of diamond as a manufacturable semiconductor will allow it to be used in both analog and digital systems as well as photonic applications with smart sensors. Large-area silicon wafers and epitaxial layers (200 to 300 mm) will affect all microelectronic VLSI systems from computers to signal processing. Silicon quality and defect control continue to be important areas for Navy investment.

Recommendation

Materials are used in every aspect of naval operations. In the future, entirely new and enhanced existing materials will be designed and manufactured using a computational approach in which the physical and mechanical properties of materials are understood on an atomic scale. The nanophase materials engineered in this way will be tailored to meet specific requirements and to be reliable and robust at lower life-cycle cost. The Department of the Navy should strongly support the development of this materials design and processing approach.