4

Potential Surfactant Additives: The Search for the Oxymoron

Paul Becher

Paul Becher Associates Ltd.

According to the program, I am expected to discuss potential surfactant additives. This is a difficult problem, because prior to hearing the talks at this meeting, it was impossible to determine what these additives were, in fact, to be added to. I may say that this problem has not become much easier, but I shall return to that point a little later.

Let me concentrate instead on the subtitle of my presentation, namely, ''The Search for the Oxymoron." Since this is an educated audience, I will assume that everyone knows what an oxymoron is. However, on the statistically small chance that some member of the audience has not come across this word, I give you the following definition (American Heritage Dictionary, 1996):

ox·y·mo·ron (![]() ) n., pl.ox·y·mo·ra (

) n., pl.ox·y·mo·ra (![]() ) or ox·y·mo·rons. A rhetorical figure in which incongruous or contradictory terms are combined, as in a deafening silence and a mournful optimist. [Greek

) or ox·y·mo·rons. A rhetorical figure in which incongruous or contradictory terms are combined, as in a deafening silence and a mournful optimist. [Greek ![]() , from neuter of

, from neuter of ![]() , pointedly foolish: oxus, sharp; see OXYGEN +

, pointedly foolish: oxus, sharp; see OXYGEN + ![]() , foolish, dull.] —ox´y·mo·ron 'ic (

, foolish, dull.] —ox´y·mo·ron 'ic (![]() ) adj.—ox´y·mo·ron'i·cal·ly adv.

) adj.—ox´y·mo·ron'i·cal·ly adv.

However, the oxymoron for which we are searching is (as you might guess) "nonflammable fuel." You will at once assure me that what we are seeking is actually "reduced flammability," and I will agree. But the further target is, at least, worth thinking about.

The oxymoron in question is not particularly new. I recall using it in, I believe, 1945. At that time, I was serving as an enlisted research chemist in the Air Force laboratories at Wright Field, Dayton, Ohio. My general area of activity was work on petroleum products used in military aircraft, including fuels, lubricants, and hydraulic fluids. A principal target was the development of a nonflammable hydraulic fluid.

We did, in fact, succeed in developing a usable fluid, and I share in a patent (U.S. Patent 2,470,792) which, to the best of my knowledge, has never actually been tested, much less used, by the Air Force (or for that matter, anyone else). I am not too unhappy about this result because I have since developed some doubts about the toxicity of the principal ingredient. Nonetheless, I may perhaps be able to claim priority in this area over most attendees to this workshop. I should point out that even in 1945 we recognized that the term nonflammable fuel was an oxymoron. However, we also understood that it was, in principle, obtainable and, perhaps, important.

While teaching in the Georgia University system, I did a small amount of research into the synthesis of the principal ingredient of our patented hydraulic fluid. This resulted in my one and only citation in the Beilstein Handbook of Organic Chemistry. However, subsequent employment by the Colgate-Palmolive Company and the Atlas Powder Company, which I followed through its various name changes finally to ICI Americas, shifted my interest to surface-active materials. So I allowed this particular oxymoron to fall into disuse.

Although my research interests have changed, my fate seems to be involved in this problem. About 20 years ago, I was invited to participate in a study by a Bureau of Ships committee to consider the problem of the flammability of hydraulic fluids in submarines. Flammability, as anyone who has ever been inside a submarine knows, is an even greater hazard in a submarine than in aircraft. Nowhere in a submarine is one more than a few feet from a hydraulic line. In addition, one has the option of parachuting from an airplane, but the same option does not present itself in a submerged vessel. The committee met here in Washington, D.C. to consider the problem. Although the Navy's not unreasonable lack of interest in retrofitting the entire submarine fleet limited our options rather severely, a report was issued. As far as I know, none of the recommendations was ever implemented.

My final experience with this problem actually completed my tour of the military services, as well as resurrecting, at last, the oxymoron. I was called to join a committee at the U.S. Army Fuels & Lubricants Laboratory in San Antonio, Texas, to consider problems involving fuel fires in military vehicles. This is a substantial problem because many military vehicles, tanks and the Bradley vehicle, for example, are run by diesel engines where the fuel doubles as engine coolant. Thus, at any time there may be as many as 400 gallons of diesel fuel sloshing about the vehicle.

The Army also proved to be unwilling to retrofit, and other restrictions seriously reduced the possible solutions to the problem. Nonetheless, a report was issued. To the best of my knowledge, the recommendations for further study were not implemented.

It will be noted that I have qualified the results of my tour of the services by saying in each case, "to the best of my knowledge" or "as far as I know." The reason for the qualification is obviously the possibility of "military secrecy" (another oxymoron?). The fact that we are here today suggests, however, that no great measure of success has been achieved in the intervening years.

Now, to return to my principal theme: in what way can surface-active agents, new or old, contribute to progress in this area? The obvious answer is as stabilizers in multiphase systems. Some form of emulsion seems an obvious approach. The limitation that no water be included in the formulation has been imposed. It should be noted that hydrocarbon-water systems have been used extensively as fuels, notably in diesel engines. Generally, these have been water-in-oil systems and have been investigated with a view to reducing emissions and costs, rather than to reducing flammability. An interesting review of some research in this area was recently given by Thompson (Thompson, 1990). In addition, some work has been done on using oil-in-water emulsions as heating or power-plant fuel, namely using emulsions of heavy crude, as exemplified by Orimulsion fuel (Briceno et al., 1990; Marcano et al., 1991).

These studies reveal that fuel emulsions can indeed burn. Unfortunately, I have not been able to determine if studies on the prevention or limitation of burning have been carried out. I have identified a suggestive paper by Kitamura and coworkers dealing with water-in-oil emulsions (Kitamura et al, 1991). This paper suggests that the flash point decreases with increasing surface area per unit volume of the emulsion. Since the utility of the emulsion as a fuel depends on its ability to burn, it is obvious that this clue must be employed with some caution.

All of the papers I consulted in preparing this presentation on the use of surface-active agents have included very conventional surfactants in the formulations. This is not surprising because there are literally thousands of surface-active materials available to the investigator or formulator. The laws of thermodynamics being what they are, one may expect that all of these materials will act in pretty much the same way. For any given system, these thousands of surfactants may shrink to a few suitable ones. The methods of determining the appropriate ones are well known and are described in a number of places, including in my own work.

In conclusion, new approaches to this problem may be rather limited. Although it may be that no current product meets the needs of a new system subjected to, for example, environmental extremes, the synthesizer of new materials will be guided by the wealth of previous experience, as well as by the laws of thermodynamics.

REFERENCES

American Heritage Dictionary (3rd ed.). 1996. CD-ROM version.

Becher, P., and W. Schelsinger. 1949. U.S. Patent 2,470,792.

Becher, P. In press. Emulsions: Theory and Practice (3rd ed.). American Chemical Society (ACS) Monograph. Washington, D.C.: ACS.

Briceno, M.I., M.L. Chiroinos, I. Layrisse, G. Martinez, G. Nunez, A. Padron, L. Quintero, and H. Rivas. 1990. Emulsion technology for the production and handling of extra heavy crude oils and bitumens. Revista Tecnica Intevep 10(1):5-14.

Kitamura, Y., Q. Huang, Y. Oka, and A Williams. 1991. Flashing of superheated water-in-oil emulsions. Journal of Chemical Engineering of Japan 23:711–715.

Marcano, N., M. Pourkashanian, and A. Williams. 1991. The combustion of bitumen-in-water emulsions . Fuel 70(8):917–923.

Thompson, R.V. 1990. To fly to float: a half life of research and development. Transactions of the Institute of Marine Engineering 102(1):1–16.

5

Fire Safety in Military Aircraft Fuel Systems

Robert G. Clodfelter

AFP Associates Inc.

INTRODUCTION

Because of the large quantity and dispersed storage of fuel on board aircraft, there is a high probability that aircraft accidents will involve fire in one way or another. The probability of fire is increased by the aircraft design requirement for lightweight structures for fuel containment. Fire could result from a fuel explosion in a fuel tank, fuel leakage into dry bays, cabin areas, cargo bays, or engine compartments, or from a fuel release on impact. Whether the fire or explosion is caused by the initial event or by a secondary cause, the result is often catastrophic.

One way to reduce the aircraft fire problem is to develop a fuel that is less susceptible to combustion in locations other than the engine. This is a challenging technical and economic goal, especially considering the requirements of aircraft operation and fuel availability. Candidate "fire-safe" fuels should have the availability, reasonable cost, and suitable physical and chemical properties for direct utilization in operational aircraft without extensive fuel system modifications or serious degradation of aircraft performance. Because of these stringent requirements, most of the successful efforts to reduce the aircraft fire hazard have been improvement in prevention and protection areas rather than development of fire-safe fuel. This paper uses the term fire-safe in the broad sense, i.e., any change in fuel that improves fire safety.

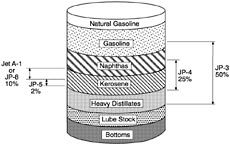

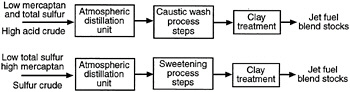

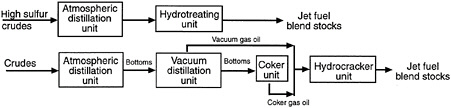

The Air Force's recent conversion from JP-4 (which has Jet B as its commercial equivalent) to JP-8 fuel is a step in the right direction from the standpoint of fire safety. Army aircraft use the same fuel as the Air Force. The Navy has used JP-5 fuel for many years for fire safety reasons. Properties of these military fuels and commercial fuels (Jet A and Jet A-1) are given in Table 5-1. The production of these fuels is illustrated in Figure 5-1 as a percentage obtained by simple distillation of an average crude oil. By using refinery techniques, such as hydrocracking, hydrotreating, and reforming, these percentages can be adjusted on demand. However, fewer added refinery costs are associated with converting heavy bottom fuels to high vapor pressure fuels (low flash point temperature) than vice versa.

The use of JP-5 and JP-8 was implemented to reduce the availability of fuel vapors for ignition and to reduce the amount of fuel vapor which could support a reaction. The use of antistatic additives in aircraft fuels (a specification requirement for JP-4 and JP-8 but not for Jet A or Jet A-1) is helpful for minimizing static as a potential ignition source. The lack of an antistatic additive may have been a contributing factor in the recent TWA 800 accident (17 July 1996). Other

TABLE 5-1 Comparison of the Properties of Aviation Fuels

|

|

JP-4 |

JP-8 |

Jet A-1 |

Jet A |

JP-5 |

|

Minimum Flash Point, °F |

-20 |

100 |

100 |

100 |

100 |

|

Maximum Freeze Point, °F |

-72 |

-53 |

-53 |

-40 |

-51 |

|

Lbs/gal |

6.3 |

6.7 |

6.7 |

6.8 |

6.8 |

|

BTUs/gal |

118,900 |

124,500 |

124,500 |

125,700 |

126,000 |

|

Vapor Pressure, psi |

2-3 |

|

|

|

|

|

Viscosity, cSt@-4°F |

2.4 |

4.2 |

4.2 |

5.5 |

5.5 |

|

Acid NR, mg KOH/g |

0.015a |

0.015a |

0.1 |

0.1 |

0.015a |

|

a Allow up to 0.022. |

|||||

FIGURE 5-1 Availability of distillate fuels.

attempts to make fuels more fire safe have included developing modified fuels, such as gels, emulsions, and antimisting kerosene (AMK). Tests on modified fuels have demonstrated potential reductions in ignition and flame propagation by the mists and sprays normally associated with "neat" fuels in the event of a crash landing and structural failure. All of the currently known modified fuels, however, have serious operational and logistical problems mainly associated with fuel transfer, storage, and engine performance. Many of the proposed solutions for these problems have inherent negative safety factors and present new design challenges. Needless to say, modified fuels have only been used in test programs and not operational service.

The search for a less hazardous fuel has taken two fundamental approaches. The first entails reducing the availability of fuel vapors for ignition and limiting their availability for feeding the combustion process. This may be accomplished by increasing the flash point temperature of the fuel (lowering the vapor pressure), a fuel property that can be easily measured. Fuels with a wide range of flash point temperatures are currently available. Gasoline has a flash point temperature of about -60°F, whereas aviation jet fuels have flash points in the 100¹ to 150°F range (with the exception of JP-4 [Jet B] which has a flash point near 0°F). Unfortunately, increasing the flash point temperature of a fuel has negative operational and performance effects, such as increased viscosity, increased freeze point temperature, and problems with engine starting and engine relight at altitude. These problems can be minimized by refinery techniques and design or procedural changes with some increase in fuel cost and operational inconvenience.

The second approach to the search for fire-safe fuel involves modifying the fuel to reduce the ignition and flame propagation of mists and sprays normally associated with neat fuels in a crash situation. This approach has few fire safety benefits for neat fuels with high vapor pressures, i.e., for low flash point fuels (Gandee and Clodfelter, 1974). This is one reason the Air Force showed limited interest in the many modified fuel programs that were being conducted in the U.S. and United Kingdom in the 1960s, 1970s, and into the 1980s. The Air Force was using JP-4, a high vapor pressure fuel, during this time and had many other concerns to address associated with their planned conversion from JP-4 to JP-8. This conversion was completed, at all but a few locations, in 1995. Since the changeover to JP-8 fuel, the Air Force and commercial airlines are using fuel with the same vapor pressure. The Air Force fuel (JP-8), however, contains several additives, some of which are not required in the commercial fuel (Jet A and Jet A-1). See Table 5-2.

Based on the experience of the Air Force during their conversion to JP-8, operational fuel changes are very complex and time-consuming in addition to being expensive. In 1967, when the Air Force initiated efforts to evaluate the combat benefits of JP-8, commercial airlines had more than 15 years of operational experience with Jet A and Jet A-1, the commercial equivalent of JP-8. Even with this long-term experience, the first JP-8 conversions at NATO bases didn't occur until 1978.

A study team of the Coordinating Research Council (CRC) reviewed the JP-8 (Jet A and Jet A-1) and JP-4 (Jet B) accident experience from 1952 to 1974 (CRC, 1975). The study team reported that:

TABLE 5-2 Characteristics of Current Military Fuel Additives

|

Fuel Additive |

Comments |

|

Antioxidants |

Reduces or prevents formation of gums and peroxides Key ingredient in JP-8+100 |

|

Metal Deactivator |

Deactivates trace metals Maintains thermal oxidate stability |

|

Corrosion Inhibitors/Lubricity Enhancers |

Originally required to protect pipelines Removal from fuel caused significant wear problems Minimum adjusted to protect F-111 NATO, ASCC investigating potential of lowering minimums |

|

FSII |

Water in fuel caused crashes Prevents biological growth Allows A/C and ground storage sumps to be drained in winter |

|

Static Dissipator |

1960s USAF experienced 1 or 2 static-initiated fires per year Rash of fires when A/C equipped with foam A/C currently equipped with conductive foam With conversion to JP-8, need to continue is being evaluated |

|

Source: Personal communication from C.L. Delaney and W.E. Harrison III, USAF Wright Laboratories, November 1996. |

|

-

In 200 survivable accidents with spilled fuel that were reviewed, there were 7 to 19 percent fewer fires with JP-8 than with JP-4 at the 95 percent confidence level.

-

In 13 in-flight accidents involving fuel releases or fuel tank explosions that were studied, there were more fires with JP-4 (100 percent) than with JP-8 (44 percent).

-

Ground accidents with JP-4 resulted in more aircraft destroyed (78 percent) than ground accidents with JP-8 (0 percent). 13 events were analyzed.

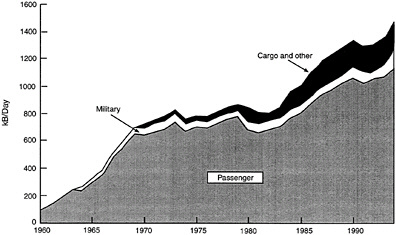

Even after these CRC fire-safety results had been released, and combat benefits of using JP-8 had been identified (Beery et al, 1975), the Air Force conversion was not completed until 1995. Considering that fire-safe fuel has greater pay offs in terms of flight safety and combat survivability for the military than for commercial aviation, and considering that the military uses only one-tenth of the fuel used by U.S. airlines (see Figure 5-2), the fuel change of this type should have been easier to justify and less difficult to implement for the military then for commercial aviation. The total time for the military's conversion to JP-8 was 28 years. The number of aircraft involved in commercial aviation, combined with the number of airports and airlines and their associated infrastructures, suggest that a commercial fuel change would involve a significant phase-in time. Operational compatibility between the old and new fuels will therefore be essential.

FIGURE 5-2 Demand for kerosene jet fuel in the United States. Source: Personal communication from C.L. Delaney and W.E. Harrision III, USAF Wright Laboratories, November 1996.

Despite these concerns, it is appropriate to address periodically opportunities for the development of a fire-safe fuel. Technical people tend to be optimistic about achieving the short-term goals but pessimistic about the long-term possibilities. It is possible that an AMK-type fire-safe fuel could be developed in the distant future. Against this backdrop, a brief discussion of jet fuels, fuel flammability, the fire problem (including fire prevention and protection techniques), cost/benefit analysis, and future aircraft trends follows.

JET FUELS

Jet fuels in the United States have been evolving since the 1940s (Martel, 1987). JP-1, the first jet fuel specified in the United States (1944), was a kerosene with a freeze point temperature of -77 °F and a minimum flash point temperature of 109°F. The availability of JP-1 was limited to about 3 percent of the average crude oil. JP-2 (1945) was an experimental fuel that was found to be unsuitable because of its viscosity and flammability.

JP-3 (1947 to 1951), the second operational fuel, had a high vapor pressure similar to aviation gasoline. Because of its high vapor pressure and because jet aircraft tend to fly at higher altitudes than reciprocating engine-powered aircraft, losses from fuel boil-off and vapor lock were problems.

JP-4 fuel (1951 to 1995), also designated as NATO F-40 and Jet B, a blend of gasoline and kerosene with a Reid vapor pressure restriction of 2 to 3 psi has fewer problems with boil-off and vapor lock. JP-4 has a freeze point of -77°F and a flash point temperature of about 0°F (not a specification requirement). JP-4 was the primary jet fuel used by the U.S.

Air Force from 1951 to 1995. In the mid 1980s an antistatic additive was added to JP-4 for fire-safety reasons.

JP-5 fuel (1952 to the present), also called NATO F-44, has a 140°F minimum flash point temperature. This kerosene fuel is currently the primary fuel used by the U.S. Navy and was developed mainly in response to fire-safety concerns on ships. JP-5 fuel has a freeze point temperature of -51°F and does not contain an antistatic additive.

JPTS (1956), developed for the U-2, is a highly refined kerosene with a low freeze point of -64°F and a thermal stability additive package (CJFA-5). Its minimum flash point temperature is 109°F.

JP-6 (1956), developed for the XB-70, is similar to JP-5 but has a lower freeze point (-66°F) and more thermal stability. The flash point temperature is not a specification requirement. JP-7 (1960s), developed for the SR-71, has a low vapor pressure and excellent thermal stability for high altitude and mach 3+ operations. It has a freeze point of -47°F and a minimum flash point temperature of 140°F.

Jet A and Jet A-1 (1950s to the present) are the two fuels used by commercial airlines. Both fuels have a 100°F minimum flash point temperature for fire-safety reasons. Jet A has a freeze point of -40°F and Jet A-1 has a freeze point of -53°F. Because of its lower freezepoint, Jet A is more widely available and is, therefore, more widely used. Commercial fuels in the United States are not required to contain antistatic additives and generally do not.

Finally, JP-8, also known as NATO F-34, was first introduced at NATO bases in 1978 and is currently the primary fuel used by the U.S. Air Force. JP-8 is very similar to Jet A-1, but it contains an icing inhibitor, a corrosion/lubricity enhancer, and an antistatic additive (see Table 5-2). The U.S. Air Force conversion to JP-8 was virtually complete in 1995 and was undertaken for fire-safety and combat survivability reasons.

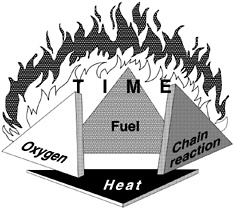

FUEL FLAMMABILITY

The classic fire pyramid or fire tetrahedron (shown in Figure 5-3) illustrates the four elements necessary for a sustained hydrocarbon fire: heat for ignition, fuel, oxygen, and free radicals. The first three elements must be in the proper range and state for ignition and chain branching reactions must occur to maintain the reaction process. The first three elements must also be available in the proper balance for a sufficient period of time for ignition to occur. The required time increases near the flammability and ignition energy limits. All fire prevention, fire protection, or fire-safe fuel must negate at least one of these elements in some way. By this criterion, the two basic fuel properties used for first order assessments of a fuel's hazardous nature were established.

FIGURE 5-3 The fire pyramid.

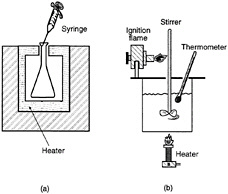

FIGURE 5-4 Autoignition temperature (AIT) and flash point temperature measurement apparatus.

The first and most important fuel property in many fire-safety scenarios is flash point temperature. Figure 5-4 is a simplified sketch of the equipment used to determine the flash point temperature of a fuel. The test fuel is placed in a container, the liquid fuel is slowly and uniformly heated and its temperature monitored. Periodically, as the temperature is increased, a large ignition source is inserted into the fuel container, until the lowest temperature at which a flash occurs is identified. This temperature is called the flash point and is

a measure of the availability of fuel vapors for ignition. In relation to the fire pyramid, the flash point temperature is a good estimate of the minimum fuel-air ratio necessary for ignition. The flash point temperature is close to, but slightly higher (5 to 10°F) than, the lower flammability limit. The flash point test involves downward flame propagation whereas the lower flammability limit test involves upward flame propagation. Because upward flame propagation is easier to achieve than downward flame propagation, it requires fewer fuel vapors at a lower temperature.

The apparatus used to determine the minimum autoignition temperature (AIT), or spontaneous ignition temperature, of a fuel is also illustrated in Figure 5-4. A 500-ml flask is slowly and uniformly heated. At a known temperature, a small amount of fuel is injected. This is followed by a 10-minute period during which any flash or light emitted from the flask is noted. This procedure is repeated a number of times with varying amounts of injected fuel at various temperatures to determine the lowest temperature at which an indication of ignition is observed.

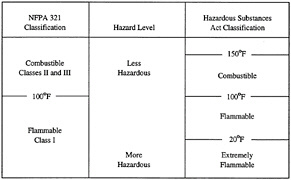

In terms of the fire pyramid, the AIT of a fuel can be viewed as the lower limit at which a hot surface can cause ignition. Unfortunately from a fire-safety point of view, these two properties (flash point temperature and AIT) relate to each other in different directions for most fuels. For example, aviation gasoline (Grade-100) has a flash point temperature of -50°F (bad) and an AIT of 824°F (good). JP-8 has a flash point temperature of 100°F (good) and an AIT of 435°F (bad). In most real world situations, however, JP-8 is considered much less hazardous than aviation gasoline (see Figure 5-5 for the fuel hazard classification used by the National Fire Protection Association [NFPA] and in the Hazardous Substances Act). The relative fire hazard of a fuel can be better estimated from the flash point temperature than the AIT. However, many fuel combustion characteristics must be evaluated under real world conditions and then assessed against operational problems to evaluate potential fire hazard benefits as a function of fuel properties.

Can the number of aviation fatalities and injuries be reduced in a cost-effective manner by using a fuel with a higher flash point temperature, a lower probability of ignition in a crash situation, or some combination of other fuel properties? A commercial aviation switch to a higher flash point fuel (similar to JP-5) seems possible with reasonable effort and would result in some fire-safety benefits. An AMK-type fuel may have more potential fire-safety benefits, but a conversion of operational aircraft may be impractical in the final analysis. Before a conversion in initiated, detailed study of the aircraft fire problem covering these two fire-safe fuel approaches and their potential operational problems must be done.

Some fuel characteristics that should be assessed when evaluating the fire-safety benefits of a fuel are:

-

volatility/atomization

-

flash point

-

autoignition temperature (AIT)

-

flame spread rate over a pool

-

burning velocity (vapor-air mixture)

-

fuel-air mixture, including equilibrium and nonequilibrium (venting, sloshing, vibration, spray, mists, foams) conditions

-

electrical characteristics (static accumulation)

-

extinguishing characteristics

Some environments that should be considered when assessing the fire-safety benefits of a fuel are:

FIGURE 5-5 Flammable liquids classification from the National Fire Protection Association (NFPA) and Hazardous Substances Act as related to flash point.

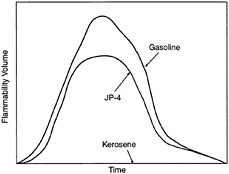

FIGURE 5-6 Rate of flammability volume buildup.

-

in-flight operations

-

ground operations

-

combat threats (projectiles, fragments, high explosive incendiary, etc.)

-

terrorist activities

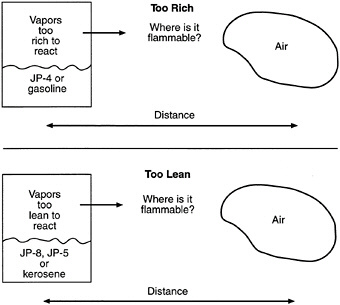

FIGURE 5-7 Flammable zone between leaking fuel-rich vapors and ambient air.

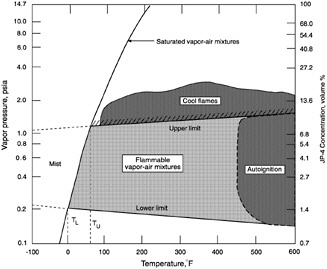

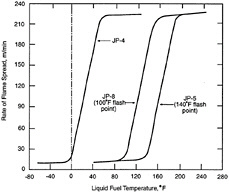

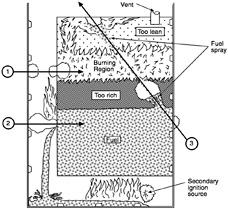

Figure 5-6 illustrates the relative rate of fuel-vapor generation and the flammability volume associated with a fuel spill at ambient conditions for kerosene, JP-4, and gasoline. Fuels with a flash point temperature above the ambient temperature have no flammable zone. Figure 5-7 illustrates the flammable zone between a leaking fuel rich mixture and ambient air. Leaking fuels with a flash point temperature above the ambient temperature have no flammable zone, assuming that no sprays or mists are present. Flammable regions for JP-4 under equilibrium conditions are shown in Figure 5-8, including the important flammable zone below the flash point temperature when sprays and mists may be present. The rates of flame spread across a spill of JP-4, JP-8, and JP-5 are shown in Figure 8. The flame spread rate is strongly dependent on flash point temperature. The flammability properties of several common aircraft fluids are given in Table 5-3, where the safe hot surface temperature is the temperature at which the probability of ignition is about 10-3 (Clodfelter, 1990).

THE FIRE PROBLEM

The general fire problem is the same for military and commercial aircraft, except for the combat threat to military

FIGURE 5-8 Flammable regions for JP-4.

aircraft (the projectile threat is illustrated in Figure 5-10). Some fire prevention, detection, and control measures are given in Table 5-4. In addition to the measures in Table 5-4, several active and passive fuel system and dry bay fire protection techniques have been studied over the years. Some of these techniques are listed below:

FIGURE 5-9 Flame spread across a jet fuel spill.

-

flame arrestor foam

-

inerting (nitrogen enriched air [NEA], N2, CO2, halon 1301 [CF3Br]) systems

-

explosion suppression systems

-

self sealing fuel tanks

-

crash resistance fuel tanks

-

dry bay protection (void filler materials, extinguishing systems, purge mats, powder packs)

-

fire proofing, fire resistance, fire hardening

-

gelled/emulsified fuels

-

antimisting kerosene (AMK)

-

fuel fogging

All but the last three protection techniques have been successfully used on operational aircraft. Flame arrestor foams have been used very successfully on many military fighter aircraftto prevent fuel tank explosions. Inerting systems are currently used to protect the fuel tanks of SR-71, C-5, OV-22, C-17, AH-64, and F-22 aircraft. As a result of the recent TWA 800 accident, fuel tank inerting systems will be conscientiously reconsidered for commercial aircraft.

COST/BENEFIT ANALYSIS

Changing fuels or adding fire protection hardware to an aircraft will require cost/benefit analysis prior to approval and

TABLE 5-3 Flammability Properties of Aircraft Fluids

|

|

Fuels |

Hydraulic |

Lubricants |

|||

|

|

JP-4 (Jet B) |

JP-8 (Jet A, Jet A1) |

JP-5 |

Mil-H 5606 |

MIL-H 83282 |

MIL-L 7808 |

|

Flash Point (°F) |

-10 to 10 |

100 |

140 |

210 |

435 |

425 |

|

Auto Ignition Temperature (°F) |

445 |

435 |

435 |

435 |

650 |

750 |

|

Lower Flammability Limit (vol pct) |

1.3 |

0.6 |

0.6 |

1.2 |

1.4 |

|

|

Upper Flammability Limit (vol pct) |

8.2 |

4.7 |

4.5 |

7.1 |

7.7 |

|

|

Hot Surface Ignitiona Temperature (°F) |

840 |

820 |

820 |

625 |

675 |

915 |

|

Safe Hot Surfaceb Temperature (°F) |

690 |

670 |

670 |

475 |

525 |

765 |

|

a Minimum based on six different references. b For bleed air ducts and fluids at ambient temperature. |

||||||

funding. A cost/benefit analysis for specific protection techniques may also include similar cost/benefit analyses for other prevention/protection techniques that may achieve the same safety goal. Some of the effects of fuel properties on aircraft operations/performance and fire safety are shown in Table 5-5. Unfortunately, in many cases, the fuel characteristics desired for optimal operation are different from those desired for optimal fire safety.

The factors in Table 5-5 should be included in any decision regarding a fuel change. In addition, a minimum number of operational factors regarding aircraft performance should be addressed. These include:

FIGURE 5-10 Fire problem associated with projectiles piercing the fuel tank.

-

cold engine starting (viscosity at low temperature, fouling/coking)

-

engine relight envelope (viscosity, vapor pressure, fouling/coking)

-

engine control anomalies (fouling/coking)

-

augmentor performance

-

engine maintenance (fouling/coking)

-

fuel transfer (viscosity, freeze temperature, vapor pressure)

-

fuel system maintenance

-

range (BTU density)

The following economic factors (at a minimum) should be considered:

-

price per gallon

-

ground handling (storage, transfer, special procedures and equipment)

The following strategic factors regarding fuel availability should be considered:

-

local

-

worldwide

-

interchangeability

The following safety factors should be considered:

-

ground handling (storage, transfer)

-

combat (fuel tanks, dry bays, weapons bays, engine compartments)

-

flight safety (fuel tanks, dry bays, engine compartments)

-

safety hazards

TABLE 5-4 Fire Prevention, Fire Detection, and Fire Control Techniques (MIL-F-87168)

|

Aircraft Fire Safety Goals |

Techniques |

|

Fire and Explosion Hazard Prevention |

Combustible material hazard reduction Subsystem hazard reduction Isolation Separation Ventilation Cooling Drainage Electrical Bonding and Lightning Protection Post crash fire prevention |

|

Fire and Explosion Hazard Detection |

Detection system location Performance Alarm output alerm set point and clearance |

|

Fire and Explosion Hazard Control |

Control adjacent area hazards Fluid control Ventilation termination Electrical ignition source control Fire barriers Fire hardening Smoke and hazardous vapor control Overheat control Fire extinguishing Ground fire fighting |

|

Source: Department of Defense, 1992. |

|

A cost/benefit analysis includes the cost of an item/system over its useful life compared to the benefits of the item/system during the same time period. The total cost or life cycle cost (LCC) of a system is the total cost at the end of its lifetime, including all expenses for research and development, production, modification, transportation, introduction of the item/system into the inventory, new facilities, training, performance, operations, support, maintenance, disposal, and any other

TABLE 5-5 Effects of Fuel Properties on Aircraft Performance and Fire Safety

|

Fuel Property |

Best for Operations |

Best for Fire Safety |

|

Heat of Combustion |

high |

low |

|

Flash Point |

depends |

high |

|

Viscosity |

low |

high |

|

Density |

high |

|

|

Atomization |

high |

low |

|

Vapor Pressure |

depends |

low |

|

Freeze Point |

low |

|

|

Thermal Stability |

high |

|

|

Resistivity |

unknown |

low |

costs of ownership penalties, less any salvage revenue at the end of its lifetime. LCC by itself is useful only when two or more competing items/systems provide the same total benefits or the same performance. On the other hand, the benefits of an item/system include performance enhancement, increased probability of mission completion, risk reduction benefits to personnel, equipment, facilities, products, lost revenue, and any other benefits during the ownership period.

The cost/benefit analysis involves determining the difference between prevention/protection system costs (LCC) and the benefits over a specific period of time, usually 20 years for aircraft systems. These costs and benefits will not occur in the same year. Therefore, all values must be converted to present value. For aircraft fire protection systems and fire-safe fuels, the parameters associated with a cost/benefit analysis are affected by the number and type of aircraft, the different types of air bases and airports affected, domestic vs. overseas operations, number of military and commercial aircraft affected, peace/war, sortie rate, flight hours, weight, volume, fuel costs, and performance factors.

FUTURE TRENDS

Research and development of aircraft fire-safety should be compatible with current and future treands in aircraft design.

Higher performance aircraft and higher thermally efficient engines are a given for the future. Also, composite fuel tanks have the potential for more effective fuel containment on ground impact. Heat sink requirements will increase because of increased electronic equipment cooling, hotter engines, and associated thermal loads. Because engines will be more efficient, there will be less fuel flow to the engines for cooling; therefore, more hot fuel will be recirculated to the fuel tanks.

The overall effects of these trends will be higher fuel system temperatures and higher engine surface temperatures. The upper limit for the fuel temperature at the engine combustor nozzles is about 325°F for current fuels. The Air Force is currently conducting operational tests on JP-8 fuel with antioxidant additives (personal communication with C.L. Delaney and W.E. Harrison III, USAF Wright Laboratories, November 1996). This test fuel is designated as JP-8+100. The ''+100" denotes an increase in the upper limit for the fuel at the combustor nozzles from 325°F to 425°F. In terms of fire safety, these trends mean a higher probability of flammable mixtures in fuel tanks with the current fuels, a higher probability of hot surface ignition, a faster buildup of flammable zones, and larger flammable zones associated with fuel release into aircraft compartments or on the ground.

SUMMARY

The search for a fire-safe fuel involves many complex operational issues and technical challenges. To be successful, a long-term commitment will be required. Given the always limited resources available to address safety concerns, the potential for the highest payoff, the greatest reduction in aircraft related deaths/injuries, must be determined in relation to the technical risks. It appears to this author that a switch to a higher flash point fuel similar to JP-5 is possible with reasonable effort and that this would result in some fire-safety benefits. An AMK-type fuel may have the potential for more fire-safety benefits, but a conversion to operational aircraft may be impractical in the final analysis. Fuel tank inerting and antistatic fuel additives may be the next big steps for improving the fire safety of commercial aircraft. In any case, a detailed study should be done of the aircraft fire problem and the two fire-safe fuel approaches and the potential operational problems of each before a fire-safe fuel program is initiated.

REFERENCES

Beery, G.T., R.G. Clodfelter, G.W. Gandee, D.M. Spear, and D.C. Wight. 1975. Assessment of JP-8 as a Replacement Fuel for the Air Force Standard Jet Fuel JP-4: Part I. AFAPL-TR-74-71. Wright-Patterson Air Force Base, Ohio: Air Force Aero Propulsion Laboratory.

Clodfelter, R.G. 1990. Hot surface ignition and aircraft safety criteria. Society of Automotive Engineers Transactions 99(4):521–539.

Coordinating Research Council (CRC). 1975. Aviation Fuel Safety 1975. CRC Report No. 482. New York: Aviation Fuel, Lubricant, and Equipment Research Committee, CRC.

Department of Defense (DOD). 1992. Fire and Explosion Hazard Protection Systems: General Specification for Aircraft. MIL-F-87168. Washington, D.C.: DOD.

Gandee, G.W., and R.G. Clodfelter. 1974. Evaluation of the Effectiveness of Anti-Mist Fuel Additives in Prevention of Aircraft Fuel Tank Ullage Fires and Explosions. AFAPL-TR-73-111. Wright-Patterson Air Force Base, Ohio: Air Force Aero Propulsion Laboratory.

Martel, C.R. 1987. Military Jet Fuels: 1944–1987. AFWAL-TR-87-2062. Wright-Patterson Air Force Base, Ohio: Air Force Wright Aeronautical Laboratories.

6

Rheology: Tools and Methods

Saad A. Khan, Joseph R. Royer, and Srinivasa R. Raghavan

Department of Chemical Engineering

North Carolina State University

INTRODUCTION

In this paper, we attempt to give the reader a basic understanding of rheology, a scientific discipline of great utility in characterizing complex, microstructured media. Rheology is formally defined as the study of deformation and flow behavior in various materials (Macosko, 1994). Since its humble origins in the 1920s in the laboratories of Eugene Bingham at Lehigh University, rheology has developed into a mature field of wide-ranging applicability.

Systems investigated using rheology can typically be classified as soft condensed matter or as complex fluids. Examples include macromolecular systems, such as polymer melts and solutions, gels, and biological fluids, as well as colloidal and multiphase systems, such as dispersions, emulsions, foams, and surfactant solutions. Typically, these materials are viscoelastic, i.e. they exhibit a combination of viscous and elastic properties. Such complex behavior cannot be characterized purely in terms of simple parameters, such as the material viscosity or elastic modulus.

One of the objectives of this paper is to indicate the possible applications of rheology towards designing improved aviation fuels. Although an aviation fuel typically behaves like a viscous liquid, the introduction of certain additives can cause the system to show a viscoelastic response (Hoyt et al., 1980). In that case, the rheology of the system becomes important, and rheological studies will be necessary for accurately modeling the flow in the aircraft engine. Moreover, it is possible that a controlled amount of viscoelasticity may prove to be beneficial to the overall performance of the aviation fuel. For instance, the addition of an "antimisting" component to the fuel can reduce the fire hazard in case of a fuel leak (Chao et al., 1984).

Our agenda for this paper is ambitious: we would like to cover the most important rheological principles, techniques, and methods, as well as indicate specific applications—all within about 20 pages. Clearly, we have to be very selective in the topics we choose to describe. Our focus will be on reviewing the material parameters obtained using rheology and the correlation of these parameters to material microstructure. In this context, the microstructure implies the spatial disposition of molecules, particles, or other entities in the system over length scales on the order of microns (Barnes, 1993). We will consider the three most common kinds of rheological techniques, viz. steady-shear rheology, dynamic rheology, and extensional rheology. We will then provide some specific examples for the applications of rheology to materials characterization and design. For the interested reader, we have supplied an extensive list of references for obtaining more detailed information on various aspects of rheology as well as on specialized rheological methods.

VISCOELASTIC BEHAVIOR

The science of rheology attempts to bridge the gap between solid mechanics (which deals with perfectly elastic solids) and fluid mechanics (which deals with perfectly viscous liquids). Thus, the rheologist is typically interested in viscoelastic systems that exhibit a combination of elastic and viscous behavior. To understand viscoelasticity, it will be helpful to consider first the cases of perfect elasticity or viscosity, which can be interpreted in terms of simple relationships such as Hooke's law for solids and Newton's law for liquids, respectively. We will now consider these two laws and indicate their applicability, or lack thereof, for various materials.

Fundamental relationships linking force and material deformation are called constitutive equations (Bird et al., 1987). For an elastic solid, the constitutive equation is Hooke's law, which states that the applied shear-stress (τ) is proportional to the produced shear-strain (γ) or alternately:

τ=Gγ

(1)

Here, the shear-stress (τ) is the shear force per unit area, and the strain (γ) is defined as the relative change in length. The proportionality constant (G) is called the shear modulus

and is an intrinsic property of an elastic solid. For Hookean solids when the stress is removed, the strain becomes zero and the material regains its original shape and structure. Thus, the elasticity of a material represents its ability to regain its shape and structure after deformation, i.e., to store deformation energy. Most metals and ceramics obey Hooke's law at small strains.

A similar constitutive equation exists for a viscous or Newtonian liquid. Newton's law of viscosity states that the shear stress (τ) is proportional to the rate of strain, or shear rate (![]() ).

).

![]() (2)

(2)

The proportionality constant (η) is defined as the viscosity of the material. Thus, a Newtonian liquid will undergo a constant rate of deformation under an applied stress, and when the stress is removed it will remain in the shape and structure it has adopted. The viscosity of a material is a measure of its internal resistance to flow and reflects the rate at which energy is dissipated in the material. Many small-molecule liquids, such as water, honey, and various oils, obey Newton's law.

As we have indicated, there are several materials that obey these constitutive equations. These materials can be completely characterized by measuring the respective parameters, G or η. But in reality, many systems, such as colloids, polymers, and gels, do not obey these simple constitutive relations. Instead, these materials have properties between those of a Hookean solid and a Newtonian liquid and can be classified as non-Newtonian or viscoelastic. For these materials, the viscosity is a function of shear-rate and, hence, not constant, and the shear modulus has two components signifying elastic and viscous character respectively.

Many simple experiments can demonstrate viscoelastic or non-Newtonian behavior (Boger and Walters, 1993; Bird et al., 1987; Schramm, 1994). First, consider "silly putty," which is a poly(dimethyl siloxane) (PDMS) elastomer of moderate molecular weight. When a ball of silly putty is dropped onto a solid surface, it bounces back like a rubber ball, thereby behaving almost like an elastic solid. However, if the putty is placed on that same solid surface for some time, it will slowly flow under the stress of gravity, thus showing behavior characteristic of a highly viscous fluid. Therefore, silly putty can behave both like an elastic solid or a viscous liquid, depending on the time scale of the deformation.

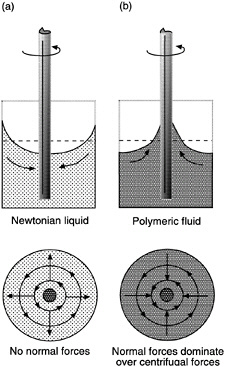

A second example of non-Newtonian behavior is "rod climbing" (or the Weissenberg effect). When a vertical rod is rotated in a container of Newtonian fluid, such as water, the inertial forces acting on the fluid cause it to move away from the rod. This creates a situation where the fluid level at the rod is lower than the fluid level at the container walls (Figure 6-1a). If the same experiment is run in a container of polymeric fluid, the flow changes directions and moves toward

FIGURE 6-1 Rod climbing (Weissenberg effect). (a) In Newtonian fluids, centrifugal forces generated by the rotation push the fluid away from the rod. (b) In non-Newtonian fluids, normal forces are stronger than centrifugal forces and drive the fluid inward toward the rod.

the rod. This phenomenon is called rod climbing and is caused by the influence of normal stresses on flow properties (Figure 6-1b). These normal stresses create tension along the circular lines of flow and generate pressure toward the center, which drives the polymeric fluid up the rod.

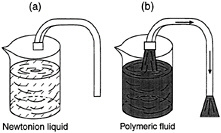

Another dramatic illustration of viscoelastic effects is the "tubeless siphon" experiment. When a Newtonian liquid, such as water, is drained out of a container through a siphon, the tube must remain under the level of liquid in order for the liquid to continue to flow. However, a polymeric (non-Newtonian liquid) can continue to flow up and through the siphon even after the tube is raised above the liquid level (Figure 6-2). The fluid undergoes extensional flow (stretching) in this case, and the elastic nature of the polymeric fluid enables it to be extended upwards and sucked into the tube.

FIGURE 6-2 Tubeless siphon. (a) Newtonian fluid cannot be siphoned unless tube is below fluid level. (b) Normal stresses allow non-Newtonian fluid to be siphoned even when tube is above fluid level.

STEADY-SHEAR RHEOLOGY

Simple steady-shear flow is the easiest flow to generate and is, therefore, of central importance in rheology. Most of the rheological data reported in the literature is for steady-shear material functions. Moreover, flows occurring in a

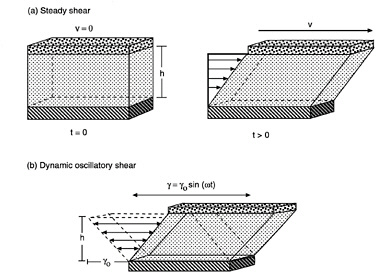

FIGURE 6-3 Two types of shear deformation. The arrows represent the velocity field in the fluid in each case. (a) Steady shear of a fluid between two parallel plates. At time t = 0, the system is at rest. At t > 0, the top plate is made to attain a constant velocity (v). (b) Dynamic (oscillatory) shear of a fluid between parallel plates. The top plate moves in a sinusoidal fashion with a maximum strain amplitude (γ0).

number of industrial processes, such as extrusion or flow-through circular dies, approximate steady-shear flow.

We will try to provide a basic understanding of steady-shear flow (Bird et al., 1987). In Figure 6-3a, two parallel plates are shown, between which lies a generic fluid. Suppose that both plates are initially at rest with no flow occurring. At a time t = 0, the upper plate is made to instantaneously attain a constant velocity (v). This results in the generation of a shear stress (τ) in the fluid from the cohesive forces between the fluid molecules. As the fluid flows, specific fluid elements (i.e., tiny packets of fluid that remain together at all times during the experiment) can be tracked as a function of time. It is easy to see that every fluid element will undergo the same strain, and that the local strain everywhere in the fluid will be equal to the overall shear strain. In the same way, the shear rate (![]() ) which is the rate of change of shear strain, can be shown to be constant throughout the fluid and equal to (v/h ). Thus, the shear rate applied on the system can be estimated from the velocity (v) applied to the top plate and the distance (h) between the plates.

) which is the rate of change of shear strain, can be shown to be constant throughout the fluid and equal to (v/h ). Thus, the shear rate applied on the system can be estimated from the velocity (v) applied to the top plate and the distance (h) between the plates.

From a steady-shear flow experiment, three material functions can be measured, viz. the viscosity (η), and the first and second normal-stress coefficients (ψ1 and ψ2). Among these, the viscosity (η) is the simplest and most important material

function and can be calculated from the measured shear stress (τ), and the applied shear rate (![]() ) by:

) by:

(3)

Note that this expression is analogous to Newton's law for simple liquids, with the caveat that the viscosity here (more properly termed the apparent viscosity) is a function of shear rate and not a constant parameter. The normal-stress coefficients (ψ1 and ψ2) are estimated in a similar manner by measuring the force per unit area exerted in directions normal to the direction of flow. However, they are much harder to measure accurately. The interested reader is referred to books by Ferry (1980) and Bird et al. (1987) for discussions of normal stresses.

Rheological experiments under steady shear are performed using "viscometric flows" that are indistinguishable from simple steady flow for all practical purposes (Dealy and Wissbrun, 1990). Thus, the three material functions that govern the behavior of the fluid (η, ψ1, and ψ2) can be obtained experimentally. Let us now examine some typical examples of material behavior under steady shear. We will focus on the most important material parameter, the steady-shear viscosity as a function of shear-rate, η(![]() ). Four types of behavior can be distinguished: Newtonian, shear thinning, yield stress (followed usually by shear thinning), and shear thickening. The last three are all examples of non-Newtonian or viscoelastic behavior.

). Four types of behavior can be distinguished: Newtonian, shear thinning, yield stress (followed usually by shear thinning), and shear thickening. The last three are all examples of non-Newtonian or viscoelastic behavior.

A plot of viscosity versus shear-rate or shear-stress is called a flow curve. It is common practice to plot the flow curve on a log-log plot as shown throughout Figure 6-4. The simplest type of steady-shear response is Newtonian behavior (Figure 6-4a), which implies a constant viscosity for the system, independent of shear rate. This is also manifested as a linear relationship between shear stress and shear rate (Newton's law), with the slope of the line defining the viscosity. Most low molecular-weight liquids and gases show Newtonian behavior.

Among non-Newtonian phenomena, the most widely observed is shear thinning, which implies a decrease in viscosity over a range of shear rates. This behavior is exhibited by most polymeric solutions and melts (Ferry, 1980), as well as by a large number of colloidal systems (Russel et al., 1989). In the simplest case, the sample shows Newtonian behavior at low shear rates and shear thinning at higher shear rates (Figure 6-4b). Thus, at low shear rates, the viscosity attains a constant value called the zero-shear viscosity (η0). However, as the shear rate is increased, there occurs a critical shear rate (![]() ), above which the viscosity of the sample decreases. Examples of shear thinning fluids include blood, saliva, various sauces, and creams.

), above which the viscosity of the sample decreases. Examples of shear thinning fluids include blood, saliva, various sauces, and creams.

Shear thinning sometimes occurs in conjunction with yield-stress behavior (Macosko, 1994). In this case, the system will not show any motion until a certain critical or yield stress (τy) is reached. Below the yield-stress, the viscosity of the material approaches infinity (Figure 6-4c), and the system responds in a plastic-like fashion. Above the yield stress, the material typically shows shear thinning. When viscosity is plotted versus shear rate, the existence of a yield stress is reflected as a characteristic slope of -1 in the low shear rate portion of the plot (Figure 6-4c). Some materials approximate Newtonian behavior beyond the yield stress, and these materials are called viscoplastics or Bingham plastics, after Eugene Bingham who first described paint this way in the 1920s. Materials that show a yield-stress appear to have a solid-like consistency when at rest, but when stirred or agitated, they can be made to flow quite easily. Food substances, such as mayonnaise, ketchup, and salad dressing, are good examples.

Modeling the steady-shear response has been a constant endeavor for rheologists. Several models have been formulated, particularly for shear thinning and yield-stress behavior. We will only mention two of the simplest and most convenient models. For shear thinning, the power-law model is most frequently used:

![]() (4)

(4)

The model contains two parameters, the consistency (K) and the power-law index (n). A value of n = 1 corresponds to Newtonian behavior; for shear thinning fluids n < 1. The simplest model that captures yield-stress behavior is the Bingham model used to describe viscoplastics:

![]() (5)

(5)

This model allows no motion below the yield stress (τy) and Newtonian flow behavior above τy. Numerous other models have been proposed for various shapes of flow curves, discussions of which can be found in Macosko (1994), Barnes (1993), and Larson (1988).

Shear thickening is a form of non-Newtonian behavior that is observed much less frequently (Barnes, 1989). As its name implies, shear thickening involves an increase in viscosity over a range of shear rates. This can be seen from Figure 6-4d, where the viscosity begins to increase at a critical shear rate, ![]() , until it reaches a maximum value at a shear-rate,

, until it reaches a maximum value at a shear-rate, ![]() , following which it begins to drop. The viscosity increase typically occurs over a narrow range of shear-rates. This is in contrast to shear thinning, where the viscosity can decrease continuously over several decades of shear rate. Shear thickening phenomena are observed in a few concentrated colloidal dispersions and some polymer solutions.

, following which it begins to drop. The viscosity increase typically occurs over a narrow range of shear-rates. This is in contrast to shear thinning, where the viscosity can decrease continuously over several decades of shear rate. Shear thickening phenomena are observed in a few concentrated colloidal dispersions and some polymer solutions.

In the examples given above, the flow curves represent equilibrium or steady-state behavior. Some materials, however, take a long time to reach steady state at constant shear,

FIGURE 6-4 Examples of material behavior under steady shear (flow curves): (a) Newtonian; (b) shear thinning; (c) yield stress, shown in plots of viscosity vs. shear stress and shear rate; and (d) shear thickening.

i.e., their viscosity shows a continuous change with time of shear. The time-dependent phenomenon where the viscosity continuously decreases with time of shear is called thixotropy (Mewis, 1979). Thixotropic materials may also take considerable time to return to an at-rest state after being subjected to intense shear. These phenomena are widely observed in paints, adhesives, sealants, etc.

All rheological behavior, whether time-dependent or related to changes in shear, arises from changes in the microstructure of the system. This aspect will be a recurring theme in this paper. For example, consider a colloidal dispersion that shows yield stress and shear thinning. Such behavior typically signifies the presence of a particulate network structure in the system at rest and the shear-induced breakdown of the network into individual particles. The correlation between rheology and microstructure can be better understood after we discuss dynamic rheology and the linear viscoelastic response of different materials.

DYNAMIC RHEOLOGY

In dynamic shear flow (also called oscillatory shear), a sinusoidally varying deformation (strain) is applied to the sample (Ferry, 1980):

![]()

(6)

where γ0 is the strain-amplitude (i.e. the maximum applied deformation) and ∞ is the frequency of the oscillations. Figure 6-3b is a schematic representation of dynamic shear flow, and this can be compared to Figure 6-3a, which shows steady shear flow. The shear stress generated by the oscillatory shear will again be sinusoidal but will be shifted by a phase angle (δ) with respect to the strain waveform:

![]()

(7)

Using trigonometric identities, the stress wave can be decomposed into two components, one in-phase with the strain and the other out-of-phase by 90 degrees:

τ = τ0 cos(δ) sin(ωt) + τ0 sin(δ) cos(ωt)

(8)

We can rewrite the above expression in terms of two material functions (G´ and G´´):

![]()

(9)

(10)

(11)

The elastic modulus (G´), which is related to the stress in phase with the imposed strain, provides information about the elastic nature of the material. Because elastic behavior implies the storage of deformational energy in the system, this parameter is also called the storage modulus. The viscous modulus (G´´), on the other hand, is related to the stress component, which is completely out-of-phase with the displacement. This parameter characterizes the viscous nature of the material. Note that the out-of-phase component of the stress would be in phase with the sinusoidal deformation rate (![]() ). Because viscous deformation results in the dissipation of energy, the G´´ parameter is also called the loss modulus.

). Because viscous deformation results in the dissipation of energy, the G´´ parameter is also called the loss modulus.

A purely elastic material would exhibit a non-zero elastic modulus and a viscous modulus G´´ = 0. In contrast, a purely viscous material would show a show a zero elastic modulus, and its stress response would be 90 degrees out-of-phase with the strain (γ) and in-phase with the shear rate (γ). A viscoelastic material will exhibit non-zero values for both G´ and G´´. The above analysis assumes that the measurements are made in the "linear viscoelastic" (LVE) regime of the sample under consideration (Ferry, 1980). The conditions for linear viscoelasticity are that the stress be linearly proportional to the imposed strain and that the torque response involve only the first harmonic. The first condition requires that the moduli G´ and G´´, in the LVE regime, should be independent of the strain-amplitude. The absence of higher harmonics in the stress response, as stipulated in the second condition, ensures that the response remains sinusoidal.

If these two conditions are met, the elastic and viscous moduli would truly be material functions. They would, however, be functions of the frequency of oscillation (∞). A plot representing the moduli as a function of frequency, i.e., G´ (∞) and G´´(∞), is called the dynamic mechanical spectrum of the material. Such a plot is extremely useful because it represents a signature of the microstructure in the material. We can also define several auxiliary parameters based on the quantities derived above (Ferry, 1980). One such parameter is the complex viscosity (η*), which is defined as:

(12)

The variation of complex viscosity with frequency is analogous to the variation of steady viscosity versus shear-rate. (Note that both frequency and shear-rate have units of s-1). Empirical correlation rules between the steady and complex viscosities, indicate a link between steady and dynamic rheology (Cox and Merz, 1958; Doraiswamy et al., 1991; Raghavan and Khan, 1997).

The two dynamic moduli G´ and G´´ represent a clear distinction between elastic and viscous behavior in the same material. This helps to clarify the viscoelastic nature of a given sample. A simple model that captures the essential features of linear viscoelastic behavior is the Maxwell model, originally proposed by James Clerk Maxwell in 1867. In this model (shown in Figure 6-5), a viscoelastic sample is assumed to have two distinct elements: an elastic spring and a viscous dashpot connected in series (Macosko, 1994). The elastic spring has a shear-modulus (G0), and the viscous component has a viscosity (η0).

A characteristic parameter of a viscoelastic system is its relaxation time (λ), which in the case of the Maxwell model is equal to η0/G0. The relaxation time is a measure of the time required for stresses to relax in a viscoelastic material. Recall that under deformation, the stresses relax instantaneously for a viscous liquid; they never relax for an elastic solid. The Maxwell model is useful for simple viscoelastic systems, such as polymer solutions or melts, which exhibit a single relaxation time. We should mention that there are specific experiments to probe relaxation behavior, e.g., stress relaxation after a step strain, creep at constant stress, etc. A discussion of these experiments falls beyond the scope of this paper; details can be found in Bird et al. (1987), Ferry (1980) and Macosko (1994).

FIGURE 6-5 Maxwell model for a viscoelastic material. The system is considered to be a series combination of two distinct segments: an elastic spring (modulus G0) and a viscous dashpot (viscosity η0).

Perhaps the most important advantage of dynamic shear is that it allows us to characterize microstructures without disrupting them in the process. The net deformation imposed on the sample is minimal because the experiments are restricted to small deformations (strain amplitudes) within the LVE regime of the sample. As a result, the linear viscoelastic moduli reflect the microstructures present in the sample at rest. This is to be contrasted with steady shear, where the material functions are always obtained under flow conditions that correspond to relatively drastic deformations. Consequently, the microstructure under steady flow will be very different from the microstructure under static conditions. We can, therefore, correlate dynamic rheology to static microstructures and steady rheology to changes in microstructure caused by flow.

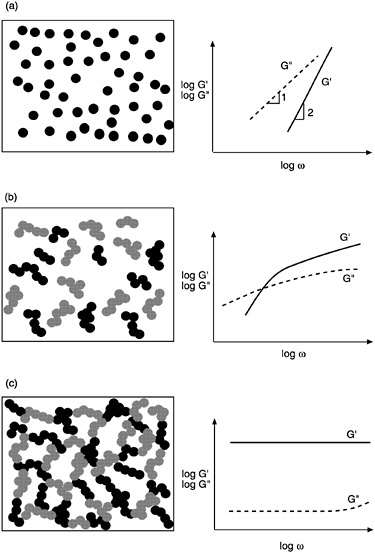

We will now illustrate the types of responses seen in dynamic frequency spectra, and furthermore, the correlation of these responses with material microstructure. We will also point out the steady-shear rheological behavior corresponding to these microstructures. Two classes of materials will be considered, colloidal dispersions and polymer melts. Colloidal dispersions are obtained by dispersing solid, colloidal-sized particles in a liquid (which, for simplicity, is assumed to be a purely viscous medium). The extent to which the particles flocculate depends on the strength of colloidal interaction forces between them (Russel et al., 1989). Various microstructures are thus possible, as illustrated in Figure 6-6.

In the simplest dispersions, inter-particle forces are negligible, i.e., each particle is discrete and does not "feel" the presence of its neighbors. These are classified as "non-flocculated" or stabilized dispersions. The typical dynamic rheological response of these systems (Figure 6-6a) consists of a dominant viscous modulus (G´´) which exceeds the elastic modulus (G´) over the complete range of experimental frequencies (Macosko, 1994). The slopes of the G´—ω and G´´—ω lines are often close to 2 and 1 respectively (note that frequency spectra are typically plotted in a log-log fashion as were the steady-shear flow curves). Under steady flow, the zero-shear viscosity of these dispersions will be relatively low, and the systems will show Newtonian or shear thickening behavior. (The concentration of solid particles has to be very high for shear thickening to occur). Note that the addition of colloidal particles always leads to an increase in viscosity over the pure liquid, but only a moderate increase is observed if the particles are non-interacting.

If the inter-particle forces are fairly strong, there will be a tendency for the particles to adhere to one another and form larger structures called aggregates or flocs (Mewis and Spaull, 1976). A flocculated microstructure is shown in Figure 6-6b along with its characteristic frequency spectrum. Note that G´ becomes larger than G´´ at high frequencies but remains smaller at low frequencies. Both quantities show a weaker dependence on frequency, with lower slopes in the terminal zone (as compared to Figure 6-6a). Thus, dynamic rheology shows the viscoelastic nature of these systems as they exhibit comparable elastic and viscous character. The viscosity of a flocculated dispersion greatly exceeds the viscosity of a non-flocculated system. The steady-shear response is non-Newtonian and shear thinning, corresponding to the breakup of flocs into smaller and smaller units until they are reduced to individual particles.

Under conditions of strongly attractive inter-particle forces and high particle concentrations, flocculation of the system will be significant. Ultimately, the flocs will overlap with one another until a single floc fills the whole volume (Macosko, 1994). This corresponds to a situation where a three-dimensional network of particles extends throughout the system. A system containing a network-type microstructure is called a gel. The dynamic mechanical spectrum of a gel shows a frequency-independent elastic modulus (G´) that greatly exceeds the viscous modulus (G´´) (Figure 6-6c). Thus, a gel behaves principally as an elastic material because of the presence of a continuous network. The level of elastic modulus (G´) can be correlated to the rigidity (i.e., the density of cross-links) in the network. In steady shear, a gel will show a yield stress at low shear, followed by shear thinning at higher shear rates. The yield stress signifies that a minimum stress is required to disrupt the cross-links in the network. Shear thinning reflects the progressive reduction in floc size as a result of shear.

FIGURE 6-6 Dynamic rheology and microstructure of colloidal dispersions. In each case the frequency spectra (G´ and G´´ as functions of frequency ω) are shown with their corresponding microstructure. (a) Stabilized dispersion. (b) Weakly flocculated dispersion. (c) Strongly flocculated dispersion (gel).

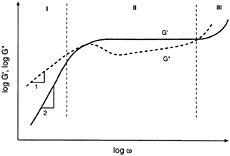

We now consider the dynamic rheology of polymer melts over a range of molecular weights. This leads us to a consideration of "time-scales," a factor we largely ignored in the case of colloidal dispersions. Polymer melts can show very different behavior depending on the time-scales (or equivalently, the frequencies) probed in a rheological experiment (Dealy and Wissbrun, 1990). Note that low frequencies correspond to large time-scales and vice-versa. A typical rheological experiment may be conducted in the frequency range of 10-2 to 102 rad/s, but data over a larger span of frequencies can be obtained by a procedure called time-temperature-superposition (TTS) (Ferry, 1980). This procedure utilizes the equivalence of time and temperature in the rheological context, i.e., dynamic rheological data obtained at higher temperatures is equivalent to data at longer time-scales (lower frequencies). Using TTS, we can generate data for a high molecular weight, monodisperse polymer melt over an extremely wide range of frequencies (10-5 to 104 rad/s), as illustrated schematically in Figure 6-7.

The plot shown in Figure 6-7 (note that both axes are on logarithmic scales) can be divided into three regions (Ferry, 1980). Region I corresponds to low frequencies (i.e., long time-scales) and is called the terminal region. It represents the frequency range that is experimentally accessible at any given temperature. We find that in the terminal zone both G´ and G´´ increase steadily with frequency and the viscous modulus G´´ is larger than the elastic modulus G´. The relations G´~ ω2 and G´´~ ω are typically found to be valid in this region, leading to slopes of 2 and 1 respectively for the lines. In Region II, the moduli cross over at a critical frequency, ωc, and G´ becomes greater than G´´. The inverse of ωc corresponds

FIGURE 6-7 Dynamic mechanical spectrum (G´ and G´´ as functions of frequency ω) for a typical polymer melt over a wide range of frequencies (typically 10-3 to 104 rad/s). The expanded frequency range is made possible by time-temperature-superposition (TTS). Region I is the terminal zone. Region II is the crossover/plateau region. Region III is the high-frequency regime.

to the longest relaxation time for the polymer melt. The curves also begin to flatten and G´ plateaus off at a value given by ![]() (plateau modulus). Finally, in Region III, the moduli again increase with frequency, although to a smaller extent than in the terminal zone.

(plateau modulus). Finally, in Region III, the moduli again increase with frequency, although to a smaller extent than in the terminal zone.

The existence of a plateau in the frequency spectrum is caused by the presence of entanglements in the polymer melt. Entanglements can be envisioned as kinks in the polymer chain caused by segment to segment contacts with neighboring chains (Ferry, 1980; Macosko, 1994). The effect of entanglements is significant only for polymers with a molecular weight that exceeds the entanglement molecular weight (Me). The length of the plateau region gives an indication of the extent of polymer chain entanglement. Thus, for a lower molecular-weight melt, the plateau region would be much smaller in width, and the crossover of G´ and G´´ would occur at a higher frequency (smaller relaxation time).

The steady-shear rheology of a polymer melt is very sensitive to its molecular weight (Ferry, 1980; Bird et al., 1987). Low molecular weight melts are Newtonian liquids. As the molecular-weight increases, shear thinning begins to occur beyond a critical shear rate (![]() ). The curves resemble the schematic shown in Figure 6-4b (and again in Figure 6-10) with a viscosity plateau (η0) followed by shear thinning. As the molecular weight increases, shear thinning begins to set in at lower shear rates. From a microstructural point of view, shear thinning reflects a decrease in the density of entanglement with increasing shear because of progressive stretching and uncoiling of polymer chains (Ferguson and Kemblowski, 1991). An important trend in polymer rheology is the increase in zero-shear viscosity (η0) with molecular weight (M) of the polymer melt (Ferry, 1980):

). The curves resemble the schematic shown in Figure 6-4b (and again in Figure 6-10) with a viscosity plateau (η0) followed by shear thinning. As the molecular weight increases, shear thinning begins to set in at lower shear rates. From a microstructural point of view, shear thinning reflects a decrease in the density of entanglement with increasing shear because of progressive stretching and uncoiling of polymer chains (Ferguson and Kemblowski, 1991). An important trend in polymer rheology is the increase in zero-shear viscosity (η0) with molecular weight (M) of the polymer melt (Ferry, 1980):

(13)

Thus, η0 is initially proportional to the molecular weight but increases more sharply once the entanglement molecular weight (Me) is exceeded. This indicates the critical role played by entanglements in polymer science.

RHEOLOGICAL MEASUREMENTS (STEADY/DYNAMIC SHEAR)

So far, we have indicated the two most important types of rheological techniques, i.e., steady shear and dynamic (oscillatory) shear. We have concentrated on a few important material functions, viz., the steady viscosity (η), and the dynamic moduli (G´ and G´´). In this section, we briefly describe how these parameters are measured in practice. Rheological measurements are typically performed on a rheometer. There are several categories of rheometers, with the most prominent being capillary rheometers (which utilize

pressure-driven or Poiseuille flows) and rotational rheometers (which use drag flows). Capillary rheometers are capable of measuring only the steady-shear properties of a fluid, not the dynamic rheological properties. For this reason, we will focus solely on rotational instruments.

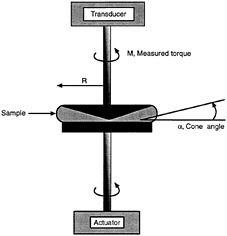

Two types of rotational rheometers exist: stress-controlled rheometers and strain-controlled rheometers (Ferguson and Kemblowski, 1991; Schramm, 1994). In a strain-controlled rheometer, a known deformation (strain or shear rate) is applied to the fluid, and the stress is detected. Typically, the strain is applied by rotating one segment of the geometry, and a transducer connected to the other segment measures the stress. A stress rheometer operates in the opposite fashion, by applying a controlled stress and measuring the resulting deformation. In the past few years, stress rheometers have become immensely popular because of their great sensitivity and wide torque range. Rotational rheometers also can use a multitude of different geometries. Concentric cylinder (Couette), parallel plates, and cone-and-plate are the most common geometries. For the purpose of illustration, we will consider the use of a cone-and-plate geometry on a strain-controlled rheometer and show how rheological quantities are calculated.

A schematic diagram of a cone-and-plate geometry is shown in Figure 6-8. The device consists of a small-angle

FIGURE 6-8 A rheological experiment on a cone-and-plate geometry on a strain-controlled rotational rheometer. The cone has a radius (R) and cone angle (α), and its edge is truncated up to a height of 50 microns. The actuator applies a controlled deformation to the bottom plate, and the transducer connected to the cone measures the response of the sample.

cone and a flat plate. The cone angle is denoted to be , and the radius of the cone/plate is R. This geometry has several advantages: it requires only a small sample and is easier to load and clean than more complex geometries (Macosko, 1994). More importantly, a homogenous deformation is maintained throughout the sample, provided the cone angle is small (<0.2 radians). Flow is generated in a rotational geometry by moving one of the walls of the system in such a way that the fluid is dragged along with the wall. This explains why these flows are called "drag flows" (Ferguson and Kemblowski, 1991).

In Figure 6-8 we show schematically how a test would be run on a cone-and-plate geometry using a strain-controlled rheometer. The general principle is to input a deformation and measure the torque output. The raw data can be converted into rheologically relevant quantities using the physical dimensions of the cone (R, α) and the input parameters. Let us first consider a steady-shear experiment. In this case, the actuator rotates the bottom plate at an angular velocity Ω (rad/s). The shear-rate exerted on the sample is given by (Macosko, 1994):

![]()

(14)

The response of the sample is measured by the transducer in terms of a torque (M). The torque can be converted into a shear-stress (τ) as follows:

![]()

(15)

The apparent viscosity can then be calculated from the shear-stress and shear-rate by using the expression ![]() . Thus,

. Thus,

(16)

In dynamic measurements, the bottom plate is oscillated from its mean position, with the peak displacement being up to an angle Φ (in radians). The strain-amplitude is then given by (Macosko, 1994):

![]()

(17)

The response of the sample is in terms of a sinusoidal torque showing a phase lag with respect to the input strain. The peak torque (M), and the phase angle (δ), are measured by the instrument. The peak stress-amplitude (τ0) is calculated from the peak torque (M) using Eq. 15. The elastic and viscous moduli can then be calculated using Eqs. 9 and 10 respectively. The final expressions are:

(18)

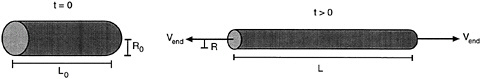

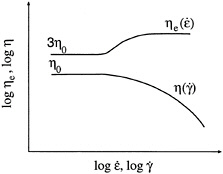

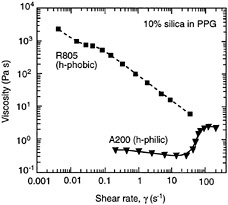

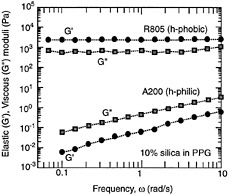

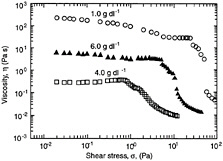

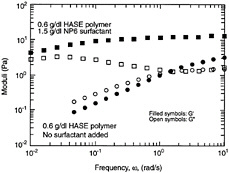

(19)