8

Electric Power and Propulsion

Introduction

The panel focused on those electric power generation, storage, and propulsion technologies that, when applied as a system, will support the electrification of ships, submarines, and land-based vehicles. It surveyed the status of key elements of power systems such as energy storage devices, electric power recovery subsystems, and battery technologies. Industrial development is ongoing in most of these areas, and current trends suggest steady improvement in capacity, density, modularity, and reliability. The naval forces can take advantage of commercial developments by actively monitoring the commercial marine power and propulsion sector and by applying a top-down systems engineering process to fleet capability upgrades.

A recent naval planning document1 outlined a development path for modernizing the power and propulsion capabilities of future surface ships and submarines. The plan does the following:

- Takes a systems approach, allowing appropriate trades for optimization of performance within the constraint of affordability;

- Takes a design approach in requiring modularity, commonality, and use of commercial technology for economy of scale wherever appropriate;

- Has initiated, and is following, a development path for those basic power generation, distribution and control, and propulsion technologies that are critical for shipboard implementation;

- Has initiated a path whereby this capability can be used to backfit existing hulls in a hybrid configuration and be fully electric in new construction platforms; and

- Provides a path for developing those critical technologies and beginning the integration of both hybrid and fully electric systems into the fleet during the next decade.

The concept appears to be sound, the enabling technologies are achievable, and the opportunity is now available to initiate a major change in the generation and use of electric power aboard ship. The benefits to the naval forces could be significant and far reaching. Advances in materials used in electromagnetic machinery, such as high-field permanent magnets and high-temperature superconductors, present opportunities for substantial increases in power density and efficiency. The electric ship approach is enabled by the ongoing revolution in electronics where advancements in solid-state semiconductor technology are being applied to power semiconductor devices. The emergence of direct electric conversion technologies, such as fuel cells, offers potential for fuel-efficient, low-emission, and low-noise sources of electrical power.

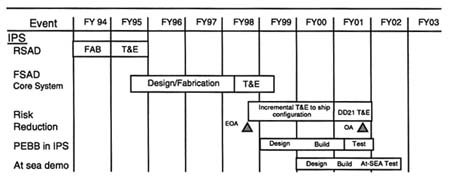

Within the plan, the Department of the Navy's integrated propulsion system (IPS) architecture will allow incorporation of developing technologies such as permanent magnet (PM) electric machines, fuel cells, and the power electronic building block (PEBB) architecture into future ship designs as programmed, preplanned replacements for the core technology in the first-generation IPS modules. Use of technology-independent module interface standards will facilitate technology insertion with minimum impact on the ship design and construction process.

IPS with electric propulsion motors allows for consideration of integrated motor and propulsor concepts. The steerable podded propulsor provides the greatest potential for meeting naval hydrodynamic and hydroacoustic requirements while also being competitive with conventional propulsors on commercial ships.

The benefits of ship electrification are as follows:

- Combat systems effectiveness. Integrated electric power and propulsion systems enable design flexibility that, in turn, will facilitate the optimization of topside arrangements for maximum combat system effectiveness.

- Survivability. The elimination of gear trains and propeller shafts, together with the flexibility and modularity of electric systems, will enable graceful degradation and rapid reconfiguration of vital systems, thus enhancing survivability.

- Signature reduction and quieting. By eliminating the mechanical link between the power plant and the propulsor (i.e., propeller), electric drive will

- enable reduction of noise and vibration by allowing acoustic isolation of the engine generators.

- Improved operational flexibility and reliability. With the power station concept, all power will be supplied by a set of prime movers that provide power to propulsion, ship service, and other designated loads. This approach will provide the flexibility to shift power between propulsion, ship service, and other electrical loads, which cannot be done with a mechanical drive ship, and can enable improved speed control and steaming efficiency and the elimination of less efficient controllable pitch propellers in favor of fixed pitch types.

- Increased flexibility and adaptability. Integrating electric power and propulsion systems will provide flexibility in servicing other loads such as environmental controls (air conditioning) and launch and recovery systems, electric armor, high-power advanced electronics, and electric weapons.

- More space available. Eliminating gears and shafts from the propulsion system will make more space available for other uses. Also, the prime mover will no longer be tied to the propeller shaft line, and the power sources can be distributed throughout the ship as necessary.

- Reduced manning. Digital control and automation, which will be an integral part of ship electrification, will reduce the requirements for human operators (in machinery spaces, for example).

- Reduced logistics. Common power and propulsion modules can be used across the fleet.

- Reduced costs. Commercial technology appears likely to be available for many of the system elements.

- Life-cycle cost and fuel-consumption savings. Overall fuel efficiency can be improved if a ship is able to operate at varying speeds over a substantial part of its operational profile, and variable speed propulsion will be enabled by electric drive.

In general, the same line of reasoning that applies to surface ship power and propulsion systems also applies to submarines. Optimization of submarine systems will be driven by stealth, safety, power density, and other requirements that differentiate surface and undersea vehicles. Submarine power and propulsion system technologies of the future will include the following:

- Very low harmonic motor controllers;

- High-power-density and high-performance solid-state inverters and converters and the components thereof;

- Electrical substitutes for systems and components that now rely on fluid transport for energy and actuation, e.g., electric actuators, electromagnetic launchers, and thermoelectric coolers;

- Motors and generators with very low acoustic and magnetic signatures, including versions that can operate submerged in seawater at high pressure; and

- New technologies for motors and generators such as superconducting magnets, cryogenic coolers, current collectors, high-field permanent magnets, liquid cooling, and active noise control.

A HTS high-torque drive motor can be one-fourth the size of a permanent magnet motor, and its efficiency can be high enough to compete with existing reduction gear/steam turbine systems. HTS motors and generators can also be quieter because the high-density magnetic fields produced allow elimination of iron cores, simplification of armature designs, and elimination of other components that create noise.

The Marine Corps relies heavily on power and propulsion technology for its vehicle power systems. The requirements for higher water speed amphibious vehicles, signature reduction, adaptability to electric power, future electric weapons, and reduction of vehicle weight all lead to the need for an integrated electric power system for future land and amphibious vehicles.

Key technologies for land and amphibious vehicles mirror those described for surface ship systems but are driven by a different set of requirements. These include the following:

- Pulsed-power systems including energy storage pulse-forming networks and very high power solid-state switching;

- Flywheel energy storage;

- High-power-density engines, including electric drive systems with a unit size of several hundred horsepower; and

- Electrical steering, suspension, and actuators.

In conclusion, the panel believes that electric power science and technology holds great promise for major technical progress and payoff in the future. The remainder of this chapter is organized to first discuss electric power generation and storage technologies and then focus on the electric ship concept and associated technologies.

Electric Power Generation and Storage Technology

Introduction

Warfare in the early 21st century will involve the use of advanced technologies and combat systems with ranges, lethality, and detection capabilities surpassing anything known in contemporary warfare. In the battle zone surrounding and including the battle group and expeditionary forces, there will be requirements for electrical power at levels from tens of watts for surveillance and communication, to kilowatts for radar and for a variety of electric motors, to hundreds of kilowatts for field-base power demand and multi-megawatts for advanced

weaponry, countermeasures, and propulsion systems. Mobility of all system elements will be essential for survival and success. Therefore, although fuel supply may dominate the total system operational weight for nonnuclear power, mobile weapons and sensors should be powered by supplies that have high specific power, are compact and quiet, and have minimal signatures in the full electromagnetic and acoustic spectra.

Nonpropulsive power generation requirements and implementations will be integrated into a single system with propulsive power generation. This, and the continued deployment of special electric loads, will determine the requirements for power distribution, storage, and conditioning.

The concept of an all-electric, or more electric, ship is gaining momentum in both U.S. and foreign navies. Simply stated, this concept embodies the use of electrical means for all power needs in lieu of other means such as mechanical, pneumatic, and hydraulic. This then provides an opportunity to standardize components and systems, reduce signatures, and better integrate the power and propulsion systems for all vehicles. The move toward increased reliance on electricity is also being applied to air vehicles and to Marine Corps amphibious and land vehicles.

Versatility in electric power availability will enable new varieties of weapons and ship systems. Some proposed new weapons present especially rigorous power supply requirements. Electrothermal, chemical, and electromagnetic guns and high-powered laser or microwave directed-energy weapons, for example, require large amounts of power over very short time periods, as do electric rail aircraft launchers (electric catapults), which are technically similar to electromagnetic guns. Sophisticated power generation, distribution, and control systems will enable local-zone power distribution and conditioning, which will enable lower platform signatures and localized platform damage control. An order-of-magnitude evolution in size and power requirements for specialized sensors and unmanned systems presents new application requirements for power storage systems.

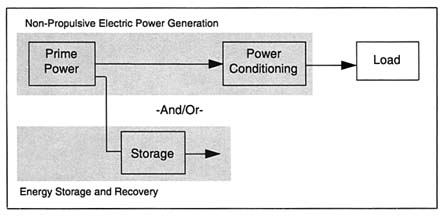

A general schematic for the type of power system addressed by the panel is presented in Figure 8.1. A prime electric power source feeds directly, or via a load-leveling or storage stage, into a conditioning stage to alter the electrical parameters for optimum reliable power distribution to a load.

The panel believes that the following three technologies will require special attention and support if the full potential of integrated electric power and propulsion systems is to be realized:

- Power generation, including advanced fuel-efficient turbogenerator power units for continuous power and for pulsed or short-duration power generation applications and direct electrochemical and electrothermal generators such as fuel cells;

- Power conditioning and distribution, including passive components, such as capacitors, inductors, and transformers, and active devices, such as power

FIGURE 8.1 Schematic of a generic power and propulsion system.

- electronic switches and inverters for continuous as well as pulsed or short-duration, high-power conditioning and distribution; and

- Energy storage, including primary and secondary electrical energy storage such as batteries, flywheels, and generator combinations, and magnetic energy storage devices.

Table 8.1 lists the technology areas covered by the panel. Technology forecasts are provided in the sections that follow.

TABLE 8.1 Electric Power Technology Areas

|

Electric Power Generation |

Energy Storage and Recovery as Electric Power |

|

Nuclear-electric generators |

Primary batteries |

|

Turboshaft engine generators |

Rechargeable batteries |

|

Piston-engine generators |

Superconducting magnets |

|

Fuel cells |

Flywheels |

|

H2 |

Pumped liquids |

|

Other |

Compressed gases |

|

Explosive/magneto-hydrodynamic |

Thermal storage |

|

Power conditioning |

|

|

Bus power |

|

|

Slow power |

|

|

Fast power |

|

|

SOURCE: Adapted from the Board on Army Science and Technology, 1993, "Electric Power Technology for Battle Zones," STAR 21: Strategic Technologies for the Army of the Twenty-First Century, National Academy Press, Washington, D.C., Table 43-1, pp. 539–540. |

|

Power Generation

The concept of the electric ship is a powerful enabler for new concepts in ship design and operation. Independent placement of propulsion and power generation elements and the integrated approach to electric power distribution will rely for their efficiency on new developments in prime power generation, conditioning, and distribution.

Electric propulsion assumes continuous generation capacity that will also provide electric power for ship auxiliary functions from the most mundane application to the more exotic ones, such as catapults and electric weapons. It will often be necessary to provide auxiliary power generation for backup, or for specific subsystems, or for zonal requirements. Aircraft and launch and recovery systems, electric armor, high-power advanced electronics, and electric weapons all require pulsed-power systems whose average power for the duration of output ranges to hundreds of megawatts. The mass and volume of generators in this class are half power unit and half power conditioning. The physical decoupling of power and propulsion subsystems afforded by electric drive will be a powerful enabler for compact, versatile, and powerful future ships.

Continuous Power Generators

For nonnuclear operation even the most efficient internal combustion engines consume their own weight in fuel in about 10 hours. Therefore, fuel storage determines overall operational system weight, and fuel supply will dominate logistics considerations. For mobile electrical generators and power conditioners, substantial weight reduction can be achieved by increasing the generating and distribution frequency from the present 60-Hz standard up to the 400-Hz range.2

Of the continuous power generation systems listed in Table 8.1, some are already in use by the naval forces. Nuclear-electric generators have potential for significant advances in specific power output. Although the pressurized water nuclear power plants currently in use do not hold much promise for greatly improved power density, a new generation of high-power-density nuclear power plants could be developed but would require substantial R&D investment. A development program could build on past R&D programs that have focused on compact, high-output reactor designs.

Turboshaft engine-generators, which represent another important class of continuous power generation systems, are currently used in military helicopters and some specialized boats. They are also being incorporated into mobile electric

power units, primarily by the Army. They burn jet fuel and have rotational speeds in excess of 20,000 rpm. The high rotational speed could be used to advantage in a high-frequency, lightweight, direct-coupled electric generator operating at 24,000 rpm (400 Hz) or higher. Typically, however, they are geared down to 60-Hz alternators, and these gears increase weight and noise.

The panel evaluated the various continuous and pulsed/short-duration power generation, power-conditioning, and energy-storage technologies by creating figures of merit in the near term (year 2000) and far term (year 2020). The selection of certain technology areas for inclusion in this report was based in part on the potential to achieve high values for figures of merit in the future. The figures of merit include functionality, mobility, supportability, manpower requirements, and cost. A significant improvement in any of these figures of merit could justify adoption of the technology by the Department of the Navy.

The panel believes that, of the various technologies evaluated, turboshaft-engine-driven alternator systems have the best potential for practical, continuous improvement in all figure of merit areas. To realize this potential, the Department of the Navy should support the development of advanced turboshaft engines such as in the DOD/NASA Integrated High-Performance Turbine Engine Technology (IHPTET) program and carry out an aggressive development effort in advanced lightweight alternators, power-conditioning control systems, and unit integration and modularization.

The electric power systems driven by turboshaft engines have the best potential for evolving into compact, lightweight units with reasonable noise control. Systems with these characteristics will be required in the future, particularly for the intermediate power ranges from 50 kW up to the megawatt level. The most significant factors controlling the specific power of an integrated unit are engine rotating speeds, generator frequency, and generated voltages. To a first approximation, the physical size of an engine is proportional to torque, and increasing the speed increases the shaft power proportionately with only a modest change in weight. The weight advantage gained by high-speed operation can be lost, however, by coupling through a gear box to heavy low-frequency generators and power conditioners. The present standard of 60-Hz generators requires that either engines with speeds greater than 3,600 rpm must be geared down to 3,600 rpm or the high-frequency alternating current (ac) that is directly generated must be rectified to direct current (dc) and then converted back to 60-Hz ac with an inverter.3 Both approaches introduce weight and cost into the system.

Design optimization studies performed for the international space station suggest a different overall approach: Let the alternator rotate at the turbine speed and produce power at that frequency. Turbine speeds of 24,000 rpm or higher are

achievable and efficient. When directly coupled, 24,000 rpm yields ac power at 400 Hz, which is the current aviation standard. Using these higher frequencies for power generation can reduce the weight of the active components in the system by a factor of about six, compared with a 60-Hz system. Solid-state converters could then be used to shift the frequency to 60 Hz for distribution. Because of the ease of converting dc to any desired frequency, it is feasible to consider dc distribution in many cases.

The voltages used for power generation and distribution also have leverage with respect to high specific power. The required conductor cross section, and hence the weight, decreases as the square of the voltage, so operating voltage is an important parameter.4 The practical voltage limit (currently about 1 kV) for mobile systems is set primarily by the reliability limits of semiconductor devices. Improvements in high-voltage semiconductor devices could permit more system-optimized voltages to be used up to the Navy standard bus transmission level of 5 kV.

As the technologies evolve over the next 20 years, the specific power of high-rpm engines should approach 10 kW/kg. Similar progress is anticipated for high-rpm alternators with stationary armatures and separately excited rotating-magnetic-flux generating units. The weights of these generators are almost inversely proportional to their rotating speed (rpm). Thus, they could be designed for 400-Hz operation and directly coupled to the gearbox output shaft at 24,000 rpm. Although some special generator units have been operated at specific powers as high as 20 kilowatts of electric power output per kilogram (kWe/kg), generators built to military standards will more generally achieve 10 kWe/kg.

At high-frequency operation, power-conditioning components are small, lightweight, and highly efficient, particularly when series resonant conversion is used in converters. Advanced technology should yield systems with power densities in the range of 15 to 30 kW/kg. Power densities as high as 100 kW/kg are conceivable for power conditioners when integrated-circuit fabrication techniques are used to manufacture integrated converters.

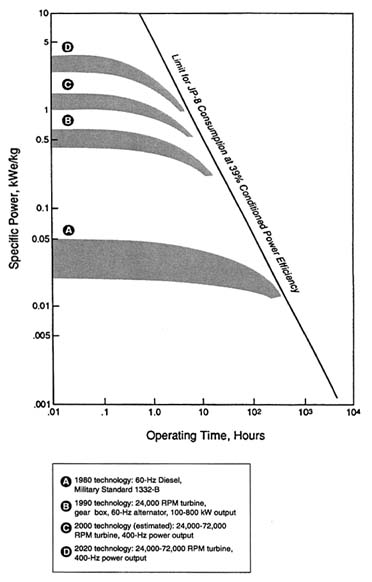

Figure 8.2 shows how the operating time affects the total specific power (power/weight ratio) for existing and estimated future mobile electric power units. The diagonal limiting line in the figure represents the maximum specific energy available from combustion of the JP-8 fuel that will be used in the Navy's diesel engines or turbine engines. An overall efficiency of 39 percent is assumed from maximum fuel heating value to conditioned electric power. The ordinate gives the specific power based on the total system weight: kilowatt-hours divided by the weight of the total integrated system, including engine, generator, power conditioner, integration factor, and fuel consumed. For many engagements

FIGURE 8.2 Specific power versus operating time for advanced turbogenerators. SOURCE: Adapted from the Board on Army Science and Technology, 1993, "Electric Power Technology for Battle Zones," STAR 21: Strategic Technologies for the Army of the Twenty-First Century, National Academy Press, Washington, D.C., Figure 43-1 p. 547.

in the future, actual operating times may be relatively short (hours to hundreds of hours). Therefore the specific power of the hardware units will be critical to mobility and initial operational capability.

Fuel cells hold promise for zonal power generation. They are a particularly efficient and clean method of utilizing hydrocarbon fuels and are appropriate for medium-sized power generation units (1 to 4 kW). Hydrogen-based fuel cells electrochemically oxidize hydrogen with oxygen (or air) and directly convert chemical energy to electric energy. The product of this combustion is water, and this combined with the extremely low signature of the cell make it a very attractive power alternative for Navy and Marine Corps operations. Because they are essentially isothermal devices and therefore not limited by heat engine thermodynamics, they can in principle have very high energy densities (watt-hours per kilogram), limited only by the specific free energy change in converting hydrogen and oxygen to water. The great obstacle to hydrogen-based fuel cells for mobile, battle-zone applications is the volumetric problem of storing hydrogen. Although hydrogen produces a great deal of energy on a weight basis, it produces very little energy on a volume basis, even when stored at high pressure.

Today hydrogen is the only fuel that can be electrochemically oxidized in a fuel-cell system at practical rates. The ideal system would directly convert the free energy of combustion of other fuels, such as hydrocarbons, into electric energy. Other fuels are used in prototype fuel-cell systems by either externally or internally reforming them to a mixture of hydrogen and carbon dioxide, then using the hydrogen electrochemically in the fuel cell. A major breakthrough in electrocatalysis would be required before other fuels could be electrochemically oxidized at useful rates.

Hydrogen fuel cells are impractical for at-sea applications because of the space required to store hydrogen, but hydrocarbon fuel conversion designs would be directly applicable to Navy use. Most units under development (primarily in the automotive industry) require higher-quality fuels than standard Navy distillates. Although there is no current evidence of an impending technical breakthrough in this area, the promise is such that near-term programs to develop converters for standard Navy fuels should be encouraged.

Pulsed-power Generators

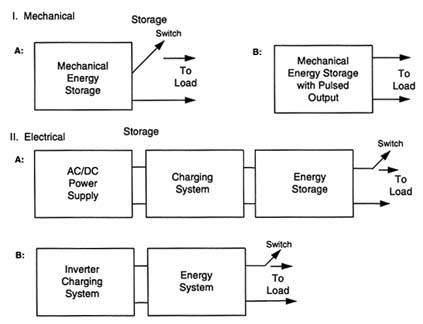

Pulsed-power generation systems can be divided into two major subsystems as illustrated in Figure 8.3: (1) energy storage or prime-power generation, followed by (2) power conditioning. The panel considered five classes of pulsed-power generation as listed below:

- Open-cycle, combustion-driven gas turbine generators. These systems burn fuel in excess air to produce hot combustion gases, which are then expanded through a turbine to drive a generator, producing the prime power. They have

FIGURE 8.3 Alternative techniques to provide multi-megawatt prime pulse power and power conditioning. Which is chosen depends on the load to be served. SOURCE: Adapted from the Board on Army Science and Technology, 1993, ''Electric Power Technology for Battle Zones," STAR 21: Strategic Technologies for the Army of the Twenty-First Century, National Academy Press, Washington, D.C., Figure 43-3, p. 552.

- very attractive power densities, particularly for high power levels, and they are good candidates for future pulsed-power generation sources.

- Magnetohydrodynamic generator driven by solid or liquid propellants . A magnetohydrodynamic channel consists of a linear array of electrodes on either side of the inside of a rectangular duct. A magnetic field is created by permanent or electromagnets oriented parallel to the electrode faces. Ionized gas is forced through this channel, and the velocity of the gas interacting with the magnetic field creates a voltage differential at the electrodes. To produce the ionized gas in these systems, solid-propellant grains or a bipropellant liquid combination burns at elevated pressure and extremely high temperature, and the propellant is seeded with an ionizable material such as potassium and then passed through a magnetohydrodynamic channel where part of the energy in the ionized gas is directly converted to electric power.

- Explosive-driven magnetohydrodynamic generator. In this system, an explosive charge is used to drive a single-shot magnetohydrodynamic power generator. The advantage of this system is that a pulse with a very high power

- level is produced, thus avoiding much of the power-conditioning requirements of other systems.

- Flywheel energy storage and power generation. Large amounts of power can be stored in a flywheel as it is spun up. By coupling the flywheel to a generator that power can be tapped rapidly. New composite materials have greatly increased the efficiency (inertia) of flywheel systems.

- Superconducting magnet energy storage and power generation. Superconducting magnet energy storage (SMES) systems make it possible to store electrical energy directly with little loss other than the power required to cool the superconductor. Direct current can be fed into a superconducting coil to create a powerful magnetic field that stores the electrical energy. The field can then be discharged through a solid-state inverter to produce pulsed power as needed. The switching times between discharge cycles can be milliseconds, and charge and discharge cycles can differ by orders of magnitude. New superconducting materials and manufacturing technologies will provide rapid development for these devices in the future.

The panel believes that three of the five categories of energy storage or prime-power generation discussed above have broad-based applicability to naval force needs for high-energy pulsed power by the year 2020. These are (1) open-cycle, combustion-driven gas turbine systems, (2) flywheel energy storage and power generation, (3) fuel cells, (4) other direct conversion technologies, and (5) superconducting magnet storage and power generation. The panel anticipates major improvements in these systems over the next 30 years.

Open-cycle Combustion

Continuous development and improvement of open-cycle, combustion-driven gas turbine systems is expected, including systems that can use a broader range of fuel types, thus easing the logistics problem. These new systems will be much more rugged than today's turbogenerators because of the introduction of advanced materials and processing methods. Also anticipated are approaches to reducing signature of the effluent stream, thus enhancing survivability.

Flywheels

Flywheels have potential for improvement in the areas of functionality, mobility, supportability, manpower, and cost. Most of the anticipated improvements in flywheels will come from major advances in composite materials with ultra-high strength-to-weight ratios. These materials will enable stored energy density to increase by an order of magnitude over high-strength steels because they can

sustain higher angular velocities. The cost of fabricating composite flywheels with optimally tailored structural properties will decline dramatically over the next 30 years, as more military and industrial applications are found.

Fuel Cells

Unlike turbogenerator technology, practical fuel cells that run on liquid hydrocarbons do not exist today. They are certainly a possibility, however, particularly in light of the advances made in the previous decade in understanding the catalytic reforming of hydrocarbons. Research in this area with the specific goal of developing a fuel cell that would run on liquid hydrocarbons (Navy distillate) and air would be worth supporting. If a breakthrough were to occur, the implications for the Navy of the future could be enormous.

Other Direct Conversion Technologies

There are other direct electrical-conversion technologies besides fuel cells, including thermionics and thermophotovoltaics, that may become viable in the future, but probably beyond the 2010 time frame. In thermionic conversion, heat is used to create electrical flow between electrodes. In the thermophotovoltaic converter, a two-step conversion process is used with heat causing an emitter to create photons that are captured by a photovoltaic cell to produce electrical energy. These technologies will likely be introduced in cogeneration schemes such as topping cycles for gas turbines or direct heat sources such as nuclear reactors or thermoelectric nuclear devices.

Superconducting Magnet Energy Storage and Generation

Superconducting magnet energy storage (SMES) is a scalable technology, and it is reasonable to consider storage capacities ranging from less than 0.001 MW/h to more than 10,000 MW/h. The technology has received government support since the mid-1980s—for example, Air force has conducted a program that demonstrates small, economically viable SMES systems for uninterruptible power and power-quality management, and the Los Alamos National Laboratory has run a program for high-discharge-capacity storage—commercial applications have focused on the high end of the scale (such as an operating load-leveling unit at the Bonneville Power Administration in Tacoma, Washington).

To achieve naval application, continued development of materials and manufacturing methods for SMES systems is required.

Power Conditioning and Distribution

Power conditioning currently represents between 50 and 80 percent of the total mass of high-power pulsed generator systems. For future Navy and Marine Corps applications, it will be essential to greatly increase the specific power density of these power conditioners. A reduction of at least an order of magnitude in specific weight is possible before intrinsic physical, chemical, or mechanical limits are reached.5 The advances will come about primarily through new, molecularly tailored materials for passive components, advances in solid-state power electronic devices, and improved techniques for heat rejection and thermal management, such as heat pipes. High-temperature superconducting cables could increase current carrying capacity by factors of three to five times that of conventional copper cables. This factor includes parasitic cooling loads. The liquid nitrogen coolant required for HTS systems is nonflammable and would tend to extinguish any electrical fire that might arise from battle damage to the cable.

Power-conditioning systems that evolve over the next 30 years will be designed to degrade gracefully. In other words, through zonal power generation and distribution and intelligent management, single-point failures will result in only a small decrement to platform performance because the systems will be designed in a way that enables the automatic bypass of the degraded element.

Current and Near-term (Out to 10 Years) Characteristics

The three main elements of all power-conditioning systems are bus power conditioning, slow power conditioning, and fast power conditioning, as described below:

- Bus power conditioning. This technology takes the electrical feed from one of the prime power sources listed above into a conditioning stage, where the voltage level is altered for optimum, reliable power distribution to a slow power conditioning stage. The major components of this first stage of power conditioning are inverters, transformers, and rectifiers. The application of HTS technology could improve transformer efficiency and yield safer equipment by eliminating the dielectric oil that sometimes poses fire and toxicity hazards.

- Slow power conditioning. The slow power-conditioning stage produces repetitive electrical pulses in the millisecond time frame. Switches, capacitors, and transformers are the major components used in this stage of power conditioning.

- Fast power conditioning. If required for the particular application, a fast

|

5 |

Board on Army Science and Science and Technology. 1993. STAR 21: Strategic Technologies for the Army of the Twenty-First Century, National Academy Press, Washington, D.C. |

TABLE 8.2 Forecast of Power Conditioning Module Power and Power Density

|

Parameter |

Today (per system) |

Tommorrow (10 years) (per module) |

Future (30 years) (per module) |

|

Average power |

|

|

|

|

kWe/kg |

0.05 |

10 |

>100 |

|

kWe |

100 |

100 |

1,000 |

|

Pulsed power (as pulsed energy) |

|

|

|

|

kJ/kg |

0.3 |

1 |

>10 |

|

kJ |

50 |

500 |

5,000 |

|

SOURCE: Adapted from the Board on Army Science and Technology, 1993, "Electric Power Technology for Battle Zones," STAR 21: Strategic Technologies for the Army of the Twenty-First Century, National Academy Press, Washington, D.C., Table 43-3, p. 543. |

|||

-

power-conditioning stage can be used to convert the pulses with a millisecond duration from the slow power-conditioning stage to pulses of a microsecond or less. This stage uses transmission lines, capacitors, switches, and magnetic devices as the primary components.

The anticipated progress in key parameters for power conditioning subsystems is indicated in Table 8.2.

Technology Forecasts

Capacitors

As naval force requirements for compact electrical power systems grow substantially over the next 30 years, the development of capacitor technology will be a major enabling technology element. For microsecond to fractional-second energy storage and discharge, capacitor technology is unequaled in the flexibility and adaptability needed to meet a broad range of future requirements.6

At present, energy conditioning at pulse repetition rates of less than 1 Hz and 10 to 30 MJ per pulse has been achieved for pulse durations from 0.05 to more than 1,000 µs. The maximum voltages decrease from megavolt levels at shorter pulse durations to tens of kilovolts at the longer pulse durations. Voltage levels are determined by the nature of the load. Innovative capacitor systems, operating at near their ultimate voltage breakdown limits, which are 10 to 15 times today's operational levels, would enable the development of lightweight systems. The

|

6 |

Board on Army Science and Technology. 1993. STAR 21: Strategic Technologies for the Army of the Twenty-First Century, National Academy Press, Washington, D.C. |

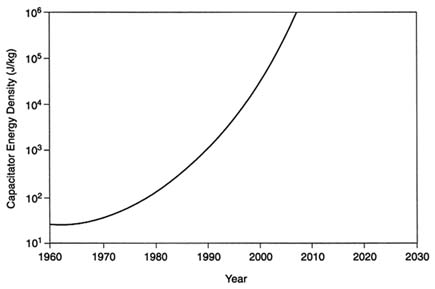

FIGURE 8.4 Projection of specific energy density for new capacitor technology.

SOURCE: Adapted from the Board on Army Science and Technology, 1993, "Electric Power Technology for Battle Zones," STAR 21: Strategic Technologies for the Army of the Twenty-First Century, National Academy Press, Washington, D.C., Figure 43-4, p. 557.

best commercial capacitors today achieve specific power densities of 1 to 10 kWe/kg and specific energy densities of 1 to 300 J/kg. Repetition rates can be as high as several kilohertz, necessitating the development of capacitor technology integrated with that of negligible-loss switching topologies and voltage-multiplication pulse transformers. Most systems can be classified by voltage according to their average power and run-time characteristics. For future naval needs (30 years out), compact systems would be enabled by capacitor energy and power densities 10 to 100 times those available today. Development of new solid and liquid materials, in conjunction with advancing methods of manufacturing technology, will likely be feasible with the use of tools emerging from current technology programs. What will be required is a tightly integrated development program for materials and components, tailored to areas of need for the three main classes of capacitor technology: polymer films, ceramics, and electrolytic capacitors.

Figure 8.4 shows recent and projected progress in capacitor energy density. Industrial capacitor developers have taken a preeminent role in the integration of materials development with the practical realization of advanced capacitors. The Department of the Navy will need to support a system-responsive, technology-based development program in each of these capacitor areas. The program goals should be demonstration hardware that will operate at the required power and energy densities.

Capacitors with specific power densities of 200 to 1,000 kWe/kg and specific energy densities of up to 20 kJ/kg may be feasible in the future. Recent discoveries have resulted in capacitors whose performance degrades gracefully and does not result in single-point failure for the system. Now the potential exists for novel capacitor technologies that offer radically different availability over the system life. Indeed, throughout the system's normal life, even in adverse environments, the failure modes of new systems will provide graceful and predictable reduction in performance, so that total system operation can be retained, although at a reduced performance level.

Table 8.3 projects the performance trends for state-of-the-art capacitor technology. It lists selected examples of several classes of advanced capacitors that further research could develop as practical, highly compact units. For large production volumes, the unit cost of these advanced units is projected to be comparable to the cost of current technology.

Inverters

The naval forces' requirement for efficiently conditioned electrical power will continue to grow dramatically over the next 30 years. Part of this requirement will come from the conditioning needed to provide a low noise—hence dc—electrical bus with the power quality, reliability, and maintainability that will keep electric-powered systems operational during warfare. Eliminating the

TABLE 8.3 Performance of State-of-the-Art and Projected Advanced Capacitor Systems

|

|

Energy Density (kJ/kg) |

|

Power Density (kW/kg) |

|

||

|

Capacitor System |

Now |

Future (2020) |

Now |

Future (2020) |

Repetition Rate (Hz) |

Critical Research Areasa |

|

Polymer film |

1.5 |

10 to 20 |

60 |

2,000 |

8100 |

Film impregnants, foils, &277b;150 °C, 1 MJ/unit |

|

Ceramic |

0.01 |

5 |

100 |

50,000 |

10,000 |

Ceramics, electrodes, >500 °C, 1 kJ/unit |

|

Electrolytic |

0.2 |

2 |

20 |

200 |

100 |

Electrolytes, separators, >200 °C, 10kJ/unit |

|

|

||||||

present single-point failure topologies that result in catastrophic failure of electrically powered assets can be accomplished by developing zonal control architectures that will be enabled by advanced inverters.7

The objective is to provide the platform with a power source that degrades gracefully when damaged during war, continuing to operate, albeit at reduced performance, so that electric-powered assets that are not directly damaged remain available for their missions. In point-failure situations, bus conditioning via bidirectional inverters would continue to supply power from generator-to-generator feed lines redundantly, isolating damaged generator members of the system and permitting load sharing under inverter control. Because no other power conditioning technology can provide this control, inverter dc bus power-conditioning is vital to the electrically powered naval forces of the future, and the Department of the Navy must ensure the development of this technology. As illustrated in Figure 8.5, up and into the early 1990s little substantive progress in cost-performance ratio was made in the power-density scaling of bus power elements for main computer systems.

Integrated, Modular Power Electronics

The Department of the Navy in partnership with industry has pursued the development of standardized, solid-state, integrated power-conditioning modules and has succeeded in achieving reductions in size and increases in efficiency, if not reduction of cost. The requirements of future weapon systems could be met through a focused development program that increases the inverter subsystem power densities by 10 to 100 times over the 0.01 to 0.2 kWe/kg of current military systems. There is a need, for example, for modular, molecularly grown, block power conditioners that are fault tolerant and whose performance degrades gracefully and for voltage management modules that are interchangeable and stackable and can be connected in parallel to create the quality of ac/dc voltages needed in the field.

Interchangeable voltage management modules would provide universal, intelligent, dc bus power conditioning, with per-module, power-break sizes that are cost effective for the Navy. Modules would probably come in sizes of 1, 10, 100, 1,000 and 10,000 kW. Power quality and electromagnetic interference management functioning would be integrated into each module. Such modules will need to integrate the passive component technologies for capacitors, inductors, and the like, with advanced power switches and intelligent control capability. A program now under way within the Department of the Navy to develop a PEBB is a step in the right direction. This effort must incorporate the best available technology into successive generations of power-conditioning systems for naval applications.

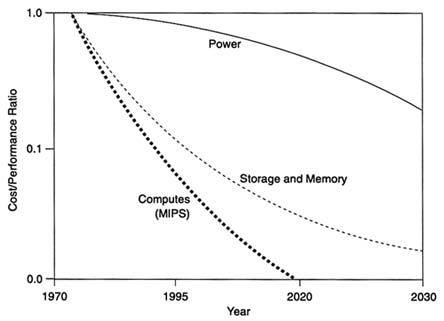

FIGURE 8.5 Technology advancement with time of major computer systems elements as a function of cost versus performance ratio. SOURCE: Adapted from the Board on Army Science and Technology, 1993, "Electric Power Technology for Battle Zones," STAR 21: Strategic Technologies for the Army of the Twenty-First Century, National Academy Press, Washington, D.C., Figure 43-5, p. 560.

The modular approach to improved power electronics will leverage commercial products for military use while reducing the effort required to develop new applications. Detailed circuit design will be unnecessary, allowing designers to concentrate on optimizing system performance.

Energy Storage and Recovery

By the year 2035, there will be a greater dependence on electric power for vehicle drives as well as for a wide array of battlefield electronics and for new electrically driven weapon systems. The reduction of the signature of power generation units will become increasingly important in the battle zone of the future, and this will likely increase the dependence of the naval forces on compact energy storage systems, either chemical or mechanical, in which the stored energy can be rapidly recovered as electric output. Electric vehicle research in the automotive industry is an important contributor to developments in long-life, high-capacity, quick-response electric energy systems and currently sustains work

in the development of reliable and highly efficient chemical and mechanical energy storage systems.

Five classes of energy storage and electric-power recovery technologies that could apply to the forces' future needs were considered by the panel, as follows:

- Batteries,

- Flywheels,

- Inductive energy storage,

- Capacitive energy storage, and

- Compressed gas or steam.

The panel concluded that of these five storage technology areas, batteries show the greatest promise for meeting near-term needs, although flywheels may provide some capability in hybrid vehicle propulsion systems. Inductive and capacitive energy storage media will require continued development to reach a level of performance to be useful in fielded systems. Compressed gas is currently used to start engines on surface ships and for ballast blow and weapons launch in submarines. Steam is used for aircraft launch on carriers. The compressed gas or steam approach is fundamentally limited and ripe for replacement by the other candidates listed above.

Batteries

The science of electrochemical energy storage is fundamentally mature. The pace of development is relatively slow, but the need for safe and reliable electric power is so pervasive that there is a constant high level of research and development. New commercial battery products find their way onto the market, as historical shortcomings in the safety and stability of materials and chemical reactions are resolved. This was the case, for instance, in the recent development of the nickel metal hydride (NiMH) battery as a replacement for the environmentally unsound nickel cadmium (NiCd) battery.

Technology development promises evolutionary progress in the realization and utility of the physical potential within the basic chemistries. Several long-term efforts in commercial and government establishments focus on improvement in shelf life, safety, volumetric and gravimetric energy values, and, in the case of secondary batteries, smart controls for charging efficiency and cycle lifetimes.

Nonrechargeable, or primary, batteries are currently used in a wide range of applications in the Navy where very low levels of electric energy (i.e., watt-hours) are required. Lithium cells with lives of 5 to 10 years are available and will undoubtedly be improved over the next 30 years. Tables 8.4, 8.5, and 8.6 summarize primary battery technology.

TABLE 8.4 Primary Cell Types With Little or No Chance of Further Development

|

Chemistry |

Cell Volt |

W-h/kg |

Notes |

|

Aluminum-Manganese Dioxide Al-MnO2 |

1.6 |

|

Unpredictable storage life; anode corrosion problems; voltage delay |

|

Magnesium-Air Mg-O2 |

3.0 |

|

Anode corrosion problems |

|

Magnesium-Bismuth OxideMg-Bi2O3 |

1.6 |

|

Voltage delay; poor, intermittent performance |

|

Magnesium-Sulfur Mg-S |

1.6 |

|

Voltage delay; high impedence; poor, intermittent performance; H2 S byproduct |

|

Zinc-Potassium Iodate Zn-KIO3 |

1.9 |

31 |

High rate; low shelf life; high reaction temperature; poor low-temperature performance |

|

Zinc-sodium Dichromate Zn-Na2Cr2O7 |

2.1 |

0.25 |

Anode corrosion problems; H2 products |

|

SOURCE: Compilation of data from Bis, R.F., J.A. Barnes, W.V. Zajac, P.B. Davis, and R.M. Murphy, 1986, Safety Characteristics of Lithium Primary and Secondary Battery Systems, NSWC TR 86-296, Naval Surface Weapons Center, Silver Spring, Md., July; and Bis, R.F., and R.M. Murphy, 1986, Safety Characteristics of Non-lithium Battery Systems, NSWC TR 86-302 Rev. 1, Naval Surface Weapons Center, Silver Spring, Md., July. |

|||

TABLE 8.5 Primary Cell Types with Promise as Prospective Power Sources

|

Chemistry |

Cell Volt |

W-h/kg |

Notes |

|

Aluminum-Silver Dioxide Al-Ag2O2 |

1.57 |

|

Pumped electrolyte; heat exchanger required |

|

Calcium-Thionyl Chloride Ca-SOCl2 |

3.0 |

|

Increased tolerance to abuse over Li |

|

Calcium-Sulfuryl Chloride Ca-SO2Cl2 |

3.2 |

|

Increased tolerance to abuse over Li |

|

SOURCE: Compilation of data from Bis, R.F., J.A. Barnes, W.V. Zajac, P.B. Davis, and R.M. Murphy, 1986, Safety Characteristics of Lithium Primary and Secondary Battery Systems, NSWC TR 86-296, Naval Surface Weapons Center, Silver Spring, Md., July; and Bis, R.F., and R.M. Murphy, 1986, Safety Characteristics of Non-lithium Battery Systems, NSWC TR 86-302 Rev. 1, Naval Surface Weapons Center, Silver Spring, Md., July. |

|||

TABLE 8.6 Primary Cell Types Currently Available

|

Chemistry |

Cell Volt |

W-h/kg |

Notes |

|

Cadmium-Mercuric Oxide Cd-HgO |

0.9 |

|

Long shelf life; sealable |

|

Calcium-Calcium Chromate (thermal) Ca-CaCrO4 |

3 |

|

Long shelf life; high voltage; 1 s to 1 h operating life; tolerates extreme environments |

|

Magnesium-Lead Chloride Mg-PbCl2 |

1.1 |

|

Seawater activited: torpedoes; emergency signaling; sonobuoys |

|

Magnesium-Manganese Dioxide Mg-MnO2 |

1.8 |

|

Transceivers; sonobuoys; beacons; good temperature performance |

|

Magnesium-Silver Chloride Mg-AgCl |

1.7 |

|

Seawater activated |

|

Zinc-Air Zn-O2 |

1.4 |

440 |

High capacity |

|

Zinc Manganese Dioxide (Leclanché) Zn-MnO2 |

1.5 |

|

|

|

Zinc-Carbon Zn-C |

3 |

105 |

Everyday flashlight cell |

|

Alkaline Zn-MnO2 |

1.25 |

100 |

|

|

Mercury Zn-HgO |

1.3 |

105 |

|

|

Zinc-Silver Chloride Zn-AgCl |

1.0 |

2.1 |

Extremely long shelf storage: low rate supply |

|

Zinc-Silver Oxide (Silver Zinc) Zn-Ag2O(2) |

1.6/1.8 |

50 to 200 |

High energy/high rate: torpedo; space; submarine; ignition; rocket |

|

SOURCE: Compilation of data from Bis, R.F., J.A. Barnes, W.V. Zajac, P.B. Davis, and R.M. Murphy, 1986, Safety Characteristics of Lithium Primary and Secondary Battery Systems, NSWC TR 86-296, Naval Surface Weapons Center, Silver Spring, Md., July; and Bis, R.F., and R.M. Murphy, 1986, Safety Characteristics of Non-lithium Battery Systems, NSWC TR 86-302 Rev. 1, Naval Surface Weapons Center, Silver Spring, Md., July. |

|||

Rechargeable battery systems capable of a large number of charging and discharging cycles will play a much greater role in the Navy and Marine Corps of the future. A significant part of future electric power requirements during combat engagements can come from advanced battery systems. Tables 8.7, 8.8, and 8.9 summarize secondary battery technology.

TABLE 8.7 Secondary Cell Types with Little or No Chance of Further Development

|

Chemistry |

Cell Volt |

W-h/kg |

Notes |

|

Cadmium-Silver ChlorideCd-AgCl |

1.0 |

|

Very fast charging; fast storage loss |

|

Zinc-Lead DioxideZn-PbO2 |

2.5 |

108 |

Anode corrosion problems; poor charging performance |

|

SOURCE: Compilation of data from Bis, R.F., J.A. Barnes, W.V. Zajac, P.B. Davis, and R.M. Murphy, 1986, Safety Characteristics of Lithium Primary and Secondary Battery Systems, NSWC TR 86-296, Naval Surface Weapons Center, Silver Spring, Md., July; and Bis, R.F., and R.M. Murphy, 1986, Safety Characteristics of Non-lithium Battery Systems, NSWC TR 86-302 Rev. 1, Naval Surface Weapons Center, Silver Spring, Md., July. |

|||

As the ships and aircraft of the future incorporate more electronics, they will require lightweight, reliable primary power sources and backup systems. This need has spurred interest in further development of thermal batteries that are designed to use the high thermal energy of combustion or an explosion to generate electricity for a very short period of time. Current thermal systems are characterized by nearly unlimited shelf life because of their nonvolatile chemistries and short-term, high-energy power output. They are currently in use in tactical missiles and short-term power backup systems. Longer operating life will enable their use in cruise missiles and sonobuoys.

Where weight is a major concern or the application calls for both long shelf and operating lives, lithium-based chemistries are a clear leader.8 Primary lithium batteries with 20-year shelf lives are in current use in smart mines and kinetic kill weapons. The U.S. Army has been a leader in the development of high-density, high-power, 6- to 12-V battery power systems for vehicles, pulsed-power weapons, remote power backup, and missile systems.9 The utility of high-power systems that are capable of operating in severe environments is driving further research on lithium battery safety issues such as handling and mitigation of volatile chemistry systems.

Nickel-hydrogen has long been the preferred spaceborne secondary battery technology. Capable of high discharge rates and nearly infinite charge-discharge cycling, nothing currently matches its reliability. Underwater applications have been dominated by silver zinc (AgZn) systems. Some silver aluminum units are in use for lower power applications such as small torpedoes and the smaller

TABLE 8.8 Secondary Cell Types with Promise as Prospective Power Sources

|

Chemistry |

Cell Volt |

W-h/Kg |

Safety |

|

Aluminum-Air Al-O2 |

1.5 to 2.1 |

80 |

Seawater activated |

|

Cadmium-Air Cd-O2 |

1.9 |

<440 |

High cost |

|

Hydrogen-Air LaNi5H6-O2 |

1.2 |

3,650 theoretical; 380 actual |

Gas cross-leakage; short cycling life; low rate |

|

Iron-Air Fe-O2 |

1.2 |

715 theoretical; 90 actual |

Electric vehicle (EV); H2, O2 production, poor thermal operation |

|

Iron-Chromium (redox) Fe-Cr |

1.2 |

120 theoretical; 30 actual |

Reactant cross-diffusion problems |

|

Nickel-Iron Fe-NiOOH |

1.3 |

263 theoretical |

EV; long life; high H2 |

|

Iron-Silver Oxide Fe-Ag2O(2) |

1.2/1.5 |

106 |

To improve Zn-Ag2O(2) life |

|

Sodium-Sulfur (glass) Na-S |

1.8 |

760 theoretical |

High temperature (350 °C) |

|

Zinc-Bromine Zn-Br2 |

1.8 |

80 |

EV; electric load leveling; Br release danger |

|

Zinc-Chlorine Zn-Cl2 |

2.1 |

826 theoretical; 200+ actual |

EV; electric load leveling; chilled recharge required |

|

Zinc-Nickel Zn-NiOOH |

1.5 |

345 theoretical; 81 actual |

EV; H2, O2 production |

|

Zinc-Silver Oxide Zn-Ag2O(2) |

1.8/1.6 |

130 |

Torpedoes, submarines, and so on |

|

Zinc-Air Zn-O2 |

1.2 |

185 |

High-capacity replacement for Ni-MH |

|

SOURCE: Compilation of data from Bis, R.F., J.A. Barnes, W.V. Zajac, P.B. Davis, and R.M. Murphy, 1986, Safety Characteristics of Lithium Primary and Secondary Battery Systems, NSWC TR 86-296, Naval Surface Weapons Center, Silver Spring, Md., July; and Bis, R.F., and R.M, Murphy, 1986, Safety Characteristics of Non-lithium Battery Systems , NSWC TR 86-302 Rev. 1, Naval Surface Weapons Center, Silver Spring, Md., July. |

|||

TABLE 8.9 Secondary Cell Types Currently Available

|

Chemistry |

Cell Volt |

W-hr/kg |

Notes |

|

Nickel-Cadmium (NiCd) Cd-NiOOH |

1.2 |

25/35/210 |

Cyl/button/vented; long life; memory problems |

|

Nickel-Metal Hydride Ni-MH |

1.2 |

65 |

Replaces Cd in NiCd |

|

Cadmium-Silver Oxide Cd-Ag2O(2) |

1.4 |

75 |

Like NiCd but lower rate |

|

Hydrogen-Nickel H2-NiOOH |

2.5 |

50 |

Pressure vessel; extremely long life; satellites |

|

Hydrogen-Silver H2-Ag2O(2) |

1.4/1.1 |

80 |

Pressure vessel; extremely long life; deep discharge |

|

Lithium-Thionyl Chloride Li-SOCl2 |

3.4 |

700 |

Primaries available as buttons; very wide temperature range; 20-year life |

|

Lithium Ion Family |

|

|

|

|

Lithium-Sulfur Dioxide Li-SO2 |

2.8 |

275 |

Wide temperature range; 20-year life |

|

Lithium-Manganese Dioxide Li-MnO2 |

3.1 |

300 |

|

|

Lithium-Titanium Sulfide Li-TiS2 |

3.6 |

|

|

|

Lithium-Manganese Disulfide Li-MnS2 |

3.6 |

|

|

|

Lithium-Sulfur Dioxide Li-SO2 |

2.8 |

275 |

Wide temperature range; 20-year life |

|

Lithium Carbon Monofluoride Li-(CF)n |

2.8 |

310 |

Long shelf life |

|

Lithium-Iodine Li-I2 |

2.7 |

230 |

Long service life (>10 years) |

|

Lithium-Copper Sufide Li-CuS |

|

|

|

|

Lead-Acid Pb-PbO2 |

|

100 |

Fuses; torpedoes; radio sonobuoys |

|

(sulfuric acid) |

2.0 |

|

|

|

(fluoroboric) |

1.8 |

|

|

|

(perchloric) |

1.9 |

|

|

|

Zinc-Silver Oxide Zn-Ag2O(2) |

|

|

|

|

Zinc-Manganese Dioxide Zn-MnO2 |

1.2 |

|

"Renewal" brand; needs smart charger |

|

SOURCE: Compilation of data from Bis, R.F., J.A. Barnes. W.V. Zajac, P.B. Davis, and R.M. Murphy, 1986, Safety Characteristics of Lithium Primary and Secondary Battery Systems, NSWC TR 86-296, Naval Surface Weapons Center, Silver Spring, Md., July; and Bis, R.F., and R.M. Murphy, 1986, Safety Characteristics of Non-lithium Battery Systems, NSWC TR 86-302 Rev. 1, Naval Surface Weapons Center, Silver Spring, Md., July. |

|||

off board vehicles, but AgZn batteries are widely used for high-power applications. These can provide up to 100 kW over 15 minutes and, together with advanced electric motors, can propel a torpedo at high speed.

Anticipated Technology Advances

The maturity of research in electrochemical power systems provides the benefit of some measure of predictability of future developments. There is nothing that currently matches the high power densities of vented nickel-cadmium batteries to provide the starting power for an aircraft engine in -40 °C weather, and there will not likely be a shift from conventional lead acid and NiCd batteries in this application for the next 10 or 15 years. New aircraft designs, including the F-22, are incorporating existing battery systems. Sealed NiCds are slowly being developed for these applications and are in limited flight use in the commercial sector, but they have yet to demonstrate the high power densities and low maintenance levels of the mainline systems. And, only slightly further in the future, NiMH developments show great promise for increased power densities and lower cost.

Most battery chemical reactions are bidirectional and can be implemented in either primary or secondary cell designs. Those chosen for today's array of secondary battery types are those for which the characteristics of the charge/discharge cycle are the most benign. Whether for these more natural secondary batteries or for tomorrow's more critical designs, positive control over the battery's operational status and charging parameters is becoming a critical enabling technology. The recent commercial availability of rechargeable alkaline batteries is a case in point.

Battery charger technology has advanced markedly in recent years.10 Propelled by the adoption of the more exotic commercial batteries such as lithium cells, the smart charger is becoming ubiquitous in laptop computers, for instance. Most of the problems associated with electrochemical cell development have to do with their susceptibility to anode corrosion, the production of explosive or noxious gases during charging, and the many deleterious effects of overcharging. Built-in sensors for determining temperature, pressure, along with state of charge, and microcontrollers built into the battery effectively control most of these effects and consequently improve battery life, performance, reliability, and safety. Cooperative strategies between battery controllers and the host system controller can optimize selected system/battery performance parameters such as individual cell control, load shedding, or temporary capacity reduction in all or part of the host.

For advanced rechargeable battery systems, significant improvements in mobility and supportability will derive from improvements in the energy density of new batteries by as much as fivefold over current state-of-the-art lead-acid

systems. Most batteries today operate at specific gravimetric capacities well below their theoretical limits. Significant improvements in battery operation can be afforded by active management techniques such as charge and discharge rate management within instantaneous chemistry, temperature, and load conditions. In addition to these operational improvements, fundamental research continues in the materials and structure of alloys, separator materials, and seals that will inevitably produce tomorrow's breakthroughs in battery size, output, and efficiency. A factor of two to three improvement over lead-acid batteries is predicted for power density. To be applicable to the needs of the naval forces, devices in research today must evolve into rugged, fully reliable batteries. Table 8.10 presents some parameters of interest for several rechargeable battery concepts.

It will be important that the Department of the Navy focus its development efforts with the objective of developing, at most, a few battery systems that will cover the broad range of future Navy and Marine Corps needs. Attention to the standardization of form factors, interfaces, and charging and handling systems will be important for reducing the logistics burden associated with widespread battery usage. For example, of the 500 battery types available to U.S. Army quartermasters, probably the world's largest battery user, 10 types represent about 90 percent of usage. Consolidation and rationalization of the mix of battery types and applications are ongoing. Military expenditures on batteries have grown from approximately $50 million is 1981 to over $190 million today.

Special Application of Batteries: Power for Remote Sensors

Future naval forces will depend on remote sensors in a variety of situations: Unmanned vehicles will patrol the skies; microbuoys will monitor the seas; target-sensitive triggers will proliferate throughout the arsenal; randomly deployable sensors will locate and monitor enemy command and control; and the marines will cast off miniature, self-forming communications networks as they advance through the littoral. These capabilities will result from the size reduction and increased functionality of microelectromechanical systems and small, long-lived, power sources. The implications for the direction of battery power evolution are clear: higher density; higher efficiency, and intelligent power management.11

Sensor Types

Airborne Sensors

Much battle space awareness information will be derived from sensors mounted on unmanned aerial vehicles (UAVs). Increased capability aboard these

TABLE 8.10 Performance of State-of-the-Art and Advanced Battery Systems

|

|

W-h/kg |

|

W/kg |

|

W-h/liter |

|

$/kW-h |

|

|

|

Battery System |

Now (to 2000) |

Future (2020) |

Now (to 2000) |

Future (2020) |

Now (to 2000) |

Future (2020) |

Now (to 2000) |

Future (2020) |

Problems |

|

State-of-art lead-acid |

35 |

40 |

110 |

150 |

80 |

100 |

150 |

100 |

Low energy density, fairly high self-discharge |

|

Bipolar lead acid |

38 |

50 |

— |

79 |

— |

85 |

— |

100 |

Costs more than conventional lead-acid, low specific power |

|

Na/S |

90 |

120 |

110 |

140 |

140 |

180 |

1,000 |

100 |

Operates at 350 °C |

|

Ni/Cd |

35 |

40 to 50 |

50 to 60 |

80 to 90 |

80 |

90 to 100 |

250 to 300 |

200 |

Sensitivity to overcharge |

|

Zn/Air |

90 |

140 |

100 |

150 |

— |

— |

— |

35 to 45 |

System weight dominated by elctrolyte weight |

|

|

Low energy efficiency |

||||||||

|

AL-Li/FeS |

80 |

150 to 200 |

95 |

180 to 220 |

— |

— |

High |

100 |

Operates at 400 °C |

|

SOURCE: Board on Army Science and Technology. 1993. "Electric Power Technology for Battle Zones," STAR 21: Strategic Technologies for the Army of the Twenty-First Century, National Academy Press, Washington, D.C., Table 43-5, p. 571. |

|||||||||

space-limited vehicles will pay dividends in the reach and effeciency of the fleet sensor suite. Miniaturization and modularity will allow rapid tailoring of these vehicles for a variety of jobs at hand, from microclimatology to target detection and location, to battle damage assessment.

Microbuoys and Unmanned Undersea Vehicles

The same technology that will empower the UAV as an inexpensive and versatile sensor platform will also enable the creation of seaborne platforms with specialized capabilities for use in the future. Deployed fleets of these robots will be capable of underwater communications, underwater intelligence actions, anti-submarine warfare, mine detection and destruction, oceanography, and seabed mapping, particularly in the littoral waters where operation with conventional submarines is problematic.

Smart Triggers

As smart weapons gain autonomy the on-board sensor and control electronics requirements will grow. As autonomous capability becomes more robust and reliable, smart triggers will be deployed on a wider variety of weapons including mines and antimine devices, long-dwell ASW robots, and long-range bombardment projectiles.

Sensor Deployments

Autonomous Sensors

High-energy, low discharge rate batteries extend available operating times, thus enabling more autonomous operation of sensor systems. Current systems are occasionally fielded for special-purpose remote sensing with electronics packages that are as large as a suitcase and with a battery suite that may be two or three times larger than that. Although the number, capability, and support requirements for smaller, more portable designs will enable a new range of remote sensor possibilities, these new sensors will also require the enhanced computational capabilities of microelectronic processors and validated, robust control programs.

Networked Sensors

A clear enabler of networked cooperative sensors is the development of reliable, very low power command and control and data exfiltration mechanisms. Microelectronic transceivers will be the key to the development of self-forming communications networks. Current commercial technology has deployed medium-bandwidth,

shoebox-sized, self-forming, and self-managing RF communications networks. These digital networks provide convenient access to mobile users. Each network component knows or can calculate its own location and locate its nearest neighbors dynamically. It is an easy extrapolation of this concept to the military battle space in the form of randomly deployable sensors or network nodes. Microelectronics and efficient power will enable miniaturization and disposability.

Stationary and Vehicle Flywheels

Flywheels are covered briefly in a previous section as energy-generation devices. Flywheels coupled directly to a variable-speed motor-generator have the potential of compactly storing large amounts of energy and rapidly delivering electric power. The motor-generator would function as a generator when the system was drawing on the energy stored in the flywheel and as a motor when energy was being stored in a flywheel by spinning it up. For many configurations, flywheels could also be spun up mechanically through the use of reciprocating or turboshaft engines. Through the use of advanced composite materials, flywheels could store as much as an order of magnitude more energy per unit of flywheel mass than can be obtained with flywheels of the best alloy steel.

The government-industry partnerships addressing hybrid electric drive for wheeled or tracked vehicles have produced innovative flywheel and motor-generator technology at the few tens of kilowatt level. U.S. Army-supported programs have developed technology for rotating inertial energy for tracked-vehicle, pulsed-power weapons applications that, although not successful to date, may have future applications to both ships and amphibious or land vehicles.

Inductive Energy Storage

Inductive energy storage, generally for use with pulsed-duty applications, has been evolving over the last decade. Cryogenically cooled aluminum inductors have been developed for low-loss, very-short-term energy storage in pulse-forming networks. SMES as described above was developed for use in high-power, directed-energy weapons applications but has evolved into applications for long-term energy storage for uninterruptible power sources. The key technologies for SMES development in the future are superconducting materials and high-strength composite materials for containment of the large forces associated with magnetic energy storage. Trends in these areas would indicate that practical superconductors operating above 100 K and composite materials with yield strengths approaching 106 psi should be available 20 to 30 years hence.

The Electric Ship

The Navy is engaged in an ongoing effort to develop an electric ship. When all the key technologies are sufficiently developed to allow the electric power generation and distribution system to be integrated with the electric propulsor, the resulting capability will represent a major change in the performance features and operating characteristics of shipboard power and propulsion systems.

The Electric Ship Concept

The electric ship approach is enabled by the so-called second electronic revolution where the rapid advancements in solid-state semiconductor technology that led to integrated circuits, microprocessors, and computers are now being applied to power semiconductor devices. Advances in the materials used in electromagnetic machinery such as permanent magnets and high-temperature superconductors also present opportunities for substantial increases in power density and efficiency. And the emergence of direct electric conversion technologies such as fuel cells provides the potential for fuel-efficient, low-emission, and low-noise sources of electrical power.

The Navy's IPS program utilizes an open-architecture, common-module approach that builds on existing commercial efforts. Within the IPS program, a family of modules is being defined that will serve as the building blocks for designing, procuring, and supporting marine power systems applicable across a broad range of ship types. To this end, shipboard power systems are divided into the following seven elements or module types:

- Power generation,

- Energy storage,

- Power conversion,

- Power distribution,

- Propulsion motors,

- Platform loads, and

- Power control.

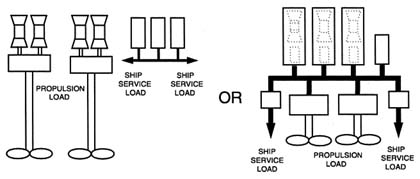

IPS is a flexible and scalable power system by virtue of its open architecture and use of common machinery modules. It has the potential to revolutionize the design, construction, and operation of U.S. naval ships by using electricity as the primary shipboard energy medium. IPS minimizes the number of prime movers by permitting any generating unit to supply either propulsion or ship service power to support ship operational priorities at any given time. The flexibility of electric power transmission allows power generation modules of up to 20 MW to be located independently from the propulsion motors and ship service power converters in whatever arrangement supports the ship's mission at the lowest

overall cost. The ability to independently position the minimum amount of machinery components in small, unmanned modules avoids the need for large engine rooms, which in turn permits greater separation and compartmentation in the ship, accruing significant benefits in manning, safety, and ship survivability. The use of small, unmanned machinery modules also permits the use of non-chlorofluorocarbon (CFC)-based fire suppression systems similar to those currently used in fleet propulsion gas turbine enclosures.

The Department of the Navy's full-scale advanced development (FSAD) system prototype incorporates a commercial marine approach to electric power generation and propulsion distribution in combination with a zonal dc electrical distribution system for ship service power. The generator is a conventional two-pole 60-Hz machine that produces the required 22-MW output power at 4,160 volts alternating current (Vac). The power is distributed in this form via conventional medium-voltage cable and switchgear to the propulsion converter that produces the voltage and frequency required by the propulsion motor. The converter consists of a diode-rectifier front end and multiple pulse-width-modulated (PWM) inverter sections connected in parallel to achieve the desired power levels. The inverter section development extends the state of the art in insulated gate bipolar transistor (IGBT)-based PWM technology to the medium-voltage range. The motor is a squirrel cage induction motor based on severe-duty commercial marine and industrial designs. The ship service dc power is produced by a conventional transformer and rectifier and distributed via dc cable and converted by ship service inverter modules (SSIMs) to 60 or 400 Hz, or variable frequency and voltage as required.

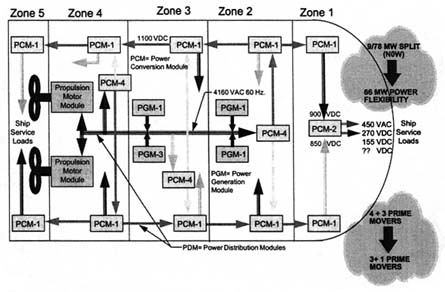

The IPS architecture will allow incorporation of developing technologies such as PM electric machines, fuel cells, and PEBB into future ship designs as programmed, preplanned replacements for the core technology in the first-generation IPS modules. Use of technology-independent module interface standards will facilitate technology insertion with minimum impact on the ship design and construction process. Figure 8.6 is a diagram of the basic IPS architecture.

Power Generation for Surface Ships

Intercooled Recuperated Gas Turbine

The intercooled recuperated (ICR) gas turbine currently under development is a derivative of the Rolls-Royce RB211 aeroengine used in air fleets around the world. Three elements have been added to the core engine to produce its 29,000 brake-horsepower (bhp) rating and 30 percent total mission fuel savings (relative to comparable existing power plants). First, an intercooler cools the gas after low-pressure compression and before second-stage compression. This reduces compressor work, allowing more power from a given engine core. This is the key to attaining the 29,000 bhp from the RB211, and it also adds to overall engine

FIGURE 8.6 Integrated power system basic architecture. SOURCE: Adapted from (1) Advanced Surface Machinery Programs Office, 1996, ''A Strategy Paper on Power for U.S. Navy Surface Ships," draft, Naval Sea Systems Command, Arlington, Va.,Figure A-1, April 8, and (2) Krolick, C.F., 1996, "Technology Insertion," in the briefing"Advanced Surface Machinery Programs (ASMP)," presented to the Panel on Technology by the Naval Sea Systems Command, Arlington, Va., May 2.

efficiency. Next, a recuperator recovers exhaust heat wasted by simple-cycle engines to preheat combustion air before ignition. Finally, variable area nozzles on the first stage of the power turbine restrict flow when operated at less than full power, raising exhaust temperature and thereby increasing recuperator effectiveness at low power. The ICR has a lower exhaust temperature than comparable engines, resulting in reduced IR signature.

Although the ICR maintains the footprint of the engines it is designed to replace, it weighs roughly twice as much and costs about $1.5 million more per engine. Recent studies on fleet introduction in the DDG-51 (forward-fit) indicate an average follow-on ship acquisition increase of $10 million per ship (including engine costs) while saving $1.5 million per ship per year in fuel costs. Studies for a two-engine surface combatant indicate that, in a new design, the fuel load and intake/exhaust reductions compared with those in simple-cycle engines more than offset the increased engine weight. The net result is that even with an increase in engine cost the overall ship acquisition cost is the same, with fuel cost savings comparable to those for the DDG-51.

The current development schedule (incorporating the recuperator recovery plan) supports introduction on the DDG-51 during FY 2001, with 3,000-hour

qualification and shock testing in FY 1998–1999. The ICR is the engine incorporated into the first IPS power generation module (PGM-1), which is envisioned to be the main power unit of the future fleet.

Advanced-cycle Gas Turbines