3

Supporting Weapon System Readiness

The steps to maintaining equipment are well known. Reliable equipment does not break down frequently. When it does, well-designed equipment is repaired easily and can be returned to use quickly. If the cause of failure is easy to discover and the maintainer has the needed training, tools, parts, and instructions, no time is wasted.

However, performance-driven design has frequently created obstacles to designing and producing the kind of reliable, maintainable equipment the Navy and Marine Corps would like to have. There are also obstacles to having all the correct maintenance resources at the right place at the right time to do repairs. The Navy and Marine Corps have learned, also, that time-based preventive maintenance is often excessive and can even cause, rather than prevent, problems. The penalty paid for excessive maintenance is lower-than-desirable readiness at higher-than-necessary cost.

Maintaining the readiness of weapon systems is a major activity of naval forces. Forty-seven percent of the Navy’s active duty enlisted force (173,000 sailors) and 24 percent of the Marine Corps (37,600 marines) are assigned to maintenance functions.1 The direct maintenance cost of aircraft and ships is at least $15 billion per where.2 Reducing the necessary maintenance needed and the

|

1 |

Calculated from FY 1995 data drawn from the Office of the Undersecretary of Defense (Personnel and Readiness), Defense Manpower Data Center, Seaside, California. |

|

2 |

Naval Center for Cost Analysis. 1996. NAVYVAMOSC: Navy Visibility and Management of Operating and Support Costs, Department of the Navy, Washington, D.C., June. |

learning required to perform it more effectively and efficiently could have substantial payoff in freeing up personnel and budgets for other needs.

Applications of technology have enabled weapon systems that not only perform more effectively but also are more reliable and more maintainable than their predecessors. Part of this trend is attributable to a natural evolution of technology—for example, the replacement of vacuum tube electronics by solid-state devices and the replacement of steam turbine engines in ships by gas turbines. The panel expects such trends to continue with, for example, next-generation gas turbine engines, replacement of much hydraulic and mechanical equipment with electromechanical devices, and possibly even the development of electric-drive ships. The panel notes also plans to reduce the numbers of different types of ships, aircraft, and other weapon systems in the forces. Such consolidations should have a marked and beneficial effect on logistic workloads.

Given whatever logistic workloads the design of forces and weapons presents, however, the panel believes that the greatest beneficial impact on readiness will come from exploiting information technology to improve logistical support practices. Information technology promises to change fundamentally the way logistic activities are performed. It will provide all participants in the business of producing and supporting weapon systems the knowledge to make “best” decisions throughout a weapon’s life cycle. This access to information, when and where needed and in the form needed, will enable the logistic system to function as an integrated process focused on weapon system readiness.

The key over the next 5 to 10 years will be managing the various applications of information technology in a way that, in fact, creates the integrated process that is possible. This will entail using information technology to bring together the acquisition process, configuration management, computer-based maintenance training, troubleshooting and repair, equipment performance monitoring, and parts supply. In the following sections, the panel describes how information technology can change the way logistic tasks are accomplished in each of the above-listed areas and how it can contribute to creating a simulation-based acquisition (SBA) process to enhance weapon system readiness.

ACQUISITION PROCESS

Logistic considerations traditionally and, in part, necessarily have followed performance considerations in the design and operation of weapon systems. Development of support equipment, technical data, training packages, and provisioning plans could not be pursued in earnest until system designs had stabilized. Logisticians were presented with a design they were to support, having had little input into its reliability or maintainability characteristics. The support system that evolved often was poorly matched to the weapon system it supported and often remained that way throughout the system’s life. The result was a cumber

some logistic system that incurred many unnecessary costs and often was slow to respond to readiness requirements.

Modern acquisition programs are abandoning paper-based design process, including technical drawings, in favor of computer-based processes. These have at their core a single, integrated, digital weapon system database that can be accessed, via computer networks, by all participants in the acquisition process, permitting real-time collaboration on design features.

By “single, integrated” is meant not literally one database in one computer, but a single set of data in which each data element, no matter who creates it or where it is stored, is entered and maintained as part of an integrated set and utilized in common by all users. No longer do the designers, manufacturers, trainers, personnel managers, and logisticians each need to create and maintain their own databases, often duplicating (imperfectly) data used by the others. These principles are being incorporated into the current design of ships (LPD 17) and aircraft (joint strike fighter [JSF]).

To the logistician, the creation and use of a single digital database enable two key logistic activities to be accomplished concurrently and interactively with weapon system acquisition:

-

Assessment of logistic features and their implications, and

-

Design and development of logistic and training support package.

Prior to design, the mission employment of a weapon system and its support concept can be simulated to determine key reliability and maintainability features. Initial designs can be simulated in virtual reality, directly from the computer-aided design database, to check such features as access to components for maintenance and vulnerability to battle damage. Working from the design database, logistic engineers can identify design-induced logistic problems early and feed them back to design engineers for correction. This ability to influence equipment design is critical to a weapon system’s readiness throughout its life because there is no substitute for high reliability. (This is an important aspect of simulation-based acquisition (SBA), a process described more fully in Volume 2: Technology of this nine-volume study.) Design of the support system—maintenance concept, test equipment, test software, diagnostic and repair procedures, and training materials, devices, and aids—can proceed concurrently with system design. Provisioning decisions can then be made on the basis of detailed design data and test information.

Use of these information technologies—simulation and single, integrated digital design databases—during the acquisition process will enable procurement of weapon systems designed from the outset for efficient and effective support and of support systems matching the weapons they are intended to support. Effective employment of information technology will result in placing into users’

hands weapon systems that can be operated for maximum effectiveness at minimum life-cycle cost.

CONFIGURATION MANAGEMENT

One of the most important benefits of a single, integrated weapon system database is having in place the capability to manage a weapon system’s configuration throughout its lifetime. Imperfect knowledge of system configuration builds inefficiencies into the foundation of the logistic system. Stocking spare parts, issuing technical data, and training technicians become expensive guessing games when the true configuration is uncertain.

The single, integrated weapon system database offers the starting point for establishing sound configuration management. The challenge then is to keep that database current throughout the system’s life. Technology for marking components will enable identification and, in some cases, recording of operating or maintenance history. Technologies range from barcoding to etchings to microchips embedded in or affixed to components. Some systems, especially electronics, will have a built-in capability for automatically sensing and reporting the identity of their components. Establishing and maintaining accurate configuration data on older systems will still be difficult, but it is essential to efficient functioning of the logistic system.

COMPUTER-BASED MAINTENANCE TRAINING

Information technology not only can improve classroom training but also can move much of the item-specific training out of the classroom to the technician’s job site. Studies show that training times in school situations typically can be reduced up to 30 percent3 by enhancing traditional instruction with self-paced, interactive, computer-based training. Learning does not suffer; in fact, it improves.

Once training is computer based, it can be exported from the classroom to the job site, saving instructor and student time and costs. So-called distance learning could be made available to technicians over a computer network, permitting them not only to learn new skills but also to refresh or enhance their skills without returning to school.

Computer-based training can be made even more effective by integrating it with the digital technical data used for diagnostics and repair, providing the

|

3 |

Orlansky, Jesse, Carl J. Dahlman, Colin P. Hammon, John Metzco, Henry Taylor, and Christine Youngblut. 1994. The Value of Simulation for Training, IDA Paper P-2982, Institute for Defense Analyses, Alexandria, Va. |

technician with training that matches perfectly the equipment to be maintained, the task at hand, and the technician’s skill enhancement needs.

TROUBLESHOOTING AND REPAIR

The Navy has had an aggressive and successful program to eliminate the need for technical manuals on board ships by digitizing technical data. The current storage medium is primarily compact disk. Digitized data are not only easier to move and take much less storage space than traditional manuals but also easier to keep current and to access.

Today’s digitized technical data are produced mostly by scanning paper-based technical documents. Tomorrow’s data will be designed as interactive aids to troubleshooting and repair activity, anticipating the technician ’s needs and presenting the information in the best order and form for the task at hand. Eventually, such “interactive electronic technical manuals” will use three-dimensional graphics to help in visualization of information and instructions.

In the future, digital technical data will be available to the technician directly from all sources that have information about the specific equipment being maintained—by type, model, series, manufacturer, production lot number, and serial number. The data will be specific to the item, not generic to the class of equipment, and will include not just drawings and instructions, but also up-to-the-minute status, diagnostic, and repair information drawn from worldwide sources and processed by autonomous or semiautonomous information systems designed to best match the information to the technician’s needs.

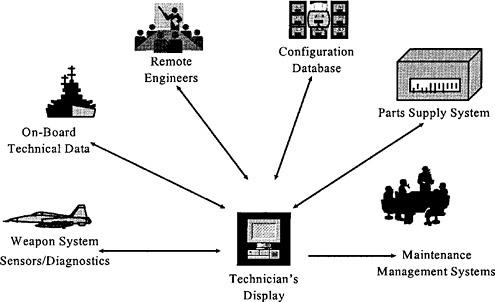

Some information will come directly from the weapon system’s sensors and built-in test equipment, some from on-board databases, some from remote databases maintained by the depots or contractors, and possibly some from engineers who are monitoring the situation remotely (see Figure 3.1).

The technician’s readout device (display) will be portable enough to be taken or worn to the site of the maintenance action. It will download data directly from the weapon system or from the on-board communications network. It will provide interactively the information that the technician needs to assess the system’s performance, make any adjustments, diagnose malfunctions, order parts, and make repairs. It will be tied electronically to the supply source so that the correct part can be identified, ordered, and provided, all without the need for error-prone manual input of data. Maintenance actions, successful and unsuccessful, will be recorded automatically in the master configuration management database and will be available for use in assessing equipment maintenance needs, technician training, and redesign requirements.

Early tests of these concepts are demonstrating great potential for improving maintenance. For example, a study done at the Air Force ’s Armstrong Laboratory compared the performance of maintenance technicians using standard paper-based technical orders (TOs) with that of others using an integrated maintenance

FIGURE 3.1 Troubleshooting and repair information.

information system consisting of interactive electronic technical manuals, having connectivity with maintenance data systems, and utilizing dynamic diagnostics. Results showed that technicians using the Integrated Maintenance Information System (IMIS) were more successful in diagnosing problems, made fewer errors, used fewer parts, and completed tasks more quickly.4 The results also showed that when using the IMIS, a general technician could perform almost as well as a specialist—in fact, better than the specialist could when using the old-style TOs. The Navy’s experience with the shipboard condition assessment system shows similar results, i.e., both a significant decrease in preventive maintenance time and a reduction in troubleshooting time. 5

EQUIPMENT PERFORMANCE MONITORING

The next major advance in equipment maintenance will be the ability to

|

4 |

Teitelbaum, Daniel, and Jesse Orlansky. 1996. Costs and Benefits of the Integrated Maintenance Information System (IMIS), IDA Paper P-3173, Institute for Defense Analyses, Alexandria, Va., May. Data reported by Donald L. Thomas. 1995. Integrated Maintenance Information System (IMIS): User Field Demonstration and Test, Armstrong Laboratory, Wright Patterson Air Force Base, Ohio, October. |

|

5 |

Naval message No. 2718512, February 1996, to USS Cape St. George, from RUCBTFA/COMNAVSURFLANT, Norfolk, Va., Integrated Condition Assessment System (ICAS) Data Collection Report. |

anticipate equipment failures so that they either can be avoided by preemptive action or else can be repaired promptly when they occur. Sensors embedded in equipment will monitor critical parameters during performance (e.g., temperature, pressure, vibration, stress, and wear). Data from sensors will be matched to design standards or performance characteristics of other similar equipment to detect trends portending equipment wear or failure. (For a more complete discussion of sensors and materials, see Volume 2: Technology of this nine-volume series.)

In some cases, equipment performance monitors may work with computer controls to “self-adjust” the equipment to optimize performance. In other cases, the data will be transmitted from the equipment while it is in use to a maintenance base or performance monitoring center, enabling technicians or engineers to alert operators regarding equipment conditions or to prepare for maintenance actions. Importantly, equipment performance monitoring will help avoid unnecessary maintenance actions, saving maintenance resources and reducing the risk of maintenance-induced damage.

PARTS SUPPLY

Assured, secure, worldwide communication of digital information will enable shared knowledge and use of inventories among ships of a battle group, fleets, shore installations, other U.S. military organizations, allied forces, and commercial suppliers. Sparing tailored to the configuration, mission, and history of each ship, aircraft, vehicle, or other major equipment will help ensure maximum readiness benefits per dollar spent on inventory. Real-time tracking of items in shipments will permit anticipation of parts arrivals, detection of delays or misshipments, and adjustment of priorities.

Rapid distribution of spare parts will maximize productive utilization of high-value assets and minimize weapon system down time.

Intelligent software and decision-support systems will simplify, speed, and improve management actions to align parts supply with readiness priorities. Techniques for rapidly manufacturing parts will provide responsive sources of resupply for some out-of-production, low-demand, or long-lead-time items. The combination of digitally controlled manufacturing and the ability to communicate digital technical data worldwide might also allow some parts to be manufactured locally. The payoff from exploiting information technology in acquiring and managing parts will be responsive, often anticipatory, support of weapon system maintenance activities and efficient use of suppliers and inventories.

As these logistic processes become more efficient and responsive, and commanders gain confidence in them during peacetime deployments and exercises, information and rapid distribution of parts will increasingly substitute for today’s large inventories at operational sites.

CREATING AN INTEGRATED WEAPON SYSTEMS READINESS PROCESS

The Navy clearly is taking the first steps toward developing the technologies described above. The technology core of the “Smart Ship ” project is the Integrated Ship Information System (ISIS) that ties together—via an on-board optical-fiber local area network—machinery control, condition assessment, damage control, and access to configuration, maintenance, and other technical data. The Integrated Condition Assessment System (ICAS) part of ISIS performs the condition monitoring, troubleshooting, information retrieval, parts ordering, and maintenance action recording.

In aviation systems, a technology demonstration project called Aviation Maintenance Integrated Diagnostics Demonstration (AMIDD) is applying some of these techniques to the F/A-18. An advanced-concept technology demonstration project has been approved recently to develop a health-monitoring system for the rotor hub of the H-60 helicopter.

The new Joint Strike Fighter program is at the forefront in just about all of these areas. The new class of amphibious warfare ship, LPD-17, is following this same model. The same is true for the Marine Corps’ advanced amphibious assault vehicle and the V-22 Osprey aircraft.

Similarly, the Navy’s Supply Systems Command is developing systems for tracking shipments and sharing inventories among ships and installations, all focused on reducing inventories at operational sites.

Many of the information technologies described by the panel will come with the natural evolution of management information systems and new weapons. For example, the storage and distribution of data will come more easily as the Navy and Marine Corps move to modern, distributed information systems, networks, and telecommunications.

Some investment and a determined effort will be required to infuse the following technologies into systems:

-

Sensors, to monitor equipment performance parameters;

-

Item identification marking, to permit accurate and, when possible, automatic configuration control;

-

Automatic data capture, to gain timely, accurate data on logistic activities;

-

Intelligent sensors and software built into logistic processes, to monitor status and performance and to aid process flow; and

-

Advanced user interfaces, to enable the technician to more easily use computer-based information (e.g., language recognition, artificial intelligence, and advanced displays).

Pulling these many technology applications together to create an enterprise

process focused on weapon system readiness will be the key to exploiting the capabilities they offer. It will not be a trivial undertaking. Private-sector companies that are exploiting these technologies warn that patching new technology onto old processes is of only marginal benefit. New ways of doing business have to be designed to exploit the technology. Traditional roles and responsibilities in the organization often have to be cast aside. Investments are needed that may not offer adequate payback incrementally but are essential to the new processes. Furthermore, changes such as those envisioned here take time (perhaps up to 10 years) and relentless determination by top managers.

The most difficult tasks will be those not tied directly to new weapon programs or platforms. Justifying the funding to retrofit new technologies into old systems or to change common support processes is the real challenge. For example, common test equipment, support equipment, maintenance management, and training serve many weapon program managers but often are not of high enough priority in any single program to get funding: “Let somebody else pay for it.” Acquiring new, high-visibility weapons almost always takes priority in the budget over fixing the old, but laying in the infrastructure and investing enough in old systems to make them compatible will be essential to creating the new process that is possible. The overarching long-range plan and architecture will signify a commitment to process change and will highlight the unpopular, but necessary, investments for success.

Information technology promises to change fundamentally the way logistic activities are performed and managed. If this technology is properly introduced and funded at all levels of the logistic chain, significant cost savings could be realized while providing far better service to the warfighter.

There is clear evidence that the Navy is embracing information technology at almost all levels of the total logistic process, starting with acquisition and continuing through parts supply, troubleshooting, and repair. However, without the technology system architecture and standardization of certain key aspects, suboptimization is the best that can be expected—not overall process redesign such as that achieved by truly world-class enterprises. Without the system architecture and such key elements as single, integrated databases, the cost of incorporating and maintaining currency will be burdensome to the Navy, and the benefits will fall far short of expectations.

Creating such a process will entail designing an architecture that defines how the various activities should relate to each other and to the ultimate goal of supporting readiness. This means not an acquisition process, a training process, a maintenance process, and a supply process but instead a single process that integrates all these functions to serve a common purpose. Databases, information systems, and communications systems must all work together to support weapon readiness activities. It will be necessary to formulate a plan—a path of evolution—based on architecture that will guide the development of essential capabili

ties and investments over the next 10 years. The plan should cut across the Navy Department and embrace the Navy, Marine Corps, hardware systems commands, Supply Systems Command, Naval Training Command, and the fleets. The plan should recognize that the other Services, various defense organizations, several government agencies, and many commercial firms play essential roles in supporting naval systems.